seat HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 132 of 1139

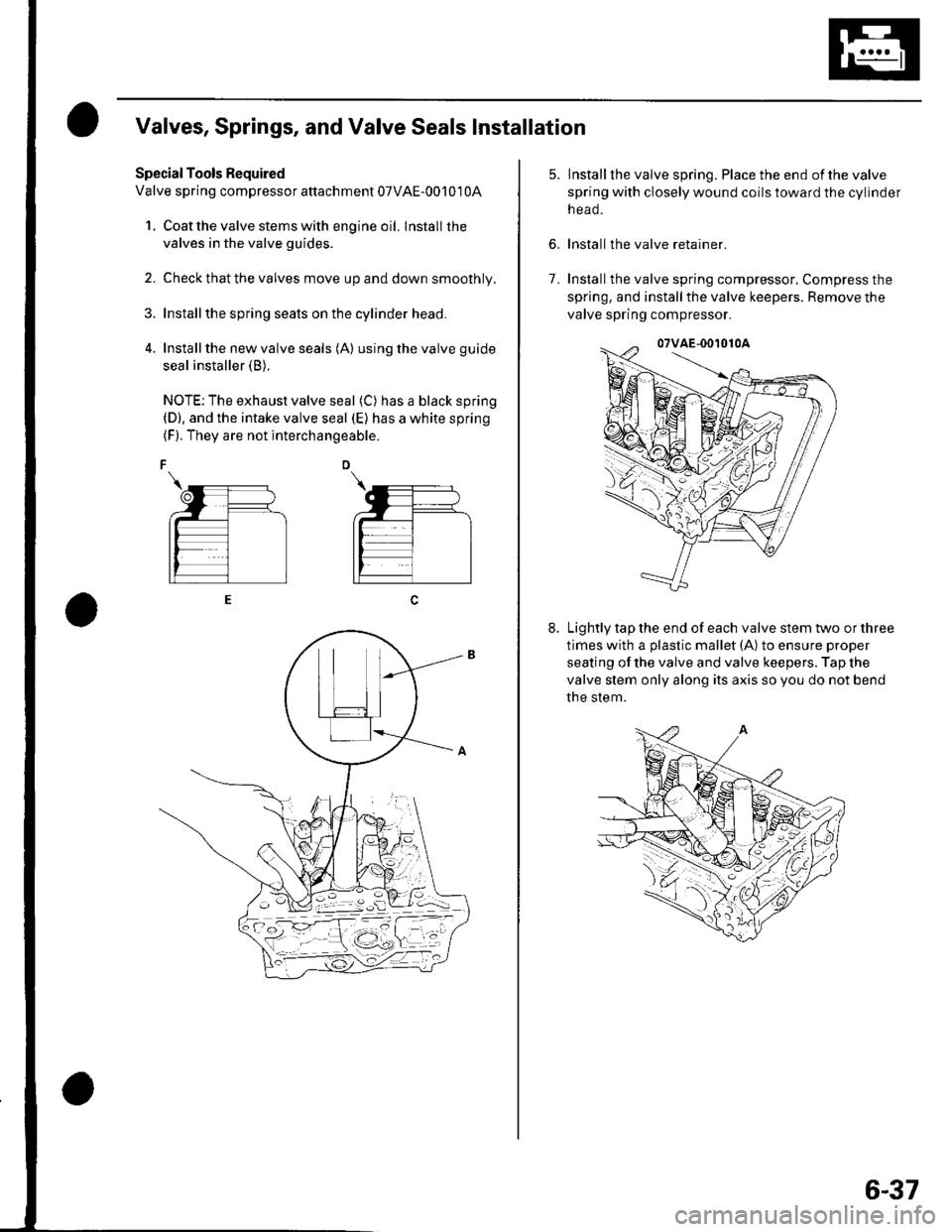

Valves, Springs, and Valve Seals Installation

Special Tools Required

Valve spring compressor attachment 07VAE-00101 0A

1. Coat the valve stems with engine oil. lnstall the

valves in the valve guides.

2. Check that the valves move up and down smoothly.

Installthe spring seats on the cylinder head.

Install the new valve seals (A) using the valve guide

seal installer (B).

NOTE: The exhaust valve seal (C) has a black spring(D), and the intake valve seal (E) has a white spring(F). They are not interchangeable.

6.

lnstallthe valve spring. Place the end ofthe valve

spring with closely wound coils toward the cylinder

n eao.

Install the valve retainer.

Installthe valve spring compressor, Compress the

spring, and install the valve keepers. Remove the

valve spring compressor.

Lightly tap the end of each valve stem two or three

times with a plastic mallet (A) to ensure proper

seating of the valve and valve keepers. Tap the

valve stem only along its axis so you do not bend

the stem.

7.

6-37

Page 137 of 1139

Gylinder Head

Cylinder Head Gover Installation (cont'd)

Set the spark plug seals (A) on the spark plug tubes.

Once the cylinder head cover (B) is on the cylinderhead, slide the cover slightly back and forth to seat

the head cover gasket.

Inspect the cover washers (C). Replace any washer

that is damaged or deteriorated.

6-42

7. Tighten the bolts in two or three steps. In the final

step, tighten all bolts, in sequence, to 9.8 N.m (1.0

kgf.m, 7.2 lbf.ft).

8. Install the dipstick (A) and breather hose iB).

\

\l'

Page 163 of 1139

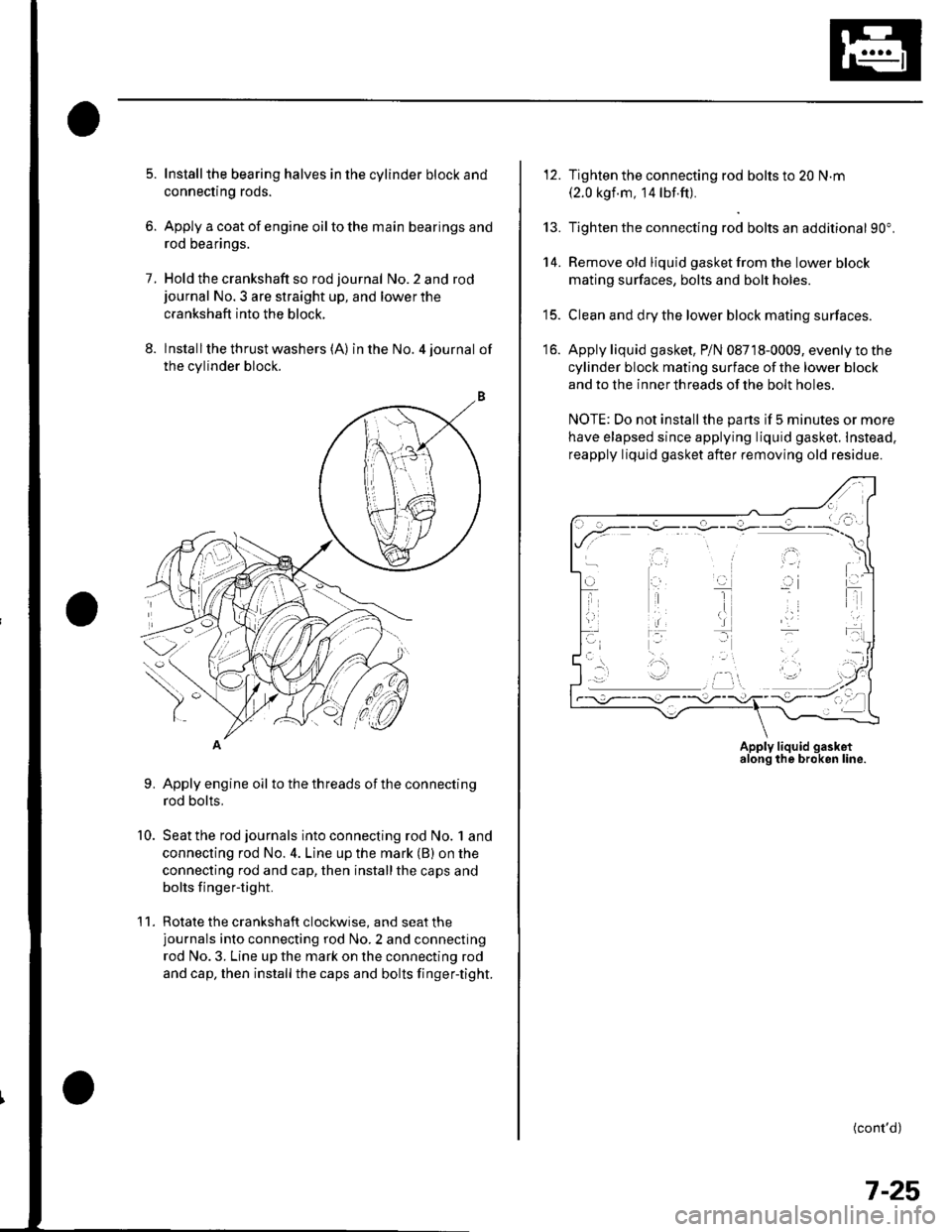

5. Installthe bearing halves in the cylinder block and

conneclrng rods.

6. Apply a coat of engine oilto the main bearings and

rod bearings.

7. Hold the crankshaft so rod journal No.2and rodjournal No. 3 are straight up, and lower the

crankshaft into the block.

8. lnstallthe thrust washers (A) in the No. 4 journal of

the cylinder block.

Apply engine oil to the threads ot the connecting

rod bolts,

Seat the rod journals into connecting rod No. 1 and

connecting rod No. 4. Line up the mark (B) on the

connecting rod and cap, then installthe caps and

bolts finger-tight.

Rotate the crankshaft clockwise, and seat thejournals into connecting rod No.2 and connecting

rod No. 3. Line up the mark on the connecting rod

and cap, then install the caps and bolts finger-tight.

9.

10.

'11 .

\-1

12. Tighten the connecting rod bolts to 20 N.m(2.0 kgf.m, 14 lbf.ft).

13. Tighten the connecting rod bolts an additional 90".

14. Remove old liquid gasket from the lower block

mating surfaces, bolts and bolt holes.

15. Clean and dry the lower block mating surfaces.

16. Apply liquid gasket, P/N 08718-0009, evenly to the

cylinder block mating surface of the lower block

and to the innerthreads ofthe bolt holes.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

(cont'd)

.\

,i,

Apply liquid gasketalong the broken line.

7-25

Page 172 of 1139

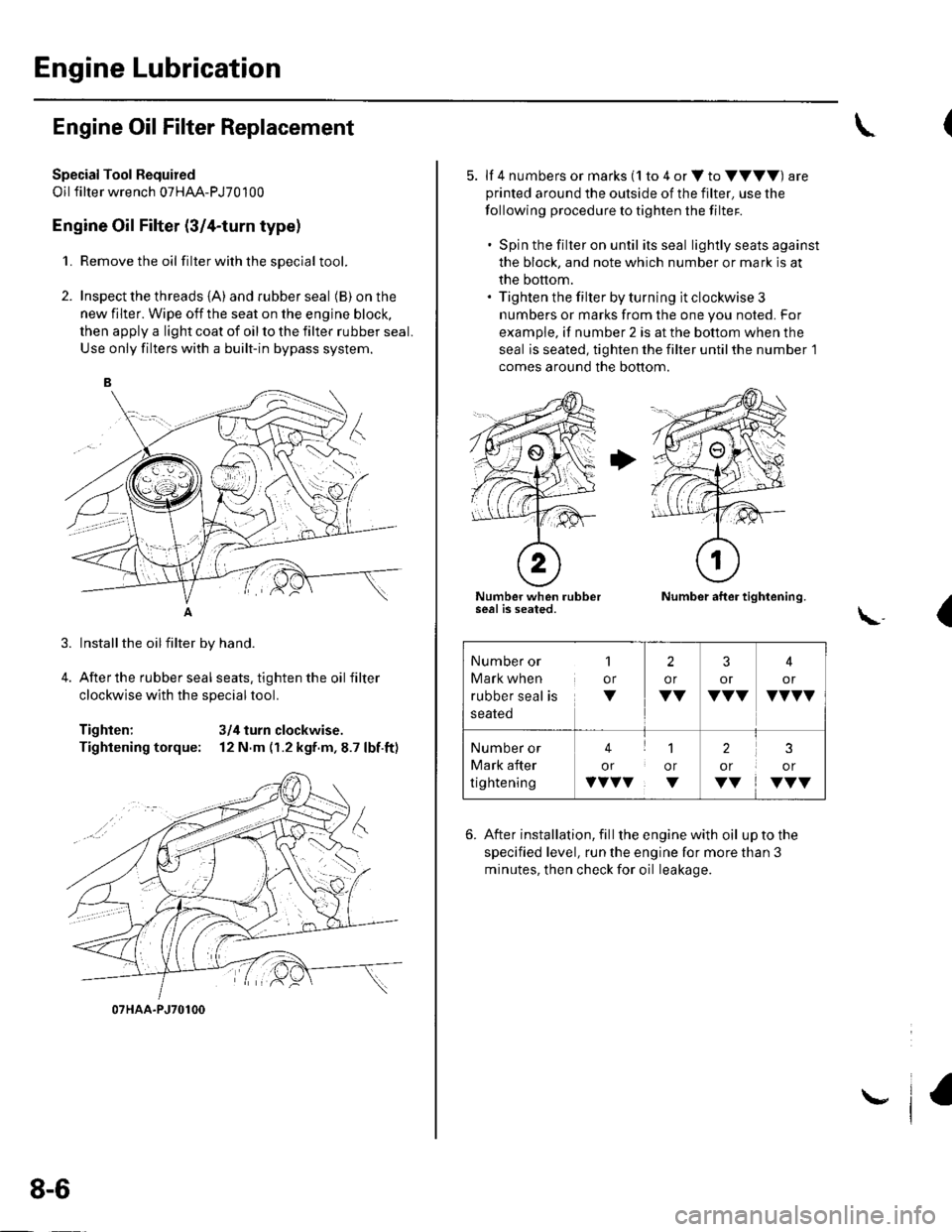

Engine Lubrication

Engine Oil Filter Replacement

Special Tool Fequired

Oil filter wrench 07HAA-PJ70100

Engine Oil Filter (3/4-turn type)

1. Remove the oil filterwiththesDecial tool.

2. Inspect the threads {A) and rubber seal (B) on the

new filter. Wipe off the seat on the engine block,

then apply a light coat of oil to the filter rubber seal.

Use only filters with a built-in bypass system.

Installthe oilfilter by hand.

After the rubber seal seats, tighten the oil filter

clockwise with the special tool.

Tighten: 3/4 turn clockwise.

Tightening torque: 12 N.m (r.2 kgf.m,8.7 lbf.ft)

07HAA-PJ70100

8-6

\,

5. lf 4 numbers or marks (1 to 4 or V to VVVV) are

printed around the outside of the filter, use the

following procedure to tighten the filter.

. Spin the filter on until its seal lightly seats against

the block, and note which number or mark is at

the bottom.. Tighten the filter by turning it clockwise 3

numbers or marks from the one you noted. For

example, if number 2 is at the bottom when the

seal is seated, tighten the filter until the number 1

comes around the bottom.

Number when rubberseal is seated.Number after tightening.

(\..

6. After installation, fill the enginewith oil uptothe

specified level, run the engine for more than 3

minutes, then check for oil leakage.

Number or

Mark when

rubber seal is

1

or

V

2

or

VV

3

or

VVV

4

or

VVVV

Number or

Mark after

tightening

41

or or

vvvv. v

2

or

VV

3

or

VVV

Page 177 of 1139

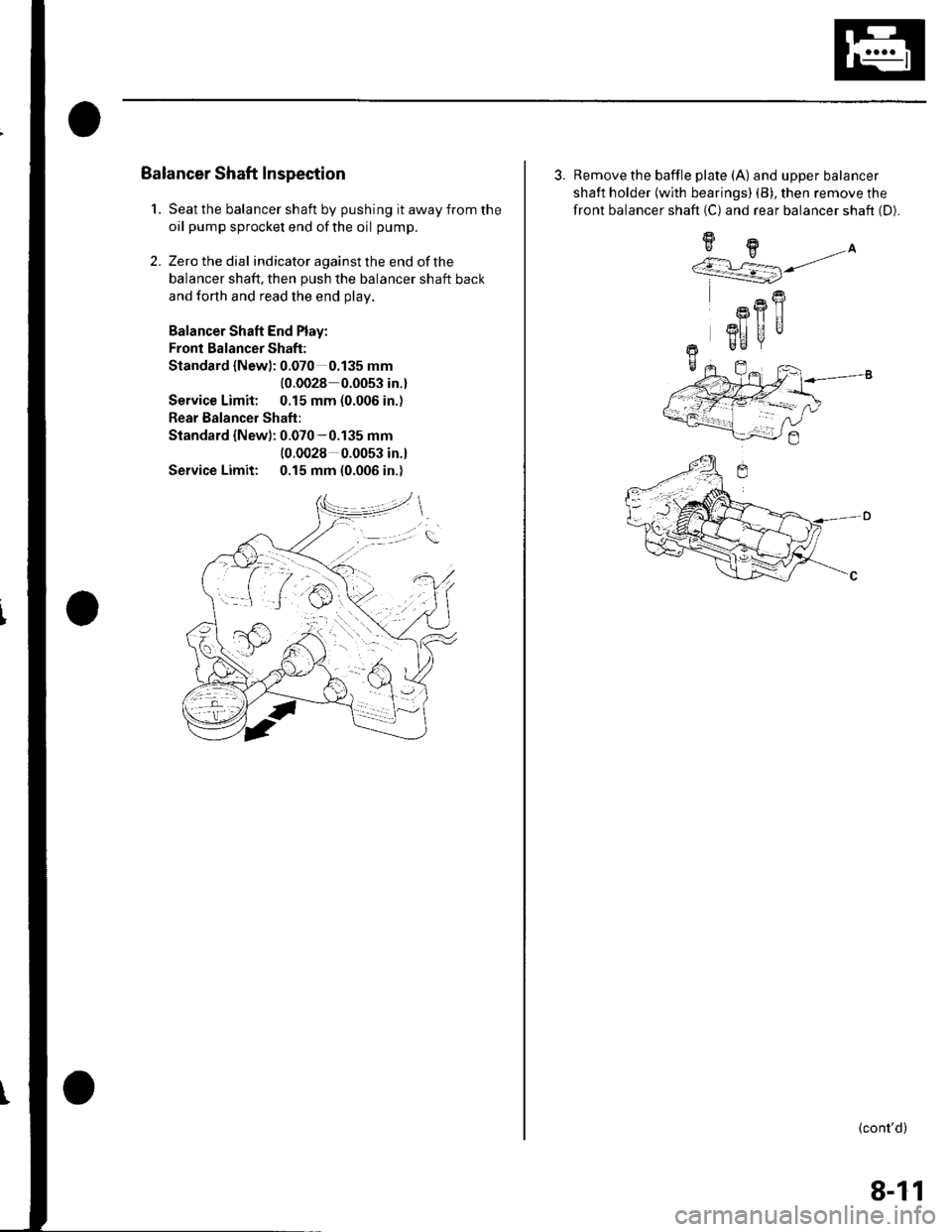

1.

Balancer Shaft Inspection

Seat the balancer shaft by pushing it away from the

oil pump sprocket end ofthe oil pump.

Zero the dial indicator against the end of the

balancer shaft, then push the balancer shaft back

and forth and read the end olav.

Balancer Shaft End Play:

Fronl Balancer Shaft:

Standard {Newl: 0.070 0.135 mm

{0.0028 0.0053 in.}

Service Limit: 0.15 mm (0.006 in.)

Rear Balancer Shaft:

Standard {New): 0.070-0.135 mm(0.0028 0.0053 in.l

Service Limit: 0.15 mm (0.006 in.)

2.

3. Remove the baffle plate (A) and upper balancer

shaft holder {with bearings) (B), then remove the

front balancer shaft (C) and rear balancer shaft (D).

9H.A''/.r L=] j/

R

Rfl|]

3I] UUr Be

+-

(cont'd)

8-11

Page 307 of 1139

PGM-FI System

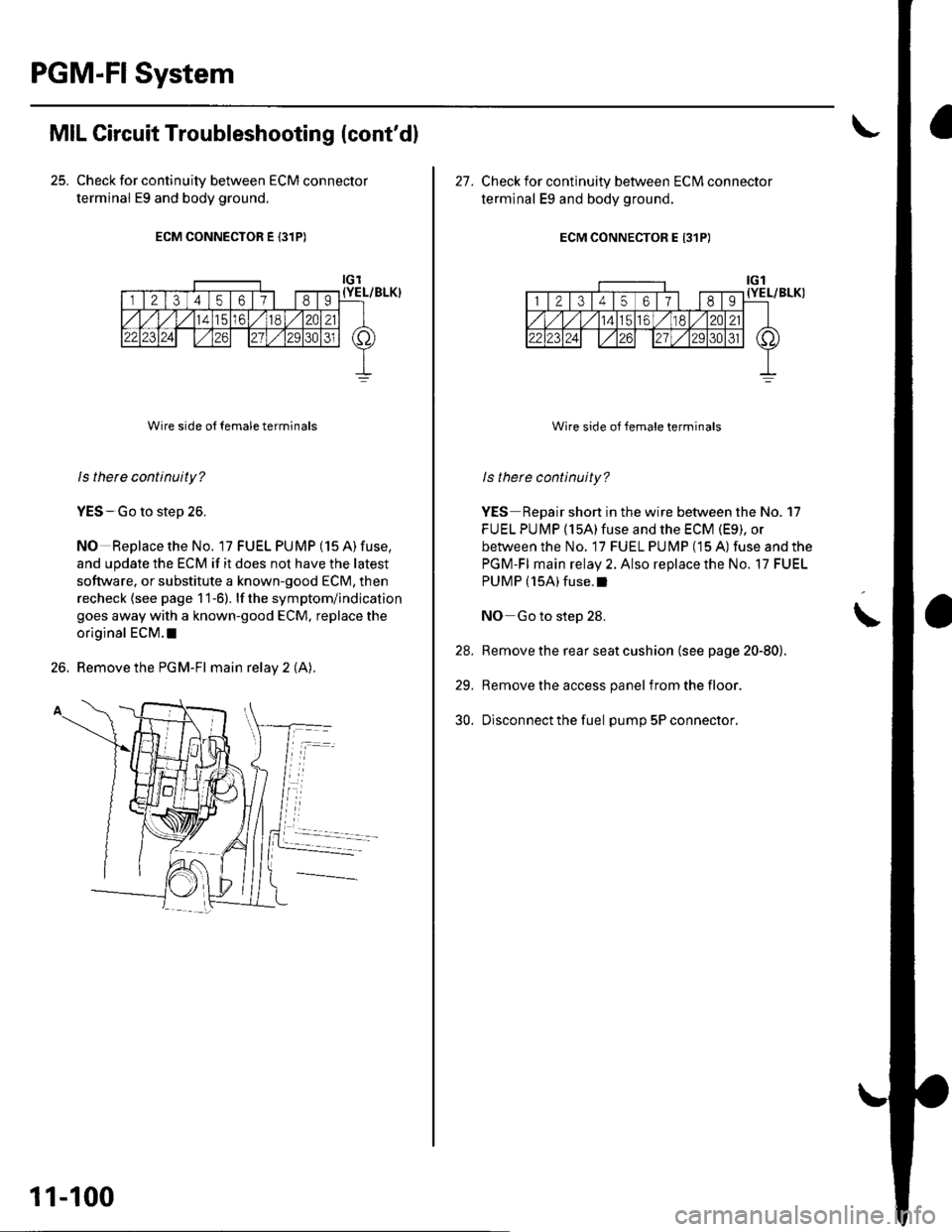

25.

MIL Circuit Troubleshooting (cont'dl

Check for continuity between ECM connector

terminal E9 and body ground.

ECM CONNECTOR E (31P)

Wire side o{ {emale terminals

ls therc continuity?

YES-Go to step 26.

NO Replace the No. lTFUELPUMP(15A)fuse,

and update the ECM if it does not have the latest

software. or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM. replace the

original ECM.I

26. Remove the PGM-Fl main relay 2 (A).

11-100

27. Check for continuity between ECIVI connector

terminal Eg and body ground.

ECM CONNECTOR E 131P)

Wire side oI Jemale terminals

ls there continuity?

YES Repair short in the wire between the No. 17

FU EL PUMP (15A)fuse and the ECM (E9), or

between the No. 17 FUEL PU MP (15 A) fuse and the

PGM-FI main relay 2. Also replace the No. 17 FUEL

PUMP (15A)fuse.l

NO Go to step 28.

Remove the rear seat cushion (see page 20-80).

Remove the access panel from the floor.

Disconnect the fuel pump 5P connector.

\

28.

29.

30.

Page 349 of 1139

![HONDA CIVIC 2003 7.G User Guide FuelSupply System

(

(

L

10.

1�].

Fuel Pump Circuit Troubleshooting (contdl

Reinstallthe PGM-Fl main relay 2.

Turn the ignition switch ON (ll).

Measure voltage between ECI\4/PCM connector

terminal E1 HONDA CIVIC 2003 7.G User Guide FuelSupply System

(

(

L

10.

1�].

Fuel Pump Circuit Troubleshooting (contdl

Reinstallthe PGM-Fl main relay 2.

Turn the ignition switch ON (ll).

Measure voltage between ECI\4/PCM connector

terminal E1](/img/13/5744/w960_5744-348.png)

FuelSupply System

(

(

L

10.

1'�].

Fuel Pump Circuit Troubleshooting (cont'dl

Reinstallthe PGM-Fl main relay 2.

Turn the ignition switch ON (ll).

Measure voltage between ECI\4/PCM connector

terminal E1 and body ground.

ECM CONNECTOB E {31P)

ls there battety voltage?

YES Go to step 12.

NO-Replace the PGM-Fl main relay 2.1

Turn the ignition switch OFF.

Reconnecl ECM connector E (31P).

Turn the ignition switch ON (ll), and measure

voltage between ECM connector terminal E1 and

body ground within the first 2 seconds after the

ignition switch was turned ON (ll).

ECM CONNECTOR E (31PI

13.

14.

Wire side of female terminals

Wire side of female terminals

11-142

t5.

to.

11.

18.

ls there battery voltage?

YES U pdate the ECM if it does not have the latest

so{1ware, or substitute a known-good ECM. then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

NO Go to step 15.

Turn the ignition switch OFF.

Remove the rear seat cushion (see page 20-80).

Remove the access panel from the floor.

Measure voltage between fuel pump 5P connector

terminal No. 5 and body ground within the first 2

seconds after the ignition switch was turned ON (ll).

FUEL PUMP 5P CONNECTOR

wire side oI female terminals

ls there battery voltage?

YES Go to step 24.

NO-Go to step 19.

Turn the ignition switch OFF.

Remove the PGM-Fl main relay 2.

19.

20.

Page 360 of 1139

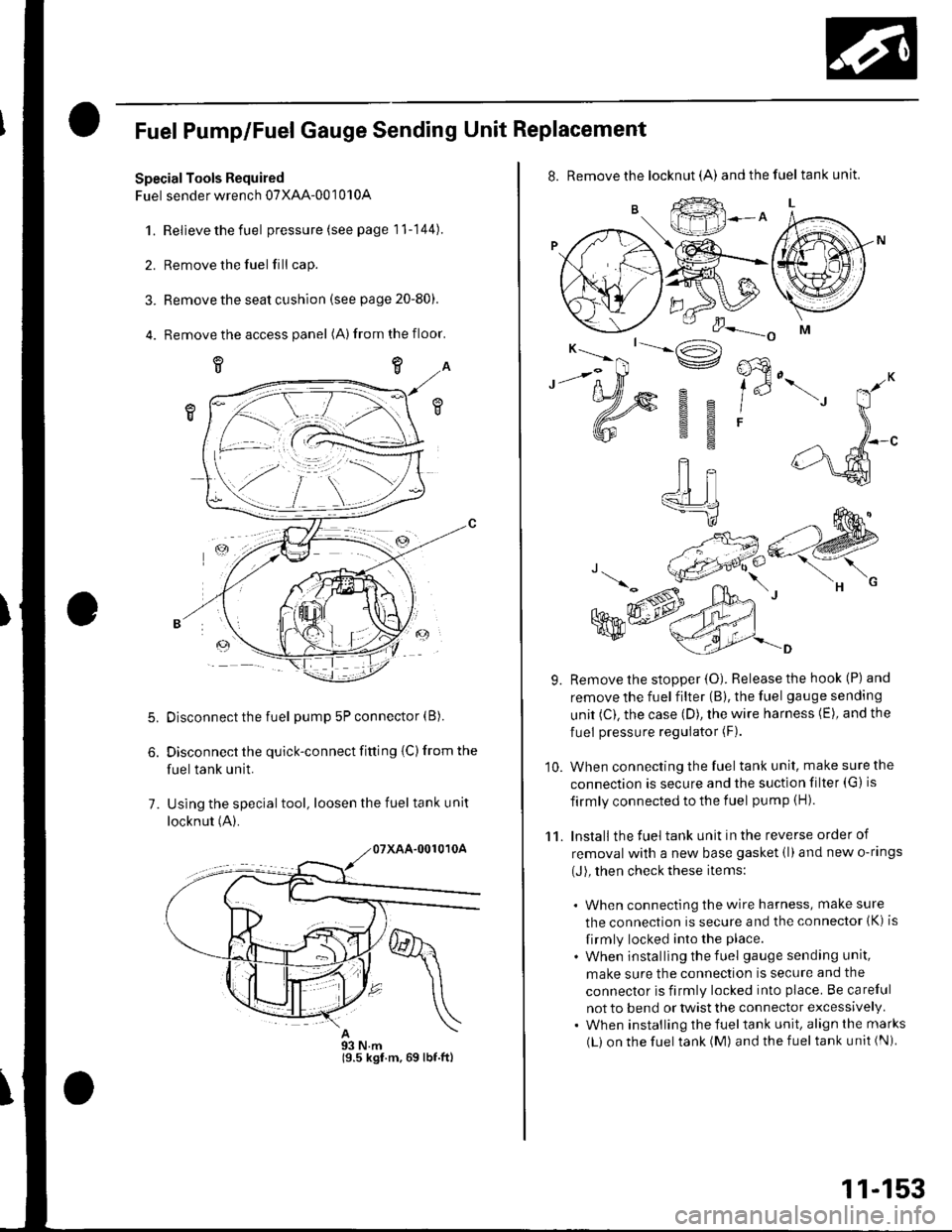

Fuel Pump/Fuel Gauge Sending Unit Replacement

SpecialTools Required

Fuel sender wrench 07XAA-001010A

1.Relieve the fuel pressure (see page 11-144).

Remove the fuel fill cap.

Remove the seat cushion (see page 20-80).

Remove the access panel (A)from the floor.

5.

7.

Disconnect the fuel pump 5P connector (B).

Disconnect the quick-connect fitting {C) from the

fuel tank unit.

Using the special tool, loosen the fuel tank unit

locknut (A).

93 N.m19.5 kgf.m,69 lbf.ftl

11-153

8. Remove the locknut (A) andthefuel tankunit.

9. Remove the stopper {O). Release the hook (P) and

remove the fuel filter (B), the fuel gauge sending

unit (C). the case (D), the wire harness (E), and the

fuel pressure regulator (F).

10. When connecting the fuel tank unit, make sure the

connection is secure and the suction filter (G) is

firmly connected to the f uel pump (H).

11. Install the fuel tank unit in the reverse order of

removal with a new base gasket (l)and new o-rings

(J), then check these items:

. When connecting the wire harness, make sure

the connection is secure and the connector (K) is

firmly locked into the place.

. When installing the f uel gauge sending unit,

make sure the connection is secure and the

connector is firmly locked into place. Be careful

not to bend or twist the connector excessively.. When installing the fueltank unit, align the marks

(L) on the fuel tank (M) and the fuel tank unit (Ni

Page 363 of 1139

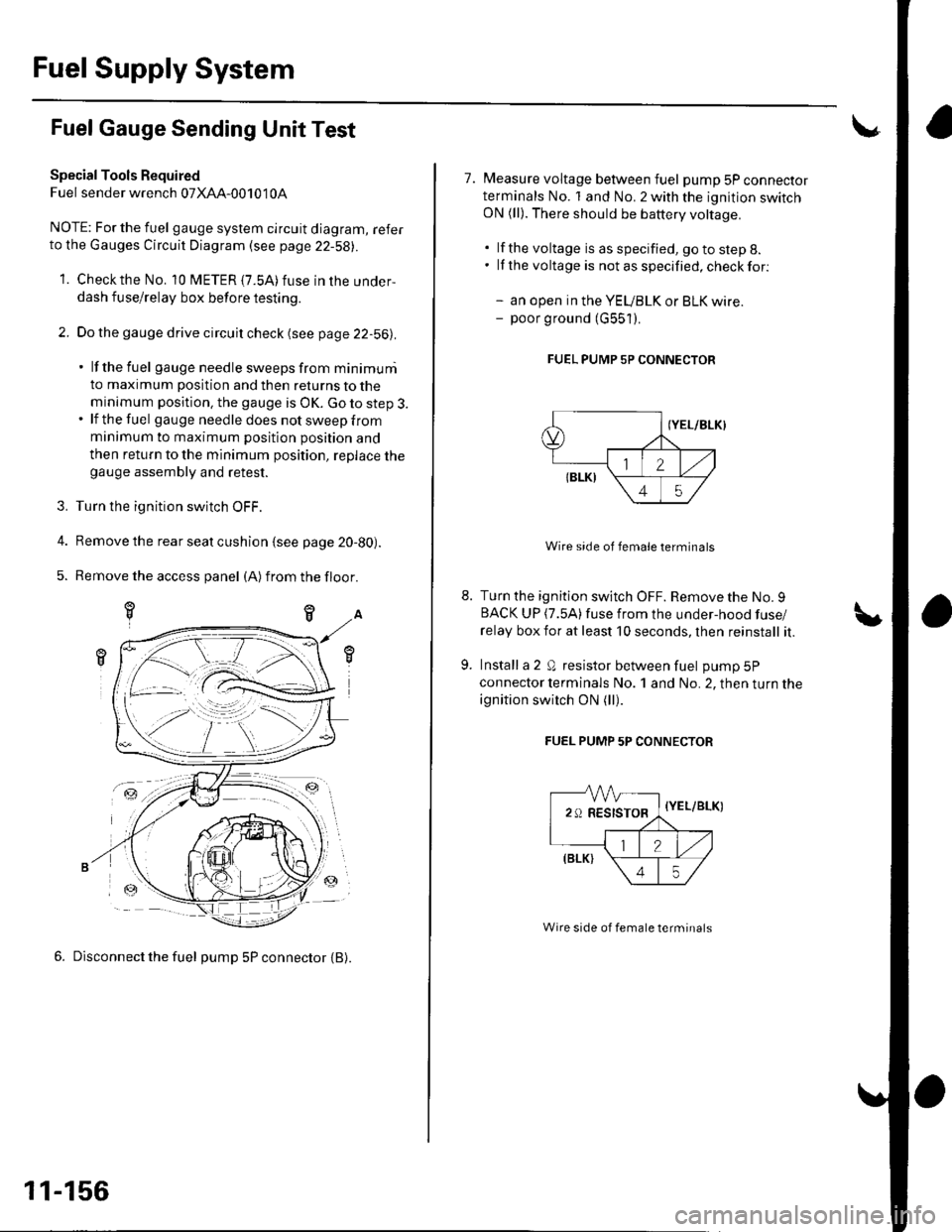

Fuel Supply System

Fuel Gauge Sending Unit Test

Special Tools Required

Fuel sender wrench 07XAA-001010A

NOTE; For the fuel gauge system circuit diagram, referto the Gauges Circuit Diagram (see page 22-58||.

1. Checkthe No. 10 fUETER {7.5A)fuse in the under-

dash fuse/relay box before testing.

2. Do the gauge drive circuit check (see page 22-56|l.

' lf the fuel gauge needle sweeps from minimuni

to maximum position and then returns to the

minimum position. the gauge is OK. Go to step 3.. lf the fuel gau ge need le does not sweep from

minimum to maximum position position and

then return to the minimum position, replace thegauge assembly and retest.

3. Turn the ignition switch OFF.

4. Remove the rear seat cushion {see page 20-80).

5. Remove the access panel (A)from the floor.

6. Disconnect the fuel pump 5P connector {B).

-ztr

11-156

7. Measure voltage between fuel pump 5P connectorterminals No. 1 and No. 2 with the ignition switchON (ll). There should be battery voltage.

. lf the voltage is as specified, go to step 8.. lf the voltage is notasspecified,checkfor:

- an open in the YEUBLK or BLK wire.- poor ground (G551).

FUEL PUMP 5P CONNECTOR

Wire side of female terminals

Turn the ignition switch OFF. Remove the No. 9BACK UP (7.5A)fuse from the under-hood fuse/

relay box for at least 10 seconds, lhen reinstall it.

Install a 2 Q resistor between fuel pump 5P

connector lerminals No. 1 and No. 2, then turn the

ignition switch ON (ll).

FUEL PUMP 5P CONNECTOR

-VVV-

29RESISTOR,

=-a

{Y

\

//,(elrt \

\45/

{YEL/BLK)

Wire side of female terminals

Page 455 of 1139

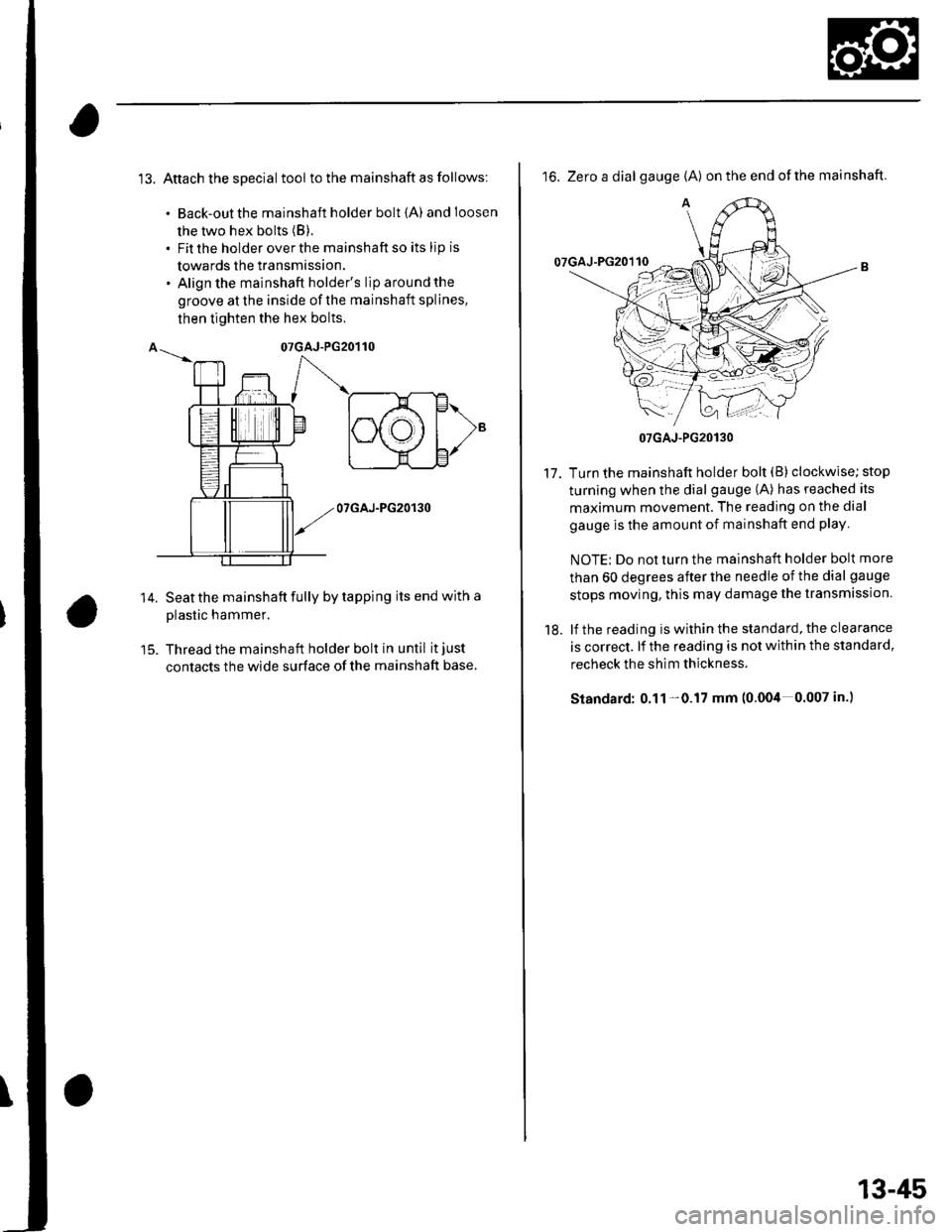

13. Attach the special tool to the mainshaft as follows:

. Back-out the mainshaft holder bolt {A) andloosen

the two hex bolts (B).

. Fit the holder over the mainshaft so its lip is

towards the transmission.. Align the mainshaft holder's lip around the

groove at the inside of the mainshaft splines,

then tighten the hex bolts.

14.

07GAJ-PG20130

Seat the mainshaft fully by tapping its end with a

plastic hammer.

Thread the mainshaft holder bolt in until it just

contacts the wide surface of the mainshaft base.

16. Zero a dial gauge {A) on the end ofthe mainshaft.

Turn the mainshaft holder bolt (B) clockwise; stop

turning when the dial gauge (A) has reached its

maximum movement. The reading on the dial

gauge is the amount of mainshaft end play

NOTE: Do not turn the mainshaft holder bolt more

than 60 degrees after the needle of the dial gauge

stops moving, this may damage the transmission.

lf the reading is within the standard, the clearance

is correct. lf the reading is not within the standard,

recheck the shim thickness.

Standard: 0.11 -0.17 mm (0.004 0.007 in.)

17.

18.

07GAJ-PG20130

13-45