CAmshaft HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 118 of 1139

Gylinder Head Removal

NOTE:. Use fender covers to avoid damaging painted

surfaces.

To avoid damage, unplug the wiring connectors

carefully whlle holding the connector portion.

To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100'F (38"C)

betore loosening the cylinder head bolts.

Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

'1.

2.

3.

Drain the engine coolant (see page 10-6).

Remove the drive belt (see page 4-26).

Remove the intake manifold {see page 9-3).

Remove the air cleaner housing (see step 7 on page

5-2t.

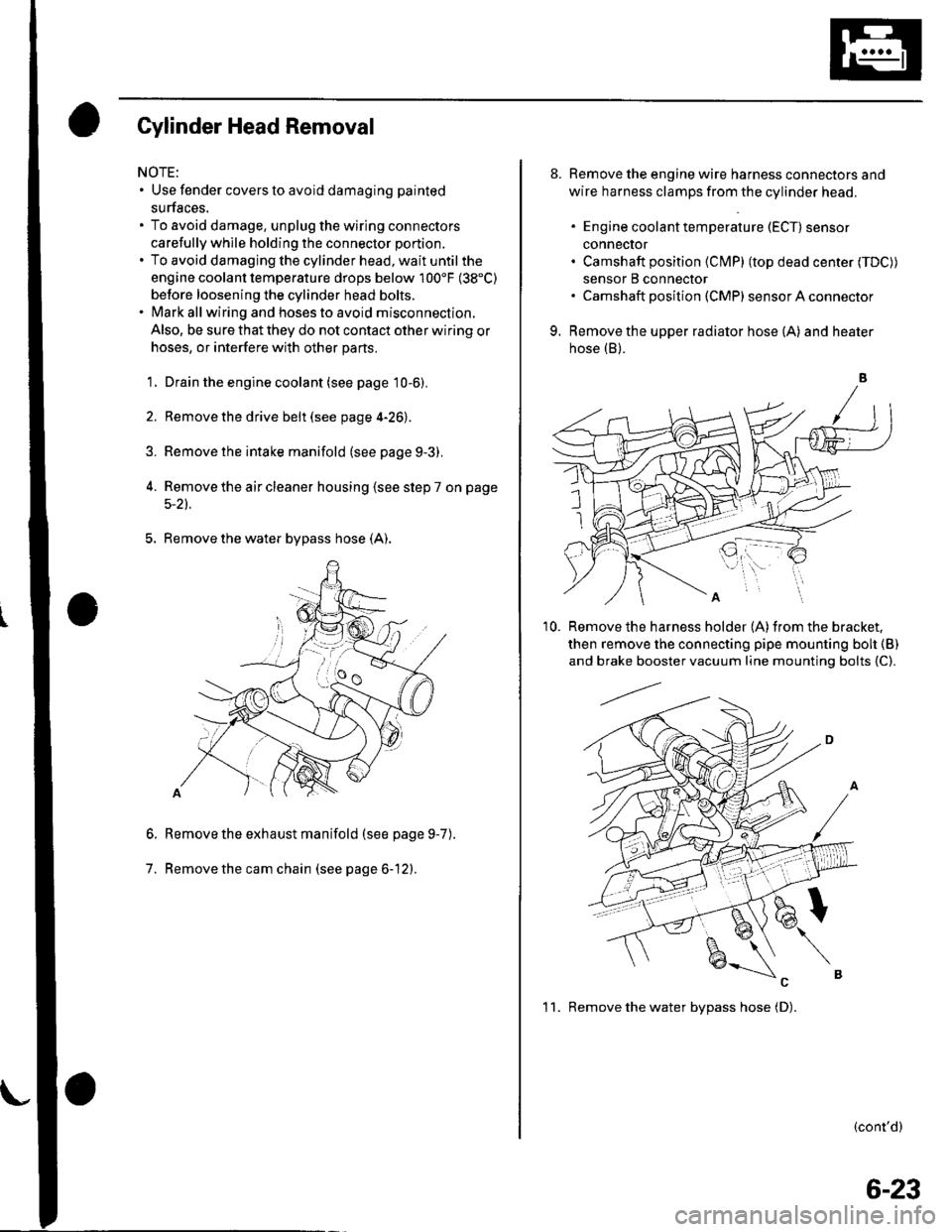

5. Remove the water bypass hose (A).

Remove the exhaust manifold (see page 9-7

Remove the cam chain (see page 6-12).

6.

7.

).

8. Remove the engine wire harness connectors and

wire harness clamps from the cylinder head.

. Engine coolant temperature (ECT) sensor

conneclor. Camshaft position (Cl\4P) (top dead center (TDC))

sensor B connector. Camshaft posilion (CMP) sensor A connector

9. Remove the upper radiator hose (A) and heater

hose (B).

'10. Remove the harness holder (A)from the bracket,

then remove the connecting pipe mounting boh {B)

and brake booster vacuum line mounting bolts {C).

(cont'd)

1 1. Remove the water bvpass hose (D).

6-23

Page 119 of 1139

Cylinder Head

tJ.

Cylinder Head Removal (cont'd)

Remove the rocker arm assembly (see page 6-26).

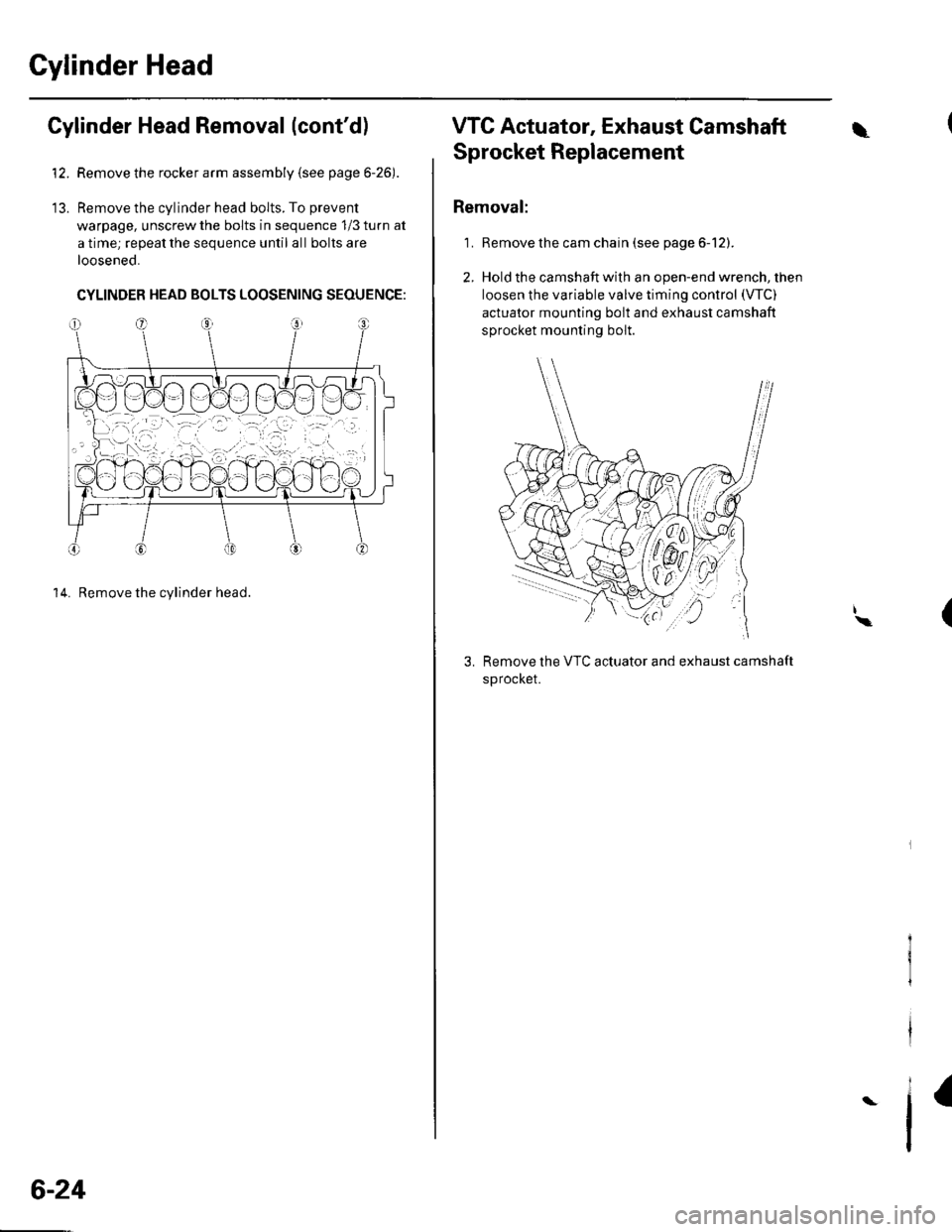

Remove the cylinder head bolts. To prevent

warpage, unscrew the bolts in sequence 1/3 turn at

a time; repeat the sequence until all bolts are

loosened.

CYLINDER HEAD BOLTS LOOSENING SEQUENGE:

14. Remove the cylinder head.

6-24

VTC Actuator, Exhaust Camshaft\

Sprocket Replacement

Removal:

1. Remove the cam chain (see page 6-12).

2. Hold the camshaft with an open-end wrench, then

loosen the variable valve timing control (VTC)

actuator mounting bolt and exhaust camshaft

sprocket mounting bolt.

Remove the VTC actuator and exhaust camshaft

sprocket.

I\(

I

Page 120 of 1139

Installation:

1. Install the VTC actuator and exhaust camshaft

sprocket.

2. Apply engine oil to the th reads of the VTC actuato r

mounting bolt and exhaust camshaft mounting bolt,

then install them.

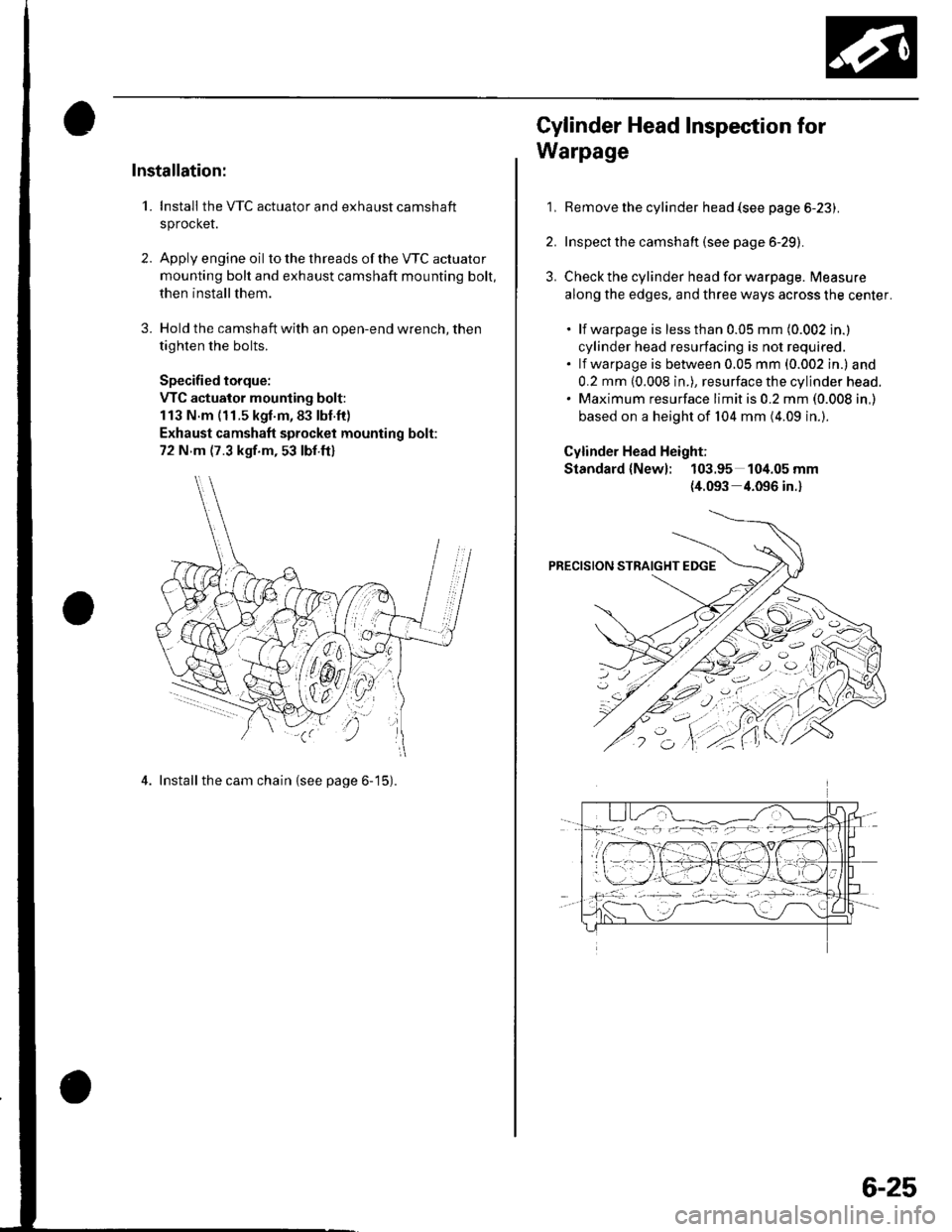

3. Hold the camshaft with an open-end wrench, then

tighten the bolts.

Specified torque:

VTC actuator mounting bolt:

113 N.m (11.5 kgl.m,83 lbl.ft)

Exhaust camshaft sprocket mounting bolt:

72 N m (7.3 kgf.m, 53 lbf.ft)

4. Install the cam chain {see page 6-15).

1,

Cylinder Head Inspection for

Warpage

Remove the cylinder head {see page 6-23).

Inspect the camshaft (see page 6-29).

Check the cylinder head for warpage. Measure

along the edges, and three ways across the center.

. lf warpage is less than 0.05 mm (0.002 in.)

cylinder head resurfacing is not required.. lf warpage is between 0.05 mm (0.002 in.) and

0.2 mm (0.008 in.), resurface the cylinder head.. Maximum resurface limit is 0.2 mm (0.008 in,)

based on a height of 104 mm (4.09 in.).

Cylinder Head Height;

Standard {New}: 103.95 104.05 mm

{4.093 4.096 in.}

6-25

Page 121 of 1139

Cylinder Head

'1.

2.

Rocker Arm Assembly Removal

Remove the cam chain (see page 6-12).

Loosen the rocker arm adjusting screws (A),

A

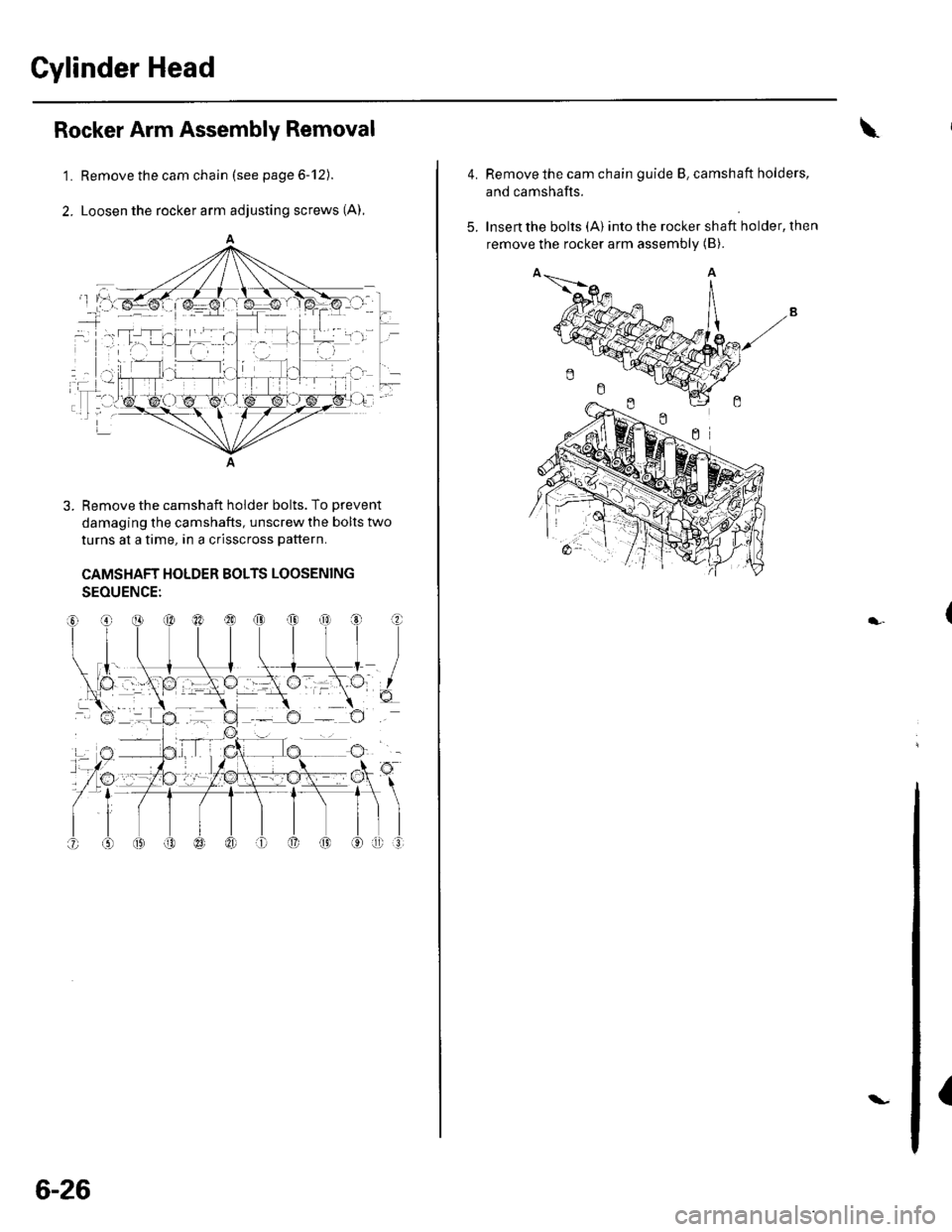

3. Remove the camshaft holder bolts. To Drevent

damaging the camshafts, unscrew the bolts two

turns at a time, in a crisscross pattern.

CAMSHAFT HOLDER BOLTS LOOSENING

SEOUENCE:

6-26

\-

4.Remove the cam chain guide B, camshaft holders,

and camshafts.

Insert the bolts (A) Into the rocker shaft holder, then

remove the rocker arm assembly (B).5.

{

Page 122 of 1139

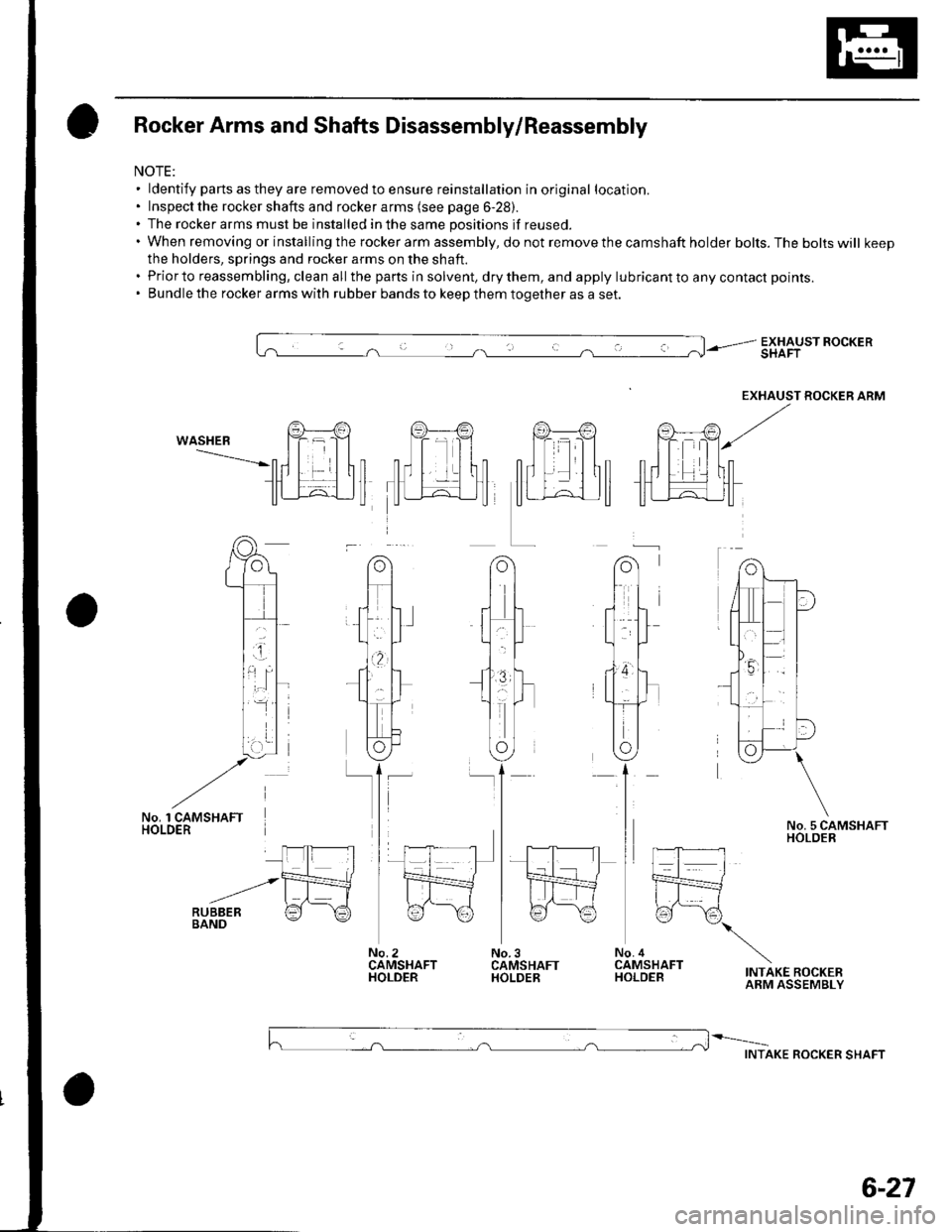

NOTE:

Rocker Arms and Shafts Disassembly/Reassembly

ldentify parts as they are removed to ensure reinstallation in original location.

Inspect the rocker shafts and rocker arms (see page 6-28).

The rocker arms must be installed in the same positions if reused.

When removing or installing the rocker arm assembly, do not remove the camshaft holder bolts. The bolts will keep

the holders, springs and rocker arms on the shaft.

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact points.

Bundle the rocker arms with rubber bands to keeD them tooether as a set.

EXHAUST ROCKERSHAFT

EXHAUST ROCKER ARM

wASHEB Yr rY Y V

l I ltnrll lln

IJI_J;-L,JLI []1_L^|l]rffin ,ffif-

INTAKE ROCKERARM ASSEMBLY

INTAKE ROCKER SHAFT

'rl)

70)

.;...1

t:l P-l

,,_tl

o

,q

'l

o

6-27

Page 124 of 1139

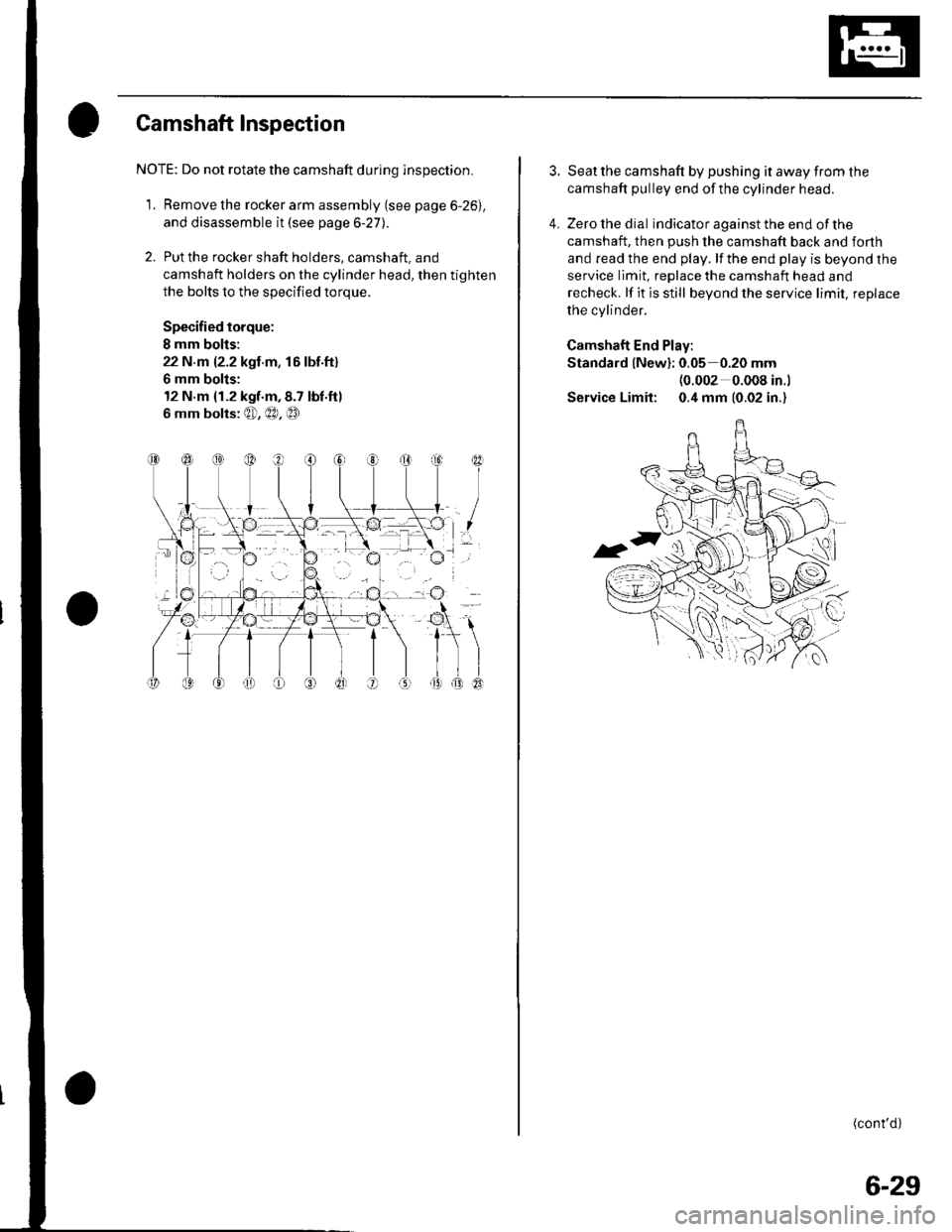

Gamshaft Inspection

NOTE: Do not rotate the camshaft during inspection.

1. Remove the rocker arm assembly (see page 6-26).

and disassemble it (see page 6-27).

2. Put the rocker shaft holders, camshaft, and

camshaft holders on the cylinder head, then tighten

the bolts to the specified torque.

Specified torque:

I mm bolis:

22 N.m {2.2 kgt m, 16lbf.ft}

6 mm bolts:

12 N.m {1.2 kgf.m,8.7 tbf.ftl

6 mm bolts: @, €0, @

I

I

3. Seat the camshaft by pushing it away from the

camshaft pulley end ofthe cylinder head.

4. Zero the dial indicator against the end of the

camshaft, then push the camshaft back and forth

and read the end play. lf the end play is beyond the

service limit, replace the camshaft head and

recheck. lf it is still beyond the service limit, replace

the cylinder.

Camshaft End Play:

Standard {New}: 0.05 0.20 mm(0.002 0.008 in.l

Service Limit: 0.4 mm (0.02 in.)

(cont'd)

6-29

Page 125 of 1139

Cylinder Head

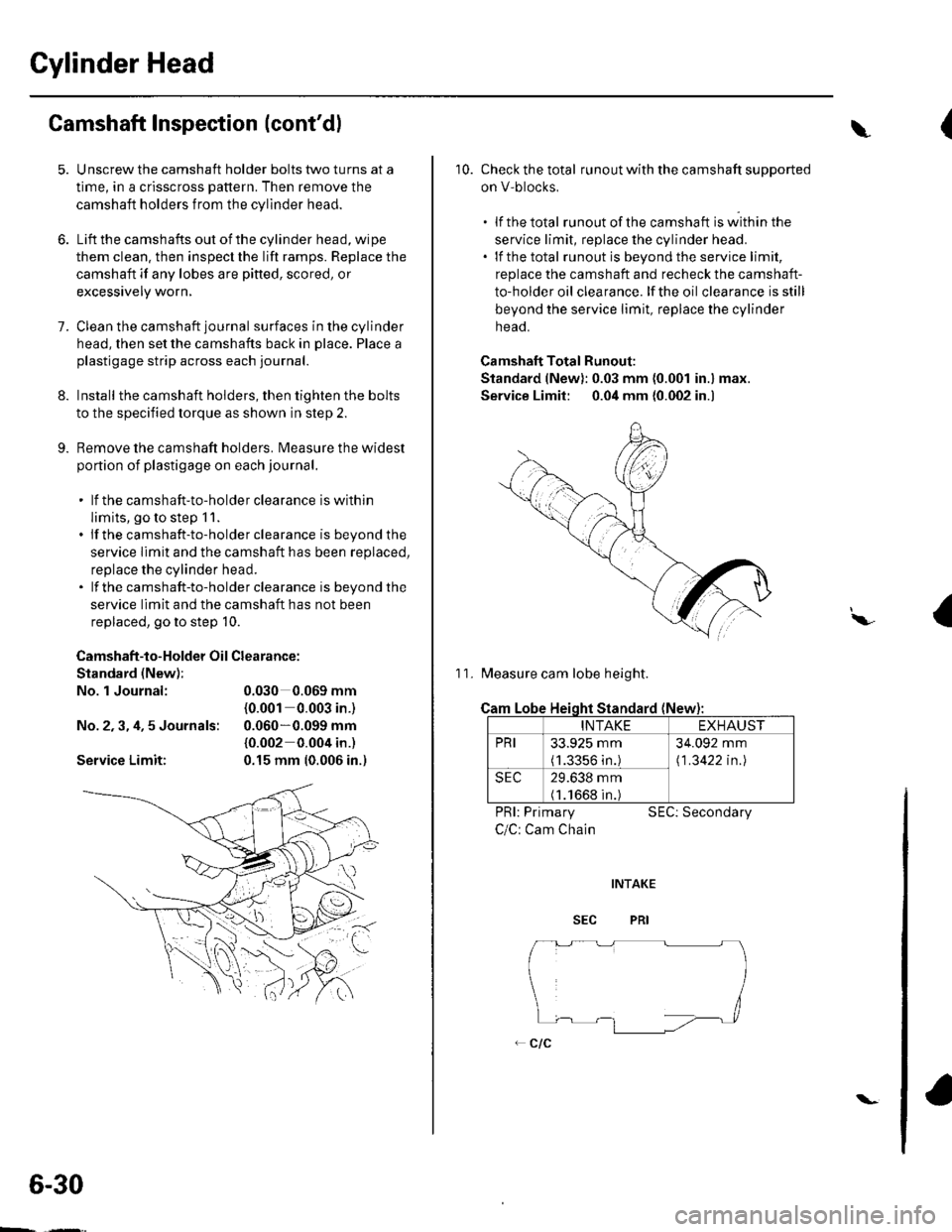

Camshaft Inspection (cont'dl

1.

9.

Unscrew the camshaft holder bolts two turns at a

time, in a crisscross pattern. Then remove the

camshaft holders from the cylinder head.

Lift the camshafts out of the cylinder head, wipe

them clean. then inspect the lift ramps. Replace the

camshaft if any lobes are pitted, scored, or

excessively worn,

Clean the camshaft journal surfaces in the cylinder

head, then set the camshafts back in place. Place a

plastigage strip across each journal.

Install the camshaft holders, then tighten the bolts

to the specified torque as shown in step 2.

Remove the camshaft holders. Measure the widest

portion of plastigage on each journal.

. lf the camshaft-to-holder clearance is within

limits, go to step 1 1.. lf the camshaft-to-holder clearance is beyond the

service limit and the camshaft has been replaced,

replace the cylinder head.. lf the camshaft-to-holder clearance is beyond the

service limit and the camshaft has not been

replaced, go to step 10.

Camshaft-to-Holder Oil Clearance:

Standard (New):

No. 1 Journal:

No.2,3,4,5 Journals:

Service Limit:

0.030 0.069 mm

{0.001 0.003 in-)

0.060*0.099 mm

{0.002 0.004 in.)

0.15 mm {0.006 in.)

6-30

\-

{\

10. Check the total runout with the camshaft supported

on V-blocks,

.lfthetotal runout of the camshaft is within the

service limit, replace the cylinder head.. lf the total runout is beyond the service limit,

replace the camshaft and recheck the camshaft-

to-holder oil clearance. lf the oil clearance is still

beyond the service limit, replace the cylinder

neao.

Camshaft Total Runout:

Standard (New): 0.03 mm (0.001 in.) max.

Service Limit: 0.04 mm {0.002 in.)

11. Measure cam lobe height.

Cam

PRI: Primary

C/C: Cam Chain

SEC: Secondary

I\,

Lobe Heioht Standard (New

INTAKEEXHAUST

PRI33.925 mm(1.3356 in.)

34.092 mm

\1 .3422 in.l

SEC29.638 mm(1.1668 in.)

Page 128 of 1139

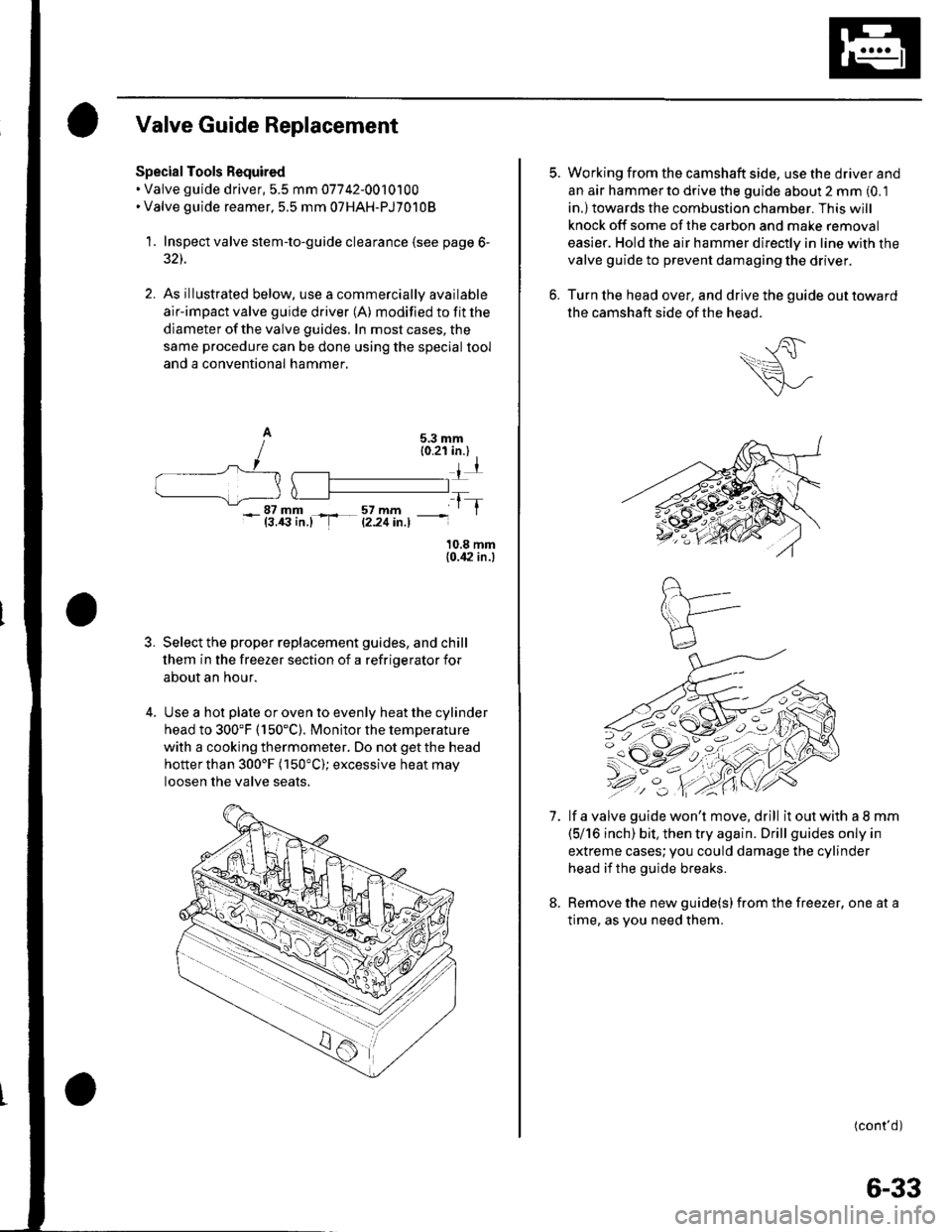

Valve Guide Replacement

Special Tools Required. Valve guide driver, 5.5 mm 07742-0010100. Valve guide reamer, 5.5 mm 07HAH-PJ7o108

1.Inspect valve stem-to-guide clearance (see page 6-

32t.

As illustrated below, use a commercially available

air-impact valve guide driver (A) modified to fit the

diameter of the valve guides. In most cases, the

same procedure can be done using the special tool

and a conventional hammer.

10.8 mm{0.,|2 in.)

3. Select the proper replacement guides, and chill

lhem in the freezer section of a refriqerator for

about an hour.

4. Use a hot plate or oven to evenly heat the cylinder

head to 300'F (150"C). Monitor the temperature

with a cooking thermometer. Do not getthe head

hotterthan 300'F (150"C); excessive heat may

loosen the valve seats.

-_|Jfillr-.-4fi'11., -

tT

7.

Working from the camshaft side. use the driver and

an aar hammerto drive the guide about 2 mm (0.1

in.)towards the combustion chamber. This will

knock off some of the carbon and make removal

easier. Hold the air hammer directly in line with the

valve guide to prevent damaging the driver.

Turn lhe head over, and drive the guide out toward

the camshaft side of the head.

lf a valve guide won't move, drill it out with a I mm

(5/16 inch) bit. then try again. Drill guides only in

extreme cases;you could damage the cylinder

head if the guide breaks.

Remove the new guide(s) from the freezer, one at a

time, as vou need them.

(cont'd)

6-33

Page 129 of 1139

Cylinder Head

Valve Guide Replacement (cont'dl

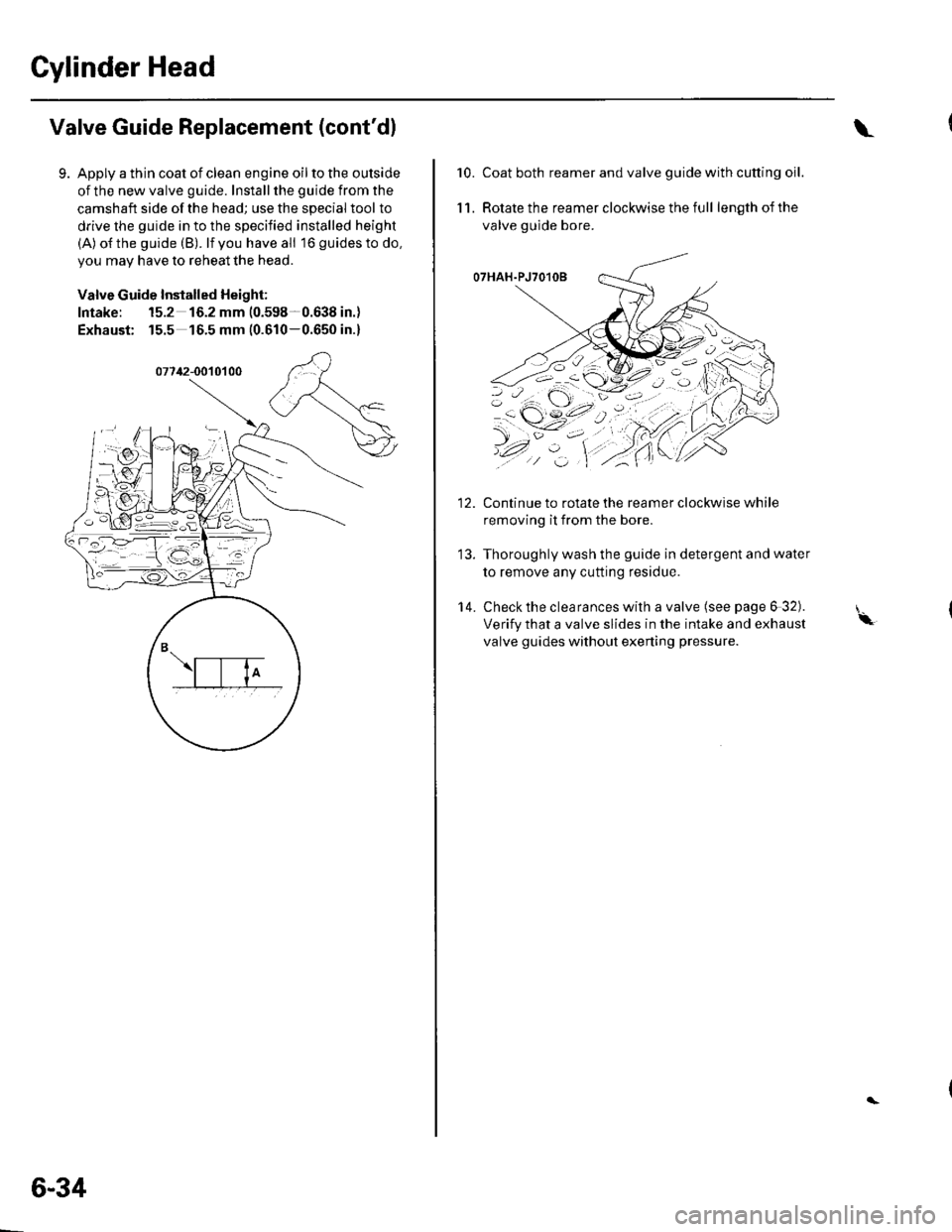

Apply a thin coat of clean engine oil to the outside

of the new valve guide. Install the guide from the

camshaft side of the head; use the special tool to

drive the guide in to the specified installed height

(A) o{the guide (B). lf you have all 16 guidesto do,

you may have to reheat the head.

Valve Guide Installed Height:

Intake: 15.2 16.2 mm (0.598-0.638 in.)

Exhaust: 15.5 16.5 mm (0.610-0.650 in.)

6-34

\

10.Coat both reamer and valve guide with cutting oil.

Rotate the reamer clockwise the full length of the

valve guide bore.

O7HAH.PJ7O1OB

Continue to rotate the reamer clockwise while

removing it from the bore.

Thoroughly wash the guide in detergent and water

to remove any cutting residue.

Check the clearances with a valve (see page 6 32).

Verify that a valve slides in the intake and exhaust

valve guides without exening pressure.

11.

14.

'-\

Page 133 of 1139

Cylinder Head

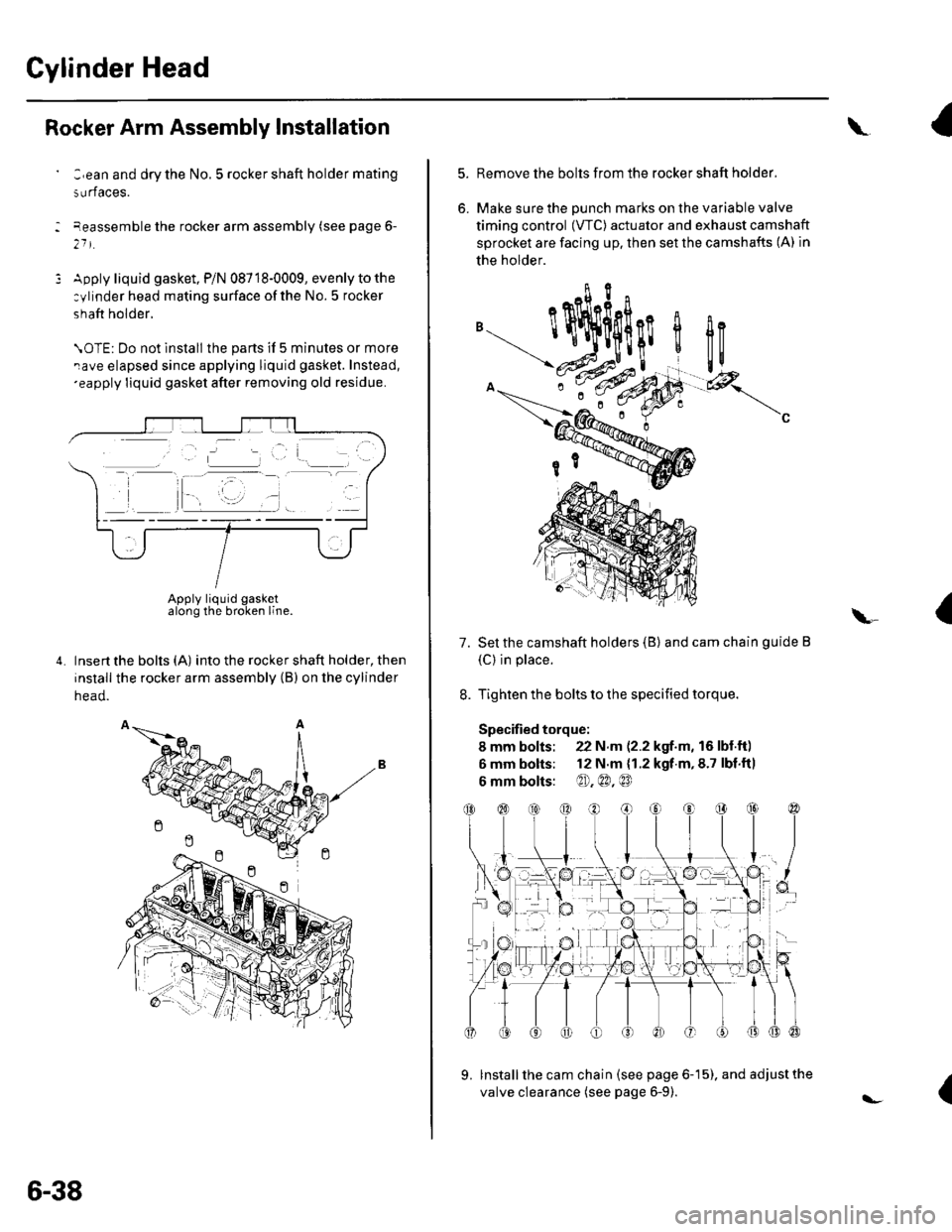

Rocker Arm Assembly Installation

:,ean and dry the No. 5 rocker shaft holder mating

surfaces.

eeassemble the rocker arm assembly (see page 6-

21 t.

Apply liquid gasket, P/N 08718-0009, evenly to the

:ylinder head mating surface ofthe No. 5 rocker

shaft holder.

\OTE: Do not lnstall the parts if 5 minutes or more

rave elapsed since applying liquid gasket. Instead,'eapply liquid gasket after removing old residue.

Insert the bolts (A) into the rocker shaft holder, then

install the rocker arm assembly (B) on the cylinder

head.

Apply liquid gasketalong the broken line.

6-38

l-

\

5.

6.

Remove the bolts from the rocker shaft holder.

Make sure the DUnch marks on the variable valve

timing control (VTC) actuator and exhaust camshaft

sprocket are facing up. then set the camshafts (A) in

the holder.

Set the camshaft holders (B) and cam chain guide B

(C) in place.

Tighten the bolts to the specified torque.

Specified torque:

8 mm bolts: 22 N.m (2.2 kgf.m, 16 lbl.ft)

6 mm bolts: 12 N.m {1.2 kgf.m,8.7 lbf.fil

6 mm bolts: @),@.@

lnstall the cam chain (see page 6-15). and adjust the

valve clearance (see page 6-9).

I

flc

a\-

7.

{