air con HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 895 of 1395

Power Steering Gearbox

Reassembly (cont'd)

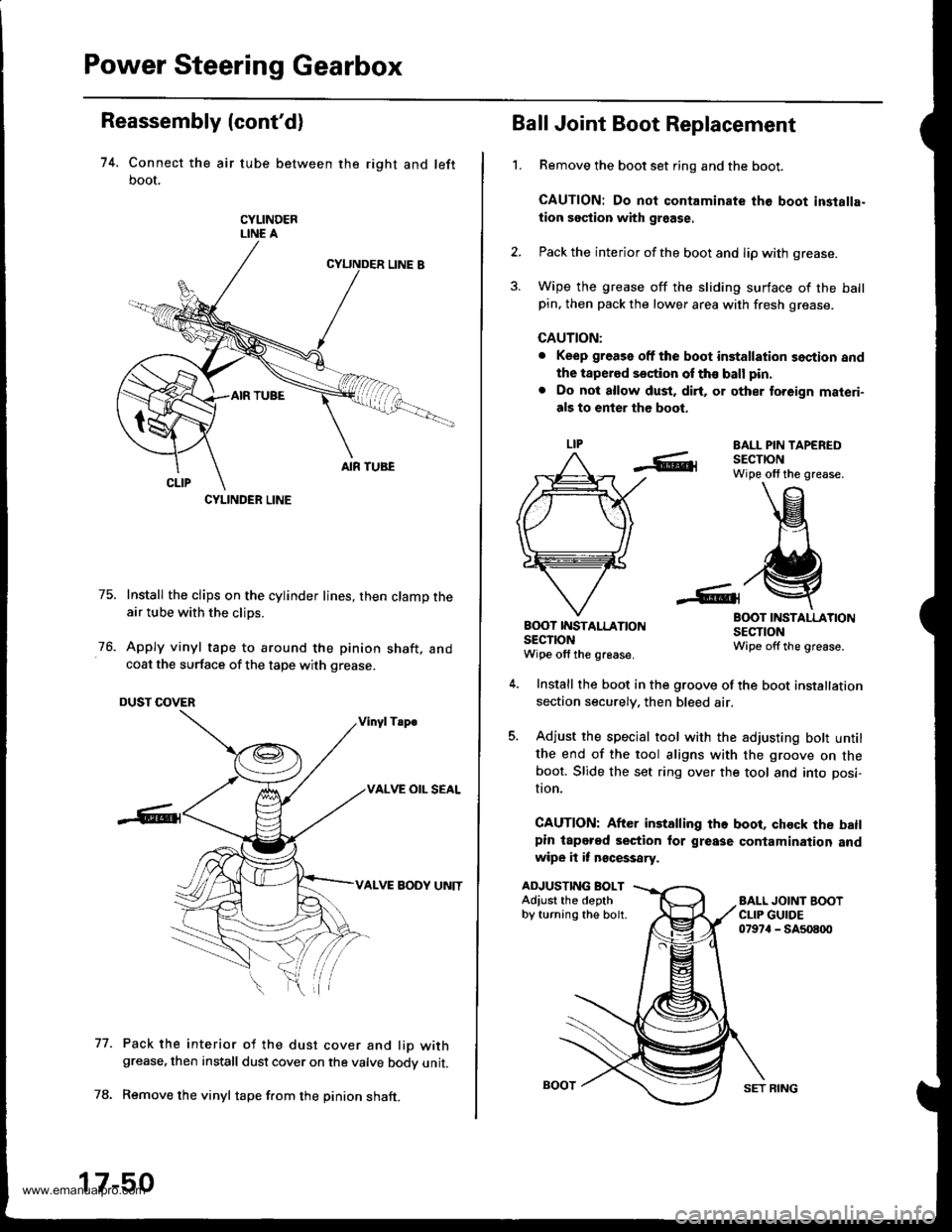

74. Connect the air tube between the right and left

boot,

CYLINDERLINE A

75. Install the clips on the cylinder lines, then clamp theair tube with the clips.

76. Apply vinyl tape to around the pinion shaft, andcoat the surface of the tape with grease.

DUST COVER

Vinyl Tsp€

VALVE OIL SEAL

VALVE BODY UNIT

Pack the interior of the dust cover and lio withgrease, then install dust cover on the valve bodv unit.

Remove the vinyl tape f.om the pinion shaft.

77.

CYLINDER LINE

17-50

SET RING

't.

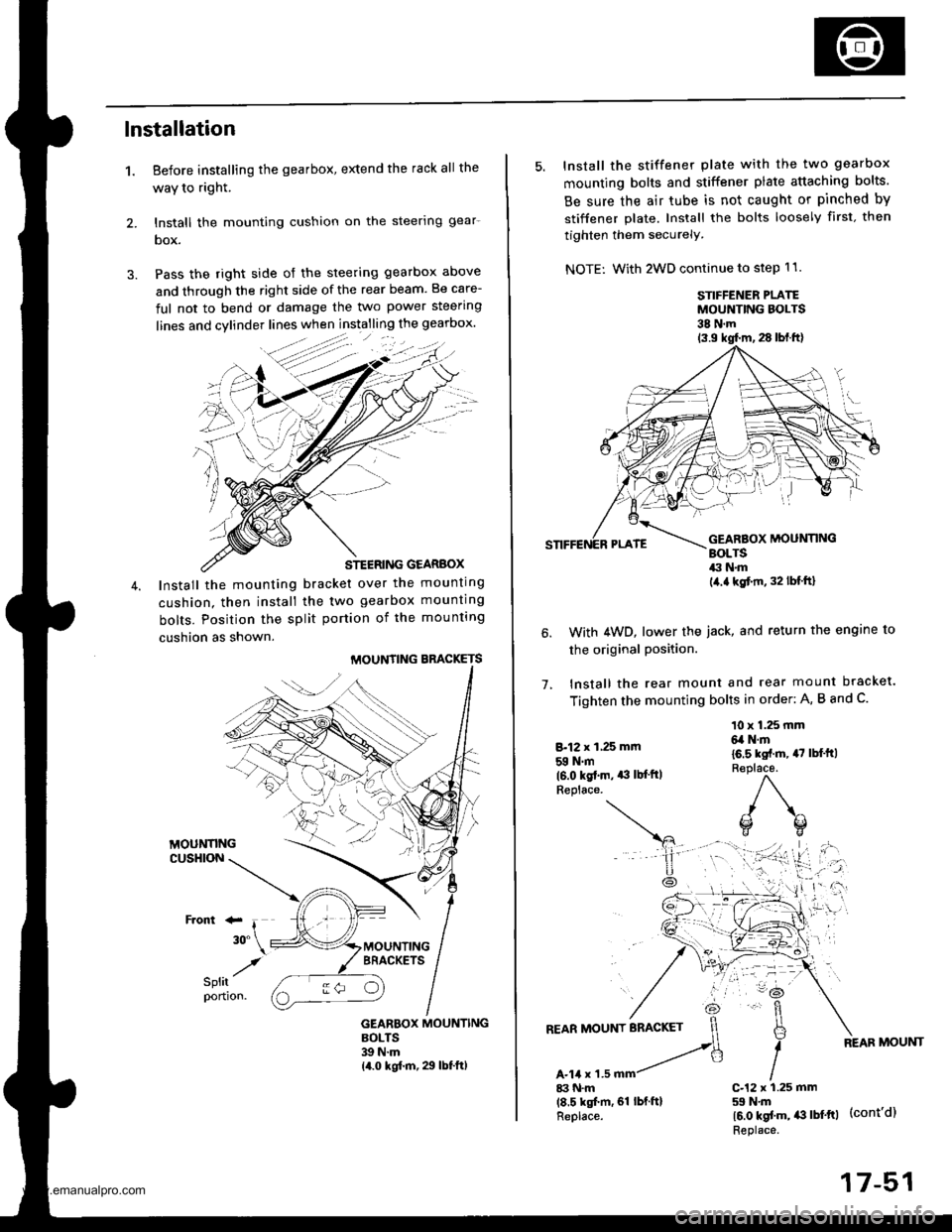

Ball Joint Boot Replacement

Remove the boot set ring and the boot.

CAUTION: Do not contaminate the boot inslalla-

tion section with graase.

Pack the interior of the boot and lip with grease.

Wipe the grease off the sliding surface of the ballpin. then pack the lower area with fresh grease.

CAUTION:

. Keep grease off the boot installation section and

the tapered section of th€ ball pin.

. Do not allow dust, dirt, or other to.eign materi-

als to enter the boot.

EALL PIN TAPEREDSECTIONWipe olf the grease.

BOOT INSTALLATIONSECTIONWipe offthe grease.

B(X)T IT{STALLATIONsEclroNWipe off the grease.

ADJUSTING BOLTAdiust the depthby turning the bolt.

Install the boot in the groove of the boot installation

section securely. then bleed air.

Adjust the special tool with the adjusting bott untilthe end of the tool aligns with the groove on theboot. Slide the set ring over the tool and into posi-

I|on.

CAUTION: After installing the boot, chock the batlpin lapered section for grease contamination andwipe it it n€cessary.

www.emanualpro.com

Page 896 of 1395

lnstallation

1. Before installing the gearbox, extend the rack all the

waY to right.

2. lnstall the mounting cushion on the steerlng gear-

box.

3. Pass the right side of the steering gearbox above

and through the right side of the rear beam. Be care-

ful not to bend or damage the two power steering

STEERING GEARBOX

Install the mounting bracket over the mounting

cushion. then install the two gearbox mounting

bolts. Position the split portion of the mounting

cushion as shown.

MOUNTING BBACKETS

GEARBOX MOUNTINGBOLTS39 N.m14.0 kgf.m, 29 lbf.ft)

:-

/

5. Install the stiffener plate with the two gearbox

mounting bolts and stiffener plate attaching bolts.

Be sure the air tube is not caught or pinched by

stiffener plate. Install the bolts loosely first. then

tighten them securely.

NOTE: With 2WD continue to step 11.

STIFFENER PLATEMOUNTING BOLTS38 N.m

1.

With 4WD, lower the iack, and return the engine to

the original Position.

lnstall the rear mount and rear mount bracket.

Tighten the mounting bolts in order: A, B and C.

8.12 x 1,25 mm

59 N.m(6.0 kgt.m. *l lb{'ftlReplace.

10 x 1.25 mm6,a N.m

16.5 kst.m, 47 lbl'ft)R€place.

)\^

o(]

17-51

www.emanualpro.com

Page 898 of 1395

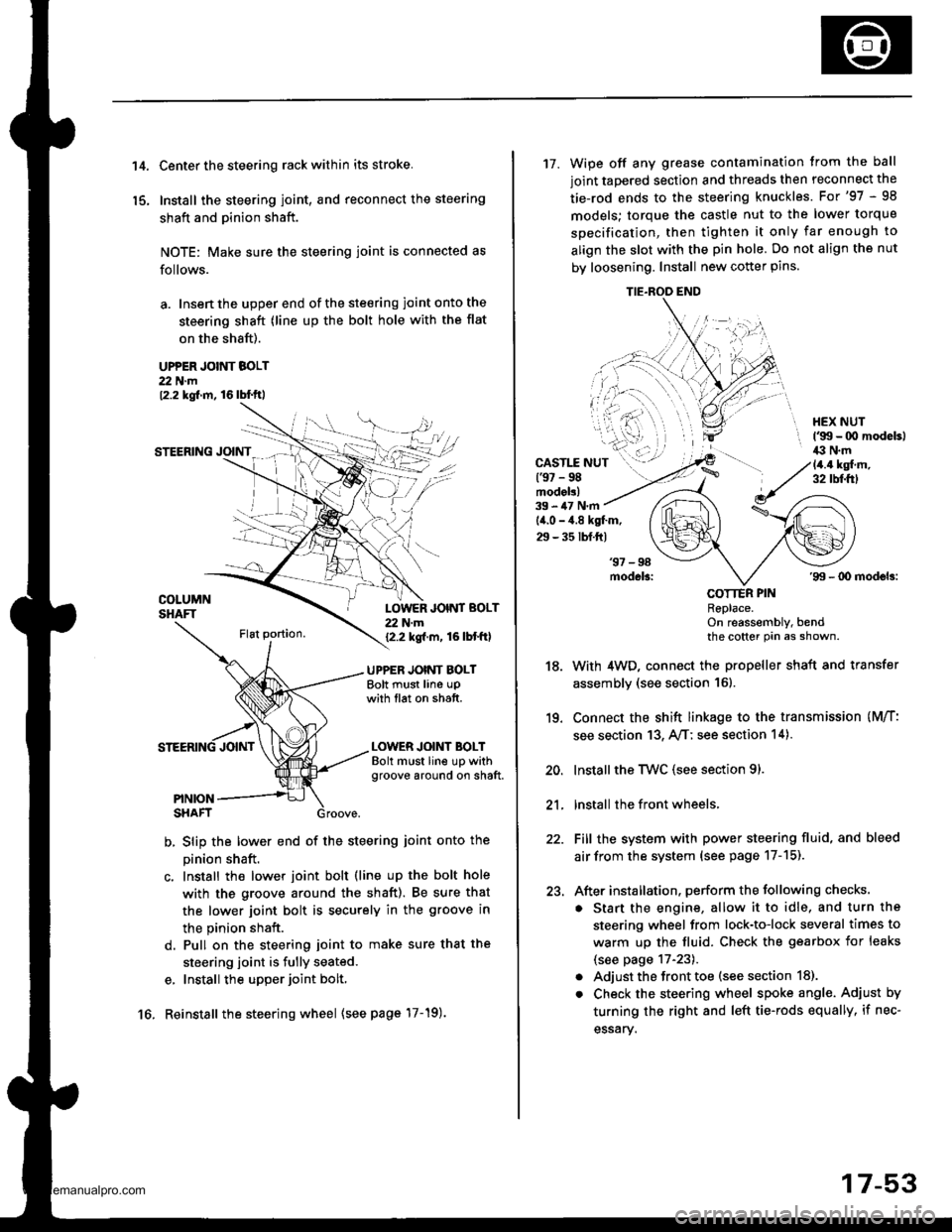

't 4.

15.

Center the steering rack within its stroke.

Install the steering joint, and reconnect the steering

shaft and pinion shaft.

NOTE: Make sure the steering joint is connected as

follows.

a. Insen the upper end of the steering joint onto the

steering shaft (line up the bolt hole with the flat

on the shaft).

UPPER JOINT BOLT22 N.m12.2 kgf.m, 16lbl.ft,

STEERING JOINT

COLUMNSHAFTLOWER JOINT BOLT22 N.m12.2 kgf.m, 16lbtftl

UPPER JOINT BOLTBolt must line upwith tlat on shatt.

LOWER JOINT BOLTBolt must line up withgroove around on shaft.

PINIONSHAFT

b, Slip the lower end of the steering ioint onto the

pinion shaft.

c. Install the lower joint bolt (line up the bolt hole

with ths groove around the shaft). Be sure that

the lower joint bolt is securely in the groove in

the pinion shaft.

d. Pull on the steering joint to make sure that the

steering joint is fully seated.

e, Install the upper joint bolt,

Reinstall the steering wheel {see page'17-19).16.

17-53

17. Wipe off any grease contamination trom the ball

joint tapered section and threads then reconnect the

tie-rod ends to the steering knuckles. For'97 - 98

models; torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the pin hole. Do not align the nut

by loosening. Install new cotter pins.

CAST1T NUT(9t - 98modol!)

HEX NUTl'g!t - 00 modeb)il:l N.m14.4 ksl.m,32 tbf.f0

39 - iU N'm

lil.o - 4.8 kgl.m,

29 - 35 tbf.ftl

18.

19.

20.

21.

22.

23.

'99 - lD modeb:

COTTER PINRePlace.on reassembly, bendthe cotter Pin as shown.

With 4WD, connect the propeller shaft and transfer

assembly (see section 16).

Connect the shift linkage to the transmission (M/T:

see section 13, A,/T; see section 14).

Installthe Twc (see section 91.

lnstall the front wheels,

Fill the system with power steering fluid, and bleed

air from the system (see page 17-15).

After installation. perform the following checks.

. Start the engine, allow it to idle, and turn the

steering wheel from lock-to-lock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-23).

. Adjust the front toe (s€e section 18).

. Check the steering wheel spoke angl€. Adjust by

turning the right and left tie-rods equally, if nec-

essary.

TIE.ROO END

www.emanualpro.com

Page 914 of 1395

Front SuspensionFront Damper

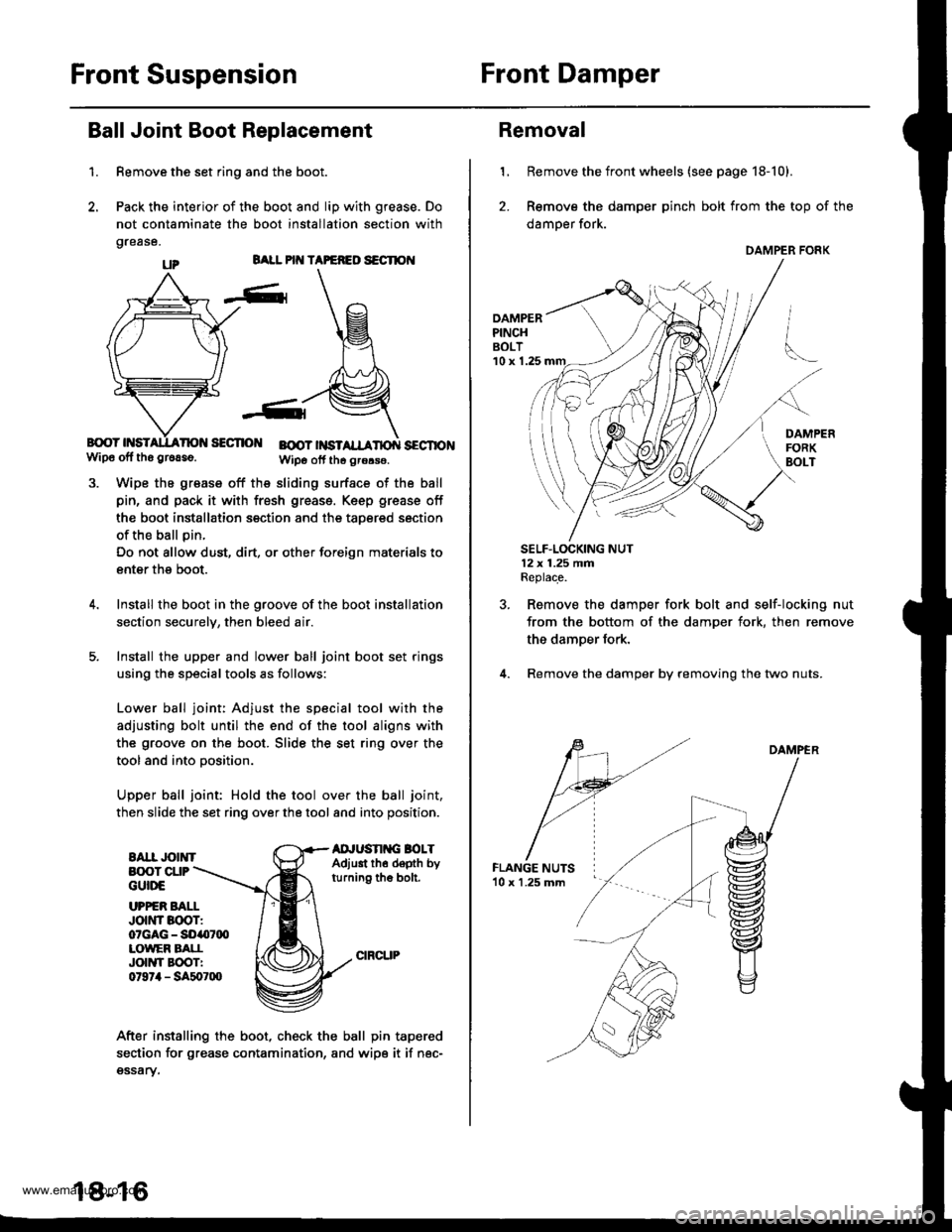

Ball Joint Boot Replacement

1.

BALL PIT{ TAPEFEO S€CTION

B{rcY HSISECTIO BOOT |NSTSECTIONwip6 off tho gr6aso.Wipo otf th6 grors€.

Wipe the grease off the sliding surface of the ball

pin, and pack it with fresh greass. Keep grease off

the boot installation section and the taoered section

of the ball pin.

Do not allow dust, dirt, or other foreign materials to

enter the boot.

Install the boot in the groove of the boot installation

section securelv, then bleed air.

Install the upper and lower ball joint boot set rings

using the special tools as follows:

Lower ball joint: Adjust the special tool with the

adjusting bolt until the end of the tool aligns with

the groove on the boot. Slide the set ring over the

tool and into oosition.

Upper ball joint: Hold the tool over the ball joint,

then slide the set ring over the tool and into position.

EAII JOINTAD'USN G BOLTAdjust th6 depth byturning the bolt.

Remove the set ring and the boot.

Pack the interior of the boot and lip with grease. Do

not contaminate the boot installation section with

grease.

B(X)T CUPGUttrE

UPPER BAI.IJott'tr Boor:07GAG - SO407q)LOWEF BATIJOIIYI EOOTI0t97il - SA507lXl

After installing the boot, check the ball pin tapered

section for grease contamination, and wipe it if nec-gssary.

18-16

Removal

1, Remove the front wheels (see page 18-10).

2. Remove the damper pinch bolt from the top of the

damper fork.

DAMPERPINCHBOLT'10 x 1.25

SELF.LOCKING NUT12x 1.25 fifiReplace.

Remove the damper fork bolt and self-locking nut

from the bottom of the damper fork, then remove

the damper fork.

Remove the damper by removing the two nuts.

DAMPER

DAMPER FORK

www.emanualpro.com

Page 931 of 1395

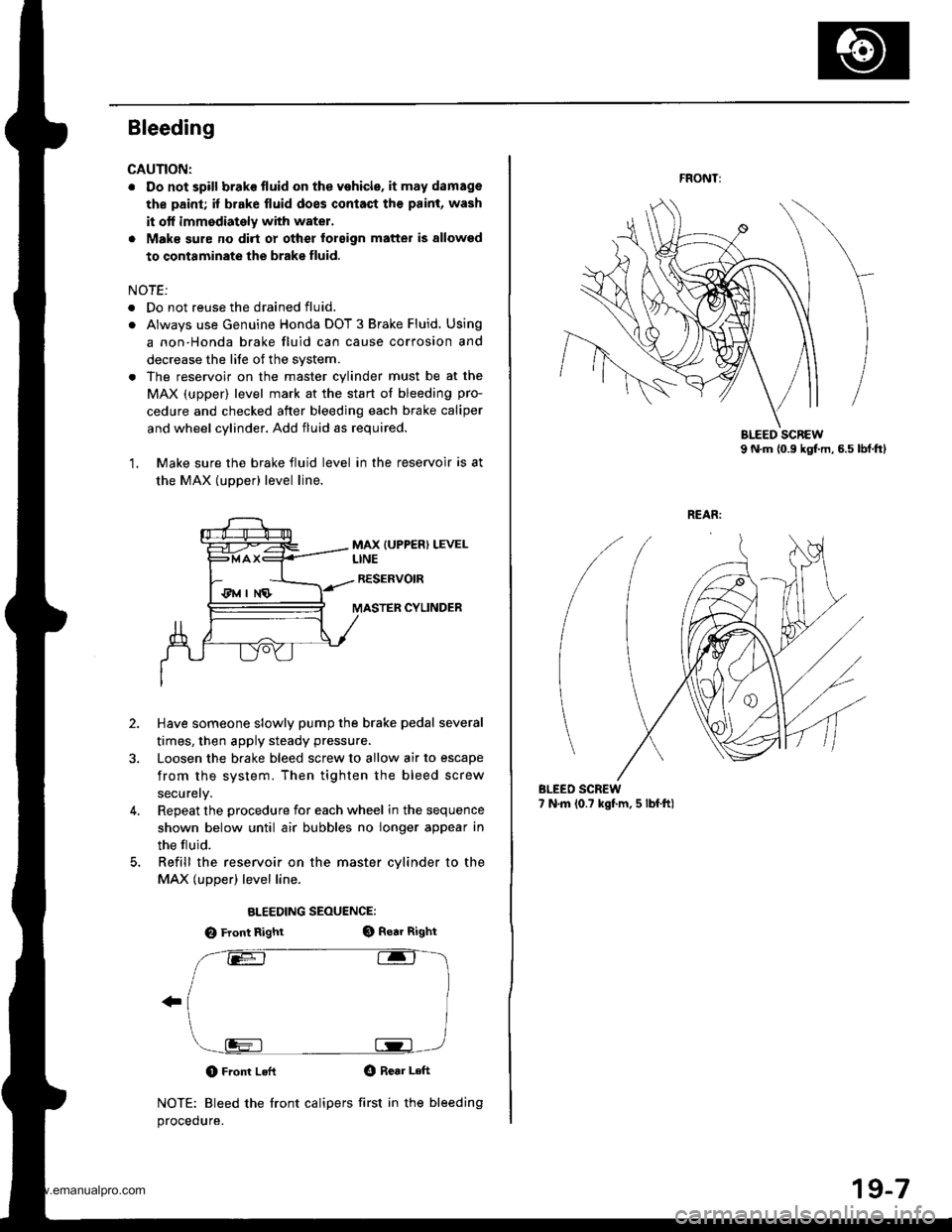

Bleeding

CAUNON:

. Do not spill brake tluid on the vehicle. it may damage

the paint; if brake fluid does contaqt th€ paint, wash

it otf immodiately with water.

. Maks sure no dirt oy other forsign matter is allowsd

to contaminate the brake fluid.

NOTE:

. Do not reuse the drained fluid.

. Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the life of the svstem.

. The reservoir on the master cylinder must be at the

MAX (upper) level mark at the start of bleeding pro-

cedure and checked after bleeding each brake caliper

and wheel cylinder. Add fluid as required.

1, Make sure the brake fluid level in the reservoir is at

the MAX (uDDer) level line.

MAX {UPPER) LEVELLINE

RESERVOIR

MASTER CYLINDER

2.

3.

Have someone slowly pump the brake pedal several

times, then apply steady pressu.e.

Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

Repeat the procedure for each wheel in the sequence

shown below until air bubbles no longer appear in

the tluid.

Refill the reservoir on the master cvlinder to the

MAX (upper) level line.

ALEEDING SEOUENCE:

O Front RightGt Rear Right

O Front LeflO Rear Left

NOTE: Bleed the front calipers first in the bleeding

procedure.

4.

FRONT:

BLEEO SCREW7 N.m (0.? kgf.m, 5 lbf.ftl

19-7

www.emanualpro.com

Page 933 of 1395

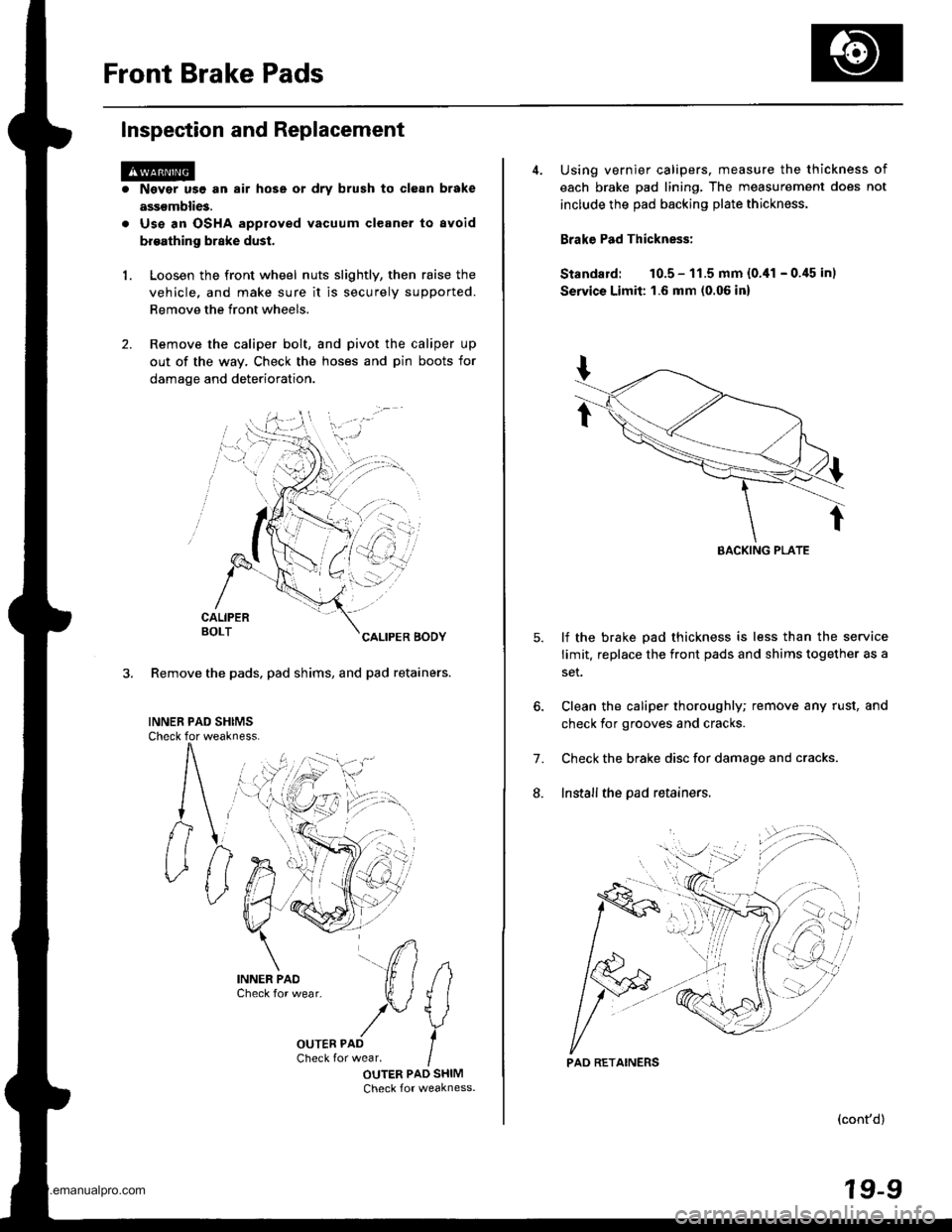

Front Brake Pads

Inspection and Replacement

1.

Nsvgr u9e an air hose or dry brush to clean brake

assemblies.

Use an OSHA approved vacuum cleaner to avoid

broathing brake dust.

Loosen the front wheel nuts slightly, then raise the

vehicle, and make sure it is securely supported.

Remove the front wheels.

Remove the caliper bolt, and pivot the caliper up

out of the way. Check the hoses and pin boots for

damage and deterioration.

CALIPERBOLTCALIPER BODY

3. Remove the pads, pad shims, and pad retainers.

INNEB PAD SHIMSCheck for weakness.

#

IOUTER PAD SHIMCheck for weakness.

i)n.

4. Using vernier calipers, measure the thickness of

each brake pad lining. The measurement does not

include the pad backing plate thickness.

Brake Pad Thickness:

Standard: 10.5 - 11.5 mm {0.,11 - 0.45 in)

Servics Limit: 1.6 mm (0.06 in)

lf the brake pad thickness is less than the service

limit. replace the front pads and shims together as a

set.

Clean the caliper thoroughly; remove any rust, and

check for grooves and cracks.

Check the brake disc for damage and cracks.

Install the pad retainers.

7.

L

(cont'd)

19-9

EACKING PLATE

'.'..i

PAD RETAINERS

www.emanualpro.com

Page 936 of 1395

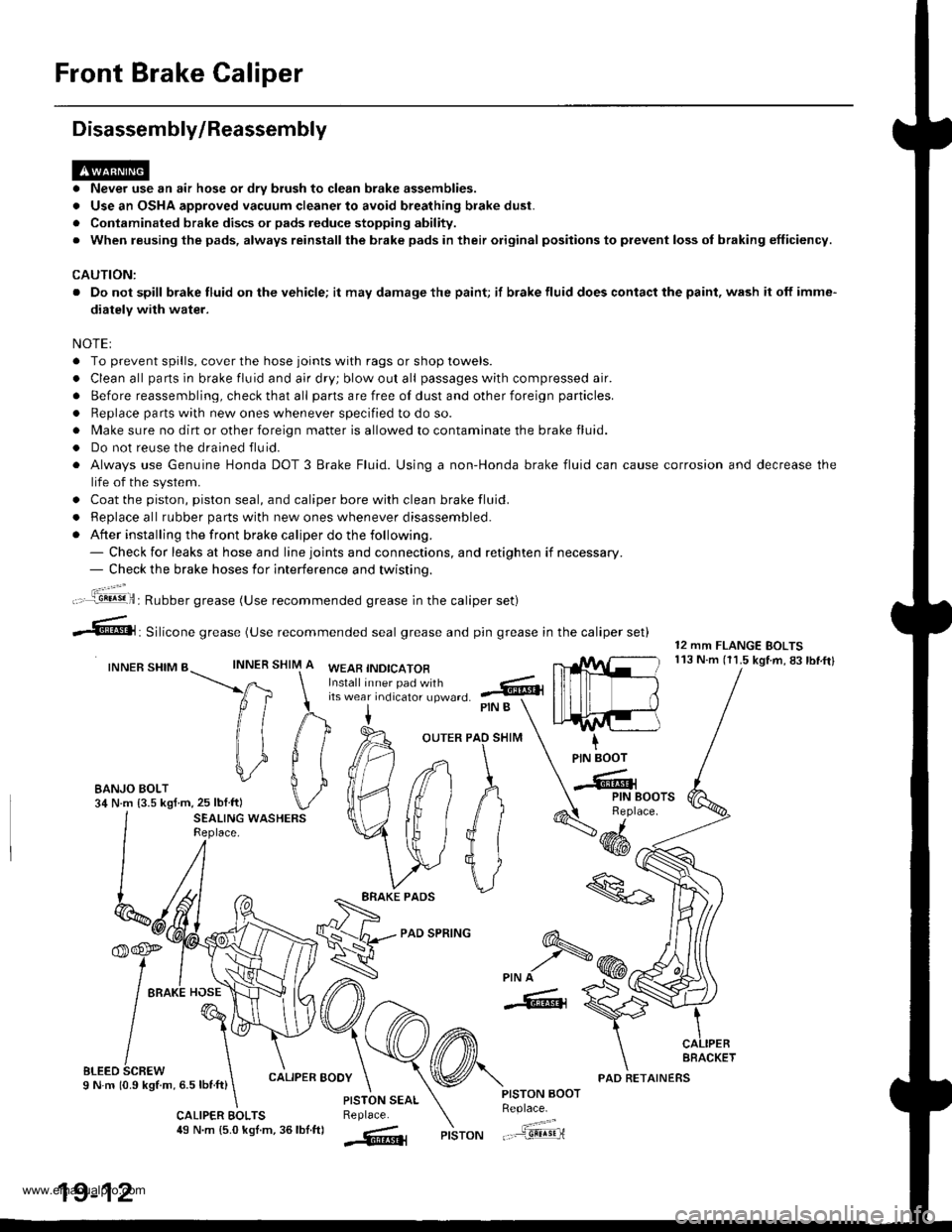

Front Brake Caliper

Disassembly/Reassembly

. Never use an air hose or dry brush to clean brake assemblies.

. Use an OSHA approved vacuum cleaner to avoid breathing brake dust.

. Contaminated brake discs or pads reduce stopping ability.

. When reusing the pads, always reinstallthe brake pads in their original positions to prevent loss ol braking efficiency.

CAUTION:

. Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid does contact the paint, wash it off imme-

diatelY with water.

NOTEI

. To prevent spills, cover the hose joints with rags or shop towels.

. Clean all pans in brake fluid and air dry; blow out all passages with compressed air.

. Before reassembling, check that all parts are free of dust and other foreign particles.

. Replace parts with new ones whenever specified to do so.

. Make sure no dirt or other foreign matter is allowed to contaminate the brake fluid.

. Do not reuse the drained fluid.

. Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

. Coat the piston, piston seal, and caliper bore with clean brake fluid.

. ReDlace all rubber oarts with new ones whenever disassembled.

. After installing the front brake caliper do the following.- Check for leaks at hose and line joints and connections, and retighten if necessary.- Check the brake hoses for interference and twistinq.

SHIM

12 mm FLANGE BOLTS113 N.m (11.5 kgtm,83lbf.ftlINNER

ft

il1

#

\i

#

PIN B

OUTER PAO SHIM

PAD SPRING

IPIN BOOT

-Cr

SEALING WASHERSReplace.4dd*

ERAKE PADS

'f,-rre

/ tto*l "o"\

t@I

/\'

sLreo 6cnew \I N m 10.9 kStm, 6.5 lbnft)

\

6-

>PIN A

-6, {

CALIPER BOOY

CALIPER EOLTS49 N.m {5.0 kgl.m, 36lbf.ftl

PISTON AOOTReplace.

"..-a=a-...,--"sEqriPISTON

t".:jil,,.'.1!!!!9!il: Rubber grease (Use recommended grease in the caliper set)

irf"i:;;T::fl,-J'I",0 .@

--6, Silicone grease (use recommended seal grease and p,n grease in the caliper set)

INNER SHIM BWEAB INDICATOR

EANJO BOLT34 N.m {3.5 kgf m,25 lblftl

PISTON SEALReplace.

AFACKET

19-12

PAD RETAINERS

www.emanualpro.com

Page 940 of 1395

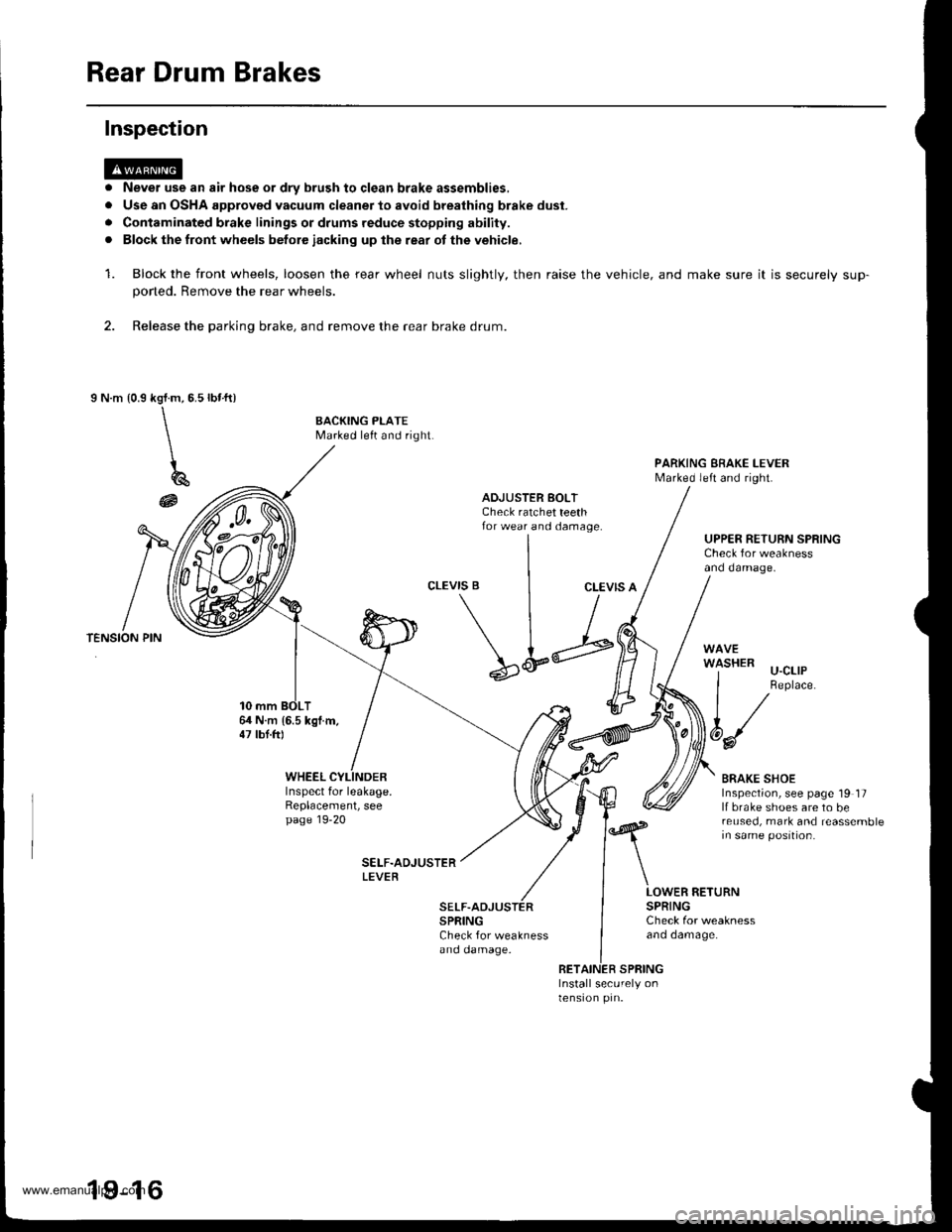

Rear Drum Brakes

Never use an air hose or dry brush to clgan brake assemblies,

Use an OSHA approved vacuum cleaner to avoid breathing brake dust.

Contaminated brake linings or drums reduce stopping ability.

Block the front wheels betore iacking up lhe rear ot the vehicle,

Block the front wheels, loosen the rear wheel nuts slightly, then raise the

poned. Remove the rear wheels.

2. Release the parking brake, and remove the rear brake drum.

I N.m {0.9rbr.ft)kgl.m,5.5

\\

\

196

@

Inspection

a

a

rl

a

1.vehicle, and make sure it is securely sup-

BACKING PLATEMarked left and right.

PARKING EBAKE I-EVERMarked left and right.

ADJUSTER BOLTCheck ratchet teethfor wear and damage.UPPER RETURN SPRINGCheck for weaknessand damage.

CLEVIS BCLEVIS A

64 N.m 16.5 kgl.m,47 lbt.ftl

\L;

SPRINGCheck for weaknessano oamage.

'l-'-' u-cllP

I Replace.

t/

6d/

BRAKE SHOEInspection, see page 19 17lf brake shoes are to bereused, mark and reassemblein same position.

WHEELInspect for leakage.Replacement, seepage 19-20

LOWER RETURNSPRINGCheck for weaknessano oamage.

RETAINER SPRINGInstall securely onlensron prn.

19-16

www.emanualpro.com

Page 952 of 1395

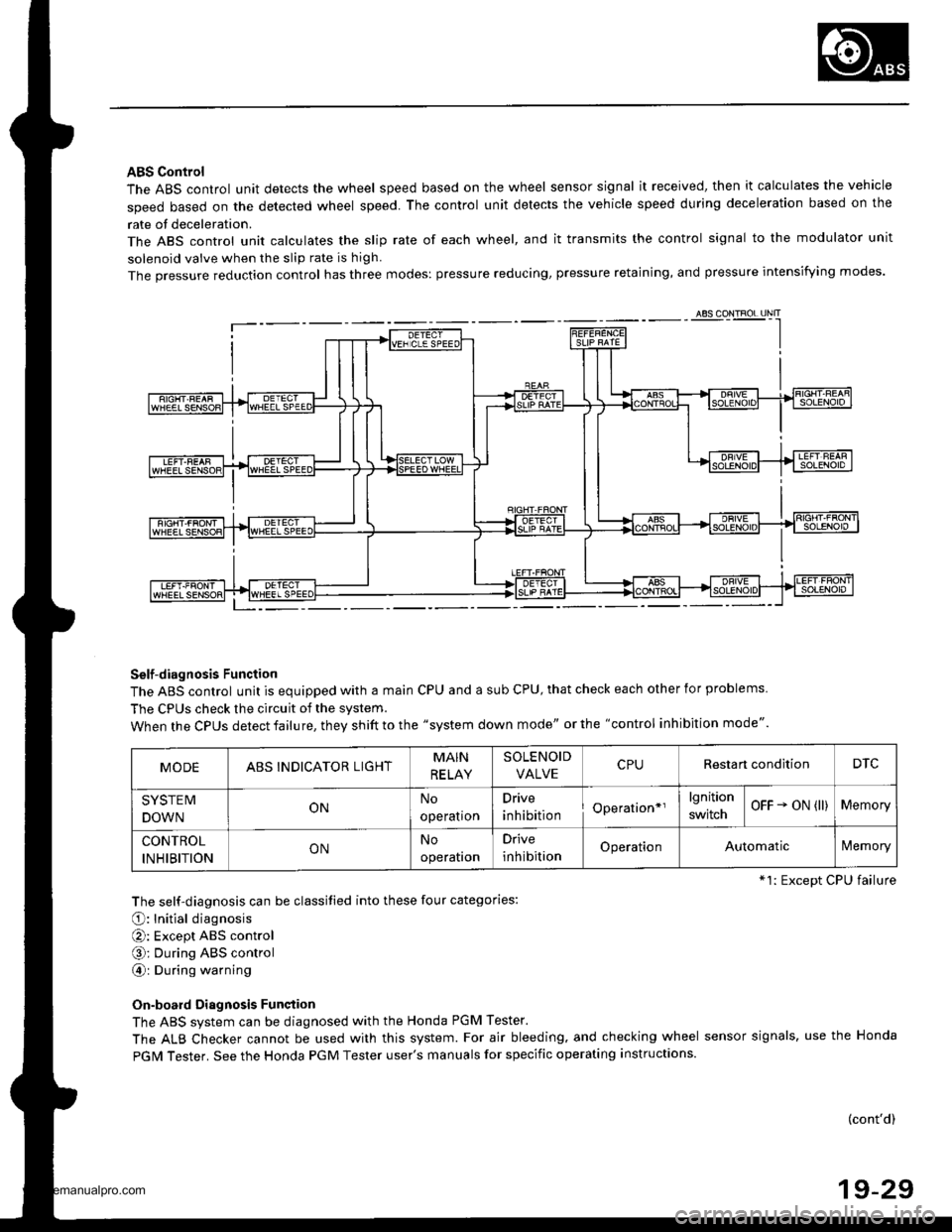

ABS Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the vehicle

speed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration based on the

rate of deceleration.

The ABS control unit calculates the slip rate of each wheel, and it transmits the control signal to the modulator unit

solenoid valve when the slip rate is high

The pressure reduction control has three modes: pressure reducing, pressure retaining, and pressure intensi{ying modes.

Self-diagnosis Function

The ABS control unit is equipped with a main cPU and a sub cPU, that check each other for problems.

The CPUs check the circuit of the system.

When the CPUS detect failure, they shift to the "system down mode" or the "control inhibition mode".

The self-diagnosis can be classitied into these four categories:

O: Initial diagnosis

O: Except ABS control

O; During ABS control

@: During warning

On-board Diagnosis Function

The ABS system can be diagnosed with the Honda PGM Tester.

The ALB Checker cannot be used with this system. For air bleeding. and checking wheel sensor signals, use the Honda

PGIM Tester. See the Honda PGM Tester user's manuals for specific operating instructions.

(cont'd)

19-29

ABS CONTROL I-INIT

MODEABSINDICATOR LIGHTMAIN

RE LAY

SOLENOID

VALVERestan conditionDTC

SYSTEM

DOWNONNo

operatron

Drive

inhibitionOperation*rlgnition

switchOFF - oN (ll)Memory

CONTROL

INHIBITIONONNo

operaton

Drive

inhibitionOperationAutomaticlVemory

*1: Except CPU failure

www.emanualpro.com

Page 960 of 1395

Kickback'1. The motor operates when the ABS is functioning. and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

2. The ABS control unit operates the solenoid valve when the brake pedal is released after the initial diagnosis You may

hear the solenoid valve operate at this time, but it is normal

Pumo Motol

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the motor operate at this

time, but it is normal.

Brake Fluid Replacement/Ail Bleeding

L Brake fluid replacement and air bleeding procedures are the same as for vehicles without ABS To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowchart procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Self-diagnosis is made at various times such as the initial diagnosis, except ABS control, during ABS control, during

acceleration, during the specified vehicle speed, etc. Therefore, the symptom canngt be checked unless the check

conditions match with the problem conditjons

3. When the ABS jndicator does not come on during the test-drive. but troubleshooting is performed based on the DTC,

check lor loose connectors, poor contact of the terminals, etc., before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustratjons show the female terminals with a single outline and the male terminals with a double out-

l ne.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu, and follow the tester's prompts.

19-37

www.emanualpro.com