Clutch HONDA CIVIC 2003 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 451 of 1139

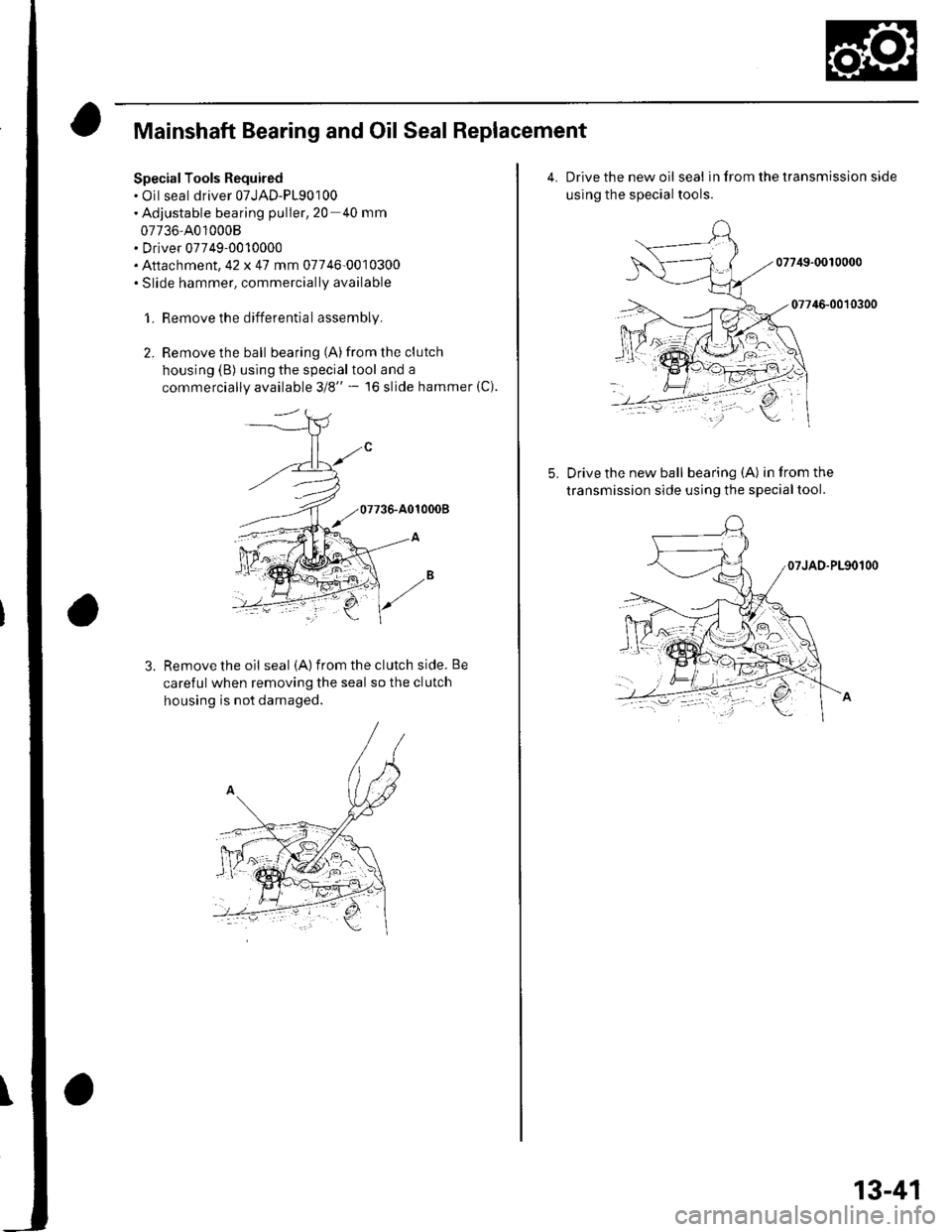

Mainshaft Bearing and Oil Seal Replacement

Special Tools Required. Oil seal driver 07JAD-P190100. Adjustable bearing puller,20 40 mm

07736-4010008. Driver 07749-0010000. Attachment,42 x 47 mm 07746-0010300. Slide hammer, commercially available

1. Remove the differential assembly,

2. Remove the ball bearing (A)from the clutch

housing (B) using the specialtool and a

commercially available 3/8" - l6 slide hammer (C).

Remove the oil seal (A) from the clutch side. Be

careful when removing the seal so the clutch

housing is not damaged.

4.Drive the new oil seal in from the transmission side

using the special tools.

07749-0010000

07746-0010300

Drive the new ball bearing (A) in from the

transmission side using the specialtool.

13-41

Page 452 of 1139

Manual Transmission

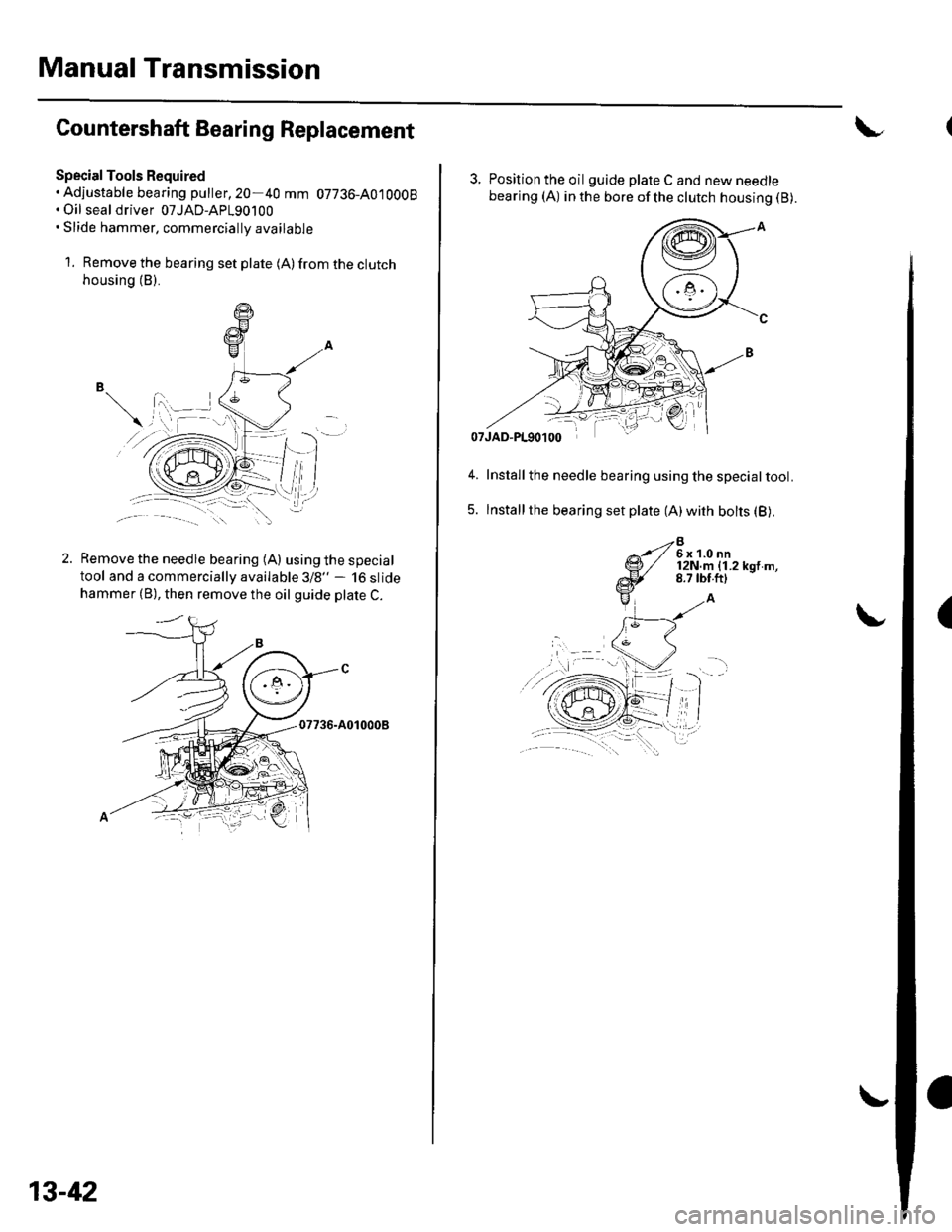

Countershaft Bearing Replacement

Special Tools Required. Adiustable bearing puller,20-40 mm 07736-A0tOOOB. Oil seal driver 07JAD-AP190100. Slide hammer, commercially available

1. Remove the bearing set plate (A)from the clutchhousing (B).

Remove the needle bearing (A) using the special

tool and a commercially available 3/8" - 16 slidehammer (B), then remove the oil guide plate C.

07736-A010008

13-42

3. Position the oil guide plate C and new needle

bearing (A) in the bore of the clutch housing (B).

Installthe needle bearing using the specialtool.

Installthe bearing set plate (A) wirh bolts (B).

B6x 1.0 nn12N.m {1.2 kgt m,8.7 tbf.ft)

(

Page 453 of 1139

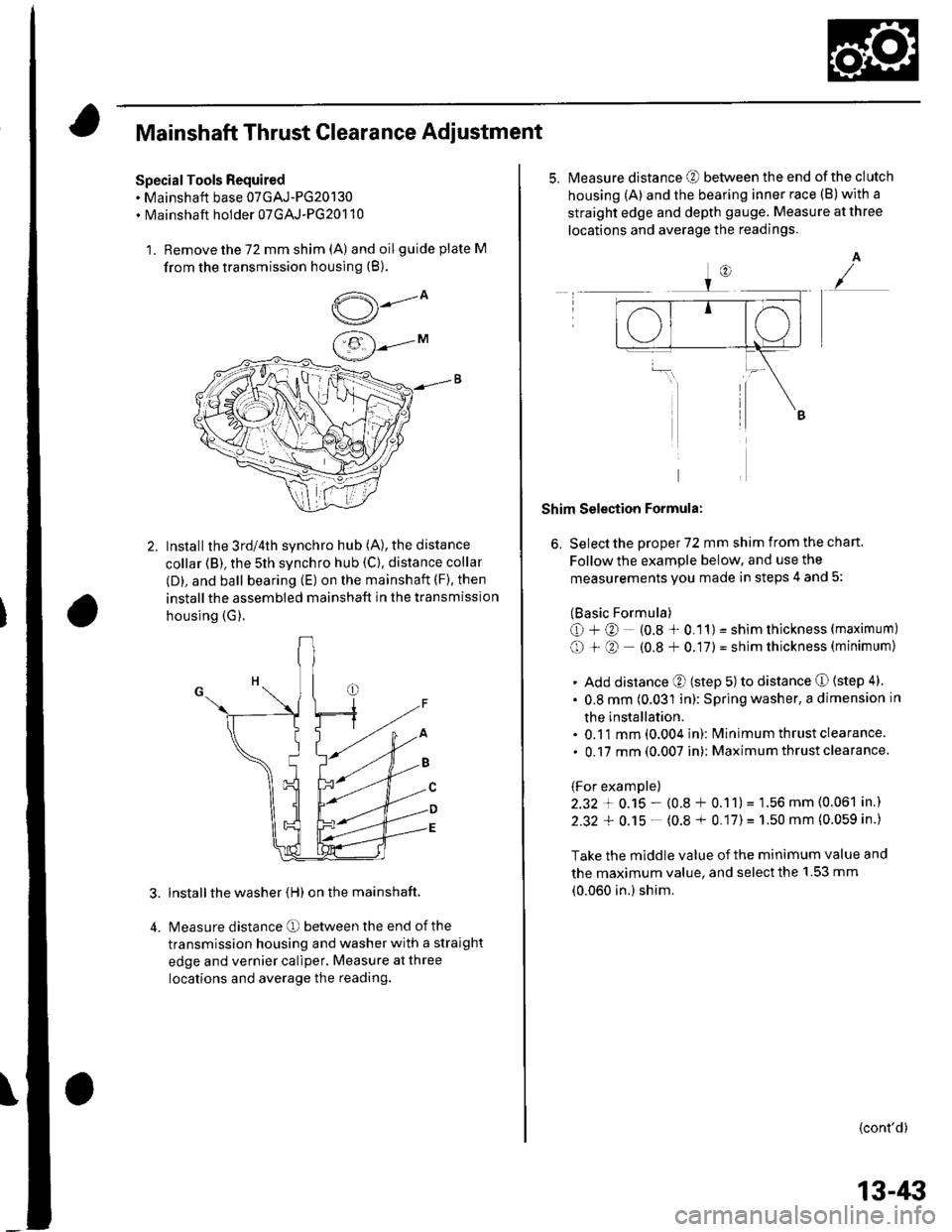

Mainshaft Thrust Clearance Adiustment

Special Tools Required. Mainshaft base 07GAJ-PG20130. Mainshaft holder 07GAJ-PG20110

1. Remove the 72 mm shim (A) and oilguide plate M

from the transmission housing (B).

,5---ov/

Installthe 3rd/4th synchro hub (A), the distance

collar (B), the 5th synchro hub {C). distance collar

(D), and ball bearing (E) on the mainshaft (F), then

installthe assembled mainshaft in the transmission

housing (G).

lnstall the washer (H) on the mainshaft.

Measure distance O between the end of the

transmission housing and washer with a straight

edge and vernier caliper. Measure at three

locations and average the reading.

5.Measure distance @ between the end of the clutch

housing (A) and the bearing inner race (B)with a

straight edge and depth gauge. Measure at three

locations and average the readings.

A

Shim Selection Formula:

6, Select the proper 72 mm shim from the chan.

Follow the example below, and use the

measurements you made in steps 4 and 5:

(Basic Formula)

O+@ (0.8 * 0.11) = shim thickness (maximum)

O + O (0.8 + 0.17) = shim thickness (minimum)

. Add distance O (step 5) to distance O (step 4)

. 0.8 mm (0.031 in): Spring washer, a dimension in

the installation.. 0.11 mm (0.004 in): lvlinimum thrust clearance

. 0.17 mm (0.007 in): Maximum thrust clearance.

(For example)

2.32 + 0.15 - (0.8 + 0.11)= 1.56 mm (0.061 in.)

2.32 + 0.15 - (0.8 + 0.17)= 1.50 mm (0.059 in.)

Take the middle value of the minimum value and

the maximum value, and select the 1.53 mm

(0.060 in.) shim.

{cont'd)

13-/li|

Page 454 of 1139

Manual Transmission

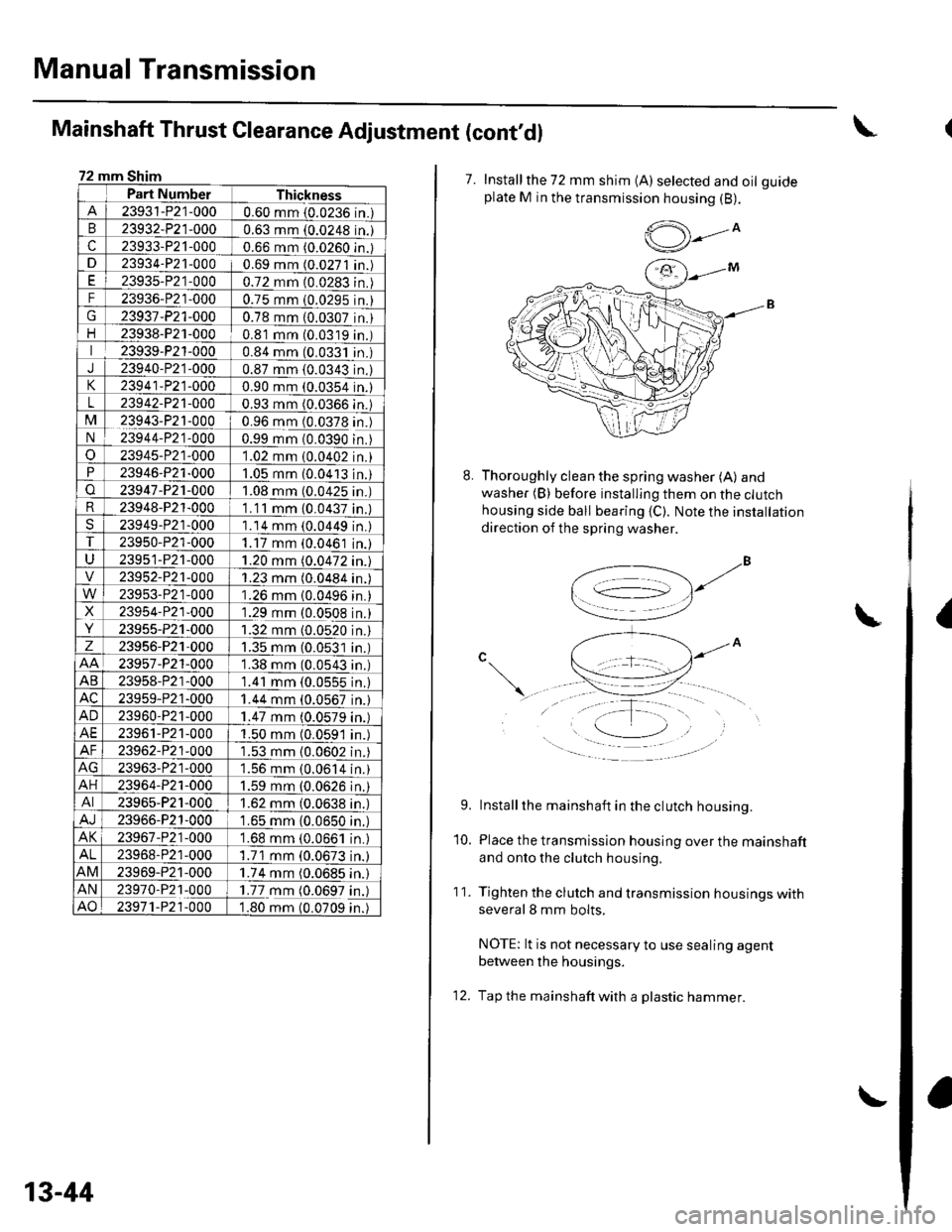

Mainshaft Thrust Clearance Adjustment (cont'dl

72 mm Shim

Part NumberThickness

23931-P21-0000.60 mm {0.0236 in.)

B23932-P21-0000.63 mm (0.0248 in.

c23933-P21-0000.66 mm (0.0260 in.D23934-P21-0000.69 mm (0.0271 in.

E23935-P21-0000.72 mm (0.0283 in.

F23936-P21-0000.75 mm (0.0295 in.

23931-P21-0000.78 mm (0.0307 in.-23938-P2'l-0000.81 mm (0.0319 in

23939-P21-0000.84 mm (0.0331 in

J23940-P21-0000.87 mm {0.0343 in,

23941-P21-0000.90 mm (0.0354 in.

L23942.P21-0000.93 mm (0.0366 in.

M23943-P21-0000.96 mm (0.0378 in.

N239 44-P21 .0000.99 mm (0.0390 in.

o23945-P21-0001.02 mm (0.0402 in.P23946-P21-0001.05 mm (0.0413 in.

o23941-P2't-000'l.08 mm (0.0425 in

R23948-P2'l-000'1 .1 1 mm {0.0437 in

23949-P21-000'1.14 mm (0.0449 inT23950-P21-0001.17 mm {0.0461n.

U23951-P21-0001.20 mm 10.0472n.

23952-P21-0001.23 mm (0.0484n.

23953-P21-0001.26 mm {0.0496n.X23954-P21-0001.29 mm (0.0508n.

23955-P21-0001.32 mm (0.0520n.z23956-P21,0001.35 mm (0.0531 in

23957-P21-0001.38 mm (0.0543 in

AB23958-P21-0001.41 mm (0.0555nAC23959-P21-0001.44 mm (0.0567n.

AD23960-P21-0001.47 mm (0.0579n.

AE23961-P21-0001.50 mm (0.0591n.AF23962-P21-OOO1.53 mm (0.0602n.AG23963-P21-000156 mm (0.0614n.

AH23964-P21-0001.59 mm (0.0626n.

AI23965-P21-0001.62 mm (0.0638 in

AJ23966-P21-0001.65 mm (0.0650 in

AK23967-P21-0001.68 mm (0.0661 in

AL23968-P2r -0001.71 mm (0.0673 in.

AM23969-P21-0001.74 mm (0.0685 in.

AN2397 0-P21-0001.77 mm (0.0697 in.AO23971-P2't-OOO1.80 mm (0.0709 in.

13-44

12.

7. Installthe 72 mm shim (A) selected and oil guideplate M in the transmission housing (B).

,6,,-oV

Thoroughly clean the spring washer (A) and

washer (B) before installing them on the clutchhousing side ball bearing {C). Note the installation

direction of the spring washer.

8.

{

10.

11.

9.lnstallthe mainshaft in the clutch housing.

Place the transmission housing over the mainshaft

and onto the clutch housing.

Tighten the clutch and transmission housings withseveral 8 mm bolts.

NOTE: lt is not necessary to use sealing agent

between the housings.

Tap the mainshaft with a plastic hammer.

Page 458 of 1139

Manual Transmission

Transmission Reassembly (cont'dl

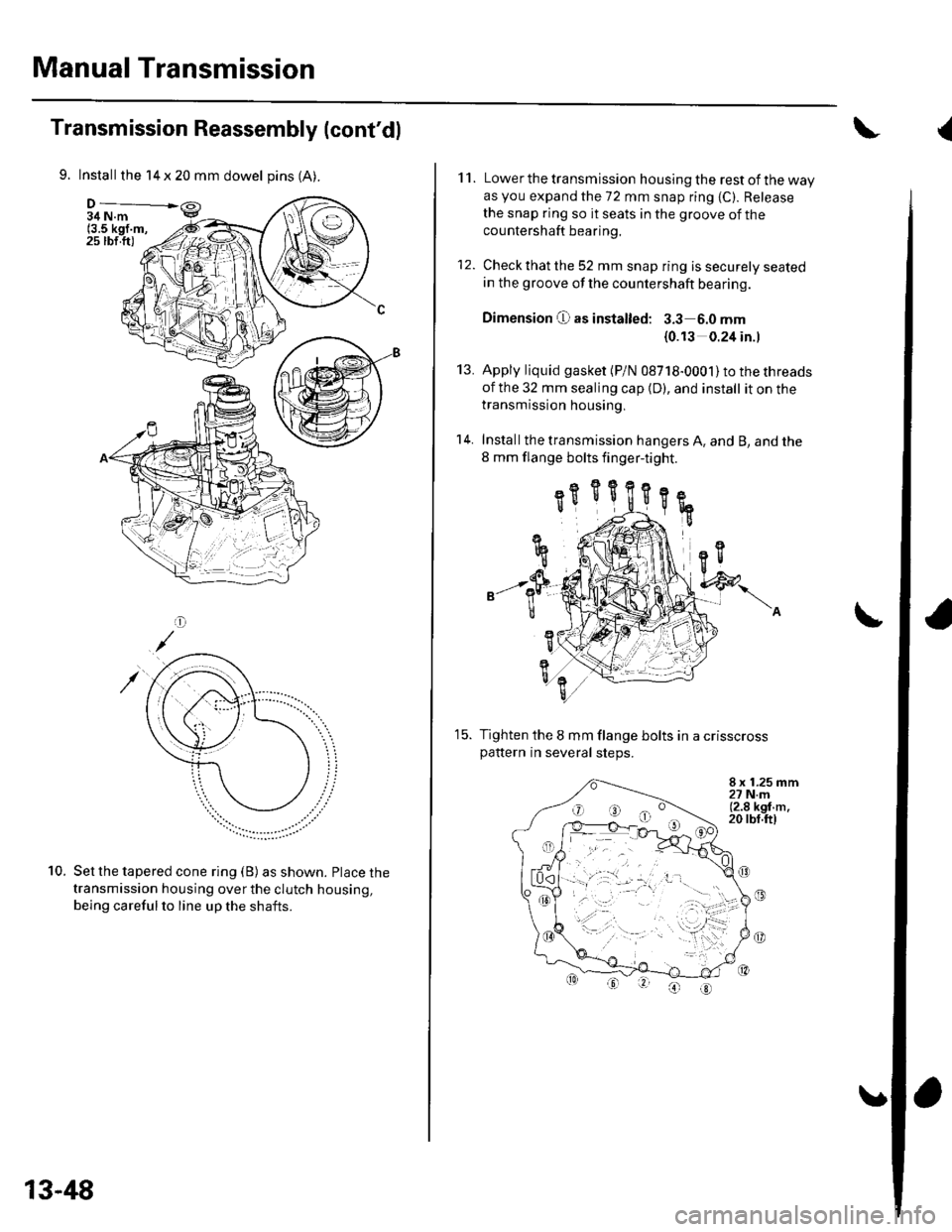

9. Install the 14 x 20 mm dowel pins (A).

34 N.m(3.5 kgf.m,25 rbf.ft)

Set the tapered cone ring (B) as shown. Place the

transmission housing over the clutch housing,

being careful to line up the shafts.

10.

13-48

11. Lower the transmission housing the rest of the wayas you expand the 72 mm snap ring {C). Release

the snap ring so it seats in the groove of the

countershaft bearing.

12. Check that the 52 mm snap ring is securely seatedin the groove of the countershaft bearing.

Dimension O as instalted: 3.3 6.0 mm

{0.13 0.24 in.l

Apply liquid gasket (P/N 08718-0001) to the threads

of the 32 mm sealing cap {D), and install it on thetransmission housing,

Install the transmission hangers A. and B, and the

8 mm flange bolts finger-tight.

13.

't4.

15.

8 x 1.25 mm27 N.m(2.8 kgf.m.20 rbf.ft)

(t

\A

e././

Tighten the 8 mm flange bolts in a crisscross

Pattern In several steDs.

(

Page 459 of 1139

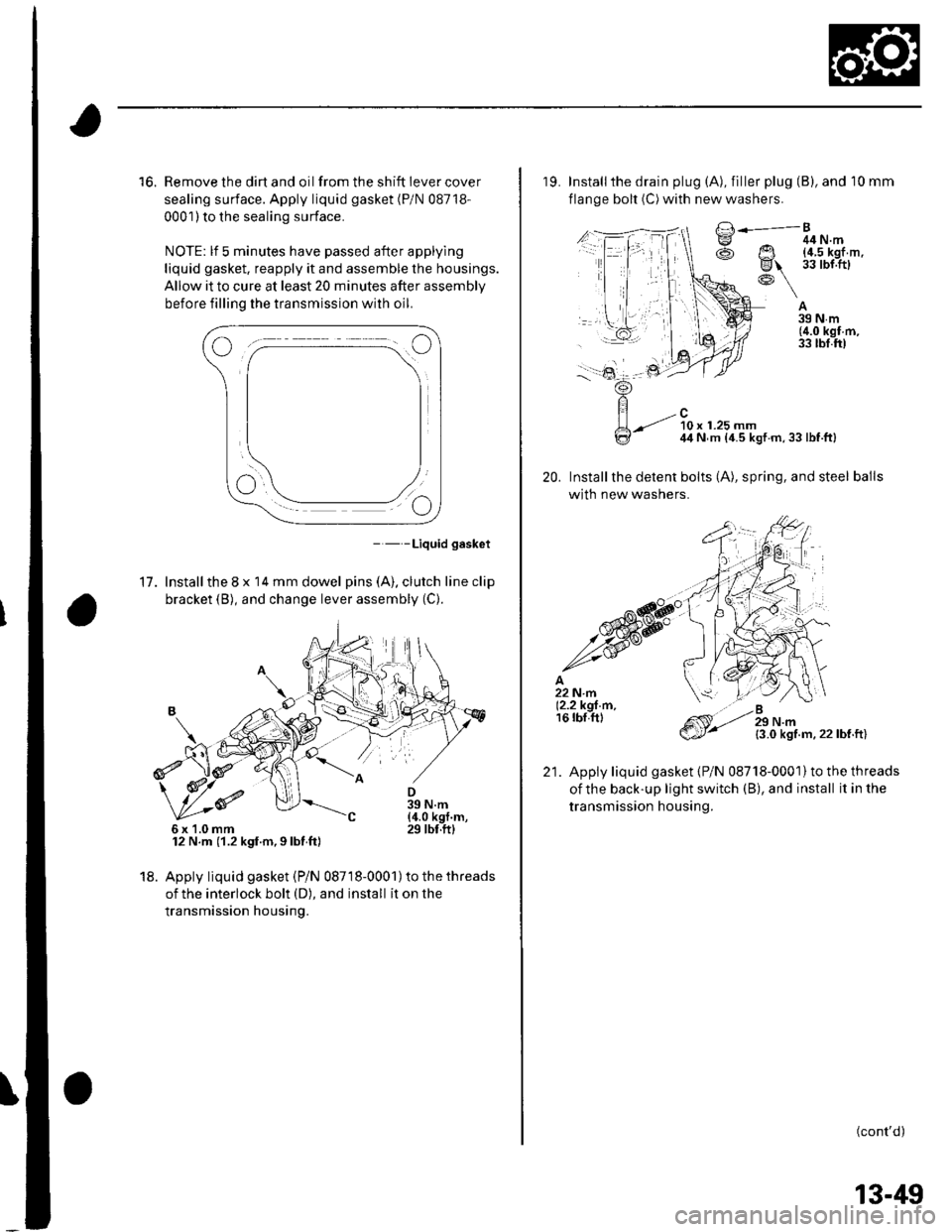

16. Remove the dirt and oil from the shift iever cover

sealing surface. Apply liquid gasket (P/N 08718-

0001) to the sealing surface.

NOTE: lf 5 minutes have passed after applylng

liquid gasket. reapply it and assemble the housings.

Allow it to cure at least 20 minutes after assembly

before filling the transmission with oil.

- - -Liquid gasket

17. Installthe 8 x 14 mm dowel pins (A). clutch line clip

bracket (B), and change lever assembly (C).

12 N.m (1.2 kgf.m,9lbt ft)

18. Apply liquid gasket (Pi N 08718-0001) to the threads

of the interlock bolt (D), and install it on the

transmission housing.

6x1.0mm

19. Installthe drain plug (A), filler plug (B), and 10 mm

flange bolt (C) with new washers.

A39Nm(4.0 kgf m,33 tbl.ft)

20.

/..l-.=,'-Bg ^ 44N.m

@ Ut !?iJl'.'l,''

R\-: \

-.-t ?0, ,.ru ^44 N m {4.5 kgt m,33lbf.ft}

Installthe detent bolts (A), spring, and steel balls

with new washers.

{3.0 kgf.m.22lbf.ft)

Apply liquid gasket {P/N 08718-0001}to the threads

oithe back-up light switch (B), and install it in the

transmission housing.

(cont'd)

21.

13-49

Page 465 of 1139

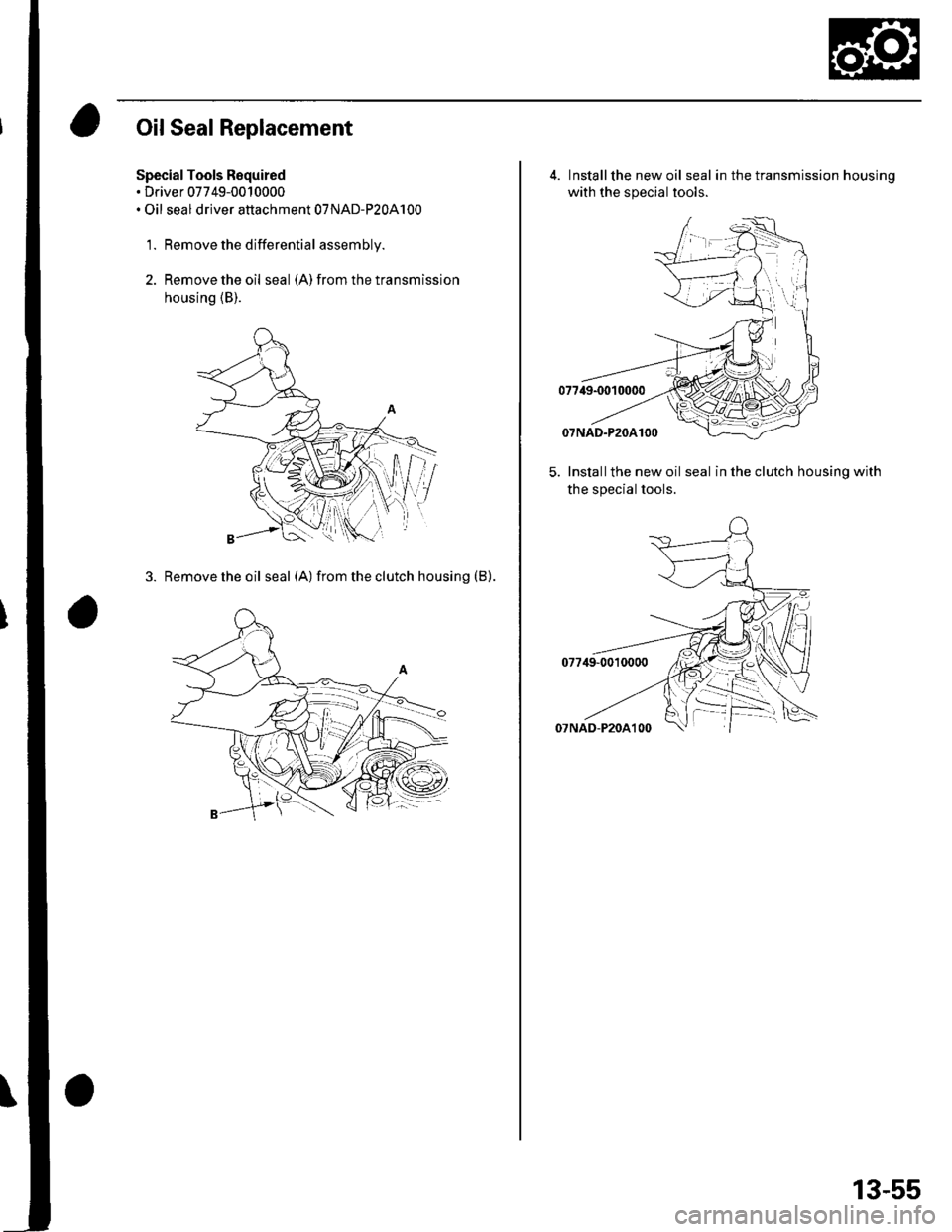

Oil Seal Replacement

Special Tools Required. Driver 07749-0010000. Oil seal driver attachment 07NAD-P20A100

1. Remove the differential assembly.

2. Remove the oil seal (A) from the transmission

housing (B).

3. Removetheoil seal (A) fromtheclutch housing (B).

4. Installthe new oil seal in the transmission housinq

with the special tools.

5. Installthe new oil seal in the clutch housing with

the special tools.

13-55

Page 466 of 1139

M/T Differential

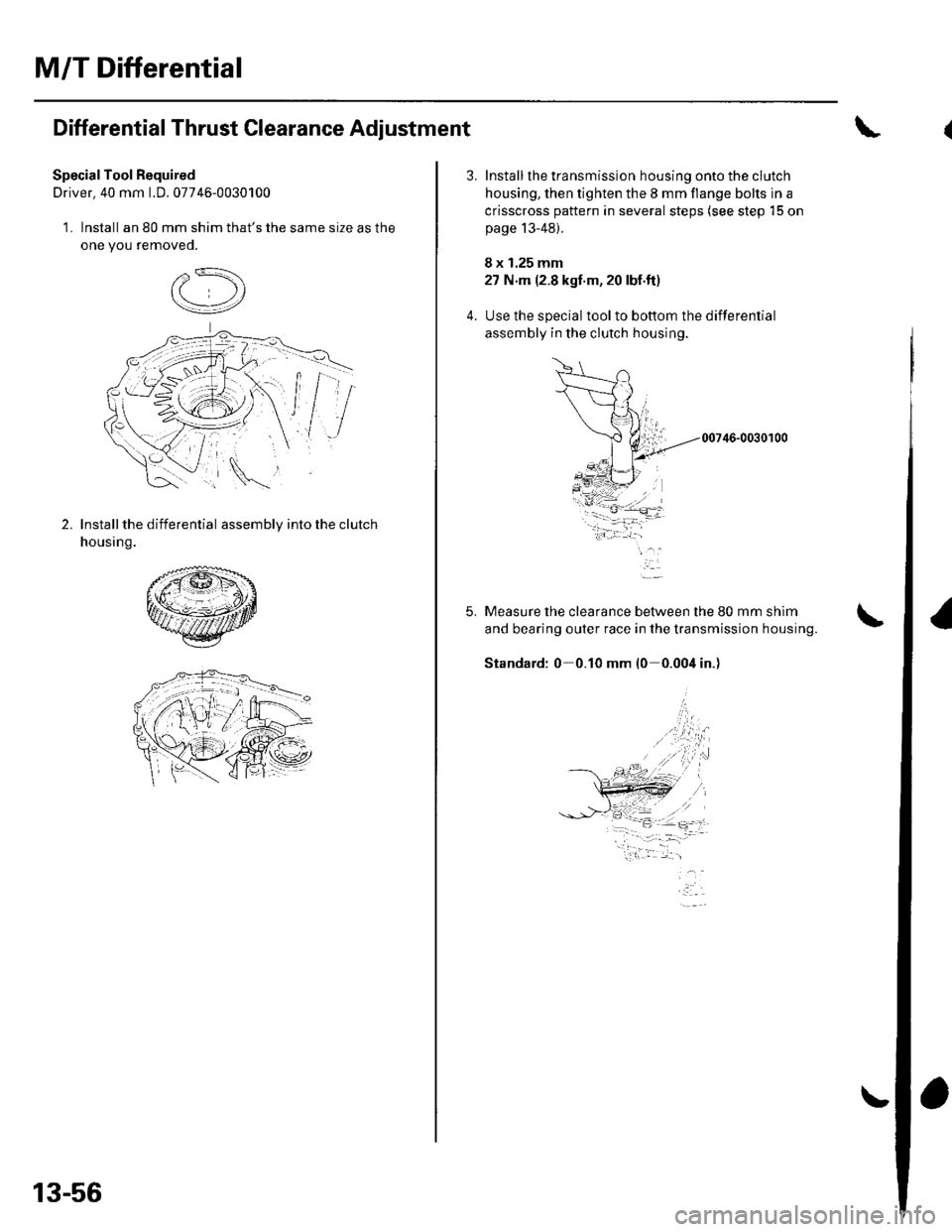

Differential Thrust Clearance Adjustment

SpecialTool Required

Driver. 40 mm LD. 07746-0030100

1. Install an 80 mm shim that's the same size as the

one you removeo.

2.Install the differential assembly into the clutch

housing.

13-56

5.

Install the transmission housing onto the clutch

housing, then tighten the 8 mm flange bolts in a

crisscross pattern in several steps (see step 15 on

page 13-48).

8 x 1.25 mm

27 N m (2.8 kgf'm, 20 lbf.ft)

Use the special toolto bottom the differential

assembly in the clutch housing.

00746-0030100

Measure the clearance between the 80 mm shim

and bearing outer race in the transmission housing.

Standard: 0 0.10 mm l0 0.004 in.)

-i.w.t ..1-- -- :,- -=.

Page 610 of 1139

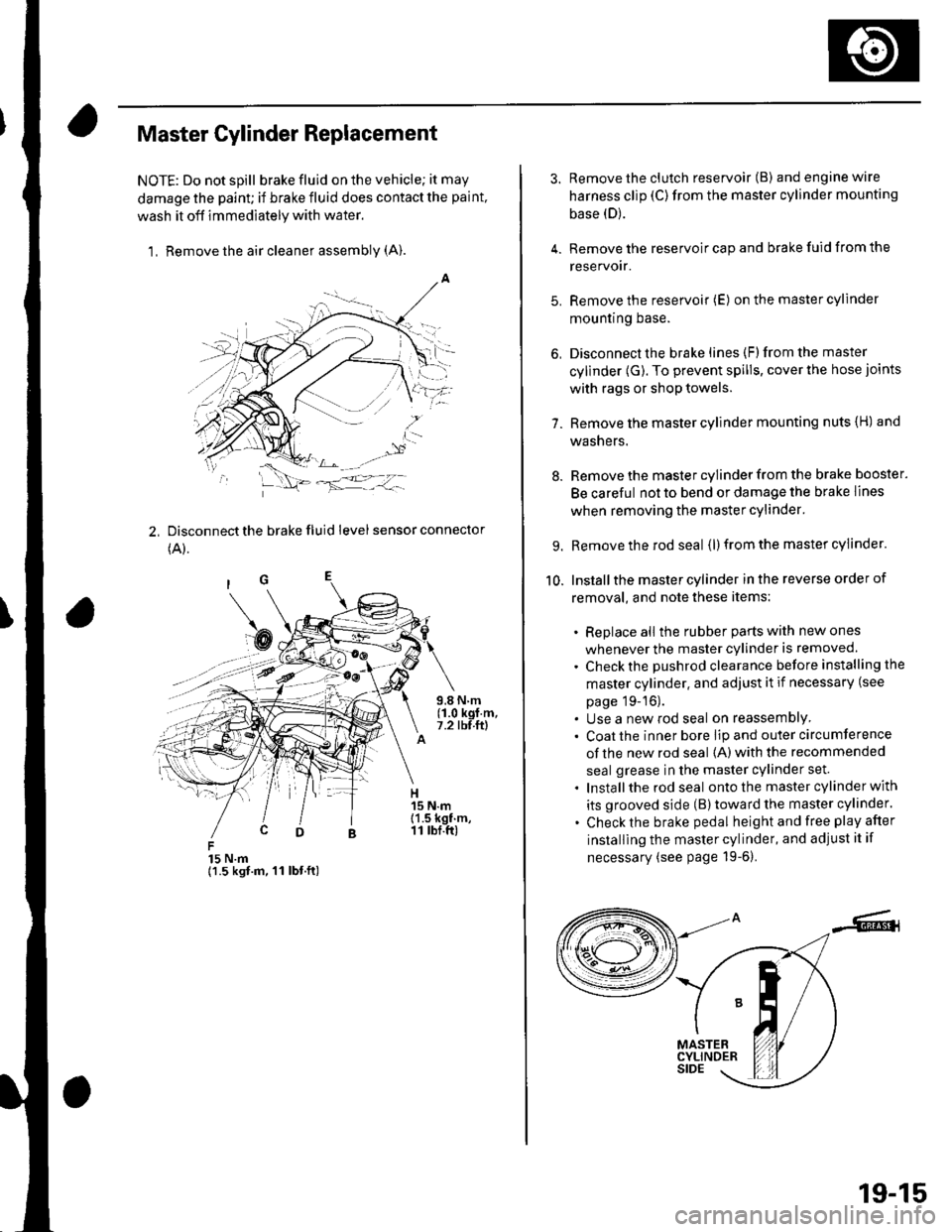

Master Cylinder Replacement

NOTE: Do not spill brake fluid on the vehicle; it may

damage the paint; if brake fluid does contact the paint,

wash it off immediately with water,

1, Remove the air cleaner assembly (A).

2, Disconnect the brake fluid level sensor connector

(A).

15 N.m{1.5 kgt.m, 11 lbt.ft)

3. Remove the clutch reservoir (B) andenginewire

harness clip (C)from the master cylinder mounting

base (D).

4. Remove the reservoir cap and brake fuid from the

reservoir.

5. Remove the reservoir (E) on the master cylinder

mountrng Dase.

6, Disconnect the brake lines (F)from the master

cylinder (G). To prevent spills, cover the hose joints

with rags or shop towels.

7. Remove the master cylinder mounting nuts {H) and

washers.

8. Remove the master cylinder from the brake booster.

Be careful not to bend or damage the brake lines

when removing the master cylinder.

9. Remove the rod seal (l) from the master cylinder.

10. Installthe master cylinder in the reverse order of

removal, and note these items:

. Replace all the rubber parts with new ones

whenever the master cylinder is removed.

. Check the pushrod clearance before installing the

master cylinder. and adjust it if necessary (see

page 19-16).. Use a new rod seal on reassemblY. Coat the inner bore lip and outer circumference

of the new rod seal {A) with the recommended

seal grease in the master cylinder set.

. Installthe rod seal ontothe master cylinder with

its grooved side (B)toward the master cylinder.

. Check the brake pedal height and free play after

installing the master cylinder, and adjust it if

necessary (see page 19-6).

19-15

Page 721 of 1139

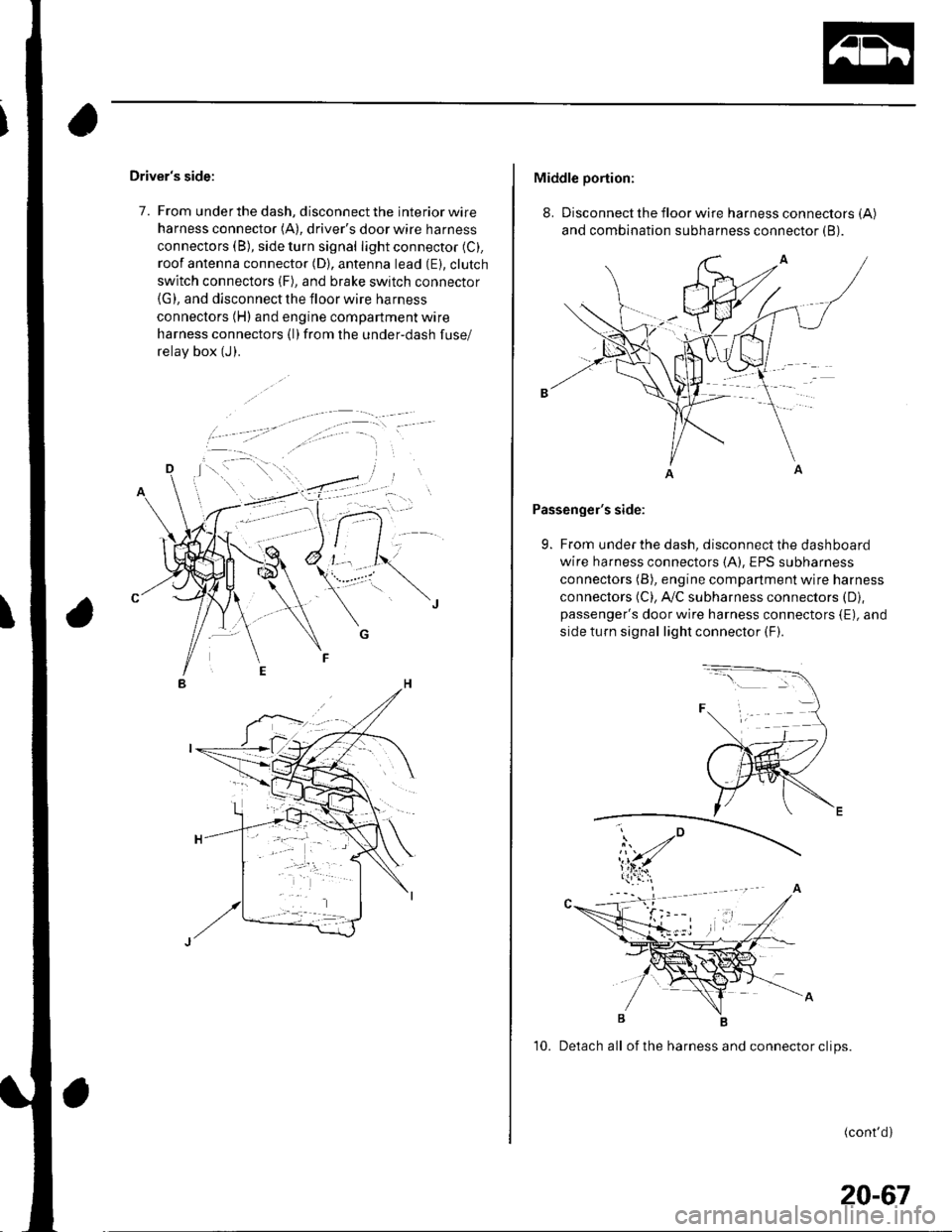

Driver's side:

7. From under the dash, disconnect the interior wire

harness connector (A), driver's door wire harness

connectors (B), side turn signal light connector (C).

roof antenna connector (D), antenna lead (E). clutch

switch connectors (F), and brake switch connector(G), and disconnect the floor wire harness

connectors (H) and engine compartment wire

harness connectors (l)from the under-dash fuse/

relav box (J).

Middle portion:

8. Disconnect the floor wire harness connectors (A)

and combination subharness connector (B).

Passenger's side:

9. From under the dash, disconnect the dashboard

wire harness connectors (A), EPS subharness

connectors (B), engine compartment wire harness

connectors (C), A,/C subharness connectors (D),

passenger's door wire harness connectors {E), and

side turn signal light connector (F).

10. Detach all of the harness and connector clips.

(cont'd)

20-67