reset HONDA CIVIC 2003 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 541 of 1139

EPS Components

(Motor RemovaUlnstallation (cont'dl

lnsiallation

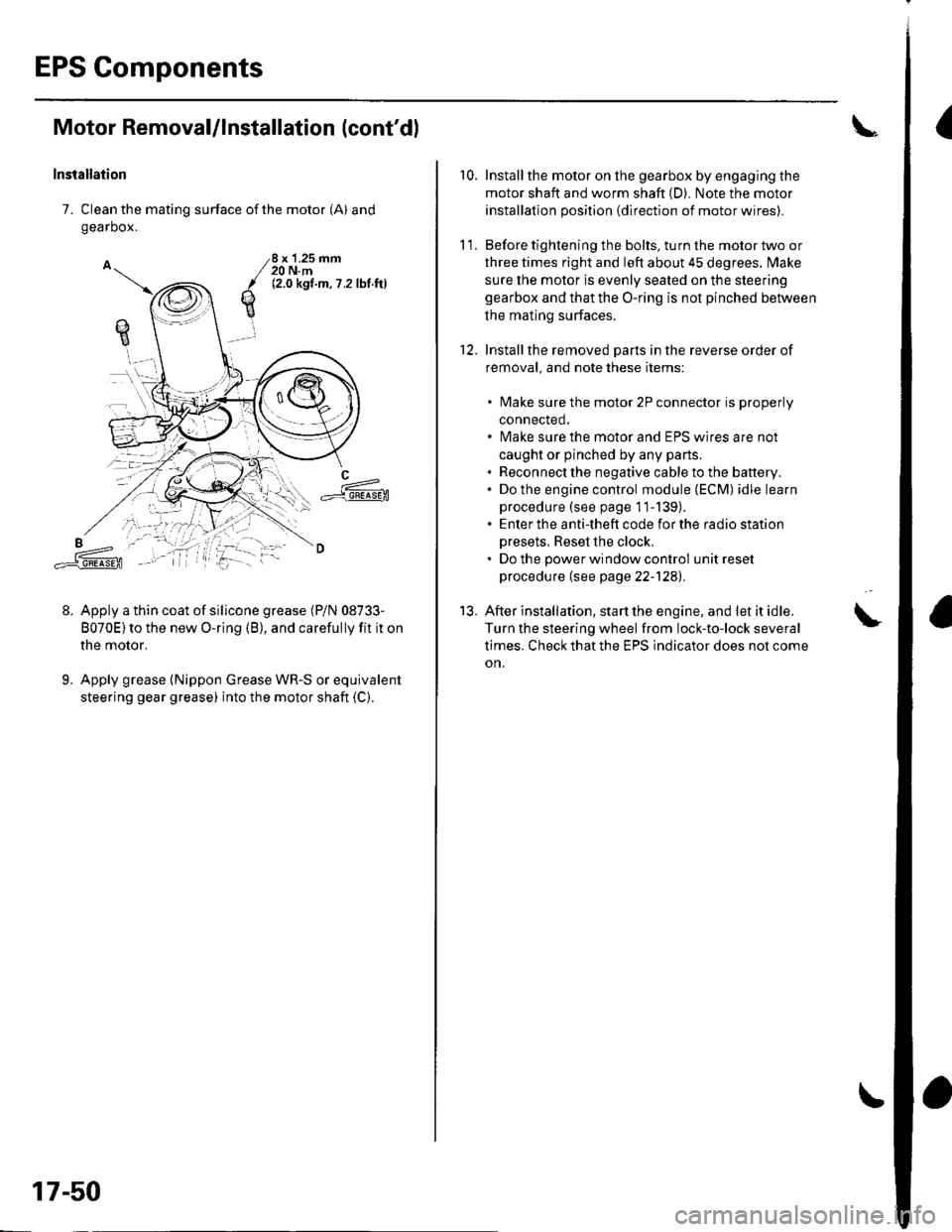

7. Clean the mating surface of the motor (A) and

gearbox.

Apply a thin coat of silicone grease (P/N 08733-

8070E)to the new O-ring (B), and carefully fit it on

the motor.

Apply grease {Nippon Grease WR-S or equivalent

steering gear grease) into the motor shaft (C).

qE

8 x '1.25 mm20 N.m12.0 kgt.m,7 .2lbl ftl

L==-c].E@

9.

17-50

r0.Install the motor on the gearbox by engaging the

motor shaft and worm shaft (D). Note the motor

installation position {direction of motor wires).

Before tightening the bolts, turn the motor two or

three times right and left about 45 degrees. lvlake

sure the motor is evenly seated on the steering

gearbox and that the O-ring is not pinched betlveen

the mating surfaces.

Installthe removed Darts in the reverse order of

removal. and note these items:

lvlake sure the motor 2P connector is properly

connected.

lvlake sure the motor and EPS wires are not

caught or pinched by any parts.

Reconnect the negative cable to the battery.

Do the engine control module (ECM) idle learn

procedure (see page 11-139).

Enter the anti-theft code for the radio station

Dresets. Reset the clock,

Do the oower window control unit reset

procedure (see page 22-1241.

After installation, start the engine, and let it idle.

Turn the steering wheel from lock-to-lock several

times. Check that the EPS indicator does not come

on.

11.

12.

13.

Page 567 of 1139

Wheel Runout Inspection

1.Raise the vehicle, and support it with safety stands

in the proper location (see page 1-5,.

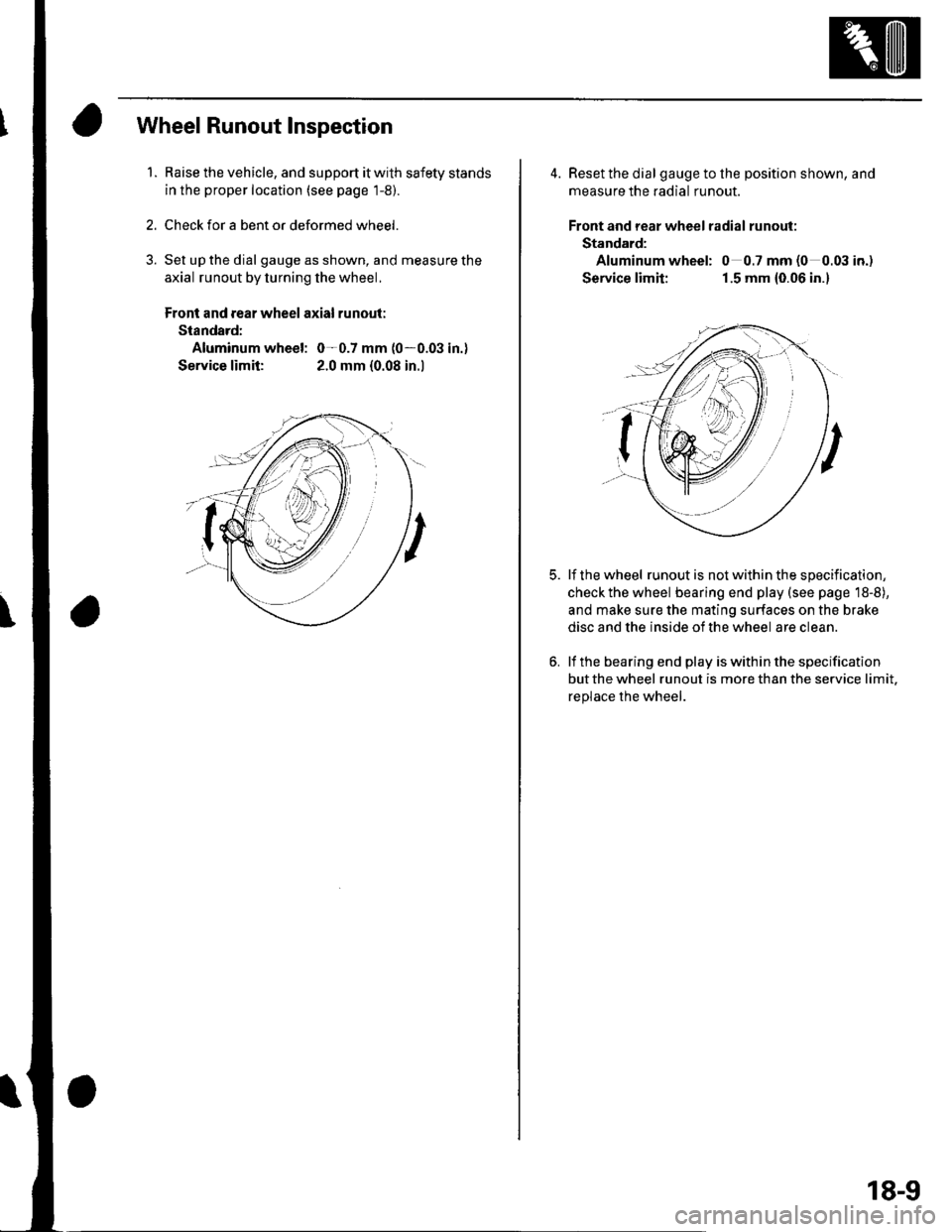

Check for a bent or deformed wheel.

Set up the dial gauge as shown, and measure the

axial runout by turning the wheel.

Front and rear wheel axial runout:

Standard:

Aluminum wheel: 0-0.7 mm (0-0.03 in.)

Service limit: 2.0 mm {0.08 in.l

4. Reset the dial gaugetothe position shown, and

measure the radial runout.

Front and rear wheel radial runout:

Standard:

Aluminum wheel: 0 0.7 mm (0 0.03 io.)

Service limit: 1.5 mm {0.06 in.}

lf the wheel runout is not within the specification,

checkthe wheel bearing end play (see page 18-8),

and make sure the mating surfaces on the brake

disc and the inside of the wheel are clean.

lf the bearing end play is within the specification

but the wheel runout is more than the service limit.

replace the wheel.

18-9

Page 716 of 1139

Dashboard

Dashboard Center Panel Removal/lnstallation

NOTE:. Put on gloves to protect your hands.. When prying with a flat-tip screwdriver, wrap it with

protective tape, and apply protective tape around the

related parts, to prevent damage.. Take care not to scratch the dashboard and related

parts.

1. Make sure you have the anti-theft code for the radio,

the write down the frequencies for the preset

buttons.

Remove these items:

. Driver's dashboard lower cover (see page 20-59)

. Passenger's dashboard lower cover (see page

20-63).. Glove box (see page 20-63).. Shift lever trim {see page 20-61).

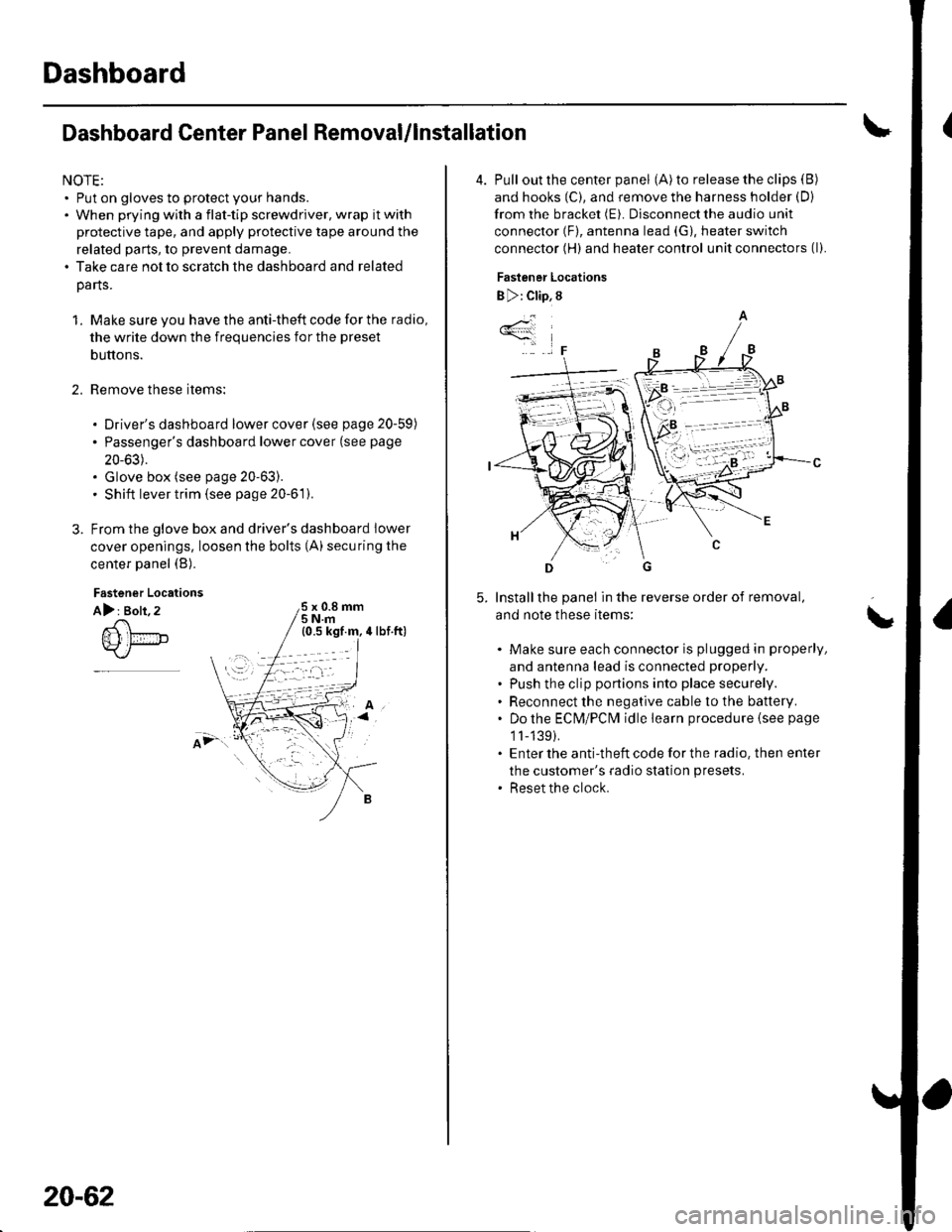

From the glove box and driver's dashboard Iower

cover openings, loosen the bolts (A) securing the

center panel (B).

2.

Fastener Locations

A): Bolt, 2x 0.8 mm5Nm

;.'

20-62

4. Pull out the center panel (A) to release the clips (B)

and hooks (C), and remove the harness holder (D)

from the bracket (E). Disconnect the audio unit

connector (F), antenna lead (G), heater switch

connector (H) and heater control unit connectors (l).

Fastener Locations

B ): Clip, 8

Installthe panel in the reverse order of removal,

and note these items:

Make sure each connector is plugged in properly,

and antenna lead is connected properly.

Push the clip portions into place securely.

Reconnect the negative cable to the battery.

Do the ECN4/PCt\4 idle learn procedure {see page

1l-139).

Enter the anti-theft code for the radio. then enter

the customer's radio station presets.

Reset the clock.

*4

,F

\

Page 720 of 1139

Dashboard

Dashboard Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations (see page 23-13) and the

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

NOTE:. When prying with a flat-tip screwdriver, wrap it with

protective tape, and apply protective tape around the

related parts to prevent damage.. Have an assistant help you when removing and

installing the dashboa rd.. Take care not to scratch the dashboard, body, and

other related parts.

. Put on gloves to protect your hands.

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

Disconnect the negative cable from the battery, and

wait at least three minutes before beginning work.

Remove these items:

. Driver's dashboard lower cover (see page 20-59). Driver's dashboard under cover (see page 20-60). Passenger's dashboard lower cover (see page

20-63). Glove box (see page 20-63). Consoles, front and rear (see page 20-57). Shift lever trim {see page 20-61). Center panel (see page 20-62). Kick panels, both sides (see page 20-50). A-pillar trim. both sides (see page 20-50). Steering column (see page 17-9)

20-66

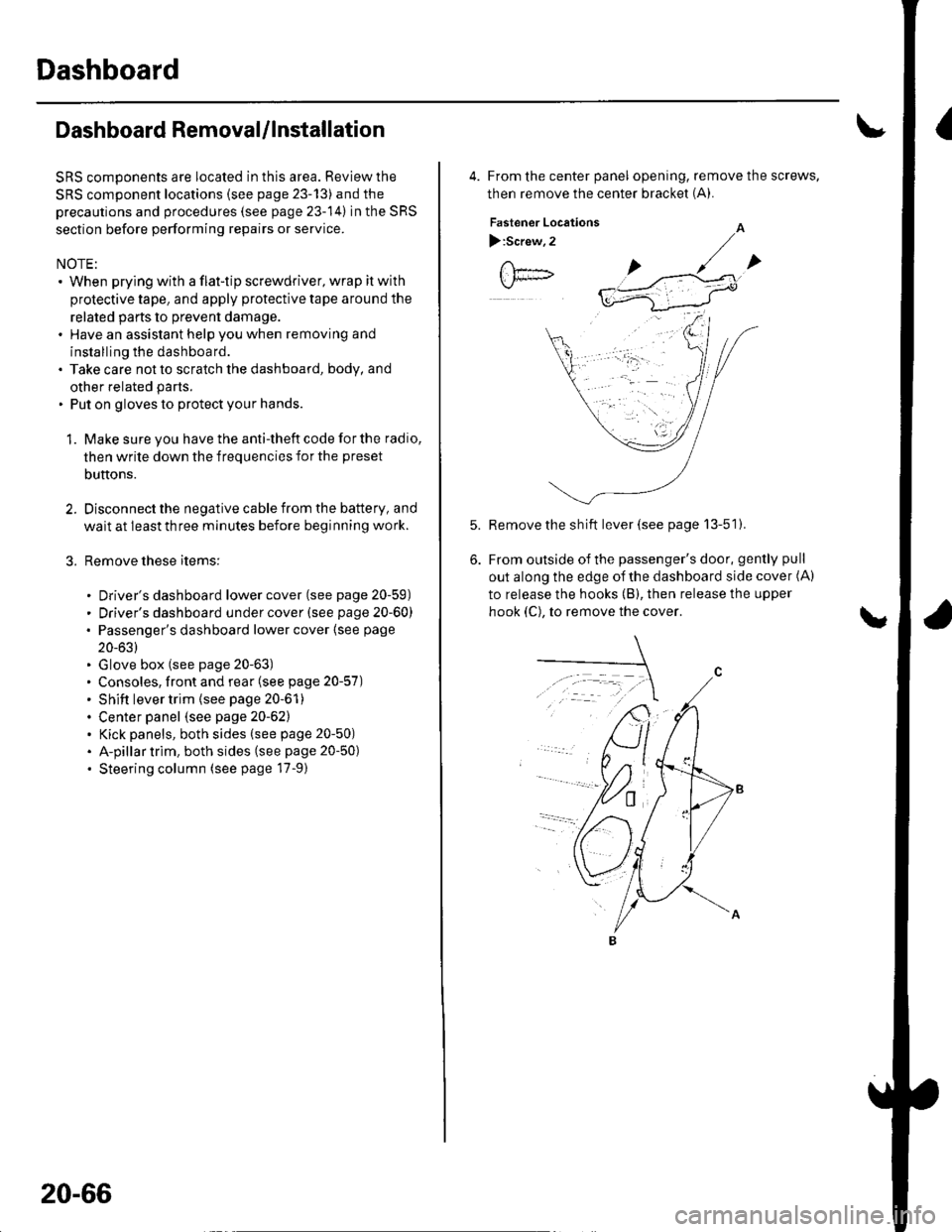

4. From the center panel opening, remove the screws,

then remove the center bracket (A).

Fastener Locations

):Screw,2

Remove the sh ift lever (see page 13-51).

From outside of the passenger's door, gently pull

out along the edge of the dashboard side cover (A)

to release the hooks (B), then release the upper

hook (C), to remove the cover.

Page 722 of 1139

Dashboard

Dashboard Removal/lnstallation

(cont'd)

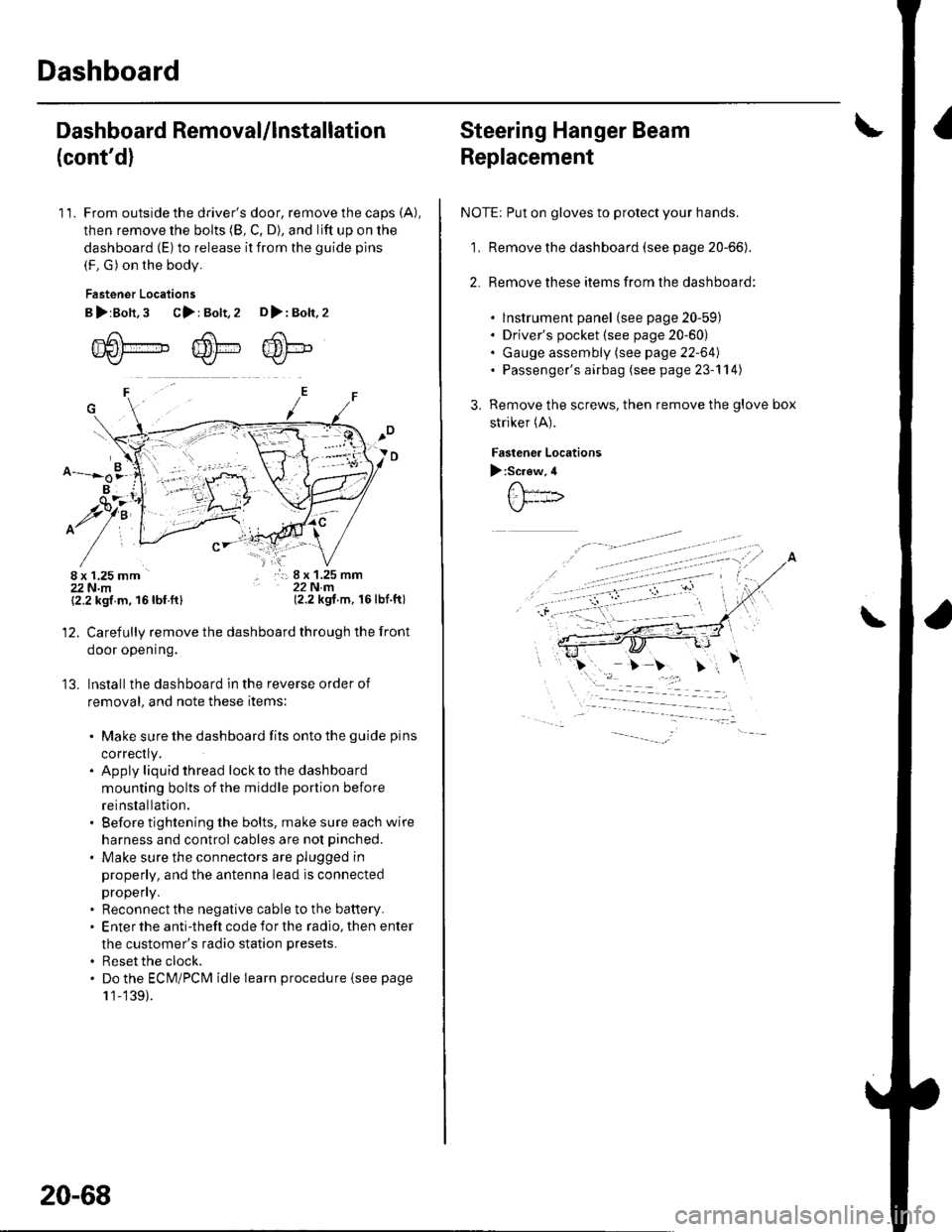

11. From outside the driver's door, remove the caps (A),

then remove the bolts (8, C, D), and lift up on the

dashboard (E) to release it from the guide pins

(F. G) on the body.

Fastener Locations

B>rBolt.3 C>: Bolt,2 D>: Bolt,2

m6[-,,,,",",,-,F6't---'' ffi'!--v{/- Kr* w-

B

$7:

^/761:

/,-,. r:; 8 x 1.25 mm22Nm(2.2 kgf.m, 16lbf.ft)

13.

{2.2 kgf m, 16lbf.ftl

Carefully remove the dashboard through the front

door opening.

lnstall the dashboard in the reverse order of

removal, and note these items:

. Make sure the dashboard fits onto the guide pins

correctly.. Apply liquid thread lock to the dashboard

mounting bolts of the middle portion before

reinstallation.. Before tightening the bolts, make sure each wire

harness and control cables are not pinched.

. Make sure the connectors are plugged in

properly, and the antenna lead is connected

propeny.. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

. Reset the clock.. Do the ECM/PCM idle learn procedure isee page

1 '1-139).

20-68

Steering Hanger Beam

Replacement

NOTE: Put on gloves to protect your hands.

1, Remove the dashboard (see page 20-66).

2. Remove these items from the dashboard:

. lnstrument panel (see page 20-59). Driver's pocket (see page 20-60). Gauge assembly (see page 22-64). Passenger's airbag (see page 23-'l 14)

Remove the screws, then remove the glove box

striker (A).

Fastenea Locations

):Screw,4

\

Page 725 of 1139

Front Seat Removal/lnstallation

For some models: SRS components are located in this

area. Review the SRS component locations (see page

23-'13) and the precautions and procedures (see page

23-14) in the SRS section before performing repairs or

service.

NOTE. When prying with a flat-tip screwdriver, wrap it with

protective tape to prevent damage.. Take care not to scratch the body or tear the seat

covers.. Put on gloves to protect your hands.

1, Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

butlons.

Disconnect the negative cable from the battery, and

wait at least 3 minutes before beginning work.

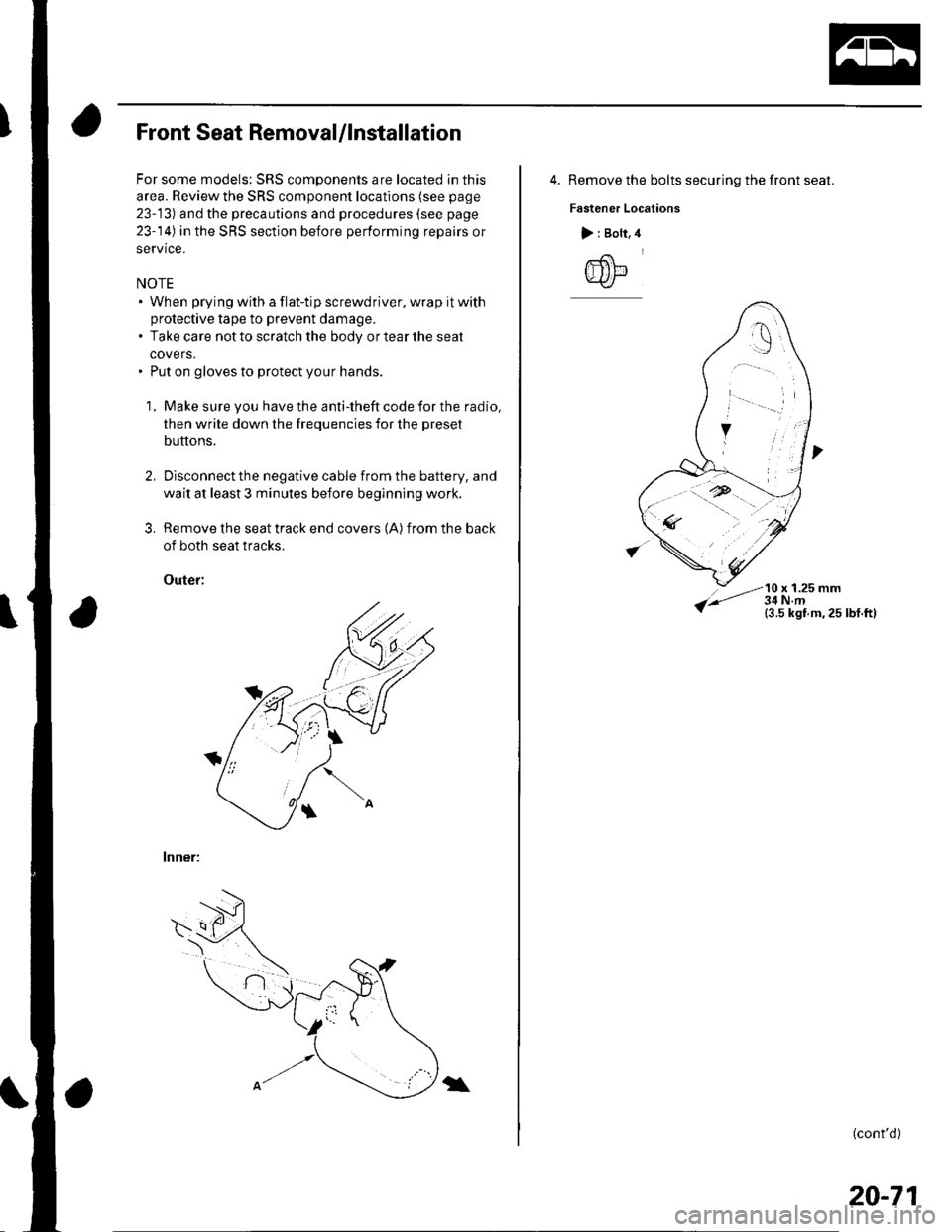

Remove the seat track end covers (A) from the back

of both seat tracks.

Outef:

lnner:

3.

\

4. Remove the bolts securing the front seat.

Fastener Locations

10 x 1.25 mm

> : Bolt,

@

(cont'd)

20-71

Page 726 of 1139

Seats

Front Seat Removal/lnstallation (cont'dl

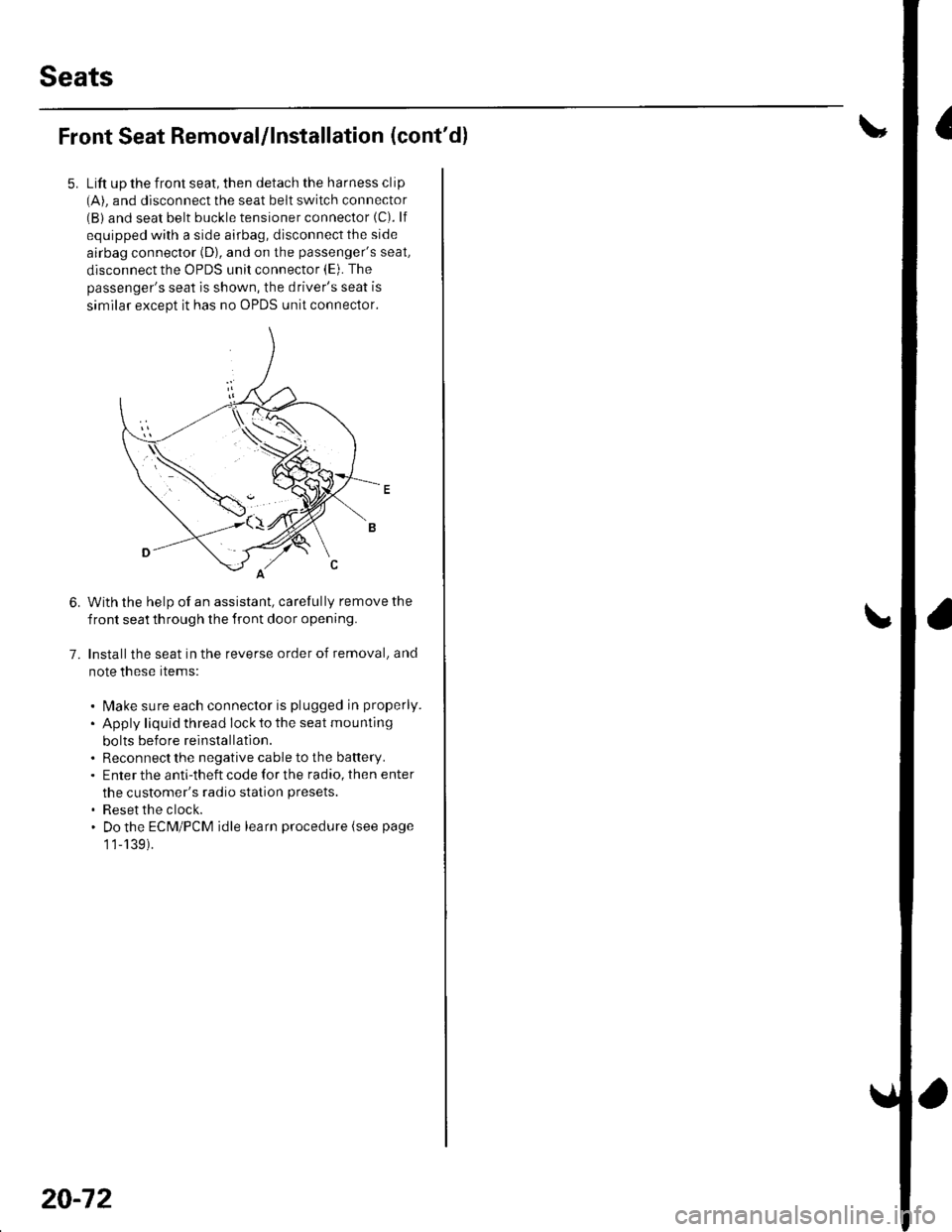

Lift up the front seat, then detach the harness clip(A). and disconnect the seat belt switch connector(B) and seat belt buckle tensioner connector (C). lf

equipped with a side airbag, disconnect the side

airbag connector (D), and on the passenger's seat,

disconnect the OPDS unit connector (E). The

passenger's seat is shown, the driver's seat is

similar except it has no OPDS unit connector.

With the help of an assistant, carefully remove the

front seat th rough the front door opening.

Installthe seat in the reverse order of removal, and

note these rtems:

. l\4ake sure each connector is plugged in properly.

. Apply liquid thread lock to the seat mounting

bolts before reinstallatlon.. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

. Reset the clock.. Do the ECM/PCM idle learn procedure (see page

1 1-139).

6.

7.

20-72

Page 810 of 1139

Dust and Pollen Filter Replacement

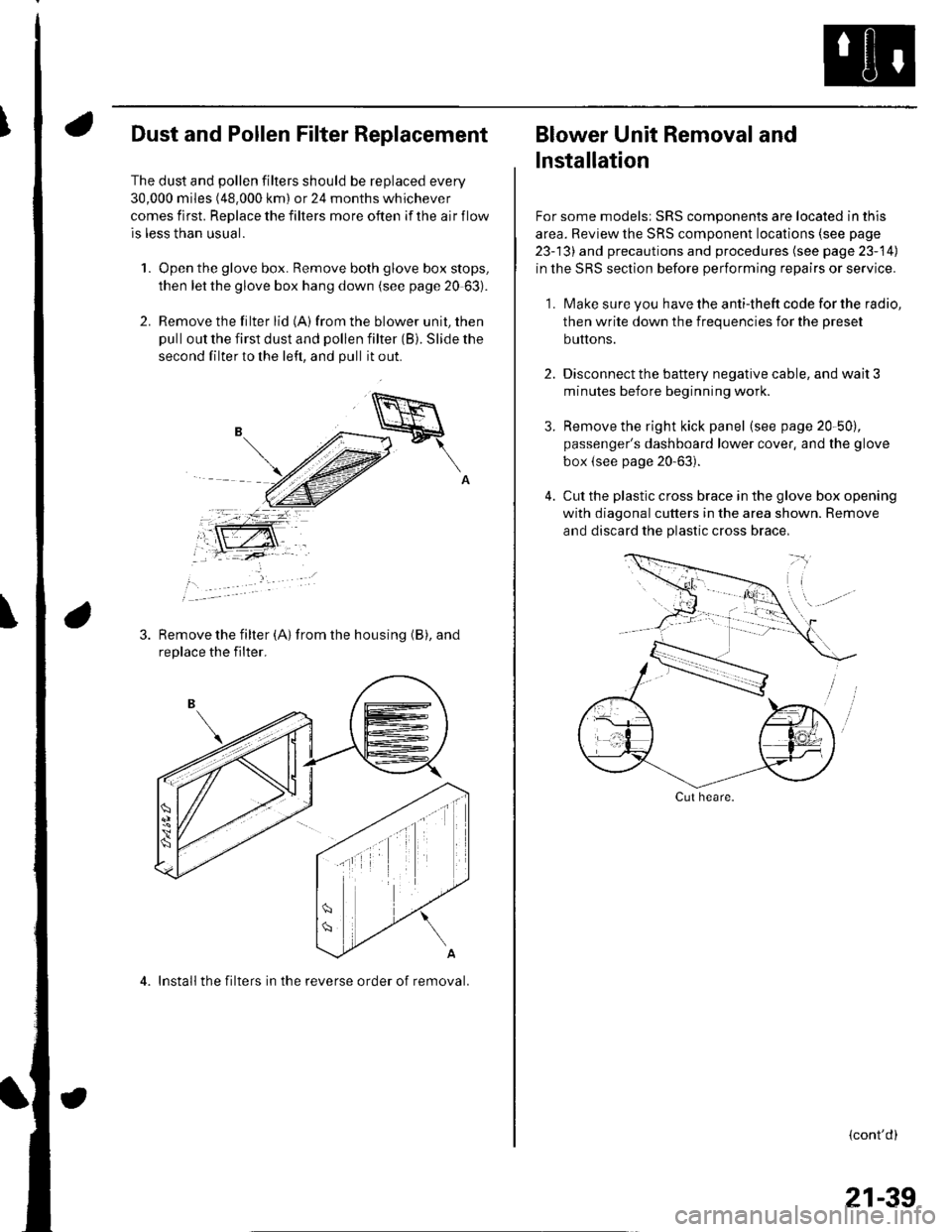

The dust and pollen filters should be replaced every

30,000 miles (48.000 km) or 24 months whichever

comes first. Replace the filters more often if the air flow

is less than usual.

1. Open the glove box. Remove both glove box stops,

then let the glove box hang down (see page 20 63).

2. Remove the filter lid (A)from the blower unit, then

pull out the first dust and pollen filter (B). Slide the

second filter to the left, and pull it out.

Remove the filter {A) from the housing (B), and

replace the filter.

4. Install the filters in the reverse order of removal.

Blower Unit Removal and

lnstallation

For some models: SRS components are located in this

area. Review the SRS component locations (see page

23-13) and precautions and procedures (see page 23-14)

in the SRS section before performing repairs or service.

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

2. Disconnect the battery negative cable, and wait 3

minutes before beginning worK.

3. Remove the right kick panel (see page 20-50),

passenger's dashboard lower cover, and the glove

box {see page 20-63).

4. Cut the plastic cross brace in the glove box opening

with diagonal cutters in the area shown. Remove

and discard the plastic cross brace,

Cut heare.

{cont'd)

21-39

Page 811 of 1139

Heating and Air Gonditioning

Blower Unit Removal and Installation {cont'd}

Remove the steering hanger beam bracket cover

from the right side of the glove box opening, then

remove the bolts and the olove box frame.

1.

8.

9.

Remove the ECM (see page 11-4).

Remove the EPS control unit (see page 17-67).

Disconnect and remove the PGM-Fl main relays

and bracket assembly, then remove the ECM

bracket.

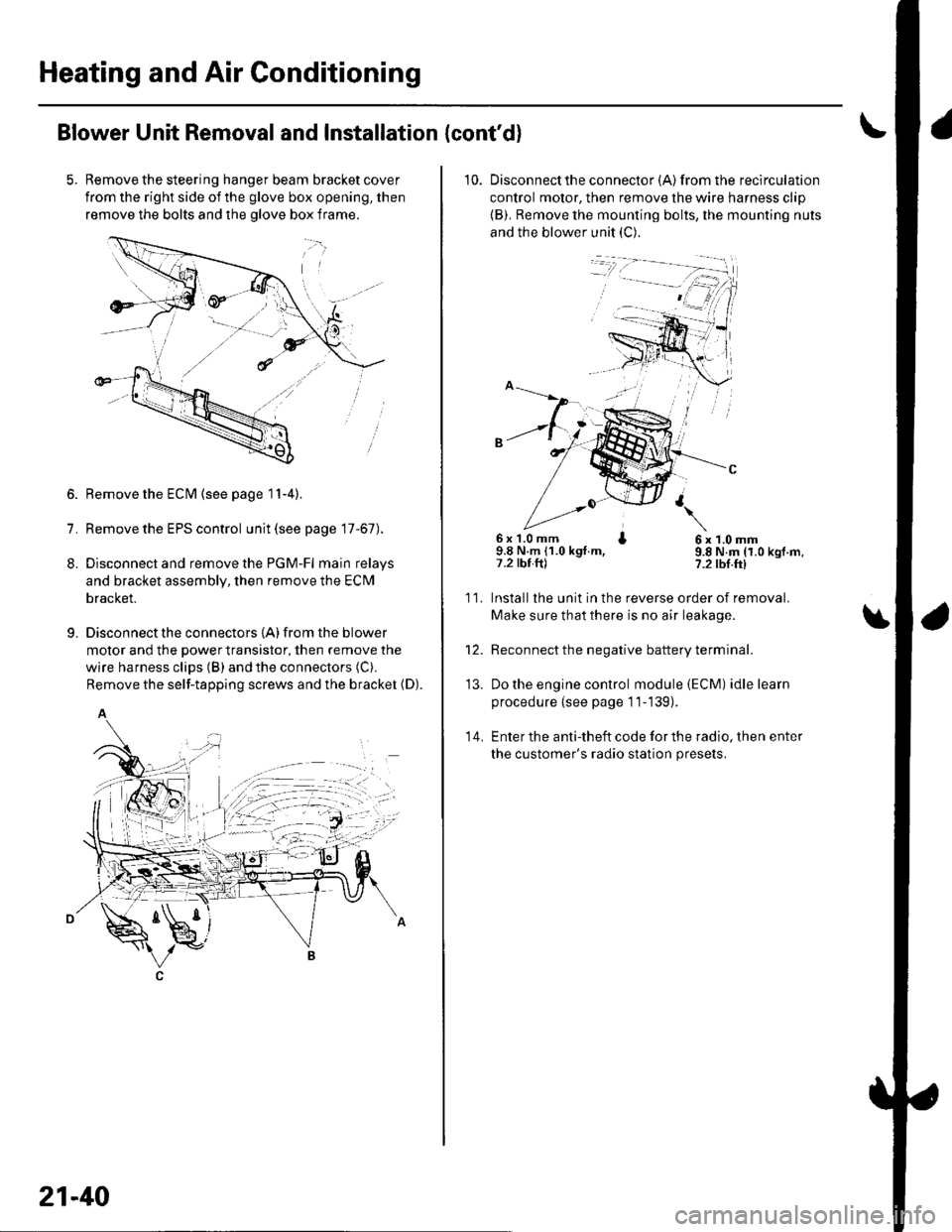

Disconnect the connectors {A) from the blower

motor and the power transistor, then remove the

wire harness clips (B) and the connectors (C).

Remove the self-tapping screws and the bracket (D).

A

21-40

10. Disconnectthe connector {A) from the recirculation

control motor, then remove the wire harness clip

{B). Remove the mounting bolts, the mounting nuts

and the blower unit (C).

6x 1.0 mm I9.8 N.m (1.0 kgt.m,7.2 tbt.ftl

6x1.0mm9.8 N.m (1.0 kgf.m,?.2 tbf.ft)

11.

14.

Installlhe unit in the reverse order of removal.

Make sure that there is no air leakage.

Reconnect the negative battery terminal.

Do the engine control module (ECM) idle learn

procedure {see page 11-139).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

\

'13.

Page 814 of 1139

Heater Unit/Core Replacement

SRS components are located in this area. Review the

SRS component locations (see page 23'13), and

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

1. Make sure you have the anti-theft code forthe radio,

then write down the freouencies for the radio's

Dreset buttons.

4.

Disconnect the negative cable from the battery,

Disconnect the suction and receiver lines from the

evaporator core (see page 21-42).

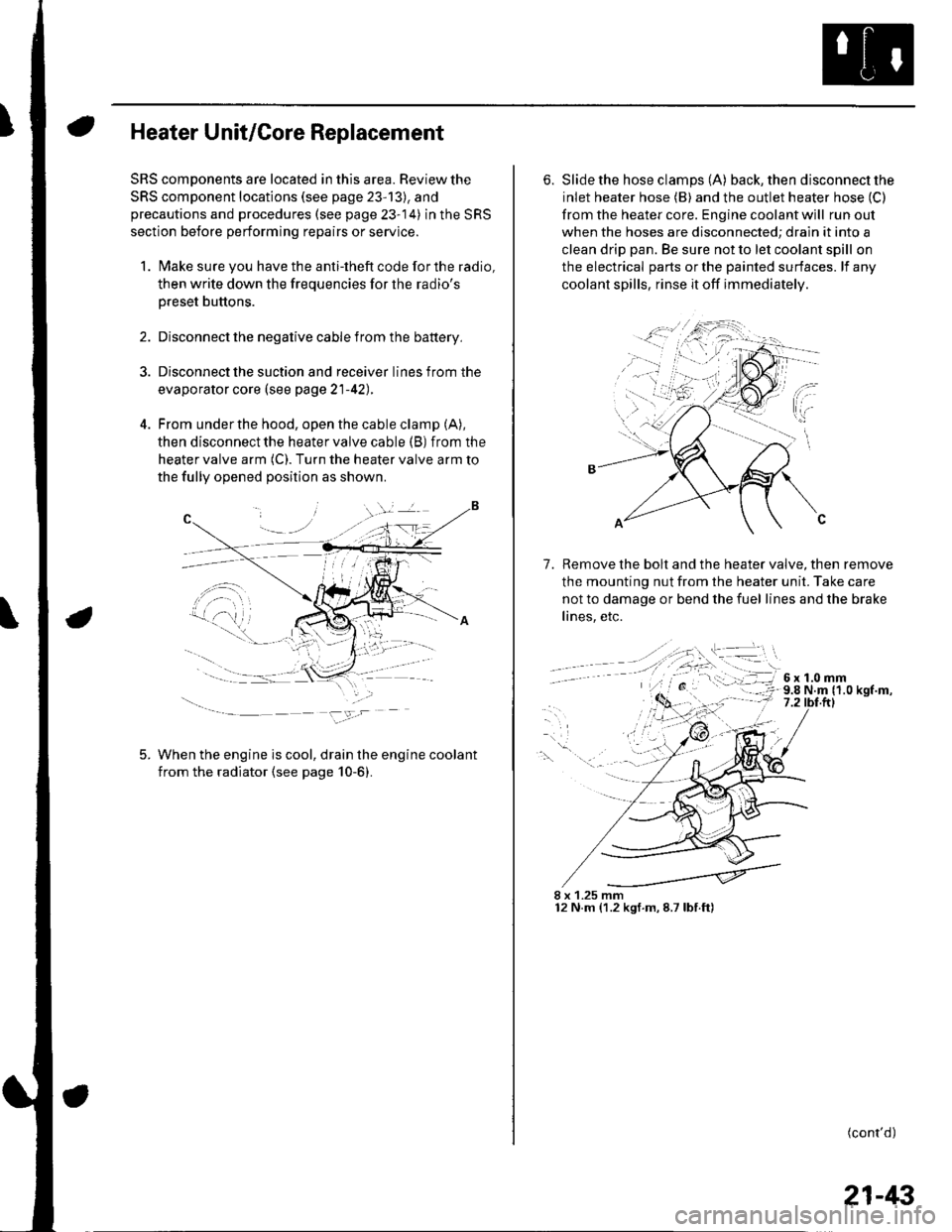

From under the hood, open the cable clamp (A),

then disconnect the heater valve cable (B) from the

heater valve arm (C). Turn the heater valve arm to

the fully opened position as shown

When the engine is cool, drain the engine coolant

from the radiator (see page 10-6).

6. Slide the hose clamps (A) back, the n d isconnect the

inlet heater hose (B) and the outlet heater hose (C)

from the heater core. Engine coolant will run out

when the hoses are disconnected; drain it into a

clean drip pan. Be sure not to let coolant spill on

the electrical parts or the painted surfaces. lf any

coolant spills, rinse it off immediately.

Remove the bolt and the heater valve, then remove

the mounting nut from the heater unit. Take care

not to damage or bend the fuel lines and the brake

lines, etc.

7.

8 x 1.25 mm12 N.m (1.2 kgf.m,8.7lbf.ft)

(cont'd)

21-43