heater troubleshooting HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 787 of 1139

Heating and Air Conditioning

DTC Troubleshooting

DTC 7: An Open in the Air Mix Control Motor

Circuit

1. Test the air mix control motor {see page 2'l-341.

ls the air mix control motor OK?

YES-Go to step 2.

NO-Replace the air mix control motor.l

2. Disconnect the air mix control motor 5P connector.

3. Disconnect heater control panel connectors A {14P)

and B (22P).

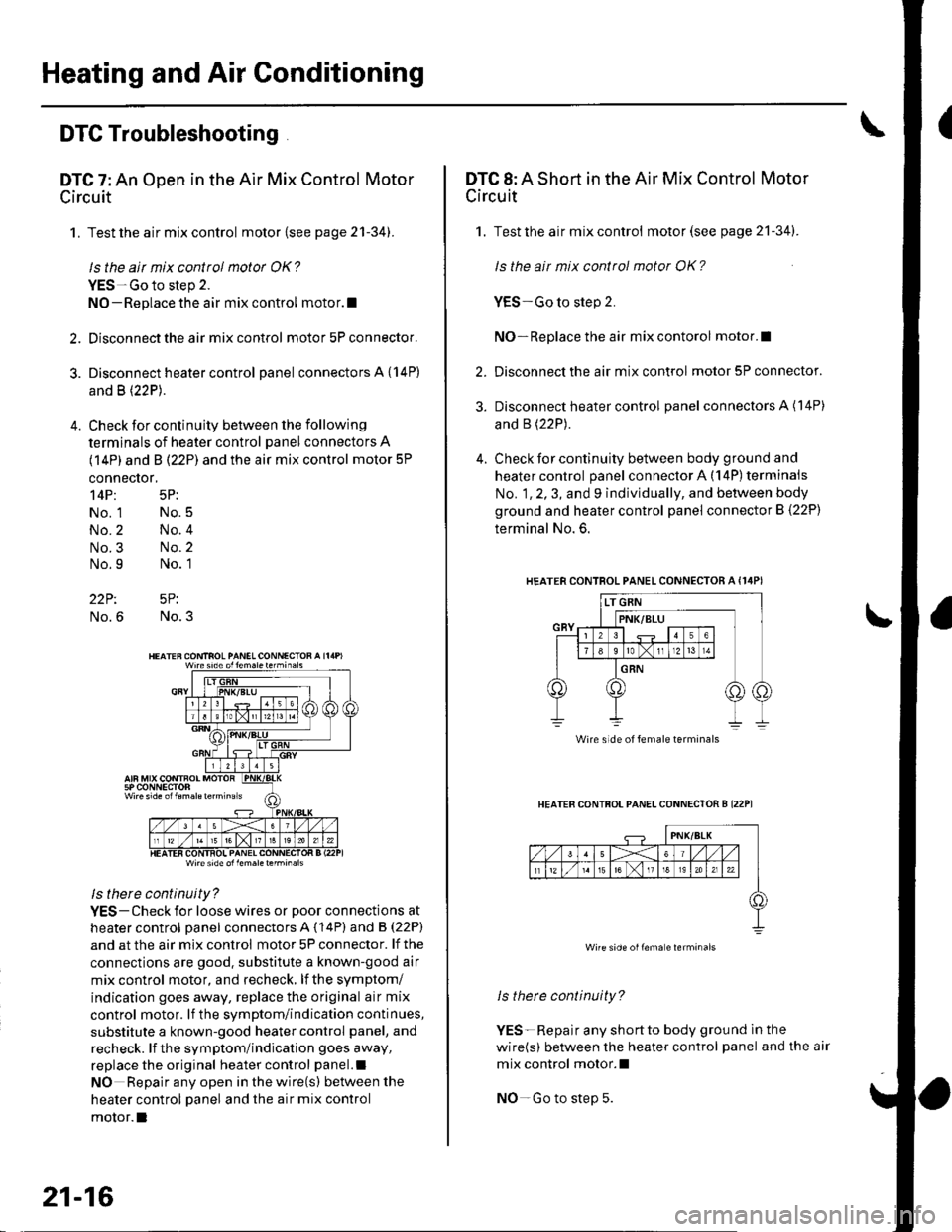

4. Check for continuity between the following

terminals of heater control panel connectors A

(14P) and B (22P) and the air mix control motor 5P

connector,

14P: 5P:

No. 1 No.5

No.2 No.4

No.3 No.2

No.9 No. 1

22P: 5P:

No.6 No.3

Wire side ol lem.letehi.6ls

ls there continuity?

YES-Check for loose wires or poor connections at

heater control oanel connectors A (14P) and B (22P)

and at the air mix control motor 5P connector. lf the

connections are good. substitute a known-good air

mix control motor, and recheck, lf the symptom/

indication goes away, replace the original air mix

control motor. lf the symptom/indication continues,

substitute a known-good heater control panel, and

recheck. lf the symptom/indication goes away,

replace the original heater control panel.l

NO Repair any open inthewire(s) ketweenthe

heater control panel and the air mix control

motor.l

21-16

DTC 8: A Short in the Air Mix Control Motor

Circuit

1. Test the air mix control motor(see page 21-341.

ls the ait mix control motor OK?

YES-Go to step 2.

NO-Replace the air mix contorol motor.I

2. Disconnect the air mix control motor 5P connector.

3. Disconnect heater control panel connectors A (14P)

and B (22P).

4. Check for continuity between body ground and

heater control panel connector A (14P) terminals

No. 1, 2, 3, and 9 individually, and between body

ground and heater control panel connector B (22P)

terminal No. 6.

HEATERCONTROL PANEL CONNECTOR A {I4PI

HEATER CONTFOL PANELCONNECTOR B I22P1

ls therc continuity?

YES-Repair any shortto body ground ln the

wire(s) between the heater control panel and the air

mix control motor.l

NO-Go to step 5.

Wire side of female terminals

Wire side oilema e lerminals

Page 789 of 1139

Heating and Air Conditioning

DTC Troubleshooting.(cont'd)

DTC 10: An Open or Short in the Mode

Control Motor Circuit

1. Test the mode control motor (see page 21-35).

ls the mode cottol motor OK?

YES Go to step 2.

NO Replace the mode control motor.I

Disconnect the mode control motor 10P connector.

Disconnect heater control panel connectors A (14P)

and B \22P1.

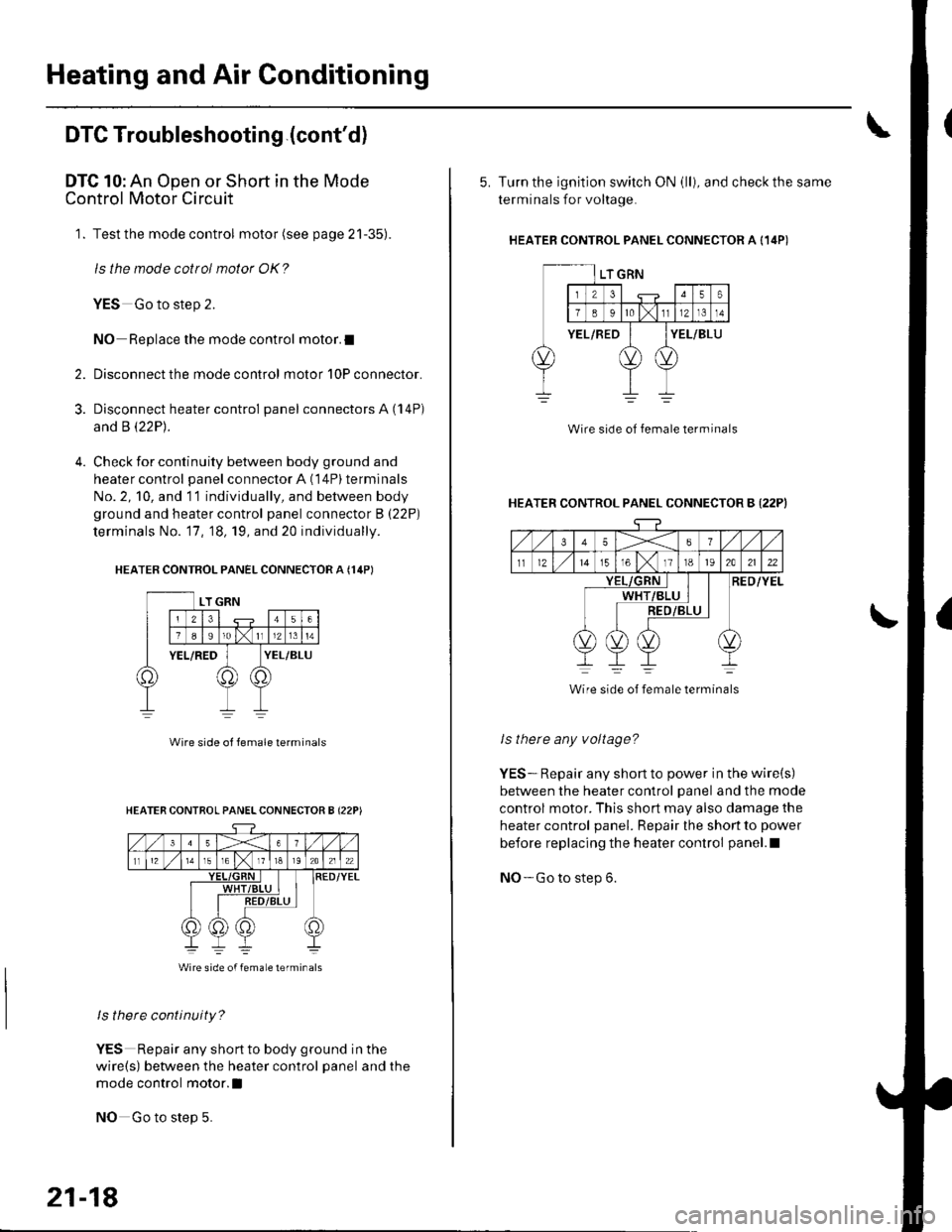

Check for continuity between body ground and

heater control panel connector A (14P) terminals

No. 2, 10, and 11 individually, and between body

ground and heater control panel connector B (22P)

terminals No. '17, 18, 19, and 20 individually.

HEATER CONTROL PANEL CONNECTOR A {14PI

2.

3.

Wire side ol lemale terminals

ls there continuity?

YES Repair any shortto body ground in the

wire(s) between the heater control panel and the

mode control motor.l

NO Go to step 5.

HEATER CONTROL PANELCONNECTOR B {22P)

Wire side of femaLe lerminals

21-18

5. Turn the ignition switch ON (ll), and check the same

terminals for voltage.

HEATEB CONTROL PANEL CONNECTOR A {14P)

Wire side of female terminal

HEATER CONTROL PANEL CONNECTOR B {22PI

35X6

tl1215T61118t92A2122

RED/YELWHT

Wire side of female terminals

ls there any voltage?

YES-. Repair any short to power in the wire(s)

between the heater control panel and the mode

control motor. This short may also damage the

heater control panel. Repair the short to power

before replacing the heater control panel.l

NO- Go to step 6.

Page 795 of 1139

Heating and Air Gonditioning

\

DTC Troubleshooting {cont'd)

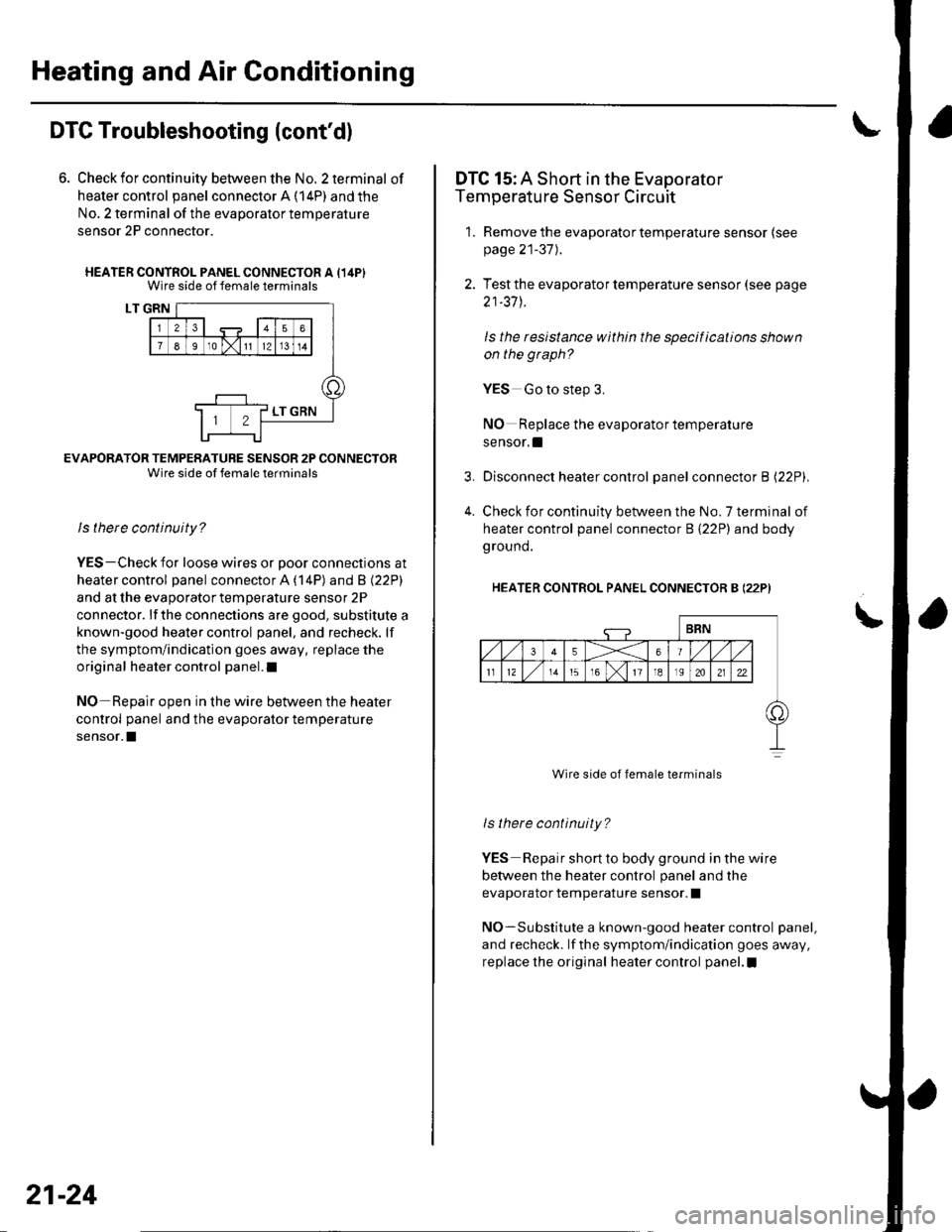

6. Check for continuity between the No. 2 terminal of

heater control panel connector A (14P) and the

No, 2 terminal of the evaporalor temperature

sensor 2P connector.

HEATER CONTROL PANEL CONNECTOR A {14PIWire side of female terminals

LT GRN

EVAFORATOR TEMPERATURE SENSOR 2P CONNECTORWire side of female terminals

ls there continuity?

YES-Check for loose wires or Door connections at

heater control panel connector A ('l4P) and B l22Pl

and at the evaporator temperature sensor 2P

connector. lf the connections are good, substitute a

known-good heater control panel, and recheck. lf

the symptom/indication goes away, replace the

original heater control panel.l

NO Reoair ooen in the wire between the heater

control panel and the evaporator temperature

sensor.I

21-24

4.

DTC 15: A Short in the Evaporator

Temperature Sensor Circuit

1. Remove the evaporator temperature sensor (see

page 21-37).

2. Test the evaporator temperature sensor (see page

21-37 J.

ls the resistance within the specifications shown

on the graph?

YES Go to step 3.

NO Replace the evaporator temperature

sensor. !

Disconnect heater control panel connector B l22Pl.

Check for continuity between the No. 7 terminal of

heater control panel connector B {22P) and body

ground.

HEATER CONTROL PANEL CONNECTOR B (22P)

Wire side of female terminals

ls there continuity?

YES Repair short to body ground in the wire

betvveen the heater control panel and the

evaporator temperature sensor. I

NO-Substitute a known-good heater control panel,

and recheck. lf the symptom/indication goes away,

replace the original heater control panel.I

Page 796 of 1139

3.

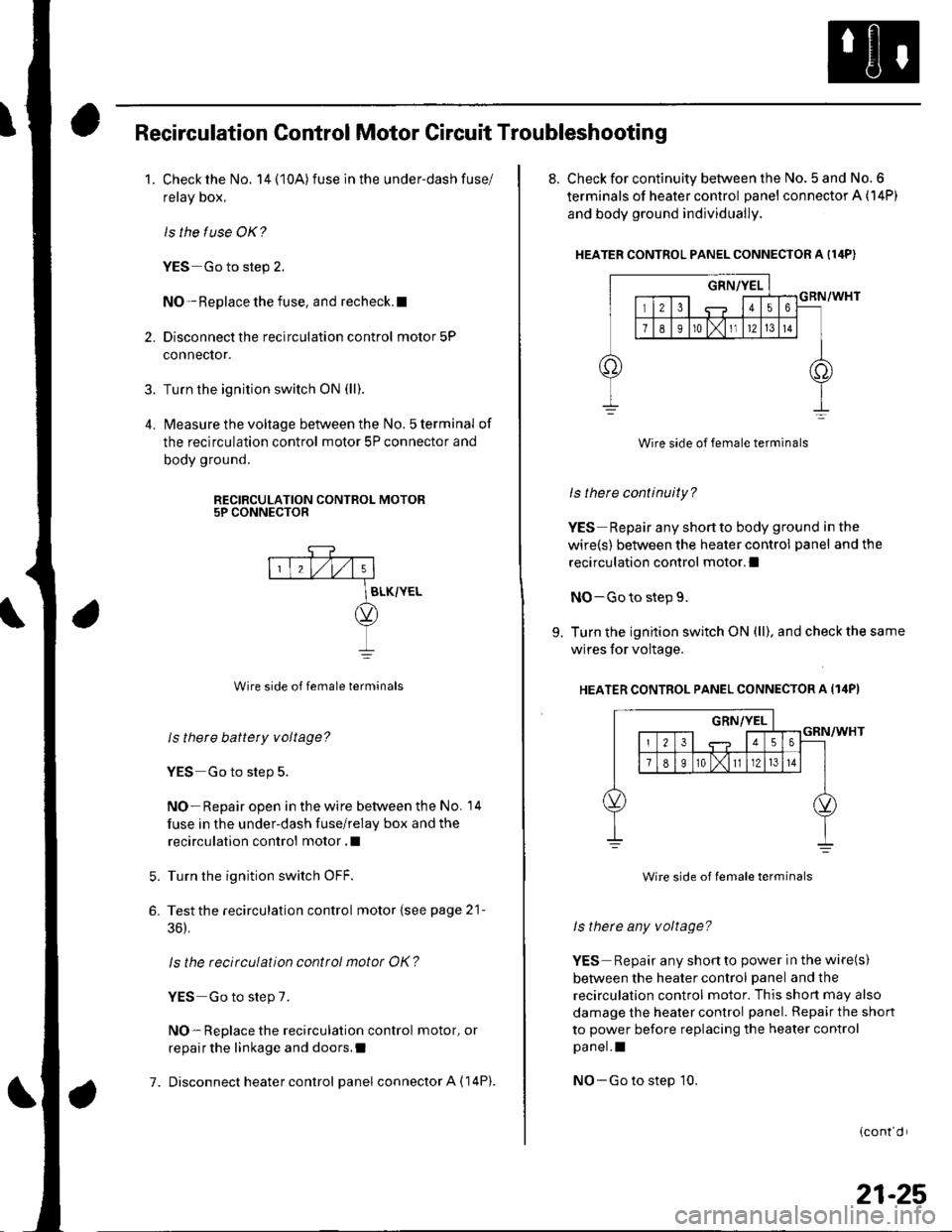

Recirculation Control Motor Circuit Troubleshooting

1. Check the No. 14('10A)fuse inthe under-dashfuse/

relay box.

ls the f use OK?

YES Go to step 2.

NO- Replace the fuse, and recheck.l

2. Disconnect the recirculation control motor 5P

conneclor.

Turn the ignition switch ON (ll).

lvleasure the voltage between the No. 5 terminal of

the recirculation control motor 5P connector and

body ground.

RECIRCULATION CONTROL MOTOR5P CONNECTOR

7.

Wire side of female terminals

ls there battery voltage?

YES Go to step 5.

NO- Repair open in the wire between the No. 14

fuse in the under-dash fuse/relay box and the

recirculation control motor .l

Turn the ignition switch OFF.

Testthe recirculation control motor {see page 21-

36),

ls the recirculation control motor OK?

YES Go to step 7.

NO- Replace the recirculation control motor, or

repair the linkage and doors.I

Disconnect heater control panel connector A (14P).

5.

6.

8. Check for continuity between the No. 5 and No. 6

terminals of heater control panel connector A (14P)

and body ground individually.

HEATER CONTROL PANEL CONNECTOR A I14P)

Wire side of female terminals

ls there continuity?

YES Repair any shortto body ground in the

wire(s) between the heater control panel and the

recirculation control motor.l

NO-Go to step 9.

9. Turn the ignition switch ON (ll), and check the same

wires for voltage.

HEATER CONTROL PANEL CONNECTOR A Il4PI

Wire side of lemale terminals

ls therc any voltage?

YES Repair any shonto power in the wire(s)

between the heater control panel and the

recirculation control motor. This shon may also

damage the heater control panel. Repair the shon

to power before replacing the heater control

pa nel. I

NO-Go to step 10.

{cont d r

21-25

Page 797 of 1139

Heating and Air Conditioning

Recirculation Control Motor Circuit Troubleshooting (cont'd!

10. Turn the ignition swirch OFF.

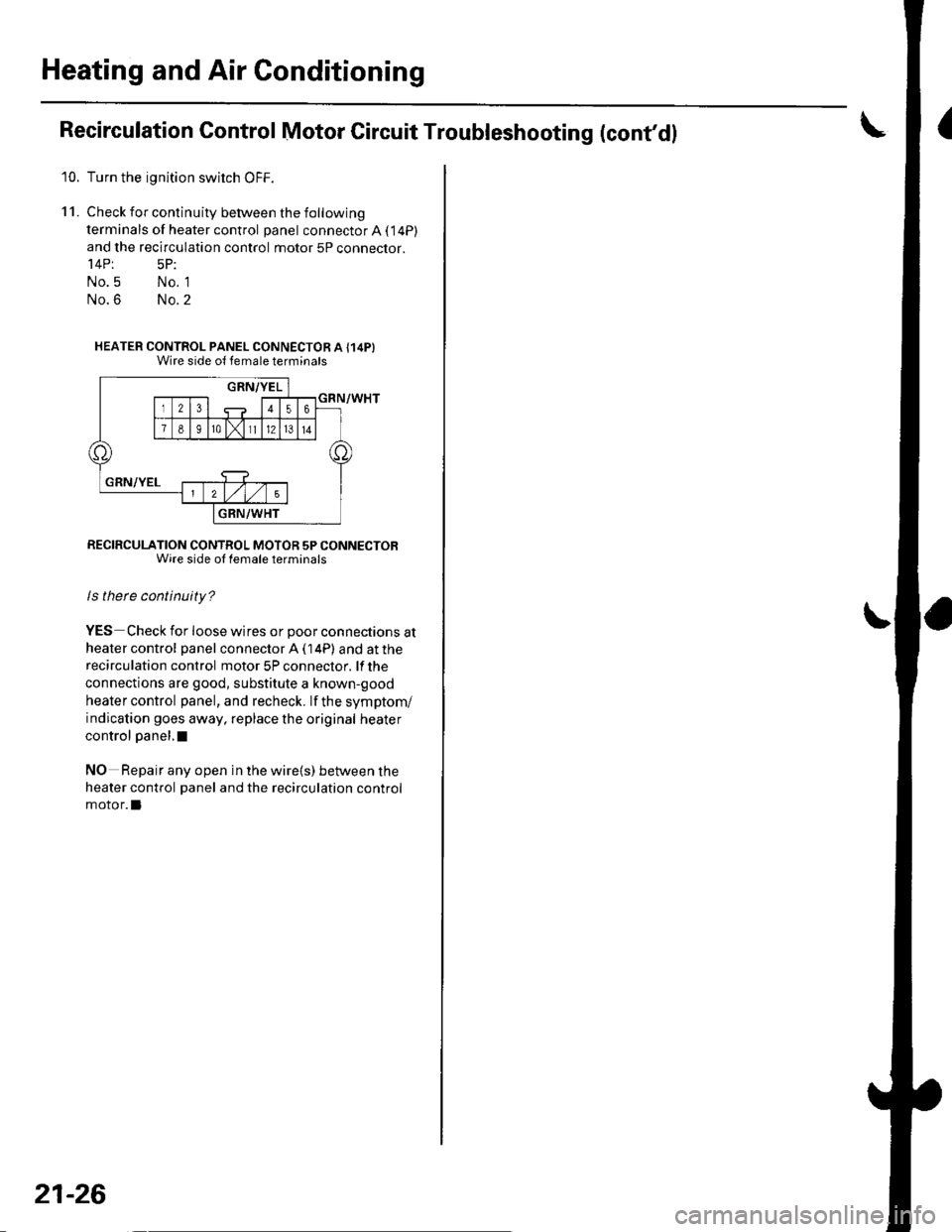

11. Check for continuity between the following

terminals of heater control panel connector A ( 14P)

and the recirculation control motor 5P connector.'l4Pt 5P:

No.5 No. 1

No.6 No.2

HEATER CONTROL PANEL CONNECTOR A {14P}Wire side ol temale terminats

RECIRCULATION CONTROL MOTOR 5P CONNECTORWire side ol lemale terminals

ls there continuity?

YES Check for loose wires or poor connections at

heater control panel connector A ( 14P) and at the

recirculation control motor 5P conneclor. lf the

connections are good, substitute a known-good

heater control panel, and recheck. lf the symptom/

indication goes away, replace the original heater

control panel,I

NO Repair any open in the wire{s) between the

heater control panel and the recirculation control

motor.l

21-26

Page 798 of 1139

Heater Control Power and Ground Circuits Troubleshooting

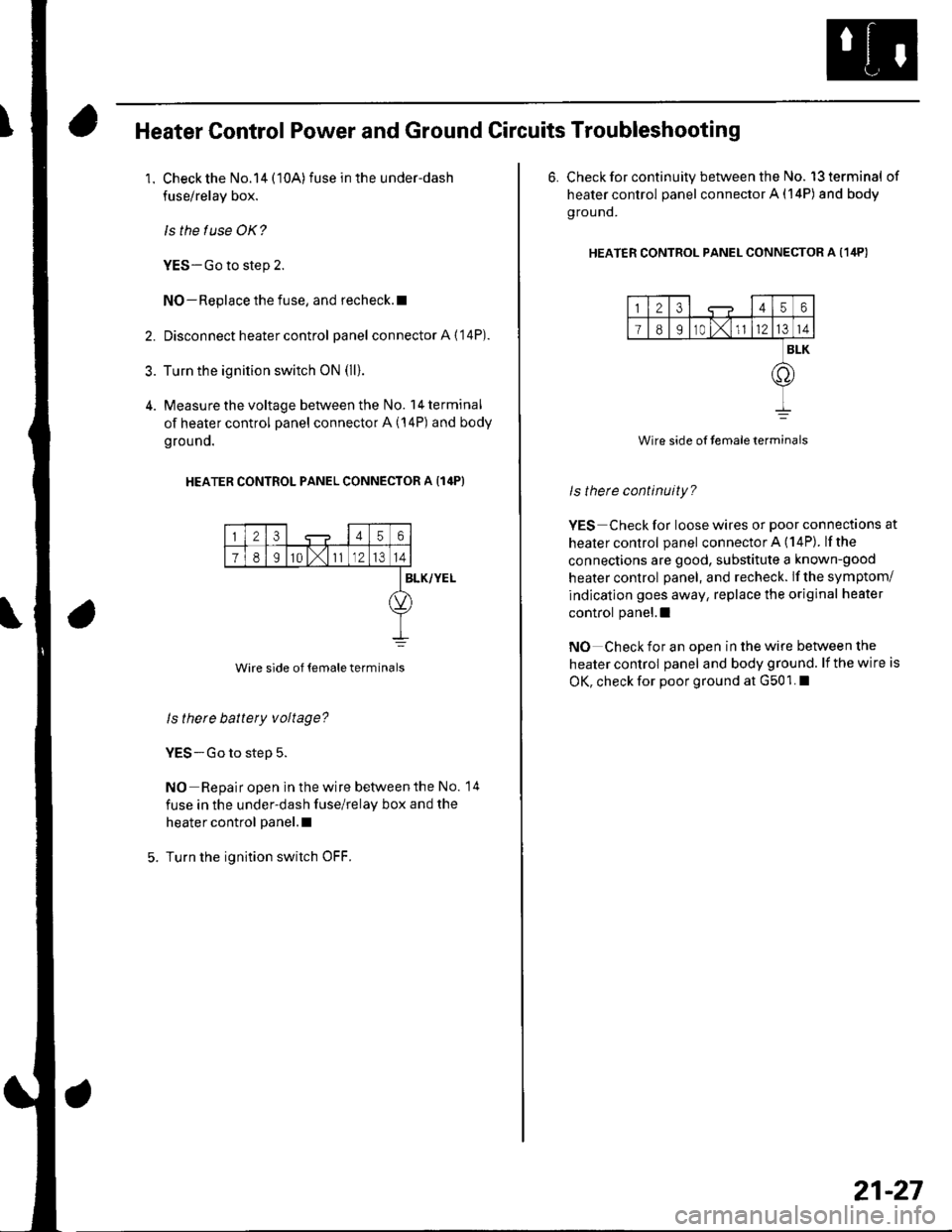

1. Check the No.14 (10A)fuse in the under-dash

fuse/relay box.

ls the f use OK?

YES-Go to step 2.

NO-Replace the fuse, and recheck.l

2. Disconnect heater control panel connectorA{'14P).

3. Turn the ignition switch oN (ll).

4. Measure the voltage between the No. l4terminal

of heater control panel connector A (14P) and body

grouno.

HEATER CONTROL PANEL CONNECTOR A {14P}

23456

78I10 l,111214

Wire side of temale terminals

BLK/YEL

ls there battery voltage?

YES-Go to step 5.

NO Repair open in the wire betvveen the No. 14

fuse in the under-dash fuse/relay box and the

heater control panel.l

Turn the ignition switch OFF.

6. Check for continuity between the No. l3terminal of

heater control panel connector A (14P) and body

g rou nd.

HEATER CONTRoL PANEL CONNEcToR A (1ilP)

123456

I89r0 t,1l1214

BLK

.o

Wire side of temaleterminals

ls therc continuity?

YES Check for loose wires or poor connections at

healer control panel connector A (14P). lfthe

connections are good, substitute a known-good

heater control panel, and recheck. lf the symptom/

indication goes away, replace the original heater

control panel.l

NO Check for an open in the wire between the

heater control panel and body ground. lf the wire is

OK, check for poor ground at G501. I

21-27

Page 803 of 1139

Heating and Air Conditioning

Compressor Clutch Circuit

Troubleshooting (cont'dl

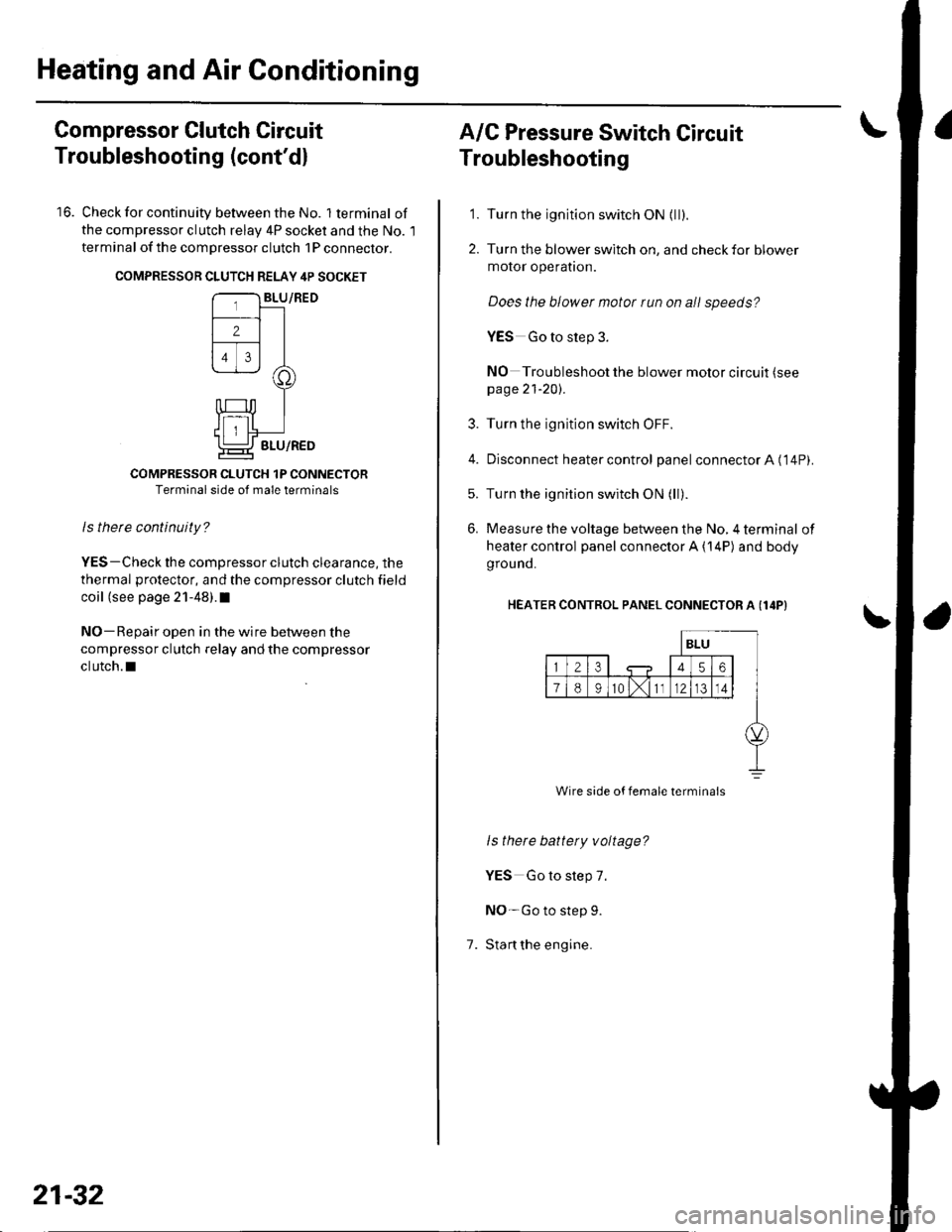

16. Check for continuity between the No. lterminal of

the compressor clutch relav 4P socket and the No. l

terminal of the compressor clutch 1P conneclor.

COMPRESSON CLUTCH RELAY 4P SOCKET

COMPRESSOR CLUTCH 1P CONNECTORTerminal side of male terminals

ls therc continuity?

YES-Check the compressor clutch clearance, the

thermal protector, and the compressor clutch field

coil (see page 21-48).I

NO-Repair open in the wire between the

compressor clutch relay and the compressor

clutch.l

21-32

A/C Pressure Switch Circuit

Troubleshooting

'1. Turn the ignition switch ON {ll).

2. Turn the blower switch on, and check for blower

motor operatron.

Does the blower motor run on all speeds?

YES Go to step 3.

NO Troubleshoot the blower motor circuit (see

page 21-20).

3. Turn the ignition switch OFF.

4. Disconnect heater control panel connectorA ('14P).

5. Turn the ignition switch ON (ll).

6. Measure the voltage between the No, 4 terminal of

heater control panel connector A {14P) and body

grou nd.

HEATER CONTROL PANEL CONNECTOR A (I4P}

1.

ls there battety voltage?

YES Go to step 7.

NO-Go to step 9.

Stan the engine.

Wire side of female termina's

Page 804 of 1139

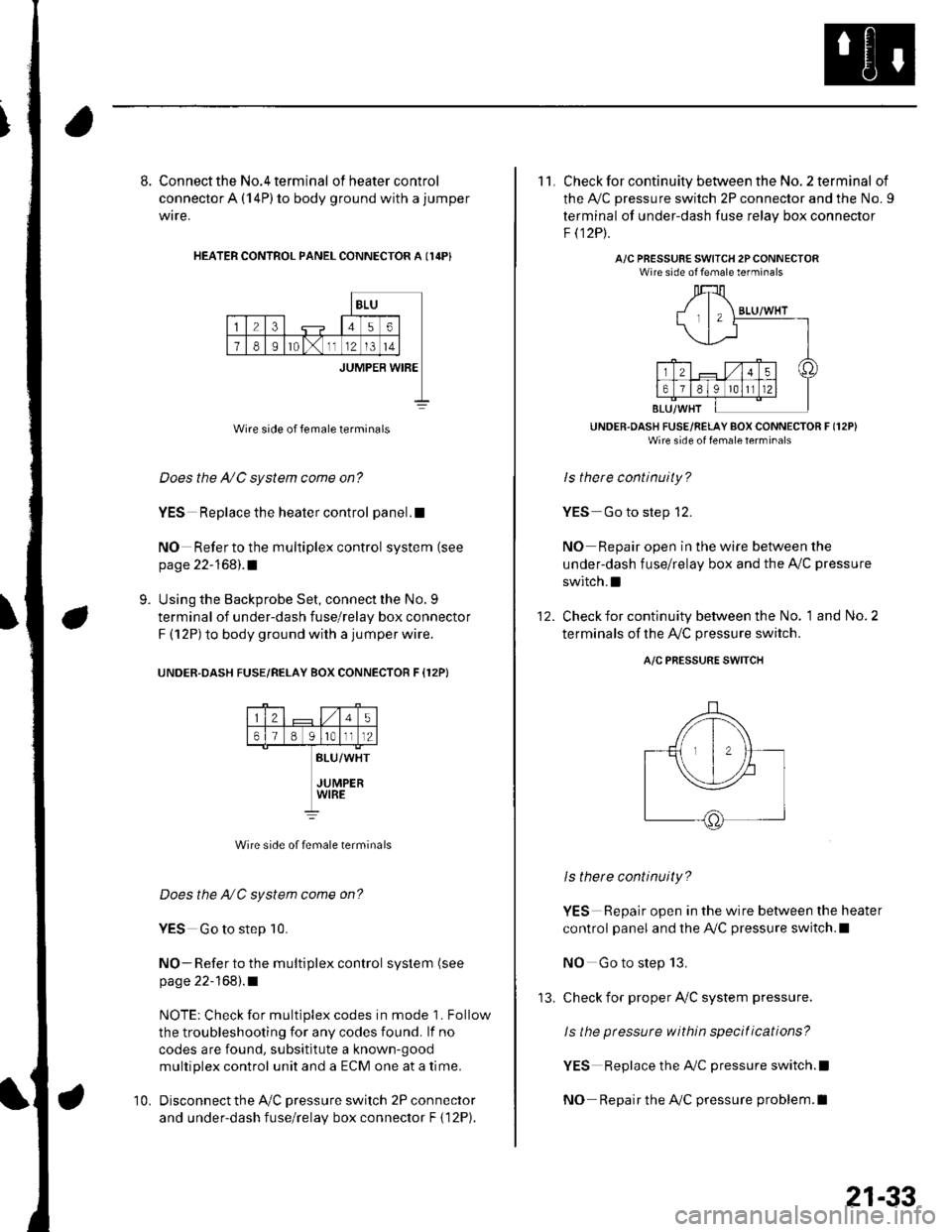

8. Connect the No.4 terminal ofheatercontrol

connector A (14P) to body ground with a jumper

wire,

HEATER CONTROL PANEL CONNECTOR A I14P}

BLU

23456

78Ir0lx1112l3t4

JUMPER WIBE

Wire side of female terminals

Does the A/C system come on?

YES Replace the heater control panel.!

NO Refer to the multiplex control system (see

page 22-168).1

Using the Backprobe Set, connect the No. 9

terminal of under-dash fuse/relay box connector

F (12P) to body ground with a jumper wire.

UNOER.DASH FUSE/RELAY BOX CONNECTOR F {12P}

9.

25

61B g lrotll2

BLU/WHT

JUMPERWIRE

Wire side of female terminals

Does the NC system come on?

YES Go to step 10.

NO- Refer to the multiplex control system (see

page 22-168).1

NOTE: Check for multiplex codes in mode '1. Follow

the troubleshooting {or any codes found. lf no

codes are found, subsititute a known-9ood

multiplex control unit and a ECM one at a time.

Disconnect the Ay'C pressure switch 2P connector

and under-dash fuse/relay box connector F { 12P).

10.

'13.

21-33

11. Check for continuity between the No. 2 terminal of

the A,/C pressure switch 2P connector and the No. 9

terminal of under-dash fuse relav box connector

F t12Pt.

A/C PRESSURE SWITCH 2PCONNECTORWire side of female terminals

UNDER.OASH FUSE/RELAY BOX CONNECTOR F (12P)

Wire side of fenale lerrrinal'

ls there continuity?

YES Go to step 12.

NO Repair open in the wire between the

under-dash fuse/relay box and the A,,/C pressure

switch.I

Check for continuity between the No. 1 and No. 2

terminals of the A,/C pressure switch.

12.

A/C PRESSURE SWITCH

ls there continuity?

YES Repair open in the wire between the heater

control panel and the A,/C pressure switch.l

NO Go to step 13.

check for proper Ay'C system pressure.

ls the pressure within specitications?

YES Replace the AilC pressure switch.l

NO Repair the AilC pressure problem.I

Page 1135 of 1139

)

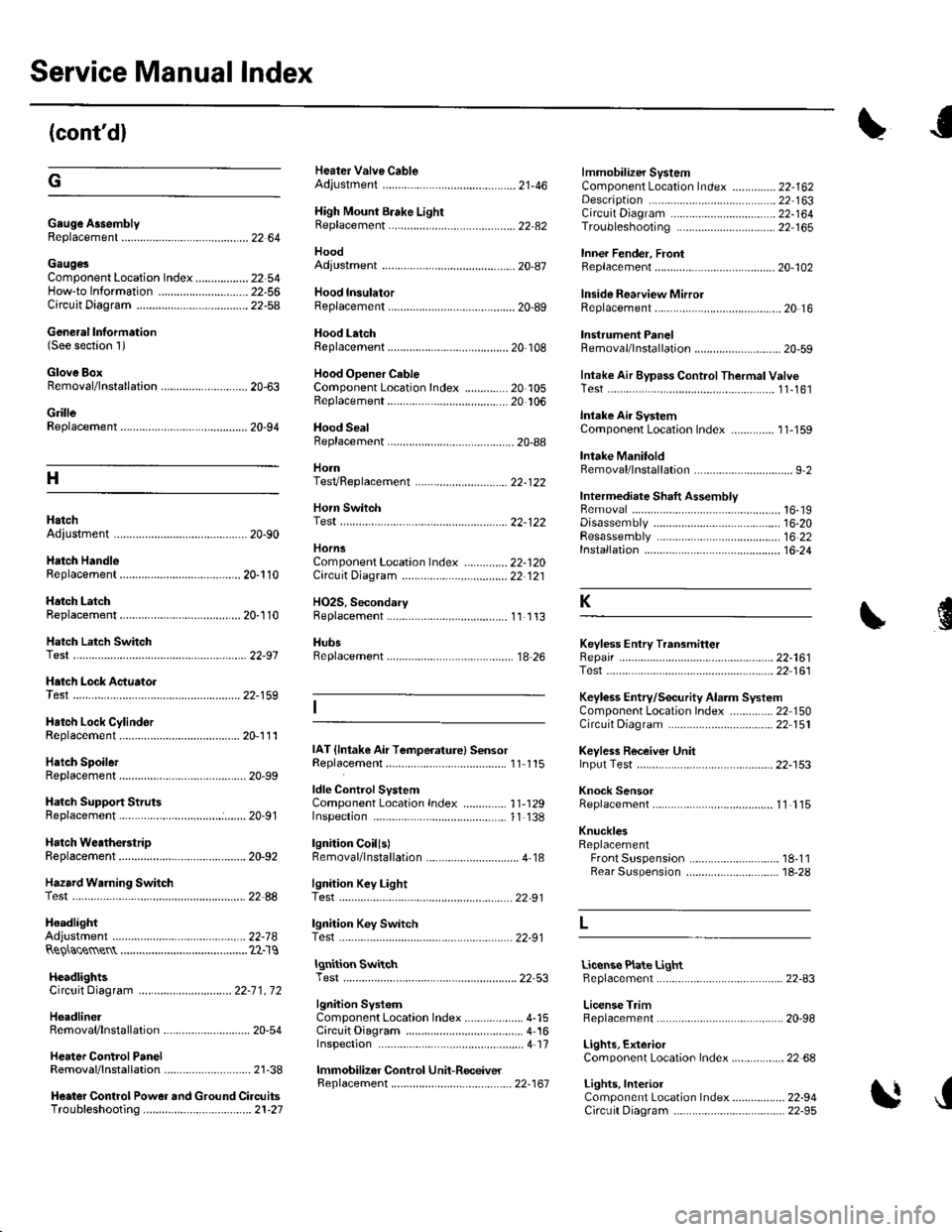

Orive BehInspecaron................ 4-26

Door PanelsRemoval/lnstallation -............................. 20-4

Door Sash TrimRep1acement......................................... 20 10

Door StrikersAdiustment ........................................... 20-13

Door Weatherst psBeplacement...........-............................. 20 1 1

EPS Conirol UnitRemoval/1nsta11ation ..................-......... 17-67

EPS Indicator CircuitTroubleshooting ................................... 17 -47

EPS MotorRemoval/lnstallation .-.......................... 17-49

EVAP CanisterRep1acement......................... ......... 11,189

EVAP Control Syst€mComponentLocation Index ..............'11-170

EVAP Two-Wey ValveTest ..........-.............-............................ 11 186

Evaporetor CoreRep1acement........................ . ... 21-42

Evaporator Tomperature SensorReplacement......................................... 21 -37Test..................................... ..........2137

EvaporrtoFHeater UnitReplacement........................................ 21 43

Exhaust ManifoldRemoval/1nsta11ation ................................ I 7

Exhaust Pipe8ep|acement............................................. 9-8

Front SpeakersRep|acement....................................... 22-102

Front SuspensionComponentLocation Index................... 18-3

Fueland EmissionsDescription ........................................... 11-12

Fuel Fill DoorAdjustment ..........-................................ 20 93

Fuel Fill Door OpenetBeplacement........................ . ............ 20.109

Fuel Fill Door Opener CableReplacement....................................... 20- lO7

Fuel FilterReplacement....................................... 1 1-152

Fuel Gauge Sending UnitTest ......................-.-..........-.................. 11'156

Fuel Injection Syslem (PGM"FIlComponent Location 1ndex................. 11-49

Fuel IniectorsRep1acemen1....................................... 1 1 1 1 l

Fuel Lines and HosesInspection .......................................... 1 1'146Removal ....................... . .. . .... 11-149Insta|1ation .......................................... 1 1 150

FuelPipe ProtectolReplacement....................................... 20-104

Fuel Pressure RegulatotReplacement....................................... 1 1-152

Fuel Pulsation DamperReplacemenl................................... 11 154

Fuel PumpReplacement,,,,,.,.,.,,,.,,,,,,,,,,,,.,.,.,,,..,.. 11-153

Fuel Pump CircuitTroubleshooting -.......-....................... 1 1-141

FuelSupply SystemComponent Location lndex .............. 11 140Adjustment................................... 11-144Test........-...-................. ... ............- 11-145

FuelTankBeplacemenl.............. . ..... .. 11 155

Fuel Tank Vapor ControlValveTest ......................-....... ... . . 11-187Replacement,,.,,...,.,,,.,.,,,,... .. .. 11 189

Fuses{See first page ofthis Index)

)

Rep|acement................. ..................... 4 26

Drive Belt Auto-tensionellnspection ............................................... 4 21Rep1acement.................................... ..4-28

Driver's PocketRemoval/lnstallation -........................... 20-60

Driver's TrayRemoval/lnstallation .........................-.- 20-65

DRL {Daytime Running LightslControl Unitlnput Test .................... ........ . . . ......22-16

DTCs(See first page olthis Index)

Dust and Pollen FillerReplacement......................................... 21-39

Dynamic Damper, DriveshaftsReplacement........................................... 16-8

ECT SensorReplacement.,.,,,.,.,,,,,,,,,,,,,,................ 1 1-1 14

El€ctrical Power Steering IEPS)Signal CircuitTroubleshooting ........ ... .. 11-135

EmblemsReplacement......................-................ 20-100

Engine AssemblyRemova1 .................................................... 5 2Installation ............._.................................. 5-9

Engine Block AssemblyComponent Location Inder ..................... 7.3

Engine Block, BareInspect|onRepair

Fan ControlsComponent Location Index................. 10'l 1Circuit Diagram .. ..... . .. . .................. 10 13

Fender Fairing, FrontReplacement...-................................... 20-103

Final Driven Gear. M/TReplacement.... . . ................................ 13-53

FrameRepair Chan............ ... ....................... 20 11 4

Frame StiffenelReplacement......-................................ 20- J'13

Front ConsoleRemoval/lnstallation ............................ 20 5lDisassembJy/Reassemb|y ................... 20 58

Front DoorsComponent Location Index................... 20-2Adiustment ........................................... 20.12

Front Driveshaft AssemblyInspeclion .................... ... ....16 3Remova1...................-...... ... .....16-3Disassembly ............................... .....165Resassemb|y ................................-......... 16-9Insta11arion ........................ ...... ............ l6 17

Front lmpact SensorsRep1acement............................ ...23 125

................7-15................1 11

)

Entry Light Control SystemComponent Location Index ...............-. 22-89Circuit Dia9ram .................................... 22 90

EPS ComponentsComponent Location 1ndex..........-...... 17-!7Description ........................ ...... ..17-24Circuit Diagram11 26(cont'd)

Page 1136 of 1139

Service Manual Index

(cont'dl

Gauge A3semblyReplacement......................................... 22 64

Gaug€sComponent Location Index ..........-...... 22 54How-to lnformation ........................22-56Circuit Diagram22-54

Heater Valve CableAdjustment ...................... .................... ?1-46

High Mount Brake Light8ep|acement......................................... 22 82

Hood

lmmobilizer SystemComponent Location In dex .............. 22-162

\

G

Description

Genoral Information(See seclion 1)

Glove BoxRemoval/1nsta11ation .......................-.... 20-63

GrilleReplacement...........-............................. 20-94

Hood lnsulatorReplacement......................................... 20-89

Hood LatchRep1acement................... ..........20 108

Hood Opener CableComponentLocation Index ..............20 105Replacement ................ . . ........... .....20 106

Hood SealBeplacement.-...........................-........... 20-88

HornTesVReplacement . . ................ ...... 22-122

CircuitDiagram ...........................22-164Troubleshooting ............................ 22,165

Inner Fender, FronlRepf acemenl....................................... 20-102

Inside Rearview MirrorReplacement..........-.............................. 20 16

Instrument PanelRemoval/1nsta11ation................. ....... 20-59

Intake Air Bypass ControlThermal ValveTesr................................ ..... ..11-161

Intake Air SystemComponent Location Index ...-.-........ 11-159

Intake ManitoldRemoval/1nsta11ation ................................ I 2

lntermediate Shaft AssemblyRemova1 ................-.-...-......................... 16-19Disassemb|y................... ... ......-.... 16,20Resassemb|y ........................................ 16 22Installation .........-...-.............................. 16-24

Keyless Entry Transmitter

Adjuslment

H

Adiustment .......

Hatch Handle

Horn SwitchTest ............-........

HornsComponent Location IndexCirc!it Diagram

H02S. SecondaryReplacement

..............22-120Replacement

22-122

22 12120-110

20-'110Hatch LatchReplacement$

K

Hatch Latch Switch

.... 11 113

HubsReplacement. ... .................................. 1A 26Test

Test

Replacement

Hatch Support StrutsBeplacement.....

Hatch WeatherstrioReplacement....

Hazard Warning Switchtest

ldle ControlSystemComponentLocation Index .............. 11-129Inspection,.,.........-.......,.,.,,,,,,.,,,.,.,..... 1'l 138

lgnition CoillslBemoval/lnstallation ...............-.............. 4 18

22-161Test ...................................................... 22 161

Keyless Entry/Security Alarm SystemComponenl Location Index .............. 22 150Circuil Diagram ................. . .............. 22 151

Keyless Receiver Unitlnput Test ............................................ 22-153

Knock SensorReplacement......-................................ 1 1 115

KnucklesReplacementFront Suspensron ............................. 18-1 1Rear Suspension ........ .................-... 18-28

Repair ...............

H.tch Lock Actuator22-159

Hatch Lock CylinderRep|acement....................................... 20,111

Hatch SpoilerIAT {lntake Air Temperature} SensorReplacement.,.........-...'11 115

20-91

20-92

.................... 22_88lgnition Key LightTest,,.,,,,.,...,......-.

H6adlightAdjustmentlgnition Key Switch

....................... 22-91

....................... 22-91..22-78TestReQ\ace$entlgnition SwitchTest .,,,.,.,.,,,,.,.,.......22-53License Plate LightReplacement...........-... - ... .....22-83

License TrimReplacement..................-...-..........-....... 20-98

Lights, ExteriorComponent Localion Index.................22 68

Lights,InteriorComponent Location Index................. 22-94CircuitDiagram .. .. ...... .... 22-95

HcadlightsCircuit Diagram .............................. 22-71, 72

HeadlinerRemoval/lnstallalion ............................ 20-54

Heater ControlPanelRemoval/1nsta11ation ............................ 21-38

Heater Control Power and Ground CircuitsTroubfeshooting......... .......................21-27

lgnition SystemComponent Location Index ................... 4-15CircuitDia9ram .................................... 4'161nspection ............................................... 4-17

lmmobilizer Control Unit-Receiver

J

22-161