Body ground HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1124 of 1395

Troubleshooting

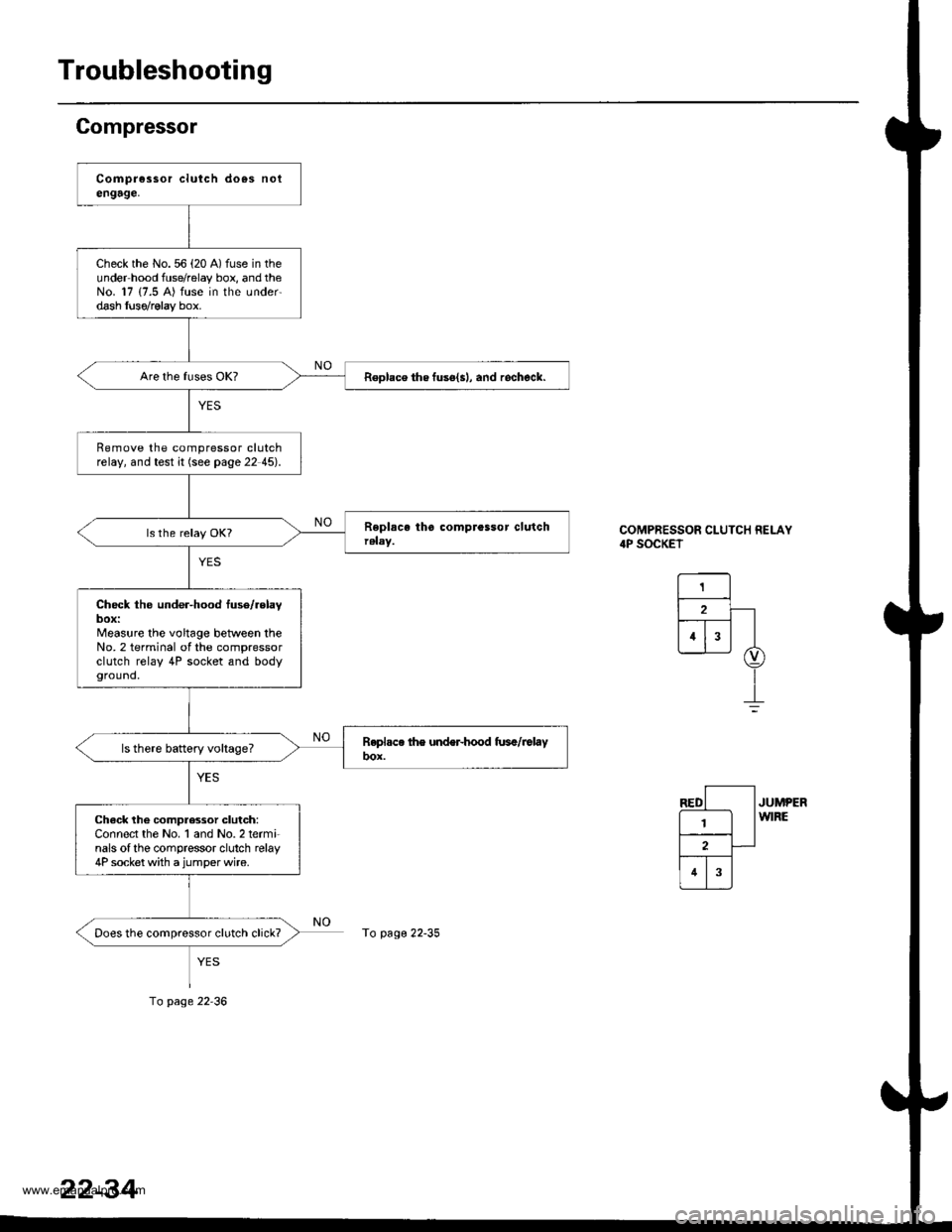

To page 22-35

Check the No. 56 (20 A) fuse in theunder hood fuse/relay box, and theNo. 17 (7.5 A) fuse in the underdash luso/rglay box.

Replace the fuso(sl, and r6check.

Remove the compressor clutchrelay, and test it (see page 22 45).

Check the under-hood fuse/relayDOX:Measure the voltage between theNo. 2 terminal of the compressorclutch relay 4P socket and bodyground,

Chack lhe complessor clutch:Connect the No. 1 and No. 2 termi-nals ofthe comoressor clutch relav4P socket with a jumper wire.

Does the comprossor clutch click?

22-34

To page 22-36

www.emanualpro.com

Page 1126 of 1395

Troubleshooting

Compressor (cont'dl

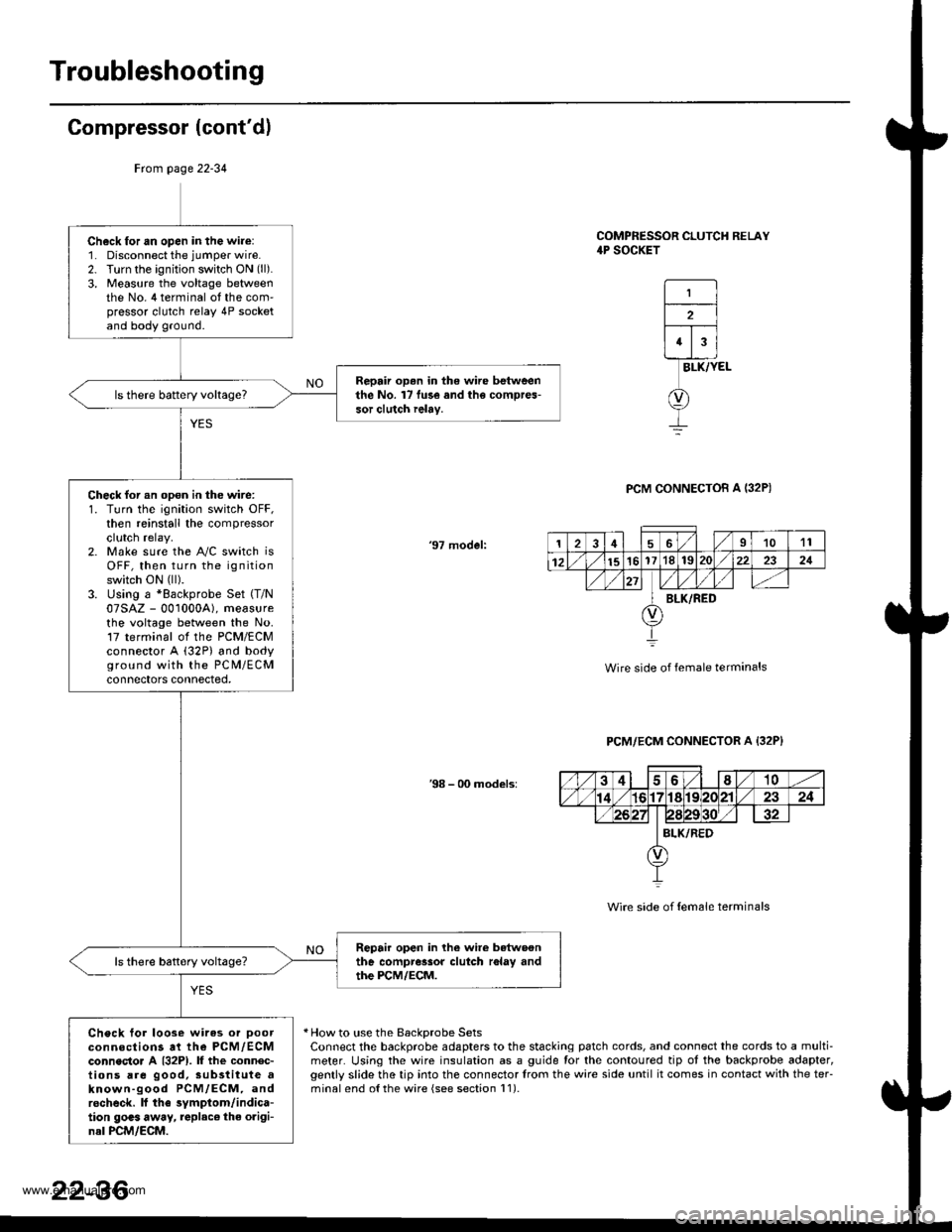

COMPRESSOR CLUTCH RELAY4P SOCKET

1

2

43

BLK/YEL

PCM CONNECTOB A I32P)

'97 model:

Wire side of female terminals

PCM/ECM CONNECTOR A {32P}

38 - 00 models:

Wire side of {em6le terminals

* How to use the BackDrobe SetsConnect the backprobe adapters to the stacking patch cords, and connect the cords to a multi-meter. Using the wire insulation as a guide for the contoured tip ot the backprobe adapter,gently slide the tip into the connector trom the wire side until it comes in contact with the teFminalend o{the wire {see section l1).

Frcm page 22-34

Ch6ck for an open in the wire:1. Disconnect the jumper wire.2. Turn the ignition switch ON (ll).

3, Measure the voltage betweenthe No. 4 terminal ot the com'pressor clutch relay 4P socketand body ground.

Repair op.n in the wire betweenthe No. l7 fu3e and the compres-sor clutch ielay.

Check for an opon in the wire:1. Turn the ignition switch OFF,then reinstall the compressorclutch relay.2. Make sure the A"/C switch isOFF, then turn the ignitionswitch ON (ll).

3. Using a *Backprobe Set (T/N

07SAZ - 001000A), measurethe voltage between the No.17 terminal ol the PCM/ECMconnector A (32P) and bodyground with the PC M/ECMconnectors connected,

Repair open in lhe wire betwoonthe compressor clutch r6lay andthe PCM/ECM.

Check tor loose wires or Doorconnections at the PCM,/ECMconnecto. A {32P1. lf the connec-tions are good, sub3titute aknown-good PCM/ECM, androcheck. lf the symptom/indica-tion goas away, replac€ the origi-nal PCM/ECM.

126I1011

12151617'181S222321

BLK/RED

22-36

www.emanualpro.com

Page 1127 of 1395

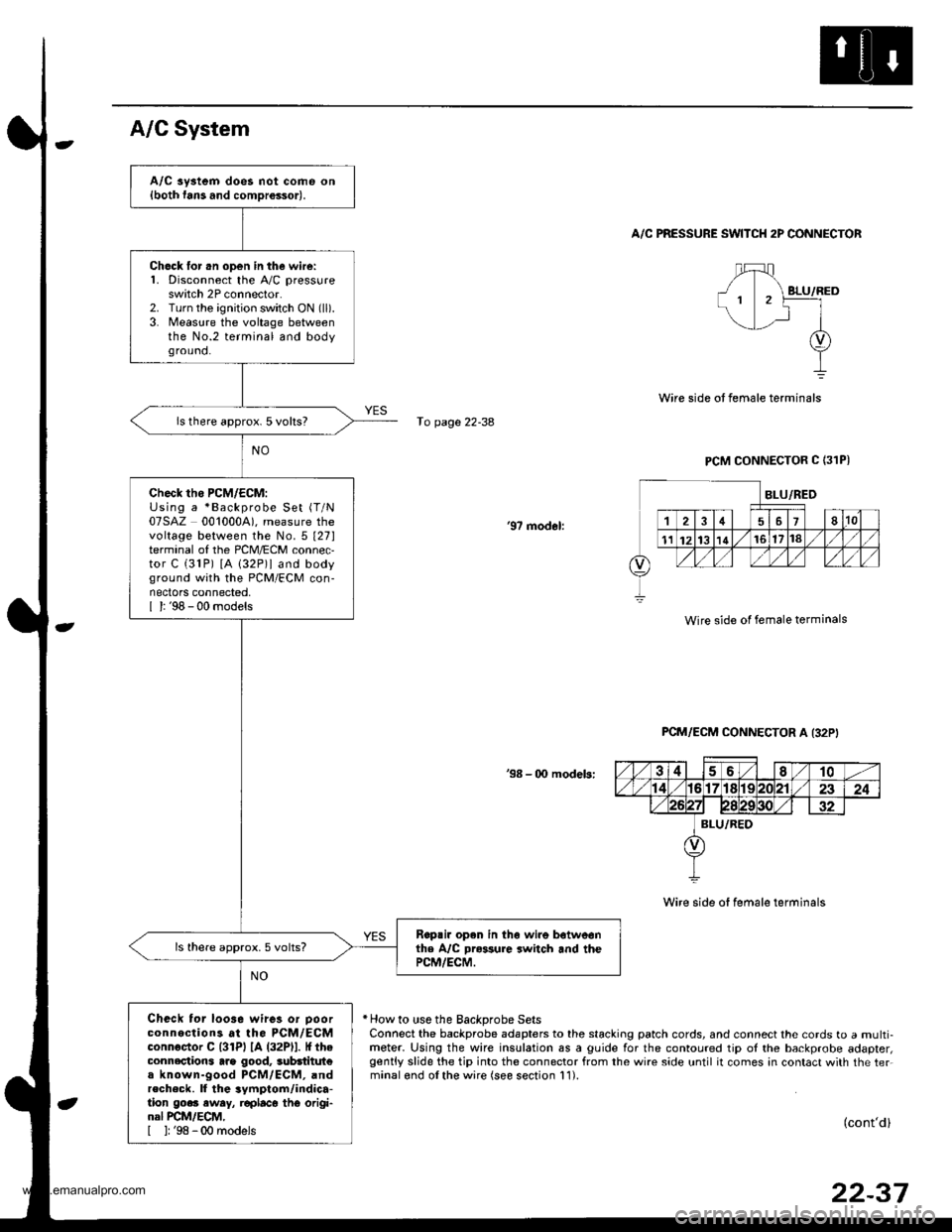

A/C aystem does not come on{both fans and comDrossor).

Ch6ck lor .n open in the wire:1. Disconnect the A,/C pressureswitch 2P connector.2. Turn the ignition switch ON (ll).

3. Measure the voltage betweenthe No.2 terminal and bodyground.

ls there approx. 5 volts?

check tho PcM/EcM:Using a *Backprobe Set (T/N

07SAZ 0010004). measure thevoltage between the No.5 t27lterminal of the PCM/ECM connec,tor C (31P) [A 132P)l and bodyground with the PCM/ECM con-nectors connected,I l: '98 - 00 models

Rop.ir open in th6 wire botweonthe A/C Dr*sure switch and thePCM/ECM.

ls there approx.5 volts?

Check tor loo3e wires or Doorconnections at the PCM/ECMconnoctor C l3lPl lA (32Pll. It theconnections arg good, 3ubdtitut€a known-good PCM/ECM, andrecheck. ll the 3ymptom/indica-tion go.. eway, r€placo thG origi-nal PCM/ECM,[ ]: '98 -00 models

A/C System

A/C PRESSURE SWITCH 2P CONNECTOR

fo page 22-38

PCM CONNECTOR C (31PI

'97 modol:

Wire side of female terminals

PCM/ECM CONNECTOR A I32P'

38 - 00 modeb:

Wire side of female terminals

* How to use the Backprobe SetsConnect the backprobe adapters to the stacking patch cords, and connect the cords to a multi-meter. Using the wire insulation as a guide for the contoured tip ol the backprobe adapter,gently slide the tip into the connector from the wire side until it comes in contact with the ter.minalond olthe wire (see section 11).

(cont'd)

22-37

www.emanualpro.com

Page 1128 of 1395

Troubleshooting

A/G System {cont'd)

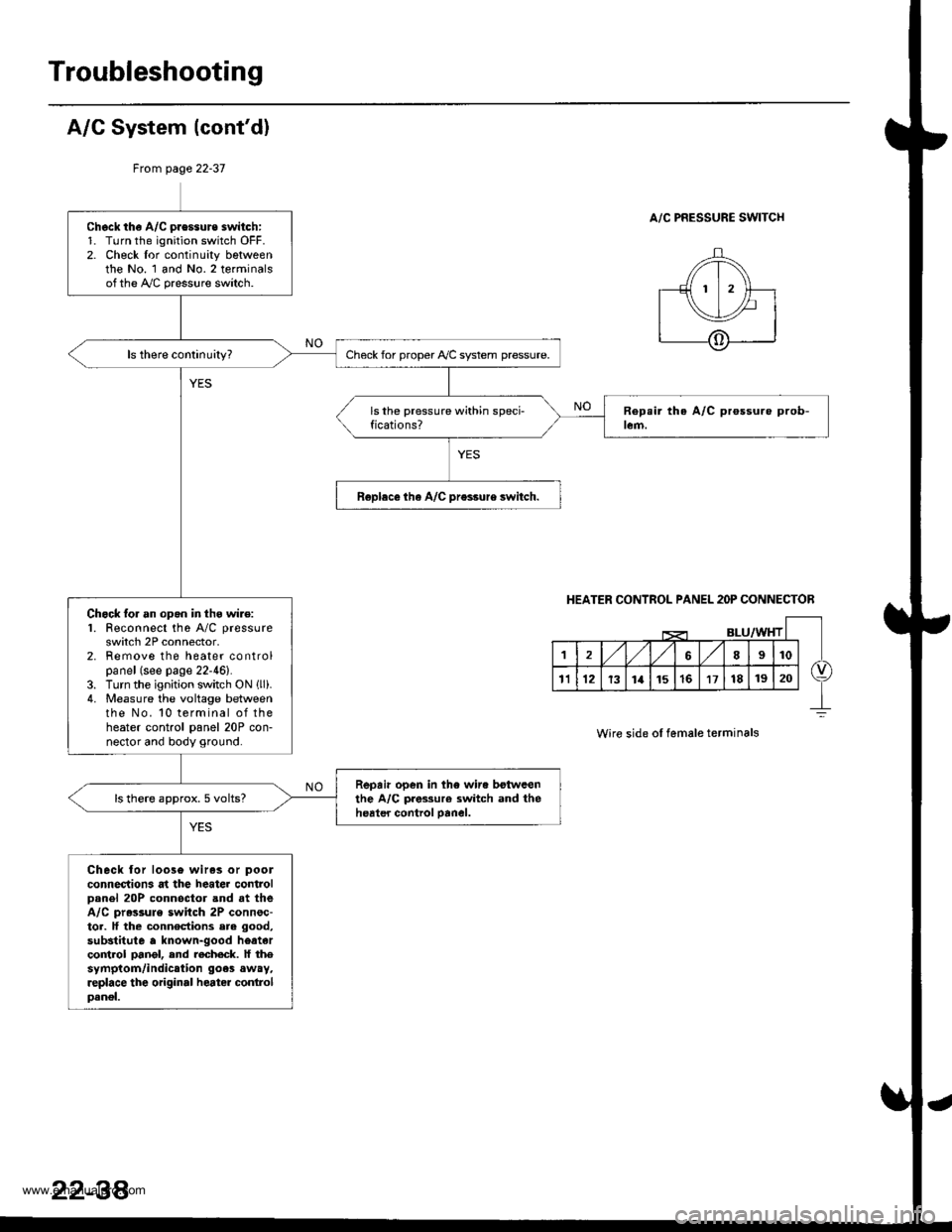

From page 22-37

A/C PRESSURE SWITCHCheck th€ A/C pressure switch:1. Turn the ignition switch OFF.2. Check lor continuity bgtweenthe No. 1 and No.2 terminalsofthe A,/C pressure switch.

Check for proper Ay'C system pressure.

Roplece tha A/C pr€ssure switch.

Chock lor an opgn in thg wire:1. Feconnect the A/C pressure

switch 2P connector,2. Remove the heater controlpanel (see page 22-46).3. Turn the ignition switch ON llli.4. Measure the voltage betweenthe No. 10 terminal of theheater control panel 20P con-nector and body ground.

Repair open in the wir. botwcenthe A/C pres3ur€ switch and theheater control oanel.ls there approx. 5 volts?

Check lor loos6 wiras or pool

connections at the heater controlDanel 20P connoctor and at theA/C pr.ssule switch 2P connsc-tor. lf the connections ere good,

substitute a known-good heatarco trol pangl, end recheck. lf thesymptom/indication goes away,replace the original heater conlrolpanel.

HEATER CONTROL PANEL 2OP CONNECTOR

Wire side ol female terminals

22-38'

www.emanualpro.com

Page 1129 of 1395

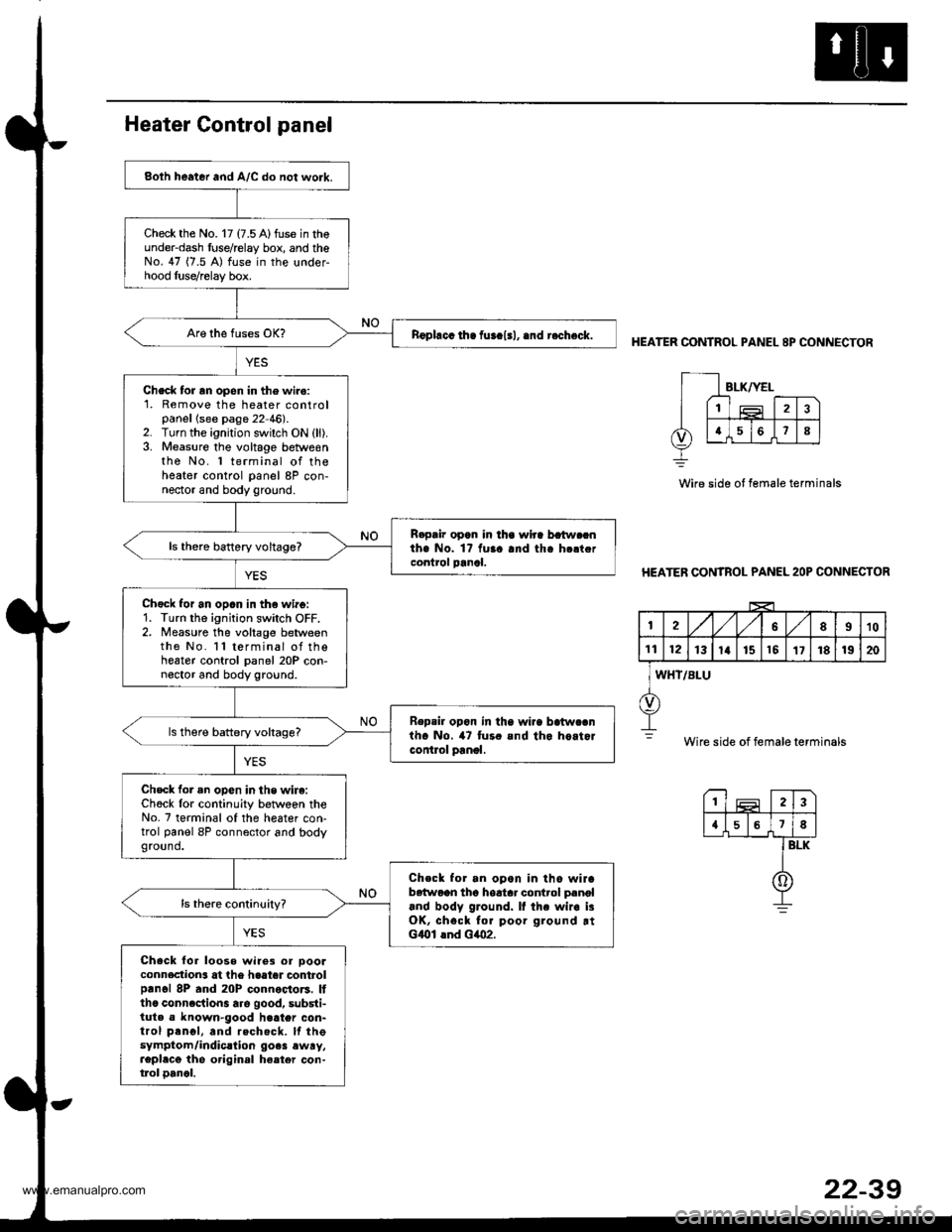

Both heater and A/C do not work.

Check the No. 17 (7.5 A)fuse in theunder-dash fuse/relay box, and theNo. 47 (7.5 A) fuse in the under-hood luse/relay box.

nophcc ih. fur.l.l, .nd r.check.

Check tor rn open in the wiro:1. Remove the heater controlpanellsee page 22 46).2. Turn the ignition switch ON (ll).3. Measure the voltage betweenthe No. 1 terminal of theheater control panel 8P con-nector and body ground.

R.pair opan in lha wlra batw.cnthe No. 1? fuaa and tha h.ltcrcontrol panal.ls thero battery voltage?

Chgck for an opan in th€ wirg:1. Turn the ignition switch OFF.2. Measure the voltage betweenthe No. l l terminal of thoheater control panel 20P con-noctor and body ground.

Repsil opon in tha wi.a batwcanth. No. 47 tur. and tho hoitorcontlol panol.

ls there battery voltags?

Check for an opon in the wire:Ch6ck lor continuity betwoen theNo. 7 terminal of the heater con-trol panel 8P connector and bodyground.

Check for an opon in tho wirab6{woon tho hoatar control p.noland body ground. It the wir. i3OK, chsck for poor ground rtGlOl lnd Glo2.

Check for loose wire3 or oooaconnection3 at the haater controlprnol 8P and 20P connoctors. Itthc conncction3 are good, substi-tuta a known-good h€ater con-trol prnol, and rechecft. lf thesymptom/indic.lion go.3 ewry,repl.cg the original ha.ter con-tlol oancl.

HEATER CONTROL PANEL 8P CONNECTOR

Wire side ot female terminals

HEATER CONTROL PANEL 2OP CONNECTOR

I2A,/1,/58910

1t12131a151517181920

WHT/BLU

Wire side of female terminals

23

{578

BLK

0

www.emanualpro.com

Page 1134 of 1395

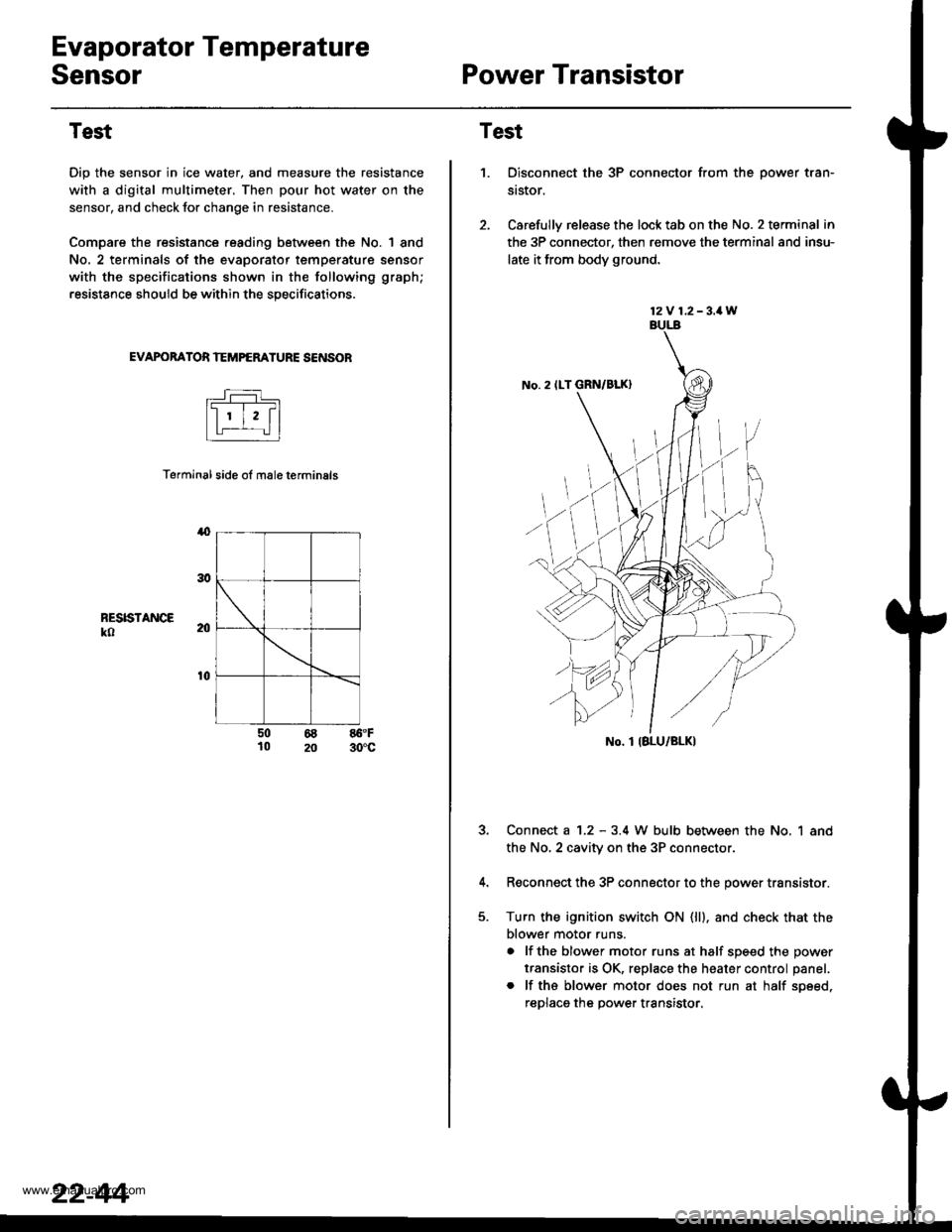

Evaporator Temperature

SensorPower Transistor

Test

Dip the sensor in ice water, and measure the resistance

with a digital multimeter. Then pour hot water on the

sensor, and check lor change in resistance.

Compare the resistance reading between the No. | 8nd

No. 2 terminals of the evaporator temperature sensor

with the specifications shown in the following graph;

resistance should be within the specifications.

EVAPOBATOR TEMPERATURE SENSOB

Terminal side ol male terminals

4

RESISTANCEko

t0

50 68 86.F10 20 30'c

22-44

12V 1.2-3.1W

No. 2 ILT GRN/BLK)

No. I IBLU/BLK)

Test

1.Disconnect the 3P connector from the oower tran-

st$or.

Carefully release the lock tab on the No. 2 terminal in

the 3P connector, then remove the terminal and insu-

late it from body ground.

Connect a 1.2 - 3.4 W bulb between the No, 1 and

the No,2 cavity on the 3P connectol

Reconnect the 3P connector to the power transistor.

Turn the ignition switch ON (ll). and check that the

blower motor runs.

a lf the blower motor runs at half soeed the oower

transistor is OK, replace the heater control panel.

. lf ths blower motor does not run at half soeed,

reDlaca the Dower transistor.

www.emanualpro.com

Page 1161 of 1395

Body Electrical

Speciaf Toofs ,...,..,.............-.23-2

Troubleshooting

Tips and Precautions ......,.,..........,.................. 23-3

Five-step Troubleshooting ........,.,.,...,,.,......... 23-5

Wire Color Codes ...,....,.. 23-5

Relay and Control Unit Locations

Engine Compartment ..,.,......,......................... 23-6

Dashboard ,.,.,..............-.- 23-7

Door ....................... .........23-10

Index to Cilcuits and Sysiems

Accessory Socket .. ,....,.,..,.,. 23-95*Airbags ................ .,....,. Sestion 24

Air Conditioning ,.,.,.... Section 22

Alternator ................... Section 4

Anti-lock Brake System {ABSI ................... Section 19'A/T Gear Position Indicator ....................... Section 1,1

Automatic Transmission System ...........,.. Section 14

Battery ................... ..............23-50

Blower Controls .,...,.,, Section 22

Charging System ....... Seqtion il

Clock -'98 Model ................ 23-98

Connector ldentification and Wire HarnessRouting .................. ......... 23.11

Cruise Control ............ Ssction 4

Dash Lights Brightness Contlo||er ..................... 23-90

Fan Conlrols ...,......,.... Section 10

Fuel Pump ,..,.,...,....,.... Section 11

Fuses...................... .,,.,.,.,.,,.,23-40*Gauges

Circuit Diagram ......-....-..23-58

Fuel Gauge .....,.,..... Section 11

Speedometer ..,..........,... 23-56

Ground Distribution ,....,.,...23-46

Hatch Glsss ODenor .........................,.,.,.,.,..,.,.,.,,. 23-121

Heater Controls .-........ Soction 21*Horns.,...,..,.,.,....... ................23"104*fgnition Switch ,,.,.,..,.,.,,.,.,.,23-51

lgnition Key Light System -'97 Mod6l .............. 23.88

-+

BODY

www.emanualpro.com

Page 1163 of 1395

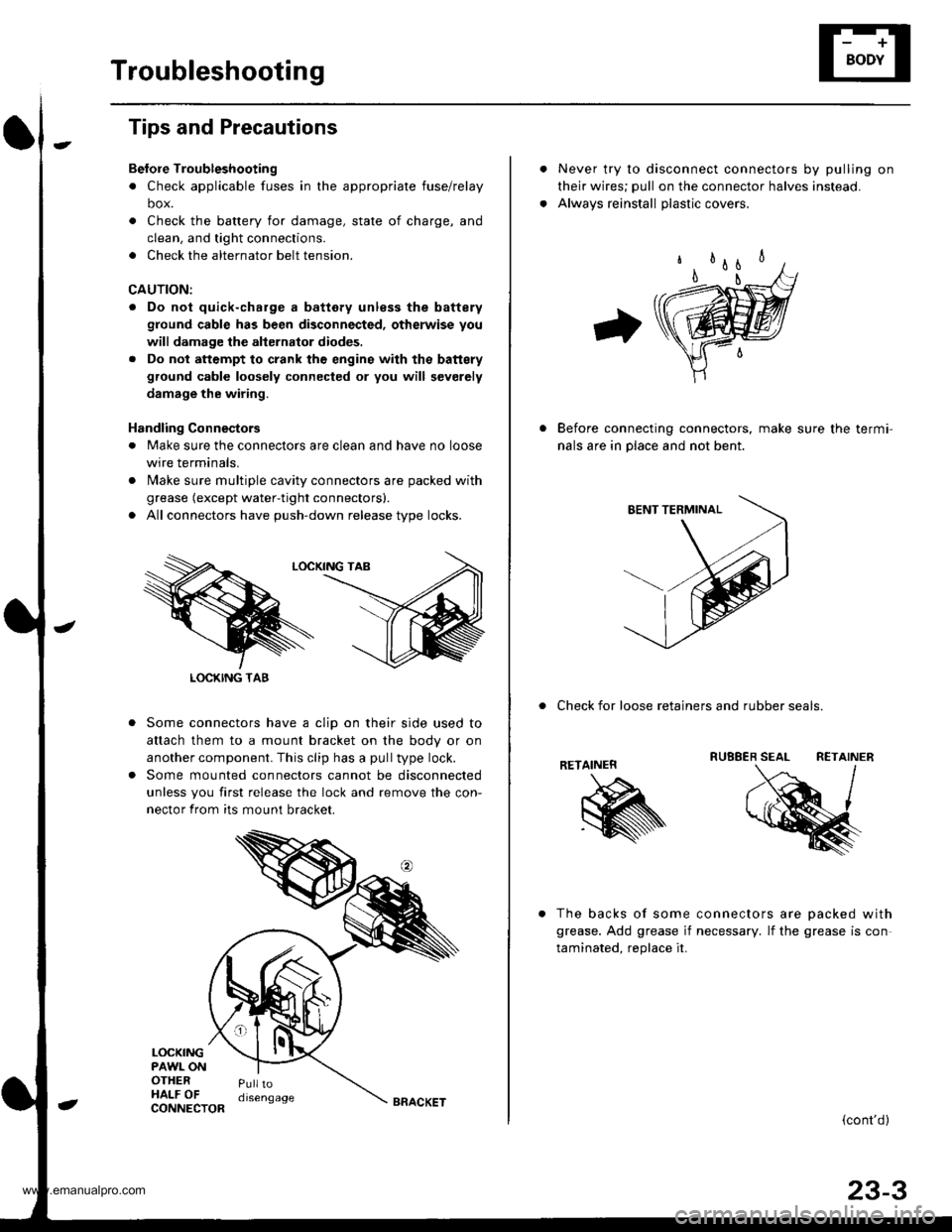

Troubleshooting

Tips and Precautions

Bef ore Troubleshootin g

. Check applicable fuses in the appropriate fuse/relay

box.

. Check the battery for damage, state of charge, and

clean. and tight connections.

. Check the alternator belt tension.

CAUTION:

. Do not quick-charge a battery unless the battery

ground cable has been disconnected, otherwise you

will damage the alternator diodes.

. Do not attempt to crank thc engins wilh the battery

ground cable loosely connected or you will severely

damage the wiring.

Handling Connestors

. Make sure the connectors are clean and have no loose

wire terminals,

. N4ake sure multiple cavity connectors are packed with

grease (except water-tight connectors).

. All connectors have push-down release type locks.

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKINGPAWL ONOTHERHALF OFPulltodisengage

LOCKING TAB

CONNECTORBRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead.

Alwavs reinstall olastic covers.

Before connecting connectors, make sure the termi-

nals are in place and not bent.

. Check for loose retainers and rubber seals.

RETAINER

The backs of some connectors are oacked with

grease. Add grease if necessary. lf the grease is con

taminated. reolace it.

{cont'd}

23-3

www.emanualpro.com

Page 1172 of 1395

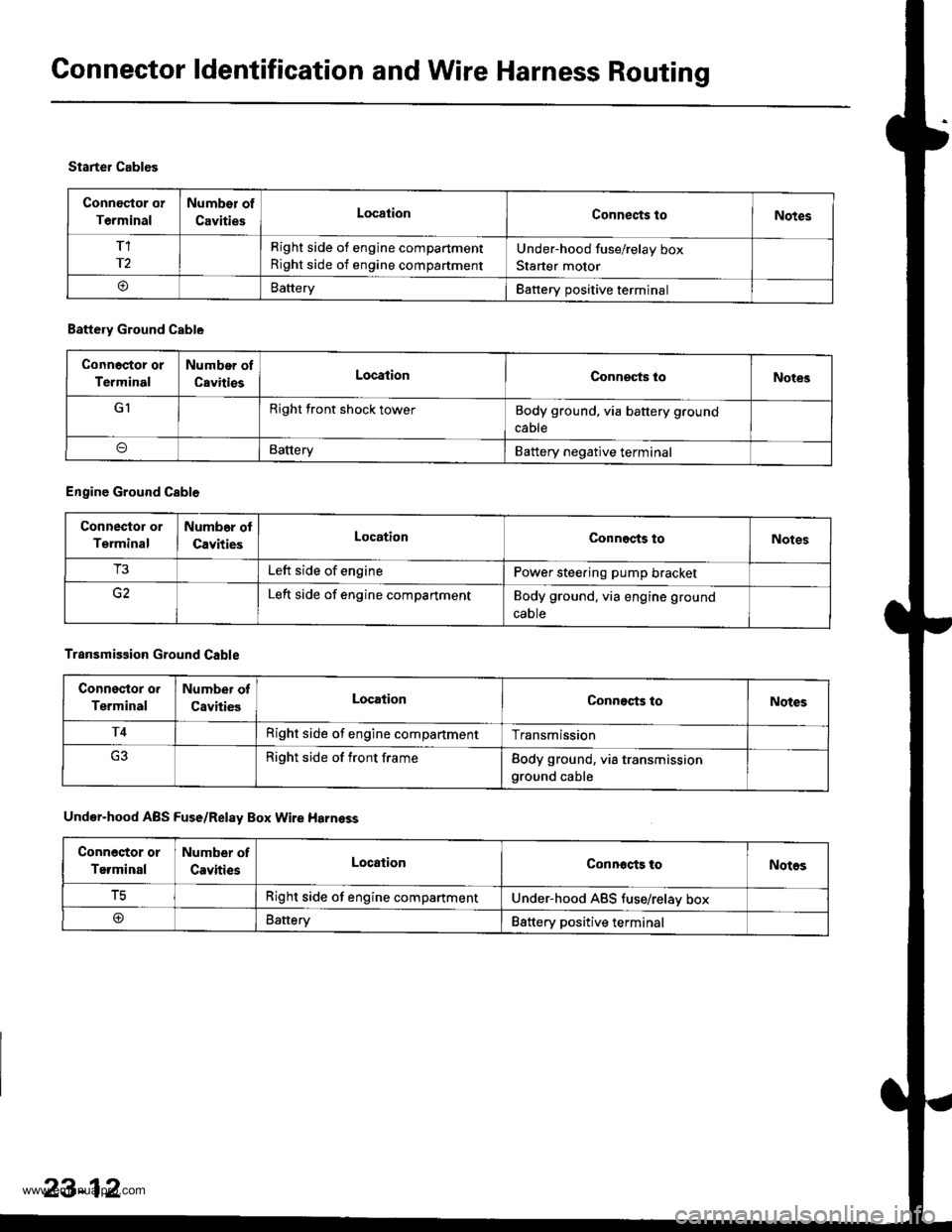

Connector ldentification and Wire Harness Routing

Connoctor or

Terminal

Number of

CavitiesLocationConnects toNotes

T1

r2

Right side of engine compartment

Right side of engine compartment

Under-hood fuse/relay box

Starter motor

oBatteryBattery positive terminal

Starter Cables

Battery Ground Cable

Connoctor or

Terminal

Number of

CavitiesLocationConneqts loNotes

GIRight front shock towerBody ground, via battery ground

cable

BatteryBattery negative terminal

Engine Ground Cable

Connector or

Terminal

Numb6r ol

CavitiesLocationConnects toNotes

T3Left side of enginePower steering pump bracket

Left side of engine compartmentBody ground. via engine ground

caote

Transmission Ground Cable

Connsstor o.

Terminal

Number of

CavitiesLocationConnects toNotes

T4Right side of engine compartmentTransmission

Right side of front frameBody ground, via transmissionground cable

Under-hood ABS Fuse/Relay Box Wire Harnsss

Conn6stor or

Terminal

Number of

CavitiesLocationConnocts toNotos

tcRight side of engine compartmentUnder-hood ABS tuse/relav box

@Battery88ttery positive terminal

23-12

www.emanualpro.com

Page 1176 of 1395

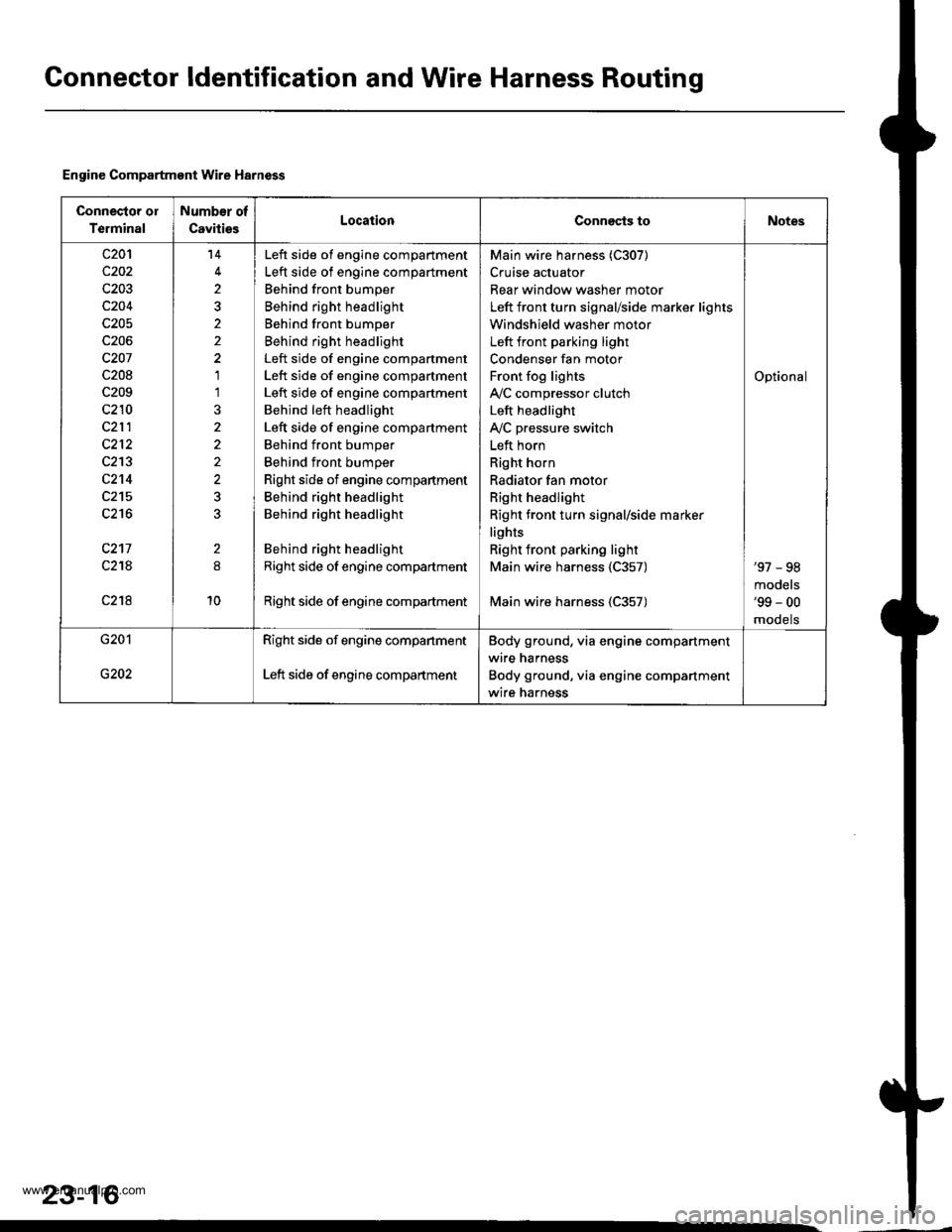

Gonnector ldentification and Wire Harness Routing

Engine Compartment Wire Harness

Connector ol

Terminal

Number of

CavitiesLocationConnects toNotes

c20'l

c202

c203

c204

c205

c206

c207

c208

c209

c210

c212

c213

c2't4

c215

c216

c217

c21A

c218

14

2

2

1'l

2

10

Left side of engine compartment

Left side of engine compartment

Behind front bumper

Behind right headlight

Behind front bumper

Behind right headlight

Left side of engine compartment

Left side of engine compartment

Left side of engine compartment

Behind left headlight

Left side of engine compartment

Behind front bumper

Behind front bumper

Right side of engine compartment

Behind right headlight

Behind right headlight

Behind right headlight

Right side of engine compartment

Right side of engine compadment

Main wire harness (C307)

Cruise actuator

Rear window washer motor

Left front turn signal/side marker lights

Windshield washer motor

Left front parking light

Condenser fan motor

Front fog lights

IVC compressor clutch

Left headlight

IVC pressure switch

Left horn

Right horn

Radiator fan motor

Right headlight

Right front turn signal/side marker

lights

Right front parking light

Main wire harness 1C357)

Main wire harness (C357)

Optional

'97 - 98

models'99 - 00

mooets

G201

G202

Right side of engine companment

Left side of engine compartment

Body ground, via engine compartment

wire harness

Body ground, via engine compartment

wire harness

23-16

www.emanualpro.com