seat HONDA CIVIC 2003 7.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 573 of 1139

18.

19.

Wash the knuckle and hub thoroughly in hlgh flash

point solvent before reassembly.

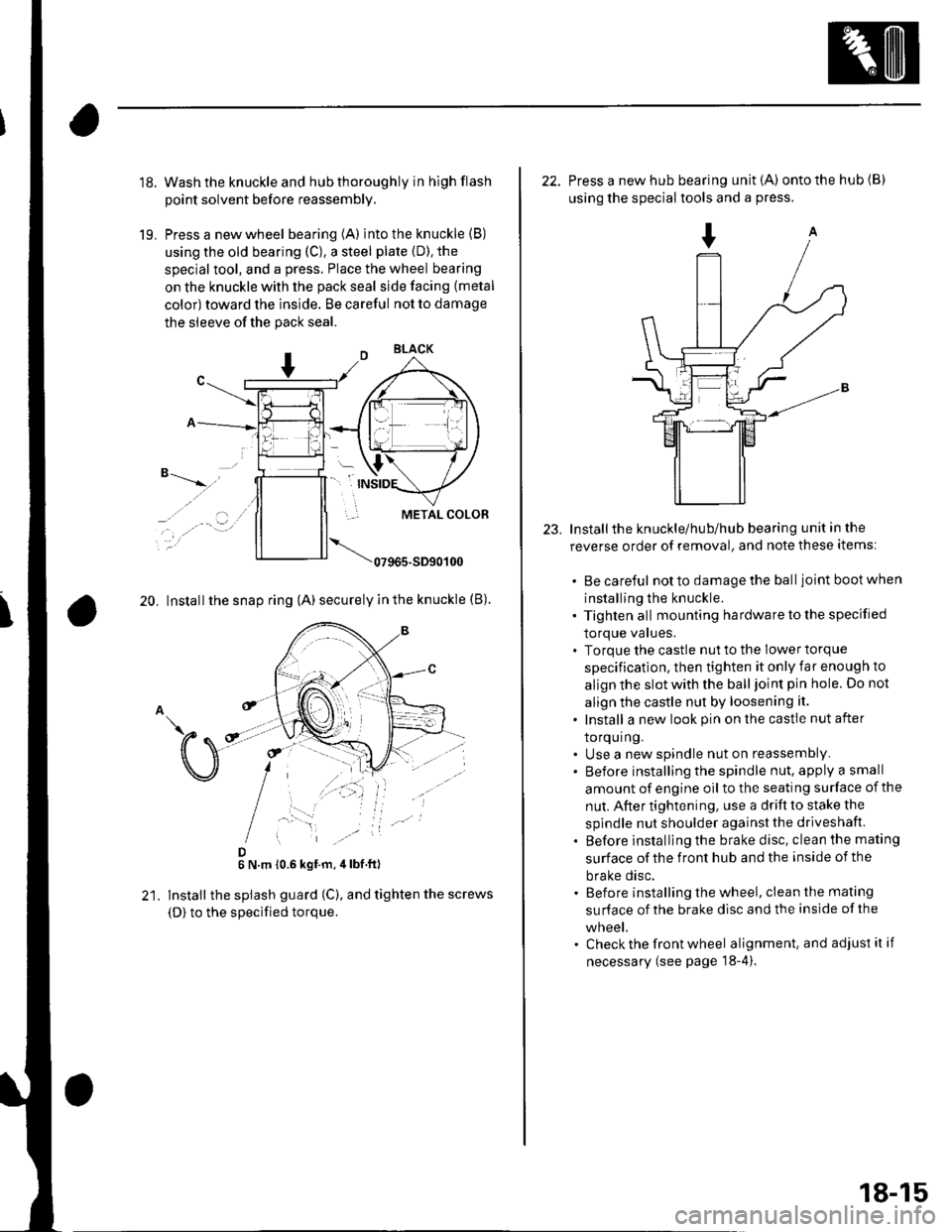

Press a new wheel bearing (A) into the knuckle (B)

using the old bearing (C), a steel plate {D). the

special tool, and a press. Place the wheel bearing

on the knuckle with the pack seal side facing (metal

color) toward the inside. Be careful not to damage

the sleeve of the pack seal.

"-t-_"*,,''

_, .' . . a-�.) ../

..-.

20. Install the snap ring (A) securely in the knuckle (B).

D6 N.m 10.6 kgf.m,4lbf ft)

lnstall the splash guard (C), and tighten the screws

(D) to the specified torque.

23.

22. Press a new hub bearing unit {A) ontothehub(B)

using the special tools and a press.

Installthe knuckle/hub/hub bearing unit in the

reverse order of removal, and note these items:

. Be careful notto damagethe balljoint bootwhen

installing the knuckle.. Tighten all mounting hardware to the specified

lOrque values.. Torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the ball joint pin hole. Do not

align the castle nut by loosening it.

. Install a new look pin on the castle nut after

torquing.. Use a new spindle nut on reassembly.. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface of the

nut. After tightening, use a drift to stake the

spindle nut shoulder against the driveshaft.

. Before installlng the brake disc, clean the mating

surface of the front hub and the inside of the

brake disc.. Before installing the wheel, clean the mating

su rface of the brake disc and the inside of the

wneet.. Check the front wheel alignment, and adjust it if

necessary (see page 18-4).

18-15

Page 574 of 1139

Front Suspension

Ball Joint Boot Replacement

Special Tools Required

Front hub dis/assembly tool 07965-5450500

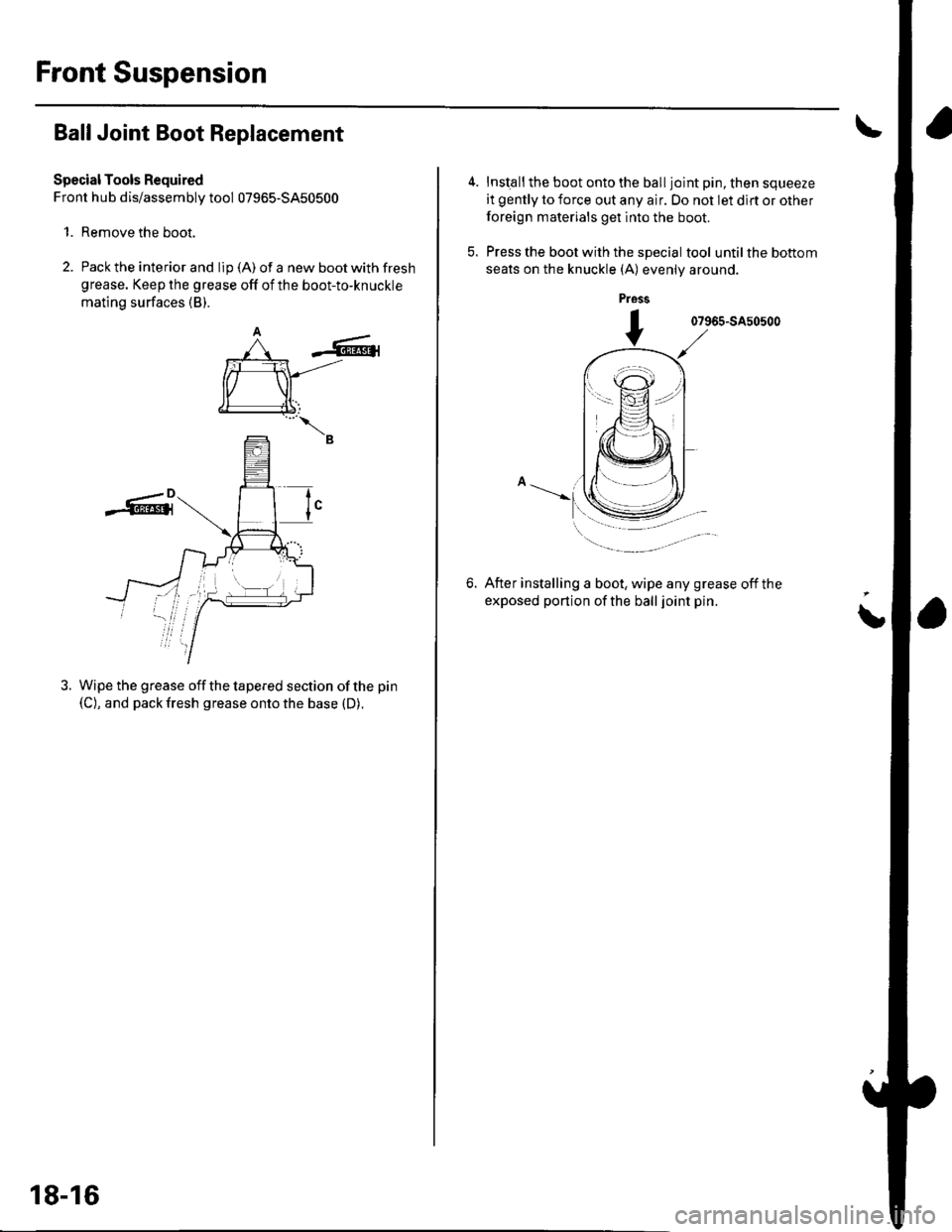

1. Remove the boot.

2. Pack the interior and lip (A) of a new boot with fresh

grease. Keep the grease off of the boot-to-knuckle

mating surfaces (B).

-6r

rffi

€l

--B

Wipe the grease off the tapered section of the pin

(C), and pack fresh grease onto the base (D).

tI

18-16

Inst€ll the boot onto the ball joint pin, then squeeze

it gently to force out any air. Do not let dlrt or other

foreign materials get into the boot.

Press the boot with the special tool until the bottom

seats on the knuckle (A) evenly around.

pross

07965-SA50500

6.After installing a boot, wipe any grease off the

exposed portion of the ball joint pin.

i

Page 580 of 1139

Front Suspension

Damper/Spring Replacement (cont'd)

Disassembly/lnspection

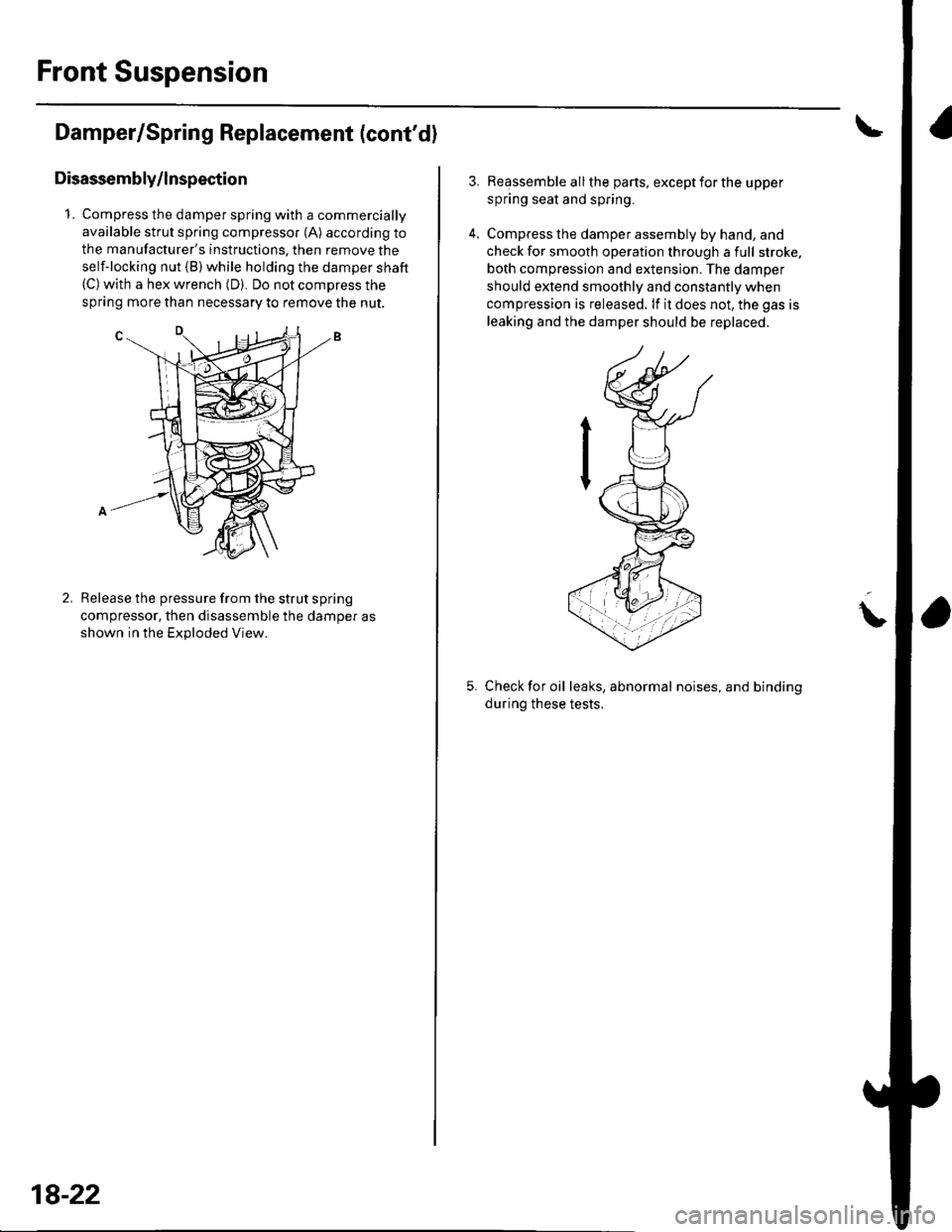

1. Compress the damper spring with a commercially

available strut spring compressor (A) according to

the manufacturer's instructions. then remove the

self-locking nut (B)while holding the damper shaft(C) with a hex wrench (D). Do not compress the

spring more than necessary to remove the nut,

Release the pressure from the strut spring

compressor, then disassemble the damper as

shown in the Exploded View.

18-22

4.

Reassemble all the pans, except for the upper

spring seat and spring.

Compress the damper assembly by hand, and

check for smooth operation through a full stroke.

both compression and extension. The damper

should extend smoothly and constantly when

compression is released. lf it does not, the gas is

leaking and the damper should be replaced.

Check for oil leaks, abnormal noises, and binding

during these tests.

\

Page 584 of 1139

Rear Suspension

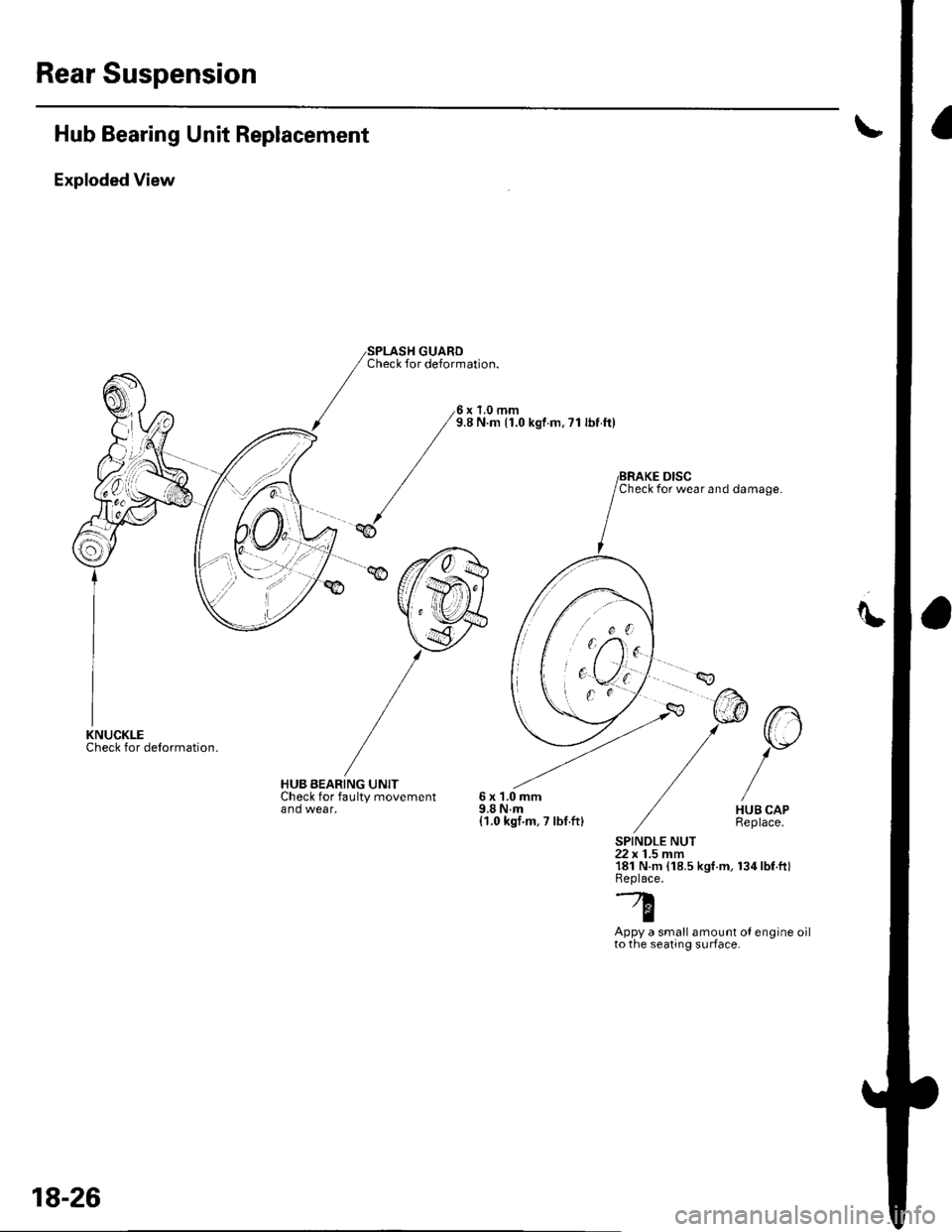

Hub Bearing Unit Replacement

Exploded View

Check for delormation.

SPLASH GUARDCheck for deformation.

x 1.0 mm9.8 N.m (1.0 kgf.m, ?1 lbf ftl

HUB BEARING UNITCheck for faulty movementand wear.6x1.0mm9,8 N.m{1.0 kgf.m, 7 lbf.ft}

un

Y

HUB CAPReplace.

SPINDLE NUT22 x 1.5 mm181 N.m {18.5 kgt.m, 134lbf.ft}Beplace.-A

TAppy a small amount oI engine oilto the seating surface.

Check for wear and damage.

,, o0'[',/-\'

KNUCKLE

18-26

Page 587 of 1139

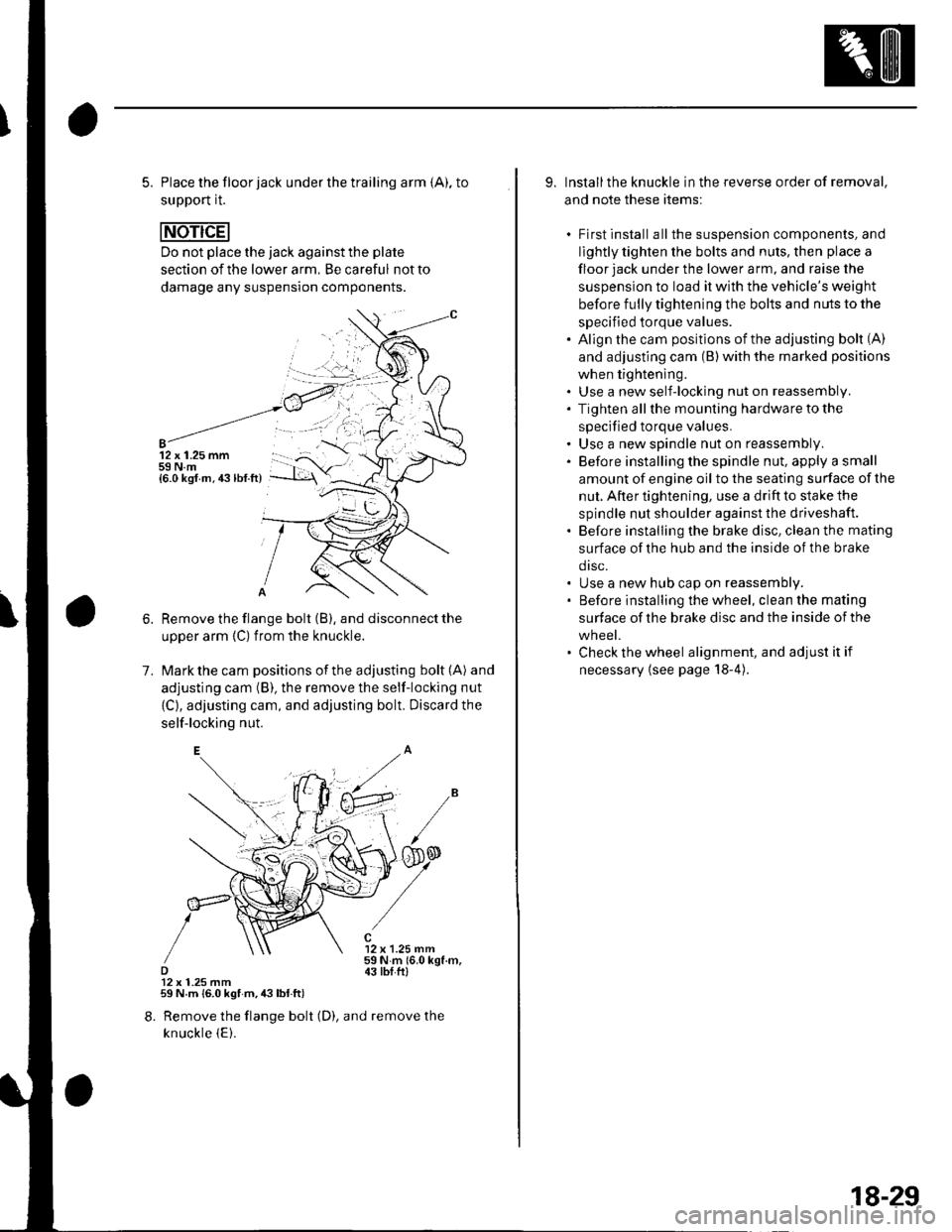

5. Place the floor jack under the trailing arm {A), to

support it.

Do not place the jack against the plate

section of the lower arm, Be careful not to

damage any suspension components.

12 x 1.25 mm59 N.m{6.0 ksf.m.43lbf.ft)

1.

Remove the flange bolt (B), and disconnect the

upper arm {C) from the knuckle.

Mark the cam positions of the adjusting bolt (A) and

adjusting cam (B), the remove the self-locking nut

{C}, adjusting cam, and adjusting bolt. Discard the

self-locking nut.

12 x 1.25 mm59Nm(6.0kgf.m,43 tbI.ftl12 x 1.25 mm59 N.m {6.0 kgf m,43lbl.ft)

8. Remove the flange bolt (D), and remove the

knuckle {E).

9. Installthe knuckle in the reverse order of removal,

and note these items:

. First install all the suspension components, and

lightly tighten the bolts and nuls, then place a

floor jack under the lower a rm, and raise the

suspension to load it with the vehicle's weight

before fully tightening the bolts and nuts to the

specified torque values.. Align the cam positions of the adjusting bolt (A)

and adjusting cam (B) with the marked positions

when tightening.. Use a new self-locking nut on reassembly.. Tighten allthe mounting hardware to the

specified torque values.. Use a new spindle nut on reassembly.. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface of the

nut. After tightening, use a drift to stake the

spindle nut shoulder against the driveshaft.. Before installing the brake disc, clean the mating

surface of the hub and the inside of the brake

drsc.. Use a new hub cap on reassembly.. Before installing the wheel, clean the mating

surface of the brake disc and the inside of the

wheel.. Check the wheel alignment, and adjust it if

necessary {see page 18-4).

18-29

Page 594 of 1139

Rear Suspension

Damper/Spring Replacement (cont'dl

Disassembly/lnspection

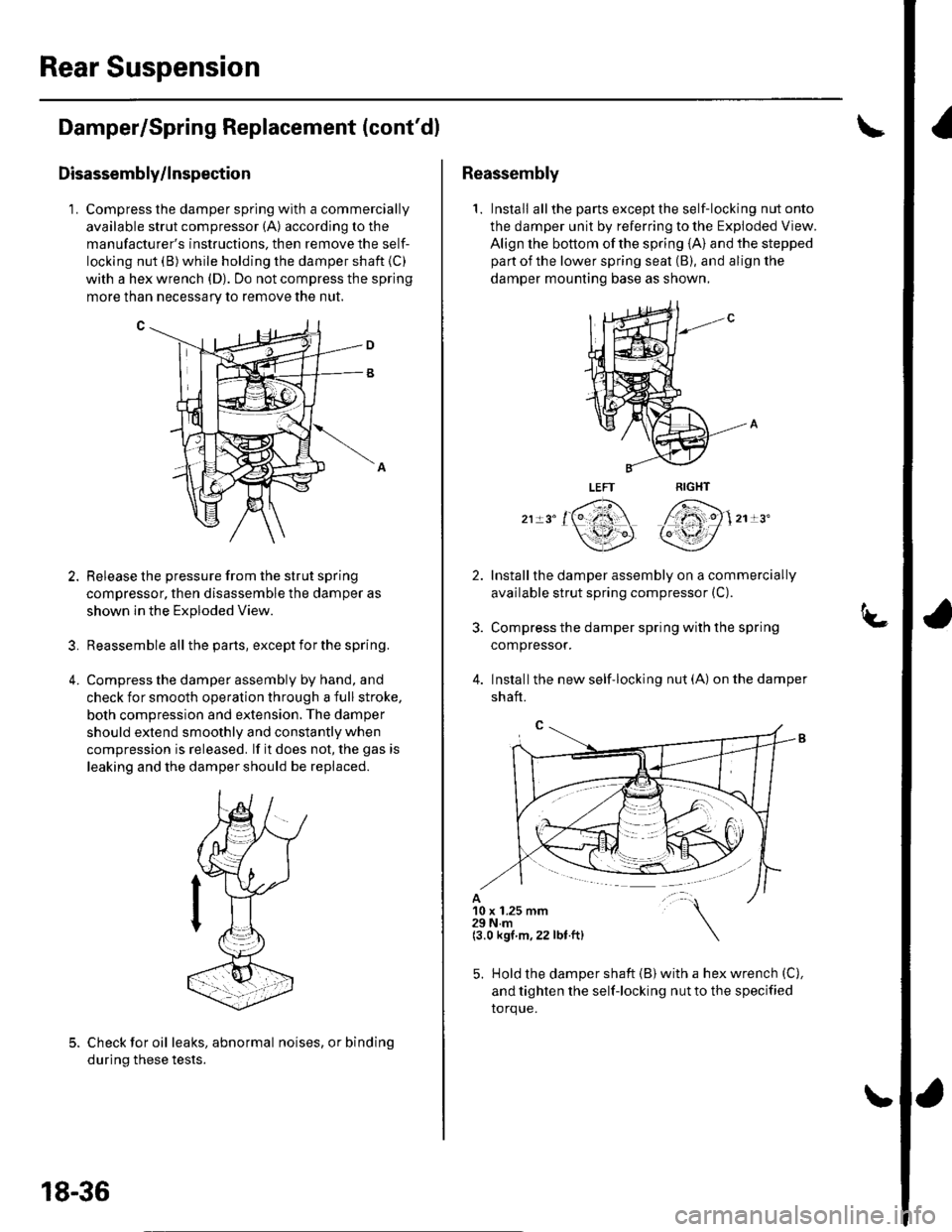

1. Compress the damper spring with a commercially

available strut compressor (A) according to the

manufacturer's instructions. then remove the self-

locking nut (B)while holding the damper shaft (C)

with a hex wrench (D). Do not compress the spring

more than necessarv to remove the nut.

Release the pressure from the strut spring

compressor, then disassemble the damper as

shown ln the Exploded View.

Reassemble all the pans, except for the spring.

Compress the damper assembly by hand, and

check for smooth operation through a full stroke,

both compression and extension. The damper

should extend smoothly and constantly when

compression is released. lf it does not, the gas is

leaking and the damper should be replaced.

?

4.

Check for oil leaks, abnormal noises, or binding

during these tests.

18-36

Reassembly

1. Install allthe partsexceptthe self-locking nutonto

the damper unit by referring to the Exploded View.

Align the bottom of the spring {A} and the stepped

part of the lower spring seat (B), and align the

damper mounting base as shown,

,, '161 7fi)1,, "

\3P qY/

Installthe damper assembly on a commercially

available strut spring compressor (C).

Compress the damper spring with the spring

compressor.

Installthe new self'locking nut (A) on the damper

shaft.

10 x 1.25 mm29Nm(3.0 kgt m,22 lbt.ft)

5. Hold the damper shaft {B) with a hex wrench (C),

and tighten the self-locking nut to the specified

torque.

Page 622 of 1139

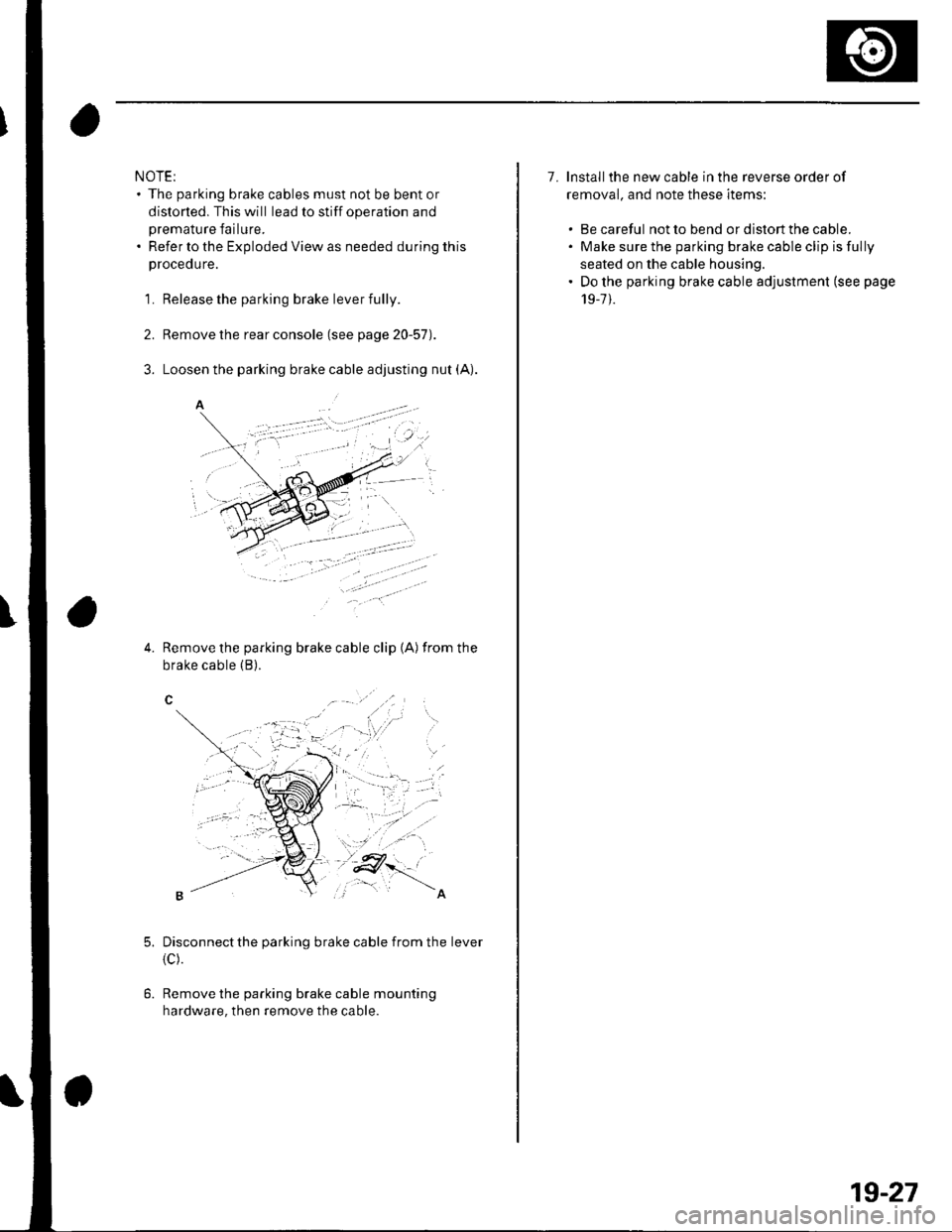

NOTE:. The parking brake cables must not be bent or

distorted. This will lead to stiff operation and

premature failure.. Refer to the Exploded View as needed during this

proceoure.

1. Release the parking brake lever fully.

2. Remove the rear console (see page 20-57).

Remove the parking brake cable clip (A) from the

brake cable (B).4.

6.

Disconnectthe parking brake cable from the lever

{c).

Remove the parking brake cable mounting

hardware, then remove the cable.

7. lnstallthe new cable in the reverse order of

removal. and note these items:

. Be careful not to bend or distort the cable.. Make sure the parking brake cable clip is fully

seated on the cable housing.. Do the parking brake cable adjuslment (see page

19-7 ).

19-27

Page 654 of 1139

Body

DoorsComponent Location Index ...........Door Panel Removal/lnstallation .....,..........Door Outer Handle ReplacementDoor Latch ReplacementDoor Glass and RegulatorReplacementDoor Sash Trim Replacement .......................

Door Glass Outer WeatherstripReplacement

Door Weatherstrip Beplacement

Door Glass Adjustment .................................Door Position Adjustment .............................Door Striker Adiustment ................................MirrorsComponent Location Index ...........................Power Mirror Replacement ...........................Mirror Holder Replacement ...........................Rearview Mirror Rep1acement ......................

GlassComponent Location Index ...........................Windshield Replacement

Bear Window Rep1acement ...........................

Ouarter Glass Replacement ..........................MoonroofComponent Location Index ...........................Symptom Troubleshooting Index

Glass Height Adjustment ...............................

Glass ReplacementWind Def lector 8ep1acement ........................Drain Channel Rep1acement ..........................Sunshade Replacement .................................Motor ReplacementFrame and Drain Tube Replacement ............Drain Channel Slider and Cable AssemblyReplacementLimit Switch Adjustment ...............................Closino Force and ODenina Draq Check ......lnterioi TrimComponent Location Index ...........................Trim Removal/lnstallation DoorArea ..........Trim Removal/lnstallation-Rear Side AreaTrim Removal/lnstallation-Cargo Floor AreaTrim Removal/lnstallation-Hatch Area .........Headliner Removal/lnstallation* Carpet Rep1acement .......................................ConsolesConsoles, Front and RearRemova l/lnsta llationFront Console Disassembly/Reassembly .....

20-220,420-620-7

20-920 t0

20- 10

20-1120-1120-1220 13

20-1420-1520-1520-16

20 1120-1920-2520-29

20,3520-3620-3720-3120-3820 3920-4020-4120,42

20 4420-4620,44

20-4920 50

20-51

DashboardInstrument Panel Removal/lnstallation ........Driver's Dashboard Lower CoverRemovat InstallationDriver's Dashboard Under CoverRemova t Insta llation

Oriver's Pocket Removal/lnstallation ............Shift Lever Trim Removal/lnstallation ..........Center Panel Removal/lnstallation ...............Passenger's Dashboard Lower CoverRemova l/lnsta llat ionx Glove Box Removal/lnstallationDashboard Side VentRemoval/lnstallation .................................. 20-64Beverage Holder Removal/lnstallation ........ 20-64Driver'sTray Removal/lnstallation ............... 20-65Passenger's Tray Removal/lnstallation ........ 20 65* Dashboard Removal/lnstallation .................. 20-66Steerinq Hanqer Beam Reolacement ........... 20-68Seats "

Component Location Index ........................... 20-10* Front Seat Removal/lnstallation ................... 20-11* Front Seat Disassembly/Reassembly-Driver's .................................. 20-73* Front Seat Disassembly/Reassembly-Passenger's ........................... 20-74* Front Seat Cover Replacement ..................... 2O-75Rear Seat Removal/1nsta11ation ..................... 20-80Rear Seat-back Latch Replacement .............. 20-81Rear Seat-backStriker Replacement ............ 20-81

20-59

20-59

Rear Seat-back Cover Replacement ............. 20-82Rear Seat Cushion Cover Replacement ....... 20.84BumpersFront Bumper Removal/lnstallation .............Rear Bumoer Removal/lnstallation ...............HoodAdjustmentHood Seal ReplacementHood Insulator Rep1acement .........................Hatch

20-6020,6020 6120-62

20-63

20-63

20,8520-86

20-4720,8820,89

20-5220-5320-5420-55

20-5720-58

Adjustment ................... 20-90Hatch Suppon Strut Replacement ................ 20-91Hatch WeatherstriD Reo1acement ................. 20-92

Fuel Fill DoorAdiustment ................... 20-93Exterior TrimFront Grille Replacement ..............Cowl Covers Replac"rn""t .. . .....................A pillar Corner Trim Replacement ................Roof lMolding Replacement ...........................Rear License Trim ReplacementHatch Spoiler 8ep1acement ...........................Emblem Rep1acement .........................

20-9420-9520-9620-9720,9820-9920-100

Page 661 of 1139

7. Pull out the outer handle (A), then remove it.

Installthe handle in the reverse order of removal,

and note these items:

. Make sure each rod is connected securelv.. Make sure the door locks and opens properly.. When installing the lock cylinder. leavetheouter

door handle bolts loose so the inner protector

does not interfere with the lock cylinder

installation, then tighten the handle bolts.. Install the lock cylinder retaining clip on the

handle, then install the lock cylinder. Be sure the

clip is fully seated in the slot on the lock cylinder.. When reinstalling the door panel, make sure the

plastic cover is installed properly, and is sealed

around the covers Derimeter.

Door Latch Replacement

NOTE: Put on gloves to protect your hands.

1. Remove these items:

3.

4.

. Door panel (see page 20-4). Plastic cover, as necessary (see page 20-2)

Raise the glass fully.

Remove the lock rod protector (see step 3 on page

20-6).

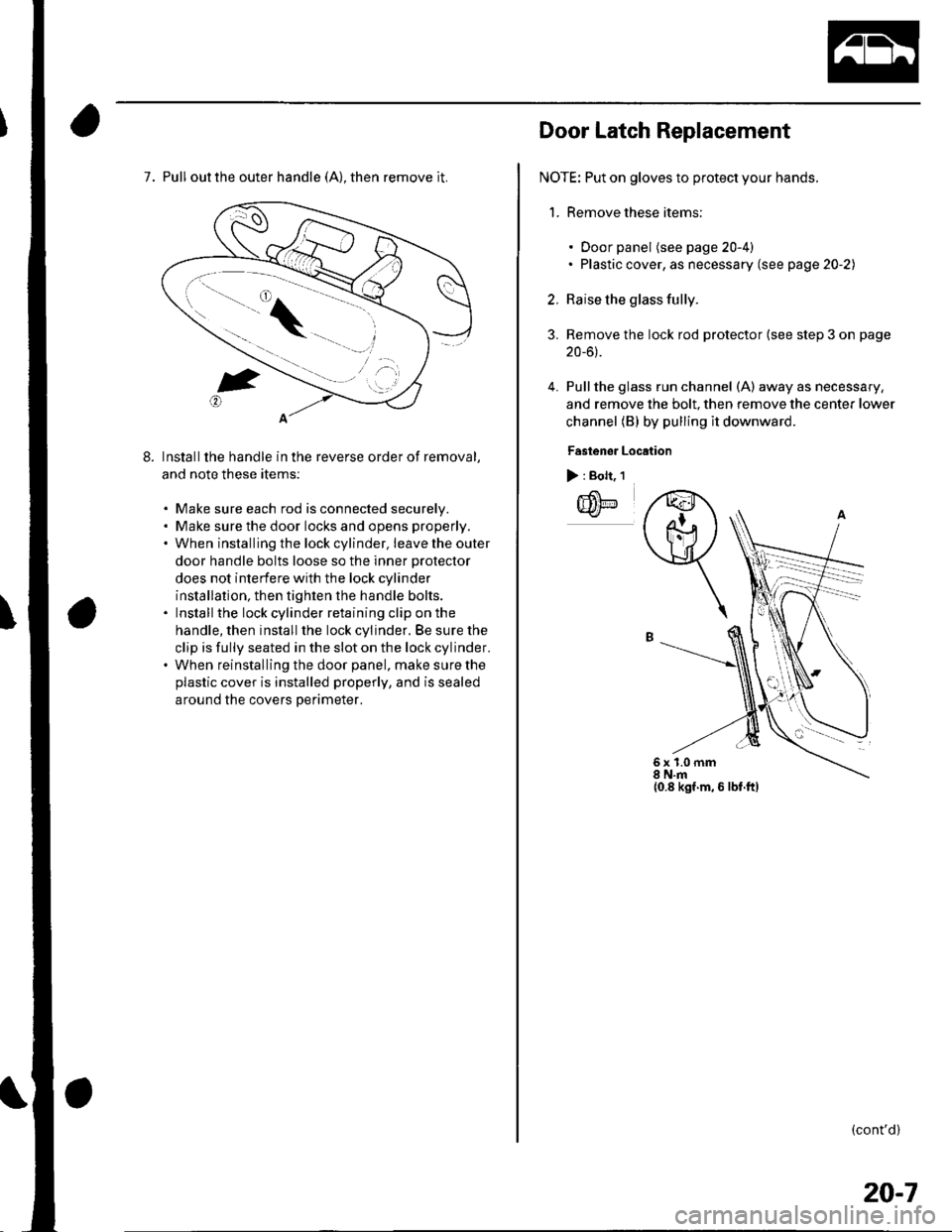

Pullthe glass run channel (A) away as necessary,

and remove the bolt, then remove the center lower

channel (B) by pulling il downward

Fastenor Location

> : Bolt, 1

IIilE

q

6x1.0mm8 N.m{0.8 kgf.m, 6 lbf.ftl

(cont'd)

20-7

Page 673 of 1139

Windshield Replacement

NOTE:. Put on gloves to protect your hands,. Wear eye protection while cutting the glass adhesive

with piano wire.. Use seat covers to avoid damaging the seats.

1. Remove these items:

. Rearview mirror (see page 20-16). Windshield wiper arms (see page 22-145)

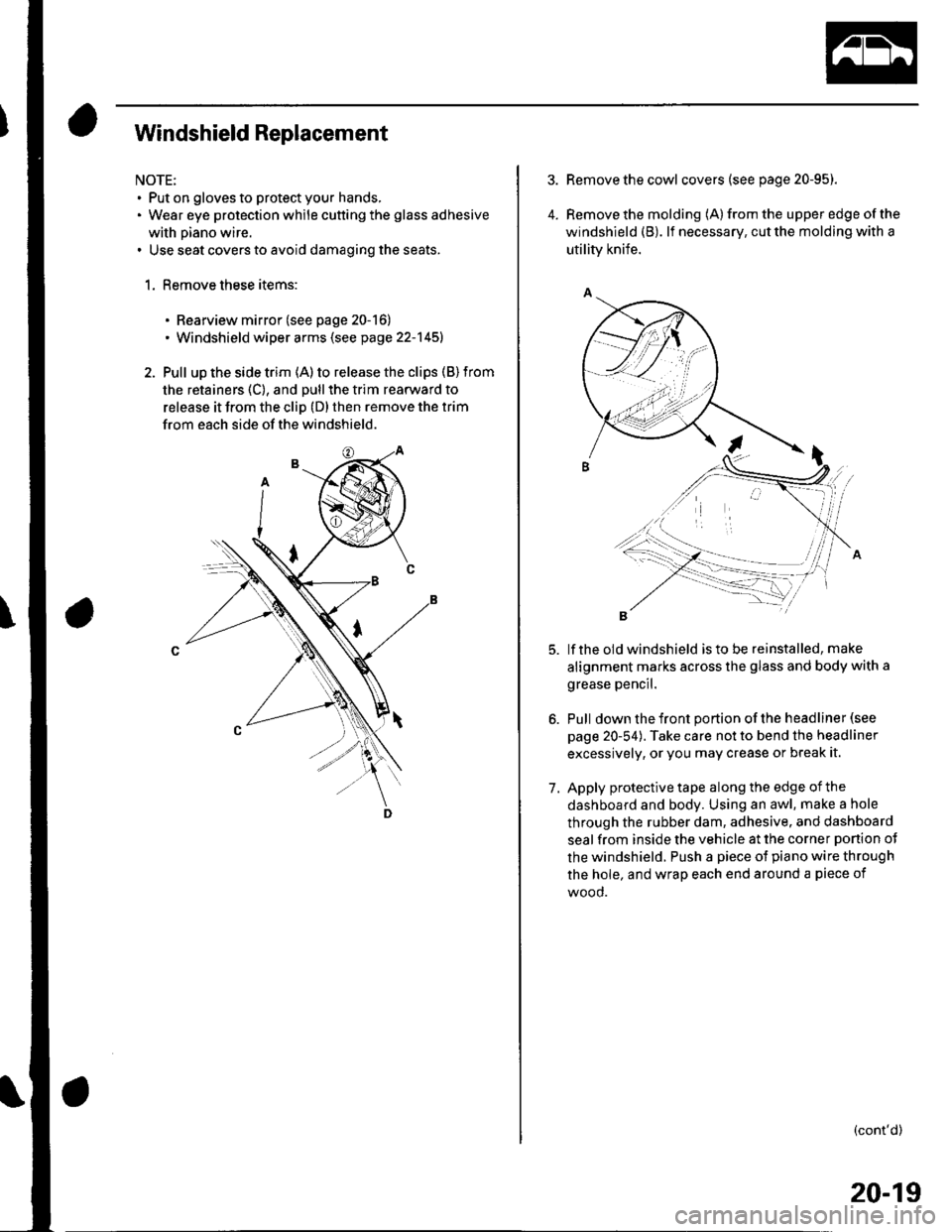

2. Pull up the side trim (A) to release the clips (B) from

the retainers (C), and pull the trim rearward to

release it from the cliD (D) then remove the trim

from each side of the windshield.

4.

Remove the cowl covers (see page 20-95).

Remove the molding (A) from the upper edge of the

windshield (B). lf necessary, cut the molding with a

utility knife.

lf the old windshield is to be reinstalled, make

alignment marks across the glass and body with a

grease pencil.

Pull down the front portion of the headliner (see

page 20-54). Take care not to bend the headliner

excessively, or you may crease or break it.

Apply protective tape along the edge of the

dashboard and body. Using an awl, make a hole

through the rubber dam, adhesive. and dashboard

seal from inside the vehicle at the corner ponion ot

the windshield. Push a piece of piano wire through

the hole, and wrap each end around a piece of

wood.

(cont'd)

7.

20-19