alternator HONDA CR-V 1997 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 361 of 1395

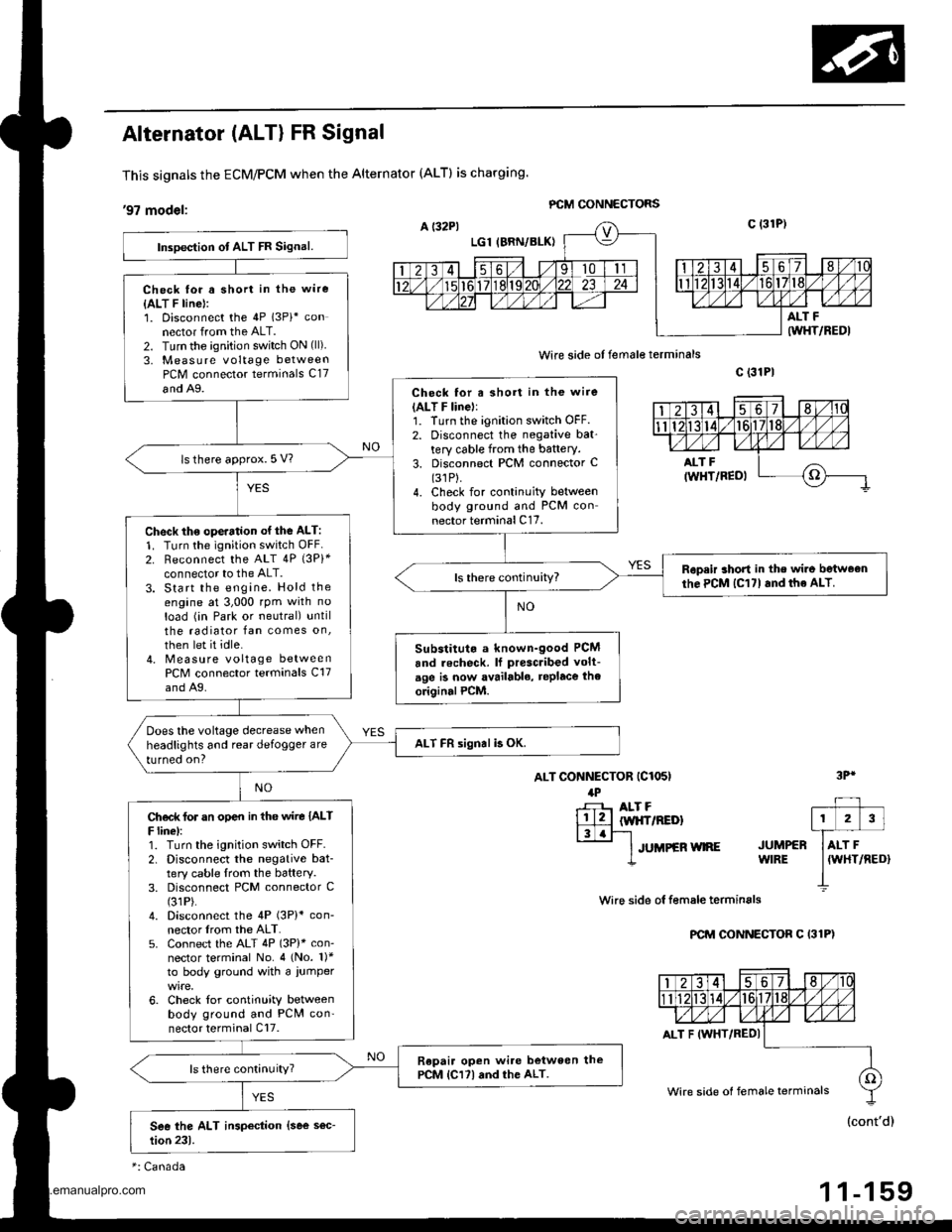

Alternator (ALT) FR Signal

This signals the ECM/PCM when the Alternator (ALTI is charging.

,97 modet: PCM GONNECTORS

wire side of female terminals

ALT CONNECTOR (C1O5I

lPr-F- ALT F

lll2llw|{frREDl|3.r-'l-

lruueen wne

c (31P|

wire side ol f€male terminals

PCM CONNECTOR C I31P)

3Pr

JUMPERWIRE

Inspection ot ALT FR Signal.

Check lor a short in the wire

{ALT F line}:1. Disconnect the 4P 13Pi* connector from the ALT.2. Turn the ignition switch ON (ll)

3, Measure voltage betweenPCM connector terminals C17

and A9.Check for a short in the wire(ALT F linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat'tery cable from the battery.3. Disconnect PCM connector C(31P).

4. Check for continuity betweenbody ground and PCM connector terminal C17.

ls there approx. 5 V?

Check th€ ope.ation of the ALT:

1. Turn the ignition switch OFF2. Reconnect the ALT 4P {3Pi*connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm with no

load (in Park or neutral) untilthe radiator fan comes on,

then let it idle.4. Measure voltage betweenPCM connector terminals C17and A9.

Ropeir short in the wir6 betweonthe PCM lC17l and the ALT.

Substitut. a known-good PCM

and recheck. lf prescribed volt-

age is now availablo, replace the

originalPCM.

Does the voltage decrease when

headlights and rear defogger are

turned on?ALT FR signal b OK.

Ch€d( for an op€n in tho wire IALTF linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat-tery cable lrom the battery.3. Disconnect PCM connector C(31P).

4. Disconnect the 4P (3P)* con-nector lrom the ALT.5. Connect the ALT 4P (3P)* con-nector terminal No. 4 (No. 1)*to body ground with a iumper

6. Check for continuity betweenbody ground and PCN4 con'nector terminal Cl7.

Repair open wi.e between thePCM lCl7l and the ALT.ls there continuity?

ALT F IWHT/REDI

Wire side of female terminals

1 1-159

www.emanualpro.com

Page 362 of 1395

![HONDA CR-V 1997 RD1-RD3 / 1.G Owners Guide

ldle Gontrol System

Alternator (ALT) FR Signal (contdl

98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr FllltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female termi HONDA CR-V 1997 RD1-RD3 / 1.G Owners Guide

ldle Gontrol System

Alternator (ALT) FR Signal (contdl

98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr FllltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female termi](/img/13/5778/w960_5778-361.png)

ldle Gontrol System

Alternator (ALT) FR Signal (cont'dl

'98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr Fl'l'ltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female terminals

ECM/PCM CONNECTOR C {31PI

Wire side of female terminals

Wire side of female terminals

ECM/PCM CONNECTOR C {31P}

": Canada

1 1-160

B (25P)

Insp€ction of ALT FR Signsl.

Check fo. a shon in th. wire {ALTF linel:1. Disconn6ct the 4P (3P)* con-nector from the ALT.2. Turn the ignition switch ON {ll).3. Measure voltage between ECM/PCM connector terminals C5and 820.Ch€ck for a sho.t in iho wirc lAlTF lino):1. Turn the ignition switch OFF.2. Disconnecl the negative bat,tery cable from the battery.3. Disconnect ECM,PCM connec-torC (31P).

4. Check for continuity betwoenbody ground and ECM/PCMconnector terminal c5.

ls there approx. 5 V7

Check the opcration of the ALT:1. Turn the ignitioo switch OFF.2. Reconnect rhe ALT 4P (3P)*connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator lan comes on,then let it idle.4. Measure voltage between ECM/PCM connector terminals C5and 820.

Roprir lhort in tho wirc bstweentho ECM/PCM {Csl and the ALT.

Substitut. r known-good ECM/PCM and roch.ck. It Droscrib.dvoltage b now lvrilabls, .eplaccth. o.igin!l ECM/PCM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR 3ignol is OK,

Chock lor an opon in tha wire (ALTF linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat-tery cable from the battery.3. Disconnect ECM/PCM con-nector C (31P).4. Disconnect the 4P 13P)* con,nector from the ALT.5. Connect the ALT 4P {3P)* con-nector terminal No. 4 1No. 1)*to body ground with a jumper

6. Check for continuity betwe€nbody ground and ECM/PCMconnector terminal C5.

Rsprir opan wiro batw.en thoECM/PCM lcsl .nd th. ALT.ls there continuity?

AI.T F IWHT/REDI

ALT F {WHT/REDI

Wire side ot Iemale terminals

www.emanualpro.com

Page 405 of 1395

EVAP PURGE CONTROL SOLENOID VALVE DUTY CONTROLLED AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154"F (68'C)

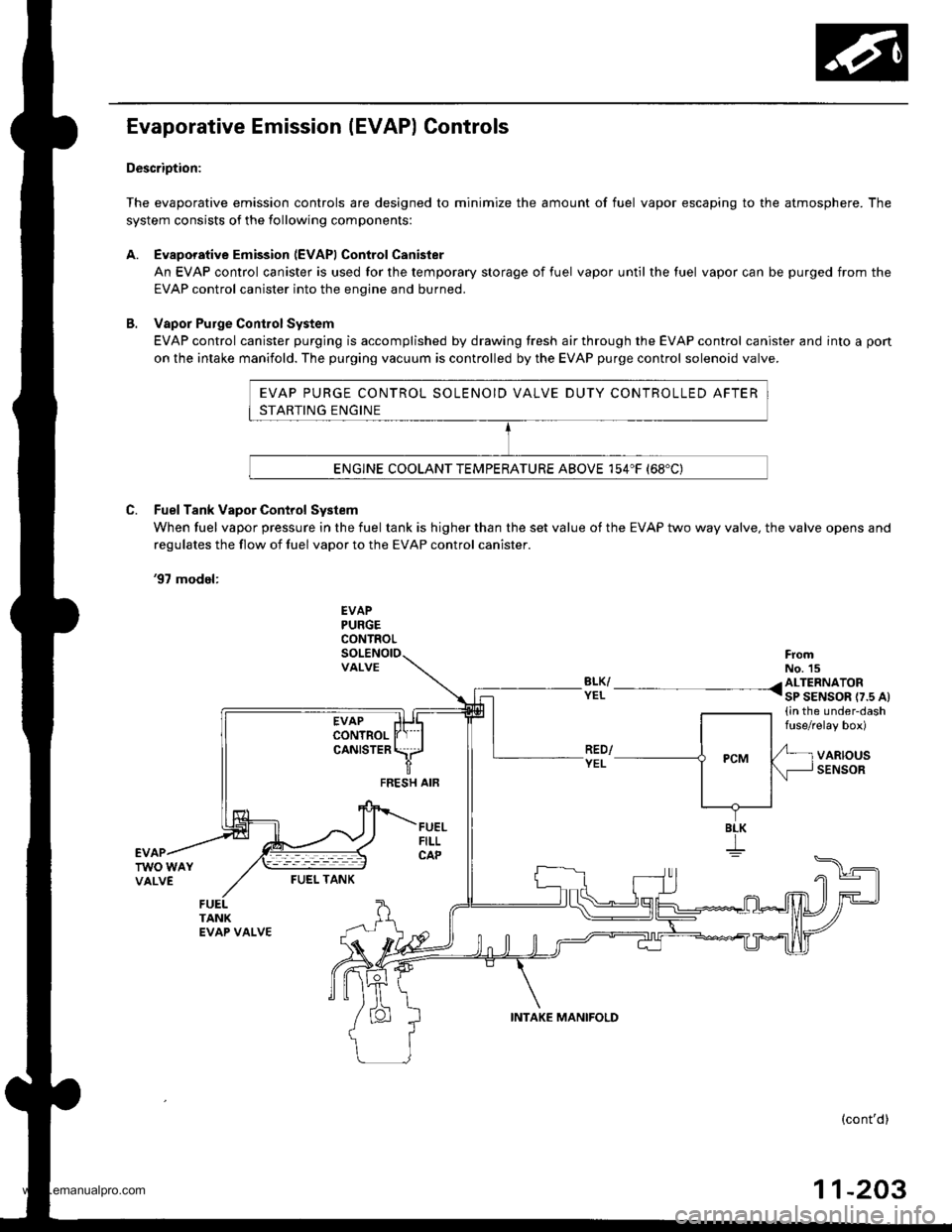

Evaporative Emission (EVAP) Controls

Description:

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAPI Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the luel vapor can be purged from the

EVAP control canister into the enqine and burned.

B. Vapor Purge ConirolSystem

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a pon

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow ot fuel vapor to the EVAP control canister.

'97 model:

EVAPPURGECONTROL

VALVEFromNo. 15BLK/ /ALTERNATORYEL I sP SENSOR r7.s At(in the under-dashfuse/relay box)

VARIOUSSENSORFEESH AIF

BLK

I

FUEI- TANK

(cont'd)

11-203

INTAKE MANIFOLD

www.emanualpro.com

Page 418 of 1395

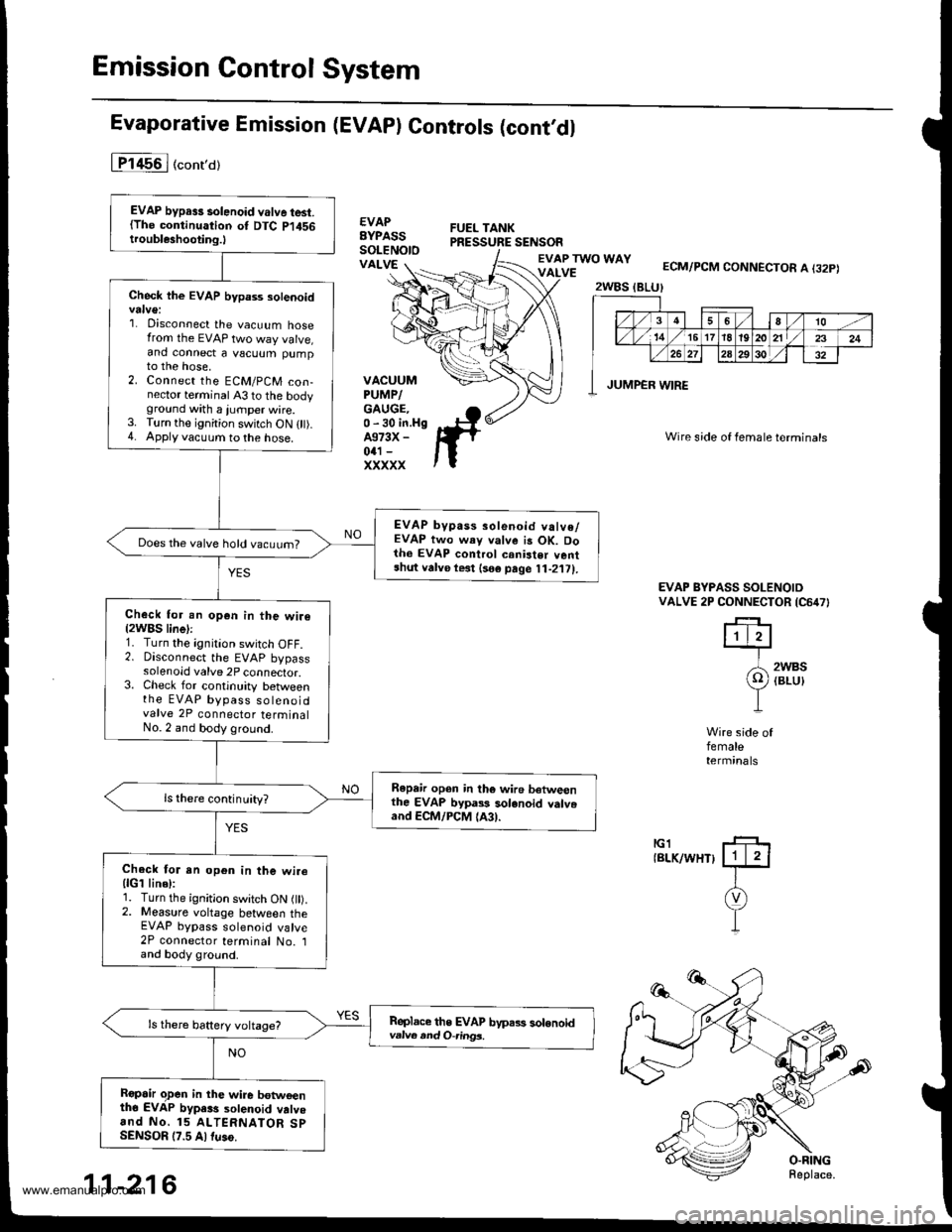

Emission Control System

Evaporative Emission (EVAPI Controls (cont,dl

1T1456I (conro)

€VAPBYPASSSoLENOtOVALVEECM/PCM CONNECTOR A I32P)

Wire side of female terminals

VACUUMPUMP/GAUGE.0 -30 in.HgA373X -

041 -

xxxxx

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR lcorlTl

2WBS(BLU}

II

Wire side offemaletermrnats

tGlIBLK/WHT}

EVAP bypa3s solenoid valve test.(The continuation ot DTC P1456troubleshooting.l

Check the EVAP bypass sotenoid

1. Disconnect the vacuum hosefrom the EVAP two way valve,and connect a vscuum pumpto the hose,2. Connect the ECM/PCM con-nector terminal 43 to the bodyground with a jurnper wire.3. Turn the ignition switch ON 0t).4. Apply vacuum to the hose.

EVAP bypass solenoid valve/EVAP two way valve is OK. Doth6 EVAP control crnister ventshut vafve le3t lso€ page 11-2'111.

Does the valve hold vacuurn?

Check for an op€n in the wir€(2WBS line):1. Turn the ignition switch OFF.2. Disconnect the EVAP bypasssolenoid valve 2P connector.3. Check for continuity betweenthe EVAP bypass so teno idvalve 2P connector terminalNo. 2 and body ground.

Repair open in the wire betweenthe EVAP bypass solenoid valv.and ECM/PCM lA3).

Chack tor an op6n in the wirellcl line):1. Turn the ignition switch ON l).2. Measure voltage between theEVAP bypass solenoid valve2P connector terminal No. land body ground.

Replace the EVAP byps.,s solonoidvatus and O-ring3.

Ropair o,pen in the wire botwoenth6 EVAP bypa$ sotenoid vatvoand No. 15 ALTERNATOR SpSENSOR (7.5 Altuso.

2WBS (BLU}

/3

7,x

4l6o/to -/

,/ 16 1718't920 211/z3

26 272A29solT32

JUMPER WIRE

11-216

www.emanualpro.com

Page 422 of 1395

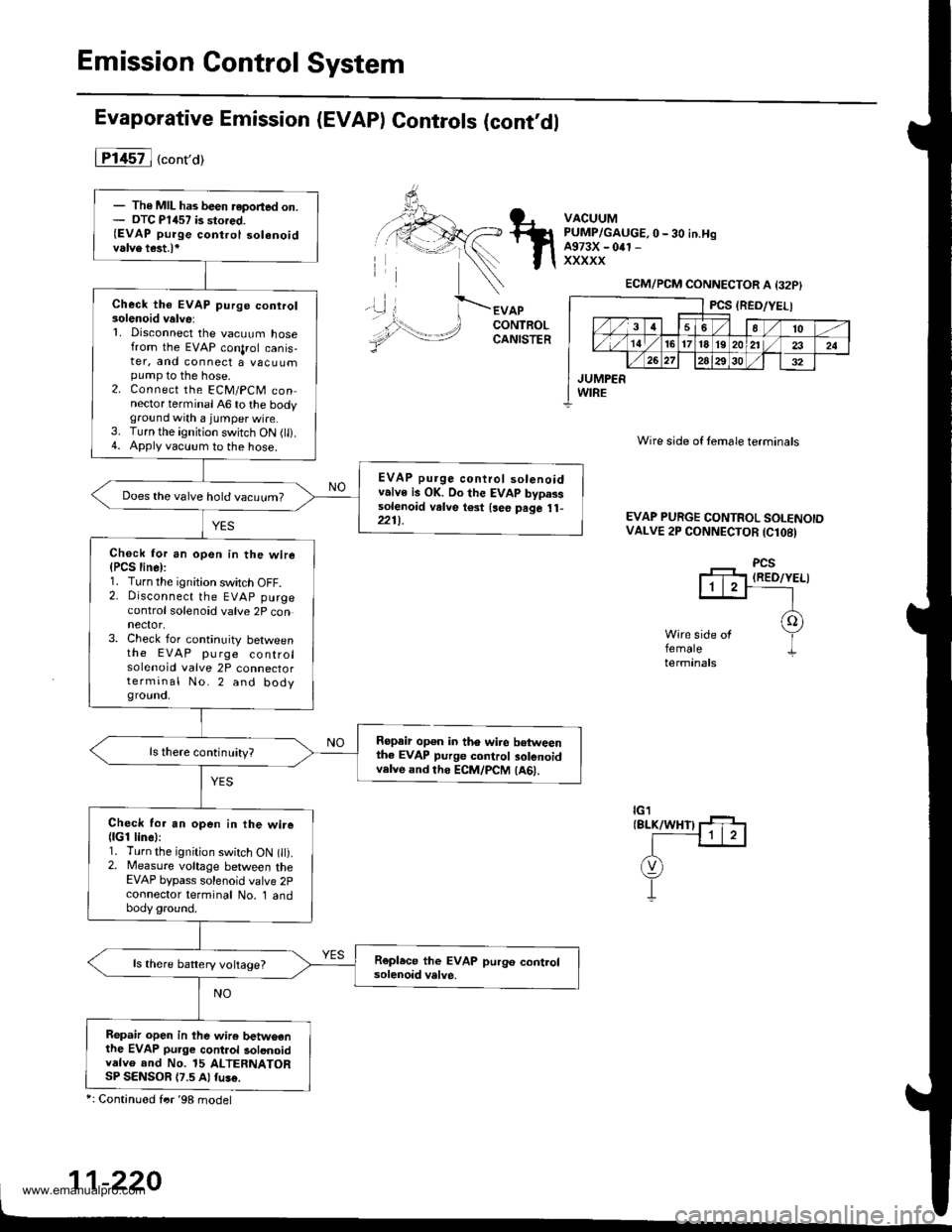

Emission Control System

Evaporative Emission (EVAP) Controls (cont,dl

iTl457l ("ont'or

APCONTROLCANISTER

Ropair op€n in th6 wire betweenthe EVAP purge control 3olenoidvelve and ths ECM/PCM (A61.

VACUUMPUMP/GAUGE, O-30 iN.HgA973X - 0rl -

xxxxx

'\)

Wire side of lemale terminals

EVAP PURGE CONTROL SOI.ENOIDVALVE 2P CONNECTOR (Cl08)

PCSIRED/YELI

femaletermanals

ECM/PCM CONNECTOR A {32P}

PCS (RED/YELI

,/3 458/'t0

,,/ 14 ,/'t61718l92024

,/ 262930

JUMPERWIRE

- The MIL has been reported on.- DTC P1457 is stored.{EVAP purge control solenoidvalve test.l*

Check the EVAP purge conrrol30lenoid velve:L Disconnect the vacuum hosefrom the EVAP conlrol canis,ter, and connect a vacuumpump to the hose.2. Connect the ECM/PCM connector terminal A6 to the bodyground with a jumper wire.3. Turn the ignition switch ON (tl).4. Apply vacuum to the hose.

EVAP purge control solenoidvalve is OK. Oo the EVAP bypasssolenoid valve t€3t {see psge 1l-221t.

Does the valve hold vacuum?

Check for an open in the wire(PCS line):1. Turn the ignition switch OFF.2. Disconnect the EVAP purgecontrol solenoid valve 2P connector,3. Check for continuity betweenthe EVAP pu rge controlsolenoid valve 2P connectorterminal No.2 and bodygrouno,

ls there continuity?

Check for an open in the wire(lGl line):1. Turn the ignition switch ON t).2. Measure voltage between theEVAP bypass solenoid valve 2pcoonector terminal No. 1 andbody ground.

ls there battery voltage?

Repah open in lhe wir6 betwoenthe EVAP pu.ge cont.ol solonoidvdlvo and No. 15 ALTERNATORSP SENSOR {7.5 Al fu!€.

*: Continued frr '98 model

1-220

www.emanualpro.com

Page 1161 of 1395

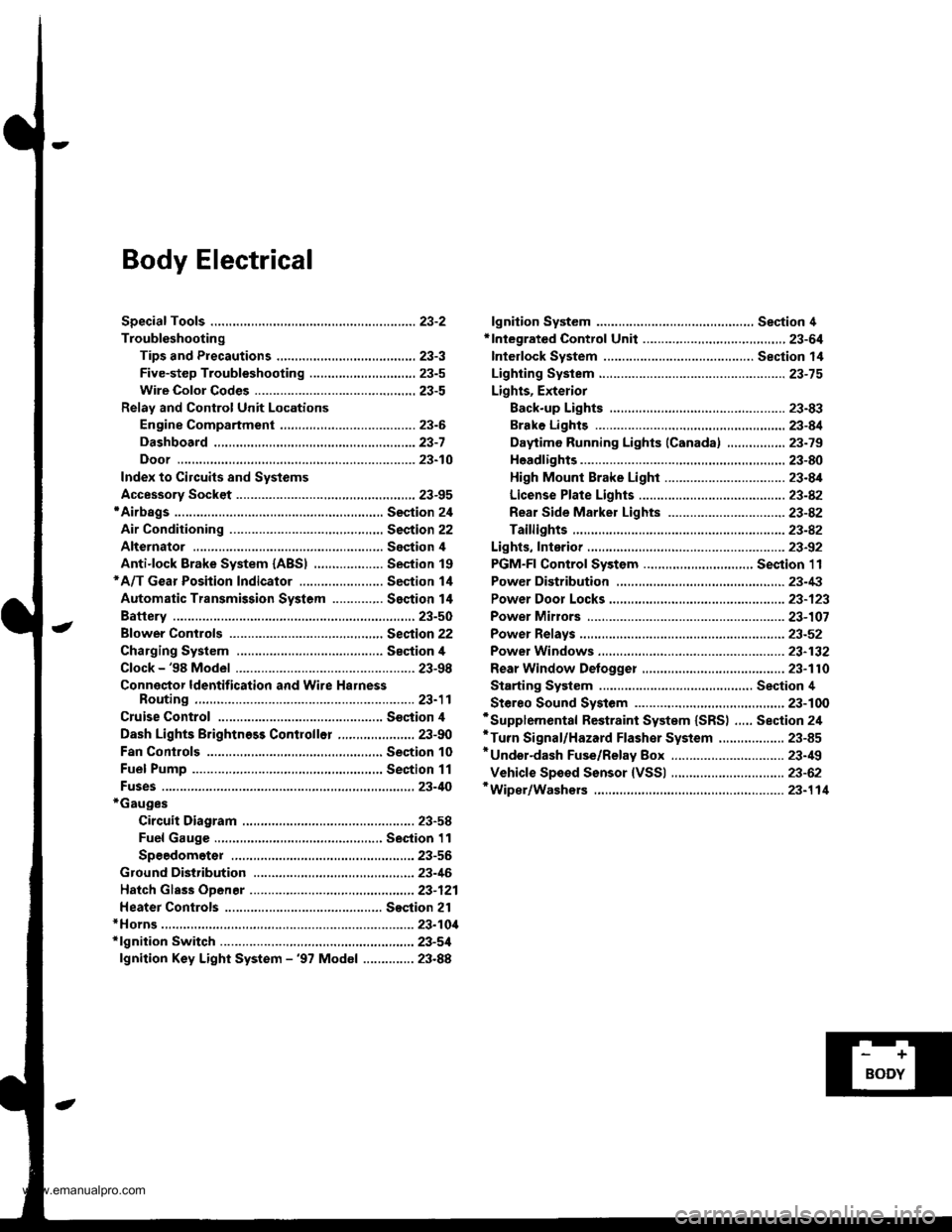

Body Electrical

Speciaf Toofs ,...,..,.............-.23-2

Troubleshooting

Tips and Precautions ......,.,..........,.................. 23-3

Five-step Troubleshooting ........,.,.,...,,.,......... 23-5

Wire Color Codes ...,....,.. 23-5

Relay and Control Unit Locations

Engine Compartment ..,.,......,......................... 23-6

Dashboard ,.,.,..............-.- 23-7

Door ....................... .........23-10

Index to Cilcuits and Sysiems

Accessory Socket .. ,....,.,..,.,. 23-95*Airbags ................ .,....,. Sestion 24

Air Conditioning ,.,.,.... Section 22

Alternator ................... Section 4

Anti-lock Brake System {ABSI ................... Section 19'A/T Gear Position Indicator ....................... Section 1,1

Automatic Transmission System ...........,.. Section 14

Battery ................... ..............23-50

Blower Controls .,...,.,, Section 22

Charging System ....... Seqtion il

Clock -'98 Model ................ 23-98

Connector ldentification and Wire HarnessRouting .................. ......... 23.11

Cruise Control ............ Ssction 4

Dash Lights Brightness Contlo||er ..................... 23-90

Fan Conlrols ...,......,.... Section 10

Fuel Pump ,..,.,...,....,.... Section 11

Fuses...................... .,,.,.,.,.,,.,23-40*Gauges

Circuit Diagram ......-....-..23-58

Fuel Gauge .....,.,..... Section 11

Speedometer ..,..........,... 23-56

Ground Distribution ,....,.,...23-46

Hatch Glsss ODenor .........................,.,.,.,.,..,.,.,.,,. 23-121

Heater Controls .-........ Soction 21*Horns.,...,..,.,.,....... ................23"104*fgnition Switch ,,.,.,..,.,.,,.,.,.,23-51

lgnition Key Light System -'97 Mod6l .............. 23.88

-+

BODY

www.emanualpro.com

Page 1163 of 1395

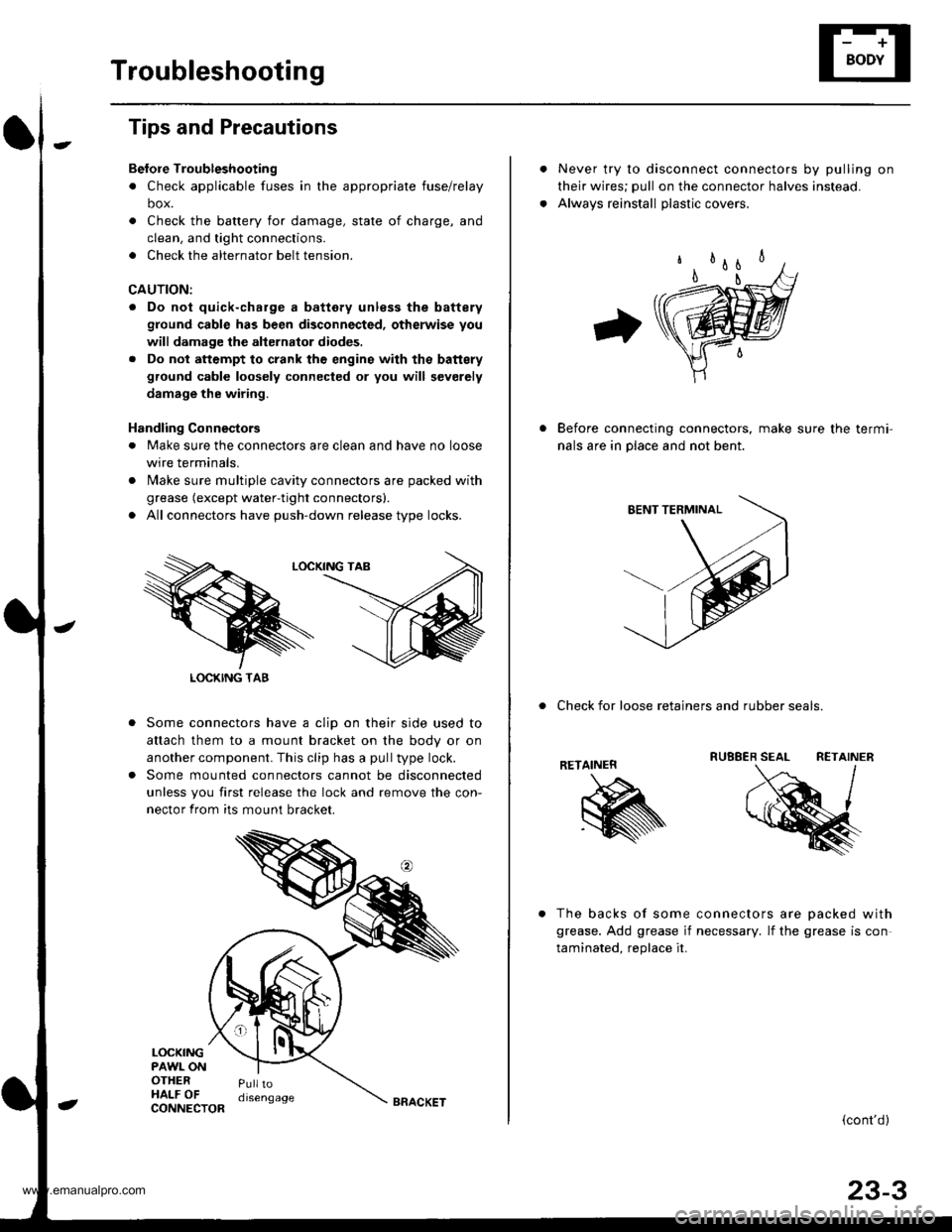

Troubleshooting

Tips and Precautions

Bef ore Troubleshootin g

. Check applicable fuses in the appropriate fuse/relay

box.

. Check the battery for damage, state of charge, and

clean. and tight connections.

. Check the alternator belt tension.

CAUTION:

. Do not quick-charge a battery unless the battery

ground cable has been disconnected, otherwise you

will damage the alternator diodes.

. Do not attempt to crank thc engins wilh the battery

ground cable loosely connected or you will severely

damage the wiring.

Handling Connestors

. Make sure the connectors are clean and have no loose

wire terminals,

. N4ake sure multiple cavity connectors are packed with

grease (except water-tight connectors).

. All connectors have push-down release type locks.

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKINGPAWL ONOTHERHALF OFPulltodisengage

LOCKING TAB

CONNECTORBRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead.

Alwavs reinstall olastic covers.

Before connecting connectors, make sure the termi-

nals are in place and not bent.

. Check for loose retainers and rubber seals.

RETAINER

The backs of some connectors are oacked with

grease. Add grease if necessary. lf the grease is con

taminated. reolace it.

{cont'd}

23-3

www.emanualpro.com

Page 1174 of 1395

![HONDA CR-V 1997 RD1-RD3 / 1.G Owners Guide

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll HONDA CR-V 1997 RD1-RD3 / 1.G Owners Guide

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll](/img/13/5778/w960_5778-1173.png)

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1l'l

c112

c113

c't 14

cl16

cl16

c117

c118

c119

c120

c121

c't22

c't23

c't25

cl26

cl27

cr 28

cl29

c130

c131

c132

c 133

c134

c134

c135

c 136

10

6

1

2

1

2

1

10

20

31

16

22

l0

l0'14

14

1

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine

Middle of engine

Behind right kick panel

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Right side of engine

Right side of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine compartment

Middle of engine

Middle of engine

Main wire harness (C304)

Main wire harness (C305):'97 - 98 models

No. 1 fuel injector

Crankshaft speed fluctuation (CKF) sensor

Alternator

Alternator

Engine oil pressure switch

No.2 fuel injector

Evaporative emission (EVAP) purge

control solenoid valve

No. 3 fuel injector

No. 4 fuel injector

Primary heated oxygen sensor(Primary HO2S) (sensor 1)

Radiator fan switch

Coolant temperature sending unit

Engine coolant temperature (ECT) sensor

Mainshaft speed sensor

Lock-up control solenoid valve

Back-up light switch

Shift control solenoid valve

Linear solenoid valve

Countershaft speed sesnsor

Starter solenoid

Distributor

Junction connector

PCM

ECIWPCM

ECM/PCM

ECM/PCM

Main wire harness (C,|:}1)

IVT gear position switch

Vehicle speed sensor (VSS)

Throttle position (TP) sensor

MAP sensor

ldle air control (lAC)valve

lntake air temperature (lAT) sensor

Junction connector

Junction connector

Power steering pressure (PSP) switch

Junction connector

Knock sensor (KS)

A/r

USA

Canada

Alr

AlT

M/'r

Afi

'97mooel

'97 model'98 - 00

mooets

'99 - 00

models

T101

r102

Left side of en0ine companment

Right side of engine compartment

Alternator

Under-hood fuse/relay box

G101Middle of engineEngine ground, via engine wire harness

23-14

www.emanualpro.com

Page 1200 of 1395

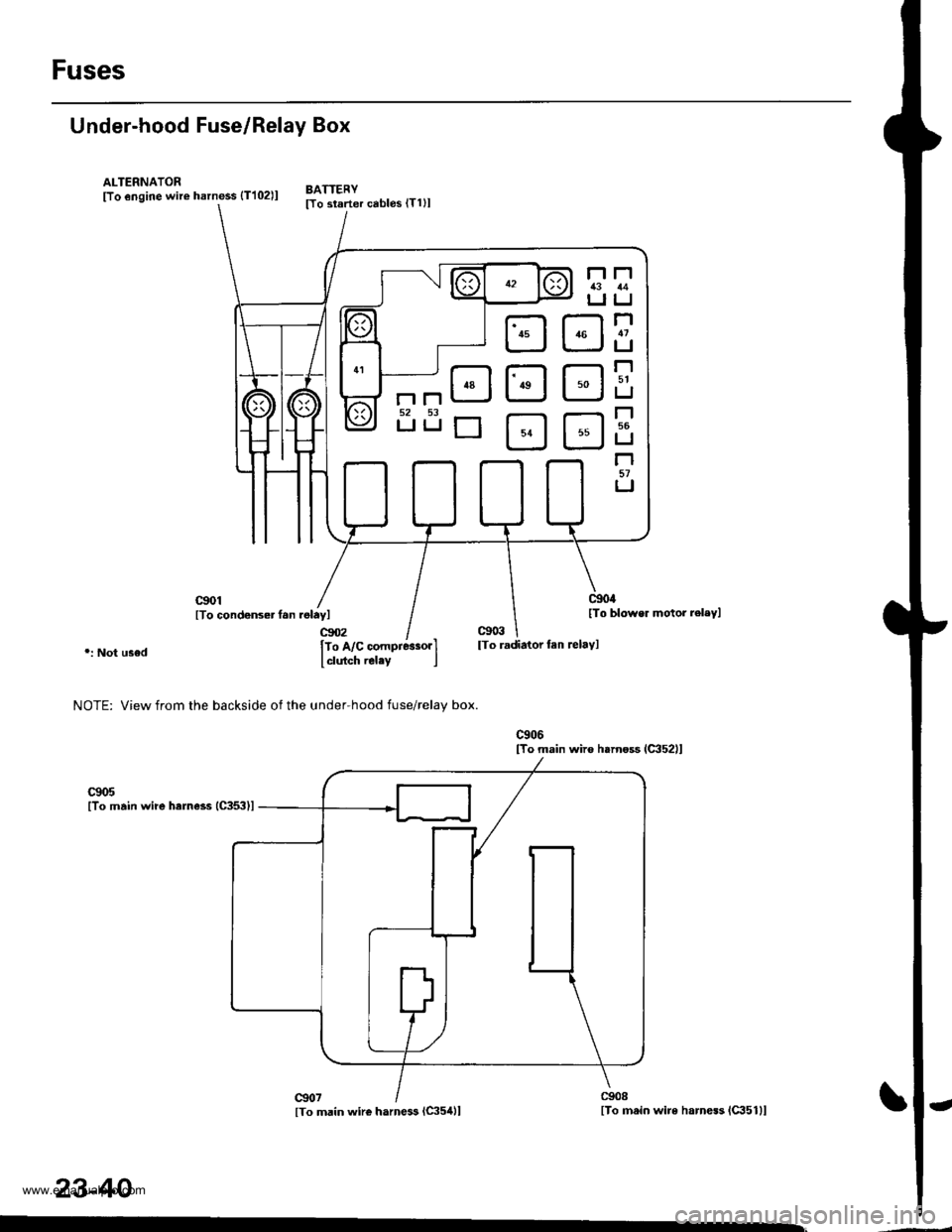

Fuses

Under-hood Fuse/Relay Box

ALTERNATOR

lTo engine wire harness {T102)l

cro1lTo condens€r tan .slayl

.: Not used

NOTE: View from the backside of the under-hood fuse/relay box.

BATTERY

lTo slarter cables lTlll

lTo main wirc harness 1C354)l

c903lTo radiator ten relavl

lTo blower motor releyl

lTo main wire harness lC351ll

c306fTo main wiro hamose (C352ll

c305lTo main wiie harnes lc353ll

DE

tr

tr

tr

r-'l

IJ

n11IJ

r'151

LI

r-'l56

IJ

r-'l57LJ

23-40

www.emanualpro.com

Page 1204 of 1395

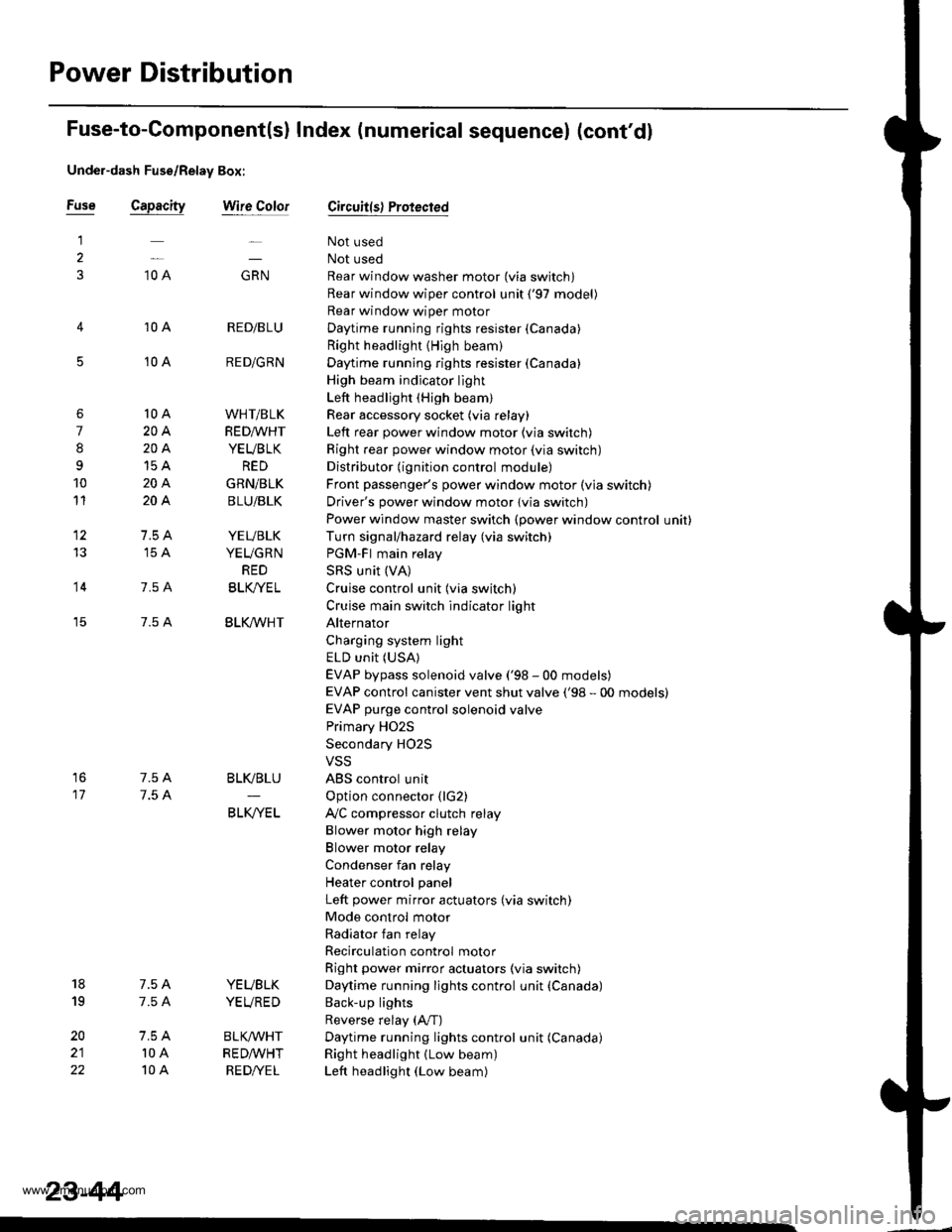

Power Distribution

Fuse

1

3

5

6

7

I

9

10

11

12

13

14

"^

RED/B LU

RED/GRN

WHT/BLK

RED/VVHT

YEUBLK

RED

GRN/BLK

BLU/BLK

YEVBLK

YEUGRN

RED

BLK/YE L

BLK/VVHT

17

7.5 A

7.5 A

BLVBLU

BLKA/EL

18

19

20

22

7.54

7.54

l0 A

10 A

YEUBLK

YEVRED

BLKAr'YHT

RED /VHT

RED/YE L

Fuse-to-Component(sl Index (numerical sequencel (cont'dl

Under-dash Fuse/Relay Box:

Capacity

10 A

10 A

10 A

10 A

20A

204

15A

204

204

7.5 A'15 A

7.5 A

7.5 A

Wire ColorCircuit{s) Protected

Not used

Not used

Rear window washer motor (via switch)

Rear window wiper control unit ('97 model)

Rear window wiper motor

Daytime running rights resister {Canada)

Right headlight {High beam}

Daytime running rights resister (Canada)

High beam indjcator light

Left headlight (High beam)

Rear accessory socket (via relay)

Left rear power window motor (via switch)

Right rear power window motor (via switch)

Distributor (ignition control module)

Front passenger's power window motor (via switch)

Driver's power window motor {via switch)

Power window master switch (power window control unit)

Turn signal/hazard relay (via switch)

PGM-FI main relay

SRS unit (VA)

Cruise control unit (via switch)

Cruise main switch indicator light

Alternator

Charging system light

ELD unit (USA)

EVAP bypass solenoid valve ('98 - 00 models)

EVAP control canister vent shut valve ('98 - 00 models)

EVAP purge control solenoid valve

Primary HO2S

Secondary H02S

VSS

ABS control unit

Option connector (lG2)

Ay'C compressor clutch relay

Blower motor high relay

Blower motor relay

Condenser fan relay

Heater control panel

Left power mirror actuators (via switch)

Mode control motor

Radiator fan relay

Recirculation control motor

Right power mirror actuators (via switch)

Daytime running lights control unit (Canada)

Back-up lights

Reverse relay (A"/T)

Daytime running lights control unit (Canada)

Right headlight (Low beam)

Left headlight (Low beam)

23-44

www.emanualpro.com