battery HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 1007 of 1139

Multiplex Control System

Multiplex Control Unit lnput Test (cont'd)

3. Inspect the connector and socket terminals to be sure they are all making good contact

.lftheterminalsarebent,looseorcorroded,repairthemasnecessary,andrecheckthesystem. llthe terminals look OK, go to step 4.

4. Reconnectthe connectorstothe under dash fuserelay box, and make surethese inputtests atthe appropriate connectors on lhe under-

dash fuse/relav box.

. lf any test indicates a problem, {ind and correct the cause, then recheck the system. lf allthe input tests prove OK, the multiplex control unit must be faulty. Replace the under_dash fuse/relay box assembly

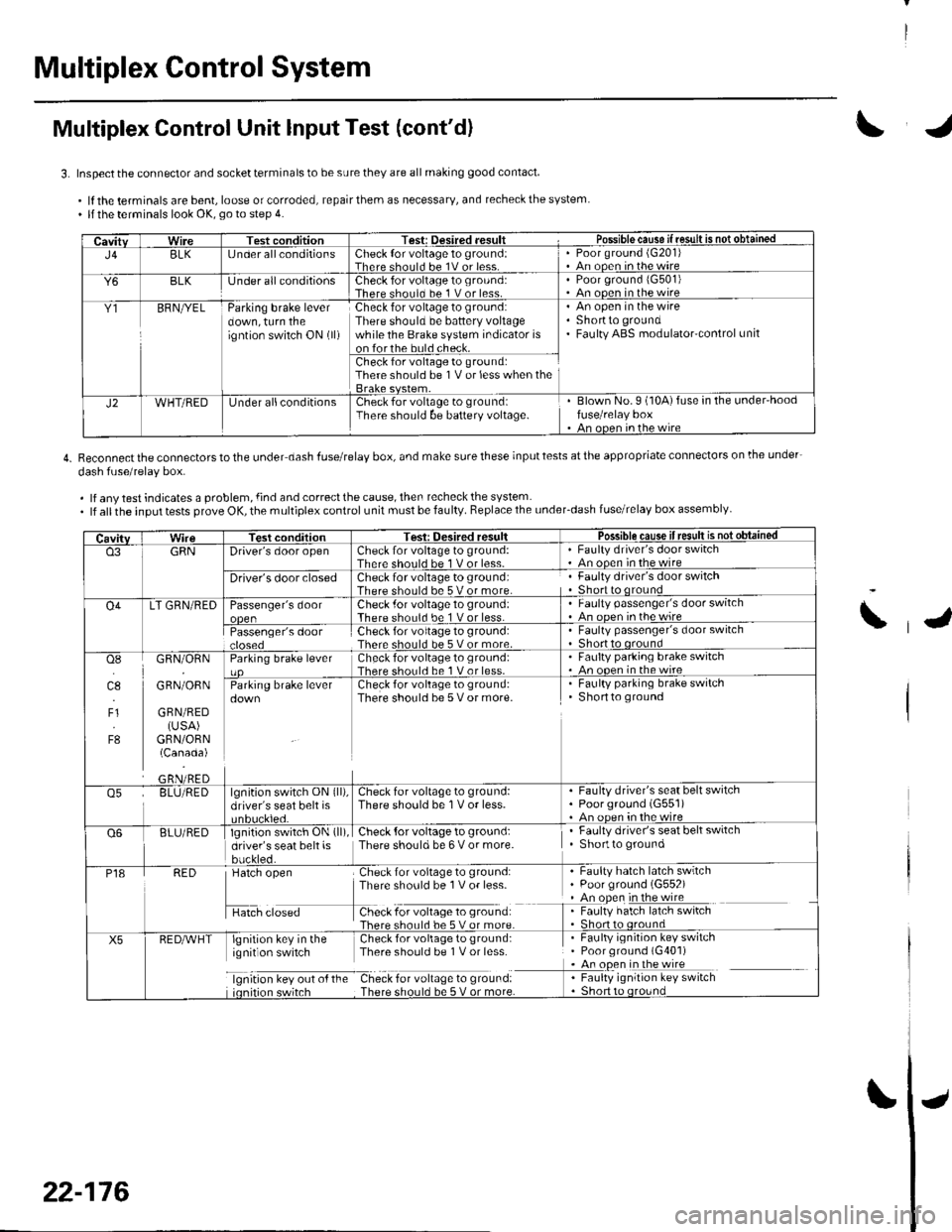

CavitvWireTest conditionTest: Desired .esult r Possible cause if resullE qS!q!!e!!ed

J4BLK[J nder all conditionsCheck {or voltage 1o ground:Therc sholl.l he 1V or lessPoor ground (G20'l)An ooen in the wire

Y6BLKlJnder all conditionsCheck for voltage to ground:There should bc 1 V or less.Poor ground 1G501)An ooen in the wire

Y1BFNryELParking brake leverdown, turn theigntion switch ON (ll)

Check for voltage to ground:There should be battery voltagewhile the Brake system indicator ison forthe buld check.

An open in the wireShortto groundFaulty ABS modulatorcontrol unit

Check for voltage to ground:There should be 1V or less when the

J2WHT/REDUnder allconditionsCheck for voltage to groundiThere should be baftery voltage.Blown No.9 (10A)fuse in the under'hoodfuse/relay boxAn oncn in rhc wire

CavitvTest conditionTesi: Oesired resultPossible cause ifresult is notobtained

o3GRNDriver's door openCheck for voltage to ground:There should be 1 V or less-Faulty driver's door switchAn ooen in the wire

Driver's door closedCheck for voltage to ground:There should be 5 V or more.Faulty driver's door switchShort to qround

O4LT GRN/REDPassenger's doorCheck .for voltage 10 ground:There should be 1 V or less.Faulty passenger's door switchAn ooen inthewire

Passenger's doorCheck for voltage to ground:There should be 5 V or more.Faulty passenger's door switchShort to oround

osI]l.l

4.,

F1

F8

GRN/ORN

GRN/ORN

GRN/RED(USA)GRN/ORN(Canada)

Parking brake leverCheck for voltage to groLrnd:There shorl.l be 1 V or less.Faulty parking brake switch. An ooen in thewireCheck for voltage to ground:There should be 5 V or more.

. Faulty parking brake switchShortto ground

o5BLU/REDlgnition switch ON (ll),

driver's seat belt isCheck for voltage to ground:There should be 1V or less.Faulty driver's seat belt switchPoorground (G551)An oDen in the wire

Q6BLU/REDlgnition switch ON (ll)

driver's seat belt isbuckled.

Check {or voltage to ground:There should be 6 V or more.Faulty driver's seat belt switchShortto ground

P18RED

H",=

Check for voltage to ground:There sho0ld be 1V or less-

f -9*:li:'^:**:':s*:*

Faulty hatch latch swrtchPoor ground (G552)An open in the wireFaulty hatch latch switch

X5lgnirion key in the Check for voliage to gtound:ignit on switch Thpre should be I V or lcss

lgnrtron kev our o{ the Check for vollage to ground:

. Faulty ignition key switch. Poor ground (G401). An open in the wire

I : [11y.'::i':::1"' **6

\

22-176

Page 1008 of 1139

IJ

IJ

IJ

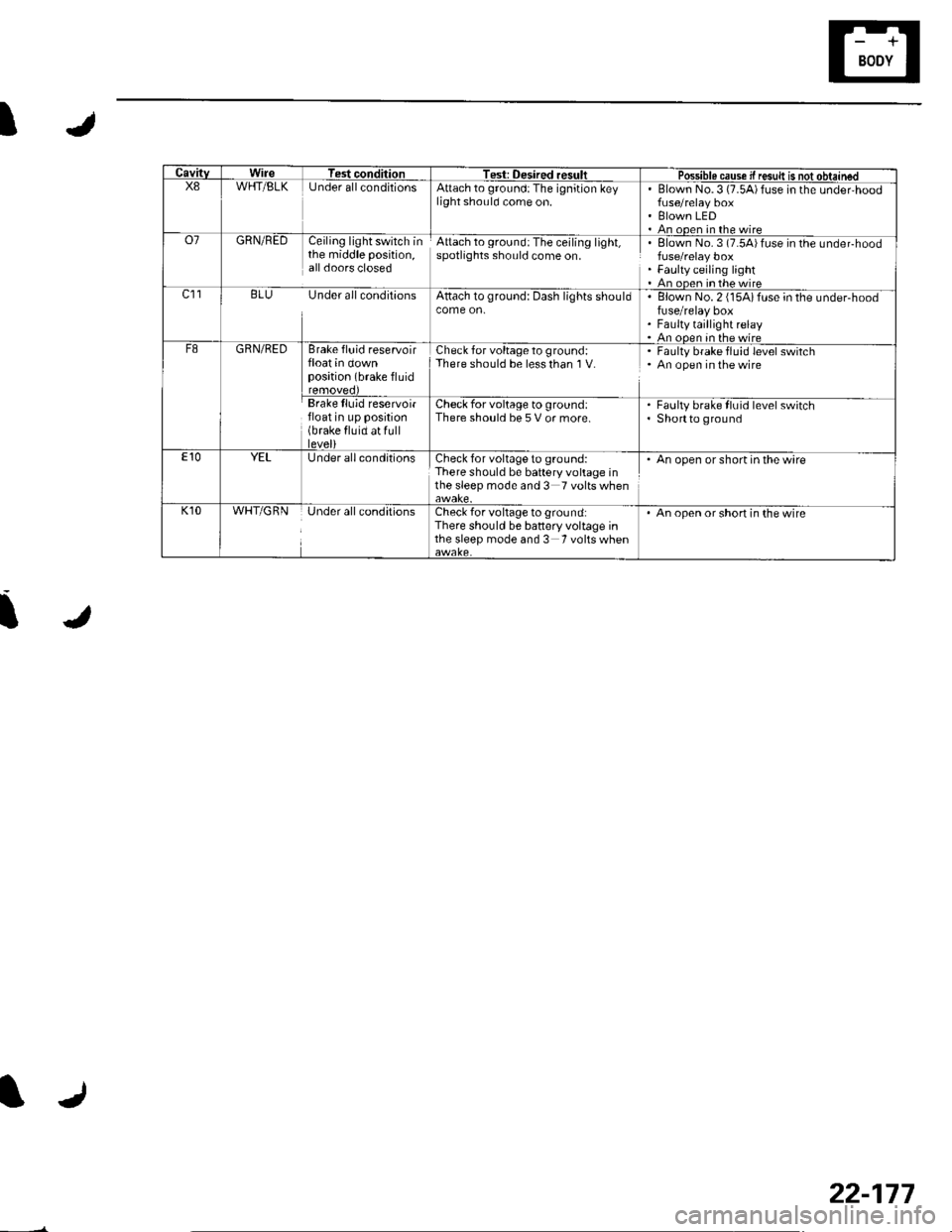

CavitvWireTest conditionTest: Desired resultPossible cause if resuk is not obtainedX8WHT/BLKUnder allconditionsAttach to ground:The ignition keylight should come on.Blown No.3 (7.5A)fuse in the under,hood

Blown LEDAn ooen in the wireo7GRN/REDCeiling light switch inthe middle position,all doors closed

Attach to ground:The ceiling light,spotlights should come on.Elown No. 3 (7.54)fuse in the undeFhood

Faulty ceiling lightAn oDen in the wirec]1BLU Under all conditionsAttach to ground: Dash lights shouldBlown No. 2 (15Aifuse in the under-hoodfuse/relay boxFaulty taillight relayAn ooen in the wireF8GRN/REDBrake fluid reservoirfloat in downposition (brake fluid

Check for voltage to ground:There should be less than I V.Faulty brake fluid level switchAn open in the wire

Brake lluid reservoirfloat in up position(brake fluid at fulllevel)

Check for voltage to ground:There should be 5 V or more.Faulty brake fluid level switchShortto ground

E10YELUnder all conditionsCheck for voltage to ground:There should be battery voltage inthe sleep mode and 3 Tvoltswhen

. An open or short in the wire

K10WHT/GRNUnder all conditionsCheck for voltage to ground:There should be battery voltage inthe sleep mode and 3 Tvoltswhen

An open or short in the wire

22-177

Page 1012 of 1139

Seat Belts

Front Seat Belt Replacement

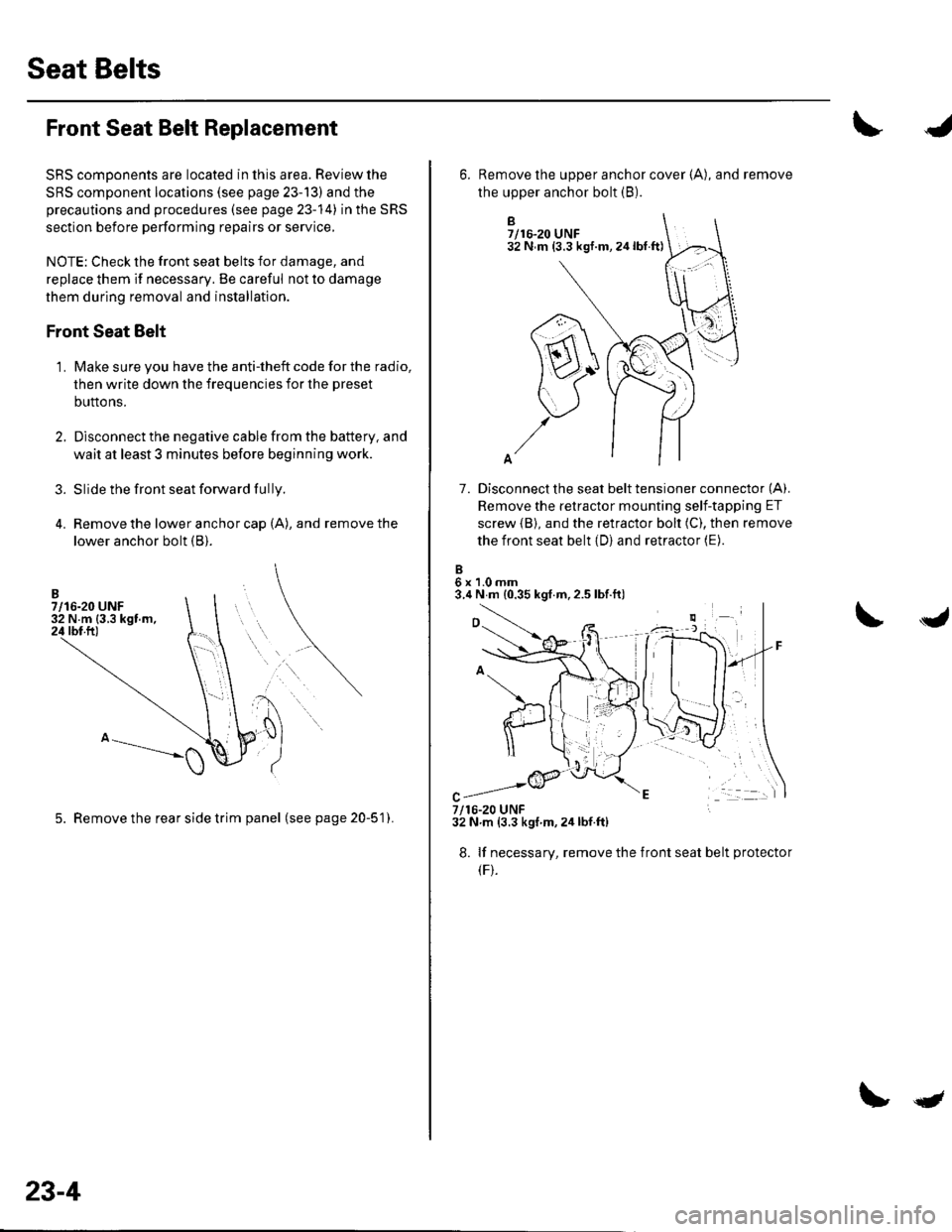

SRS comDonents are located in this area. Review the

SRS component locations (see page 23-13) and the

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service,

NOTE: Check the front seat belts for damage, and

replace them if necessary. Be careful not to damage

them during removal and installation.

Front Seat Belt

Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

Disconnect the negative cable from the battery, and

wait at least 3 minutes before beginning work.

Slide the front seat forward fully.

Remove the lower anchor cap (A), and remove the

lower anchor bolt (B).

3.

1.

5. Remove the rear side trim panel (seepage20-51).

23-4

qt

B7/16-20 UNF32 N m (3.3 kgf.m,24lbt.ft)

7. Disconnect the seat belt tensioner connector (A).

Remove the retractor mounting self-tapping ET

screw {B), and the retractor bolt (C), then remove

the front seat belt (D) and retractor (E).

6x1.0mm3.4 N m {0.35 kgf.m,2.5 lbf.ft)

6. Remove the upper anchor cover {A), and remove

the upper anchor bolt (B).

7/16-20 UNF32 N.m (3.3 kgf m,2ir lbf.ft)

8. lf necessary, remove the

(F).

front seat belt protecto

Page 1013 of 1139

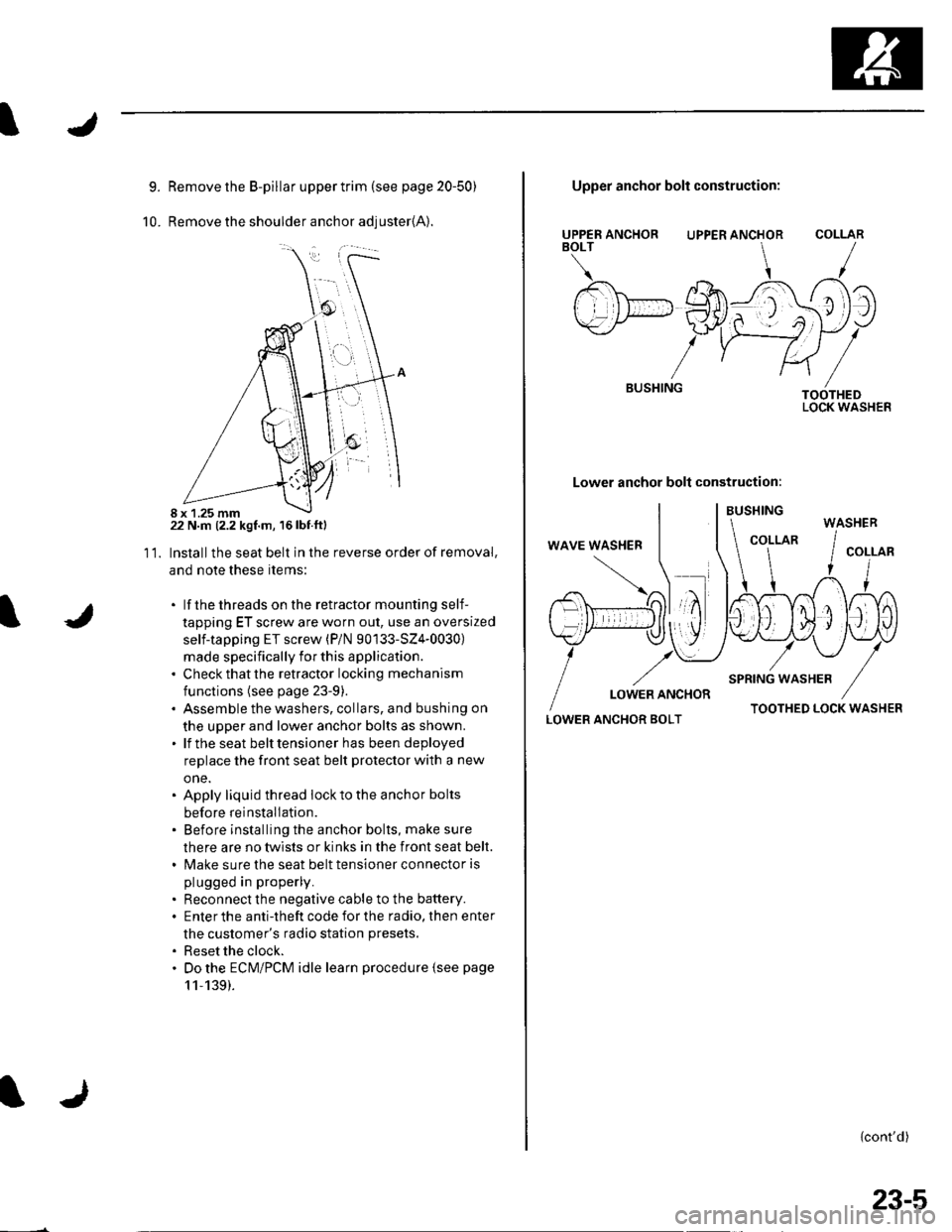

9.

10.

Remove the B-pillar upper trim {see page 20-50)

Remove the shoulder anchor adjuster{A).

22 N.m (2.2 kgf.m, 16lbf.ftl

Installthe seat belt in the reverse order of removal,

and note these items:

. lf thethreads on the retractor mounting self-

tapping ET screw are worn out, use an oversized

self-tapping ET screw (P/N 90133-SZ4-0030)

made specifically for this application.. Check that the retractor locking mechanism

functions (see page 23-9).. Assemble the washers, collars, and bushing on

the upper and lower anchor bolts as shown.. lf the seat belt tensioner has been deployed

replace the front seat belt protector with a new

one.. Apply liquid thread lock to the anchor bolts

before reinstallation.. Before installing the anchor bolts, make sure

there are no twists or kinks in the front seat belt.. Make sure the seat belt tensioner connector is

plugged in properly.

. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

. Reset the clock.. Do the ECM/PCM idle learn procedure {see page

11,139).

11.

8 x 1.25 mm

UPPER ANCHORBOLT

BUSHING

Upper anchor bolt construction:

UPPER ANCHOR

Lower anchor bolt construction:

COLLAR

TOOTHEDLOCK WASHER

LOWER ANCHOR BOLTTOOTHED LOCK WASHER

{cont'd)

WASHER

23-5

Page 1014 of 1139

Seat Belts

Front Seat Belt Replacement (cont'd)

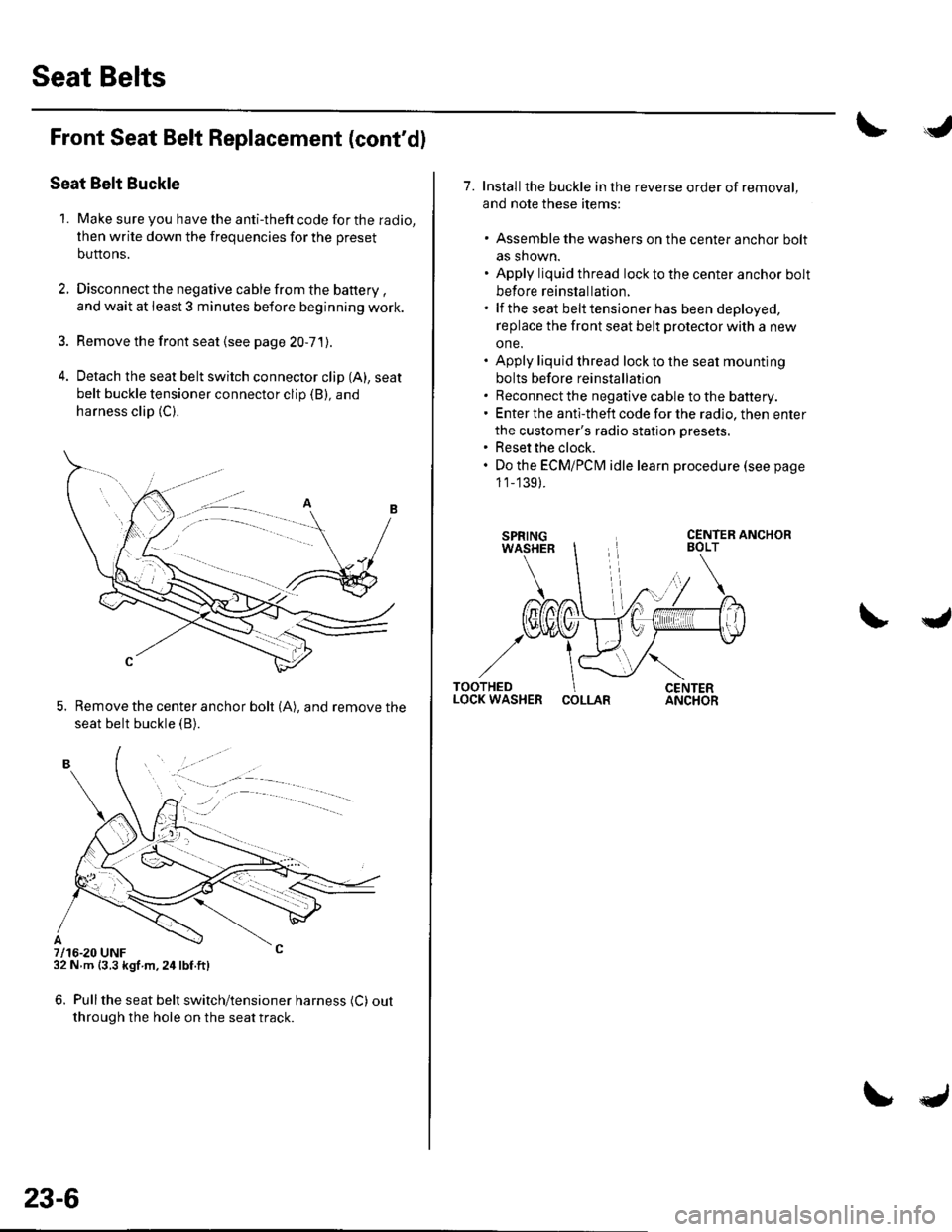

Seat Belt Buckle

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

2. Disconnect the negative cable from the battery ,and wait at least 3 minutes before beginning work.

3. Remove the front seat (see page 20-7'1).

4. Detach the seat belt switch connector clip (A), seat

belt buckle tensioner connector clip (B), and

harness clip (C).

5. Remove the center anchor bolt (A), and remove the

seat belt buckle {B).

7/16-20 UNF32 N m {3.3 kgf m,24lbf.ft)

6. Pullthe seat belt switch/tensioner harness (C) out

through the hole on the seat track.

. -.. :.a--

23-6

7. Installthe buckle in the reverse order of removal,

and note these items:

. Assemble the washers on the center anchor bolt

as shown.. Apply liquid thread lock to the center anchor bolt

before reinstallation.. lf the seat belt tensioner has been deployed,

replace the front seat belt protector with a new

one.. Apply liquid thread lock to the seat mounting

bolts before reinstallation. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.. Reset the clock.. Do the ECMiPCM idle learn procedure (see page

1 1_139).

COLLAR

Page 1021 of 1139

sRs

Precautions and Procedures

General Precautions

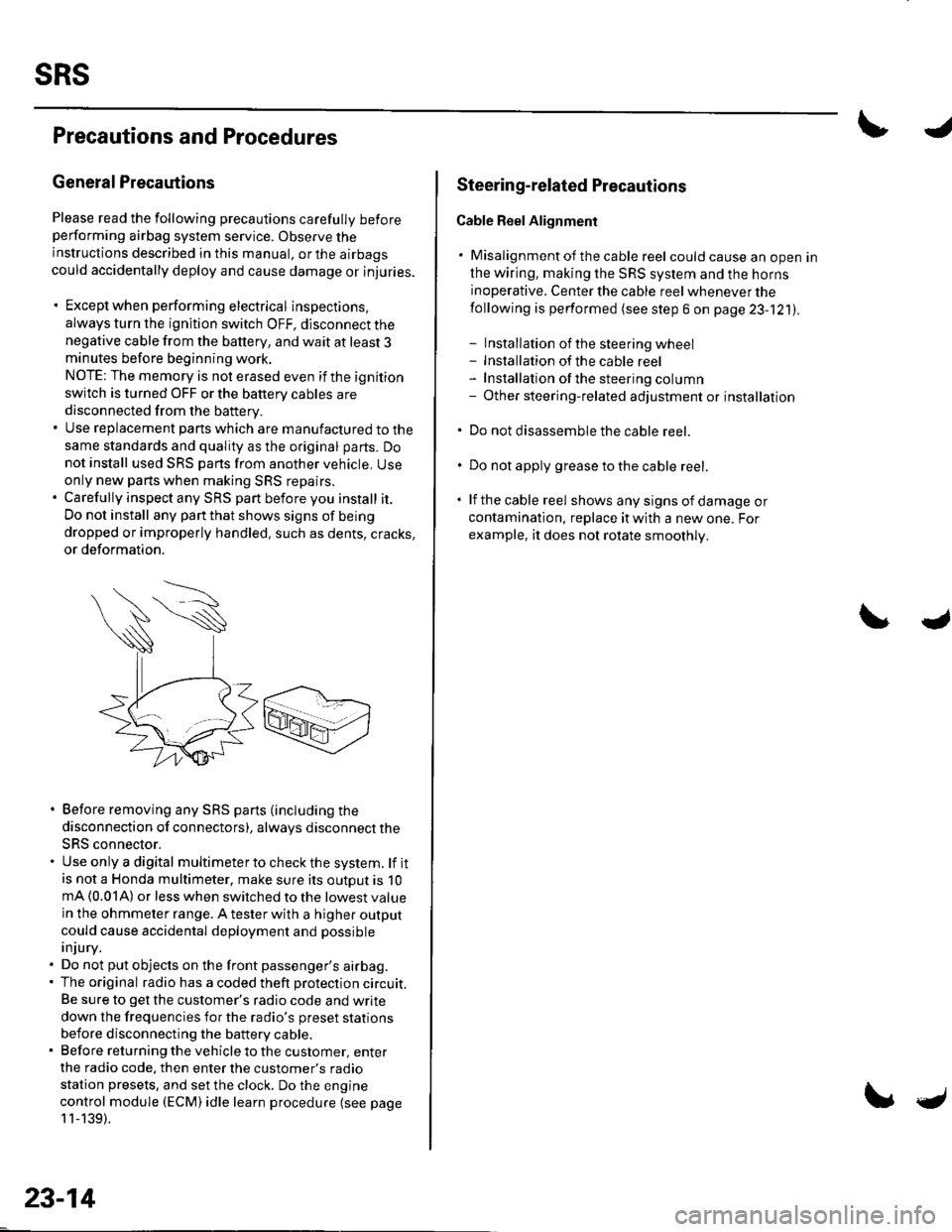

Please read the following precautions carefully beforeperforming airbag system service. Observe theinstructions described in this manual. or the airbags

could accidentally deploy and cause damage or injuries.

. Except when performing electrical inspections.

always turn the ignition switch OFF, disconnect the

negative cable from the battery, and wait at least 3minutes before beginning work.

NOTE: The memory is not erased even if the ignition

switch is turned OFF or the battery cables are

disconnected from the battery.. Use replacement pans which are manufactured to the

same standards and quality as the original parts. Do

not install used SRS parts from another vehicle. Useonly new pans when making SRS repairs.. Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being

dropped or improperly handled, such as dents, cracks,

or deformation.

. Before removing any SRS parts (including the

disconnection of connectors), always disconnect the

SRS connector.. Use only a digital multimeter to check the system. lf itis not a Honda multimeter, make sure its outout is 10mA (0.01A) or less when switched to the lowest value

in the ohmmeter range. A tester with a higher output

could cause accidental deployment and possible

injury.. Do not put objects on the front passenger's airbag.. The original radio has a coded theft protection circuit.

Be sure to get the customer's radio code and write

down the frequencies for the radio's preset stations

before disconnecting the battery cable.. Before returning the vehicle to the customer, enter

the radio code. then enter the customer's radio

station presets, and set the clock. Do the engine

control module (ECM) idle learn procedure (see page

11-139).

23-14

c

Steering-related Plecautions

Cable Reel Alignment

. Misalignment of the cable reel could cause an open in

the wiring, making the SRS system and the horns

inoperative. Center the cable reel whenever the

following is performed (see step 6 on page 23-121).

- Installation of the steering wheel- Installation of the cable reel- Installation ofthe steering column- Other steering-related adjustment or installation

. Do not disassemble the cable reel.

. Do not apply grease to the cable reel.

. lf the cable reel shows any signs of damage or

contamination. replace it with a new one. For

example, it does not rotate smoothly.

Page 1023 of 1139

sRs

Precautions and Procedures {cont'dl

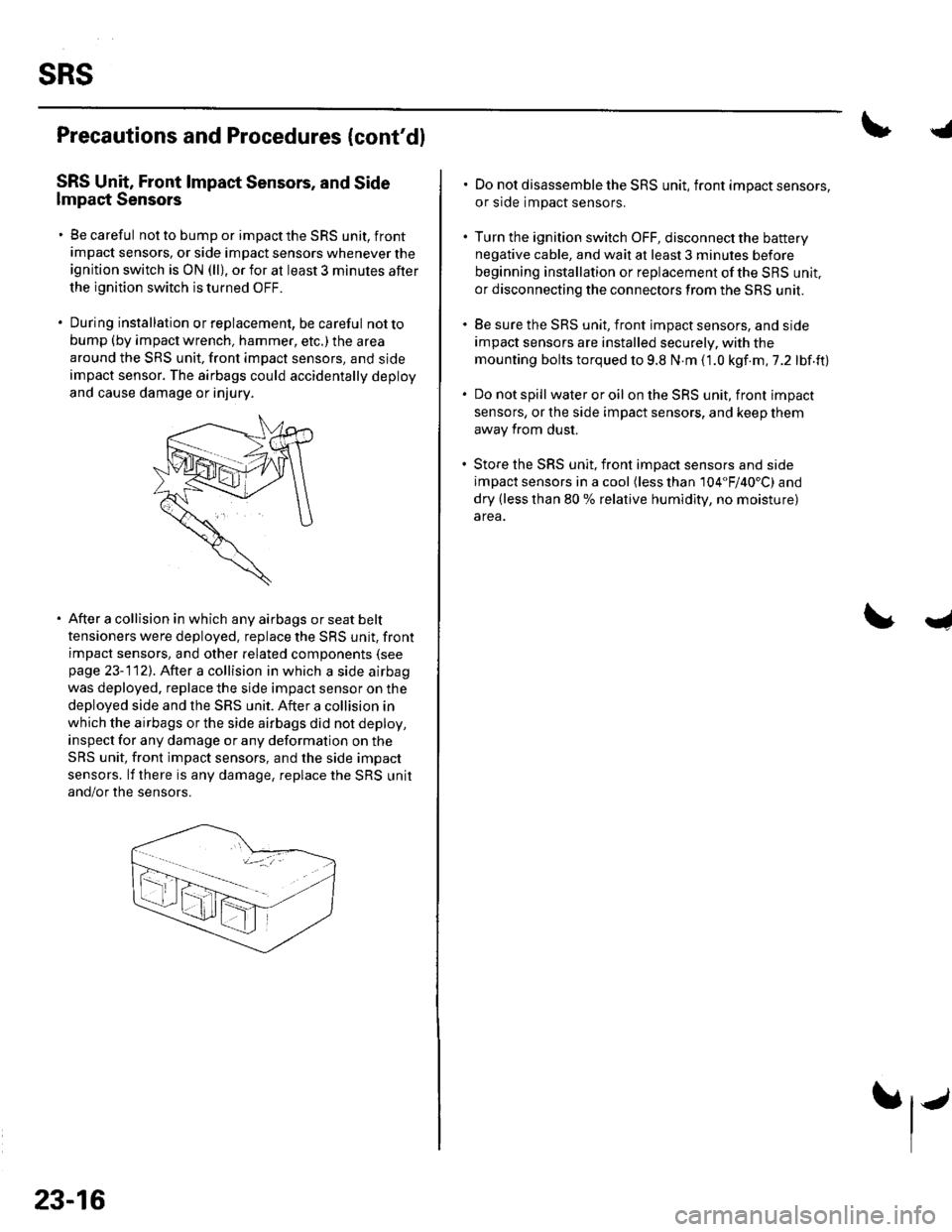

SRS Unit, Front lmpact Sensors, and Side

lmpact Sensors

. Be careful not to bump or impact the SRS unit, front

impact sensors, or side impact sensors whenever the

ignition switch is ON (ll), or for at least 3 minules after

the ignition switch is turned OFF.

. During installation orreplacement, be careful notto

bump (by impact wrench, hammer, etc.) the area

around the SRS unit, front impact sensors, and sjde

impact sensor. The airbags could accidentally deploy

and cause damage or injury.

After a collision in which any airbags or seat belt

tensioners were deployed. replace the SRS unit, front

impact sensors, and other related components (see

page 23-112). After a collision in which a side airbag

was deployed. replace the side impact sensor on the

deployed side and the SRS unit. After a collision in

which the airbags or the side airbags did not deploy,

inspect for any damage or any deformation on the

SRS unit, front impact sensors, and the side impact

sensors. lf there is any damage, replace the SRS unit

and/or the sensors.

23-16

.j

. Do not disassemble the SRS unit, front impact sensors,

or side impact sensors.

. Turn the ignition switch OFF, disconnect the battery

negative cable, and wait at least 3 minules before

beginning installation or replacement of the SBS unit,

or disconnecting the connectors from the SRS unit.

. Be sure the SRS unit, front impact sensors, and side

impact sensors are installed securely. with the

mounting bolts torqued to 9.8 N.m (1.0 kgf.m,7.2 lbf.ft)

. Do not spill wateroroil on the SRS unit, front impact

sensors, or the side impact sensors, and keep them

away from dust.

. Store the SRS unit, front imDact sensors and side

impact sensors in a cool (less than 104"F/40'C) and

dry (less than 80 % relative humidity, no moisture)

area.

I

Page 1027 of 1139

sRs

Precautions and Procedures (cont'dl

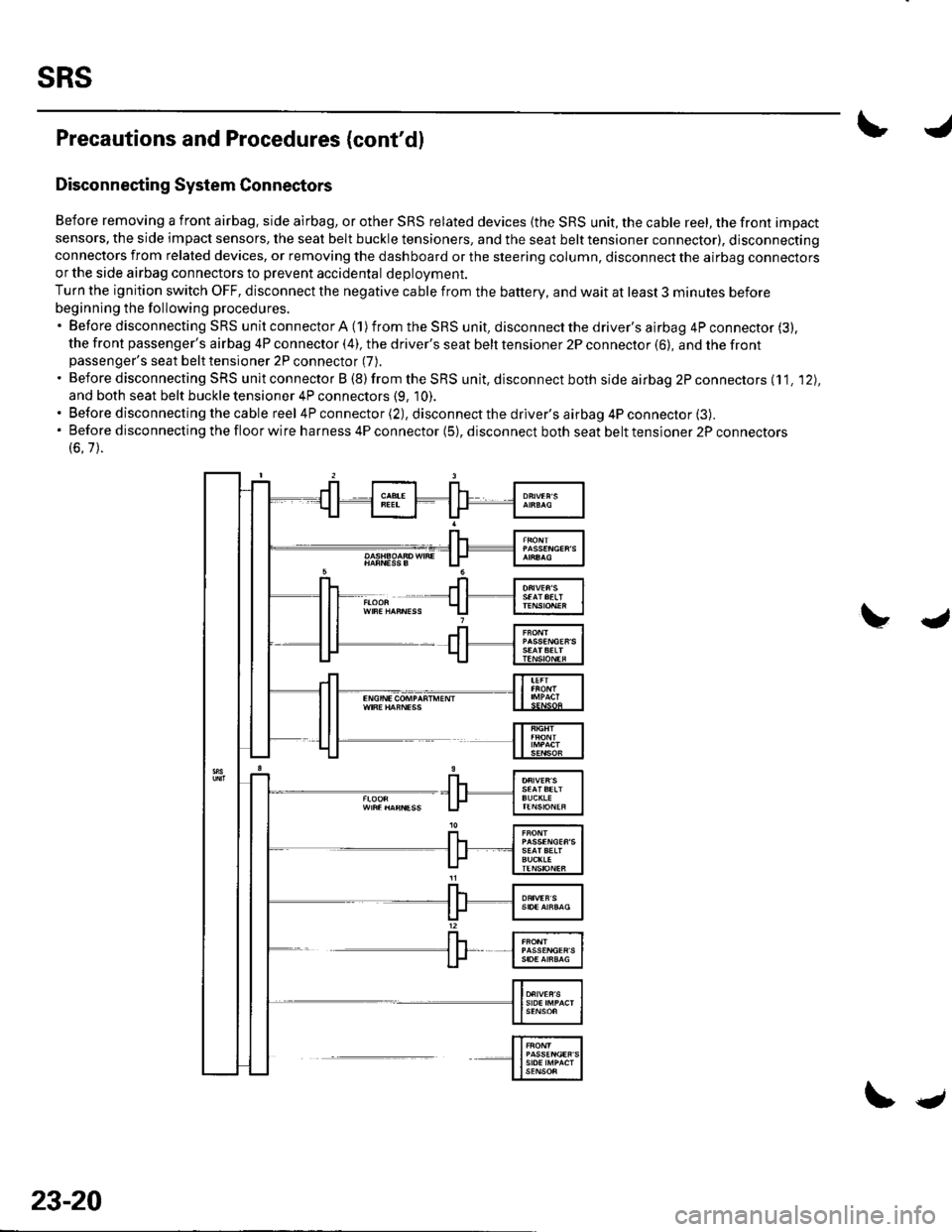

Disconnecting System Connectors

Before removing a front airbag. side airbag, or other SRS related devices {the SRS unit, the cable reel, the front impact

sensors, the side impact sensors, the seat belt buckle tensioners, and the seat belt tensioner connector), disconnectingconnectors from related devices, or removing the dashboard or the steering column, disconnect the airbag connectorsor the side airbag connectors to prevent accidental deploVment.

Turn the ignition switch OFF, disconnect the negative cable from the battery, and wait at least 3 minutes before

beginning the following procedures.'BeforedisconnectingSRSunitconnectorA(1)fromtheSRSunit,disconnectthedriver'sairbag4Pconnector(3).

the front passenger's airbag 4P connector (4), the driver's seat belt tensioner 2P connector (6), and the frontpassenger's seat belt tensioner 2P connector (7).

. Before disconnecting SRS unit connector B (8) from the SRS unit, disconnect both side airbag 2P connectors (11. '12),

and both seat belt buckle tensioner 4P connectors (9, 10).. Before disconnecting the cable reel 4P connector (2), disconnect the driver's airbag 4P connector (3).'Beforedisconnectingthefloorwireharness4Pconnector(5),disconnectbothseatbelttensioner2Pconnectors

(6.7).

23-20

\.

Page 1028 of 1139

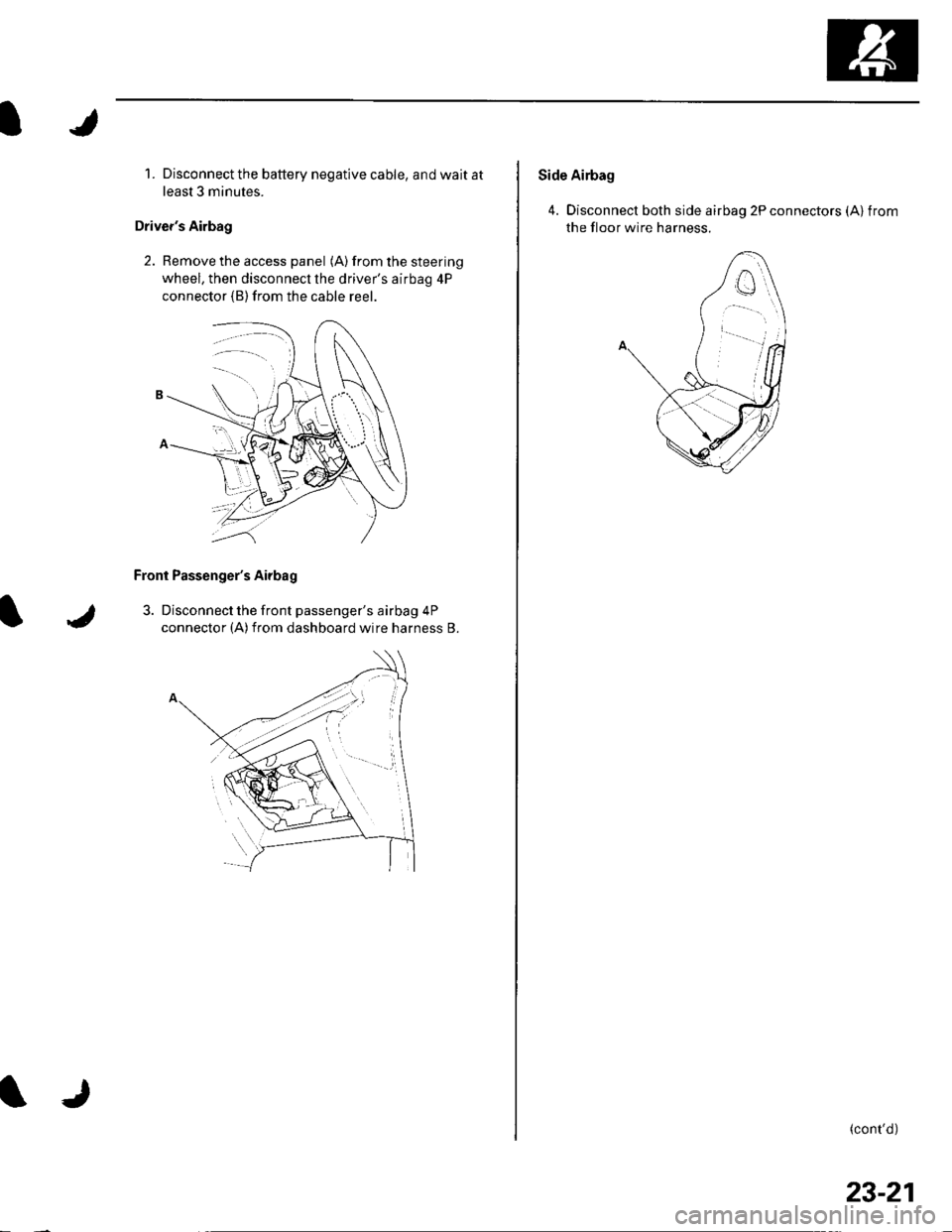

1. Disconnect the battery negative cable, and wait at

least 3 minutes.

Driver's Airbag

2. Remove the access panel (A) from the steering

wheel, then disconnecl the driver's airbag 4P

connector (B)from the cable reer.

Front Passenger's Airbag

3. Disconnect the front passenger's airbag 4P

connector (A)from dashboard wire harness B.

Side Airbag

4. Disconnect both side airbag 2P connectors (Alfrom

the floor wire harness.

(cont'd)

23-21

Page 1030 of 1139

General Troubleshooting Information

DTC (Diagnostic Trouble Codesl

The self-diagnostic function of the SRS system allows it

to locate the causes of system problems and then store

this information in memory. For easier troubleshooting,

this data can be retrieved via a data link circuit.

. When you turn the ignition switch ON (ll), the SRS

indicator will come on. lf it goes off after 6 seconds,

the system is normal.. lf there is an abnormality, the svstem locates and

defines the problem, stores this information in

memory, and turns the SRS indicator on. The data

will remain in the memory even when the ignition

switch is turned off or if the battery is disconnected.. When you connect the Honda PG lM Tester to the 16P

data link connector (DLC)to short the SCS terminal,

and turn the ignition switch ON (ll). the SRS indicator

will indicate the diagnostic trouble code (DTC) by the

number of blinks.. When you connect the Honda PGM Tester to the 16P

data link Connector (DLC), you can retrieve the DTC in

the Honda Systems "SRS" menu.. After reading and recording the DTC, proceed with

the troubleshooting procedure for th is code.

Precautions. Use only a digital multimeter to check the system. lf

it's not a Honda multimeter, make sure its output is

10 mA (0.01A) or less when switched to the smallest

value in the ohmmeter range, A tester with a higher

output could damage the airbag circuit or cause

accidental airbag deployment and possible injury.. Whenever the ignition switch is ON (ll), or has been

turned OFF for less than 3 minutes, be careful not to

bump the SRS uniU the airbags could accidentally

deploy and cause damage or injuries.. Before you remove the SRS harness, disconnect the

driver's airbag connector. the front passenger's

airbag connector, both side airbag connectors, both

seat belt buckle tensioner connectors, and both seat

belt tensioner connectors.. Make sure the battery is sufficiently charged. lf the

battery is dead or low, measuring values won't be

correct.. Do not touch a tester probe to the terminals in the

SRS unit or harness connectors, and do not connect

the terminals with a jumper wire. Use only the

backprobe set and the Honda PGM Tester. Backprobe

spring loaded lock type connectors correctly.

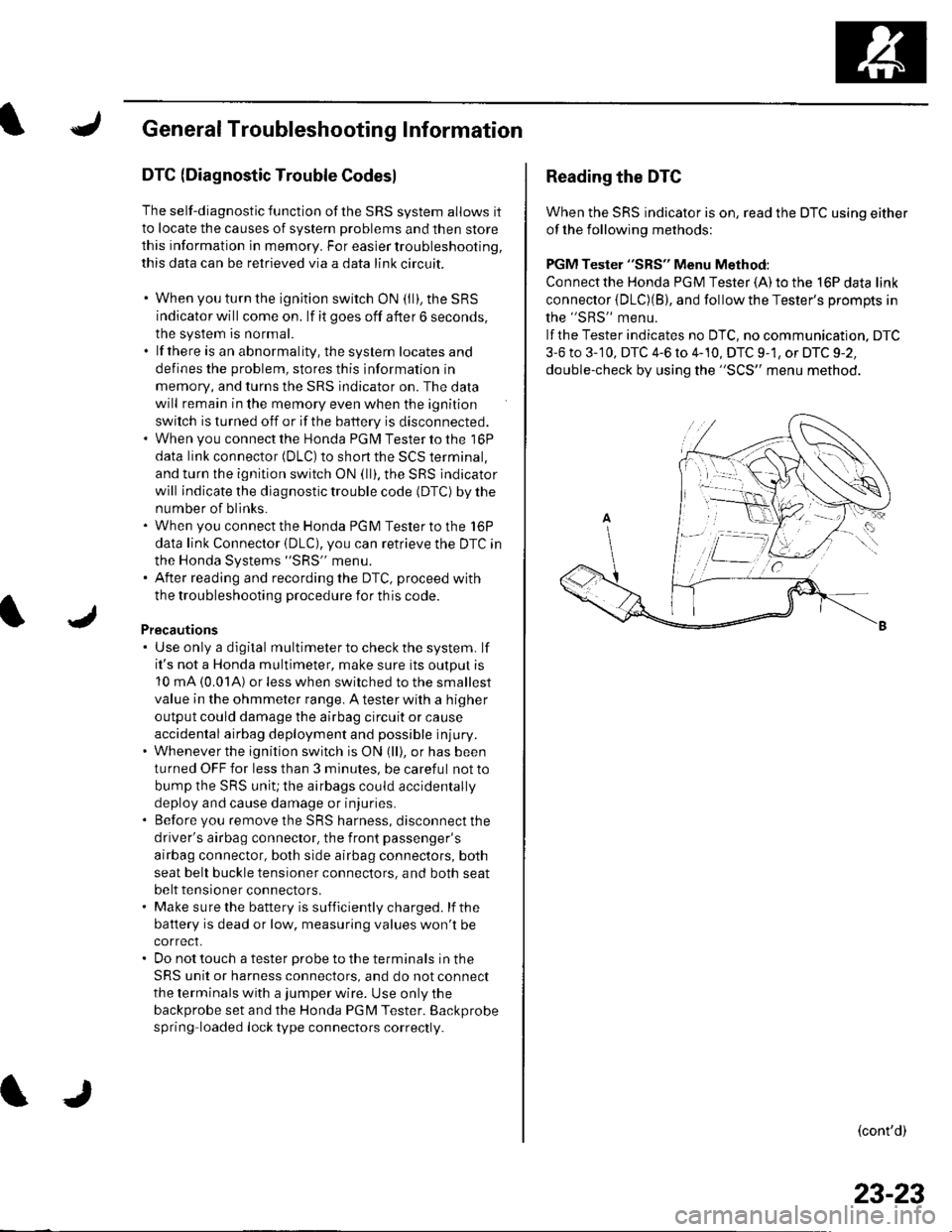

Reading the DTC

When the SRS indicator is on, read the DTC using either

of the following methods:

PGM Tester "SRS" Menu Method:

Connect the Honda PGM Tester {A) to the 16P data link

connector {DLC)(B), and follow the Tester's Drompts in

the "SRS" menu.

lf the Tester indicates no DTC, no communication. DTC

3-6 to 3-'10, DTC 4-6 to 4-10, DTC 9-1, or DTC 9-2,

double-check by using the "SCS" menu method.

(cont'd)

23-23