ect HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 808 of 1139

Evaporator Temperature Sensor

Replacement

1.Remove the driver's dashboard lower cover (see

page 20-59) and the under cover (see page 20-60).

Remove the under-dash fuse/relay box (see page

22-491.

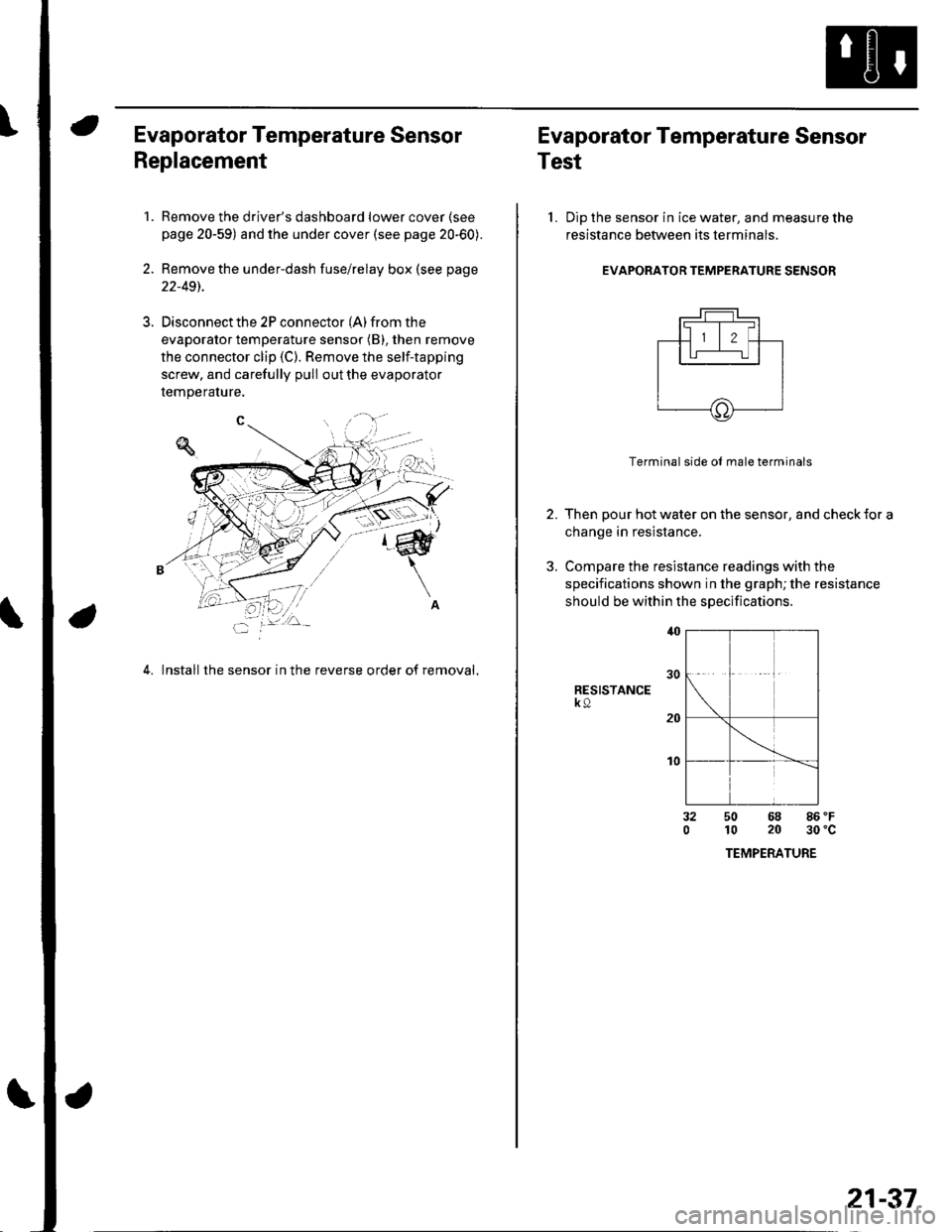

Disconnect the 2P connector (A) from the

evaporator temperature sensor (B), then remove

the connector clip (C). Remove the self-tapping

screw, and carefully pull out the evaporator

temperature.

4. Install the sensor in the reverse order of removal,

Evaporator Temperature Sensor

Test

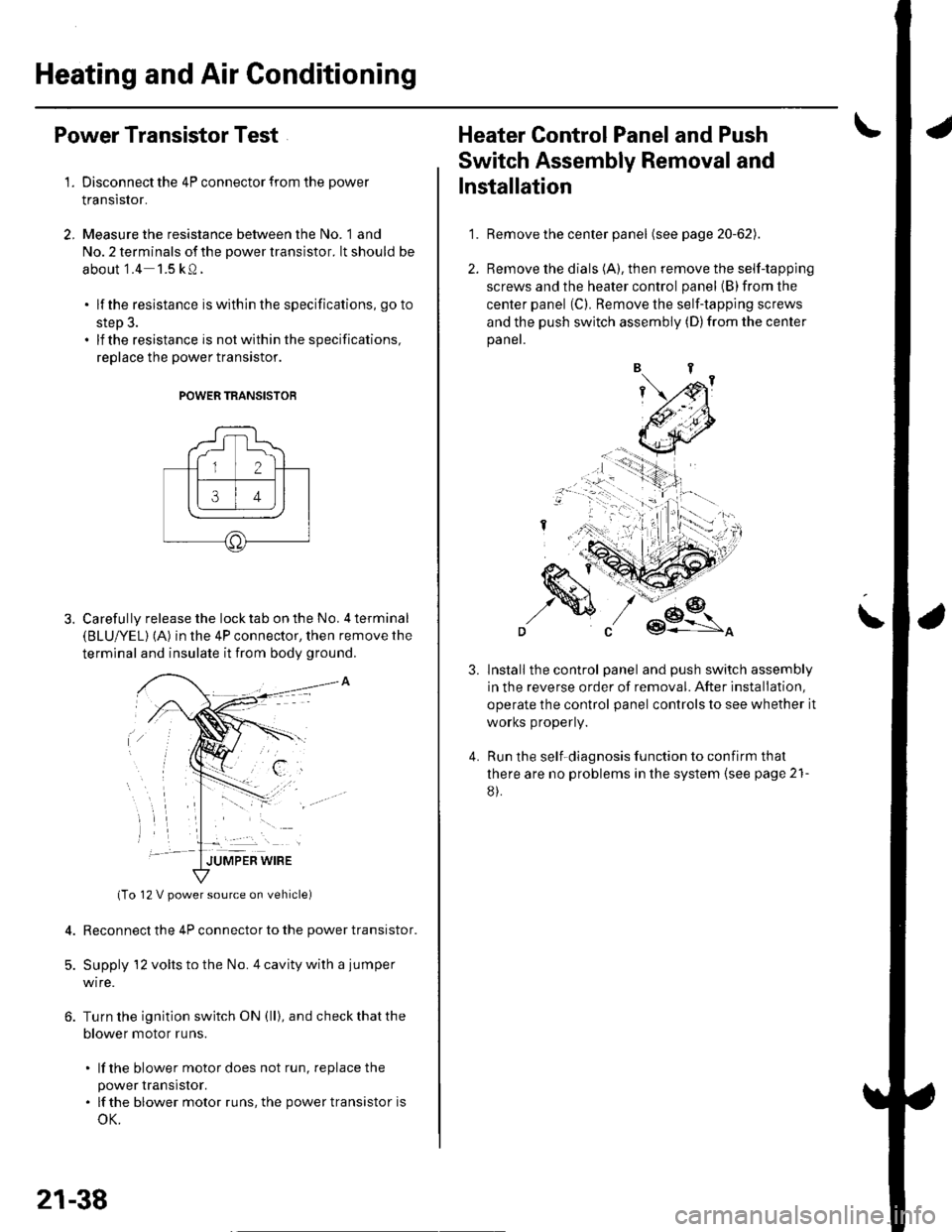

l. Dip the sensor in ice water, and measure the

resistance between its terminals

EVAPORATOR TEMPERATURE SENSOR

2.

3.

Terminal side ol male terminals

Then pour hot water on the sensor, and check {or a

change in resistance.

Compare the resistance readings with the

specifications shown in the graph; the resistance

should be within the specifications

RESISTANCEk9

t0

32050 68 86 'F

10 20 30'c

TEMPERATURE

21-37

Page 809 of 1139

Heating and Air Gonditioning

a

\

Power Transistor Test

1. Disconnect the 4P connector from the power

Iranslslor.

2, Measure the resistance between the No. 1 and

No. 2 terminals of the power transistor. lt should be

about '1.4 1.5 kQ.

. lf the resistance iswithln the specifications, go to

step 3.. lf the resistance is notwithin the specifications,

replace the power transistor.

POWER TRANSISTOB

Carefully release the lock tab on the No. 4 terminal(BLUI/EL) (A) in the 4P connector, then remove the

terminal and insulate it from body ground.

(To 12 V power source on vehicle)

Reconnect the 4P connector to the power transistor.

Supply 12 volts to the No. 4 cavity with a jumper

wire.

Turn the ignition switch ON (ll), and check that the

blower motor runs.

. lf the blower motor does not run, replace the

power rranstsror.. lf the blower motor runs,the powertransistoris

oK.

12 V power source on vehicle)

21-38

1.

Heater Control Panel and Push

Switch Assembly Removal and

Installation

Remove the center panel (see page 20-62).

Remove the dials (A), then remove the self-tapping

screws and the heater control panel (B)from the

center panel (Cl. Remove the self-tapping screws

and the push switch assembly (D)from the center

panel.

lnstall the control panel and push switch assembly

in the reverse order of removal. After installation,

operate the control panel controls to see whether it

worKs propeny.

Run the self-diagnosis function to confirm that

there are no problems in the system (see page 21-

8).

3.

4.

Page 810 of 1139

Dust and Pollen Filter Replacement

The dust and pollen filters should be replaced every

30,000 miles (48.000 km) or 24 months whichever

comes first. Replace the filters more often if the air flow

is less than usual.

1. Open the glove box. Remove both glove box stops,

then let the glove box hang down (see page 20 63).

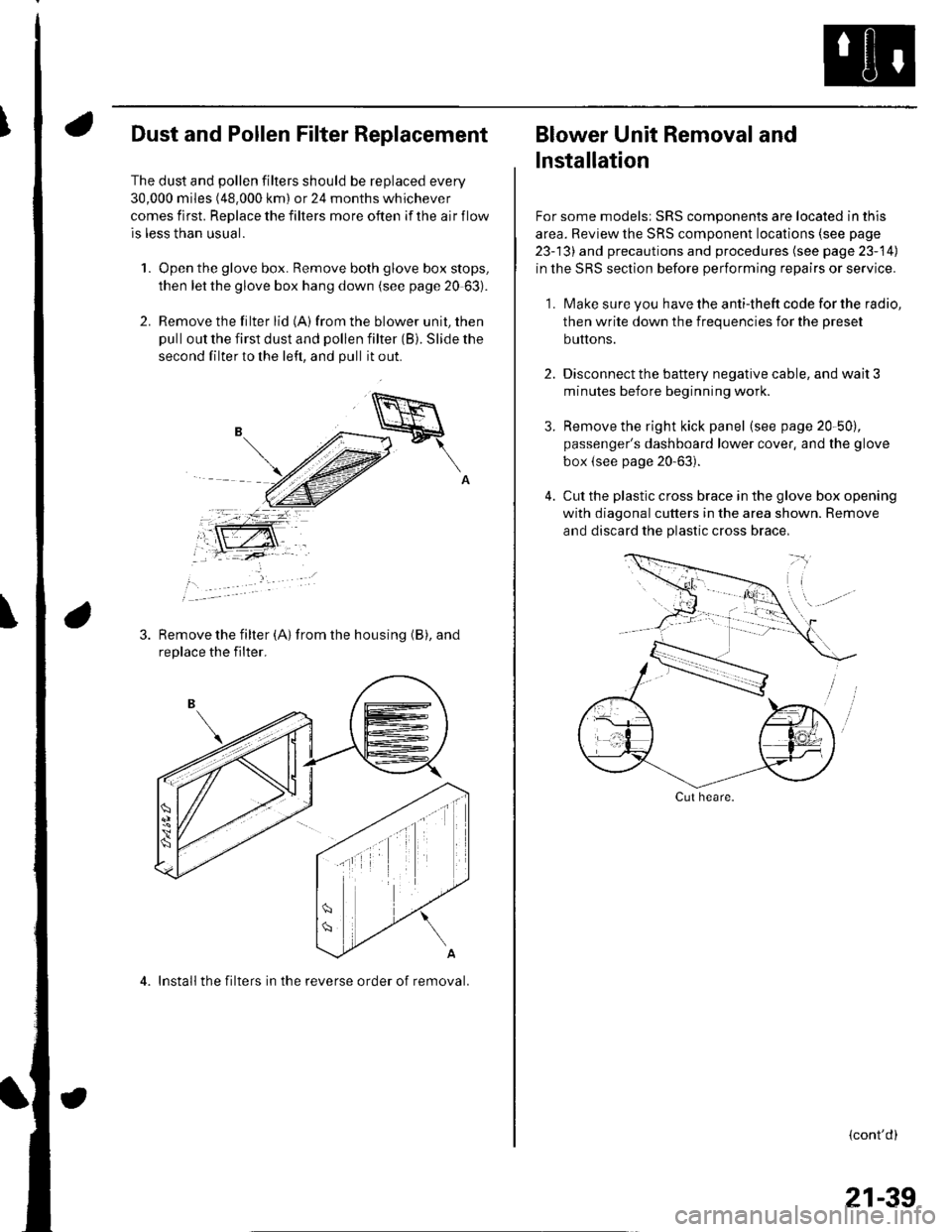

2. Remove the filter lid (A)from the blower unit, then

pull out the first dust and pollen filter (B). Slide the

second filter to the left, and pull it out.

Remove the filter {A) from the housing (B), and

replace the filter.

4. Install the filters in the reverse order of removal.

Blower Unit Removal and

lnstallation

For some models: SRS components are located in this

area. Review the SRS component locations (see page

23-13) and precautions and procedures (see page 23-14)

in the SRS section before performing repairs or service.

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

2. Disconnect the battery negative cable, and wait 3

minutes before beginning worK.

3. Remove the right kick panel (see page 20-50),

passenger's dashboard lower cover, and the glove

box {see page 20-63).

4. Cut the plastic cross brace in the glove box opening

with diagonal cutters in the area shown. Remove

and discard the plastic cross brace,

Cut heare.

{cont'd)

21-39

Page 811 of 1139

Heating and Air Gonditioning

Blower Unit Removal and Installation {cont'd}

Remove the steering hanger beam bracket cover

from the right side of the glove box opening, then

remove the bolts and the olove box frame.

1.

8.

9.

Remove the ECM (see page 11-4).

Remove the EPS control unit (see page 17-67).

Disconnect and remove the PGM-Fl main relays

and bracket assembly, then remove the ECM

bracket.

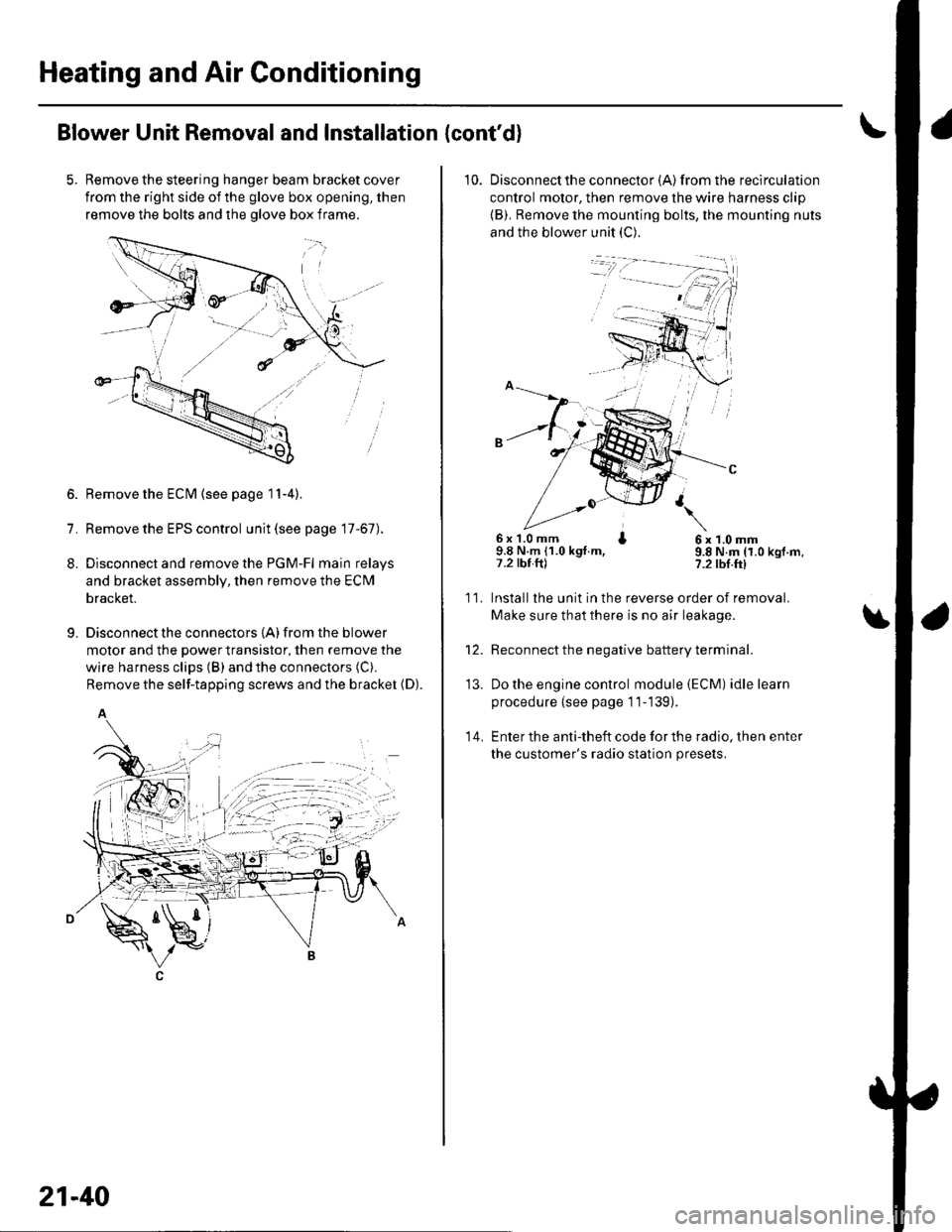

Disconnect the connectors {A) from the blower

motor and the power transistor, then remove the

wire harness clips (B) and the connectors (C).

Remove the self-tapping screws and the bracket (D).

A

21-40

10. Disconnectthe connector {A) from the recirculation

control motor, then remove the wire harness clip

{B). Remove the mounting bolts, the mounting nuts

and the blower unit (C).

6x 1.0 mm I9.8 N.m (1.0 kgt.m,7.2 tbt.ftl

6x1.0mm9.8 N.m (1.0 kgf.m,?.2 tbf.ft)

11.

14.

Installlhe unit in the reverse order of removal.

Make sure that there is no air leakage.

Reconnect the negative battery terminal.

Do the engine control module (ECM) idle learn

procedure {see page 11-139).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

\

'13.

Page 813 of 1139

Heating and Air Gonditioning

a

1.

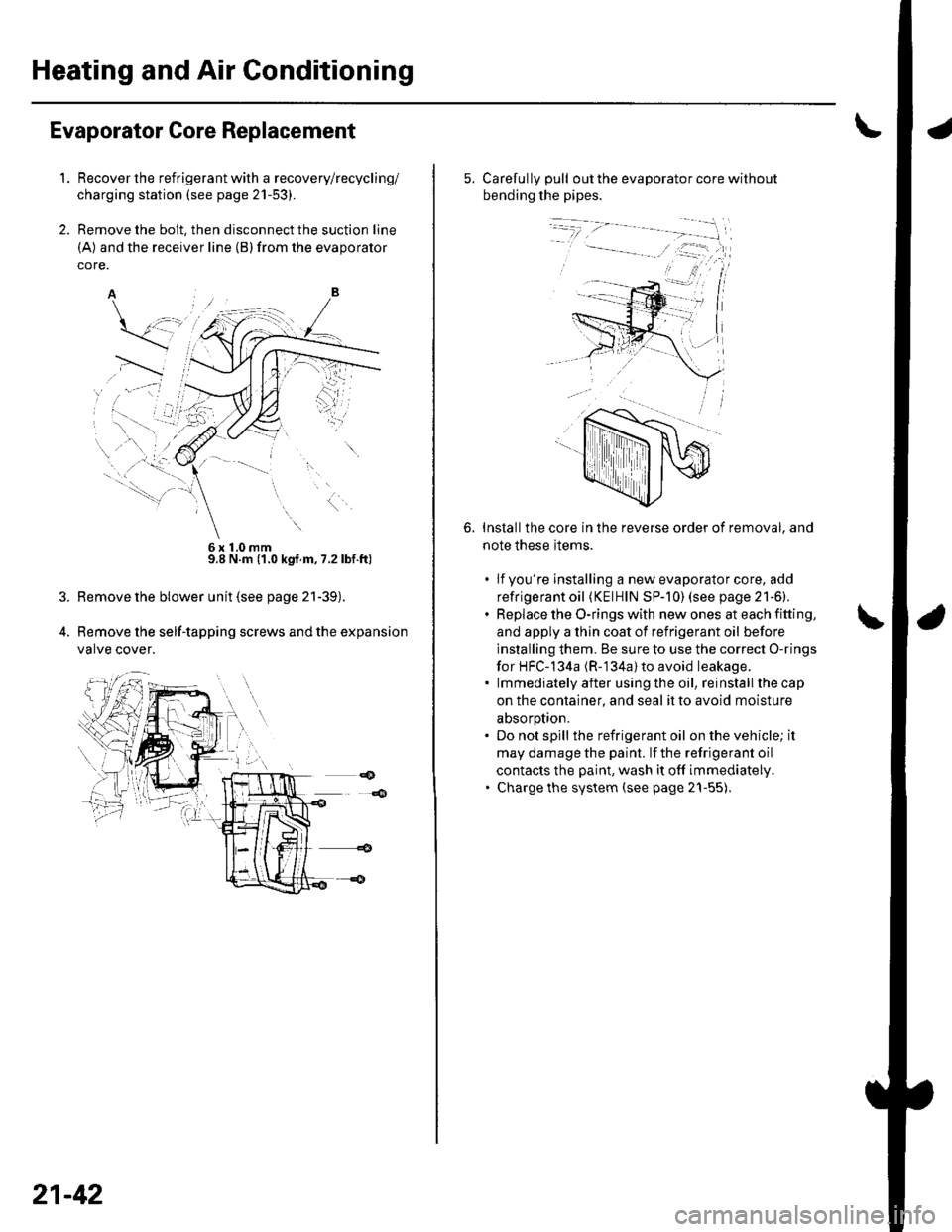

Evaporator Core Replacement

Recover the refrigerant with a recovery/recycling/

charging station (see page 21-53).

Remove the bolt, then disconnect the suction line

(A) and the receiver line (B)from the evaporator

core.

6x10mm9.8 N.m (1.0 kgt.m, 7.2lbf.ft)

Remove the blower unit (see page 21-39).

Remove the self-tapping screws and the expansion

valve cover.

21-42

5. Carefully pull out the evaporator core without

bending the pipes.

Installthe core in the reverse order of removal, and

note these items.

. lfyou're installing a new evaporator core, add

refrigerant oil (KElHlN SP-]0) (see page 21-6).. Replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil before

installing them. Be sure to use the correct O-rings

for HFC-134a (R-'134a) to avoid leakage.. lmmediatelyafter usingthe oil, reinstallthecap

on the container, and seal it to avoid moisture

absorotion.. Do not spill the refrigerant oil on the vehicle; it

may damage the paint. lf the refrigerant oil

contacts the paint, wash it off immediately.. Charge the system (see page 21-55).

6.

Page 814 of 1139

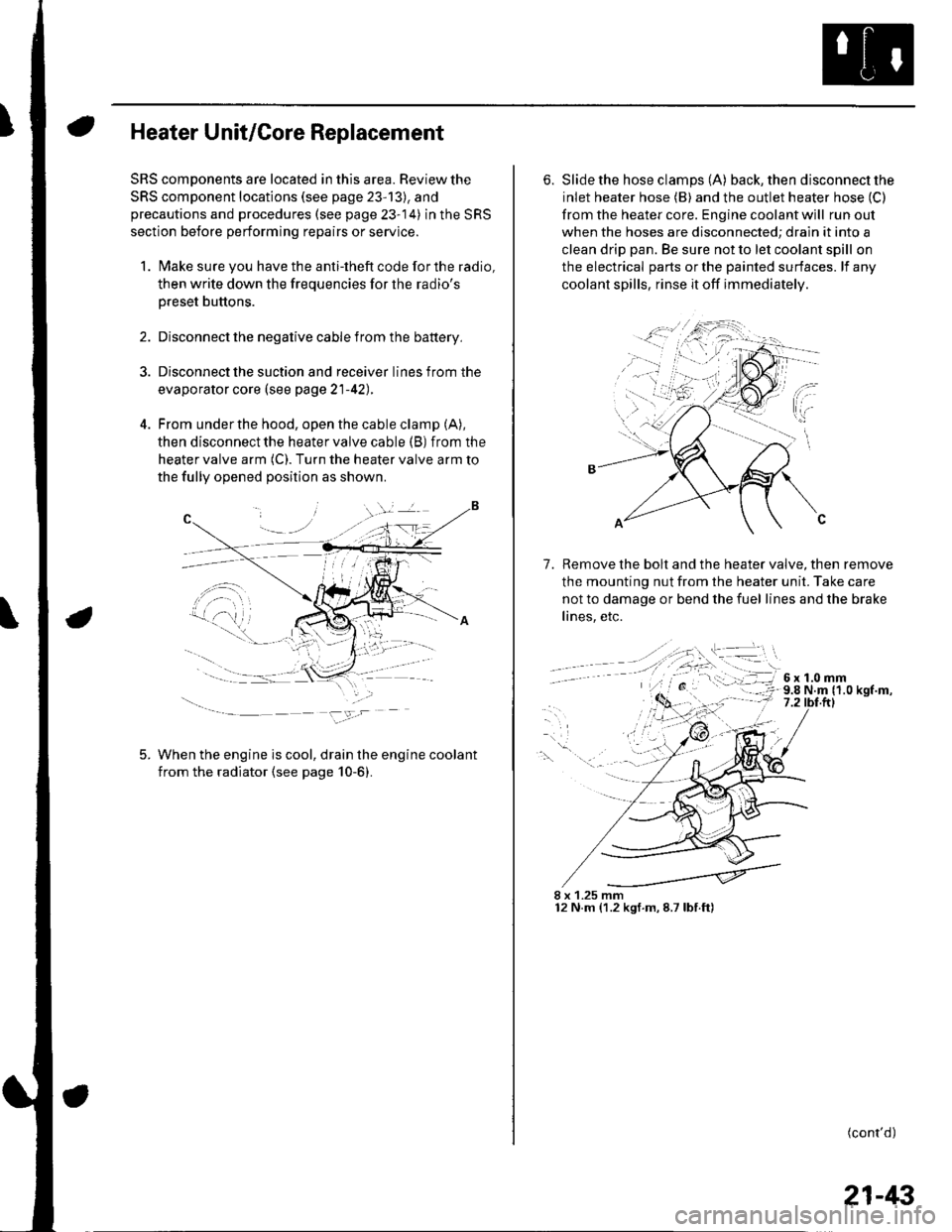

Heater Unit/Core Replacement

SRS components are located in this area. Review the

SRS component locations (see page 23'13), and

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

1. Make sure you have the anti-theft code forthe radio,

then write down the freouencies for the radio's

Dreset buttons.

4.

Disconnect the negative cable from the battery,

Disconnect the suction and receiver lines from the

evaporator core (see page 21-42).

From under the hood, open the cable clamp (A),

then disconnect the heater valve cable (B) from the

heater valve arm (C). Turn the heater valve arm to

the fully opened position as shown

When the engine is cool, drain the engine coolant

from the radiator (see page 10-6).

6. Slide the hose clamps (A) back, the n d isconnect the

inlet heater hose (B) and the outlet heater hose (C)

from the heater core. Engine coolant will run out

when the hoses are disconnected; drain it into a

clean drip pan. Be sure not to let coolant spill on

the electrical parts or the painted surfaces. lf any

coolant spills, rinse it off immediately.

Remove the bolt and the heater valve, then remove

the mounting nut from the heater unit. Take care

not to damage or bend the fuel lines and the brake

lines, etc.

7.

8 x 1.25 mm12 N.m (1.2 kgf.m,8.7lbf.ft)

(cont'd)

21-43

Page 815 of 1139

Heating and Air Conditioning

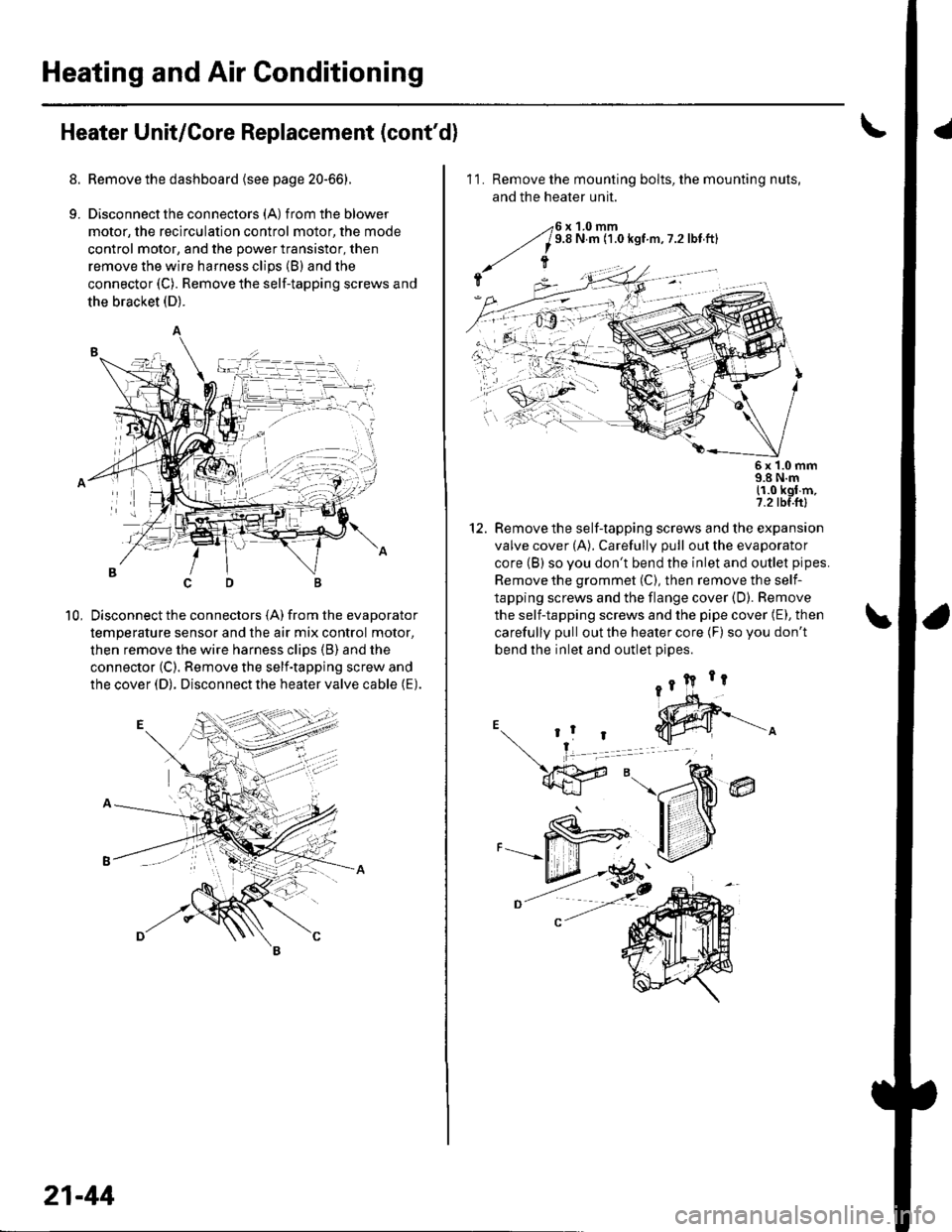

Heater Unit/Core Replacement (cont'd)

8. Remove the dashboard {see page 20-66).

9. Disconnectthe connectors (A) from the blower

motor, the recirculation control motor, the mode

control motor, and the power transistor, then

remove the wire harness clips (B) and the

connector (C). Remove the self-tapping screws and

the bracket (D).

Disconnect the connectors (A) from the evaporator

temperature sensor and the air mix control motor,

then remove the wire harness clips (B) and the

connector (C). Remove the self-tapping screw and

the cover (D). Disconnect the heater valve cable (E).

10,

7t,

21-44

11. Remove the mounting bolts, the mounting nuts,

and the heater unit.

Remove the self-tapping screws and the expansion

valve cover (A). Carefully pull out the evaporator

core (B) so you don't bend the inlet and outlet pipes.

Remove the grommet (C), then remove the self-

tapping screws and the flange cover (D). Bemove

the self-tapping screws and the pipe cover (E), then

carefully pull out the heater core (F) so you don't

bend the inlet and outlet oioes.

@

5x 1.0 mm9.8 N.m11.0 kgl m,7.2 tbf.ftl

12.

Page 817 of 1139

Heating and Air Conditioning

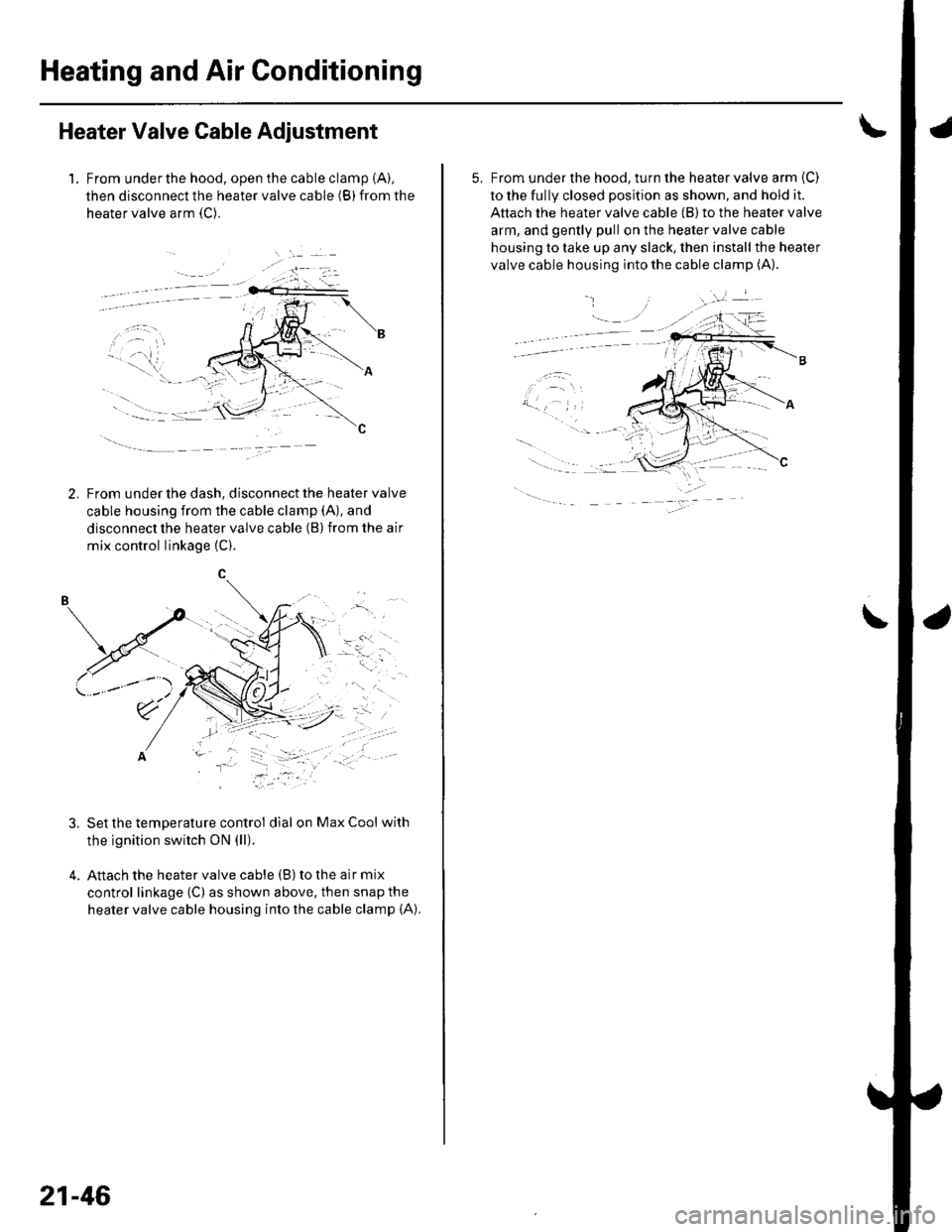

Heater Valve Cable Adjustment

1. From underthe hood, open the cable clamp {A),

then disconnect the heater valve cable (B) from the

heater valve arm {C).

tFrom under the dash, disconnect the heater valve

cable housing from the cable clamp (A), and

disconnect the heater valve cable (B) from the air

mix control linkage {C).

, t.- l

\'r2t' ''' '

' ::"'

Set the temperature control dial on Max Cool with

the ignition switch ON (ll).

Attach the heater valve cable (B) to the air mix

control linkage (C) as shown above, then snap the

heater valve cable housing into the cable clamp (A).

.'.-:',,

-"ll

.....-

21-46

5, From under the hood, turn the heater valve arm {C)

to the fully closed position as shown, and hold it.

Attach the heater valve cable (B) to the heater valve

arm, and gently pull on the heater valve cable

housing to take up any slack, then install the heater

valve cable housing into the cable clamp (A).

.

\

Page 818 of 1139

Compressor Replacement

1. lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioning

work for a few minutes, then shut the engine off.

2. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio's

preset buttons.

3. Disconnect the negative cable from the battery.

4. Recover the refrigerant with a recovery/recycling/

charging station (see page 21-53).

5. Remove the alternator (see page 4-29).

6. Remove the Ay'C condenser fan assembly (see page

10-10).

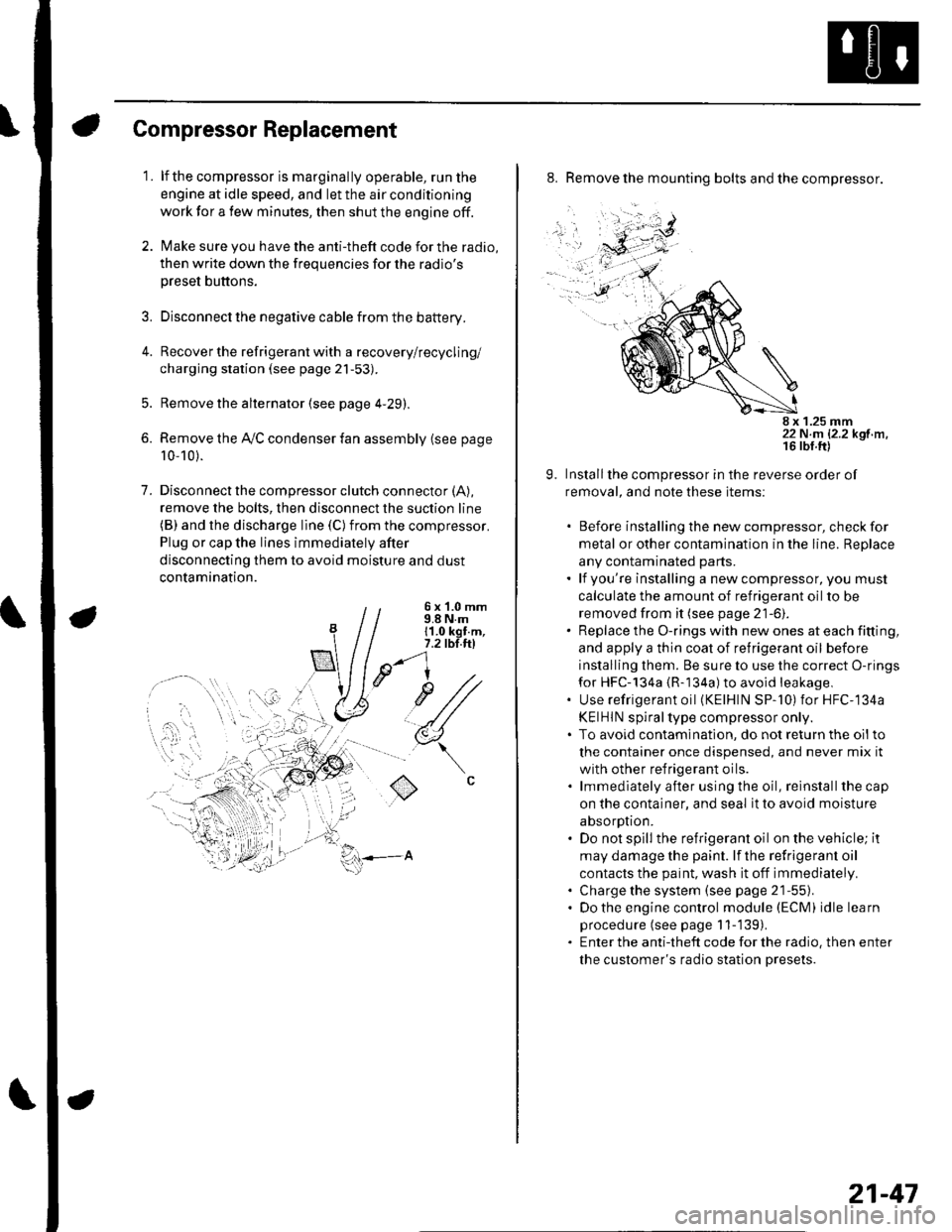

7. Disconnectthe compressor clutch connector (A),

remove the bolts, then disconnect the suction line(B) and the discharge line (C)from the compressor.

Plug or cap the lines immediately after

disconnecting them to avoid moisture and dust

contamination.

6 x '1.0 mm9.8 N.m11.0 kgt.m,7.2 tbl.ttl

u1/

(

o

8. Remove the mounting bolts and the compressor.

8 x 1.25 mm22 N.m 12.2 kgf.m.

9. Installthe compressor in the reverse order of

removal, and note these items:

. Before installing the new compressor, check for

metal or other contamination in the line. Replace

any contaminated parts.. lf you're installing a newcompressor, you must

calculate the amount of refrigerant oil to be

removed from it (see page 21-6).. Replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil before

installing them. Be sure to use the correct O-rings

for HFC-134a {R-134a) to avoid leakage,. Use refrigerant oil (KElHlN SP-'10) for HFC-134a

KEIHIN spiral type compressor only.. To avoid contaminatlon, do not return the oilto

the container once dispensed, and never mix it

with other refrigerant oils.. lmmediately after using the oil, reinstallthe cap

on the container, and seal it to avoid moisture

absorption.. Do not spill the refrigerant oil on the vehicle; it

may damage the paint. lf the refrlgerant oil

contacts the paint, wash it off immediately.. Charge the system (see page 21-55).. Do the engine control module (ECM) idle learn

procedure (see page 11-'139).. Enter the antitheft code for the radio, then enter

the customer's radio station presets.

21-47

Page 819 of 1139

Heating and Air Gonditioning

1.

Compressor Clutch Check

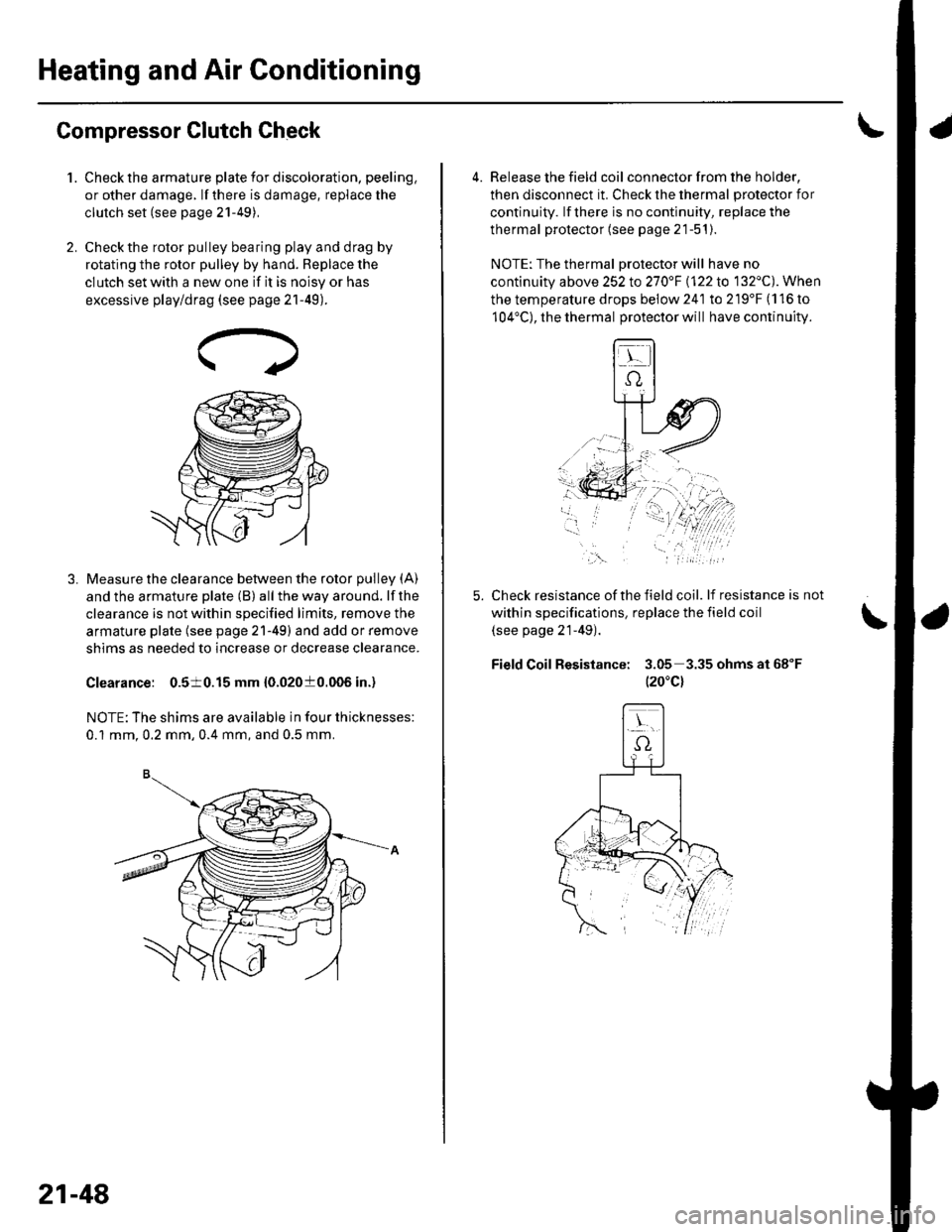

Check the armature plate for discoloration, peeling,

or other damage. lf there is damage, replace the

clutch set (see page 21-49),

Check the rotor pulley bearing play and drag by

rotating the rotor pulley by hand. Beplace the

clutch set with a new one if it is noisy or has

excessive play/drag (see page 21-49).

Measure the clearance between the rotor pulley (A)

and the armature plate (B) all the way around. lf the

clearance is not within specified limits, remove the

armature plate (see page 21-49) and add or remove

shims as needed to increase or decrease clearance.

Clearance: 0.510.15 mm {0.02010.006 in.)

NOTE: The shims are available in four thicknesses:

0.1 mm.0.2 mm,0.4 mm, and 0.5 mm.

21-48

a

4. Release the field coil con nector f rom the holder,

then disconnect it. Check the thermal protector for

continuity. lf there is no continuity, replace the

thermal protector (see page 21-51).

NOTE: The thermal Drotector will have no

continuity above 252to270"F \122lo 132'C). When

the temperature drops below 241 to 219'F (116 to

104'C), the thermal protector will have continuity.

Check resistance of the field coil. lf resistance is not

within specifications, replace the field coil

(see page 21-49).

Field Coil Resistance: 3.05 3.35ohmsat68"F

t20"c)

,\.