Idle air control HONDA CIVIC 2003 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 345 of 1139

ldle Control System

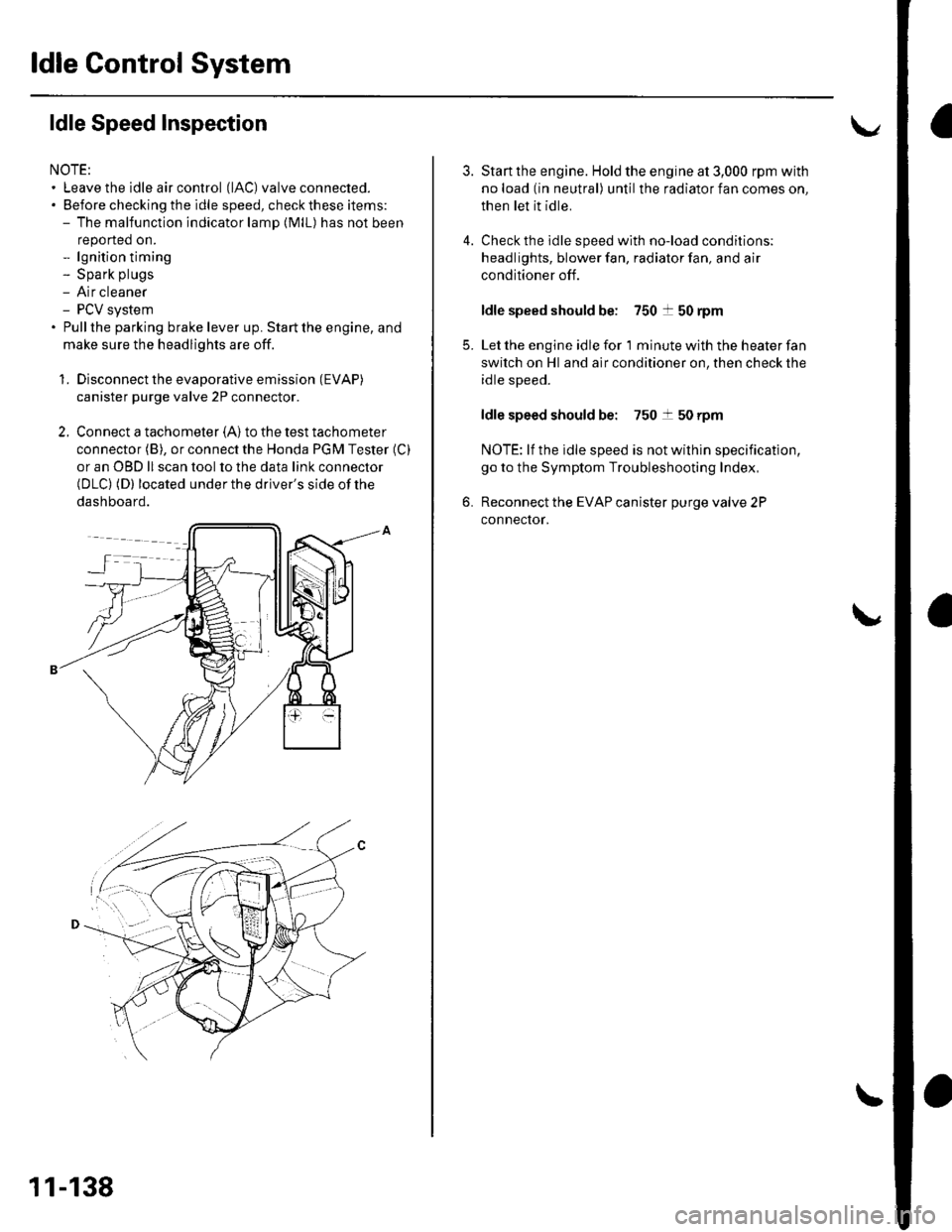

ldle Speed lnspection

NOTE:' Leave the idle air control (lAC) valve connecled.. Before checking the idle speed, check these items:- The malfunction indicator lamp (MlL) has not been

reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system. Pullthe parking brake lever up. Start the engine, and

make sure the headlights are off.

1. Disconnect the evaporative emission (EVAP)

canister purge valve 2P connector.

2. Connect a tachometer (A)to the test tachometer

connector (B), or connect the Honda PGM Tester (C)

or an OBD ll scan tool to the data link connector(DLC) (D) located under the driver's side of the

dashboard.

11-138

4.

3.

5.

6.

Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle.

Check the idle speed with no-load conditions;

headlights, blower fan, radiator fan, and air

conditioner off.

ldle speed should be: 750 t 50 rpm

Let the engine idle for 1 minute with the heater fan

switch on Hl and air conditioner on, then check the

idle speed.

ldle speed should be: 750 t 50 rpm

NOTE: lf the idle speed is not wilhin specification,

go to the Symptom Troubleshooting Index,

Reconnect the EVAP canister purge valve 2P

connector.

Page 372 of 1139

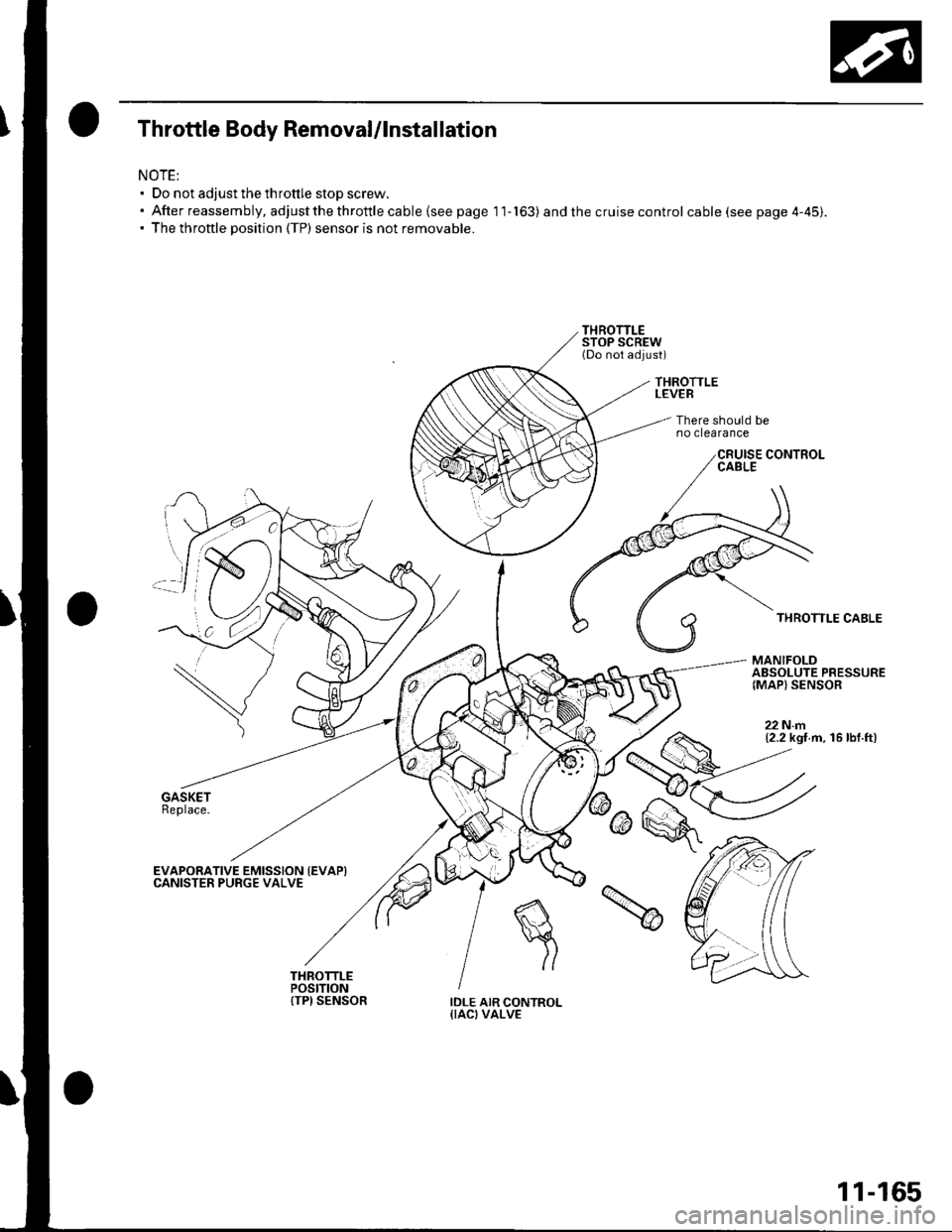

Throttle Body Removal/lnstallation

NOTE:' Do not adjust the throttle stop screw.. Afterreassembly,adjustthethrottlecable{seepagell-163) and the cruise control cable (see page 4-45).. The throttle position (TP) sensor is not removable.

THROTTLELEVER

There should beno clearance

THROTTLE CABLE

MANIFOLDABSOLUTE PRESSURE{MAP} SENSOR

22Nm(2.2 kgt.m, 16 lbf.ft)

EVAPORATIVE EMISSION {EVAPICANISTER PURGE VALVE

IDLE AIR CONTROL{IACI VALVE

11-165

Page 386 of 1139

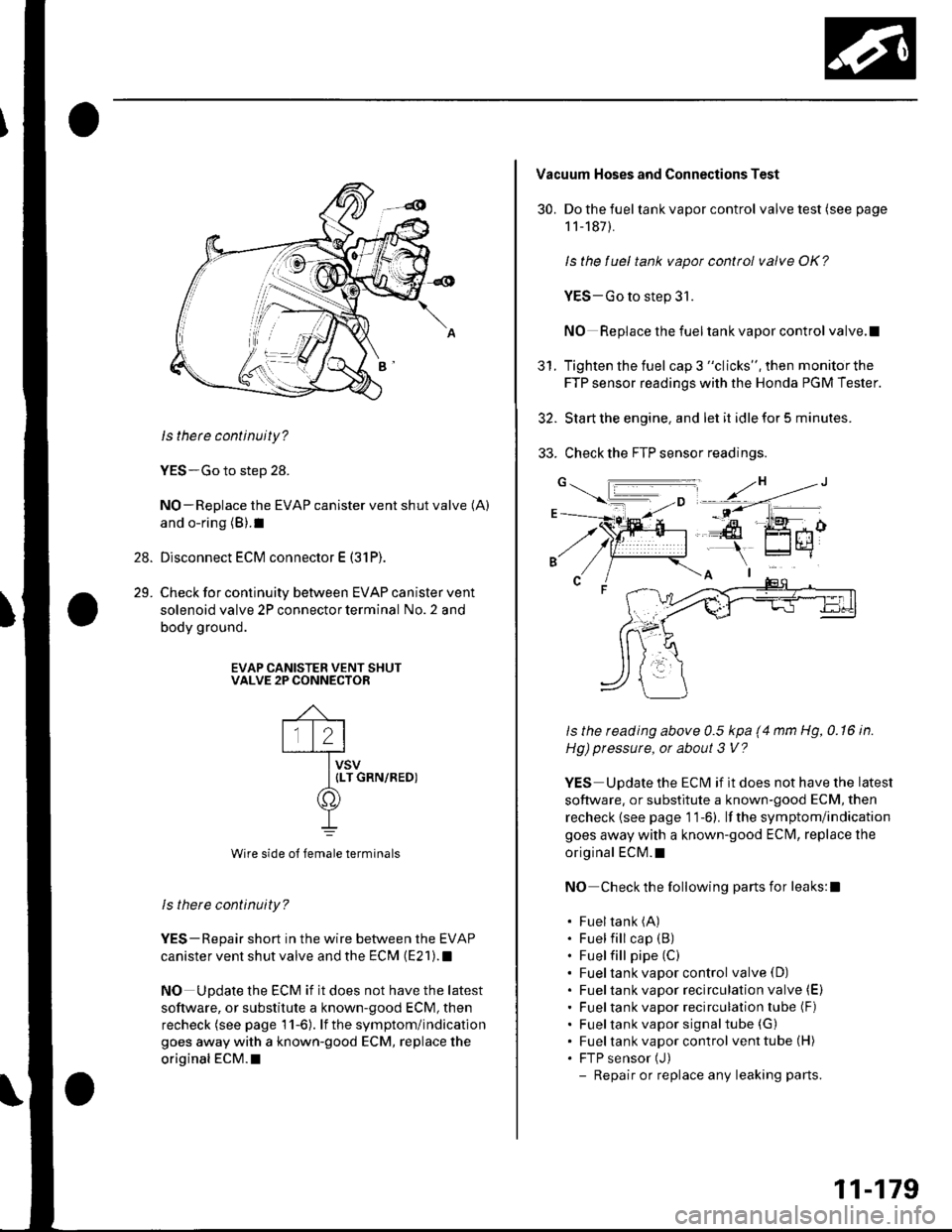

28.

29.

ls thete continuity?

YES-Go to step 28.

NO-Replace the EVAP canister vent shut valve (A)

and o-ring (B).1

Disconnect ECM connector E (31P).

Check for continuity between EVAP canister vent

solenoid valve 2P connector terminal No. 2 and

body ground.

EVAP CANISTER VENT SHUTVALVE 2P CONNECTOR

Wire side o{ female terminals

ls there continuity?

YES-Repair short in the wire between the EVAP

canister vent shut valve and the ECM (E21).1

NO Update the ECM if it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

30.

Vacuum Hoses and Connections Test

Do the fuel tank vapor control valve test (see page

1 1-187).

ls the fuel tank vapot control valve OK?

YES-Go to step 31.

NO Replace the fueltank vapor control valve.l

Tighten the fuel cap 3 "clicks", then monitorthe

FTP sensor readings with the Honda PGM Tester.

Start the engine. and let it idle for 5 minutes.

Check the FTP sensor readings.

ls the reading above 0.5 kpa (4 mm Hg, 0.16 in.

Hg) pressure, or about 3 V?

YES Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck {see page 1 1-6). lf the symptom/indication

goes away with a known-good ECfvl, replace the

original ECM.t

NO Check the following parts for leaks:l

. Fueltank (A)

. Fuel fill cap (B)

. Fuel fill pipe (C)

. Fueltank vapor control valve(D). Fueltank vapor recirculation valve (E)

. Fueltank vapor recirculation tube (F)

. Fueltank vapor signaltube (G)

. Fueltank vapor control venttube(H). FTP sensor (J)

- Repair or replace any leaking parts.

5t.

11-179

Page 423 of 1139

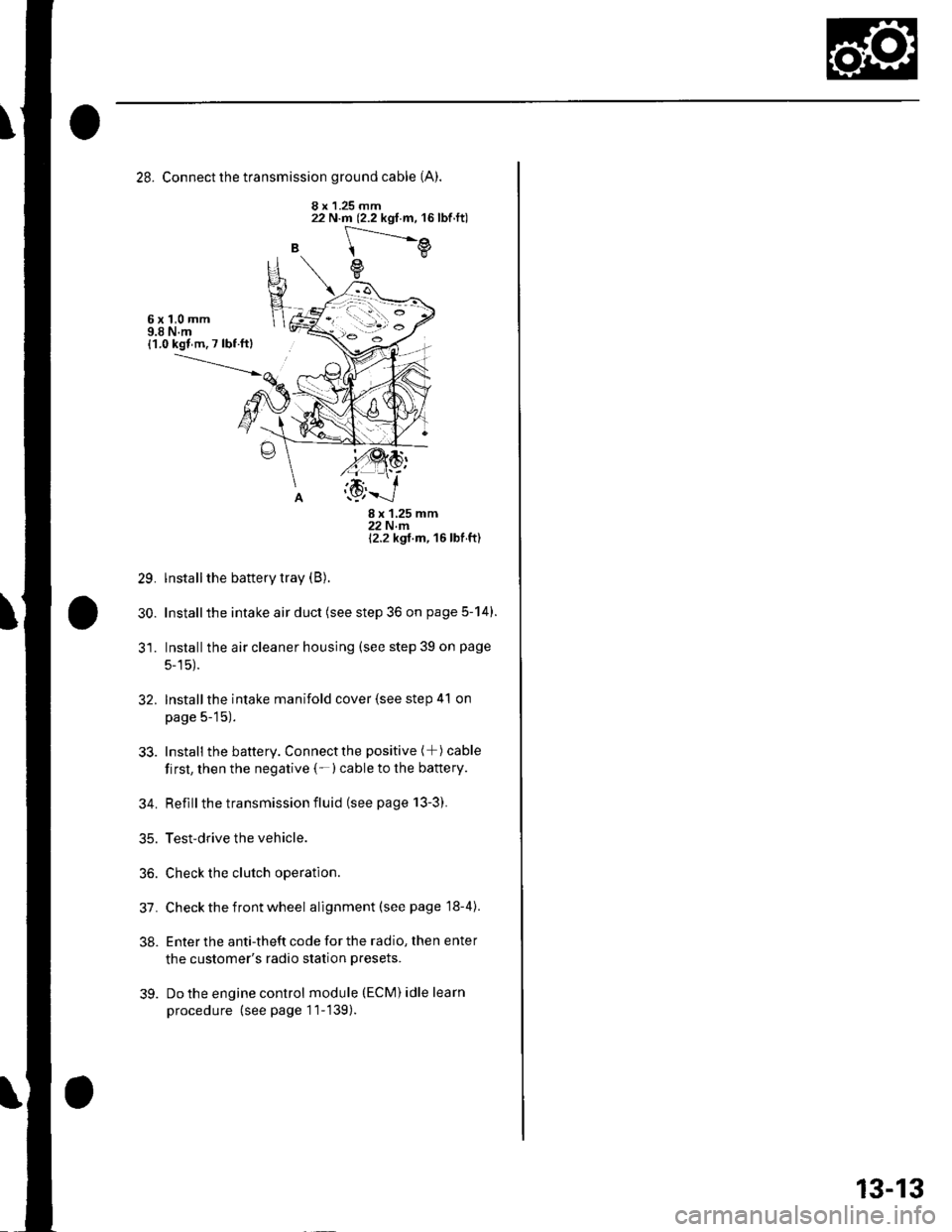

28. Connect the transmission ground cable (A).

8 x 1.25 mm

B

22 N.m (2.2 kgf.m, 16lbf.ft)

[---.-.---e

e

6x1,0mm9.8 N.m{1.0 kgl m. 7 lbf ftl

29.

30.

8x125mm22Nm12.2 kgt m, 16 lbf ft)

lnstall the battery tray (B).

Installthe intake air duct (see step 36 on page 5-14).

Installthe air cleaner housing (see step 39 on page

5-15).

Installthe intake manifold cover (see step 41 on

page 5-15).

Install the battery. Connectthe positive (+) cable

first, then the negative (-)cable to the battery.

Reflllthe transmission fluid (see page 13-3).

Test-drive the vehicle.

Check the clutch operation.

Check the front wheel alignment (see page 18-4).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Do the engine control module (ECM) idle learn

procedure (see page 11-139).

32.

33.

34.

35.

36.

31.

38.

39.

13-13

Page 500 of 1139

Steering

Steering Wheel Installation

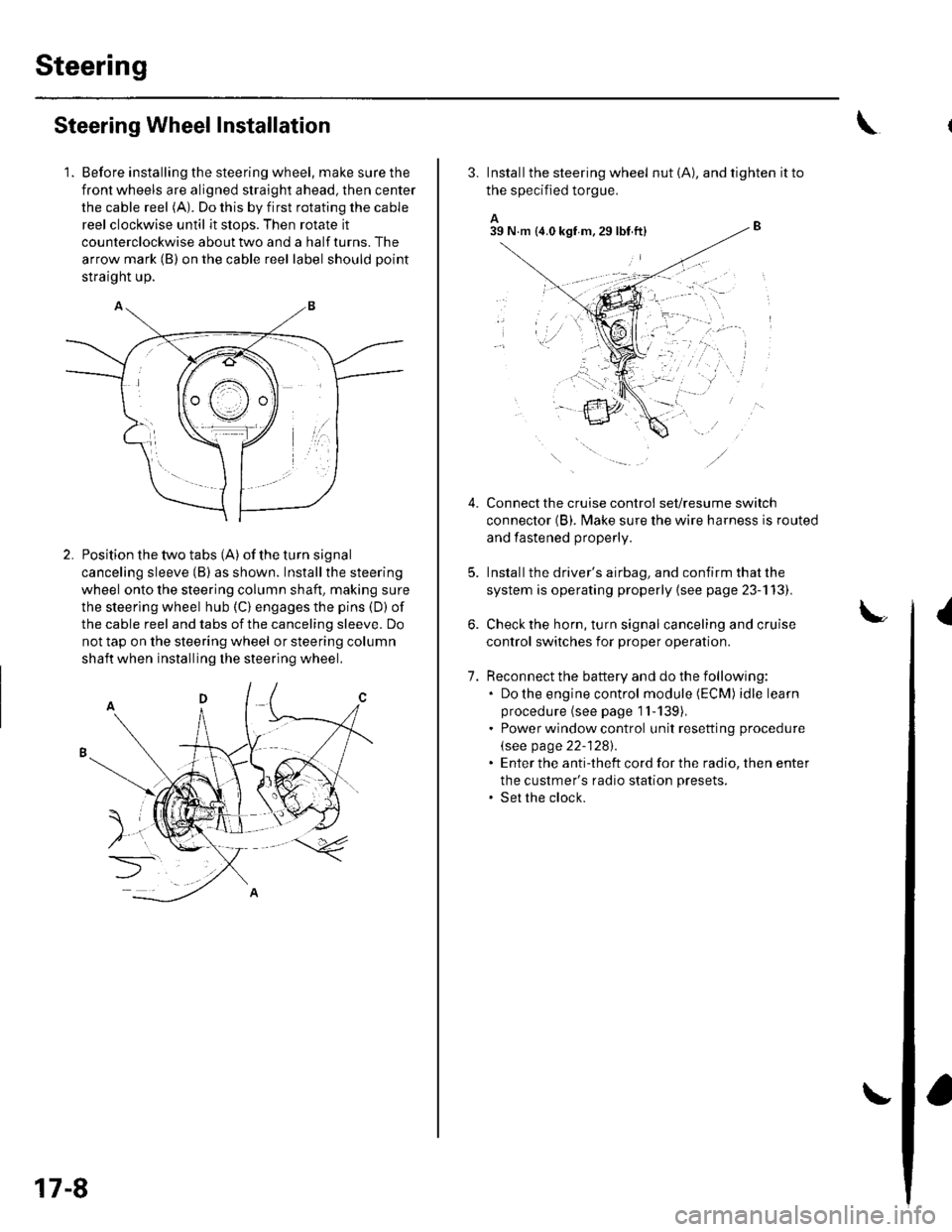

1. Before installing the steering wheel, make sure the

front wheels are aligned straight ahead, then center

the cable reel (A). Do this by first rotating the cable

reel clockwise until it stops. Then rotate it

counterclockwise about two and a half turns. The

arrow mark (B) on the cable reel label should point

straight up.

Position the two tabs (A) of the turn signal

canceling sleeve (B) as shown. Installthe steering

wheel onto the steering column shaft, making sure

the steerlng wheel hub (C) engages the pins (D) of

the cable reel and tabs of the canceling sleeve. Do

not tap on the steering wheel or steering column

shaft when installing the steering wheel.

17-8

3. Install the steering wheel nut (A), and tighten it to

the specified torgue.

A_B39 N.m (4.0 kgf m.29lbt ftl

Connect the cruise control set/resume switch

connector (B). fvlake sure the wire harness is routed

and fastened properly.

Install the driver's airbag, and confirm that the

system is operating properly {see page 23-113).

Check the horn, turn signal canceling and cruise

control switches for proper operation.

Reconnect the battery and do the following:. Do the engine control module (ECM) idle learn

procedure (see page 1l-139),. Power window control unit resetting procedure

\see page 22-1281.. Enter the anti-theft cord for the radio, then enter

the custmer's radio station presets.. Set the clock.

{

7.

lr,',,t

;. _,:!

'' '1i::..'.' l

Page 525 of 1139

EPS Gomponents

7.

8.

DTC Troubleshooting (cont'dl

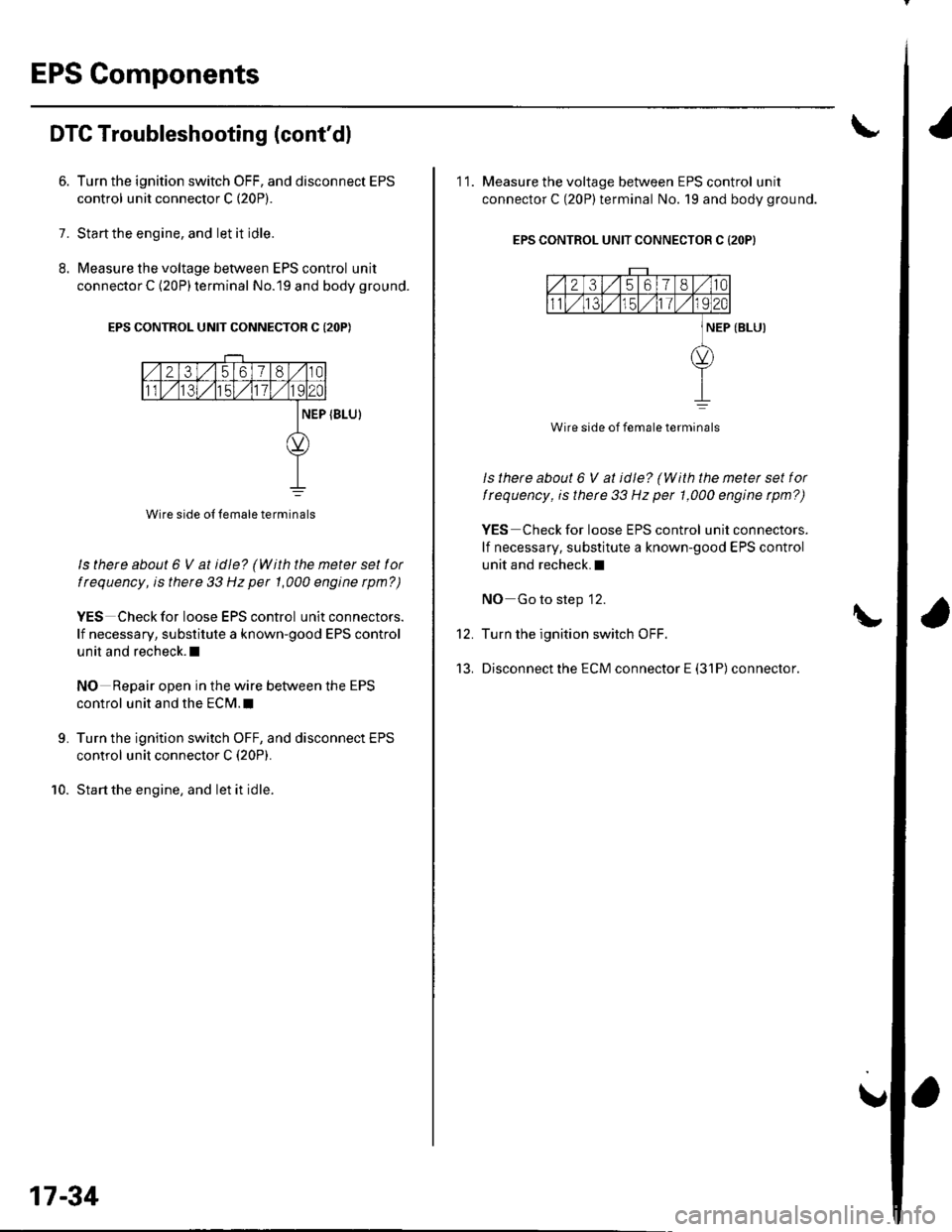

Turn the ignition switch OFF, and disconnect EPS

control unit connector C (20P).

Start the engine, and let it idle.

Measure the voltage between EPS control unit

connector C {20P) terminal No.19 and body ground.

EPS CONTROL UNIT CONNECTOR C {2OP)

ls there about 6 V at idle? (With the meter set lol

t requency, is there 33 Hz per 1,000 engine rpm? )

YES Check for loose EPS control unit connectors.

lf necessary, substitute a known-good EPS control

unit and recheck.l

NO Repair open in the wire between the EPS

control unit and the ECM.I

Turn the ignition switch OFF, and disconnect EPS

control unit connector C (20P).

Start the engine, and let it idle.

9.

10.

Wire side of {emale terminals

17-34

11. Measure the voltage between EPS control unit

connector C (20P)terminal No. 19 and body ground.

EPS CONTROL UNIT CONNECTOR C {2OPI

Wire side of female terminals

ls there about 6 V at idle? (With the metet set tor

trequency, is therc 33 Hz per 1,000 engine rpn?)

YES Check for loose EPS control unitconnectors.

lf necessary, substitute a known-good EPS control

unit and recheck.I

NO Go to step '12.

Turn the ignition switch OFF.

Disconnect the ECM connector E (31P) connector.

12.

13.

!

Page 722 of 1139

Dashboard

Dashboard Removal/lnstallation

(cont'd)

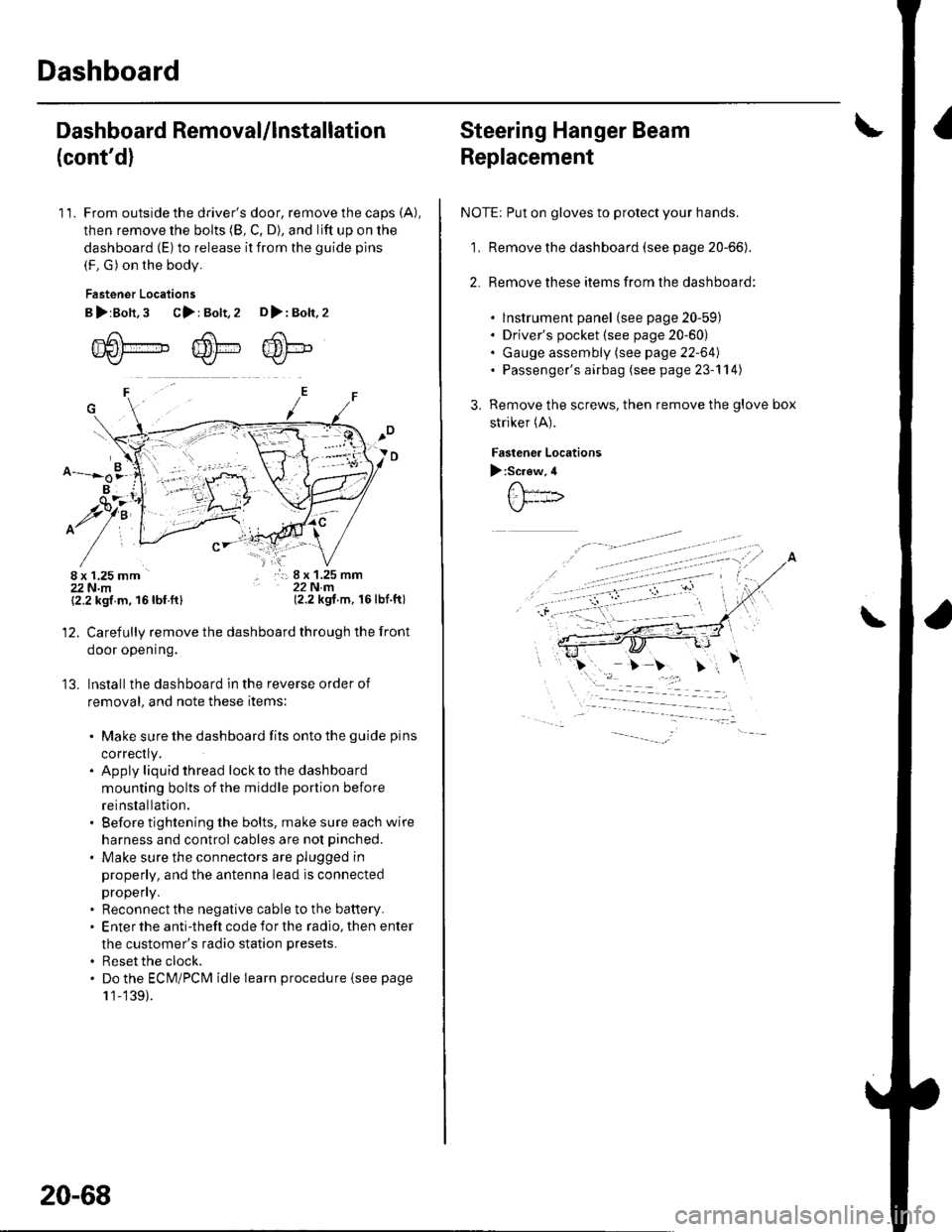

11. From outside the driver's door, remove the caps (A),

then remove the bolts (8, C, D), and lift up on the

dashboard (E) to release it from the guide pins

(F. G) on the body.

Fastener Locations

B>rBolt.3 C>: Bolt,2 D>: Bolt,2

m6[-,,,,",",,-,F6't---'' ffi'!--v{/- Kr* w-

B

$7:

^/761:

/,-,. r:; 8 x 1.25 mm22Nm(2.2 kgf.m, 16lbf.ft)

13.

{2.2 kgf m, 16lbf.ftl

Carefully remove the dashboard through the front

door opening.

lnstall the dashboard in the reverse order of

removal, and note these items:

. Make sure the dashboard fits onto the guide pins

correctly.. Apply liquid thread lock to the dashboard

mounting bolts of the middle portion before

reinstallation.. Before tightening the bolts, make sure each wire

harness and control cables are not pinched.

. Make sure the connectors are plugged in

properly, and the antenna lead is connected

propeny.. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

. Reset the clock.. Do the ECM/PCM idle learn procedure isee page

1 '1-139).

20-68

Steering Hanger Beam

Replacement

NOTE: Put on gloves to protect your hands.

1, Remove the dashboard (see page 20-66).

2. Remove these items from the dashboard:

. lnstrument panel (see page 20-59). Driver's pocket (see page 20-60). Gauge assembly (see page 22-64). Passenger's airbag (see page 23-'l 14)

Remove the screws, then remove the glove box

striker (A).

Fastenea Locations

):Screw,4

\

Page 811 of 1139

Heating and Air Gonditioning

Blower Unit Removal and Installation {cont'd}

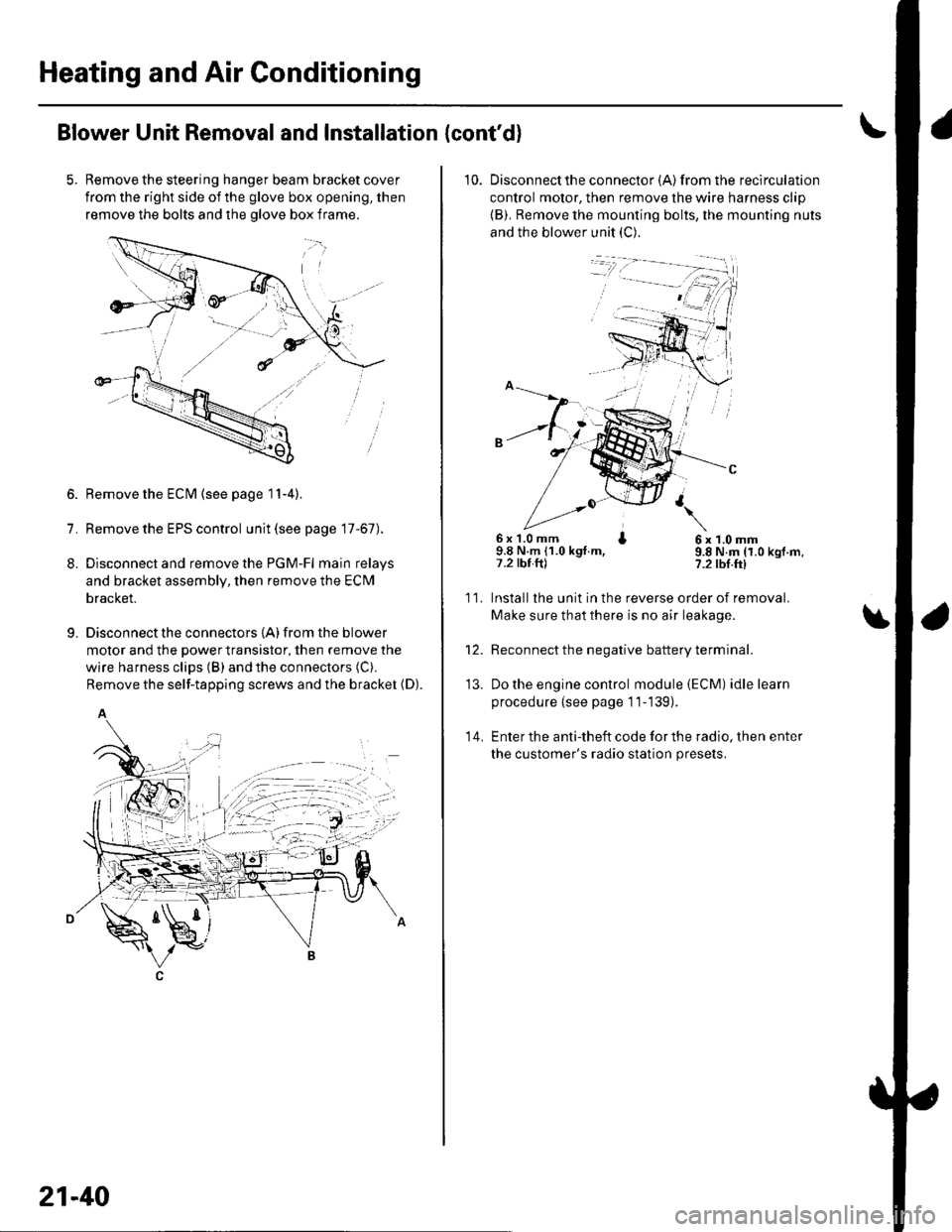

Remove the steering hanger beam bracket cover

from the right side of the glove box opening, then

remove the bolts and the olove box frame.

1.

8.

9.

Remove the ECM (see page 11-4).

Remove the EPS control unit (see page 17-67).

Disconnect and remove the PGM-Fl main relays

and bracket assembly, then remove the ECM

bracket.

Disconnect the connectors {A) from the blower

motor and the power transistor, then remove the

wire harness clips (B) and the connectors (C).

Remove the self-tapping screws and the bracket (D).

A

21-40

10. Disconnectthe connector {A) from the recirculation

control motor, then remove the wire harness clip

{B). Remove the mounting bolts, the mounting nuts

and the blower unit (C).

6x 1.0 mm I9.8 N.m (1.0 kgt.m,7.2 tbt.ftl

6x1.0mm9.8 N.m (1.0 kgf.m,?.2 tbf.ft)

11.

14.

Installlhe unit in the reverse order of removal.

Make sure that there is no air leakage.

Reconnect the negative battery terminal.

Do the engine control module (ECM) idle learn

procedure {see page 11-139).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

\

'13.

Page 816 of 1139

13. Installthe heater core and the evaporator core in

the reverse order of removal.

14. Installthe heater unit in the reverse order of

removal, and note these items:

. Do not interchange the inlet and outlet heater

hoses, and installthe hose clamps securely.. Refillthe cooling system with engine coolant (see

page 10-6).. Adjust the heater valve cable (see page 2'l-461.. Make sure that there is no coolant leakage.. Make sure that there is no air leakage.. Refer to evaporator core replacement {see step 6

on page 21-42).. Do the engine control module (ECl\4) idle learn

procedure (see page 11-139).. Enter the anti-theft code for the radio, then enter

the customer's radio station Dresets.

21-45

Page 818 of 1139

Compressor Replacement

1. lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioning

work for a few minutes, then shut the engine off.

2. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio's

preset buttons.

3. Disconnect the negative cable from the battery.

4. Recover the refrigerant with a recovery/recycling/

charging station (see page 21-53).

5. Remove the alternator (see page 4-29).

6. Remove the Ay'C condenser fan assembly (see page

10-10).

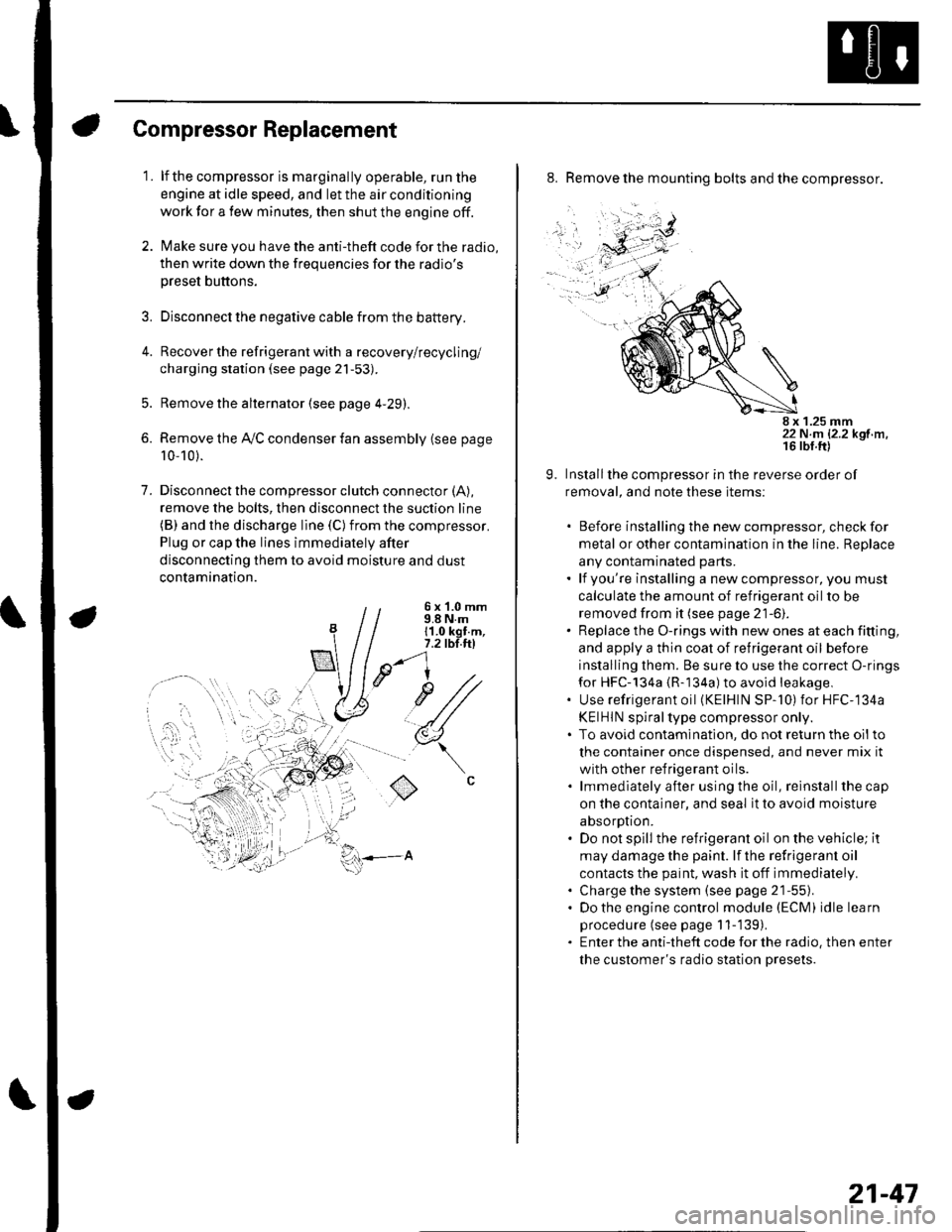

7. Disconnectthe compressor clutch connector (A),

remove the bolts, then disconnect the suction line(B) and the discharge line (C)from the compressor.

Plug or cap the lines immediately after

disconnecting them to avoid moisture and dust

contamination.

6 x '1.0 mm9.8 N.m11.0 kgt.m,7.2 tbl.ttl

u1/

(

o

8. Remove the mounting bolts and the compressor.

8 x 1.25 mm22 N.m 12.2 kgf.m.

9. Installthe compressor in the reverse order of

removal, and note these items:

. Before installing the new compressor, check for

metal or other contamination in the line. Replace

any contaminated parts.. lf you're installing a newcompressor, you must

calculate the amount of refrigerant oil to be

removed from it (see page 21-6).. Replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil before

installing them. Be sure to use the correct O-rings

for HFC-134a {R-134a) to avoid leakage,. Use refrigerant oil (KElHlN SP-'10) for HFC-134a

KEIHIN spiral type compressor only.. To avoid contaminatlon, do not return the oilto

the container once dispensed, and never mix it

with other refrigerant oils.. lmmediately after using the oil, reinstallthe cap

on the container, and seal it to avoid moisture

absorption.. Do not spill the refrigerant oil on the vehicle; it

may damage the paint. lf the refrlgerant oil

contacts the paint, wash it off immediately.. Charge the system (see page 21-55).. Do the engine control module (ECM) idle learn

procedure (see page 11-'139).. Enter the antitheft code for the radio, then enter

the customer's radio station presets.

21-47