Circuit HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 1112 of 1139

I

d

\9I

SRS Indicator Circuit Troubleshooting

The SRS Indicator Doesn't Come On

1. Turn the ignition switch ON (ll), and see if the otherindicators come on {brake system, etc).

Do the other indicators come on?

YES Go to step 2.

NO-Go to step 8.

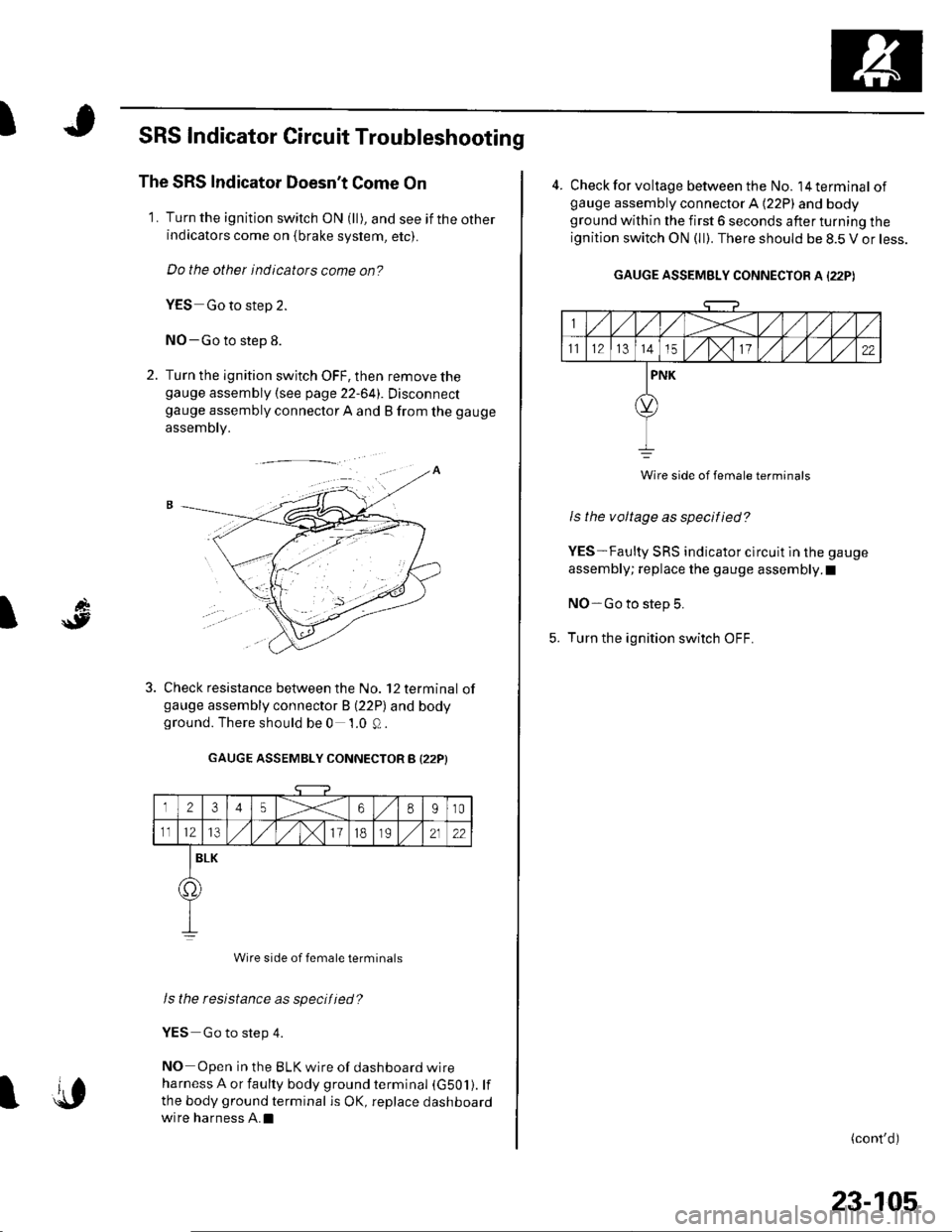

2. Turn the ignition switch OFF, then remove thegauge assembly {see page 22-641. Disconnectgauge assembly connector A and B from the gauge

assembly.

Check resistance between the No. 12 terminal ofgauge assembly connector B (22P) and bodyground. There should be 0 1.0 Q.

GAUGE ASSEMBLY CONNECTOR B I22PI

12345X68910

1112l3/)x111B2122

BLK

o.

Wire side of female terminals

Is the resistance as specified?

YES Go to step 4.

NO Open in the BLK wire of dashboard wire

harness A or faulty body ground terminal (G501). lf

the body ground terminal is OK, replace dashboard

wire harness A.Il{,

23-105

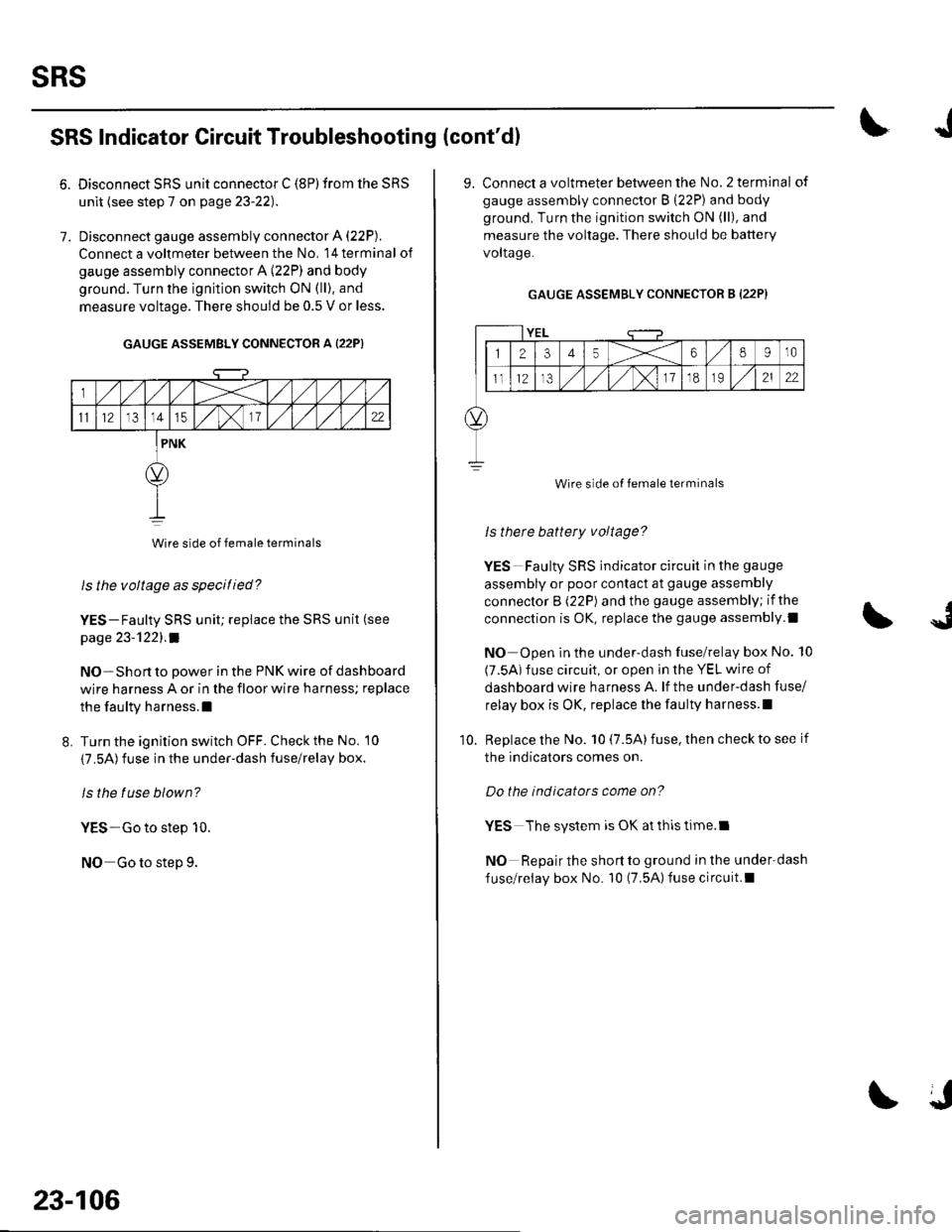

4. Check for voltage between the No. l4terminal ofgauge assembly connector A (22P) and bodyground within the first 6 seconds after turning the

ignition switch ON (ll). There should be 8.5 V or less.

GAUGE ASSEMBLY CONNECTOR A I22PI

Wire side of female terminats

Is the voltage as specified?

YES-Faulty SRS indicator clrcuit in the gauge

assembly; replace the gauge assembly.I

NO-Go to step 5.

Turn the ignition switch OFF.

(cont'd)

Page 1113 of 1139

sRs

6.

SRS Indicator Circuit Troubleshooting (cont'dl

7.

Disconnect SRS unit connector C (8P) from the SRS

unit {see step 7 on page 23-22).

Disconnect gauge assembly connector A (22P).

Connect a voltmeter between the No, l4terminal of

gauge assembly connector A (22P) and body

ground. Turn the ignition switch ON (ll), and

measure voltage. There should be 0.5 V or less.

GAUGE ASSEMBLY CONNECTOR A {22P)

Wire side of female terminals

ls the voltage as specitied?

YES-Faulty SRS unit; replace the SRS unit (see

page 23-'l22l.a

NO-Short to power in the PNK wire of dashboard

wire harness A or in the floor wire harness; replace

the faulty harness.l

L Turn the ignition switch OFF. Check the No. 10

{7.5A)fuse in the under-dash fuse/relay box.

ls the tuse blown?

YES-Go to step 10.

NO Go to step 9.

23-106

J

9. Connect a voltmeter between the No.2 terminal of

gauge assembly connector B (22P) and body

ground. Turn the ignition switch ON (ll), and

measure the voltage. There should be battery

voltaqe.

GAUGE ASSEMBLY CONNECTOR B (22P}

YEL

12345X68910

ll12,/ ,/,/x11o2122

Wire side of female terminals

ls therc battery voltage?

YES Faulty SRS indicator circuit in the gauge

assembly or poor contact at gauge assembly

connector B (22P) and the gauge assembly; if the

connection is OK, replace the gauge assembly.l

NO Open in the under-dash fuse/relay box No. 10

(7.5A) fuse circuit, or open in the YEL wire of

dashboard wire harness A. lf the under-dash fuse/

relay box is OK, replace lhe faulty harness.l

Replace the No. 10 (7.5A) fuse, then check to see if

the indicators comes on.

Do the indicators come on?

YES The system is OK at thls time.l

NO Repair the short to ground in the under-dash

fuse/relay box No. 10 (7.5A)fuse circuit.l

10.

Page 1115 of 1139

sRs

from the under-dash fuse/relav bor.

11.

18.

SRS Indicator Circuit Troubleshooting (cont'd)

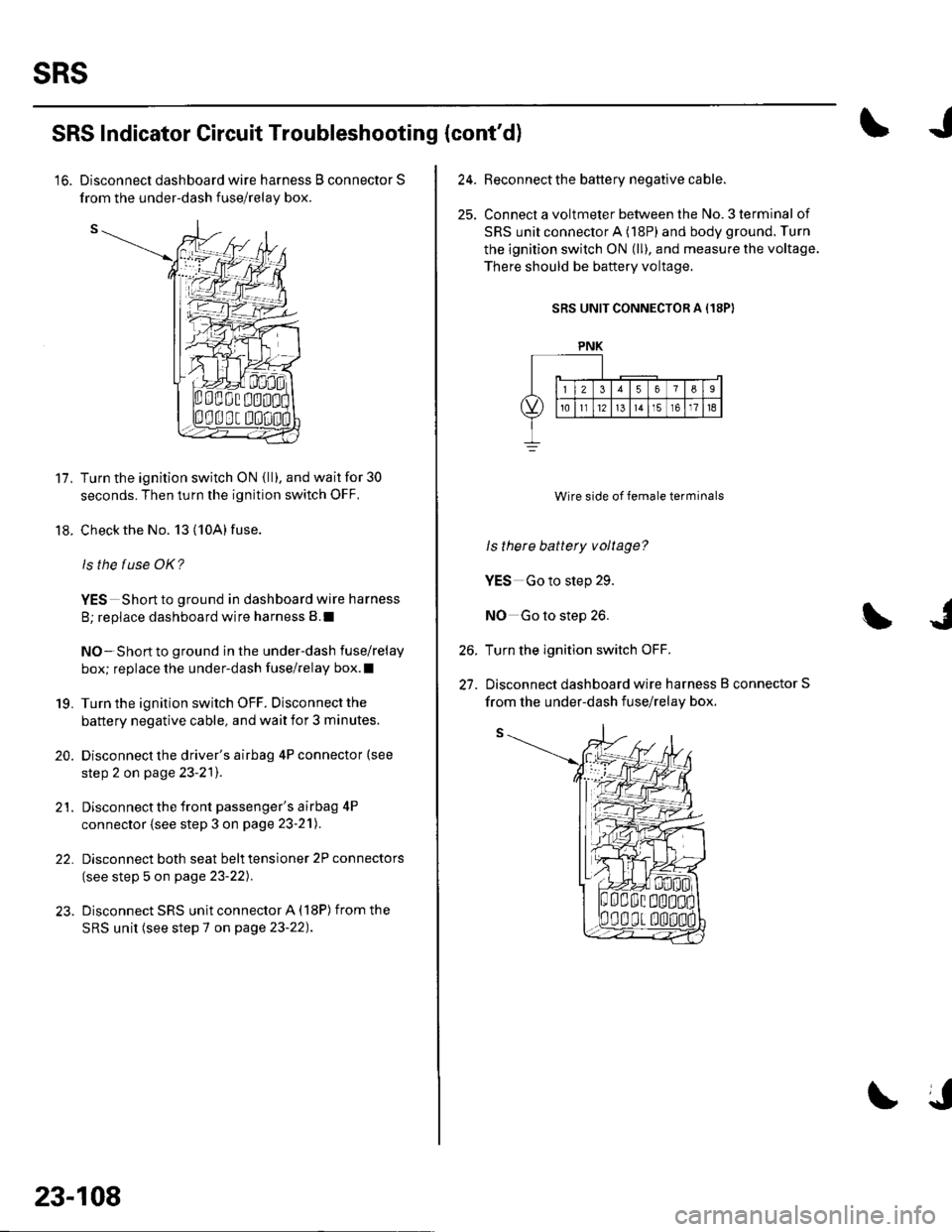

'16. Disconnect dashboard wire harness B connector S

Turn the ignition switch ON {ll), and wait for 30

seconds. Then turn the ignition switch OFF,

Check the No. 13 (10A) fuse.

ls the f use OK?

YES Short to ground in dashboard wire harness

B; replace dashboard wire harness B.I

NO-Short to ground in the under-dash fuse/relay

box; replace the under-dash fuse/relay box.l

Turn the ignition switch OFF. Disconnect the

battery negative cable, and wait for 3 minutes.

Disconnect the driver's airbag 4P connector (see

step 2 on page 23-2'l).

Disconnect the front passenger's airbag 4P

connector (see step 3 on page 23-21).

Disconnect both seat belt tensioner 2P connectors

(see step 5 on page 23-22).

Disconnect SRS unit connector A (18P) from the

SRS unit (see step 7 on page 23-22).

19.

20.

21.

22.

23-108

24.Beconnect the battery negative cable.

Connect a voltmeter between the No. 3 terminal of

SRS unit connector A (18P) and body ground. Turn

the ignition switch ON (ll), and measure the voltage.

There should be baftery voltage.

SRS UNIT CONNECTOR A (18PI

Wire side of female terminals

ls there battery voltage?

YES Go to step 29.

NO Go to step 26.

Turn the ignition switch OFF.

Disconnect dashboard wire harness B connector S

26.

27.

PNK

from the under-dash fuse/relav box.

Page 1117 of 1139

sRs

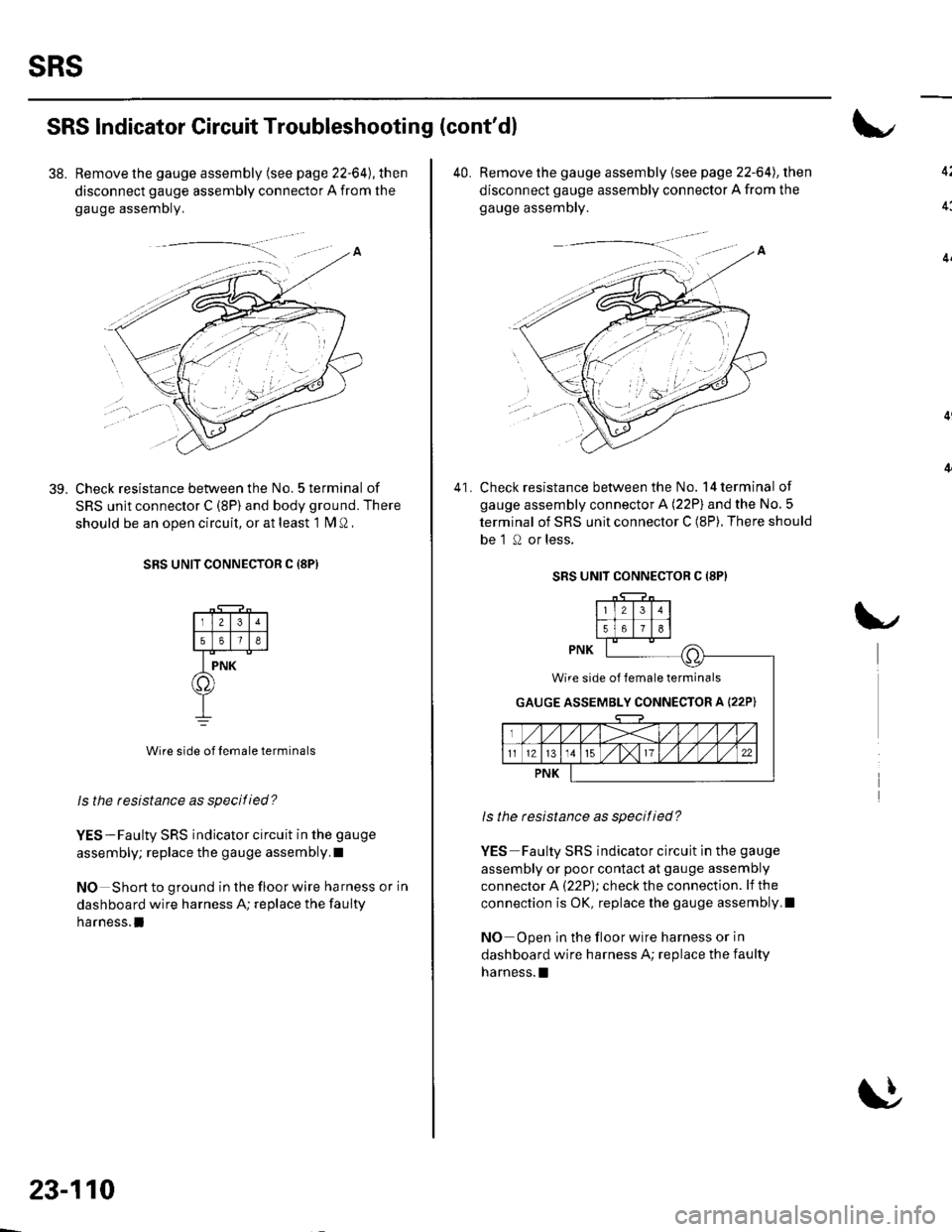

39.

SRS lndicator Gircuit Troubleshooting (cont'dl

38. Remove the gauge assembly (see page 22-64), then

disconnect gauge assembly connector A from the

gauge assemDly,

Check resistance between the No. 5 terminal of

SRS unit connector C (8P) and body ground. There

should be an ooen circuit, or at least 1 fM Q ,

SRS UNIT CONNECTOR C {8PI

Wire side of lemale terminals

ls the resbtance as specitied?

YES-Faulty SRS indicator circuit in the gauge

assembly; replace the gauge assembly.I

NO Short to ground in the floor wire harness or in

dashboard wire harness A; replace the faulty

harness.l

23-110

40. Remove the gauge assembly (see page 22-64), then

disconnect gauge assembly connector A from the

gauge assembly.

Check resistance between the No. 14 terminal of

gauge assembly connector A (22P) and the No.5

terminal of SRS unit connector C (8P). There should

be 'l 0 or less,

41.

SRS UNIT CONNECTOR C (8P}

ls the resistance as specitied?

YES Faulty SRS indicator circuit in the gauge

assembly or poor contact at gauge assembly

connector A (22P); check the connection. lf the

connection is OK, replace the gauge assembly,I

NO Open in the floor wire harness or in

dashboard wire harness A; replace the faulty

harness. !

Wire side of lemale terminals

GAUGE ASSEMBLY CONNECTOR A I22P)

Page 1119 of 1139

sRs

Component Replacement/lnspection After Deployment

NOTE: Before doing any SRS repairs. use the PGM

Tester SRS menu method to check for DTCS; refer to the

DTC Troubleshooting Index for the less obvious

deployed parts (seat beit tensioners, front sensors, side

airbag sensors, etc.)

After a collision where the seat belt tensioners

deployed, replace these items:' Seat belt tensioners. Seat belt buckle tensioners. SRS unit. Front impact sensors

After a collision where the front airbag(s) deployed.

replace these items:. SRS unit. Deployed airbag(s). Seat belt tensioners. Seat belt buckle tensioners. Front impact sensors

After a collision where the side airbag{s) deployed,

replace these items:. SRS unit. Deployed side airbag(s). Side impact senso(s)for the side(s) that deployed

During the repair process, inspect these areas:

. lnspect allthe SRS wire harnesses. Replace, don't

repair, any damaged harnesses.. Inspectthecable reelfor heatdamage. lf there is any

damage, replace the cable reel.

Afterthe vehicle is completely repaired, turn the

ignition switch ON (ll). lf the SRS indicator comes on for

about 6 seconds and then goes off, the SRS airbag

system is OK. lf the indicator does not function properly,

use the PGM Tester SRS Menu Method to read the DTC

(see page 23-23). lf this doesn't retrieve any codes, use

the Tester's SCS menu method (see page 23-24). lf you

still cannot retrieve a code, go to SRS Indicator Circuit

Troubleshooting.

23-112

\|J

Page 1124 of 1139

)

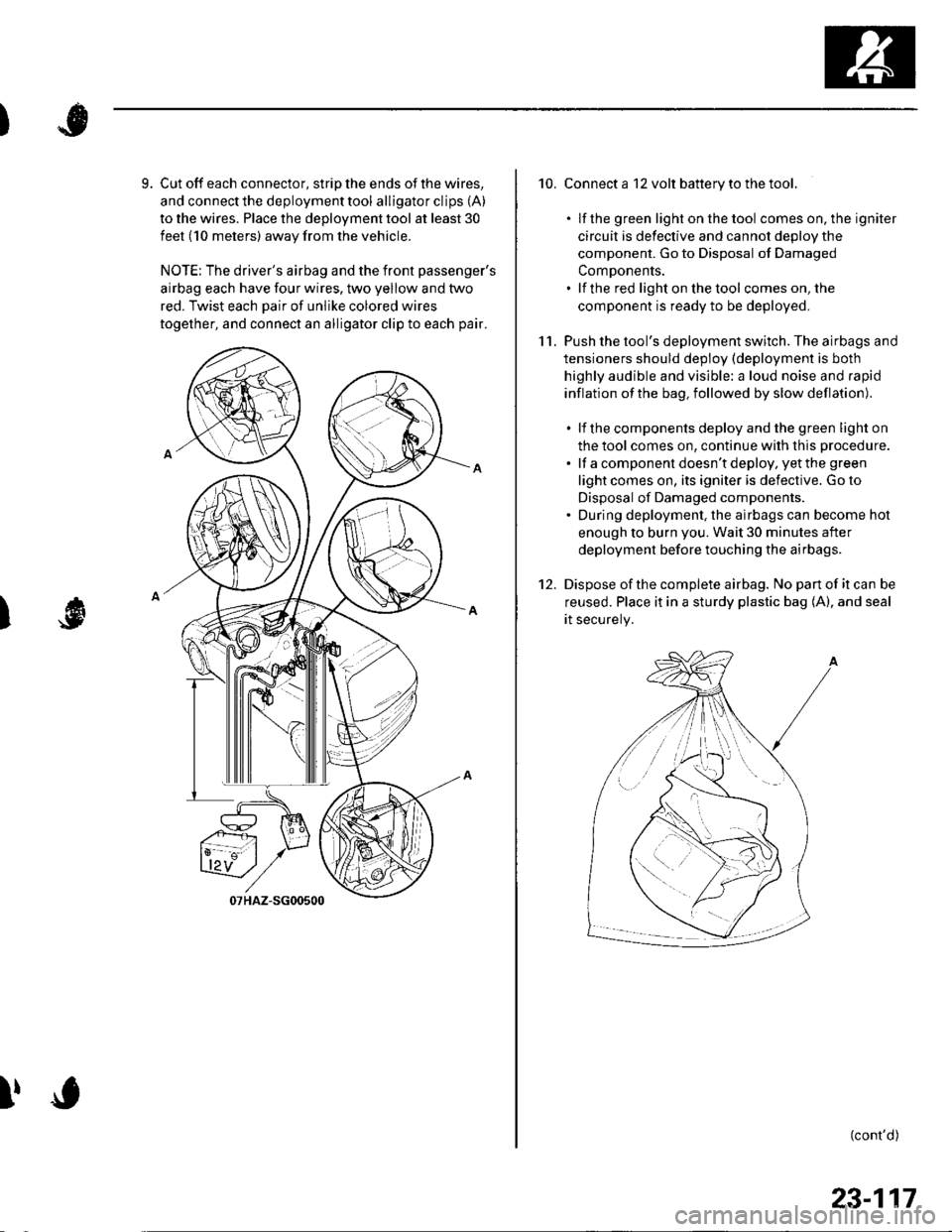

9. Cut off each connector, strip the ends of the wires,

and connect the deployment tool alligator clips (A)

to the wires. Place the deployment tool at least 30

feet (10 meters) away from the vehicle.

NOTE: The driver's airbag and the front passenger's

airbag each have four wires, two yellow and two

red. Twist each Dair of unlike colored wires

together, and connect an alligator clip to each pair.

I

!

10. Connect a 12 volt battery to the tool.

. lf the green light on the tool comes on, the igniter

circuit is defective and cannot deDlov the

component. Go to Disposal of Damaged

ComDonents.. lf the red light on the tool comes on, the

component is ready to be deployed.

11. Push the tool's deployment switch. The airbags and

tensioners should deploy (deployment is both

highly audible and visible: a loud noise and rapid

inflation of the bag, followed by slow deflation).

. lf the components deploy and the green light on

the tool comes on, continue with this procedure.

. lf a component doesn't deploy, yet the green

light comes on, its igniter is defective. Go to

Disposal of Damaged components.. During deployment, the airbags can become hot

enough to burn you. Wait 30 minutes after

deployment before touching the airbags.

12. Dispose ofthe complete airbag. No pan of it can be

reused. Place it in a sturdy plastic bag (A), and seal

rt securery.

(cont'd)

/:

i'..-':

23-117

Page 1125 of 1139

sRs

Airbag Disposal (cont'dl

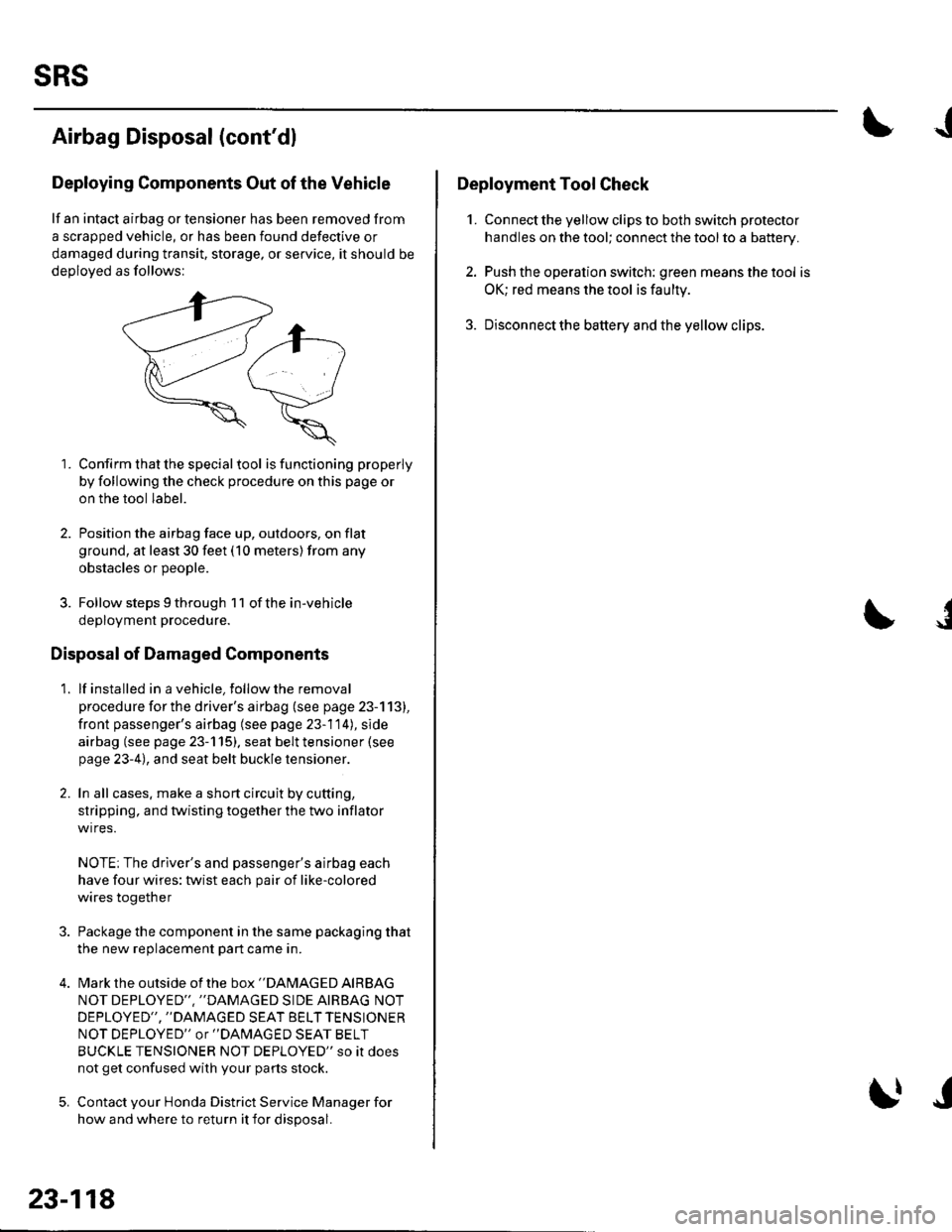

Deploying Components Out of the Vehicle

lf an intact airbag or tensioner has been removed from

a scrapped vehicle, or has been found defective or

damaged during transit, storage, or service, it should be

deoloved as follows:

1. Confirm that the special tool isfunctioning properly

by following the check procedure on this page or

on the tool label.

2. Position the airbag face up, outdoors, on flat

ground, at least 30 feet (10 meters) from any

obstacles or DeoDle.

3. Follow steps 9 through 1 1 of the in-vehicle

deployment procedure.

Disposal of Damaged Components

1. lf installed in a vehicle, follow the removal

procedure for the driver's airbag (see page 23-113),

front passenger's airbag (see page 23-114), side

airbag (see page 23-115). seat belt tensioner (see

page 23-4), and seat belt buckle tensioner.

2. In all cases. make a short circuit by cutting,

stripping, and twisting together the two inflator

wires.

NOTE; The driver's and passenger's airbag each

have four wires: twist each pair of like-colored

wires together

Package the component in the same packaging that

the new reolacement Dart came in.

Mark the outside of the box "DAMAGED AIRBAG

NOT DEPLOYED'" ''DAMAGED SIDE AIRBAG NOT

DEPLOYED", "DAMAGED SEAT BELT TENSIONER

NOT DEPLOYED" or "DAlvlAGED SEAT BELT

BUCKLE TENSIONER NOT DEPLOYED" so it does

not get confused with your parts stock.

Contact your Honda District Service Manager for

how and where to return it for disposal.

23-118

I|J

J

Deployment Tool Check

1. Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

2. Push the operation switch: green means the tool is

OK; red means the tool is faulty

3. Disconnectthe battery and the yellow clips.

J

Page 1133 of 1139

Service Manual lndex

)s

NOTE: Referto the lollowing listto look up A/C Pressure Switch CircuitDTCS, symptoms, fuses, connectors, wire Troubleshooting ......... ...-.-....-...-.-.-....-..21-32 Bharnesses, specifications, maintenanceschedules, and general serviceinlormation:

DTC Troubleshooting Indexes

A/C Signal CircuitTroubleshooting.........................-...... 11-'133 Back-up Light SwitchTest .......................................................... 13'3A/F lAir Fuel Ratiol SensorABS/TCS Components ........................ 19-34 Replacement ....................................... 1 1-113 Back-up Li9ht3EPS Components ................................. '17-22 Circuit DiagramFueland Emissions11-i A-Dillar Corner Trim

ABS Indicator Circuit

Heating/Ventilation ................................ 21-9 Replacement ...............-.....-..............-.... 20,96 Ball Joint BootssRS ........................................................ 23-28Replacement ......

... 19-52 Ball Joints

22-75

18 16

Remova1.............-.......... . ...........18-10Symptom Troubleshooting Indexes TroubleshootingABS/TCSComponents........................ 19 35Cruise Control System ..........................4 38 ABS Modulator-contml UnitEPS Components ................................. 17-23 Bemoval/lnstallation ............................ 19-57 BettervFan Controls10,12

Accessory Powor Socket Front

Blowor Pow€r Transistor

.......22 50

Blower UnitRemoval/lnstallation ............................ 21-39

Fuel and Em issions .............................. 11-10 ABS/TCS ComoonentsHeating/Ventilation..............................21 10 Component Location Index ................. 19-30 Beverage Holder

SRS ........................................................ 23'30 CircuitDiaqram.......................... 19'42Blower MotorReplacement .....21 41

21-38

Power 0istribution ...............................22-46 TesVReplacement .............................. 22'149Under-dash Fuse/Relay Box ............... 22 45Under-hood Fuse/Belay Box ...............22 44 Accessory Power Sockets

Fuse/Relay lndexes

(to harness)

Connector and Wire Harness lndexesComponent Connectors

Circuit Oiagram .................................. 22-149

Air Cleaner......2214 Rep1acemen1.....................................11-162

Air MixControl MotorMeintenence section .................... Section 3 Replacement ......................................... 21'34 Brake CelipersTest......................21-34 Overhaul19-14,23Gene.al lnlormation section........ Section 1

21.57

Airbag. Driver's

Ahernator FR Signal CircuitTroubleshooting .... .........-..........11 134

AntennaReplacement

Inspection ............................................. 19-24Rep|acement................. .................... 19-25

Bieke Meder Cylinder

Irake Discs

A

Replacement ....................................... 23 1 'l3 Inspection .................... ................... 19-13,22Repair ...........-...................................... 23 1 16Brake Fluid Level SwitchAirbag. Front Passenger's TestBeplacement....................................... 23-1 14AIC Brake LightsComponent Location fndex ...................21-3 Altemator CircuitDiagram....................................22-74Description.....................................-....21'1'l Beplacement ................ ........................... 4 29CircuitDiagram....................................21-14 Overhaul .................................................4-30 Brake Lines and Hoses

19.10

A/C CompressolReplacement .......-...-............................. 21 -41

A/C Compr€ssor ClulchRep1acement......................................... 19-15.........22-103 Inspection ............................................. 19-16Inspecton........Overhaul ..........

A/C CondenserReplacement,.,

21-442l-49 Audio Unit

Replacement

Brake PadsRemoval/lnstallation .. ........................22-100 Inspection/Rep1acement................ 19-11,20A/C Compressor Clutch CircuitTroubleshooting ................................... 21-30 Audio Unit Connector Brake Pedal22101 Adjustment..............19,6ArfC Comoressor Relief ValvcReplacement ..........-...-.......................... 21-51 Audio/Entertainment

A/C Compr$sor Thermal Protector Circuit DiagramReplacement............-............................ 21-51

Component Location In dex .................22-9A Test .......-.............. 22-84Breke Pedal Posilion Switch

Brake Pedal Position Switch Signal Clrcuit11-137

.....21 52

A/C Condenser Fan CircuitTroubleshooting ................... . . . . . .....21-28

)s

Troubleshooting

(cont'd)

Page 1134 of 1139

Service Manual Index

(cont'dl

Brake System Indicator CircuitCircuit DiagramConventional Brake Components..... 19-9TroubleshootingABS/TCS Components .... ....... ...... 19-55

Bulb, GeugeRep|acemenl................ .. ............2263

Bulb, HeadlightReplacement ......................................... 22-A1

Bumper, FrontRemoval/1nsra11ation ............................ 20 85

Bumper, RearRemoval/lnstallation... ... . .....20.86

Combination Light SwilchTesVReplacement ..............................22 80

Connecting Rod BearingsRep|acement...................... .......-....7-8

Connecting Rod Boltsf nspection ....................-.-.-.-.................... 7 -24

Connecting RodsInspection ........,,.,.,...,.,.,.,.,,,,.,,,.,.,.,.,.,.,.,.. 7 5

Connectors(See first page of this Index)

Conventional Brake Component3Component Location Index ................... 19'3Troub1eshootin9 ..................................... 19-4

Cylinder Head AssemblyComponent Location Index ..................... 6-3Inspection ................................................. 6 6Removal ..........&�23Insta11alion .............................................. 6 39

Cylinder Head Cover8emova1 ..............-.-................................. 6-22Installation ..............................................6-41

Cylinder Head, BareInspecton..,.....,.

D

c

Cable ReelReplacement....................................... 23-1 19

CamshaftInspection .......................-...-................... 6-29

Cargo Area LightTesVRep1acement ................................ 22-97

CarpetReplacement.....-...-..... ... ......-.20-55

Ceiling Light-estrReplacement ................................ 22.96

Charging SystemComponent Location Index................... 4-20Circuit Diagram ...................................... 4-21

19-8

CoolantInspection .................. ..... .. 106Replacement................. ... . .. 10 6

Coolant Temperature Gat|geTroub1eshootin9................................... 22 64

Cooling SyslemComponent Location Index................... 10-2

Countershaft BearingsReplacement............... ..................... 13-42

Cowl CoverReplacement............... .. ..... ....20-95

CrankshaftRemoval .................................................. 7 -12

Repair ..................

Inspec(on,,,,,........1 14

Dampers. FrontReplacement................ ..................... 18 20

Oampers, RearRep1acement......................................... 18-34

Dash VentsBemoval/lnstallation .-.......................... 20-64

DashboardBemoval/1nsta11ation ............................ 20-66

Oashboard Center PanelRemoval/1nstaf 1ation ............................ 20 62

Dashboard Lower CoverRemoval/lnstallation ...................... 20-59, 63

Dashboard Under CoverRemoval/lnstallation ............................ 20 60

Diff erential Carrier Bearings, M/TRep1acement,,......,...,...,.,.,,,.,.,,,........,.,. 13-54

Ditferential Oil Seals, M/T8ep1acement......................................... 13-55

Differential Pinion Gears, M/TInspection .,....-,.,,,.,..,.-,.,.........,.,.,,, 13 53

OLC CircuitTroubleshooting ................................ 1 1-109

Door GlassRep1acement.,.,,,,,,,,,,,.,,,,,,,,,,.,.,.,.,.,,,,,,.,, 20-9Adjustment. .. .....................20-11

Door Glass WeathelstripsReplacement .............-.. . . . ..........-......20 10

Door LatchesReplacement ..........-.-.............................. 20-7

Door Lock ActuatorsTest ...................................................... 22-154

Door Lock Knob SwitchesTest -......... . . . - . . . . . . . . ......22-160

Door Lock SwitchesTest ........... ............................ ............. 22-160

Door Outer HandlesRep1acemen1 ........................................... 20-6

3

Child Seat Tether AnchorRemoval/lnstaf lat;on .. ........................ 23 11

CKP (Crankshaft Position) SonsorReplacement....................................... 1 1-116

ClutchComponentLocation 1ndex................... 12-3Rep1acemen1........................................... 12-9

Clutch InteYlock SwitchTest.....-........-...-............. ...---.-.......4-6

Clutch Master CylinderReplacement........................................... 12 5

clutch PedalAdjustment ............................................. 12 4

Clutch Pedal Position SwitchTest.,.,,,,,.,,,.,.,,,,,,.,.,,,,,,,,,.,,,,,.. ......445

lnstallation.................. . ..... .....1-24

Crankshalt Main BearingsReplacement........-.-.................................. 7-6

CrankshaftOil Seal,Transmission End1nstanation .............................................. 7 28

Crankshafl PulleyRemoval/lnstallation -..................-.......... 6-1 1

Cruise Control Actuator

Troubleshooting

Clutch Slave CylindorBeplacemeit...

...................... 4-43

.......4-22

Test

12-1

RepIacement........................................... 4-44

Cruise Control Actuator CableAdjustment ............................................. 4 45

Cruise Control Main SwitchTesVRep1acement .................................. 4 42

Cruise Control Set/Resume/Cancel SwitchTesVRep1acement .................................. 4 42

Cruise Control SystomComponent Localion Inde\................... 4-36Circuit Diagram ....-................................. 4 37

Cruise Control UnitInputTest.............................. .. ...4,40CMP {Camshaft Positionl Senso]Replacement....-...-.............................. 1 1-128

CMP (TDC) SensorsReplacement............-.......................... 1 1 1 14

Page 1135 of 1139

)

Orive BehInspecaron................ 4-26

Door PanelsRemoval/lnstallation -............................. 20-4

Door Sash TrimRep1acement......................................... 20 10

Door StrikersAdiustment ........................................... 20-13

Door Weatherst psBeplacement...........-............................. 20 1 1

EPS Conirol UnitRemoval/1nsta11ation ..................-......... 17-67

EPS Indicator CircuitTroubleshooting ................................... 17 -47

EPS MotorRemoval/lnstallation .-.......................... 17-49

EVAP CanisterRep1acement......................... ......... 11,189

EVAP Control Syst€mComponentLocation Index ..............'11-170

EVAP Two-Wey ValveTest ..........-.............-............................ 11 186

Evaporetor CoreRep1acement........................ . ... 21-42

Evaporator Tomperature SensorReplacement......................................... 21 -37Test..................................... ..........2137

EvaporrtoFHeater UnitReplacement........................................ 21 43

Exhaust ManifoldRemoval/1nsta11ation ................................ I 7

Exhaust Pipe8ep|acement............................................. 9-8

Front SpeakersRep|acement....................................... 22-102

Front SuspensionComponentLocation Index................... 18-3

Fueland EmissionsDescription ........................................... 11-12

Fuel Fill DoorAdjustment ..........-................................ 20 93

Fuel Fill Door OpenetBeplacement........................ . ............ 20.109

Fuel Fill Door Opener CableReplacement....................................... 20- lO7

Fuel FilterReplacement....................................... 1 1-152

Fuel Gauge Sending UnitTest ......................-.-..........-.................. 11'156

Fuel Injection Syslem (PGM"FIlComponent Location 1ndex................. 11-49

Fuel IniectorsRep1acemen1....................................... 1 1 1 1 l

Fuel Lines and HosesInspection .......................................... 1 1'146Removal ....................... . .. . .... 11-149Insta|1ation .......................................... 1 1 150

FuelPipe ProtectolReplacement....................................... 20-104

Fuel Pressure RegulatotReplacement....................................... 1 1-152

Fuel Pulsation DamperReplacemenl................................... 11 154

Fuel PumpReplacement,,,,,.,.,.,,,.,,,,,,,,,,,,.,.,.,,,..,.. 11-153

Fuel Pump CircuitTroubleshooting -.......-....................... 1 1-141

FuelSupply SystemComponent Location lndex .............. 11 140Adjustment................................... 11-144Test........-...-................. ... ............- 11-145

FuelTankBeplacemenl.............. . ..... .. 11 155

Fuel Tank Vapor ControlValveTest ......................-....... ... . . 11-187Replacement,,.,,...,.,,,.,.,,,,... .. .. 11 189

Fuses{See first page ofthis Index)

)

Rep|acement................. ..................... 4 26

Drive Belt Auto-tensionellnspection ............................................... 4 21Rep1acement.................................... ..4-28

Driver's PocketRemoval/lnstallation -........................... 20-60

Driver's TrayRemoval/lnstallation .........................-.- 20-65

DRL {Daytime Running LightslControl Unitlnput Test .................... ........ . . . ......22-16

DTCs(See first page olthis Index)

Dust and Pollen FillerReplacement......................................... 21-39

Dynamic Damper, DriveshaftsReplacement........................................... 16-8

ECT SensorReplacement.,.,,,.,.,,,,,,,,,,,,,,................ 1 1-1 14

El€ctrical Power Steering IEPS)Signal CircuitTroubleshooting ........ ... .. 11-135

EmblemsReplacement......................-................ 20-100

Engine AssemblyRemova1 .................................................... 5 2Installation ............._.................................. 5-9

Engine Block AssemblyComponent Location Inder ..................... 7.3

Engine Block, BareInspect|onRepair

Fan ControlsComponent Location Index................. 10'l 1Circuit Diagram .. ..... . .. . .................. 10 13

Fender Fairing, FrontReplacement...-................................... 20-103

Final Driven Gear. M/TReplacement.... . . ................................ 13-53

FrameRepair Chan............ ... ....................... 20 11 4

Frame StiffenelReplacement......-................................ 20- J'13

Front ConsoleRemoval/lnstallation ............................ 20 5lDisassembJy/Reassemb|y ................... 20 58

Front DoorsComponent Location Index................... 20-2Adiustment ........................................... 20.12

Front Driveshaft AssemblyInspeclion .................... ... ....16 3Remova1...................-...... ... .....16-3Disassembly ............................... .....165Resassemb|y ................................-......... 16-9Insta11arion ........................ ...... ............ l6 17

Front lmpact SensorsRep1acement............................ ...23 125

................7-15................1 11

)

Entry Light Control SystemComponent Location Index ...............-. 22-89Circuit Dia9ram .................................... 22 90

EPS ComponentsComponent Location 1ndex..........-...... 17-!7Description ........................ ...... ..17-24Circuit Diagram11 26(cont'd)