charging HONDA CR-V 1997 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 282 of 1395

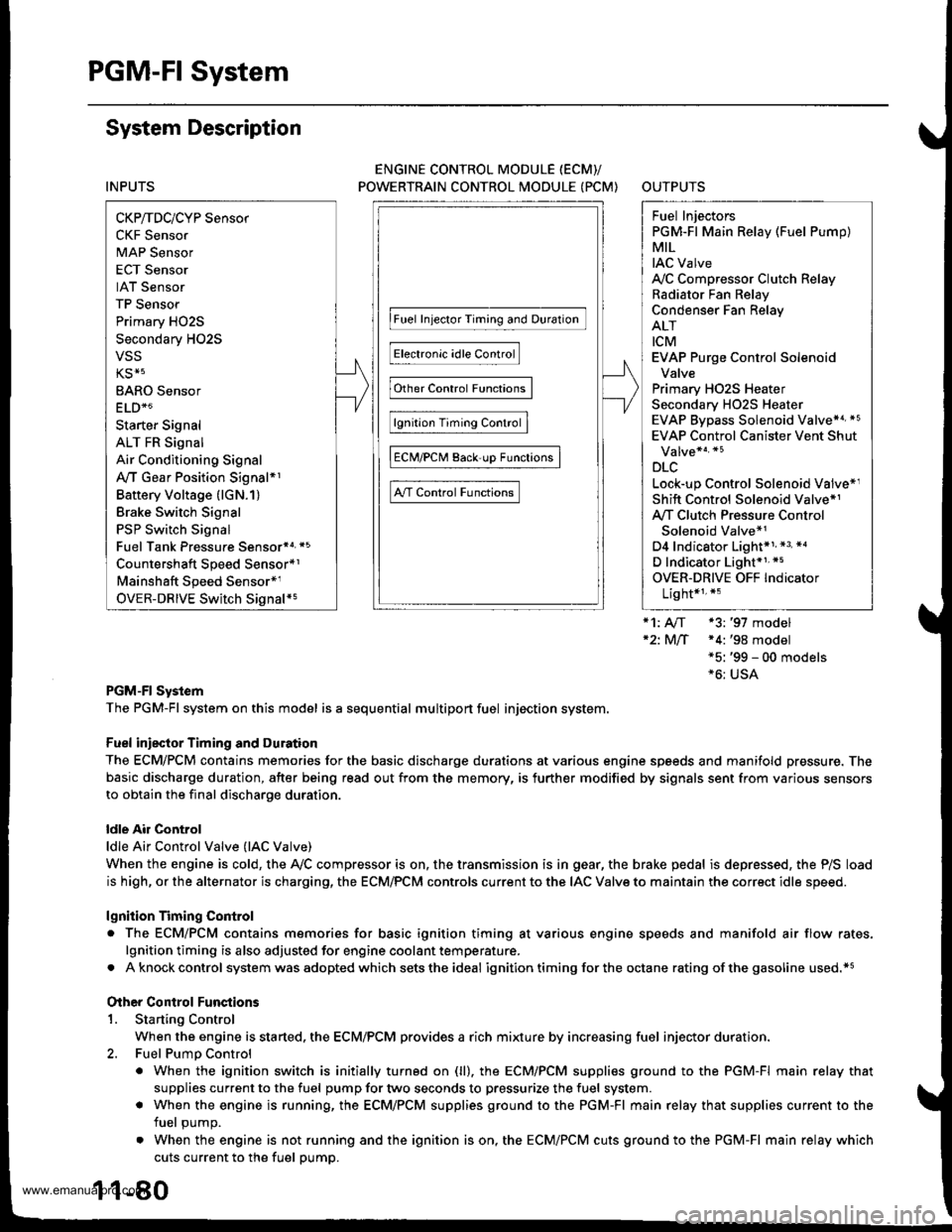

PGM-FI System

System Description

INPUTS

CKP/TDC/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

Primary HO2S

Secondary H02S

vss

KS*5

BARO Sensor

ELD*6

Starter Signal

ALT FR Signal

Air Conditioning Signal

Ay'T Gear Position Signal*1

Baftery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal

Fuel Tank Pressuae Sensor*4. *5

Countershaft Speed Sensor*1

Mainshaft Speed Sensor*r

OVER-DRIVE Switch Signal*s

ENGINE CONTROL MODULE (ECM)/

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

|iuel 1"j""- Th,rhg ""d Drrafr";-l

Et*-.nt"tdt"cont.orl

to,r*,c;;trffi;]

l.----.---:. .Lrgnrnon |lmrng Lonrror I

Ecir/PcM B*k',p Fr""il]

m;"t-ll-r*'io*l

Fuel Injectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

Ay'C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

tcM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S HeaterEVAP Bypass Solenoid Valve*a *5

EVAP Control Canister Vent Shut

DLC

Lock-up Control Solenoid Valve*l

Shift Control Solenoid Valve*1

Ay'T Clutch Pressure Control

Solenoid Valve*1

D4 Indicator Light'1 *3, *a

D Indicator Light,l *5

OVER-DRIVE OFF Indicator

Lighl*t *:

*1: A/T {3:'97 model'2: M/f +4:'98 model*5: '99 - 00 models"6: USA

PGM-Fl System

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel iniecior Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold pressure. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

o The ECM/PCM contains memories for basic ionition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. A knock control system was adopted which sets the ideal ig nition timing for the octane rating of the gasoline used.*s

Other Control Funstions

1. Starting Control

When the engine is started. the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on (ll). the ECMiPCM suppli€s ground to the PGM-FI main relay that

supplies current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM/PCM supplies ground to the PGM-FI main relay that supplies current to the

fuel oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

1 1-80

www.emanualpro.com

Page 284 of 1395

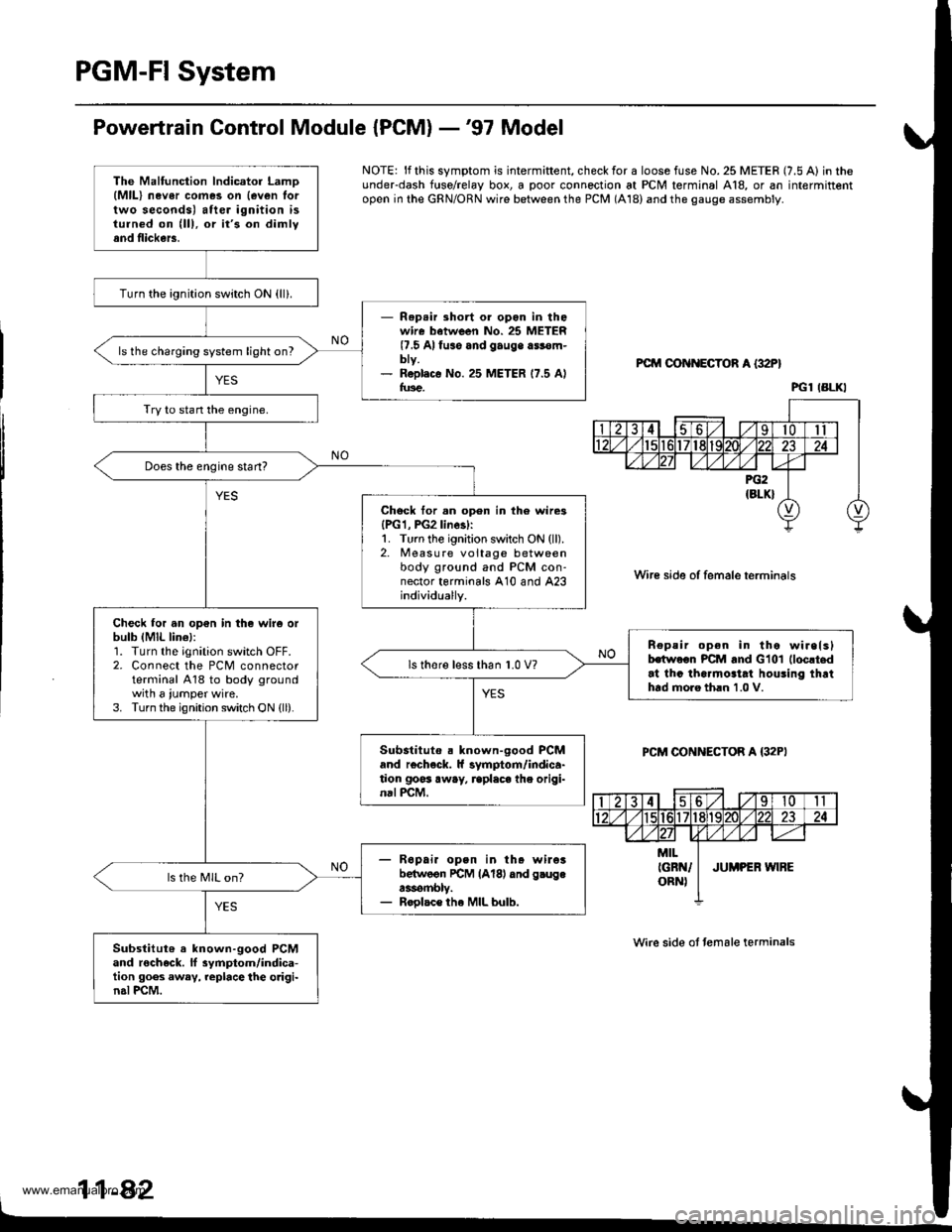

PGM-FI System

Powertrain Control Module {PCM} -'97 Model

NOTE: lf this symptom is intermiftent, check for a loose fuse No. 25 METER (7.5 A) in theunderdash f{rse/relay box, a poor connection at PCM terminal A18, or an intermittentopen in the GRN/ORN wire between the PCM (A18) and the gauge assembly.

PCM OON ECTOR A {32P}

Wire side of female terminals

PCM CONNECTOR A {32PI

Wire side ot temale terminals

11-42

The Malfunction lndicator LamD(MlL) nev6r comes on {even lortwo seconds) after ignition isturned on (lll, or it's on dimlyand flickers.

Turn the ignition switch ON {ll}.

- Rep.ir short or opon in thowire batween No. 25 METER(7.5 Alfuso and gauge a$€m-bty.- R6pl.c€ No. 25 METER 17.5 Alfus€.

ls the charging system light on?

Try to stan the engine.

Does the engine start?

Chock tor.n open in th6 wire3{PG1, PG2linesl:1. Turn the ignition switch ON (ll).2. Measure voltage betweenbody ground and PCM con-nector terminals A10 and A23individually.

Check for an op€n in the wir6 orbulb (MlL lin€l:1. Turn the ignition switch OFF.2. Connect the PCM connectorterminal A18 to body groundwith a iumper wire.3. Turn the ignition switch ON {ll).

n€peir open in tho wirelslhwoon PCM and Glol (loc!t.d

at thc tha.mo3tat houling thrthtd moro th.n 1.0 V.

ls thore l€ss than 1.0 V?

Substituto . known-good PCMand r€check. ll symptom/indica-tion goss away, rcplaca the origi-nal PCM.

- R6pai. open in th. wileibelwoon rcM lAl8l dnd g.ugea3rombly.- Roolac€ the MIL bulb.

ls the MIL on?

Substitut6 a known-good PCMand rocheck. ll 3ymptom/indica-tion goes away, replace the o.igi-n.l PCM.

PGl IBLKI

www.emanualpro.com

Page 361 of 1395

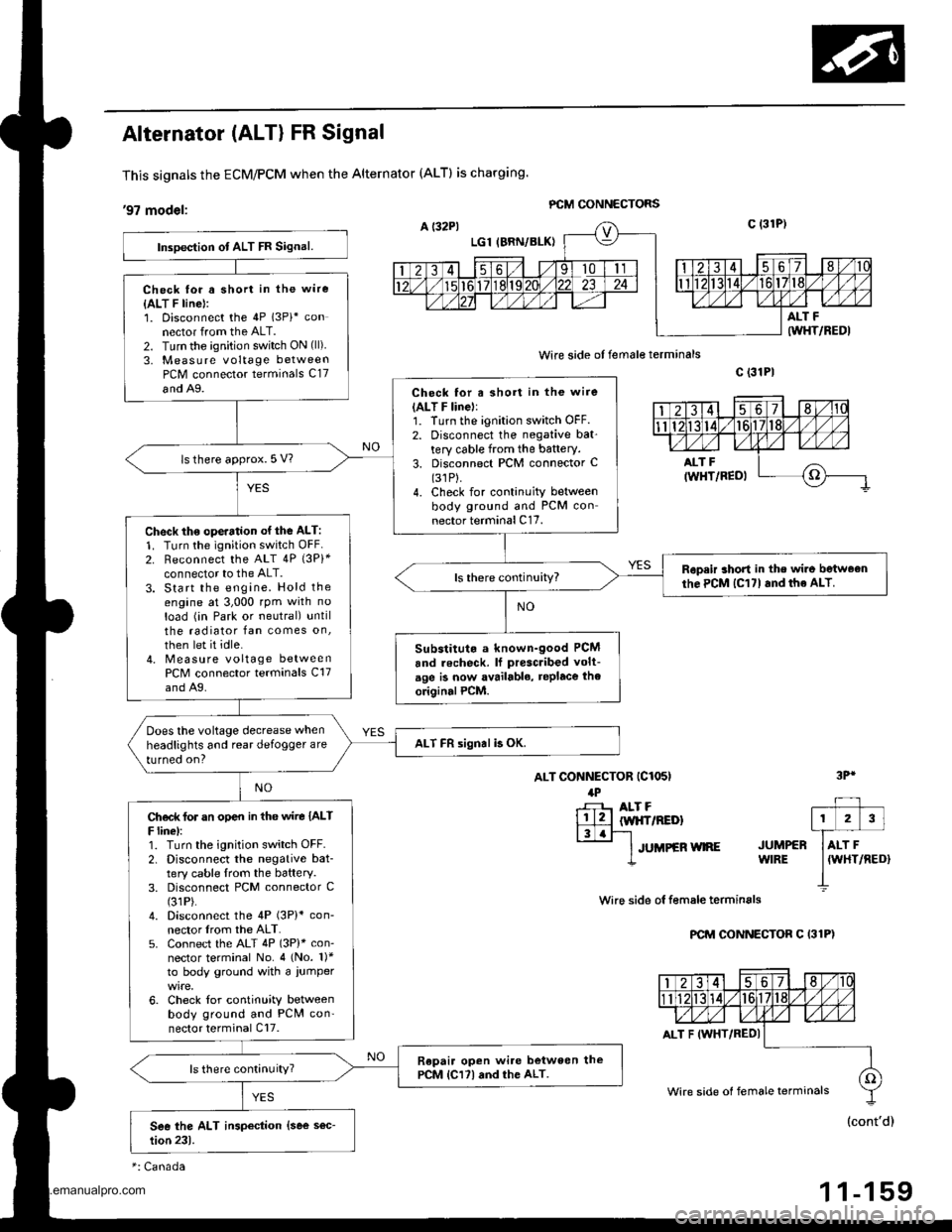

Alternator (ALT) FR Signal

This signals the ECM/PCM when the Alternator (ALTI is charging.

,97 modet: PCM GONNECTORS

wire side of female terminals

ALT CONNECTOR (C1O5I

lPr-F- ALT F

lll2llw|{frREDl|3.r-'l-

lruueen wne

c (31P|

wire side ol f€male terminals

PCM CONNECTOR C I31P)

3Pr

JUMPERWIRE

Inspection ot ALT FR Signal.

Check lor a short in the wire

{ALT F line}:1. Disconnect the 4P 13Pi* connector from the ALT.2. Turn the ignition switch ON (ll)

3, Measure voltage betweenPCM connector terminals C17

and A9.Check for a short in the wire(ALT F linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat'tery cable from the battery.3. Disconnect PCM connector C(31P).

4. Check for continuity betweenbody ground and PCM connector terminal C17.

ls there approx. 5 V?

Check th€ ope.ation of the ALT:

1. Turn the ignition switch OFF2. Reconnect the ALT 4P {3Pi*connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm with no

load (in Park or neutral) untilthe radiator fan comes on,

then let it idle.4. Measure voltage betweenPCM connector terminals C17and A9.

Ropeir short in the wir6 betweonthe PCM lC17l and the ALT.

Substitut. a known-good PCM

and recheck. lf prescribed volt-

age is now availablo, replace the

originalPCM.

Does the voltage decrease when

headlights and rear defogger are

turned on?ALT FR signal b OK.

Ch€d( for an op€n in tho wire IALTF linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat-tery cable lrom the battery.3. Disconnect PCM connector C(31P).

4. Disconnect the 4P (3P)* con-nector lrom the ALT.5. Connect the ALT 4P (3P)* con-nector terminal No. 4 (No. 1)*to body ground with a iumper

6. Check for continuity betweenbody ground and PCN4 con'nector terminal Cl7.

Repair open wi.e between thePCM lCl7l and the ALT.ls there continuity?

ALT F IWHT/REDI

Wire side of female terminals

1 1-159

www.emanualpro.com

Page 1091 of 1395

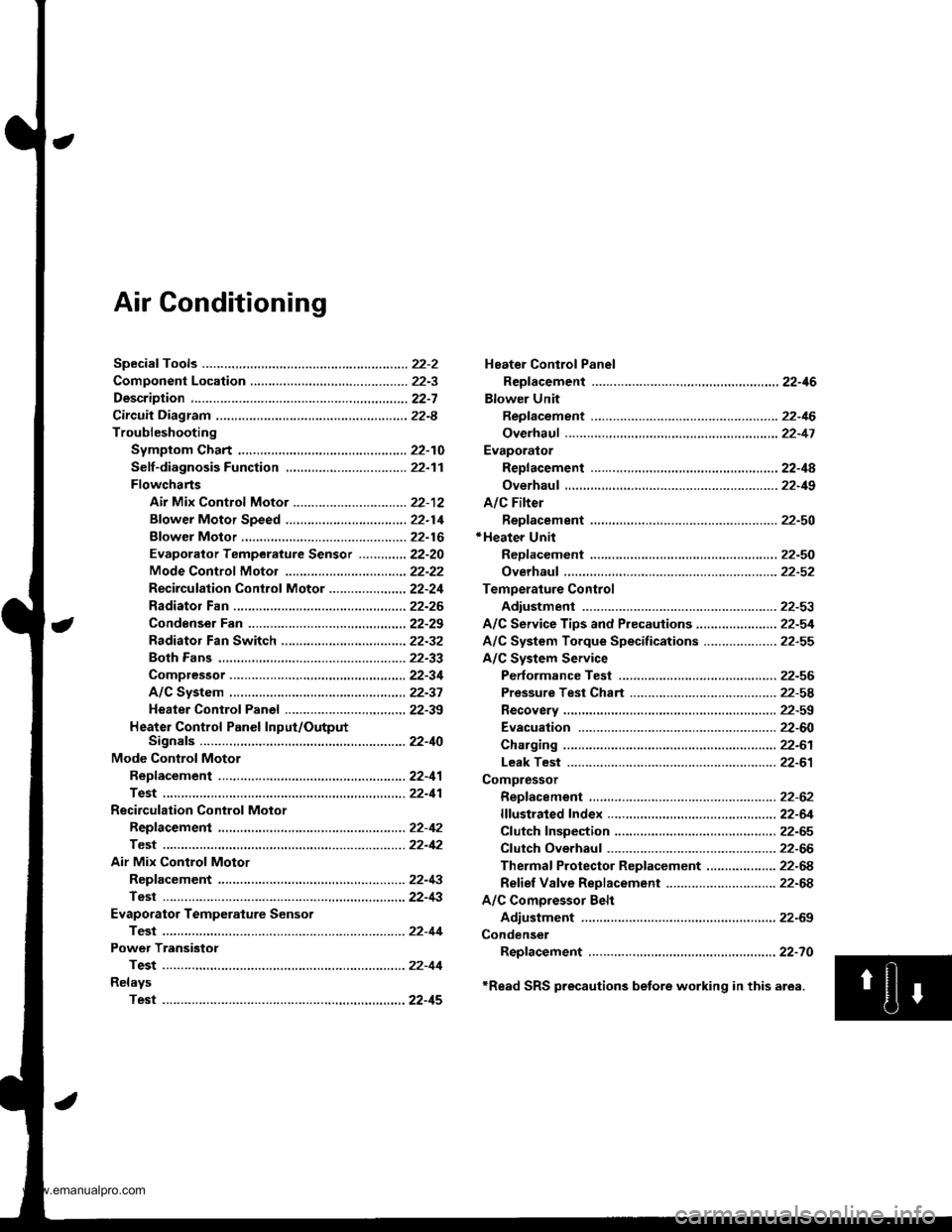

Air Conditioning

Heater Control Panel

Reofacement ,.,...,,.,..,.,.,,22-46

Blower Unit

Replacement .................. 22-46

Overhaul ...........,,,., .......-.22-17

Evaporalor

ReDlacement ...,.,.,..,......,22-4A

Overhaul ................ .........22-19

A/C Filter

Replacement ..................22-50*Heater Unit

ReDfacement ..................22-50

Overhaul ..,.,..,.,...,.. .........22-52

Temperature Control

Adiustment ....................22-53

A/C Service Tips and Precauiions............-....-.... 22-54

A/C System Torque Specifications .................... 22-55

A/C System Service

Performance Test ......,...22-56

Pressure Test Chart .-.....22-5a

Recovery ..............,. ...-.-...22-59

Evacuation -...........-........22-60

Charging ................ .......-.22-61

Leak Test ........................22-61

Compressor

Repfacement ..........-.......22-62

flfustrated Index .....,.......22-64

Cfutch fnspection .........,.22-65

Cfutch Overhaul ............- 22-66

Thermaf Protector Rep|acement ................... 22-68

Refief Valve Replacement .............................. 22-68

A/C Comoressor Belt

Adiustment .................... 22-69

Condenser

Repfacement .,.....,,.,..,.,..22-70

'Read SRS precautions betore working in this area.

www.emanualpro.com

Page 1097 of 1395

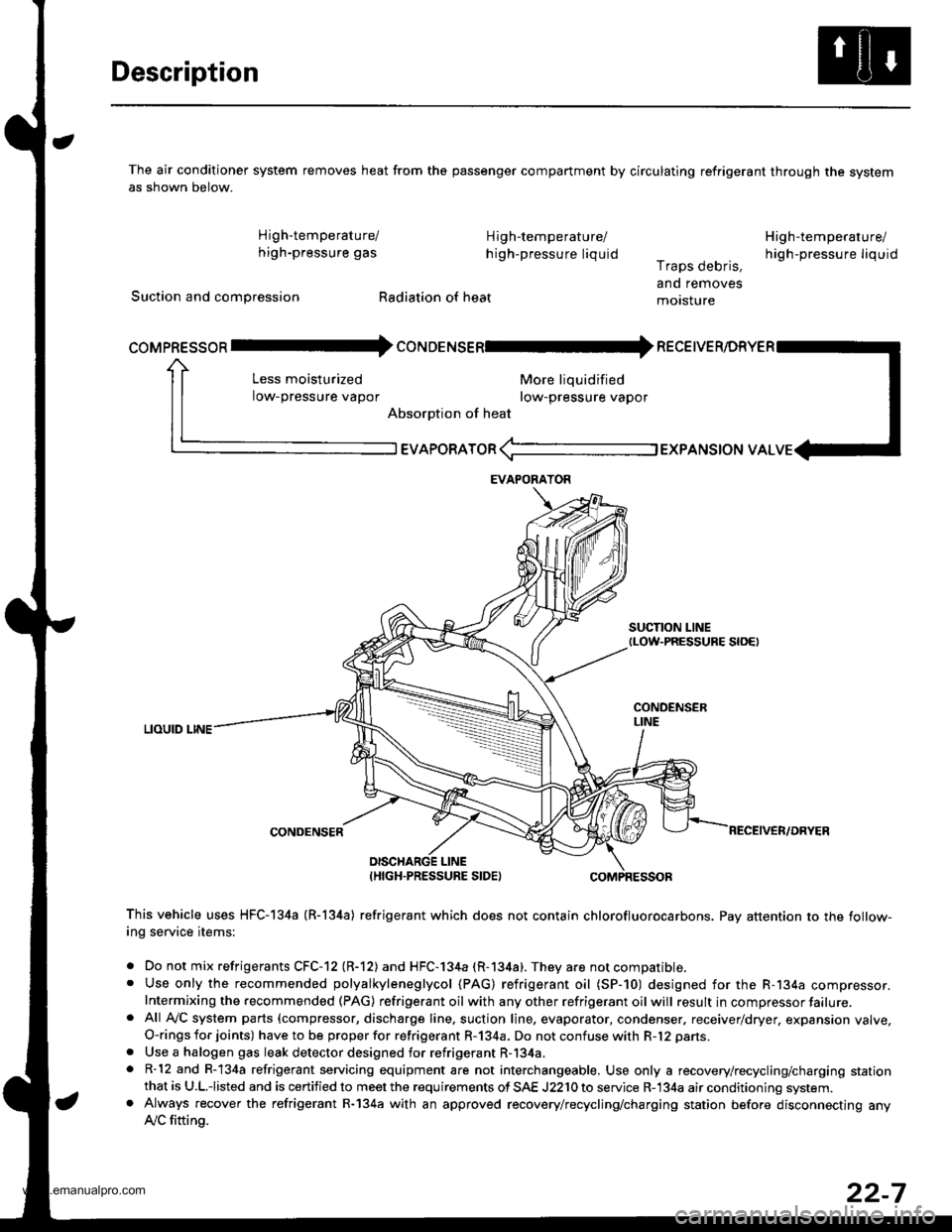

Description

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the systemas shown below.

High'temperature/ High-temperature/

high-pressure gas h igh-pressure liquid

Suction and compression Radiation of heat

High-temperature/

high-pressu re liq uidr raps oeons,

and removes

motsture

More liquidified

row-pressure vapor

EVAPoRAToR (-l EXPANSToN vAL

SUCTION LINEtLow-PRESSURE S|OEt

LIOUID LINE

CONDENSER

coMpREssoR Il- coruoerusenl* necetve

Less moisturized

low-pressure vapor

Absorption of heat

DISCHARGE LINEIHIGH.PRESSURE SIDEI

This vehicle uses HFC-I34a (R-l34a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-ing service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-l34a (R-134a). They are not compatible.. Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (SP-10) designed for the R-134a compressor.Intermixing the recommended (PAG) refrigerant oil with any other refrigerant oil will result in compressor failure.. Afl Ay'C system parts (compressor, discharge line. suction line, evaporator, condenser. receiver/dryer, expansion valve,O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a recovery/recycling/charging stationthat is U.L.iisted and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning system.. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting anylVC fitting.

EVAPORAYOR

22-7

www.emanualpro.com

Page 1138 of 1395

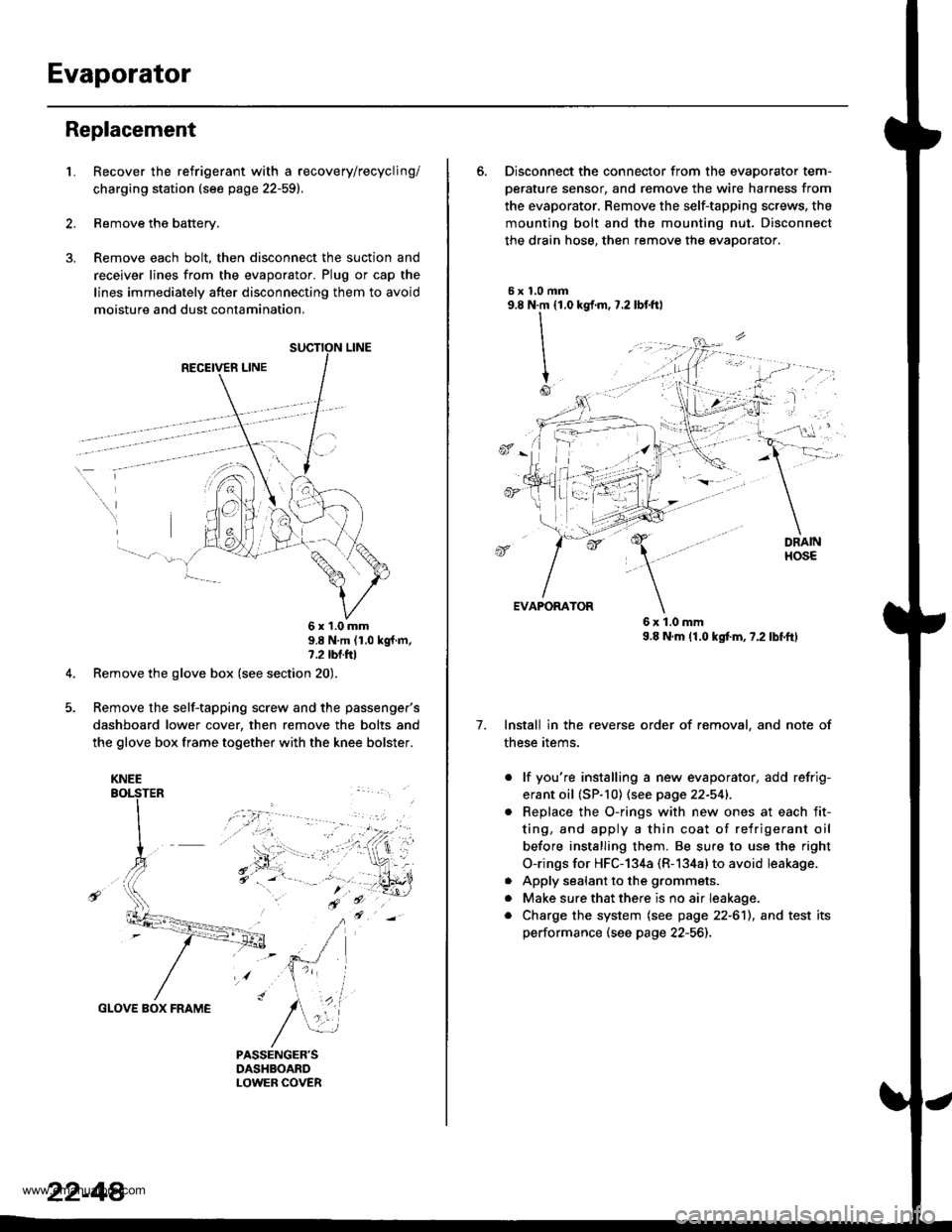

Evaporator

Replacement

1.Recover the refrigerant with a recovery/recycling/

charging station (see page 22-59).

Remove the battery.

Remove each bolt, then disconnect the suction and

receiver lines from the evaporator. Plug or cap the

lines immediately after disconnecting them to avoid

moisture and dust contamination,

RECEIVER LINE

..

\

6x1.0mm9.8 N'm (1.0 kgf m,7.2 tbl.ttl

Remove the glove box (see section 20).

Remove the self-tapping screw and the passenger's

dashboard lower cover, then remove the bolts and

the glove box frame together with the knee bolster.

GLOVE BOX FRAME

KNEE

22-44

6. Disconnect the connector from the evaoorator tem-

oerature sensor. and remove the wire harness from

the evaporator. Remove the self-tapping screws, the

mounting bolt and the mounting nut. Disconnect

the drain hose, then remove the evaporator.

5xl,0mm9.8 N.m {1.0

II

I

Io

kgf.m, 7.2 lbf.ftl

, -l: "

7.

EVAPORATOR

6x1.0mm9.8 N.m (1.0 kgtm,7.2lbf.ftl

Install in the reverse order of removal, and note of

these items.

. lf you're installing a new evaporator, add refrig-

erant oil (SP.10) (see page 22-541.

Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them. Be su.e to use the right

O-rings for HFC-134a (R-134alto avoid leakage.

Apply sealant to the grommets.

Make sure that there is no air Ieakage.

Charge the system (see page 22-6'll, and test its

performance (see page 22-56]-,

a

a

a

www.emanualpro.com

Page 1144 of 1395

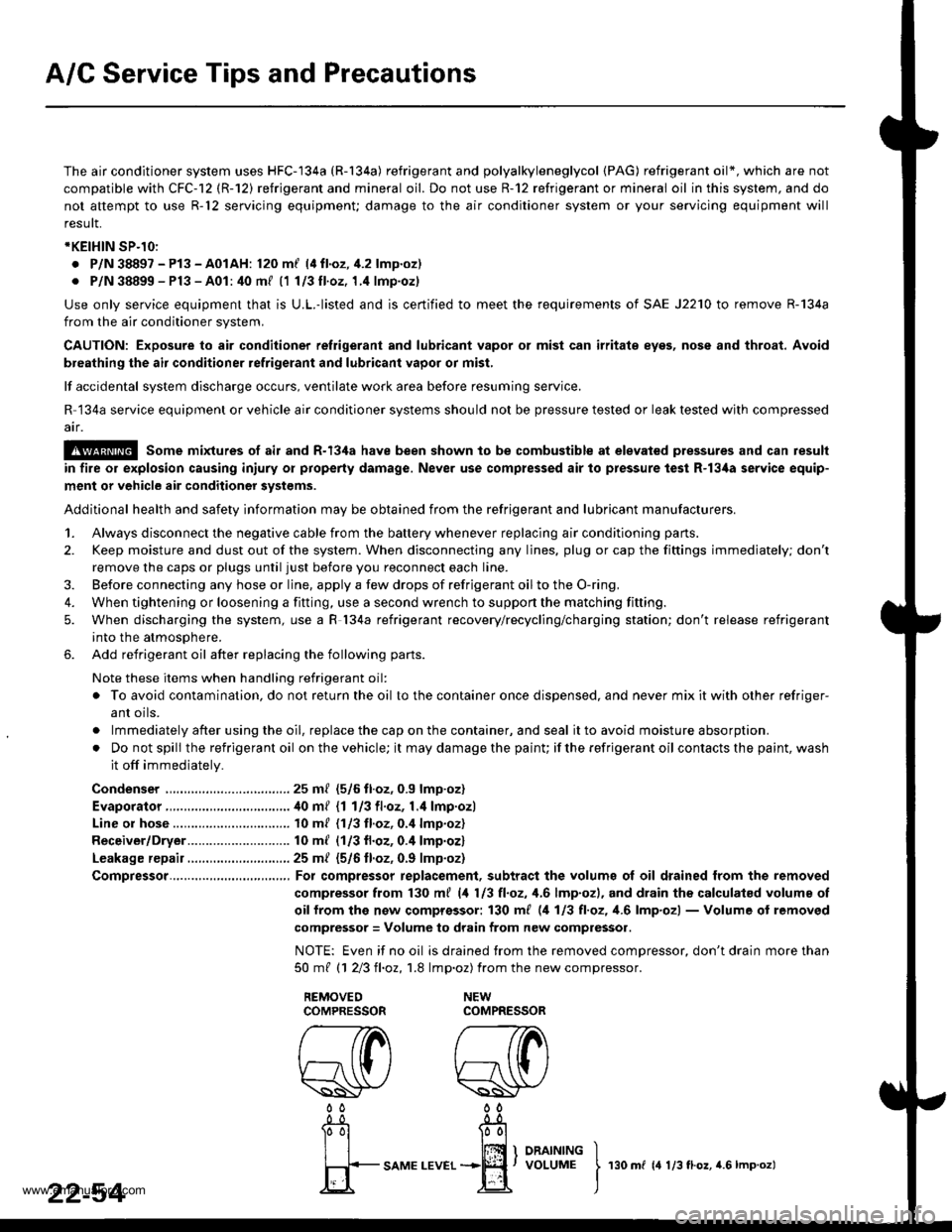

A/C Service Tips and Precautions

The air conditioner system uses HFC-'134a (R-134a) refrigerant and polyalkyleneglycol {PAG) refrigerant oil*, which are not

compatible with CFC-12 (R-12) refrigerant and mineral oil. Do not use R-12 refrigerant or mineral oil in this system, and do

not attempt to use R-12 servicing equipmenu damage to the air conditioner system or your servicing equipment will

resutr.

*KEIHIN SP-10:

. P/N 38897 - Pl3 - A01AH: 120 m{ (4 fl.oz, il.2 lmp.oz)

. P/N 38899 - Pl3 - A01: 40 mf 11113tl.oz,1.4 lmp.oz)

Use only service equipment that is U.L.-listed and is certified to meet the requirements of SAE J2210 to remove R-134a

from the air conditioner system,

CAUTION: Exposure to air conditioner refrigerant and lubricant vapor or misl can irritats eyes, nose and throat. Avoid

breathing the air conditioner refrigerant and lubricant vapor or mist,

lf accidental system discharge occurs, ventilate work area before resuming service.

R 134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with compressed

air.

E@ Some mixtures of air and R-13,1a have been shown to be combustible at elevat€d pressures and can result

in fire or explosion causing iniury or property damage. Never use complessed air to pressure test R-l3,[a service equip-

ment or vehicle air conditioner systems.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.

1. Always disconnect the negative cable from the battery whenever replacing air conditioning parts.

2. Keep moisture and dust out of the system. When disconnecting any lines, plug or cap the fittings immediately; don't

remove the caps or plugs until just before you reconnect each line.

3. Before connecting any hose or line. apply a few drops of refrigerant oilto the O-ring,

4. When tightening or loosening a fitting, use a second wrench to support the matching fitting.

5. When discharging the system, use a R l34a refrigerant recovery/recycling/charging station; don't release refrigerant

into the atmosphere.

6. Add refrigerant oil after replacing the following parts.

Note these items when handling refrigerant oil:

o To avoid contamination, do not return the oil to the container once dispensed, and never mix it with other refriger-

ant oils.

. lmmediately after using the oil, replace the cap on the container, and seal it to avoid moisture absorption.

. Do not spill the refrigerant oil on the vehicle; it may damage the painu if the refrigerant oil contacts the paint, wash

it off immediately.

Condenser . 25 ml (5/6 tl.oz, 0.9 lmp.oz)

Evaporator.,................................40 m/ 11 113ll.oz,l.4 lmp.ozl

Line or hose ........... 10 ml (1/3 fl.oz, 0.4 lmp.oz)

Receiver/Dryer....... 10 ml (1/3 fl.oz, 0.4 lmp.oz)

Leakage repair............................ 25 m/ (5/6 ll.oz, 0.9 lmp.oz)

Compressor.......,..., For compressor replacement, subtract the volumg ol oil drained from the removed

compressor from 130 m{ (4 113 tl.oz, 1,6lmp.ozl, and drain the calculatsd volume of

oif from the now comprossor: 130 ml (,1 113 tl,oz, 1.6lmp'ozl - Volume of removed

compressor = Volume to drain from new compressor.

NOTE: Even if no oil is drained trom the removed compressor, don't drain more than

50mt 11 213ll,oz,1.8 lmp.oz) from the newcompressor.

22-54I

rso m r rr:0.o., r.s r-o.o.t

www.emanualpro.com

Page 1146 of 1395

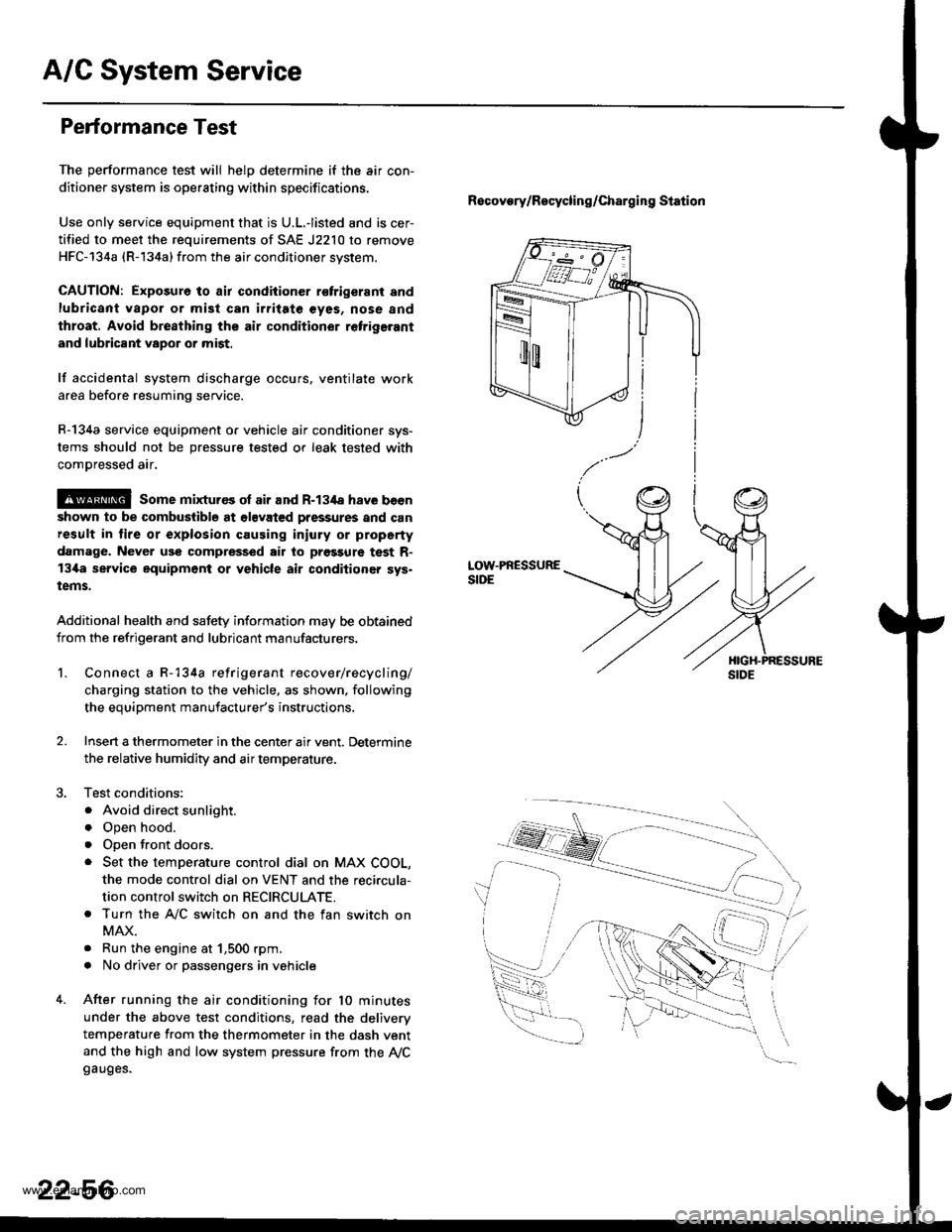

A/G System Service

Performance Test

The performance test will helD determine if the air con-

ditioner system is operating within specifications.

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner svstem.

CAUTION: Exposure to air condiiioner r€trigerant and

lubricant vapor or mist can irritate €yes, nose and

throat. Avoid bre8thing the air conditioner retrige.ant

and lubricant vapor or mist,

lf accidental system discharge occurs. ventilate work

area before resuming service.

R-134a service equipment o. vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comDressed air.

@ some mixtur€s ol air and R-134a have becn

shown to be combuslible at olsvated pressures and can

result in lire or explosion causing iniury or property

damage. Never use compressed air to prgssure test R-

13i[a service equipment or vehicle air conditioner sys.

tems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

Recovory/Recycling/charging station

LOW.PRESSURESIDE

1.Connect a R-134a refrigerant recover/recycling/

charging station to the vehicle, as shown. following

the equipment manufacturer's instructions,

Insen a thermometer in the center air vent. Determine

the relative humidity and air temperature.

Test conditions:

. Avoid direct sunlight.

o Open hood.

. open front doors.

. Set the temperature control dial on MAX COOL,

the mode control dial on VENT and the reci.cula-

tion control switch on RECIRCULATE.

. Turn the A,/C switch on and the fan switch on

MAX.

. Run the engine at 1,500 rpm.

. No driver or passengers in vehicle

After running the air conditioning for 10 minutes

under the above test conditions, read the deliverv

temperature from the thermometer in the dash vent

and the high and low system pressure from the Ay'Cgauges.

2.

22-56

www.emanualpro.com

Page 1148 of 1395

A/C System Service

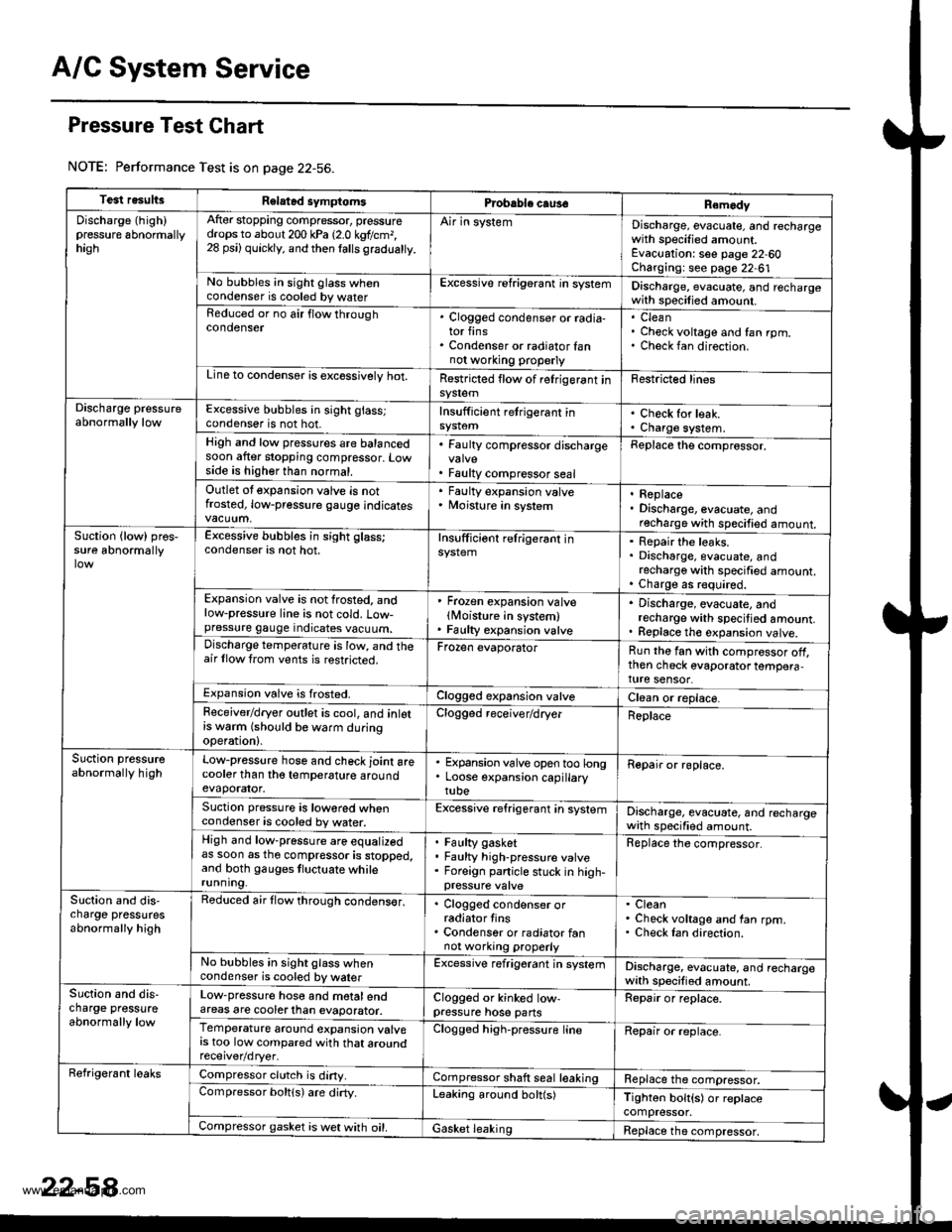

Pressure Test Chart

NOTE: Performance Test is on page 22-56.

Test resultsRelatad symptomsPrcbable caus€Remody

Discharge (high)pressure 6bnormallyhagh

After stopping compressor, pressuredrops to about 200 kPa 12.0 kgtlcm,,28 psi) quickly, and then lalls gradualty.

Air in systemDischarge, evacuate, and rechargewith specified amount.Evacuation: see page 22-60Charging: see page 22-61No bubbles in sight glass whencondenser is cooled by waterExcessive refrigerant in systemDischarge, evacuate, and rechargewith specilied amount.Reduced or no air flow throughcondenser. Clogged condenser or radia-tor fins. Condenser or radiator fannot wo.king properly

CleanCheck voltage and fan rpm.Check fan direction.

Line to condensor is excossivelv hot.Restricted flow of relrigerant insy$emFestricted lines

Discharge pressureabnormally lowExcessive bubbles in sight glass;condenser is not hot.Insufficient retrigerant inCheck for leak.Charge system.High and low pressures are balancedsoon after stopping compressor. Lowside is higher than normal.

. Faulty compressor discharge

. Faulty compressor seal

Replace the comprossor.

Outlet ot expansion valve is notfrosted, low-pressure gauge indicates

' Faulty expansion valve. Moisture in system. Replace. Discharge, evacuate, andrecharge with specified amount.Suction {low) pros,sure abnormallyExcessive bubbles in sight glass;condenser is not hot.Insufficiont relrigerant inRepair the leaks.Discharge, evacuate, andrecharge with specified amount.Charge as r€quired.Expansion valve is not frosted, andlow-pressure line is not cold. Low-pressure gauge indicates vacuum.

' Frozen expansion valvelMoisture in system). Faulty expansion valve

. Discharge, evacuate, andrecharge with specitied amount.. Replace th€ expansion valve.Discharge temperature is low, and theair llow trom vents is restricted.Frozen evaporatorRun the fan with compressor off,then check evaporator tempera,ture sensor.Expansion valve is frosted.Clogged expansion valveClean or replace.Feceiver/dryer outlet is cool, and inlotrs w6rm (should be warm duringoperation).

Clogged receiver/dryerReplace

Suction pressureabnormally highLow-pressure hose and check joint arecooler than tho temperature aroundevaporator.

. Expansion valve open too long. Loose expansion capillarytube

Repair or roplace.

Suction pressure is lowored whencondenser is cooled by water.Excessive refrigerant in systemDischarge, evacuate, and rechargewath specified amount.High and low-pressure are equalizedas soon as tho compressor is stopped,and both gauges tluctuate whilerunning.

Faulty gasketFaulty high-pressure valveForeign panicle stuck in high-

Replace the compressor.

Slction and dis,charge pressutesabnormally high

Reduced air flow through condens€r,. Clogged condenser orradiator tins. Condenser or radiator fannot working properly

CleanCheck voltage and fan rpm.Check Ian direction.

No bubbles in sight glass whencondenser is cooled by walerExcessive refrigerant jn systemDischarge, evacuate, and rechargewith specified amount.Suction and dis-charge pressureabnormally low

Low-pressure hose and motalendareas are cooterlhan evaporator.Clogged or kinked low-pressure hose pansRepair or replace.

Temperature around expansion valvers too low compared with that aroundClogged high-pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny.Compressor shaft seal leakingReplace the compressor.Compressor boltls) are dirty.Leaking around bolt(s)Tighton bolt{s) or replacecompressor.Compressor gasket is wet with oil.Gasket leakingReplace the compressor,

www.emanualpro.com

Page 1149 of 1395

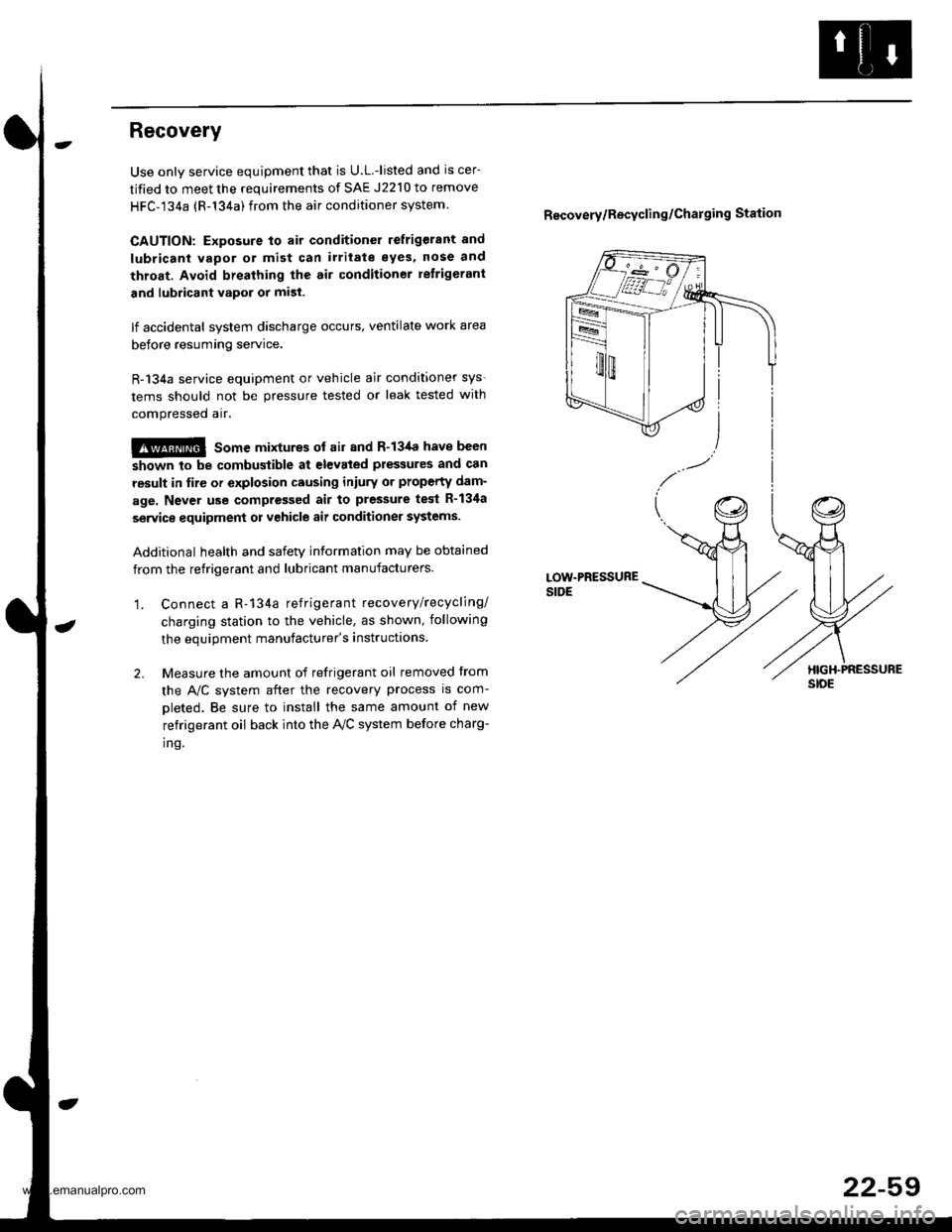

Recovery

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and

lubricant vapor or mist can irritate eyes, nose and

throat. Avoid brqathing the air conditioner retrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work area

before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed arr.

@@ some mixtures of air and R-134a have been

shown to be combustible at elevated plessures and can

result in fire or explosion causing iniury or property dam-

age. Never use compressed air to pressure tect R-134a

service equipment or vehicle air conditioner systems.

Additional health and safety intormation may be obtained

from the refrigerant and lubricant manufacturers.

'1. Connect a R-134a refrigerant recove rylrecycling/

charging station to the vehicle, as shown, following

the equipment manufacturer's instructions

2. Measure the amount of refrigerant oil removed trom

the A,/C system after the recovery process is com-

oleted. Be sure to install the same amount of new

refrigerant oil back into the AVC system before charg-

inq.

Recovery/Recycling/Charging Station

22-59

www.emanualpro.com