indicator relay HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 57 of 1139

Gharging System

Charging Circuit Troubleshooting

lf the charging system indicator does not come on or

does not go off, or the battery is dead or low, test these

items in the order listed below:

Battery (see page 22-50)

Charging system indicator

Alternator and regulator circuit

Alternator control system

Charging System Indicator Test

1. Turn the ignition switch ON {ll).

Does the chatging system indicator come on?

YES Go to step 2.

NO Go to step 3.

2. Start the engine.

Does the charging system indicator go off?

YES-Charging system indicator circuit is OK. Go

to the Alternator and Regulator circuit Test. t

NO-Go to step 3.

3. Turn the ignition switch OFF.

4. Troubleshoot the multiplex control system (see

page 22 172).

ls the multiplex control system OK?

YES Go to step 5.

NO Check the multiplex control system as

indicated by the diagnostic trouble code (DTC) (see

step 8 on page 22-172).1

5. Disconnect the engine wire harness 6P connector

from the starter sub harness 6P connector.

4-22

\"4

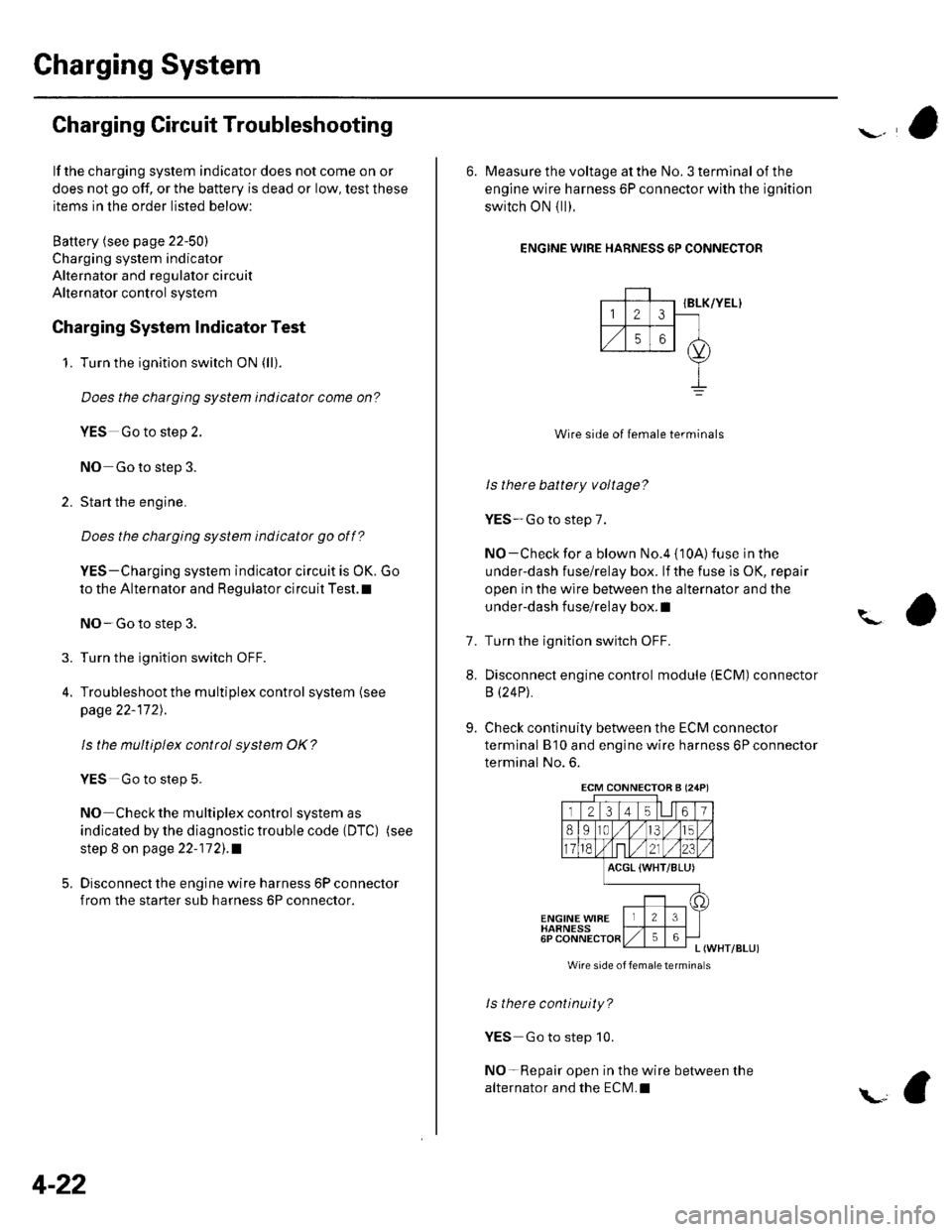

6. Measure the voltage at the No. 3 terminal of the

engine wire harness 6P connector with the ignition

switch ON { ll).

ENGINE WIRE HARNESS 6P CONNECTOR

IBLK/YEL}

Wire side of female terminals

ls there battery voltage?

YES-Go to step 7.

NO-Check for a blown No.4 {10A) fuse in the

under-dash fuse/relay box. lf the fuse is OK, repair

open in the wire between the alternator and the

under-dash fuse/relay box. I

Turn the ignition switch OFF.

Disconnect engine control module (ECM) connector

B (24P).

Check continuity between the ECM connector

terminal B'10 and engine wire harness 6P connector

terminal No. 6.

?

7.

8.

9.

ACGL {WHT/BLU)

ENGINE WIBEHARNESS6PL (WHT/BLUI

Wire side of femaletermina s

ls there continuity?

YES Go to step 10.

NO-Repair open in the wire between the

alternator and the ECN4.I

ECM CONNECTOB A (24P)

Page 59 of 1139

Gharging System

Charging Circuit Troubleshooting (cont'd)

6. Start the engine. Hold the engine at 3,000 rpm with

no load (in Neutral) until the radiator fan comes on,

then let it idle.

7. Raise the engine speed to 2,000 rpm, and hold it

there.

8. Turn the headlights (high beam) on, and measure

voltage at the under-hood fuse/relay box terminal.

ls the voltage between 13.9 and 15.1 v?

YES-Go to step 9.

NO Repair or replace the alternator components

(see page 4-30).1

9. Read the amperage at '13.5 V.

NOTE: Adjust the voltage by turning the blower

motor, rear window defogger, brake lights. etc. ON.

ls the amperage 604 ot morc?

YES-Alternator/regulator operation is OK. I

NO Repair or replace the alternator components(see page 4-30).1

4-24

\,

Alternator Control System Test

NOTE: After troubleshooting, perform the engine

control module (ECM) idle learn procedure (see page

11-139).

1 . Check for proper operation of the electrical load

detector (ELD) by checking the malfunction

indicator lamp (MlL) (see page 1 l-3). lf a DTC is

present, diagnose and repair the cause before

continuing with this test.

2. Disconnect the engine wire harness 6P connector

from the starter sub harness 6P connector.

3. Start the engine, and turn the headlights (high

beam) ON,

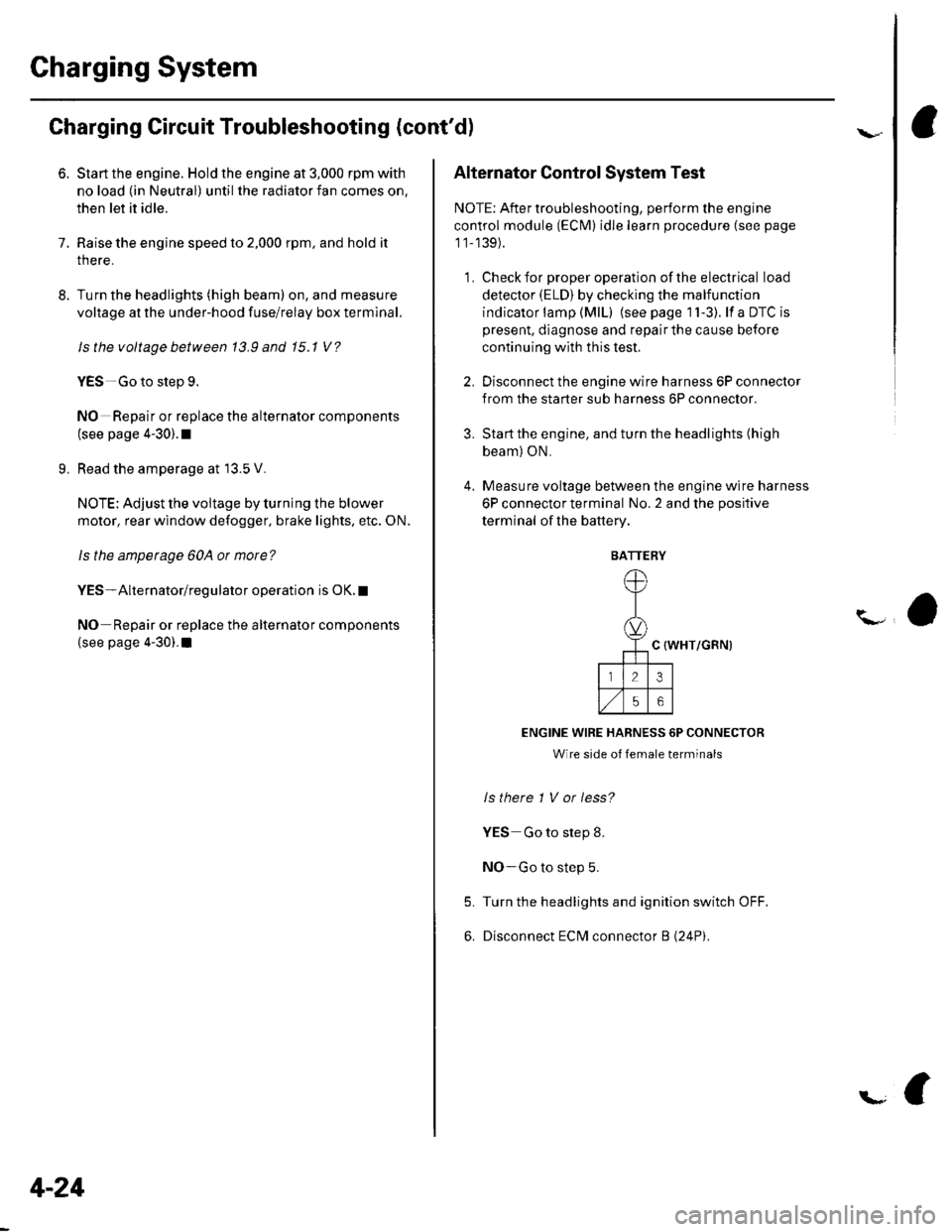

4. Measure voltage between the engine wire harness

6P connector terminal No. 2 and the positive

terminal of lhe battery.

C {WHT/GRN)

ENGINE WIRE HARNESS 6P CONNECTOR

Wire side of female terminals

ls there 1 V or less?

YES Go to step 8.

NO-Go to step 5.

Turn the headlights and ignition switch OFF.

Disconnect ECM connector B (24P).

5.

6.

BATTERY

Page 73 of 1139

Cruise Control

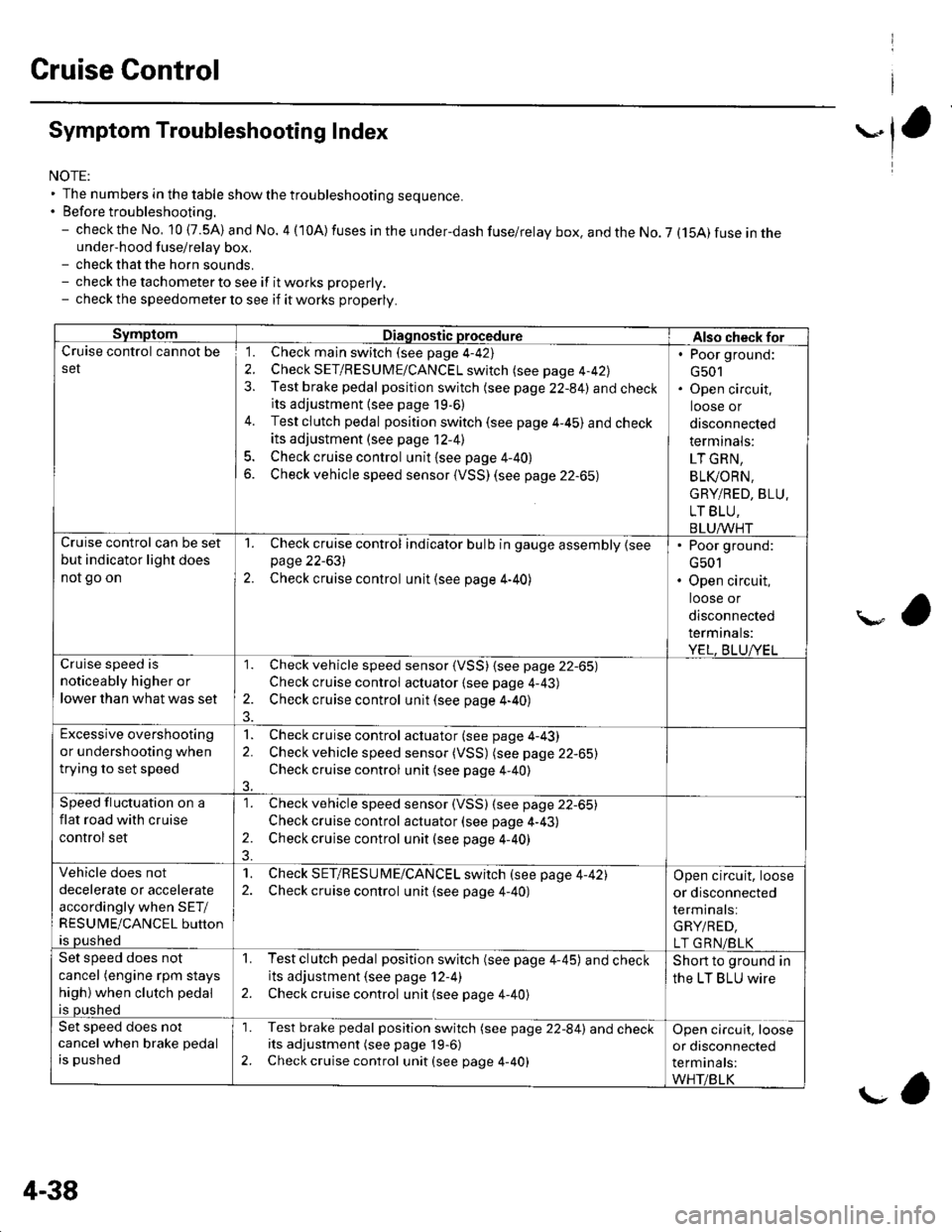

Symptom Troubleshooting Index

NOTE:' The numbers in the table showthetroubleshooting sequence.. Before troubleshooting.- check the No, 10 (7.5A) and No. 4 (10A) fuses in the under-dash fuse/relay box. and the No. 7 (15A) fuse in theunder-hood fuse/relay box,- check that the horn sounds.- check the tachometer to see if it works properly.- check the speedometer lo see if it works properly.

SymptomDiagnostic procedureAlso check forCruise control cannot be

set

1. Check main switch (see page 4-42)

2. Check SET/RESUME/CANCEL switch (see page 4-42)

3. Test brake pedal position switch (see page 22-84) and checkits adjustment {see page 19,6)

4. Test clutch pedal position switch (see page 4-45) and check

its adjustment (see page 12-41

5. Check cruise control unit {see page 4-40}

6. Check vehicle speed sensor (VSS) (see page 22-65)

. Poor ground:

G501. Open circuit,

loose or

disconnected

term inals:

LT GRN,

BLI(ORN.

GRY/RED, BLU.

LT BLU,

BLUAA/HTCruise control can be set

but indicator light does

not go on

1. Check cruise control indicator bulb in gauge assembly {seepage 22-631

2. Check cruise control unit (see page 4-40)

. Poor ground:

G501. Open circuit,

loose or

disconnected

termrnats:

YEL, BLUA/ELar, 'i.a c^aa.l ic

noticeably higher or

lower than what was set

1. Check vehicle speed sensor (VSS) {see page 22-65)

Check cruise control actuator {see page 4-43)

2. Check cruise control unit (see page 4-40)

Excessive overshooting

or undershooting when

trying to set speed

1. Check cruise control actuator (see page 4-43)

2. Check vehicle speed sensor (VSS) (see page 22-65)

Check cruise control unit (see page 4-40)

3.

Speed fluctuation on a

flat road with cruise

control set

1. Check vehicle speed sensor (VSS) (see page 22-65)

Check cruise control actuator (see page 4-43)

2. Check cruise control unit (see page 4-40)

Vehicle does not

decelerate or accelerate

accordingly when SET/

RESUME/CANCEL button

is pushed

1. Check SET/RESU ME/CANCEL switch (see page 4-42)2. Check cruise control unit {see page 4-40)

Open circuit, loose

or disconnected

terminals:

GRY/RED,

LT GRN/BLKSet speed does not

cancel (engine rpm stays

high) when clutch pedal

is pushed

1. Testclutch pedal position switch (see page 4-45) and checkits adjustment (see page 12-4)

2. Check cruise control unit (see page 4-40)

Short to ground in

the LT BLU wire

Set speed does not

cancel when brake pedal

is pushed

'1. Test brake pedal position switch (see page 22-84) and checkits adjustment (see page 19-6)

2. Check cruise control unit (see page 4-40)

Open circuit, loose

or disconnected

terminals:

WHT/BLK

4-38

g,

Page 76 of 1139

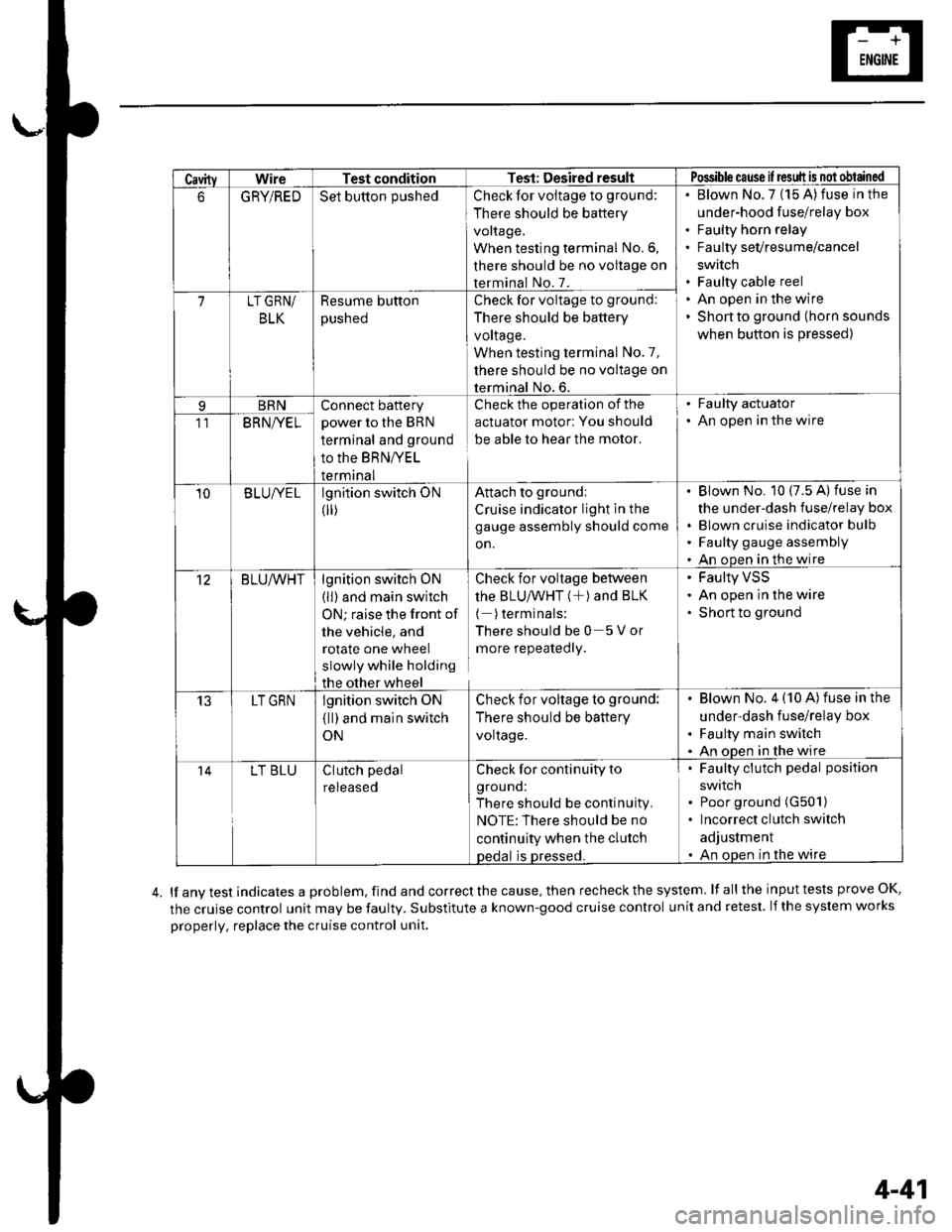

CavityWireTest conditionTest: Desired resultPossible cause il result is not obtained

6GRYiREDSet button pushedCheck for voltage to ground:

There should be battery

voltage,

When testing terminal No.6,

there should be no voltage on

terminal No. 7.

Blown No.7 (15 A)fuse in the

under-hood fuse/relay box

Faulty horn relay

Faulty sevresume/cancel

swrtch

Faulty cable reel

An open in the wire

Shon to ground (horn sounds

when button is pressed)

7LT GRN/

BLK

Resume button

pusneo

Check for voltage to ground:

There should be battery

voltage.

When testing terminal No.7,

there should be no voltage on

terminal No. 6.

BRNConnect battery

power to the BRN

terminal and ground

to the BRNIVEL

termrnal

Check the operation of the

actuator motor: You should

be able to hear the motor.

. Faulty actuator. An open in the wire11BRNI/EL

10B LUIVE Llgnition switch ON

0r)

Attach to groundi

Cruise indicator light in the

gauge assembly should come

on.

Blown No. 10 (7.5 A) fuse in

the under-dash fuse/relay box

Blown cruise indicator bulfl

Faulty gauge assembly

An open in the wire

12BLU/VVHTlgnition switch ON

(ll) and main switch

ON; raise the front of

the vehicle, and

rotate one wheel

slowly while holding

the other wheel

Check for voltage between

thE BLU/VVHT (+) ANd BLK

( )terminals:

Thereshouldbe0 5Vor

more repeatedly.

Faulty VSS

An open in the wire

Short to ground

13LT GRNlgnition switch oN

{ll) and main switch

ON

Check for voltage to ground:

There should be battery

voltage.

Blown No. 4 (10 A)fuse in the

under-dash fuse/relay box

Faulty main switch

An oDen in the wire

14LT BLUClutch pedal

reteaseo

Check for continuity to

grouno:

There should be continuity.

NOTE:There should be no

continuity when the clutch

oedal is Dressed.

Faulty clutch pedal position

swtlcn

Poor ground (G501)

Incorrect clutch switch

adjustment

An open in the wire

lf any test indicates a problem, find and correct the cause, then recheck the system. lf all the input tests prove OK,

the cruise control unit may be faulty. Substitute a known-good cruise control unit and retest. lf the system works

properly, replace the cruise control unit.

4-41

Page 304 of 1139

MIL Circuit Troubleshooting

1. Connect an OBD ll scan tool/Honda PGM Tester

(see page 11-3).

2. Turn the ignition switch ON (ll) and read the OBD ll

scan tool/Honda PGM Tester.

Does the OBD ll scan tool/Honda PGM Tester

communicate with the ECM?

YES Go to step 3.

NO Go to troubleshooting " DLC Circuit

Troubleshooting" (see page 11-109).

3. Check the OBD ll scan tool/Honda PGM Testerfor

DTCs.

Are any DTCs ind icated?

YES Go to the DTC Troubleshooting Index.

NO-Go to step 4.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON (ll)and watch the

lMalfunction Indicator Lamp (MlL).

Does the MIL come on and stay on for more than

20 seconds aftet turning the ignition switch

oN (tr)?

YES lf the MIL always comes on and stays on, go

to step 76. But if the lMlL sometimes works

normally, first check for these problems.

. An intermittent short in the wire between the

ECIM (E29) and the data link connector (DLC).

. An intermittent short in the wire between the

ECM (E31) and the gauge assembly.

NO lf the MIL is always off, go to step 6. But if the

lvllL sometimes works normally, first check for

these problems.

. A loose No. 10 METER (7.5A) fuse in the under

dash fuse/relay box.. A loose No. 20 lG (40A) (Canada: 50A)Iuse in the

under-hood fuse/relay box.. A ioose No. 6 ECU (ECM) (15A) fuse in the under-

hood fuse/relay box.

. A loose No. 17 FUEL PUMP (15A)fuse in the

under-dash fuse/relay box.. A poor connection at ECM terminal E31.. An intermittent open in the GRN/ORN wire

between the ECM (E31) and the gauge assembly.. An intermittent short in the wire between the

ECM (A21) and the manifold absolute pressure

(MAP) sensor.. An intermittent short in the wire between the

ECI\4 (A20) and the throttle posilion (TPi sensor.. An intermittent short in the wire between the

ECM (E5) and the fuel tank pressure (FTP) sensor.

6. Turn the ignition switch OFF.

7. Turn the ignition switch ON (ll).

ls the low oil pressure light on?

YES Go to step 10.

NO-Go to step 8.

8. Inspectthe No. 10 l\4ETER (7.5A)fuse inthe under-

dash fuse/relay box.

ls the luse OK?

YES Go to step L

NO Repair shon in the wire between No. 10

METER (7.5A)fuse and the gauge assembly. Also

replacethe No. 10 METER {7.5A) fuse.l

9. Inspect the No. 20 lG1 (40A) (Canada: 50A) fuse in

the under-hood fuse/relay box.

ls the f use OK?

YES Repair open in the wire between the No. 20

lG (40A) {Canadar 50A)fuse and the gauge

assembly. lf the wire is OK, test the ignition switch

{see page 22 53).

NO Repair short in the wire between No. 20 lG

(40A) lCanada: 50A)fuse and the under'dash fusel

relay box. Also replace the No.20 lG (40Ai

(Canada: 50A) fuse.I

(conr'd)

11-97

Page 365 of 1139

Fuel Supply System

1.

4,

Low Fuel Indicator Test

Do the fuel gauge sending unit test (see page 11,

rcol.

. lf the system is OK, go to step 2.. lf the system has any malfunction, repair it.

Turn the ignition switch OFF. Remove the No. 9

BACK UP (10A) fuse from the under-hood fuse/

relay box for at least 30 seconds, then reinstall it.

Turn the ignition switch ON (ll) with the float at the

E (EMPry) position.

. lf the low fuel indicator is on, go to step 4.. lf the low fuel indicator is not on, refer to the low

fuel indicator Circuit Diagram (see page 22-58)

and check the circuit.

Turn the ignition switch OFF. Remove the No. 9

BACK UP (10A) fuse from the under-hood fuse/

relay box for at least 30 seconds, then reinstall it.

Lift the float above the LOW position.

. lf the lowfuel indicatorgoes off,the system is OK.. lf the low fuel indicator is still on, refer to the low

fuel indicator Circuit Diagram {see page 22-58),

and check the circuit.

11-158

\,

Page 533 of 1139

EPS Components

11.

12.

DTC Troubleshooting (cont'dl

Substitute a known-good EPS control unit, and

connect all the disconnected connectors.

Sta rt the engine, and turn the steering wheel from

lock to lock several times.

Does the EPS indicator come on?

YES Go to step 13.

NO -Check for loose or poor connections at the

EPS control unit and the motor connections. lf the

connections are good, replace the EPS control unit

and recheck.l

Stop the engine, and verity the DTC.

ls DTC 43 indicated?

YES-Replace the steering gearbox motor and

recheck. tl

NO-Perform the appropriate troubleshooting for

the code indicated.l

13.

17-42

DTC 47: EPS Control Unit lnternal Circuit(Power Relay)

1. Clear the DTC.

2. Start the engine.

Does the EPS indicator come on?

YES-Go to step 3,

NO-Check for loose wires or poor connections, lf

the connections are good, the system is OK at this

time.I

3. Stop the engine, and verify the DTC.

ls DTC 47 indicated?

YES Check for loose EPS control unit connectors.

lf necessary, substitute a known-good EPS control

unit and recheck.l

NO Perform the appropriate troubleshooting for

the code indicated.I

(

Page 535 of 1139

EPS Components

DTC Troubleshootang (cont'dl

DTC 62: EPS Control Unit Internal Circuit

(Fail-safe Relay Stuck ON)

'1. Clear the DTC.

2. Start the engine.

Does the EPS indicator come on?

YES-Go to step 3.

NO-Check for loose wires or poor connections. lf

the connections are good, the system is OK at this

time.I

3. Stop the engine, and verify the DTC.

ls DTC 62 indicated?

YES-Check for loose or poor connections at the

EPS control unit. lf the connections are good,

substitute a known-good EPS control unit. lf the

symptom/indication goes away, replace the

original EPS control unit and recheck.l

NO-Perform the appropriate troubleshooting for

the code indicated. t

17-44

DTC 64: Battery Voltage is Excessively Low

(Fail-safe Relay Contact Failure and Motor

Voltage FallOff)

1. Clear the DTC.

2. Start the engine.

Does the EPS indicatot come on?

YES Go to step 3.

NO Check for loose wires or poor connections. lf

the connections are good, the system is OK at this

trme.l

3. Stop the engine, and verify the DTC.

ls DTC 64 indicated?

YES Go to step 4.

NO Perform the appropriate troubleshooting for

the code indicated.

4. Check the No. '18 (604) fuse in the under-hood fuse/

relay box, and reinstallthe fuse if it is OK.

Is the f use OK?

YES Go to step 5.

NO Replace the fuse and recheck.l

5. Disconnect EPS control unit connector A (2P).

6. Measure the voltage between EPS control unit

connector A (2P) terminal No. 1 and body ground.

-Blwt{r/Bl.ur Hl

\9

I

ls there battety voltage?

YES - Check for loose or poor connections at the

EPS control unit connectors, and check for a poor

ground at G 15 1. lf necessary, substitute a known-

good EPS control unit and recheck.l

NO Repair open in the WHT/BLU wire between

the No. 18 (60,4)fuse and EPS control unit.l

(

Page 538 of 1139

EPS Indicator Circuit Troubleshooting

1.Turn the ignition switch ON (ll), start the engine,

and watch the EPS indicator.

Does the EPS indicator come on?

YES lf the EPS indicator comes on and goes off, it's

OK. lf the EPS indicator stays on or blinks. go to

step 12.

NO Go to step 2.

Turn the ignition switch OFF, then ON (ll) again,

and watch the brake system indicator,

Does the brake system indicator come on?

YES-Go to step 3.

NO Repair open in the indicator power source

circuit.l. Blown No. 10 (7.5A)fuse.

. Open in the wire between the No. 10 (7.5A) fuse

and gauge assembly.. Open circuit inside the under-dash fuse/relay box,. Faulty gauge assembly.

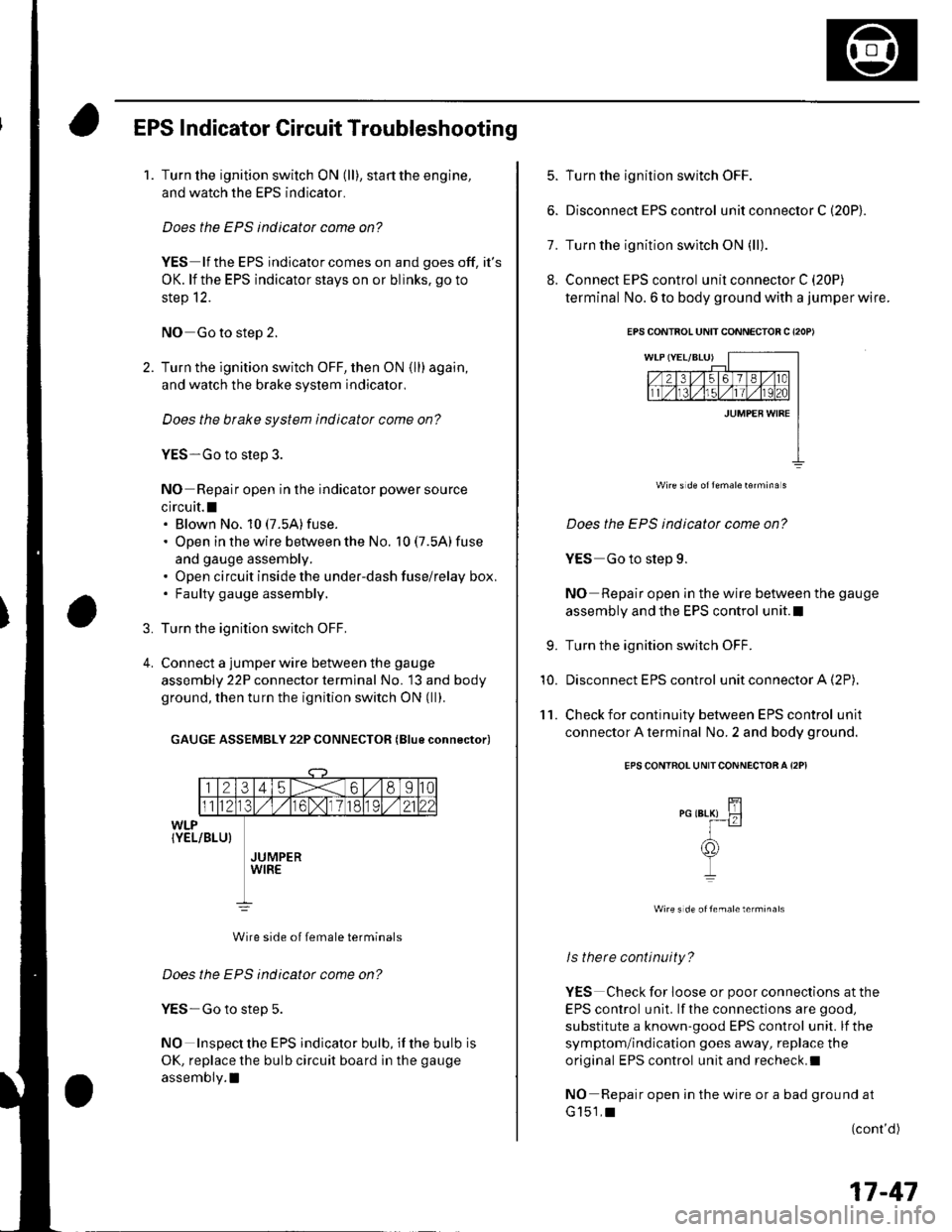

Turn the ignition switch OFF,

Connect a jumper wire between the gauge

assembly 22P connector terminal No. 13 and body

ground, then turn the ignition switch ON (ll).

GAUGE ASSEMBLY 22P CONNECTOR (Blue connector)

Wire side of female terminals

Does the EPS indicator come on?

YES-Go to step 5.

NO Inspect the EPS indicator bulb, if the bulb is

OK, replace the bulb circuit board in the gauge

assembly.l

3.

4.

5. Turn the ignition switch OFF.

6. Disconnect EPS control u n it connector C (20P).

7. Turn the ignition switch ON (ll).

8. Connect EPS control unit connector C (20P)

terminal No. 6 to body ground with a jumper wire.

Wire s d€ oflemale16rmina s

Does the EPS indicatot come on?

YES Go to step 9.

NO Repair open in the wire between the gauge

assembly and the EPS control unit.l

Turn the ignition switch OFF.

Disconnect EPS control unit connector A (2P),

Check for continuity between EPS control unit

connector A terminal No. 2 and body ground.

EPS CONTROL UNITCONNECTOA A I2PI

wire s de oftemale terminals

ls there continuity?

YES Check for loose or poor connections at the

EPS control unit. lf the connections are good,

substitute a known-good EPS control unit. lf the

symptom/indication goes away, replace the

original EPS control unit and recheck.I

NO Repair open in the wire or a bad ground at

G151,t(cont'd)

9.

10.

'l 1.

EPS CONTBOL UNIT CONNECTOB C {2OP)

17-47

Page 539 of 1139

EPS Components

I

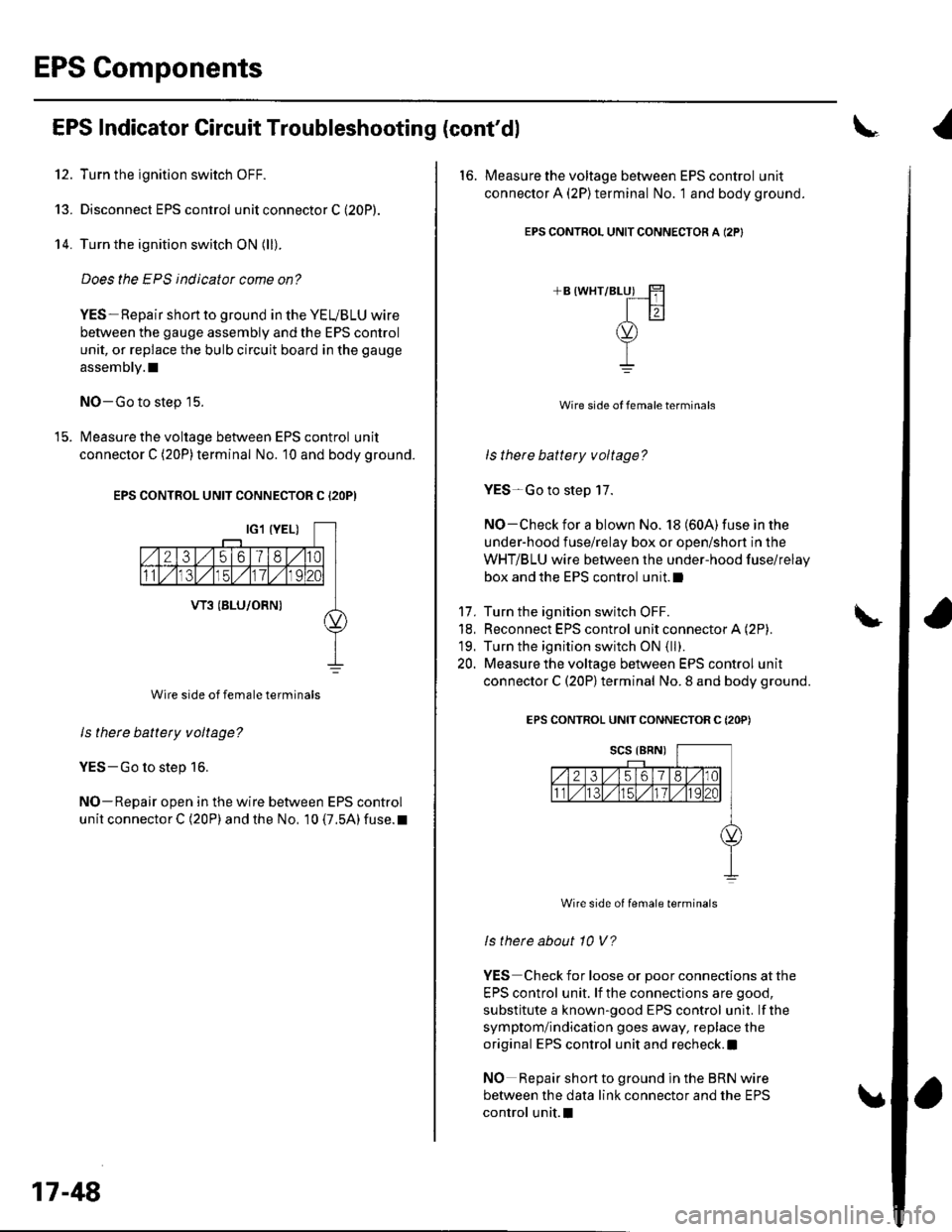

12.

EPS Indicator Circuit Troubleshooting (cont'dl

Turn the ignition switch OFF.

Disconnect EPS control unit connector C (20P).

Turn the ignition switch ON (ll).

Does the EPS indicator come on?

YES-Repair short to ground in the YEUBLU wire

between the gauge assembly and the EPS control

unit, or replace the bulb circuit board in the gauge

assembly.l

NO-Go to step 15.

Measure the voltage between EPS control unit

connector C (20P)terminal No. 10 and body ground.

EPS CONTROL UNIT CONNECTOR C I2OP)

Wire side of female terminals

ls there battery voltage?

YES-Go to step 16.

NO-Repair open in the wire between EPS control

unit connector C (20P) and the No, 10 (7.5A) fuse. t

13.

14.

17-48

16. Measure the voltage between EPS control unit

connector A (2P)terminal No. '1 and body ground.

EPS CONTROL UNITCONNECTON A (2P}

+B (WHT/BLUI H

Itr

v-L

17.

18,

19.

20.

Wire side of female terminals

ls there battery voltage?

YES-Go to step 17.

NO-Check for a blown No. 18 (604) fuse in the

under-hood fuse/relay box or open/short in the

WHT/BLU wire between the under-hood fuse/relay

box and the EPS control unit.l

Turn the ignition switch OFF.

Reconnect EPS control unit connector A (2P).

Turn the ignition switch ON (ll).

Measure the voltage between EPS control unit

connector C (20P)terminal No. 8 and body ground.

EPS CONTROL UNIT CONNECTOR C (2OP)

Wire side of female terminals

ls therc about 10 V?

YES Check for loose or poor connections at the

EPS control unit. lf the connections are good,

substitute a known-good EPS control unit. lf the

symptom/indication goes away, replace the

original EPS control unit and recheck.l

NO Repair short to ground in the BRN wire

between the data link connector and the EPS

control unit.I