HONDA CIVIC 2003 7.G Repair Manual

Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 61 of 1139

Charging System

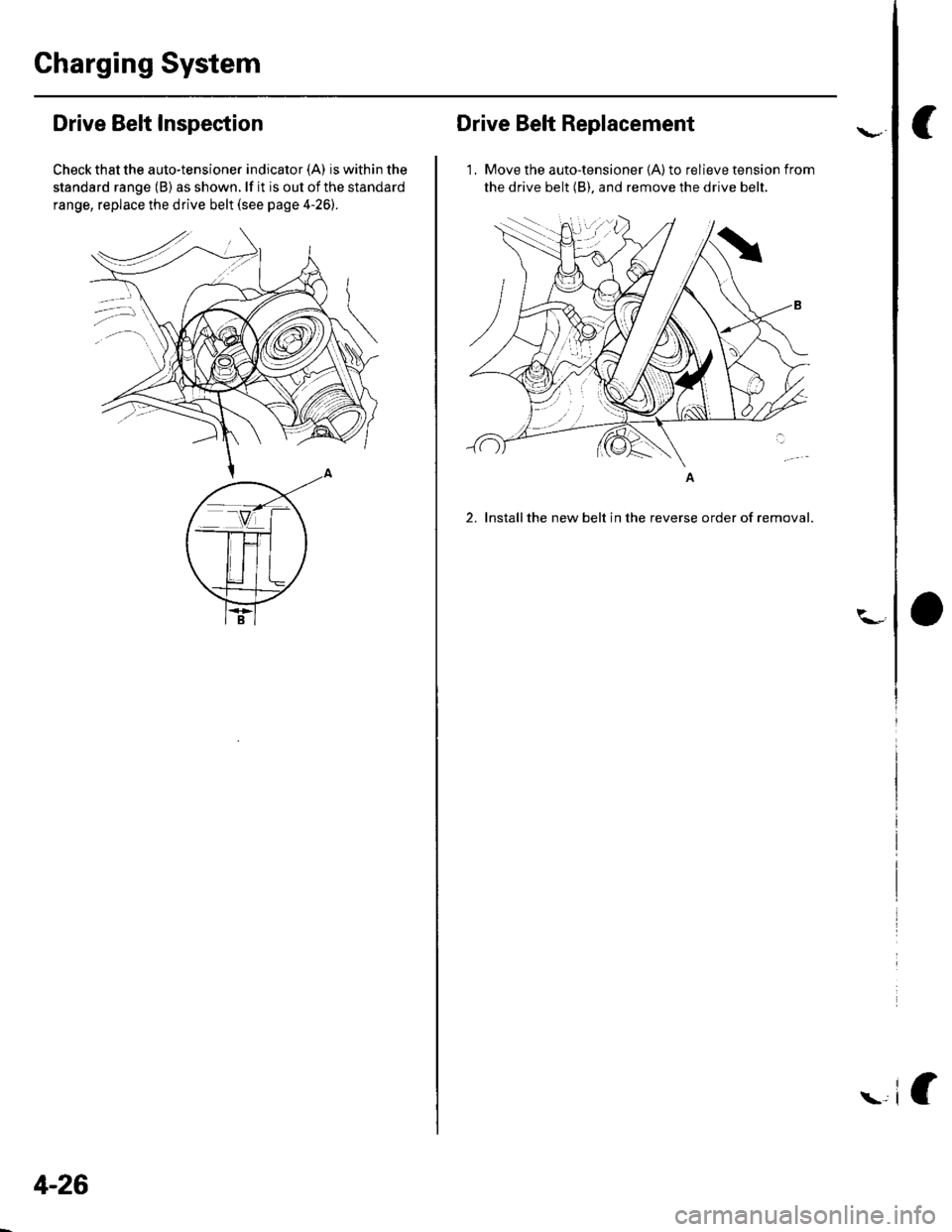

Drive Belt Inspection

Check that the auto-tensioner indicator (A) is within the

standard range (B) as shown. lf it is out of the standard

range, replace the drive belt (see page 4-26).

4-26

Drive Belt Replacement

1, Move the auto-tensioner (A) to relieve tension from

the drive belt (B). and remove the drive belt.

2. Installthe new belt in the reverse order of removal.

Page 62 of 1139

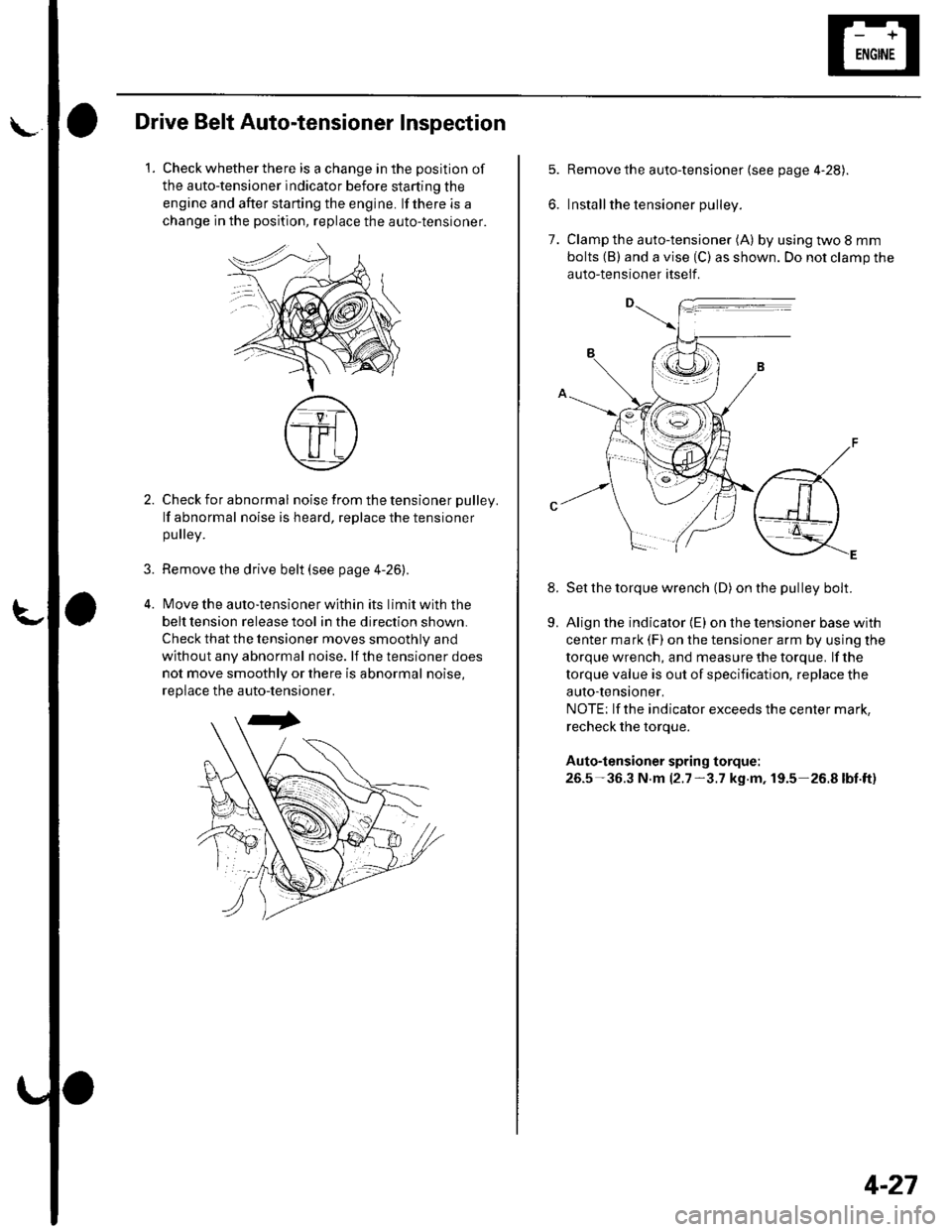

\Drive Belt Auto-tensioner Inspection

1.Check whether there is a change in the position of

the auto-tensioner indicator before starting the

engine and after starting the engine. lf there is a

change in the position, replace the auto-tensioner.

3.

Check for abnormal noise from the tensioner pulley.

lf abnormal noise is heard, replace the tensioner

pulley.

Remove the drive belt (see page 4-26).

lMove the auto-tensioner within its limit with the

belt tension release tool in the direction shown.

Check that the tensioner moves smoothly and

without any abnormal noise. lf the tensioner does

not move smoothly or there is abnormal noise,

replace the auto-tensioner.

7.

8.

Remove the auto-tensioner (see page 4-28).

Install the tensioner pulley.

Clamp the auto-tensioner (A) by using two 8 mm

bolts (B) and a vise (C) as shown. Do not clamp the

auto-tensioner itself .

Set the torque wrench (D) on the pulley bolt.

Align the indicator {E) on the tensioner base with

center mark (F) on the tensioner arm by using the

torque wrench, and measure the torque. lf the

torque value is out of specification, replace the

auto-tensioner,

NOTE; lf the indicator exceeds the center mark,

recheck the torque.

Auto-tensioner spring torque:

26.5-36.3 N.m 12.7-3.7 kg.m, 19.5-26.8lbt.ft)

9.

4-27

Page 63 of 1139

Charging System

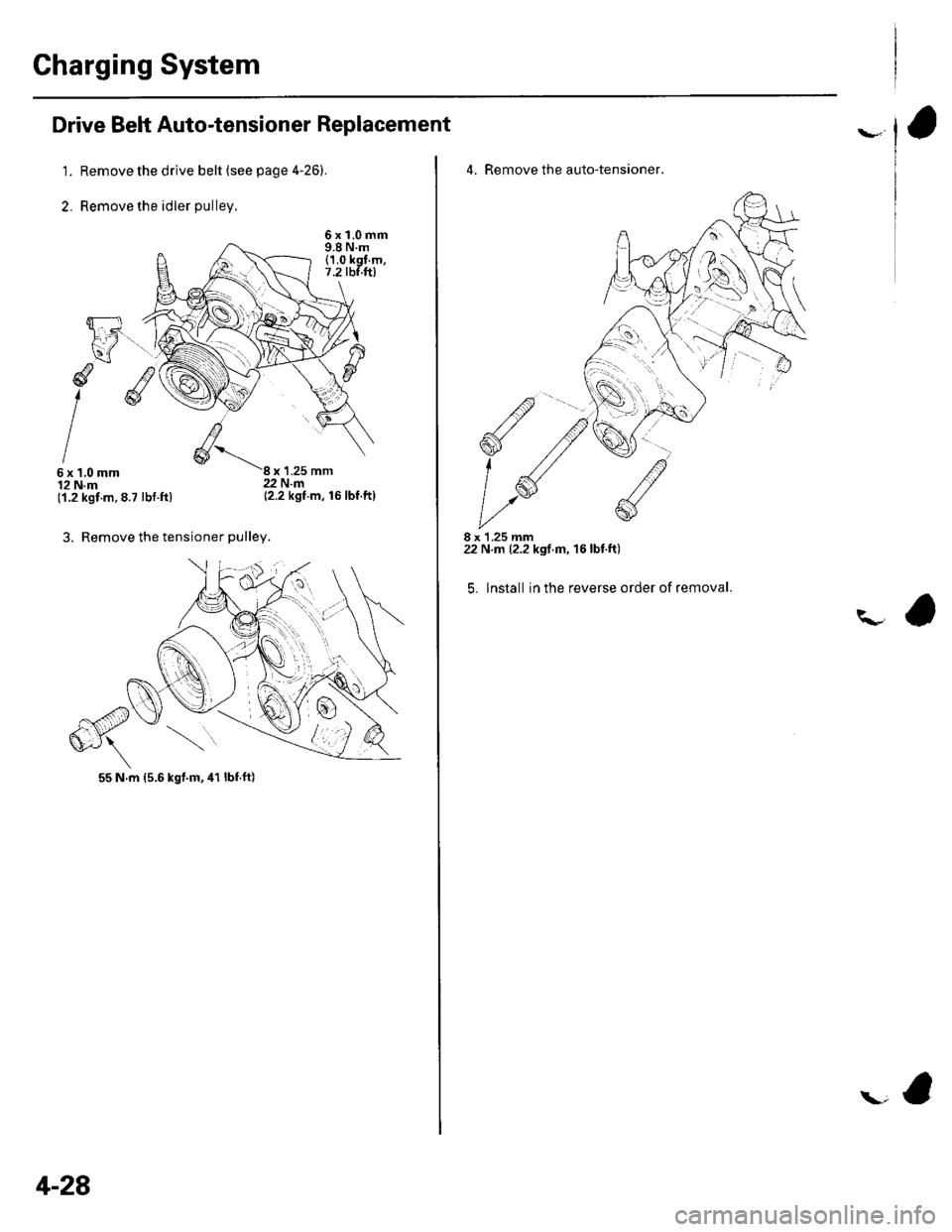

Drive Belt Auto-tensioner Replacement

1. Remove the drive belt (see page 4'26).

2. Remove the idler pulley.

6xl.0mm9.8 N.m(1,0 kgl.m,7.2 tbf.ft)

d

I6x1,0mm12 N.m('1.2 kgt.m.8.7 lbt.ft)

3. Remove the tensioner pulley.

x 1.25 mm22 N.m{2.2 kgt m, 16 lbf ft}

4-28

4. Remove the auto-tensioner,

8 x 1.25 mm22 N.m (2.2 kgf.m, 16lbt.ft)

5. lnstall in the reverse order of removal.

\-a

Page 64 of 1139

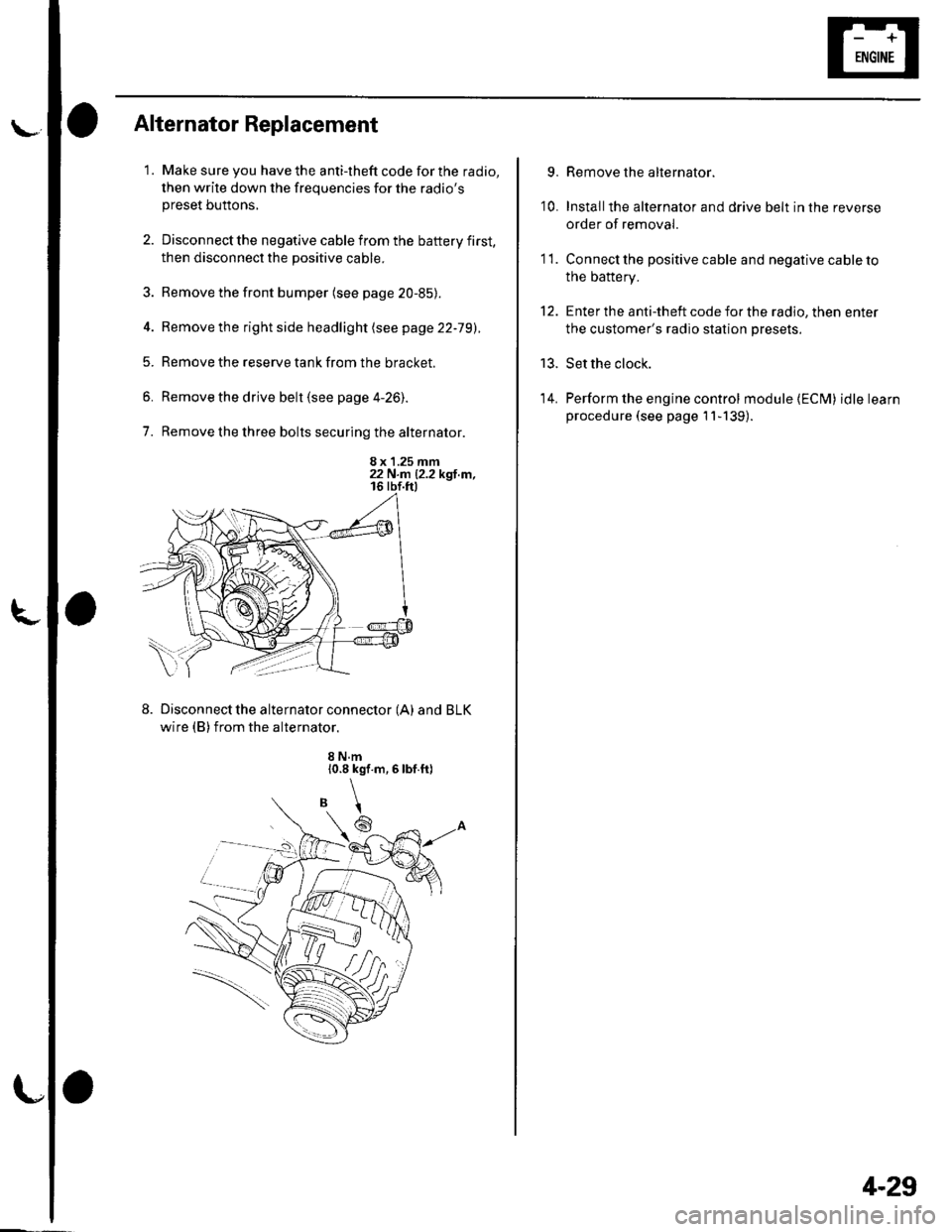

l\-Alternator Replacement

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio'spreset buttons,

2. Disconnect the negative cable from the battery first,

then disconnect the positive cable.

3. Remove the front bumper (see page 20-85).

4. Remove the right side headlight (see page 22-79).

5. Remove the reserve tank from the bracket.

6. Remove the drive belt (see page 4-26).

7. Remove the three bolts securing the alternator.

8 x 1.25 mm22 N.n 12.2 kgl.m,

Disconnect the alternator connector (A) and BLK

wire (B) from the alternator.

8 N.m10.8 kgf.m,6lbf.ft)

\

6

'I 1.

9.

10.

13.

14.

Remove the alternator.

Installthe alternator and drive belt in the reverse

order of removal.

Connect the positive cable and negative cable to

the battery.

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Set the clock.

Perform the engine control module {ECM) idle learn

procedure (see page 11-139).

tt.

4-29

Page 65 of 1139

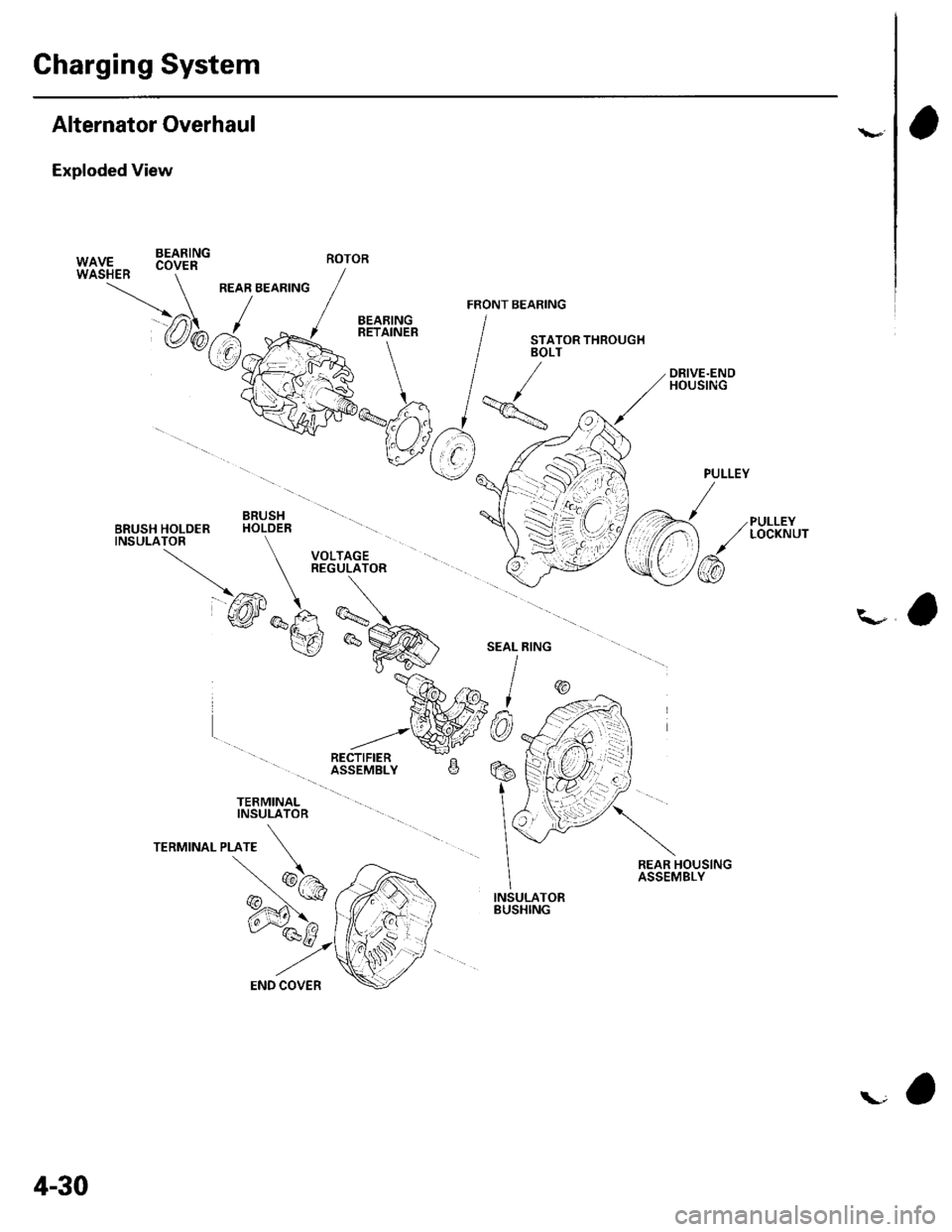

Charging System

Alternator Overhaul

Exploded View

BEARING

PULLEYLOCKNUT

\-a

TERMINALINSULATOR

REAR HOUSINGASSEMBLY

INSULATORBUSHING

PULLEY

/

\/

/@

W|UF., .oy." -

/

REAR BEARING / ,/ ./ FRoNr B

@b.J.y{=RE+LN'"'

IvVFko"-% /

qtr*njlv

V( r),

"V

BRUSH \11BRUSH HOLOER HOLDER -\

TNSULATOR \l VOLTAGE }

\-

REGULATOR (-

@*F, -\:

v_re *^i

\gP^@' I

*ffilw9

ROTOR

4-30

Page 66 of 1139

L

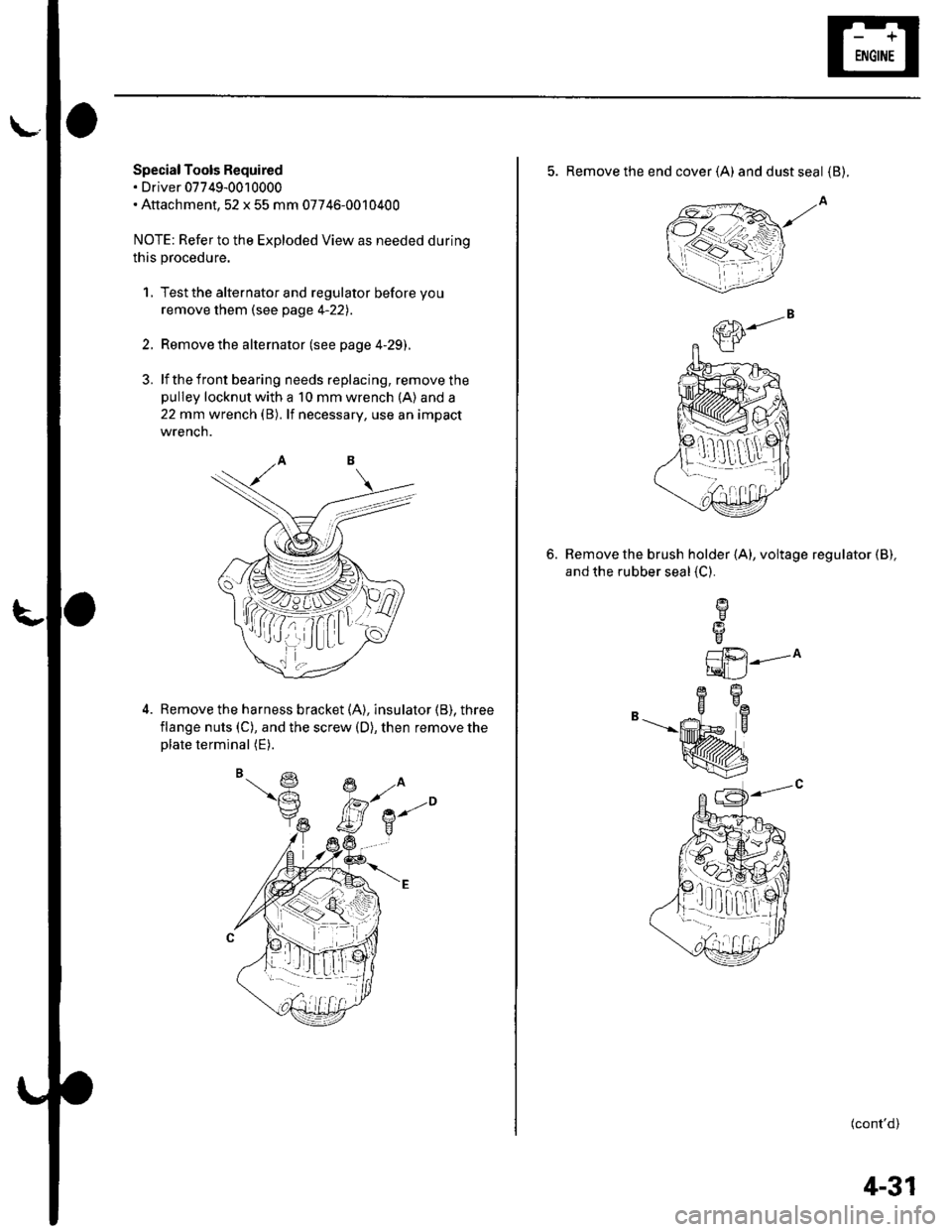

Special Tools Required. Driver 07749-0010000. Attachment,52 x 55 mm 07746-0010400

NOTE: Refer to the Exploded View as needed during

this procedure.

1, Test the alternator and regulator before you

remove them (see page 4-22l,.

2. Remove the alternator (see page 4-29).

3. lf the front bearing needs replacing, remove thepulley locknut with a 10 mm wrench (A) and a

22 mm wrench (B). lf necessary, use an impact

wrencn.

Remove the harness bracket (A), insulator (B). three

flange nuts (C), and the screw (D), then remove theplate terminal (E).

,( ( , tt I;r_ lLt

5. Remove the end cover (A) anddustseal {B).

Remove the brush holder (A), voltage regulator (B),

and the rubber seal {C}.

6.

L1i.21---^

tqLJ

B-"--|.

(cont'd)

1!q[-dr,:l

4-31

Page 67 of 1139

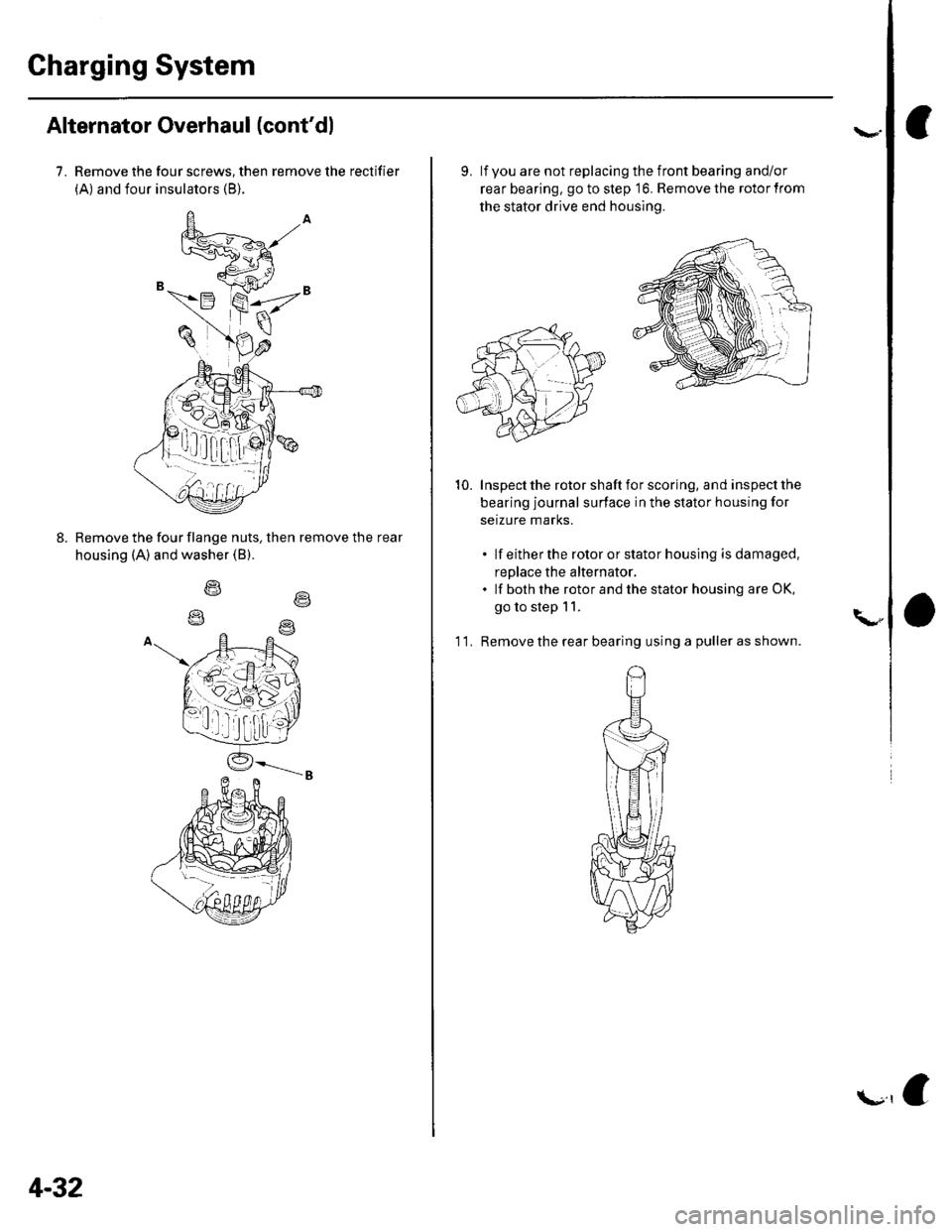

Charging System

Alternator Overhaul (cont'dl

7. Remove the four screws, then remove the rectifier

(A) and four insulators (B).

Remove the four flange nuts, then remove the rear

housing (A) and washer (B).

o\

4-32

f.r,e

9. lf you are not replacing the front bearing and/or

rear bearing, go to step '16. Remove the rotor from

the stator drive end housing.

Inspect the rotor shaft for scoring, and inspect the

bearing journal surface in the stator housing for

setzure marks.

. lf eitherthe rotororstatorhousing isdamaged,

replace the alternator,. lf both the rotor and the stator housing are OK,

go to step 11.

'l 1. Remove the rear bearing using a puller as shown.

10.

\"

Page 68 of 1139

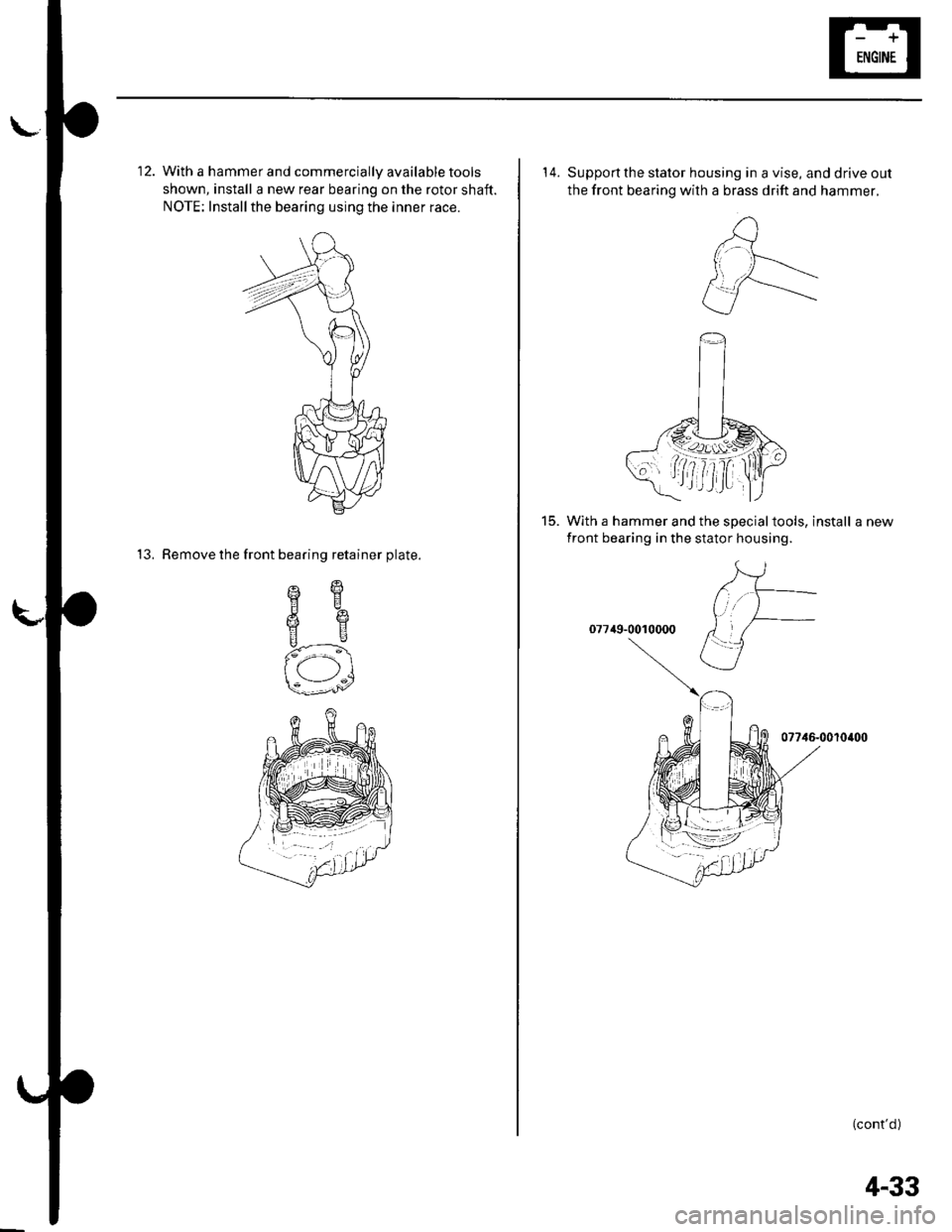

\-

12. With a hammer and commercially available tools

shown, install a new rear bearing on the rotor shaft.

NOTE: Installthe bearing using the inner race.

13. Remove the front bearing retainer plate.

sqHE

6e

us

f-\

-:1s---'^/

14. Supportthe stator housing in a vise, and drive out

the front bearing with a brass drift and hammer.

15. With a hammer and the specialtools, install a new

front bearing in the stator housing.

07749-0010000

07746-0010400

(cont'd )

4-33

Page 69 of 1139

Charging System

Alternator Overhaul (cont'd)

Rectitier Test

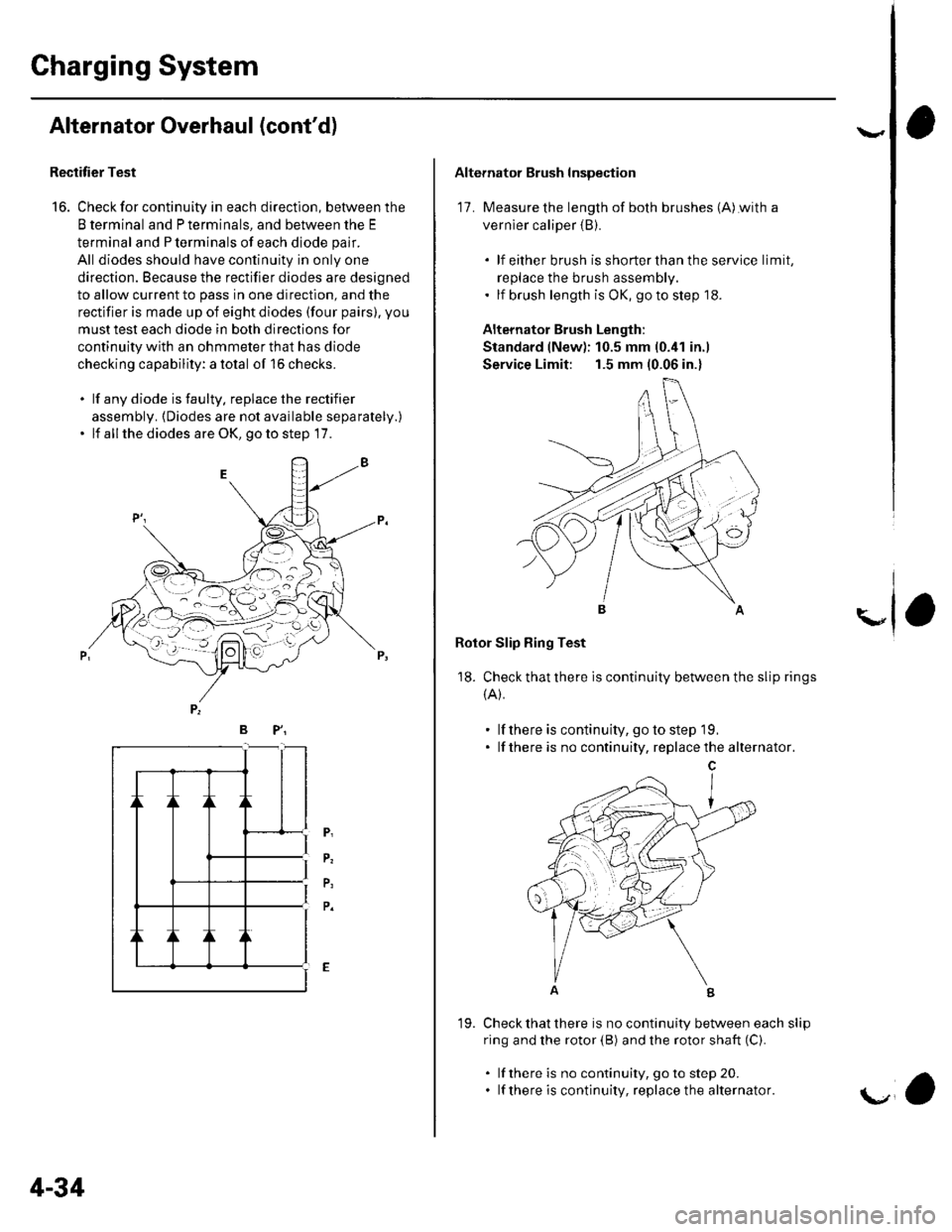

16. Check for continuity in each direction, between the

B terminal and P terminals, and between the E

terminal and P terminals of each diode pair.

All diodes should have continuity in only one

direction. Because the rectifier diodes are designed

to allow current to pass in one direction, and the

rectifier is made up of eight diodes (four pairs). you

musttest each diode in both directions for

continuity with an ohmmeter that has diode

checking capability: a total of 16 checks.

. lf any diode is faulty. replace the rectifier

assembly. {Diodes are not available separately.)' lf all the diodes are OK, go to step 17.

/--:',t- -L . --- -o \-- l'-=

BP"

P,

P.

P,

P.

4-34

19.

'a

Alternator Brush Inspection

17. Measure the length of both brushes (A)with a

vernier caliper {B).

. lf either brush isshorterthanthe service limit,

replace the brush assembly.. lf brush length is OK, go to step '18.

Alternator Brush Length:

Standard (New): 10.5 mm (0.41 in.)

Service Limit: 1.5 mm (0.06 in.)

Rotor Slip Bing Test

18. Check that there is continuity between the slip rings

{A).

. lf there is continuity, go to step 19.. lf there is no continuity, replacethe alternator.

Check that there is no continuity between each slip

ring and the rotor (B) and the rotor shaft (C).

. lf there is no continuity, goto step 20.. lf there is continuity, replace the alternator.

\"

Page 70 of 1139

Stator Test

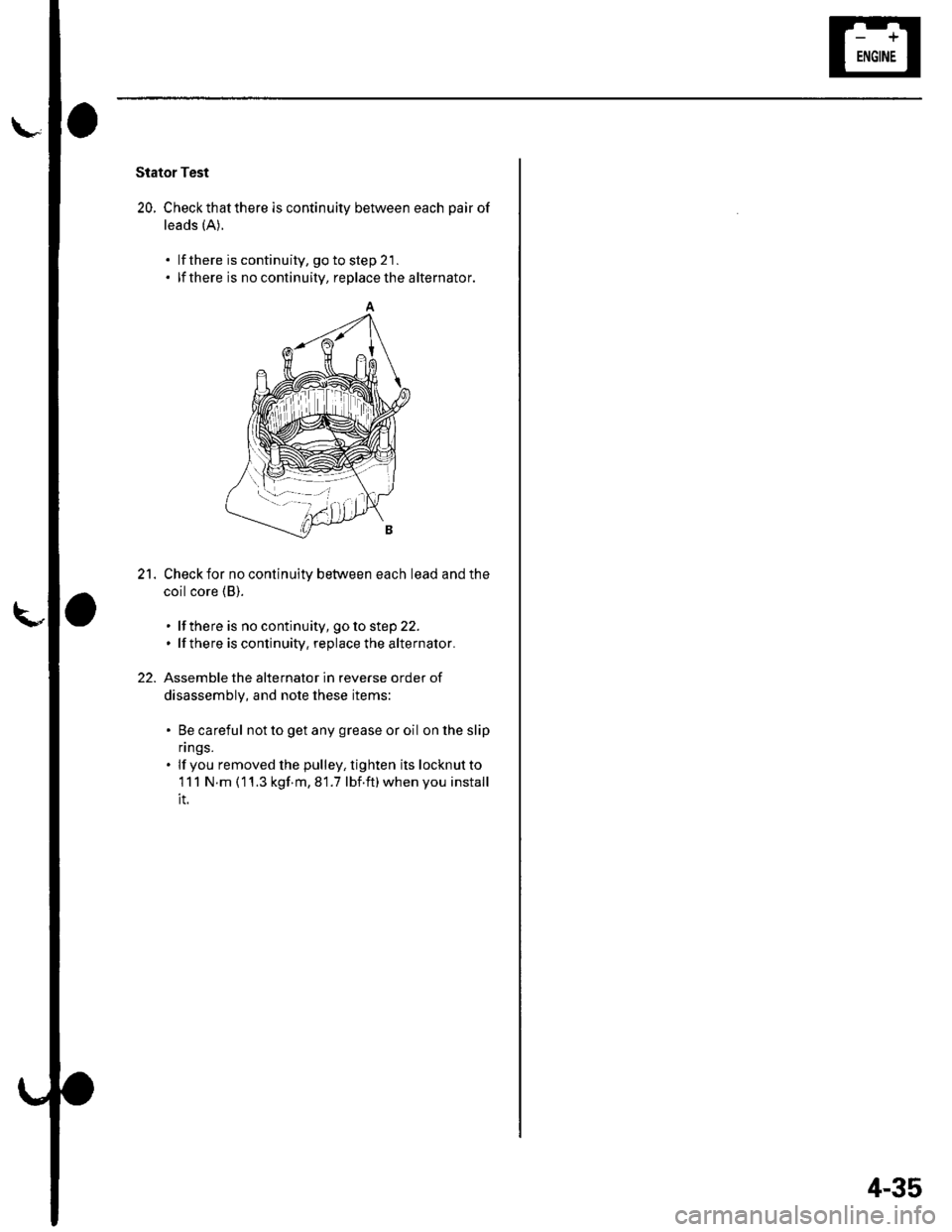

20. Checkthatthere is continuity between each pair of

leads (A).

lf there is continuity, go to step 21 .

lf there is no continuity, replace the alternator.

Check for no continuity between each lead and the

coil core (B).

. lf there is no continuity, goto step 22.. lfthere is continuity, replace the alternator.

Assemble the alternator in reverse order of

disassembly, and note these items:

. Be careful not to get any grease or oil on lhe slip

n ngs.. lf you removed lhe pulley, tighten its locknutto

111 N.m (11.3 kgf m,81.7 lbf.ft)whenyou install

it.

21.

22.

'--l-- --i

4-35