cat HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 612 of 1395

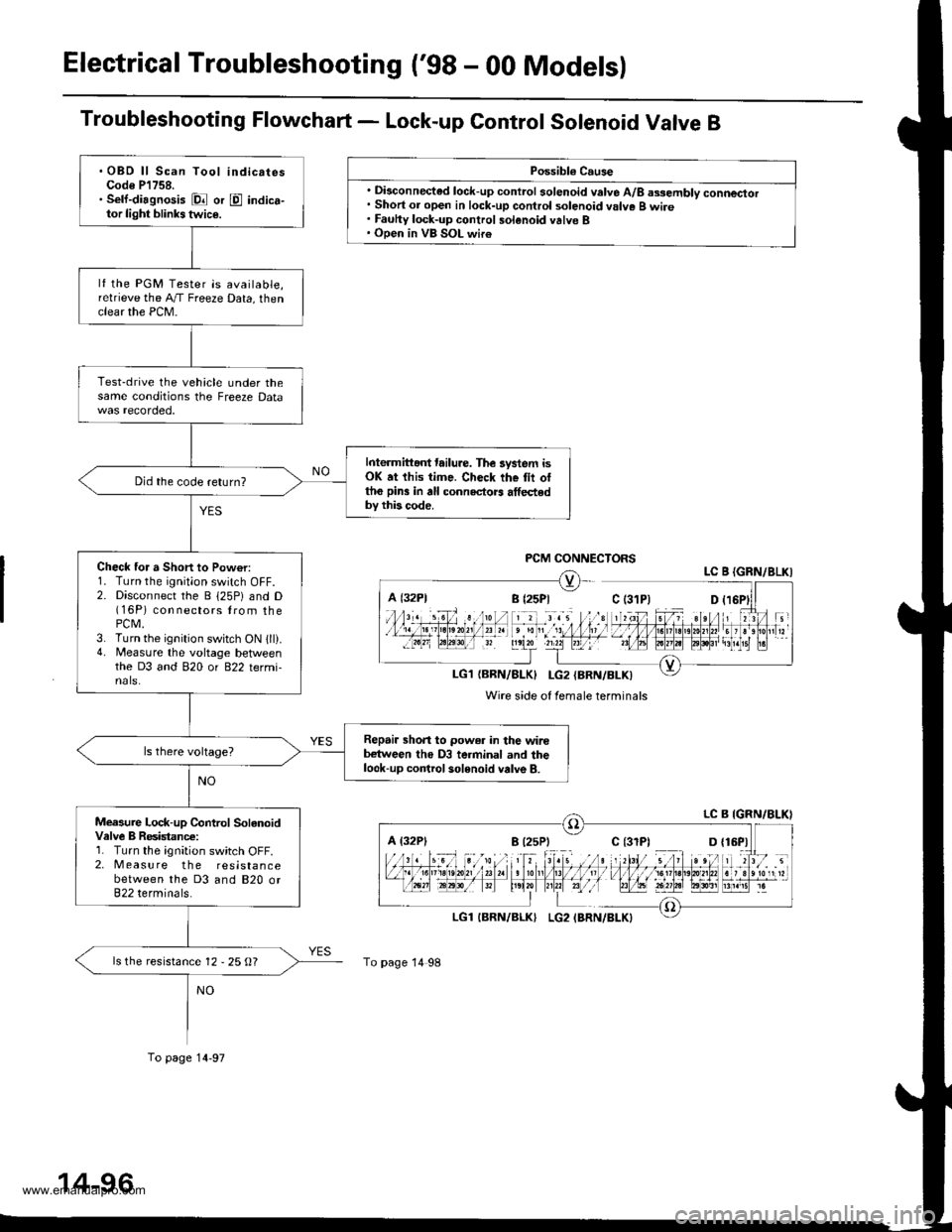

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Lock-up Control Sotenoid Valve B

Possibl€ Cause

. Disconnected lock-up control solenoid valve A/8 assembly connector. Short or open in lock-up control solenoid valve B wire. Fauhy lock-up control solenoid valve B. Open in VB SOL wir€

PCM CONNECTORSLC B {GRN/8LKI

LG1{BRN/BLK} I-G2{BRN/BLK)

Wire side of female terminals

A {32P1

To page 14 98

.OBD ll Scan Tool indicatesCode P'l758.. Sell-diagnosis Dl or E indica-tor light blinks twic€.

lf the PGM Tester is available,relrieve the A,/T Freeze Data, thenclear the PCM-

Test-drive the vehicle under thesame conditions the Freeze Data

Interm ittant tailure. The lystem isOK at this time. Check the tii ottho pin3 in all connectors athedby this code.

Did the code return?

Check for a Short to Pow€r:1. Turn the ignition switch OFF.2. Disconnect the B 125P) and D(16P) con nectors lrom thePCM.3. Turn the ignition switch ON 1ll).4. Measure the voltage betlveenthe D3 and 820 or 822 termi-nals.

Repair shon to power in the wirebetween tho D3 terminal and thelook-up control solenoid valve B.

Measure Lock-up Control SolanoidValve B Resistanc€:1. Turn the ignition switch OFF.2. Measure the resistancebetween the D3 and 820 or822 terminals.

ls the resistance 12 - 25 O?

To page 14-97

www.emanualpro.com

Page 615 of 1395

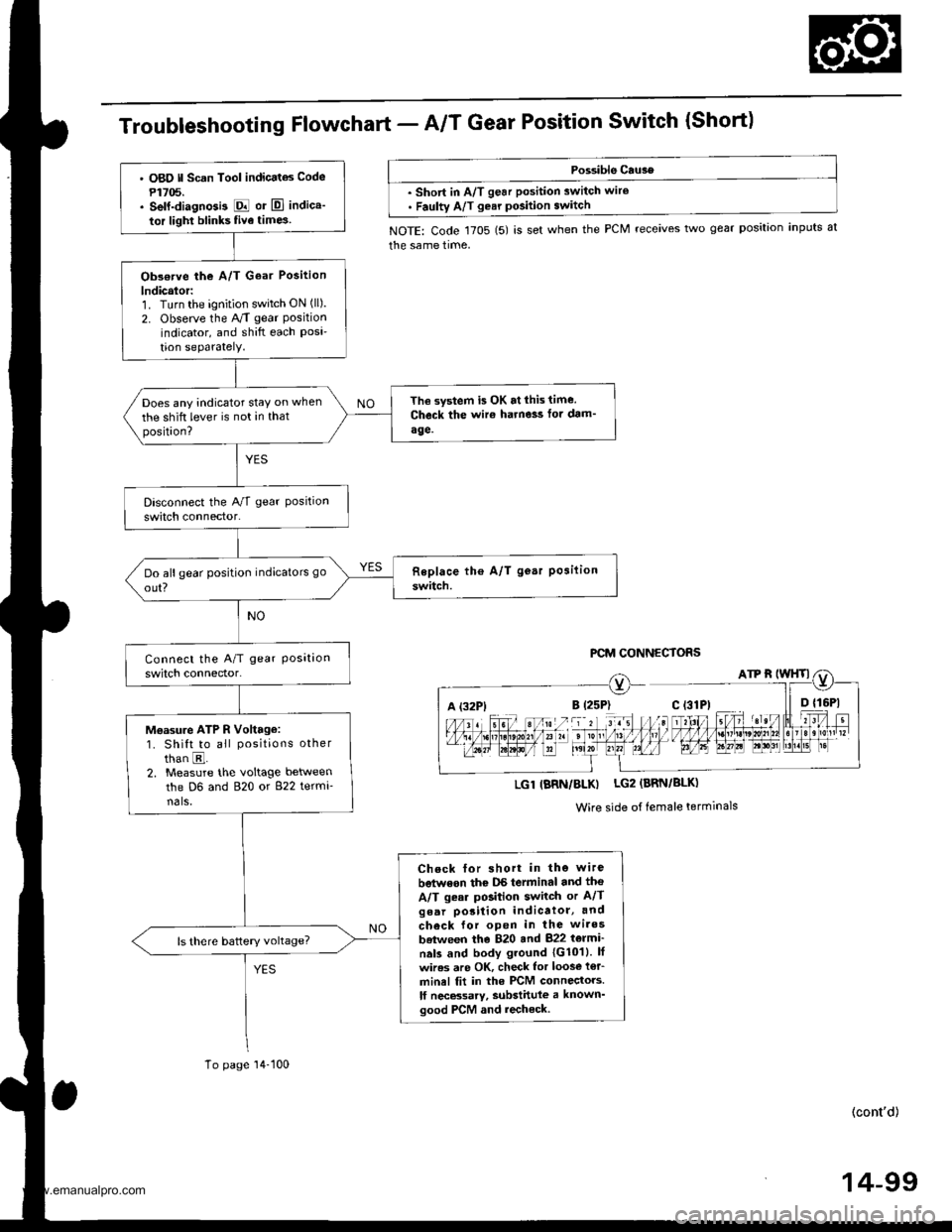

TroubleshootingFfowchart - AIT Gear Position Switch {Short)

Possible Cau3e

. short in A/T gear position switch wire. Faulty A/T gear pGition switch

NOTE: Code 1705 (5) is set when the PCM receives two gear position inputs at

the same time,

PCM CONNECTORS

A (32P1

LGl IBRN/BLK) LG2 (BRN/BLK)

Wire side of female terminals

' O8O ll Scan Tool indicatas Code

P1705.. self-diagnGi3 E or El indica'

tor light blinks five time3

Obs€rve the A/T Goar Position

lndicalor:1. Turn the ignition switch ON (ll).

2. Observe the A/T gear Positionindicator, and shift each Posi'tion seParatelY.

The system is OK at lhis time.

Check the wir€ harne3s fot dam'

age.

Does any indicator stay on when

the shift lever is not in thatposition?

Moasu.e ATP R Voltage:1. Shift to all positions other

than E.2. Measure the voltage between

the D6 and 820 or 822 termi-nals,

Check for short in the wire

betwoon thc DS terminal and tho

A/T gear position switch or A/Tgear porition indicatol, and

check for open in the wires

batween the 820 and 822 t6lmi'

nals and body ground 1G1011. lf

wires are OK, check lor loos€ i€r_

minel fit in the PCM connectors.

lf necBsarv, substittlle a known'good PCM and recheck.

To page'14-100

(cont'd)

14-99

www.emanualpro.com

Page 616 of 1395

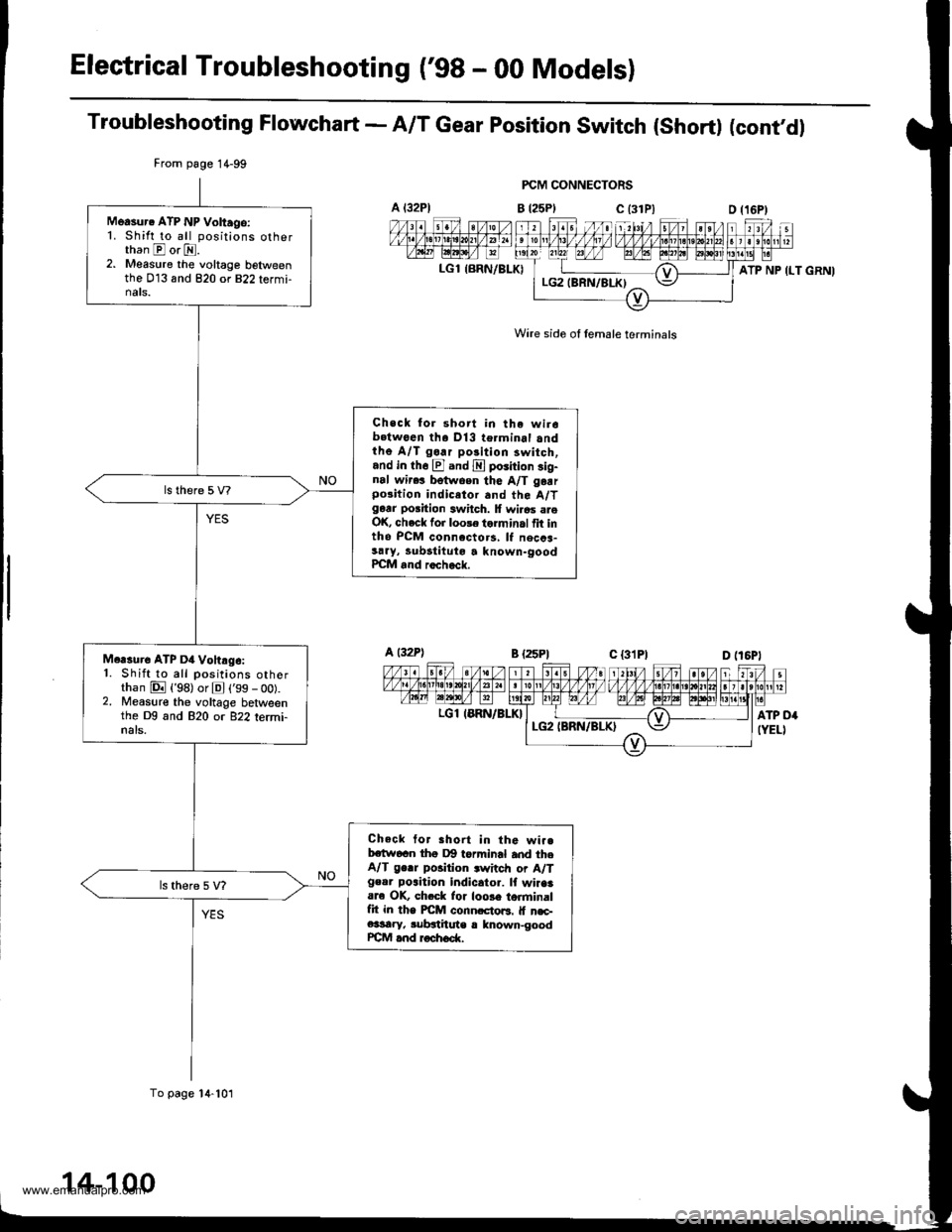

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - A/T Gear position switch (short) (cont'dl

FCM CONNECTORS

B t25Plc (31P)

Wire side of lemale terminals

A t32Pl

LGl {BRN/BLK)

From page 1 4-99

To page 14-101

Measur. ATP NP Voltago:1. Shift to all positions otherthan E or E.2. Measure the voltage belweenthe 013 and 820 or 822 termi-nats.

Check for short in the wir6b.twoen tha Dl3 terminal andthe A/T go.r polition 3witch,and in th6 El and E poiition sig-nal wir.! betwoen the A/T garrpo3ition indicetor and the A/Tgarr position switch. lf wi.6s areOK, check for loole torminal fit intho PCM connccto.s, lf necca-sary, lubstituto a known-goodPCM and rocheck.

Mcrsure ATP D4 Vohrg6:1. Shift to all positions otherthan E {'98) or El ('99 - oo).2. Measure the voltage betweenthe Dg and 820 or 822 termi-nals.

Check tor Bhort in the wi..bctw6cn thg Dg torminal and theA/T ge.r position .witch or A/Tgeor poaition indicator. lf wiaaaare OK, ch.ck lor loose torminalfit in the PICM conn.cto6. lf n€c-e3sary, subgthute r lnown-goodrcM and roch6d(.

ATP NP ILT GRNI

a t32Pl

LGl IERN/BLK}

14-100

www.emanualpro.com

Page 617 of 1395

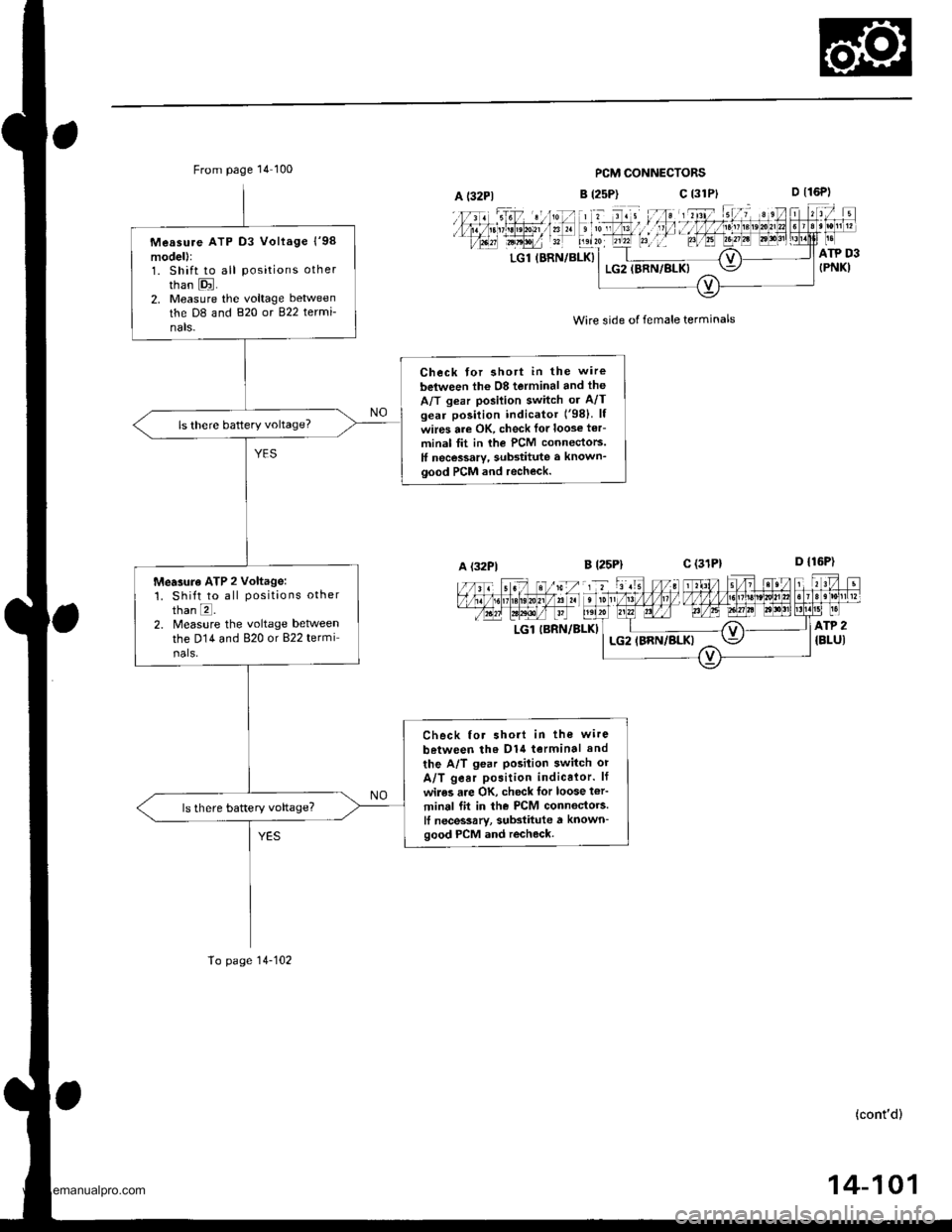

From page 14 100PCM CONNECTORS

B (2sP)c (31P}

' t d. , lll;;l';nl, :if

D t16P)

D {16P1

ATP D3{PNK)LGl (BRN/BLK}LG2IBRN/BLK)

Wire side of female terminals

B l25Plc (31P1

LGl IBRN/BLKI

A (32P1

Measure ATP D3 Vollage l'98model):1. Shift to all positions other

than E.2, Measure the voltage between

the D8 and 820 or 822 termi-

nals-

Check for shott in the wire

belween lh6 08 terminal and the

A/T gear posilion switch or A/Tgear position indicator ('98) lf

wires are OK, check lor loose ter-

minal tit in rhe PCM connectors.

ff necessary, substitute a known_good PCM and recheck.

ls there battery voltage?

Mearure ATP 2 voltage:1. Shift to all positions otherthan E.2. Measure the voltage betweenthe D14 and 820 or 822 termi

nals.

Check for short in the wire

between tho D1{ terminal and

the A/T gear posilion switch or

A/T gear position indicalor. lf

wiles are OK, check for loose t€r'

minal fit in the PCM connectors.It necessarv, substitute a known-good PCM and recheck.

To page 14-102

(cont'd)

14-101

www.emanualpro.com

Page 618 of 1395

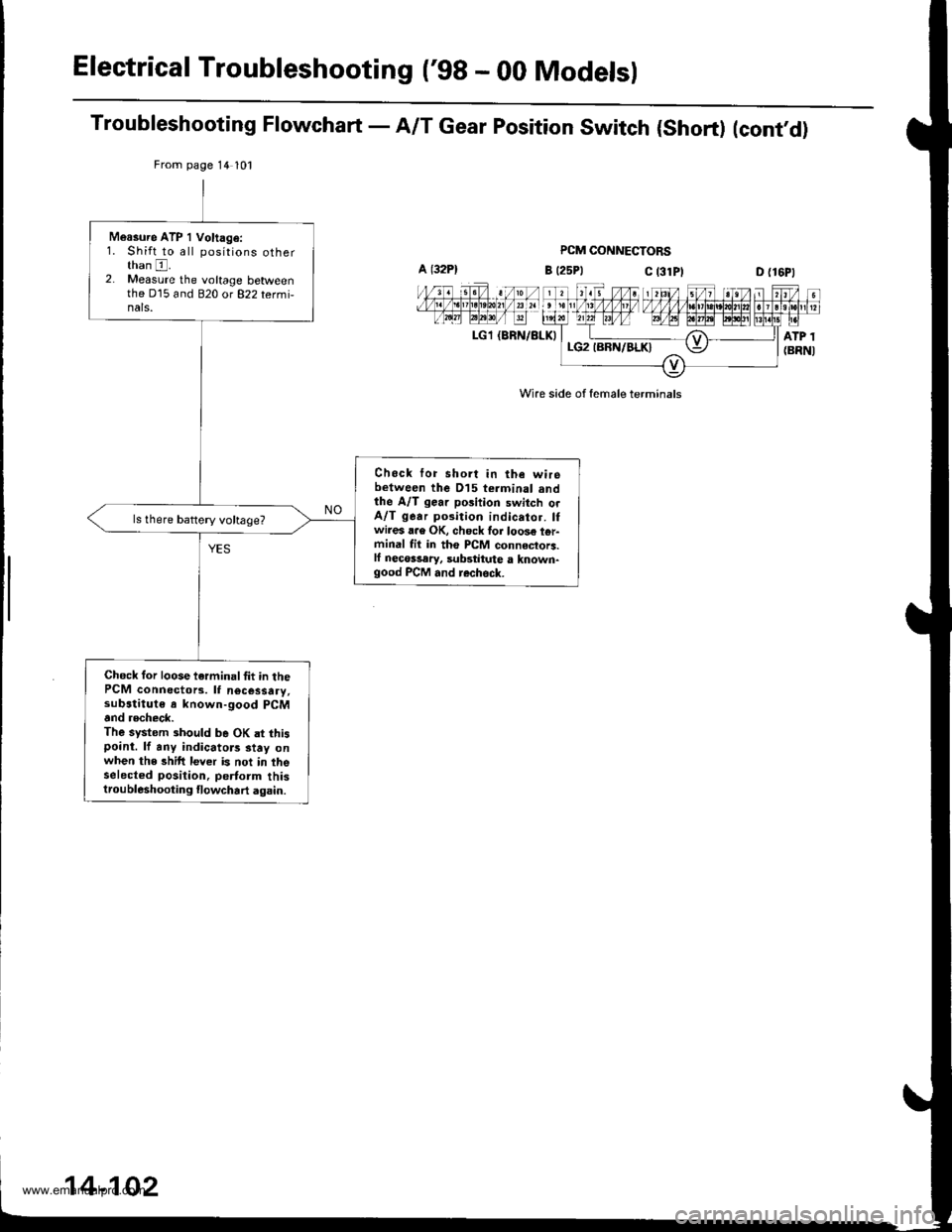

Electrical Troubleshooting ('gg - 00 Modelsl

Troubleshooting Flowchart - A/T Gear position switch {short) (cont,d)

PCM CONNECTORS

B t25Ptc t3lPlD {16P1

LGl {BRN/BLK)

Wire side of female terminals

From page 14 101

Measure ATP 1 Voltag€:1. Shift to all positions otherthan E.2. Measure the voltage betweenthe D15 and 820 ot 822 tetmi-nals.

Chock lor short in the wirebetween the D15 terminal andthe A/T gear position switch orA/T gear position indicator. lfwires a.e OK, ch6ck for loos€ t6r-minal fil in tho PCM connectorc.ll neco$ary, substiiute a known-good PCM and rechsck.

Chock for loose terminalfit in thePCM connectors. lf nocessary,sub3titut€ s known-good PCMand recheck.The system 3hould be OK at thispoint. lf any indicators stay onwhen the shift lever is not in iheselect€d position, pertorm thistroubleshooting tlowchart again.

www.emanualpro.com

Page 619 of 1395

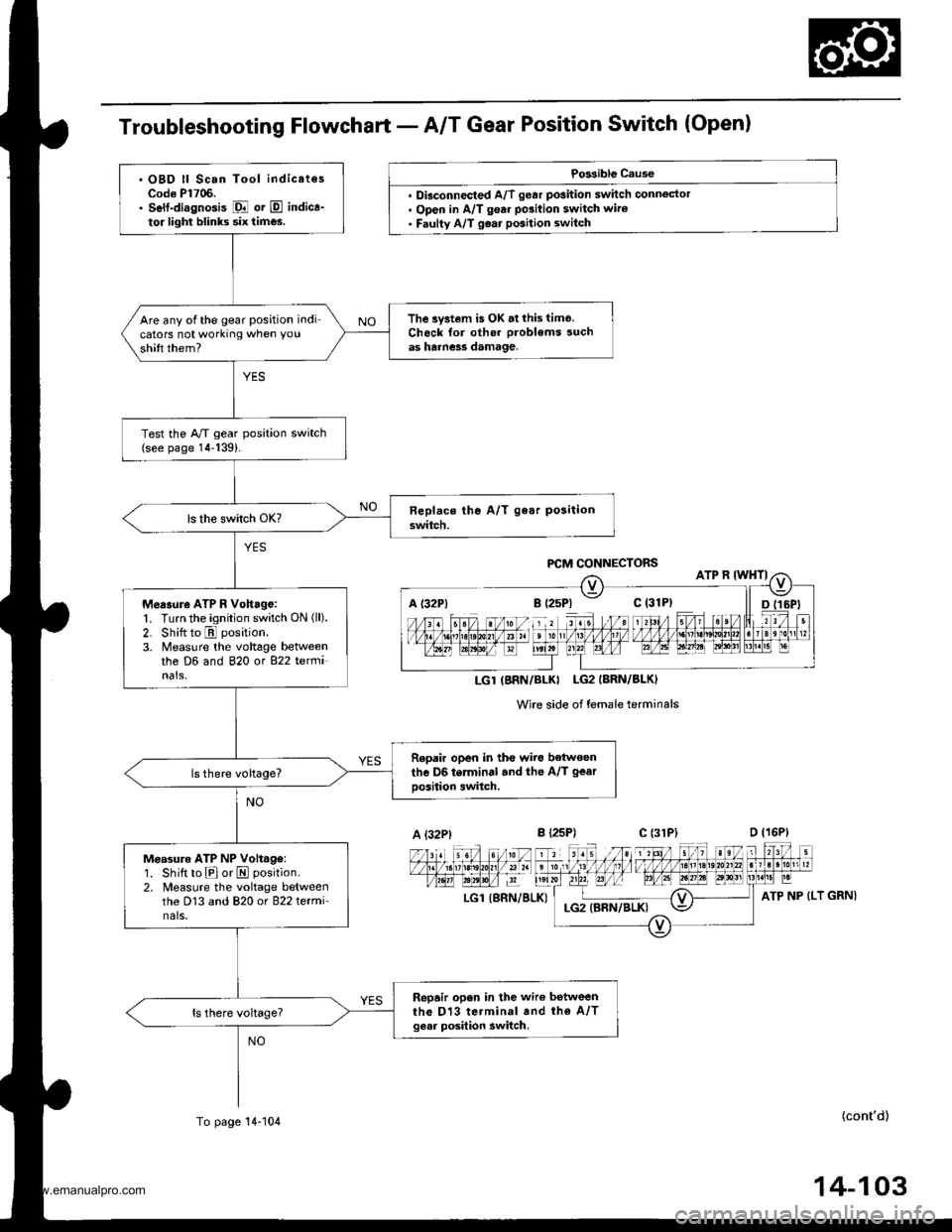

Troubleshooting Flowchart - A/T Gear Position Switch (Open)

Po$iblg Cause

. Dbconnected A/T gear position switch connoctor. Open in A/T gear po3ition switch wiro. Faulty A/T g€ar position switch

Wire side of female terminals

LGl {SRN/BLK)

{cont'd)

P,CM CONNECTORS

LGT(BNN/BLKI LG2IBRN/BLK)

A {32P)c l31P)

ATP NP (LT GRN}

. OBD ll Scan Tool indicatesCodo Pl706.. Self-diagnosis Fl or E indica-to. lighl blinks six times.

The system is OK.tthis time.Check for oth6r probl€ms suchas harne3s damage.

Are any ofthe gear position indicators not working when you

shift them?

Test the A/T gear position switch(see page 14-139).

Measure ATP R Vohago:1. Turn the ignition switch ON (ll).

2. Shitt to E position.

3. Measure ihe voltage betweenthe D6 and 820 ot 822 tetfiinals,

Repair open in tho wiro betwoenthe D6 terminal and the A/T gear

oosition switch.

Measure ATP NP Volt.g€:1. Shift to Elor E position.

2. Measure the voltage betweenthe D13 and 820 or 822 terminals,

Repair open in the wiro betweenth€ Dl3 terminal and th€ A/Tgesr posilion awitch.

To page 14-104

14-103

www.emanualpro.com

Page 622 of 1395

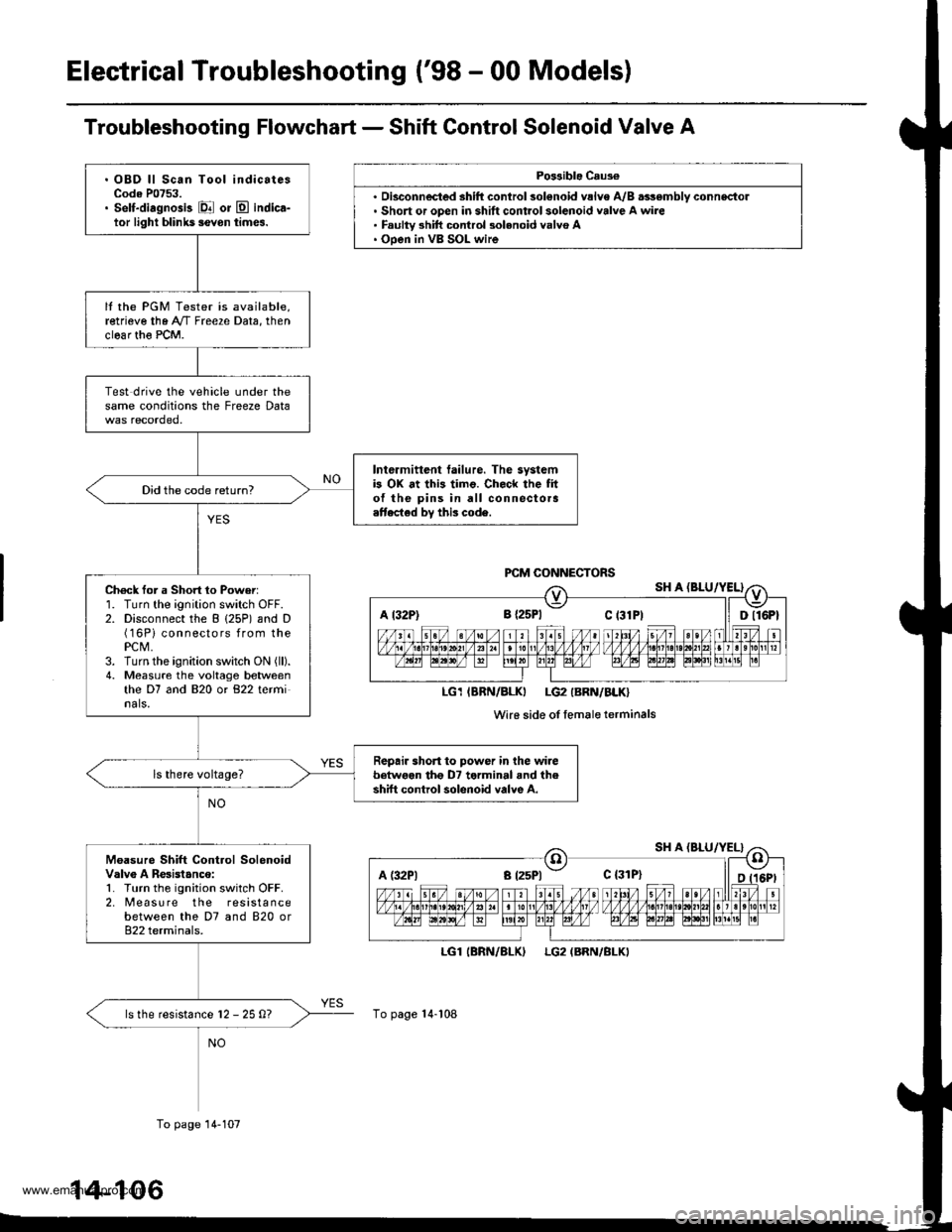

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Shift Control Solenoid Valve A

Po$ible Caus€

'. Short or open in shift control solenoid valve A wire. Faulty 3hift control 3olenoid valvo A. Ooen in VB SOL wire

LGl

To page 14-108

(BRN/BLKILG2 (BRN/BLKI

A t32P) 8 {2sPl Ct3lPt ll Dll6Pt

LG1IBRN/BLKI LG2IBRN/BLK}

Wi16 side of femaleterminals

A (:l2Pl a t25Pl - c {31P}

. OBD ll Scan Tool indicatesCode P0753.. Self-diagnosis El or E indica-tor light blihk5 ievon times.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear th€ PCM.

Test drive the vehicle under thesame conditions the Freeze Data

Intermittent tailure. The systemb OX at this timo. Check the fito{ the pins in all connectora.ttected by this code.

Did the code return?

Ch6ck for a Short 1o Power:1. Turn the ignition switch OFF.2. Disconnect the B (25P) and D(16Pi connectors from thePCM,3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe D7 and 820 or 822 terminals.

Repair short to power in the wirebetwoen tho D7 terminal and theshift control solenoid valve A.

Moasure Shift Control SolenoidValv6 A Resistanco:1. Turn the ignition switch OFF.2. [reasu re the resistancebetween the D7 and 820 or822 terminals.

ls the resistance l2 - 25 0?

To page 14-107

14-106

www.emanualpro.com

Page 625 of 1395

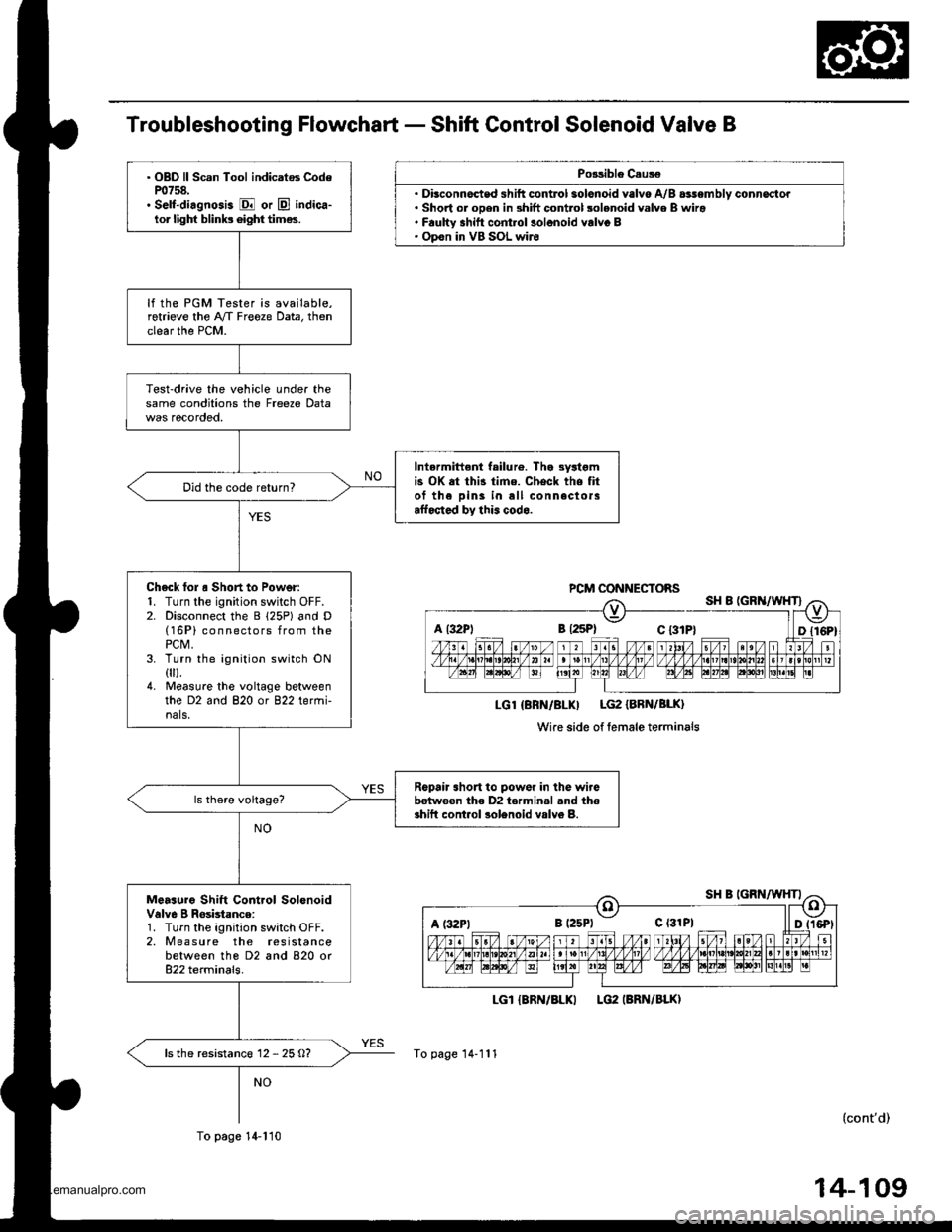

Troubleshooting Flowchart - Shift Control Solenoid Valve B

Po3sible C.us€

.Dt. Short or oDen in shift control solenoid valve B wira' F.ulW shitt cont.ol solonoid valvc B. Opon in VB SOL wir6

LGI {8RN/BLKI

To page 14-111

PCM CONNECTOBS

LGl {BRN/BLKI LG2 {BRN/BLK}

Wire side of lemale terminals

a l32Pl B {2sPl c t3tP}

c (31P1

. OBD ll Scan Tool indicatos CodeP0758.. Self-di.gnosis E or E indica-lor lighf blinb 6ight times.

lf the PGM Tester is available.retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intermittent failu16. Tha 3yltgmis OK at thi3 time. Check the fitof the Dins in all connectorsaffocted by this codo.

Did the code return?

Check lol o Short to Power:1. Turn the ignition switch OFF.2. Disconnect the B 125P) and D(16P) connectors from thePCM,3. Turn the ignition switch ON0ll.4. Measu.e the voltage betweenthe D2 and 820 or 822 termi-nals.

Ropair short to powor in lhe wirebetwoon the D2 termin.l .nd thoshift cont.ol solenoid vslv6 B.

Measuro Shift Control SolonoidValve I Rosbtance:1. Turn the ignition switch OFF.2. M easu re the resistancebetween tho D2 and 820 or822 terminals.

ls the resistanc€ 12 - 25 O?

To page 14-110

LG2 IBRN/BLKI

(cont'd)

www.emanualpro.com

Page 628 of 1395

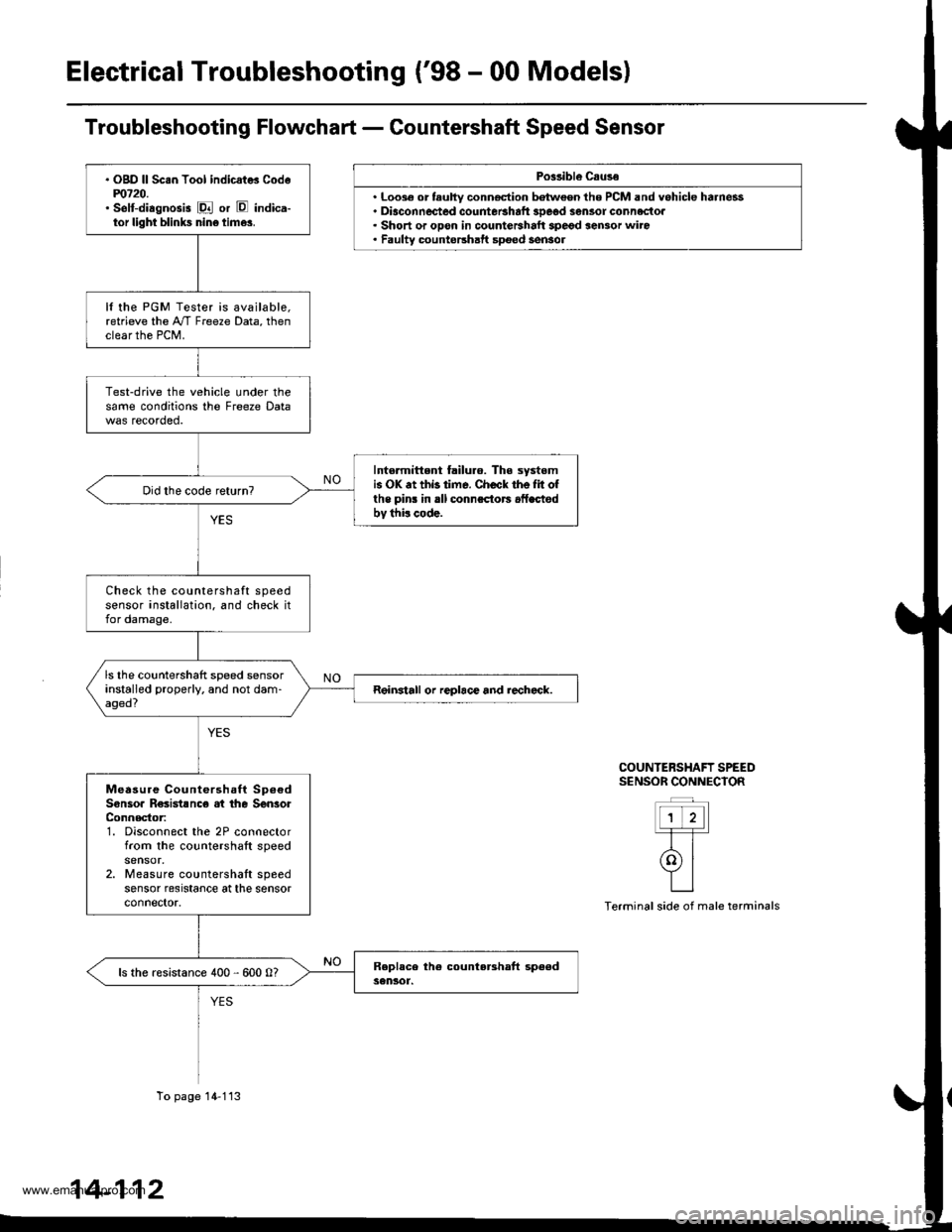

Electrical Troubleshooting ('98 - 00 Models)

Po$ibl€ Csuse

. Loo3€ or tauhy conn€ction batween the PCM and vehicle harness. Diaconnected countetshaft 3Deod sensor connectoa. Short or opon in countershalt spegd sensor wiro. Faulty countershatt spoed sensol

COUNTERSHAFT SPEEDS€NSOR CONNECIOR

ttt'l-T-T-

rolYILI

Terminal side of male terminals

. OgD ll Sc.n Tool indicat* Codem720.' selt-diagnosis E or E indica-tor light blinks nin6 time3.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intormittent failuro. The systomis OK .t thb time. Check the Iit ofthe pins in rll connsctors .fLctodbv thi! code.

Check the countershaft speedsensor installation. and check itfor damage.

ls the countershaft speed sensorinstalled properly. and not dam-aged?Reinstall or replace and rechcck.

Measure Countershaft Sp6€dSonsoa R€sistsnc€ at the SenlorConnector:1. Disconnect the 2P connectorfrom the countershaft speed

2. Measure countershaft speedsensor resrstance at the sensorconnector.

ls the resistance 400 - 600 0?

To page 14-113

14-112

www.emanualpro.com

Page 630 of 1395

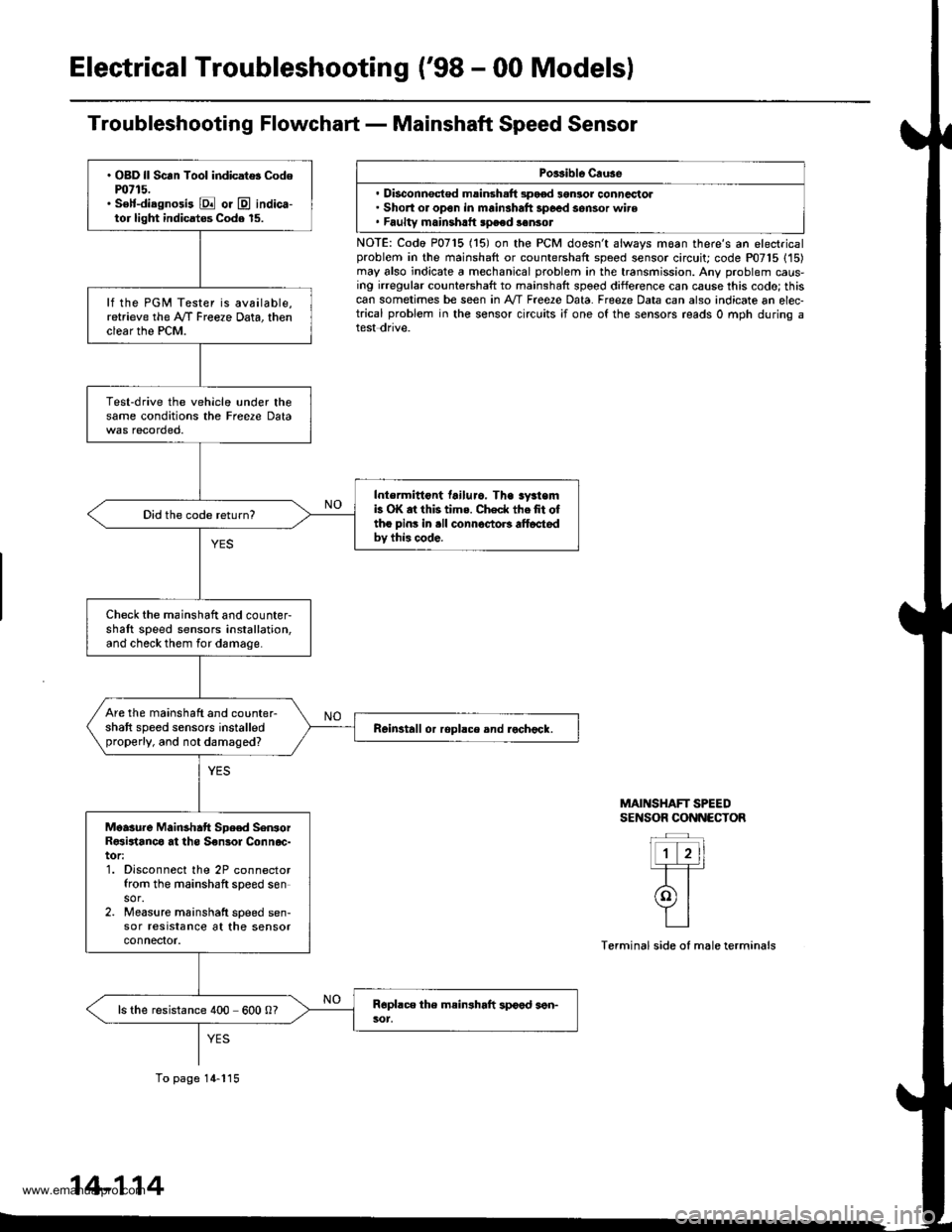

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Mainshaft Speed Sensor

Porsible Cruse

. Disconnsct€d msinsh.ft 3pood 3gnlor conncctol. Short or open in mainshaft 3poed sensor wire. Faultv mainshrtt speed sonsot

NOTE: Codo P0715 (15) on the PCM doesn't always moan there's an electricalproblem in the mainshaft or countershaft speed sensor circuit; code P07'15 (15)may also indicate a mechanical problem in the transmission. Any problem caus-ing irregular countershaft to mainshaft spoed difference can cause this codo; thiscan sometimes be seen in A'/T Free2e Data. Freeze Data can also indicate an elec-trical problem in the sensor circuits ;f one of the sensors reads 0 mph during atest dnve.

MAINSHAFT SPEEDSENSOR CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indicat$ Codem715.. S€lf-diagnosi3 E or @ indica-tor light indicatos Code 15.

lf the PGM Tester is available,retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freere Data

Intermittont tailuro. Tha sy3temb OK at this tims. Check thefit oftho pins in .ll connoctoB alt6ctedbv this code.

Did the code return?

Check the mainshaft and counter-shaft speed sensors installation,and check them for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reinstall or ropllce and rochock.

Moasure Mainshatt Spe€d SenrorR€sirtanco at ths S€nsol Connoc-tor:1. Disconnect the 2P connectorfrom the mainshaft speed sensor.2. Measure mainshatt speed sen-sor resrstance at the sensorconnefior.

ls the resistance 400 600 0?

To page 14-115

14-114

www.emanualpro.com