Crank HONDA CR-V 1997 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 348 of 1395

PGM-FI System

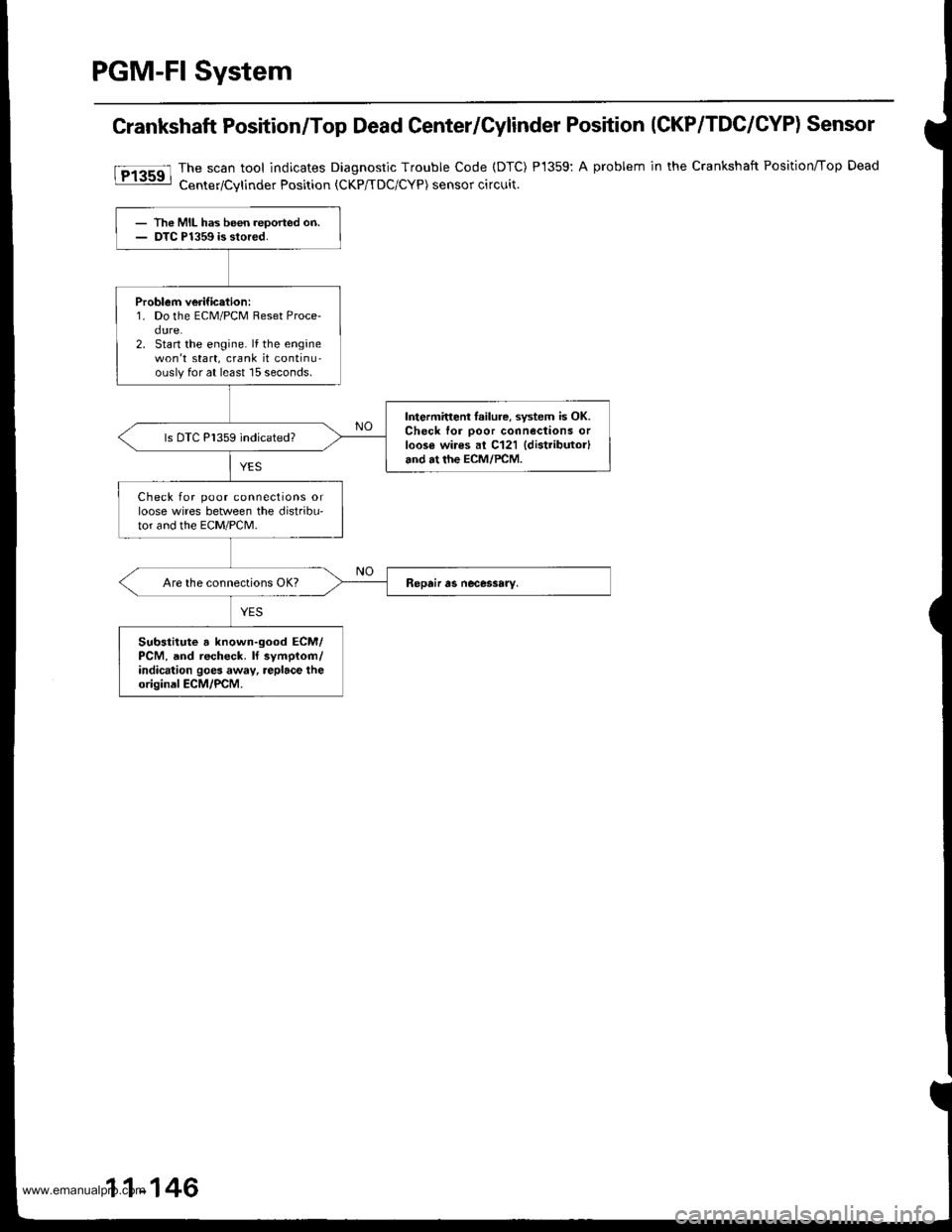

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYP) Sensor

The scan tool indicates Diagnostic Trouble Code (DTC)

Center/Cvlinder Position tCKP/TDC/CYP) sensor circuit.

P1359:A problem in the Crankshaft Position/Top Dead

- The MIL has been reoorted on.- DTC P1359 is stored.

Problem verific.tion:1. Do the ECM/PCM Reset Proce-dure.2. Start the engine. lf the enginewon't start, crank it continu-ouslyfor at least 15 seconds.

Intermitteni lailure, system is OK.Check for ooor connections orloos€ wires al C121 {distributor}and at the ECM/PCM.

ls DTC P1359 indicated?

Check for poor connections orloose wires between the distribu'tor and the EcM/PcM.

Substitute a known-good ECM/PCM, and recheck. ll symplom/indication goes away, replace theoriginal ECM/PCM.

11-146

www.emanualpro.com

Page 363 of 1395

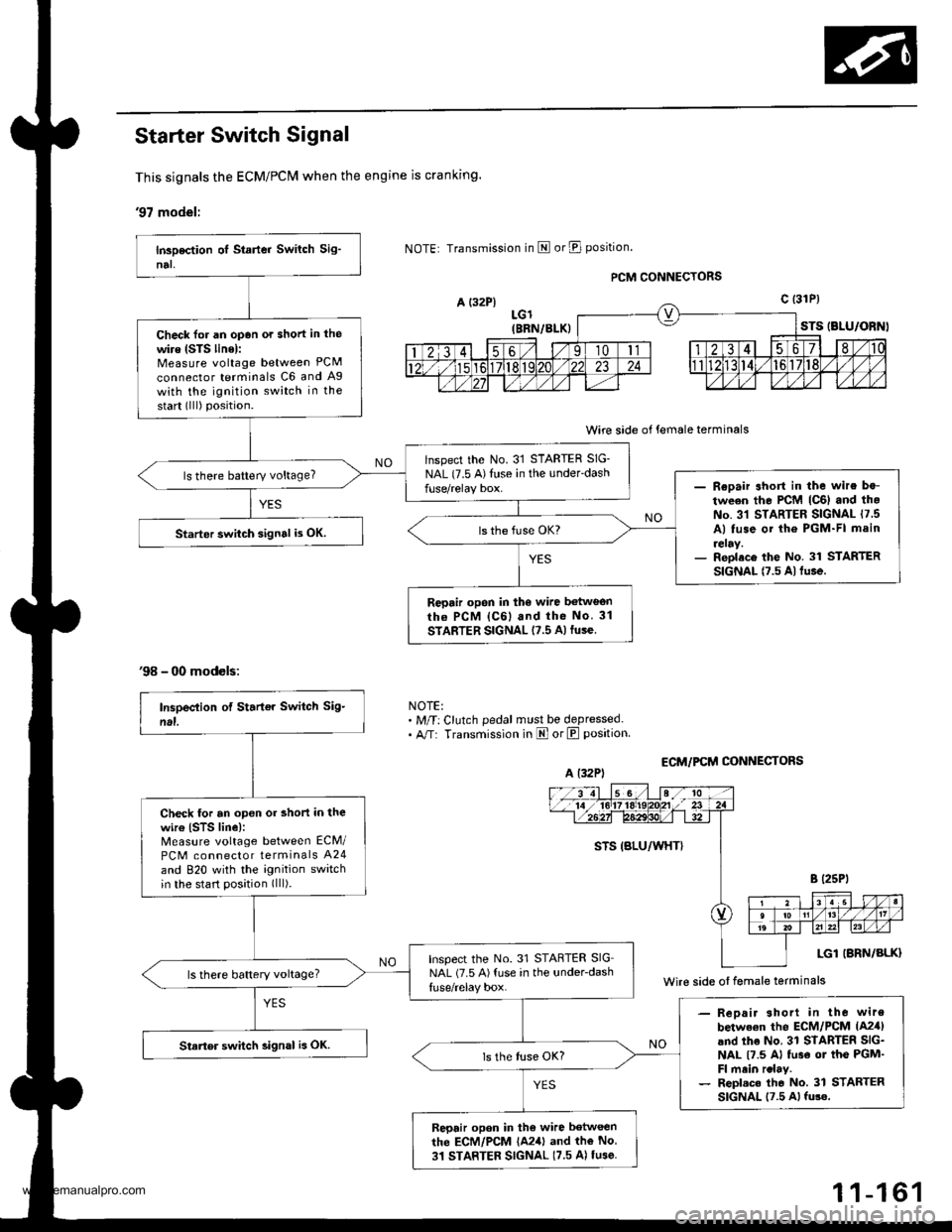

Starter Switch Signal

This signals the ECM/PCM when the engine is cranking.

'97 model:

A {32P}

'98 - 00 models:

Transmission in E or E position.

LGl(BBN/BLK)

PCM CONNECTORS

Wire side of female terminals

ECM/PCM CONI{ECTORS

STS (BLU/ORNI

c t31P)

NOTE:. M/T: Clutch pedal must be depressed.. A/T: Transmission in E orE position

Check for an opan ot short in the

wire (STS linel:Measure voltage between PCM

connector terminals C6 and Ag

with the ignition switch in the

start (lll) position.

lnspect the No. 31 STARTER SIG-

NAL (7.5 A)Illse in the under'dashls there battery voltage?- Reoair short in the wire be-

tween the PCM lc6l and th.No. 31 STARTER SIGNAL 17 5A) tuse ot the PGM-FI main

reray.- Reolace the No. 31 STARTERSIGNAL t7.5 Altu.e.

Starter swiich signal i3 OK.

Repair opon in the wire betweonrh6 PCM lc6l and the No 31

STARTER SIGNAL 17.5 A)fuse.

A (32P)

Wire side oI female terminals

Check tor an open or short in thewir€ (STS line):Measure voltage between ECM/

PCM connector terminals A24

and 820 with the ignition switchin the start position (lll).

Inspect the No. 31 STARTER SIGNAL (7.5 A){use in the under-dashls there battery voltage?

- Reoair shorl in the wire

betwe€n the ECM/PCM lA2,fland the No, 31 STARTER SIG-NAL t7.5 Al tu3€ ot the PGM'Fl main rclay.- Repl.c. tho No. 31 STARTERSIGNAL 17.5 Al fu3e.

Starter switch 3ignal is OK.

Repair opon in tho wire between

the ECM/PCM {A241 and the No

31 STARTER SIGNAL (7.5 A) tu3e

1 1-161

www.emanualpro.com

Page 401 of 1395

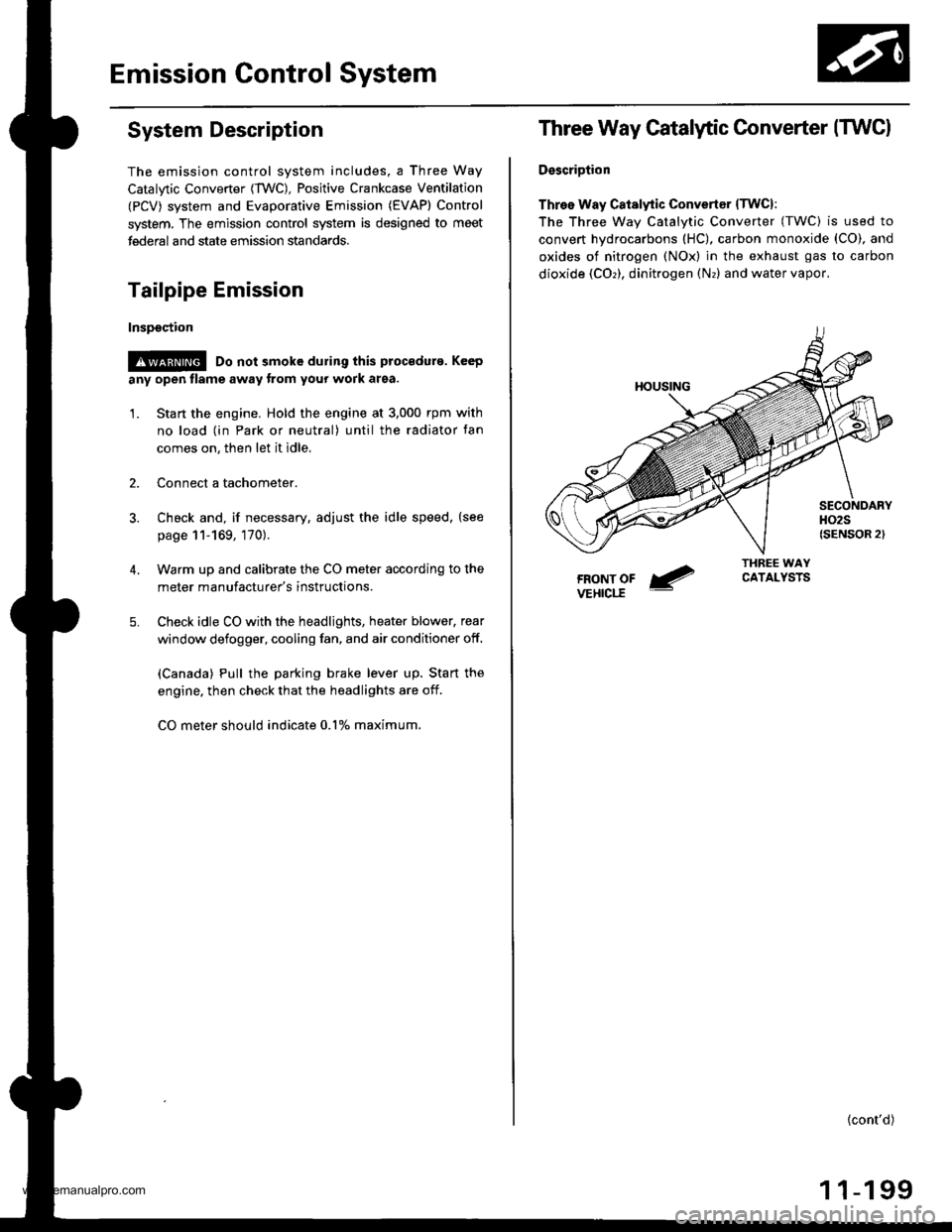

Emission Control System

System Description

The emission control system includes, a Three Way

Catalytic Converter {TWC), Positive Crankcase Ventilation

(PCV) svstem and Evaporative Emission (€VAP) Control

system. The emission control system is designed to meet

federal and state emission standards.

Tailpipe Emission

Inspsction

!@ Do not smoke during this procsdura. Keep

any open tlame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Check and, if necessary, adjust the idle speed, (see

page 11-169, 170).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with the headlights, heater blower, rear

window defogger, cooling fan, and air conditioner off.

(Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

CO meter should indicate 0.1% maximum.

4.

Three Way Catalytic Converter (TWCI

DsscriDtion

Three Way Catalytic Convertsr lTwcl:

The Three wav Catalvtic Converter (TWC) is used to

convert hydrocarbons (HC), carbon monoxide (CO), and

oxides of nitrogen (NOx) in the exhaust gas to carbon

dioxide (COr), dinitrogen (Nr) and water vapor,

{cont'd)

1 1-199

www.emanualpro.com

Page 403 of 1395

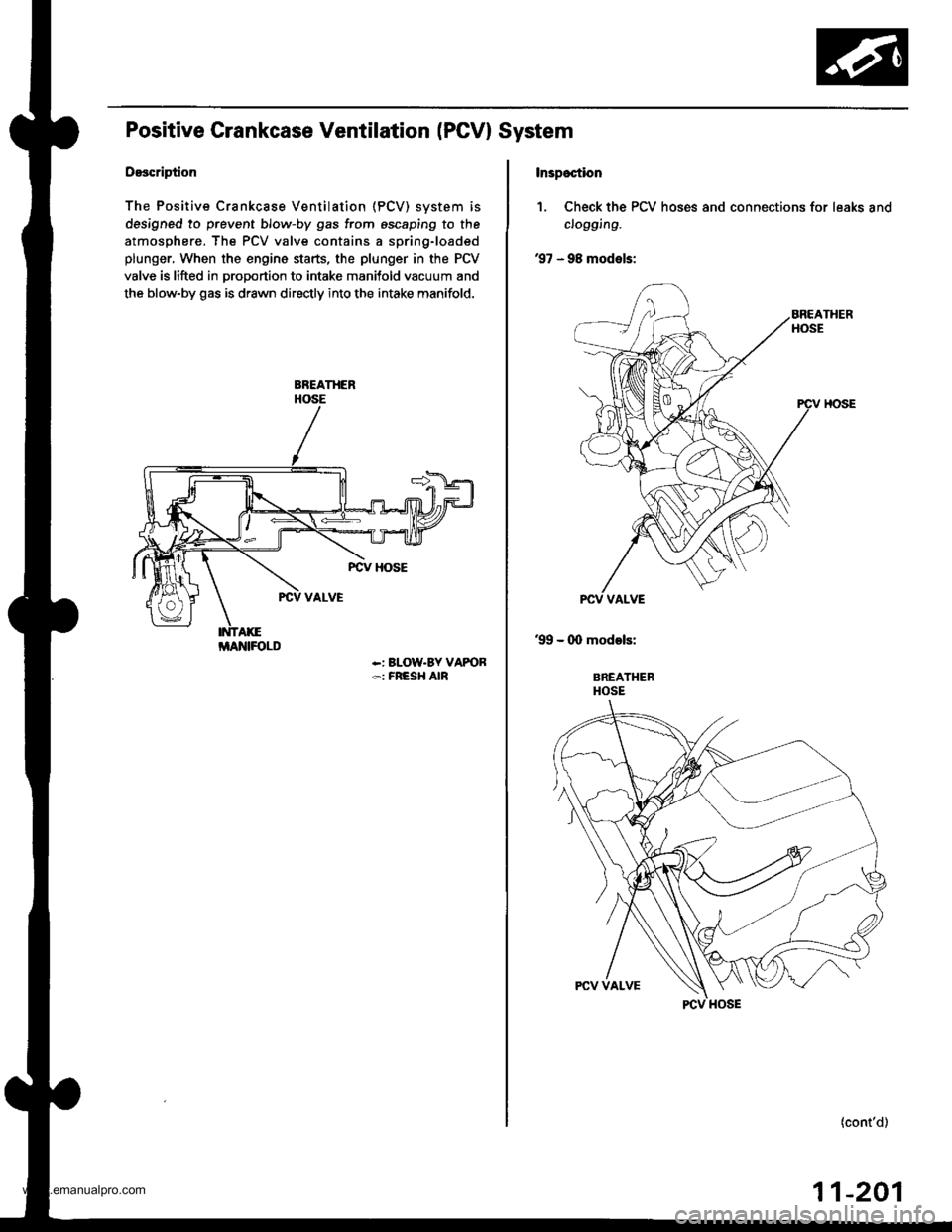

Positive Grankcase Ventilation (PGVI System

Description

The Positive Crankcase Ventilation (PCV) svstem is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger, When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manitold vacuum and

the blow-by gas is drawn directly into the intake manifold.

-: BLOW.BY VAPOR-: FRESH AIR

i/lAlrllFOLD

Inspoction

1. Check the PCV hoses and connections for leaks and

clogging.

'97 - 98 models:

'99 - (X) models:

BREATHERHOSE

(cont'd)

11-201

www.emanualpro.com

Page 404 of 1395

Emission Control System

Positive Crankcase Ventilation (PCV) System (cont'dl

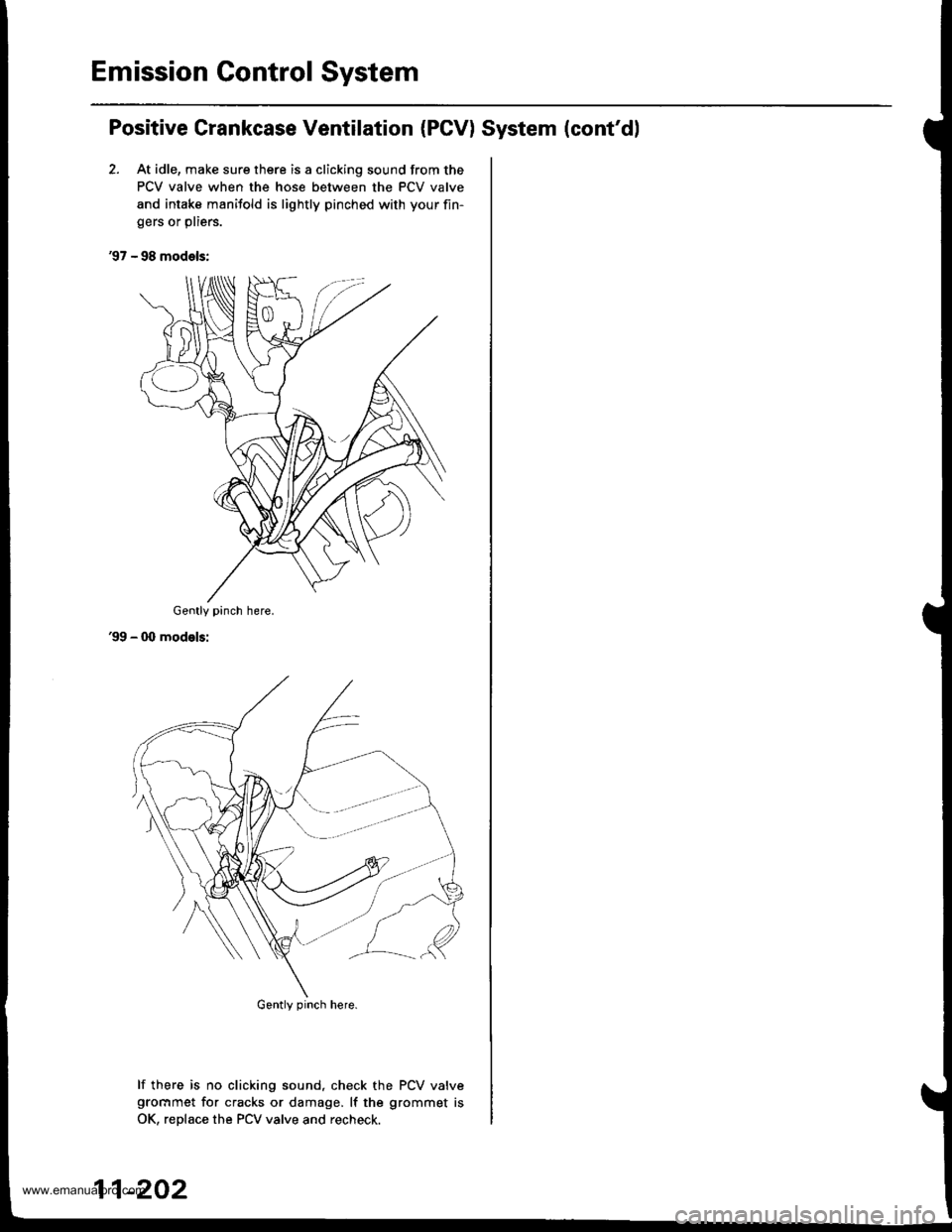

2. At idle, make sure there is a clicking sound from the

PCV valve when the hose between the PCV valve

and intake manifold is lightly pinched with your fin-

gers or pliers.

'97 - 98 models:

'99 - 00 modelsi

lf there is no clicking sound, check the PCV valvegrocrmet for cracks or damage, lf the grommet is

OK, reDlace the PCV valve and recheck.

Gently pinch here.

Gently pinch here.

11-202

www.emanualpro.com

Page 436 of 1395

Flywheel

Inspection

2.

3.

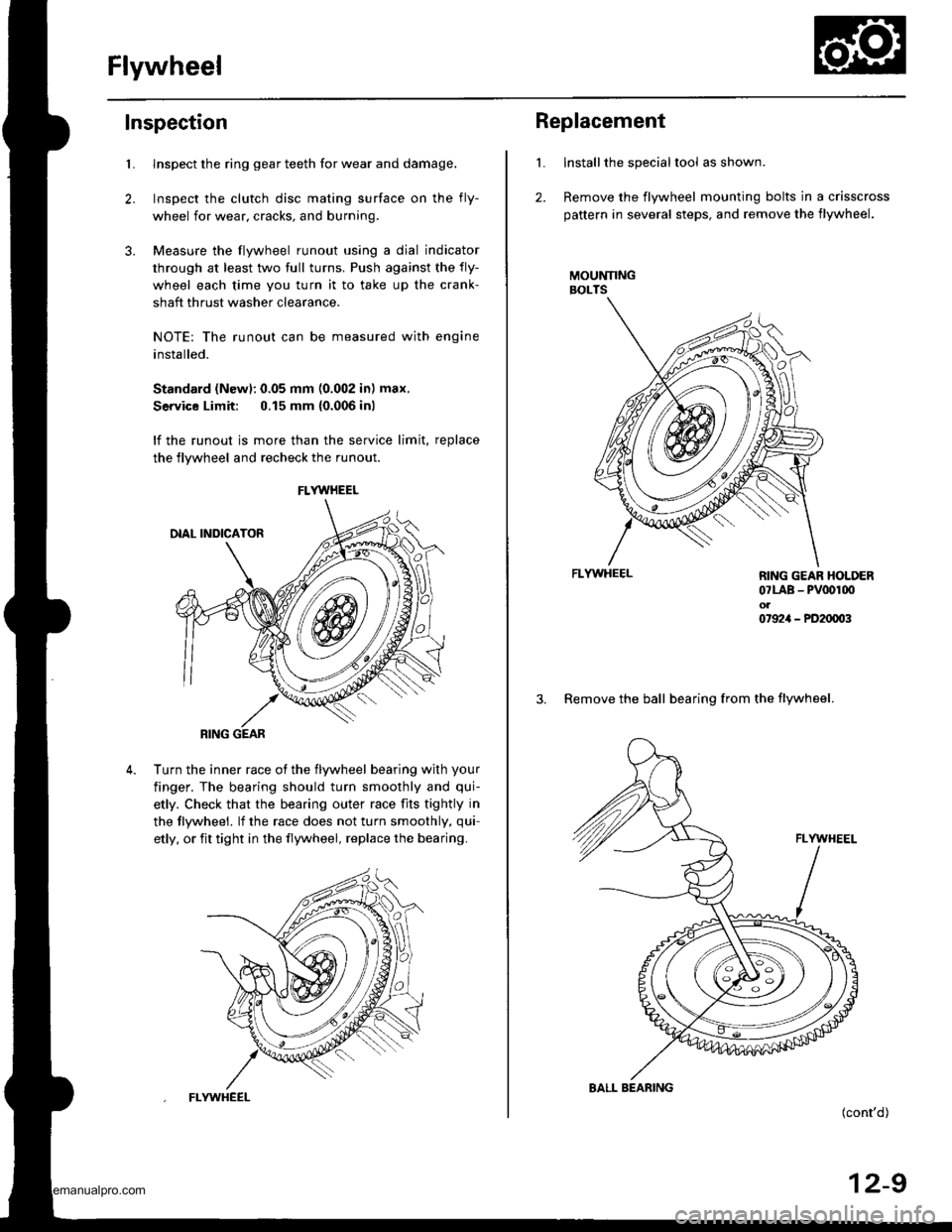

Llnspect the ring gear teeth for wear and damage.

Inspect the clutch disc mating surface on the fly-

wheel for wear, cracks, and burning

Measure the flywheel runout using a dial indicator

through at least two full turns. Push against the fly-

wheel each time you turn it to take up the crank-

shaft thrust washer clearance.

NOTE: The runout can be measured with engine

installed.

Standard (Newl: 0.05 mm (0.002 in) max.

Service Limit: 0.15 mm {0.006 inl

lf the runout is more than the service limit, replace

the flywheel and recheck the runout

Turn the inner race ot the flywheel bearing with your

finger. The bearing should turn smoothly and qui-

etly. Check that the bearing outer race fits tightly in

the tlywheel. lf the race does not turn smoothly, qui-

etly, or fit tight in the flywheel, replace the bearing.

FLYWHEEL

RING GEAR

FLYWHEEL

L

2.

Replacement

Installthe special tool as shown.

Remove the flywheel mounting bolts in a crisscross

pattern in several steps, and remove the flywheel.

MOUNNNGBOLTS

FLYWHEEL

(cont'd)

12-9

RING GEAR HOLDER07LAB - PV00r00ol07924 - PD20003

3. Remove the ball bearing from the flywheel.

BALL BEARING

www.emanualpro.com

Page 437 of 1395

FlywheelClutch Disc, Pressure Plate

Replacement (cont'dl

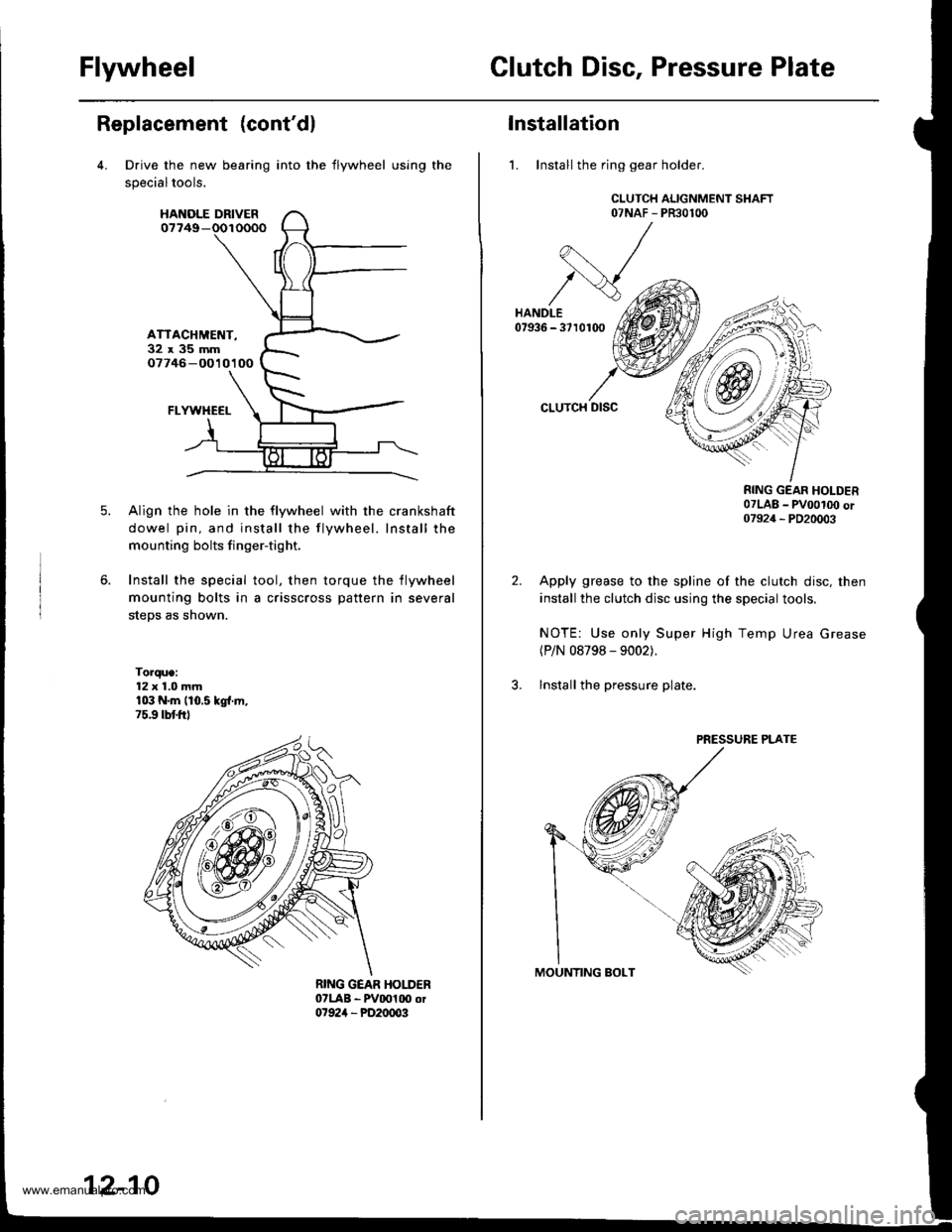

Drive the new bearing

specialtools.

HANOLE DRIVER07749-

ATTACHMET{T-32x35mm07746 -O010100

FLYWHECI-

Align the hole in the flywheel with the crankshaft

dowel pin, and install the flywheel. Install the

mounting bolts finger-tight.

Install the special tool, then torque the flywheel

mounting bolts in a crisscross pattern in several

steps as shown.

Torque:12 x 1.0 mmr03 N.m (10.5 kgl.ln,75.9 tbtftl

into the flywheel using the

12-10

Installation

1. Install the ring gear holder.

CLUTCH ALIGNMENT SHAFT07NAF - PR30100

CLUTCH DISC

RING GEAR HOLDER07LAB _ pvoot(x) or07924 _ PD20003

Apply grease to the spline of the clutch disc, then

install the clutch disc using the special tools.

NOTE: Use only Super High Temp Urea Grease(P/N 08798 - 9002).

lnstall the pressure plate.

PRESSURE PLATE

www.emanualpro.com

Page 519 of 1395

Description

General Operation

The Automatic transmission is a 3-element torque converter and triple-shaft electronically controlled unit which provides 4

speeds forward and 1 reverse speed The unit is positioned in line with the engine'

There are two tvoes of automatic transmission on CR-V; the four-wheel drive (4WD) model ('97 - 00)' and the front-wheel

drive (2WD) model ('98 - 00).

Toroue Converter, G€ars, and Clutches

The torque converter consists of a pump. turbine. and stator assembly in a single unit. The torque converter is connected to

the engine crankshatt. These parts turn together as a unit as the engine turns. Around the outside of the torque converter is

a ring gear which meshes with the starter pinion when the engine is started. The torque converter assembly serves as a fly-

wheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts: the mainshaft. the countershaft, and the sub-shaft. The mainshaft is in line with

the engine crankshaft. The mainshaft includes the 1st, 2nd. and 4th clutches, and gears lor 3rd,2nd,4th. reverse and 1st

(3rd gear is integral with the mainshaft, while reverse gear is integral with the 4th gear). The countershaft includes the 3rd

clutch and gears for 3rd,2nd, 4th, reverse, 1st, and park. Reverse and 4th gears can be locked to the countershaft at its cen-

ter, providing 4th gear or reverse, depending on which way the selector is moved. The sub-shaft includes the lst-hold

clutch and gears for lst and 4th.

The gears on the mainshaft are in constant mesh with those on the countershaft and sub-shaft. When certain combinations

of gears are engaged by the ctutches, power is transmitted from the mainshaft to the countershaft to provide E, D!, tr, tr,

and E position ('97 - 98 models). and E. E, E, and E position ('99 - 00 models)'

Electlonic Control

The electronic controt system consists of the Powenrain Control Module (PCM), sensors, a linear solenoid, and four

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions. The PCM is

located below the dashboard, under the kick panel on the passenger's side.

Hydraulic Control

The valve bodies include the main valve body, the secondary valve body, the regulator valve body, the servo body, and

the lock up valve body. They are bolted to the torque converter housing. The main valve body contains the manual valve,

the 1-2 shift valve, the 2nd orifice control valve. the CPB {Clutch Pressure Back-up) valve, the modulator valve, the servo

control valve. the relief valve, and ATF pump gears. The secondary valve body contains the 2-3 shift valve, the 3-4 shift

valve, the 3,4 orifice control valve. the 4th exhaust valve and the CPC (Clutch Pressure Control) valve. The regulator valve

bodv contains the pressure regulator valve, the torque converter check valve, the cooler relief valve, and the lock-up con-

trol valve. The servo body contains the servo valve which is integrated with the reverse shift tork, and the accumulators

The lock-up valve body contains the lock-up shift valve and the lock-up timing valve. The linear solenoid and the shift con-

trol solenoid valve Ay'B are bolted to the outside of the transmission housing, and the lock-up control solenoid valve Ay'B is

bolted to the outside of the torque converter housing. Fluid trom the regulator passes through the manual valve to the

various control valves. The clutches receive fluid from their respective feed pipes or internal hydraulic circuit

ShiftControl Mechanism

input from various sensors located throughout the vehicle determines which shift control solenoid valve the PCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches. engaging that clutch and its corresponding gear. The shift control solenoid valves A and B are

controlled by the PCM.

Lock-up Mechanism

tn E! position (,97 - 98 modets) and in E position ('99 - O0 models), in 3rd and 4th, and in Del position in 3rd ('97 - 98

models) and in El position with Over,Drive (O/D) is OFF (by pressing rhe O/D switchl in 3rd ('99 - 00 models), pressurized

fluid is drained from the back of the torque converter through a fluid passage, causing the lock-up piston to be held

against the torque converter cover, As this takes place, the mainshaft rotates at the same speed as the engine crankshaft.

Together with hydraulic control, the PcM optimizes the timing of the lock-up mechanism The lock-up valves control the

range of lock-up according to lock-up control solenoid valves A and B, and the linear solenoid. When lock-up control

solenoid valves A and B activate, the modulator pressure changes. The lock-up control solenoid valves A and B and the

linear solenoid are controlled by the PCM.

{cont'd)

14-3

www.emanualpro.com

Page 555 of 1395

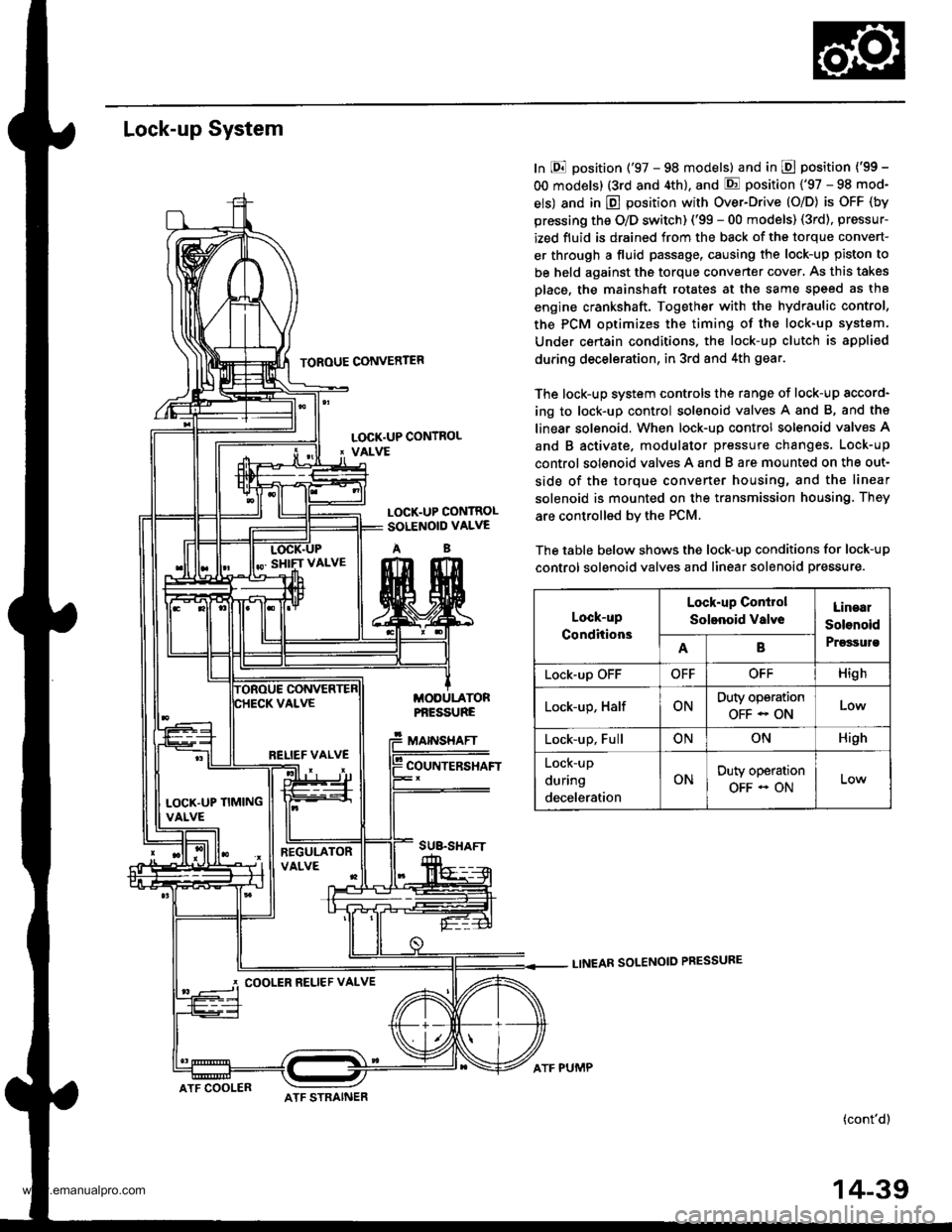

Lock-up System

TOROUE CONVERTER

In E position ('97 - 98 models) and in E position ('99 -

OO models) (3rd and 4th), and E position ('97 - 98 mod-

els) and in E position with Over-Drive (O/D) is OFF (by

pressing the O/D switch) ('99 - 00 models) (3rd), pressur-

ized fluid is drained from the back of the torque convert-

er through a fluid passage, causing the lock-up piston to

be held against the torque converter cover, As this takes

Dlace, the mainshaft rotates at the same speed as th8

engine crankshaft. Together with the hydraulic control,

the PCM optimizes the timing of the lock-up system.

Under certain condltions. the lock-up clutch is appli€d

during deceleration, in 3rd and 4th gear.

The lock-up system controls the range of lock-up sccord-

ing to lock-up control solenoid valves A and B, and ths

linear solenoid. When lock-up control solenoid valves A

and B activate. modulator pressure changes. Lock-up

control solenoid valves A and B are mounted on the out-

side of the torque converter housing, and the linear

solenoid is mounted on the transmission housing. They

are controlled bv the PCM.

The table below shows the lock-up conditions for lock-up

control solenoid valves and linear solenoid pressure.

LINEAR SOLENOID PRESSURE

(cont'd)

LOCK.UP CONTROL' VALVE

LOCK.UP CONTROLSOLENOID VALVE

AB

MODULATORPf,ESSURE

MAINSHAFT

COUNTERSHAFT

SUB.SHAFT

Lock-up

Conditions

Lock-up Conirol

Solenoid valveLinaal

Solenoid

PrgssulsAB

Lock-up OFFOFFOFFHigh

Lock-up, HalfONDuty operation

OFF - ONLow

Lock-up, FullONONHigh

Lock-up

during

deceleration

ONDuty operation

OFF - ON

RELIEF VALVE

LOCK'UP TIMINGVALVE

COOLER RELIEF VALVE

ATF COOLERATF STRAINER

ATF PUMP

14-39

www.emanualpro.com

Page 688 of 1395

Transmission

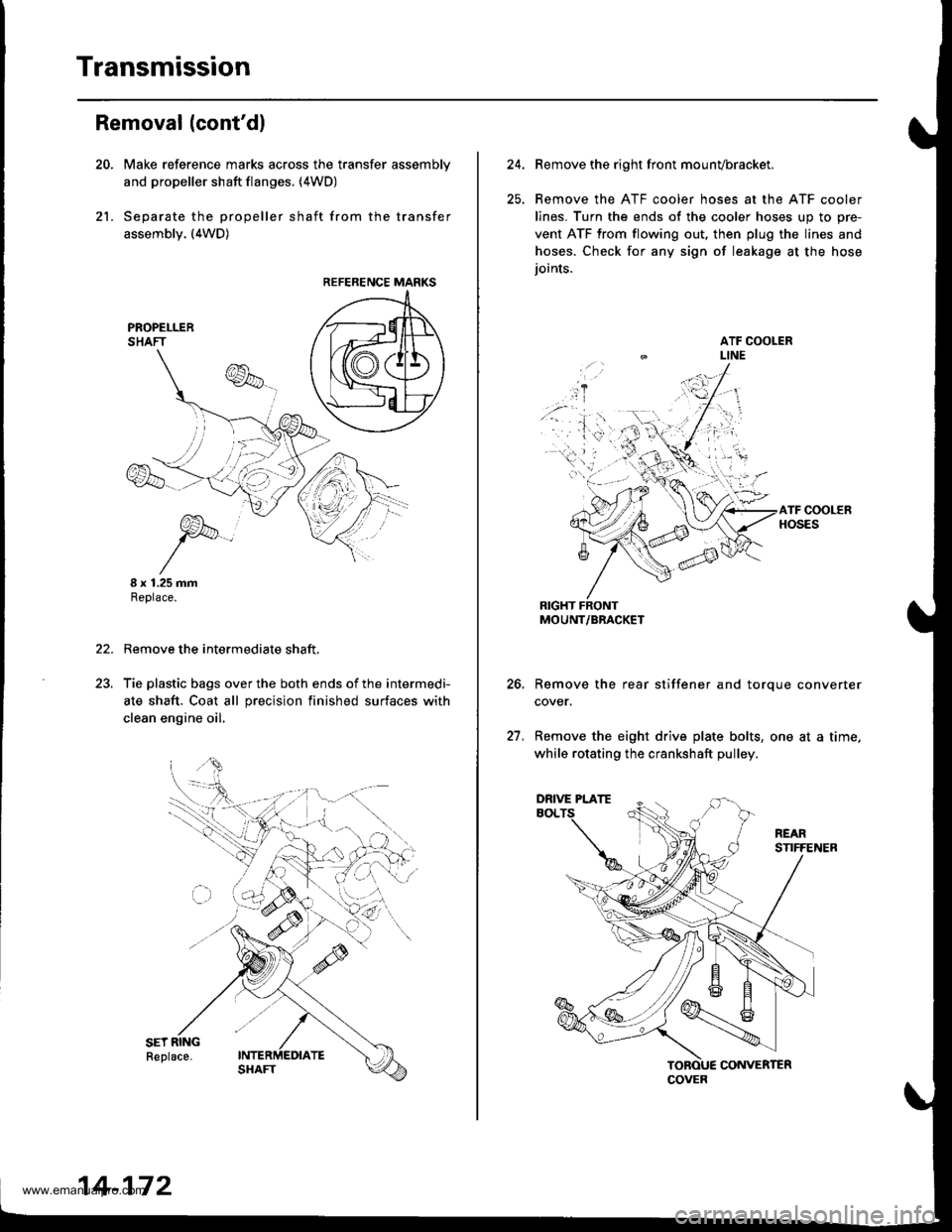

21.

Removal (cont'dl

Make reference marks across the transfer assemblv

and propeller shaft flanges. (4WD)

Separate the propeller shaft from the transfer

assembly. (4WD)

I x 1.25 mmReplace.

Remove the intermediate shaft,

Tie plastic bags over the both ends of the intermedi-

ate shaft. Coat all precision finished surfaces with

clean engine oil.

22.

REFERENCE MARKS

14-172

24.Remove the right front mounvbracket.

Remove the ATF cooler hoses at the ATF cooler

lines. Turn the ends of the cooler hoses uo to ore-

vent ATF from flowing out, then plug the lines and

hoses. Check for any sign of leakage at the hose

ioints.

RIGHT FRONTMOUNT/BRACKET

Remove the rear stiffener and torque converter

cover.

Remove the eight drive plate bolts, one at a time.

while rotating the crankshaft pulley.

27.

COVER

DRIVE PLATE

www.emanualpro.com