Crank HONDA CR-V 1997 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 122 of 1395

1.

2.

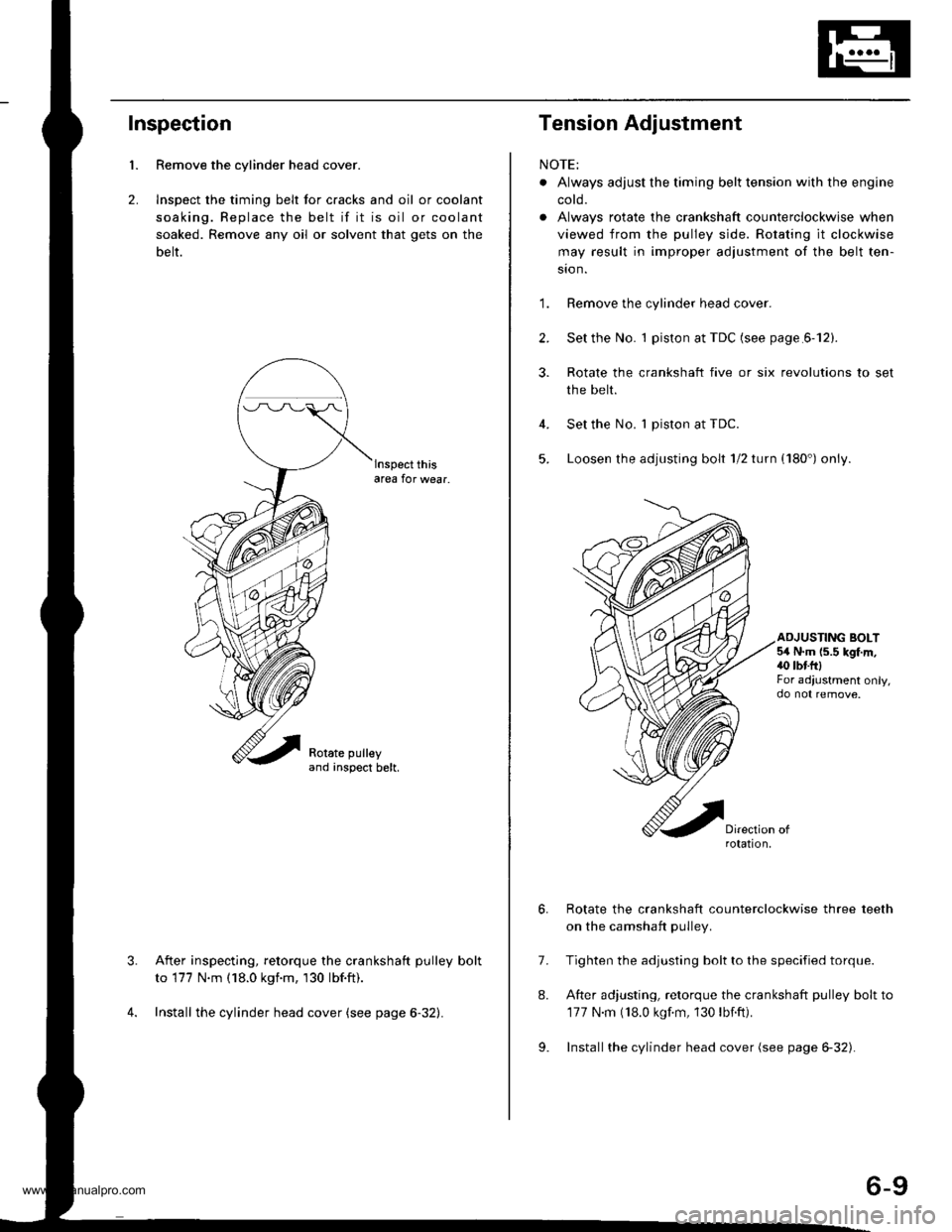

Inspection

Remove the cylinder head cover.

lnspect the timing belt for c.acks and oil or coolant

soaking. Replace the belt if it is oil or coolant

soaked. Remove any oil or solvent that gets on the

belt.

lnspect thisarea for wear.

After inspecting, retorque the crankshaft pulley bolt

to 177 N.m (18.0 kgnm, 130 lbf.ft).

Install the cylinder head cover (see page 6-32).

3.

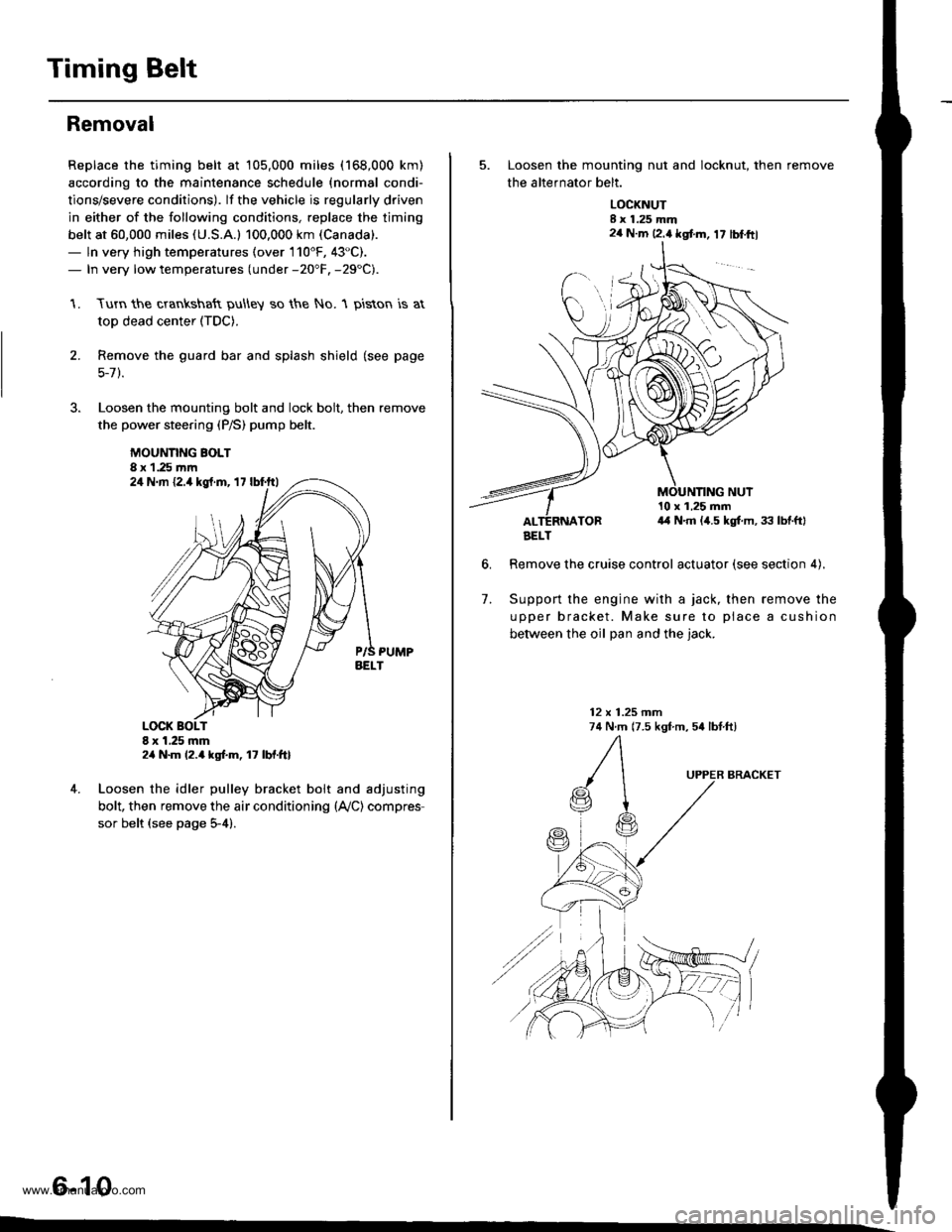

Tension Adjustment

NOTE:

. Always adjust the timing belt tension with the engine

coto.

. Always rotate the crankshaft counterclockwise when

viewed from the pulley side. Rotating it clockwise

may result in improper adiustment of the belt ten-

sion.

'1. Remove the cylinder head cover

2. Set the No. 1 piston at TDC (see page.6-12).

3. Rotate the crankshaft five or six revolutions to set

the belt.

Set the No. 1 piston at TDC.

Loosen the adjusting bolt 1/2 turn (180') only.

4.

5.

ADJUSTING BOLT5,4 N.m (5.5 kgf.m,40 tbtftlFor adiustment only,

7.

8.

Rotate the crankshaft counterclockwise three teeth

on the camshaft pulley.

Tighten the adjusting bolt to the specified torque.

After adjusting, retorque the crankshaft pulley bolt to

177 N.m (18.0 kgf.m, 130 lbf.ft).

Installthe cylinder head cover (see page 6-32).9.

rotation,

6-9

www.emanualpro.com

Page 123 of 1395

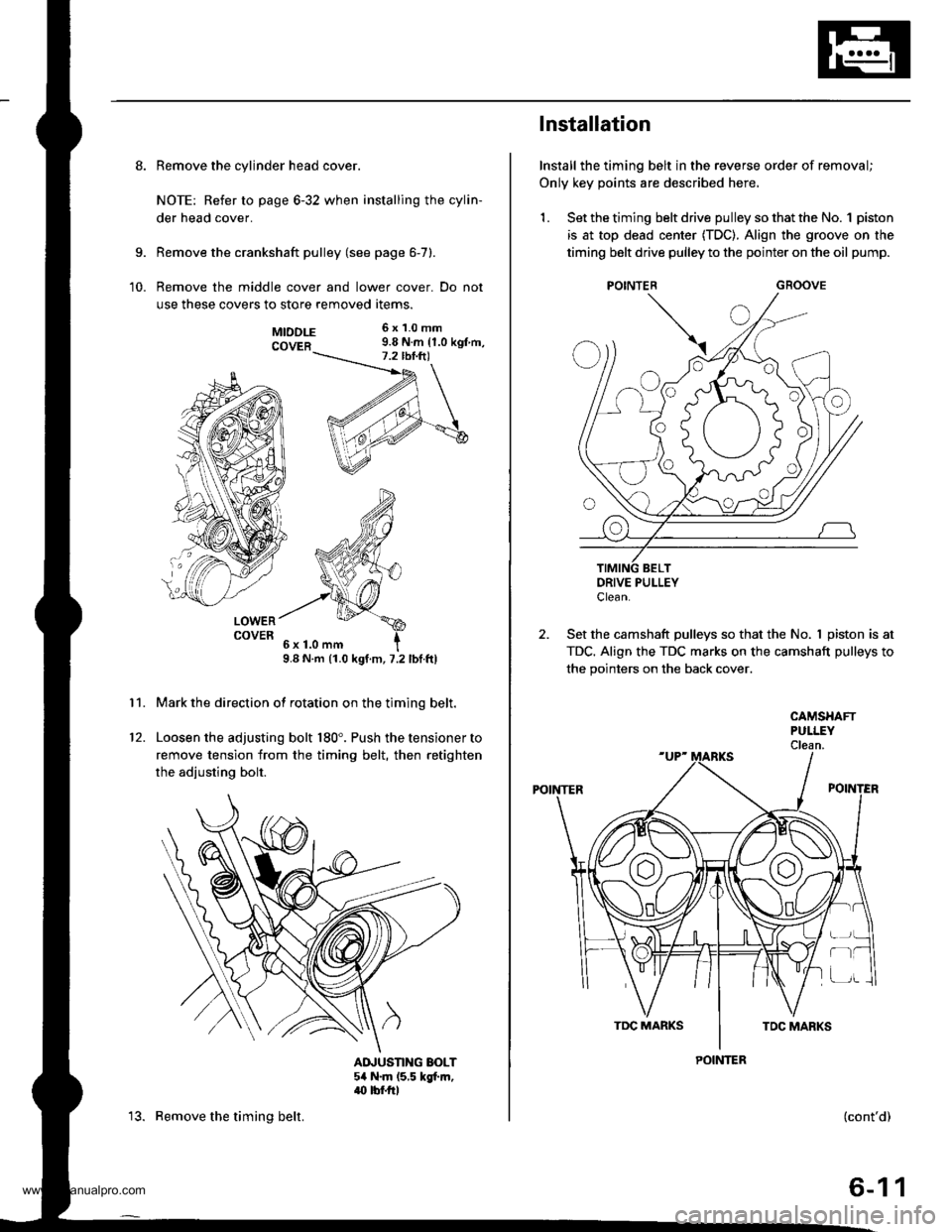

Timing Belt

Removal

Replace the timing belt at 105,000 miles (168,000 km)

according to the maintenance schedule {normal condi-

tions/severe conditions). lf the vehicle is regularly driven

in either of the following conditions, replace the timing

belt at 60,000 miles (U.S.A.l 100.000 km (Canada).

- ln very high temperatures (over 110'F, 43"C).- In very low temperatures (under -20"F. -29"C).

Turn the crankshaft pu\ley so the No. 1 piston is at

top dead center (TDC).

Remove the guard bar and splash shield (see page

5-7 ).

Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt.

MOUNNNG BOLT8 x 1.25 rnm

1.

2.

,l

4. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (lVC) compres

sor belt (see page 5-4).

6-10

24 N.m {2.4 kgt.m, 17 lbf.ftl

24 N.m 12.4 kgf.m, lt lbf.ftl

5. Loosen the mounting nut and locknut, then remove

the altefnator belt.

LOCKNUTI x 1.25 mm2a N.m 12.4 kgt m, 17 lblftl

6.

10 x 1,25 mm4,1 N.m (,1.5 kgt m, 33 lbtftl

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil Dan and the iack.

12 x 1.25 mm74 N.m (7.5 kgf m, 54 lbtftl

7.

BRACKET

AELT

www.emanualpro.com

Page 124 of 1395

8. Remove the cylinder head cover.

NOTE: Refer to page 6-32 when installing the cylin-

der head cover.

Remove the crankshaft pulley (see page 6-7).

Remove the middle cover and lower cover. Do not

use these covers to store removed items.

9.

10.

11.

MTDDLE 6x1.0mm

COVER 9.8 N.m {1.0 kgt m,

LOWERCOVER

9.8 N.m (1.0 kgt.m, 7.2 lbf.ftl

Mark the direction of rotation on the timing belt.

Loosen the adjusting bolt 180'. Push the tensioner to

remove tension from the timing belt, then retighten

the adiusting bolt.

AINUSTING BOLT54 N.m (5,5 kgt m,.(} tbf.rrl

12.

13. Remove the timing belt.

Installation

Install the timing belt in the reverse order of removal;

Only key points are described here,

1. Set the timing belt drive pulley so that the No. 1 piston

is at top dead center (TDC). Align the groove on the

timing belt drive pulley to the pointer on the oil pump.

GROOVE

DRIVE PULLEYClean.

2. Set the camshaft pulleys so that the No. I piston is at

TDC. Align the TDC marks on the camshaft pulleys to

the pointers on the back cover.

POINTER

CAMSHAFTPULLEYClean.

POINTER

r-t

(cont'd)

6-11

www.emanualpro.com

Page 125 of 1395

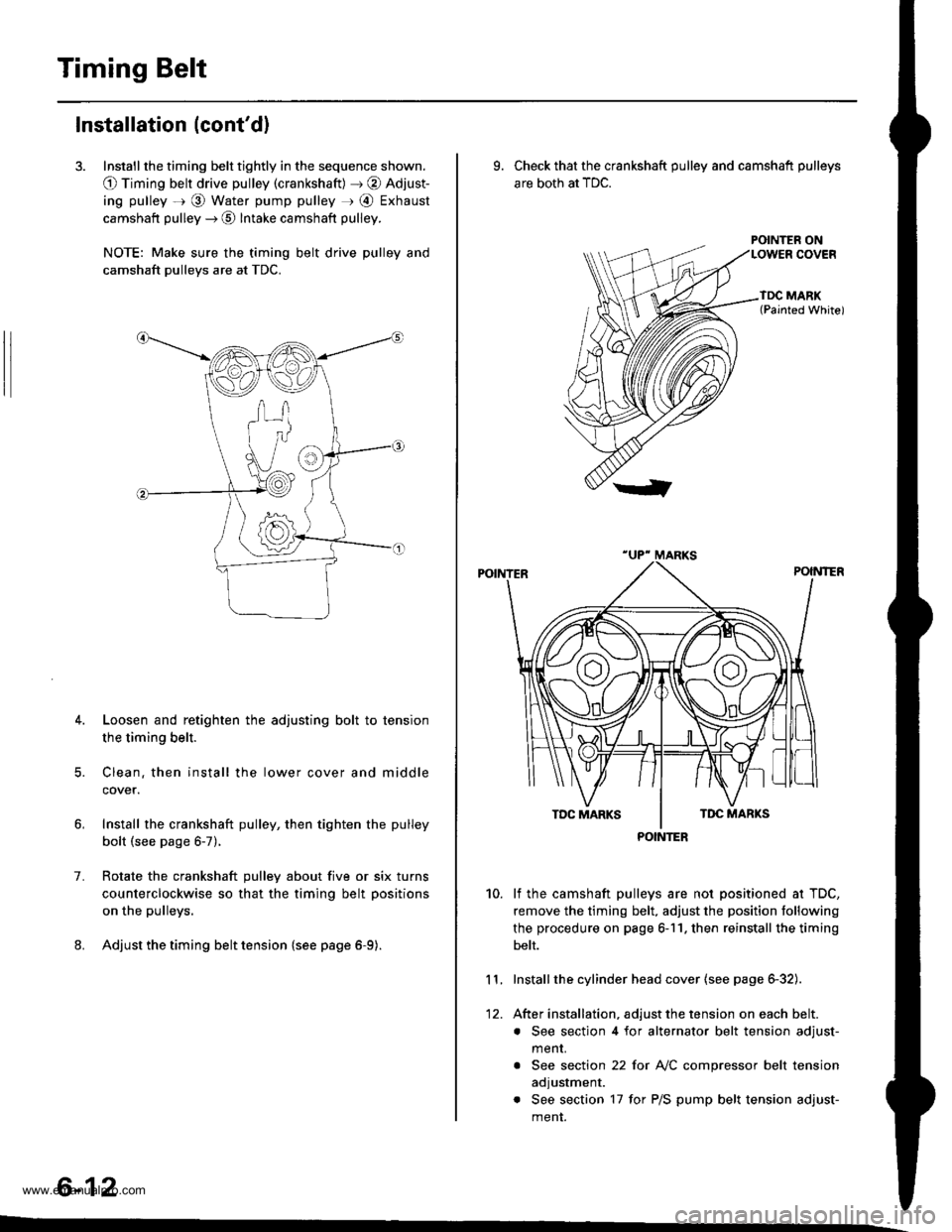

Timing Belt

Installation (cont'd)

3. Install the timing belt tightly in the sequence shown.

O Timing belt drive pulley (crankshaft) J @ Adjust-

ing pulley =r @ Water pump pulley r @ Exhaust

camshaft pulley --) @ Intake camshaft pulley.

NOTE: Make sure the timing belt drive pulley and

camshaft pulleys are at TDC.

4. Loosen and retighten the adjusting bolt to tension

the timing belt.

5. Clean. then install the lower cover and middle

cover.

Install the crankshaft pulley, then tighten the pulley

bolt (see page 6-7).

Rotate the crankshaft pulley about five or six turns

counterclockwise so that the timing belt positions

on the pulleys.

Adjust the timing belt tension {see page 6-9).

1.

6-12

9. Check that the crankshaft pulley and camshaft pulleys

are both at TDC.

POINTER ON

lf the camshaft pulleys are not positioned at TDC,

remove the timing belt. adjust the position following

the procedure on page 6-11. then reinstall the timing

belt.

Installthe cylinder head cover (see page 6-32).

After installation, adjust the tension on each belt.

. See section 4 for alternator belt tension adjust-

menr.

. See section 22 for NC compressor belt tension

adjustment.

. See section 17 for P/S pump belt tension adjust-

ment.

10.

11.

12.

POINTER

www.emanualpro.com

Page 126 of 1395

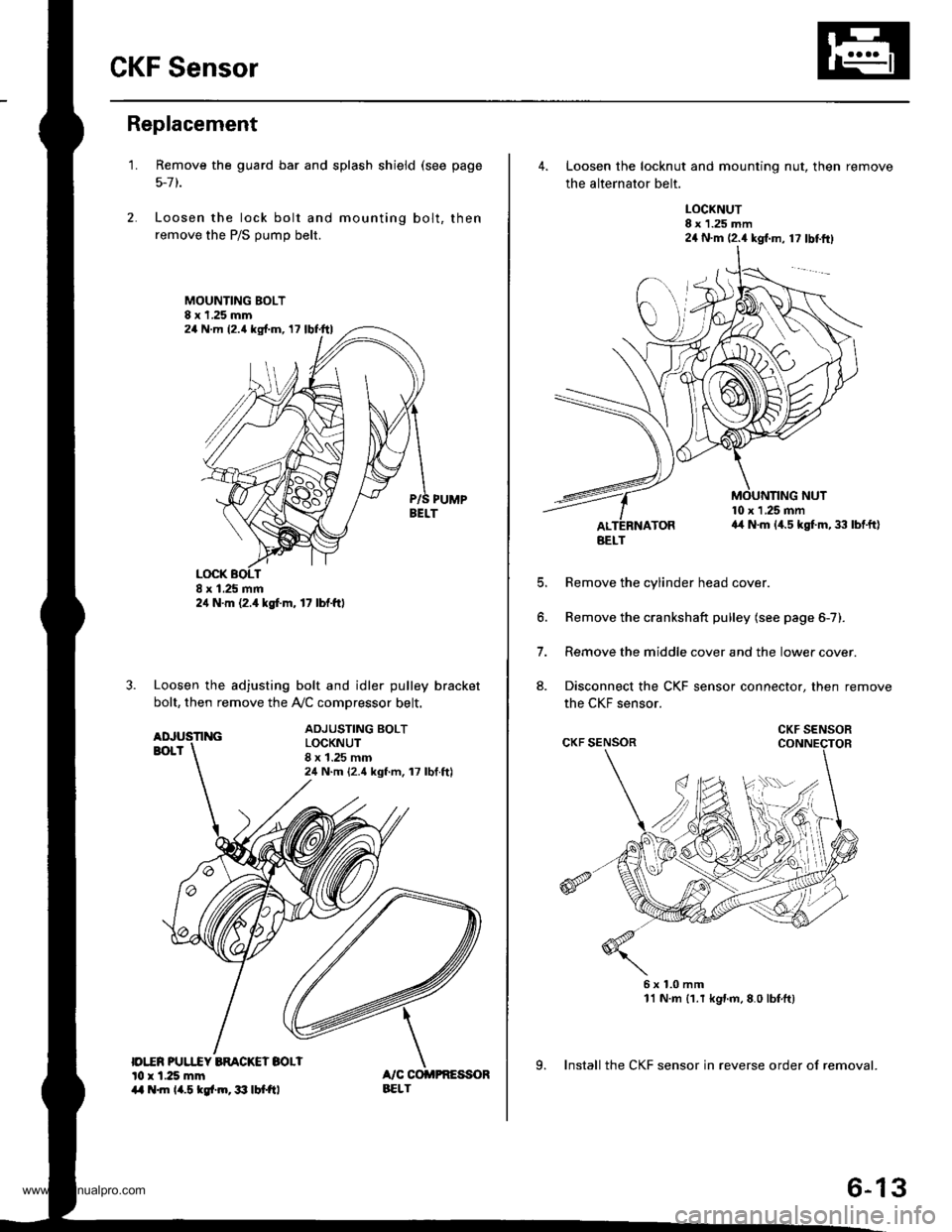

CKF Sensor

Replacement

1.

|o|'ln PUUCY BMCKET SOLIl0 r 1.25 mm14 .m 14.5 kgl.m,3:' lbtftl

Remove the guard bar and splash shield (see page

5-7 t.

Loosen the lock bolt and mounting bolt, then

remove the P/S pump belt.

MOUNTING BOLT8 x 1.25 mm

PUMPBELT

Loosen the adjusting bolt and idler pulley bracket

bolt, then remove the Ay'C comDressor belt.

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N.m {2.4 kgf.m, 17 lbf.ft)

24 N.m (2.{ kgf.m, 17 lbf.ttl

24 N.m 12.4 lgf.m, 17 lbl.ftl

4. Loosen the locknut and mounting nut, then remove

the alternator belt.

LOCKNUT8 x 1.25 mm24 N.m (2.4 kgl.m, 17 lbtftl

10 x 1 .25 mma4 N.m (4.5 kgt m, 33 lbtft)

E

6.

7.

aJ.

Remove the cylinder head cover.

Remove the crankshaft pulley (see page 6-7).

Remove the middle cover and the lower cover.

Disconnect the CKF sensor connector, then remove

the CKF sensor.

6x1.0mm11 N.m {1.r kgnm,8.0 lbfft)

9. Install the CKF sensor in reverse order of removal.

BELT

CKF SENSOR

6-13

www.emanualpro.com

Page 131 of 1395

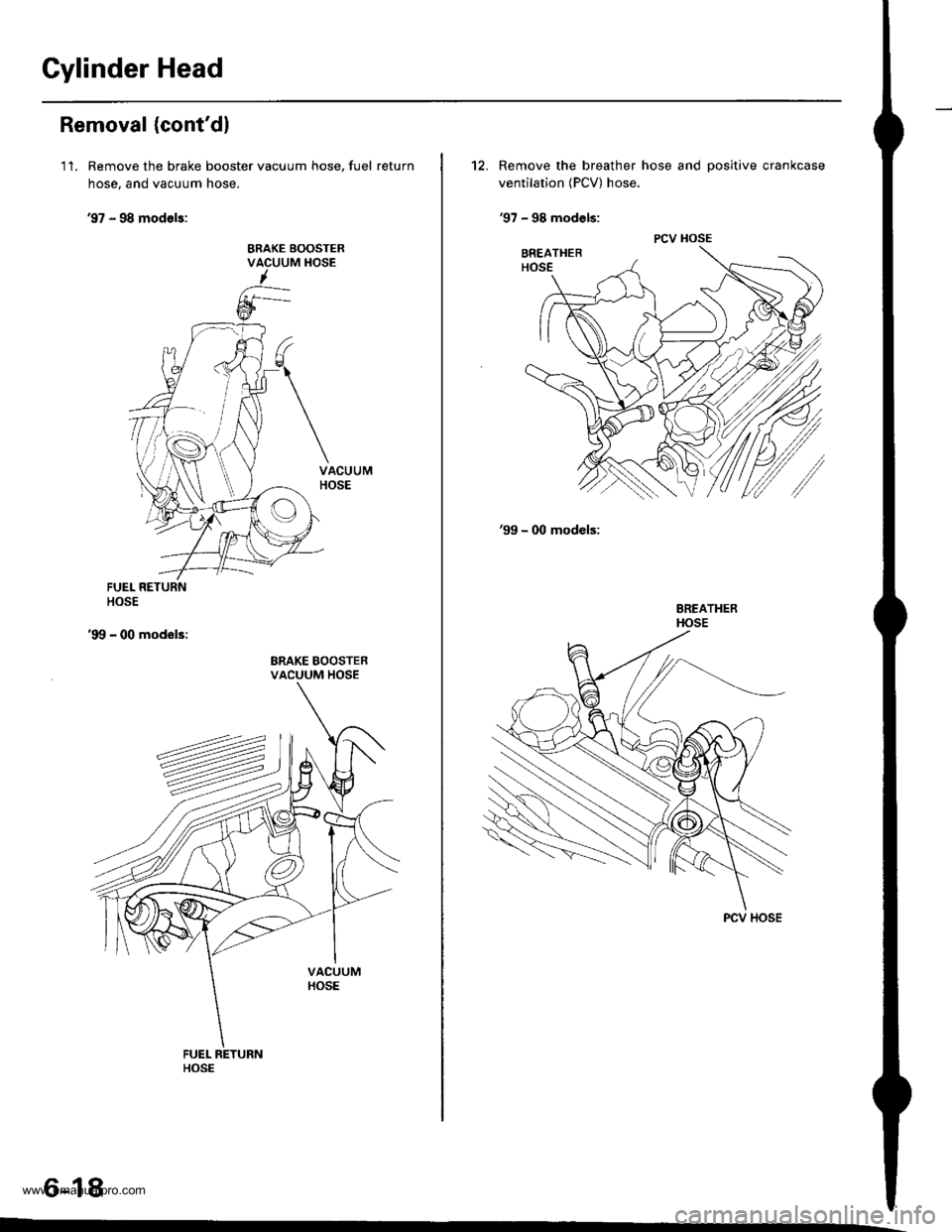

Gylinder Head

Removal (cont'dl

'11. Remove the brake booster vacuum hose. fuel return

hose, and vacuum hose.

'97 - 98 modsls:

VACUUMHOSE

BRAKE BOOSTEBVACUUM HOSE

6-18

BRAKE BOOSTER

12. Remove the breather hose and oositive crankcase

ventilation (PCV) hose,

'97 - 98 models:

BREATHEBHOSE

PCV HOSE

'99 - 00 models:

BREATHERHOSE

PCV HOSE

www.emanualpro.com

Page 147 of 1395

Engine Block

Speciaf Tools .............7-2

lllustrated lndex ................................... 7-3

Flywheel and Drive Plate

Replacement ..,.,....7-5

Connecting Rod and Grankshaft

End Play .................7-6

Main Bearings

Cfearance ...............7 -7

Selection ................7-8

Connecting Rod Bearings

Clearance ...............7-8

Selection ................7-9

Pistons and Crankshaft

Removal .................7-9

Crankshaft

Inspection .............. 7-11

Pistons

fnspection ..............7-12

fnstaflation .............7-20

Cylinder Block

Inspection ..............7-13

Piston Pins

Removal ..,.......,,..... 7-14

Installation ............. 7-15

Inspection .............. 7-16

Connecting Rods

Selection ................7 -14

Piston Rings

End Gap .................7 -17

Ring-to-Groove Clearance ............... 7 -17

Replacement .........7-18

Alignment .............. 7-18

Crankshaft Oil Seal

lnstallation ............. 7-19

Crankshaft

lnstalfation .............7-20

Oil Seals

fnstalfation ....,..,.....7-23

www.emanualpro.com

Page 149 of 1395

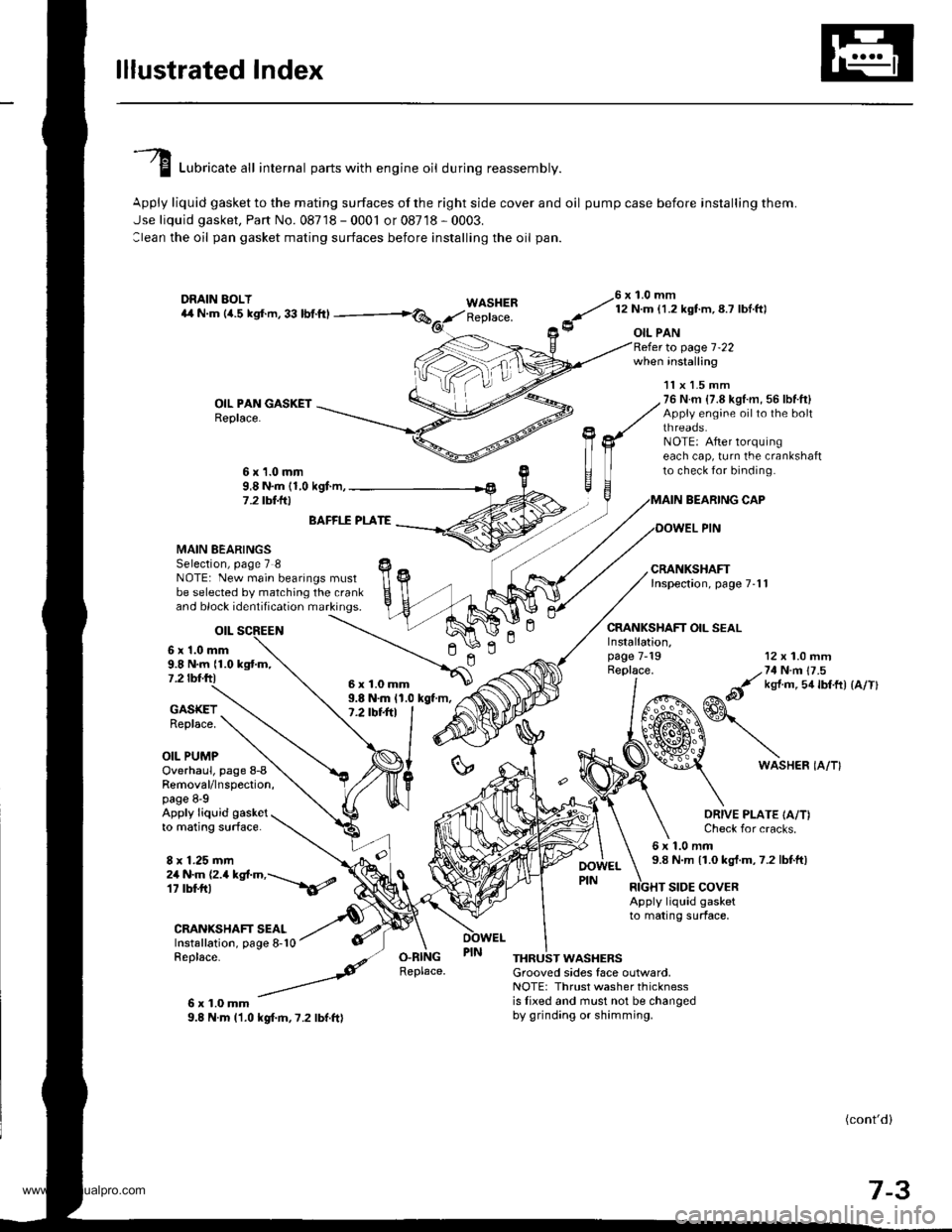

lllustrated lndex

I Luori""t" "tl internal parts with engine oil during reassembly.

Apply liquid gasket to the mating surfaces of the right side cover and oil pump case before installing them.

Jse liquid gasket, Part No. 08718 - 0001 or 08718 - 0003.

:lean the oil pan gasket mating surfaces before installing the oil pan.

WASHERReplace.

76 x 1.0 mm

y' t:n- l.zxstm, 8.7 lbl ftl

9 oIL PAN

OIL PAN GASKETReplace.

to page 1-22when installing

BEARING CAP

OOWEL PIN

CRANKSHAFT OIL SEAL

11x 1.5 mm76 N.m {7.8 kgl.m, 56 lbf.ft}Appiy engine oilto the boltthreaos.NOTE: After lorquingeach cap, turn the crankshaftto check for binding.6x1.0mm9,8 N.m (1,0 kgf.m,7 .2 tbt.lrl

n

MAIN BEARINGSSelection, page 7 8NOTE: New main bearings mustbe selected by matching the crankand block identification markings.

otL

6 x'1.0 mm9.8 N.m {1.0 kgtm,7.2 tbf.ftl

BAFFI.f PLATE

9.8 N.m 11.0 kgt m,7.2 tbt+tl

12 x 1.0 mm

/,71N n 17 .5

&it ks{ m 5a lbtft) {a/Tl

GASKETReplace.

OIL PUMP

Installation,page 7-19Replace.

ln

6WASHER IA/T}Overhaul, page 8-8Removal/lnspection,page 8-9Apply liquid gasketto mating surface.

8 x 1.25 mm

ORIVE PLATE IA/T)Check for cracks.

6x1.0mm9.8 N.m 11.0 kgt.m,7.2 lbtft)2a N.m (2.a kgt.m,---\6/

CRANIGHAFT SEALInstallation, page 8-10Replace-

6x1.0mm9.8 N.m l'1.0 kgf.m,7.2 lbf.ft)

RIGHT SIDE COVERApply liquid gasketto mating surface,

O.RINGReplace.THRUST WASHERSGrooved sides face outlvard,NOTE: Thrust washer thicknessis lixed and must not be changedby grinding or shimming.

(cont'd)

7-3

6x1.0mm

www.emanualpro.com

Page 150 of 1395

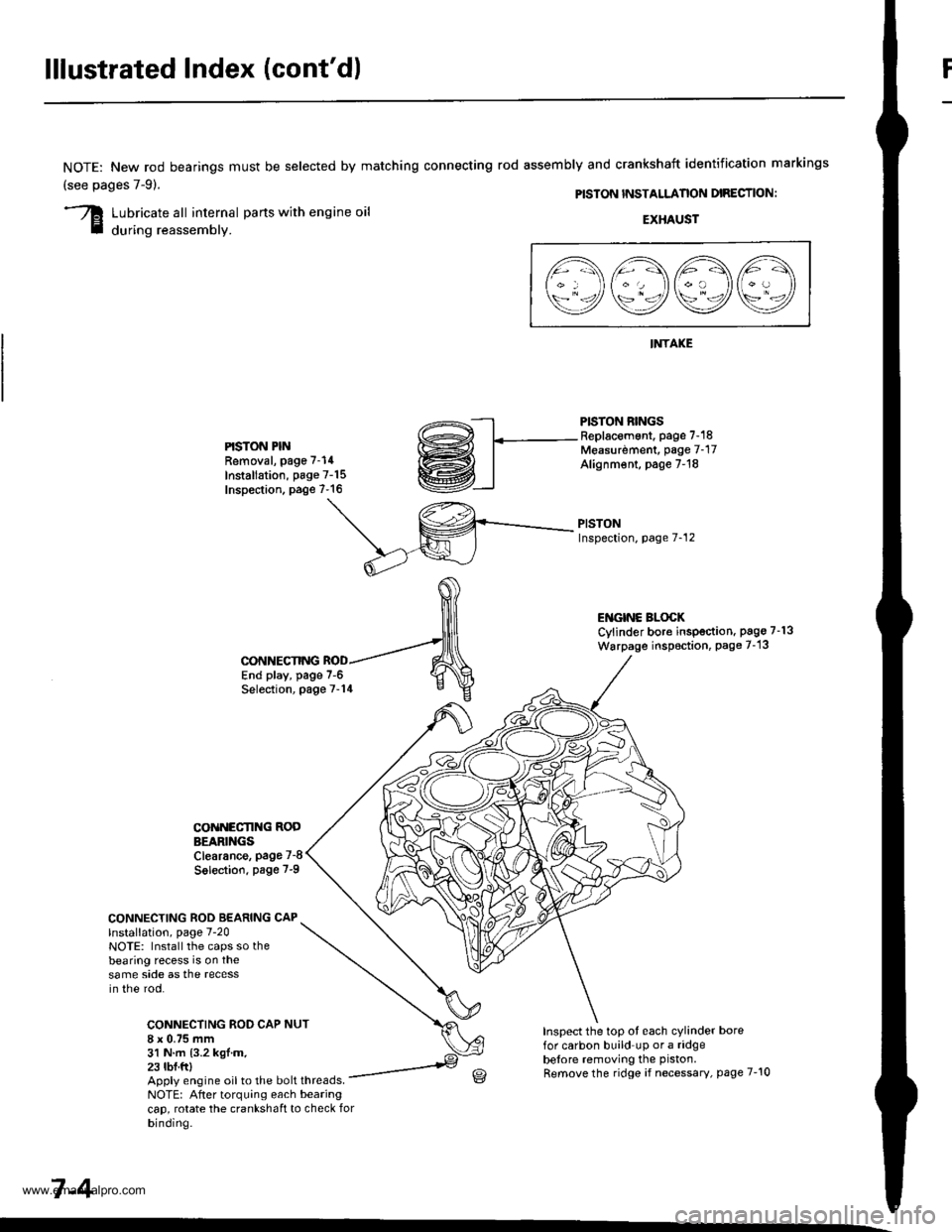

lllustrated Index (cont'd)

NOTE: New rod bearings

(see pages 7-91.

must be selected by matching connecting rod assembly and crankshaft identification markings

PISTON INSTALLANON DIRECTION:

Lubricate all internal parts with engine oil

during reassembly.EXHAUST

INTAKE

PISTON RINGSReplacement. page 7-18Measurdment, page 7-17Alignm€nt, page 7-18

PISTONInspection, page 7-12

l1\AAtr\

\9q9Q9e/

PISTON PINRemoval, page 7-14

Installation, page 7-15Inspection. page 7-16

ENGINC BLOCKCylinder bore inspection. pago 7-13

Warpage inspoction, Page 7-'13

CONNECTING ROD BEARING CAPlnstallation, page 7-20NOTE: Install the caps so thebearing recess is on thesame side as the recessin the rod.

CONNECTING ROD CAP8 x 0.75 mm31 N.m {3.2 kgl.m.23 tbf.ftl

CONNECTING

COiINECI'ING RODBEARINGSClearance, page 7-8

Solection. page 7-9

NUT

End play, page 7-6Selection, page 7-14

Inspect the top ot each cylinder borefor carbon build up or a ridgebelore removing the piston.

Remove the ridge if necessary, page 7-10Apply engine oil to the bolt threads.NOTE: After torquing each bearingcap, rotate the crankshaft to check forbinding.

7-4

www.emanualpro.com

Page 151 of 1395

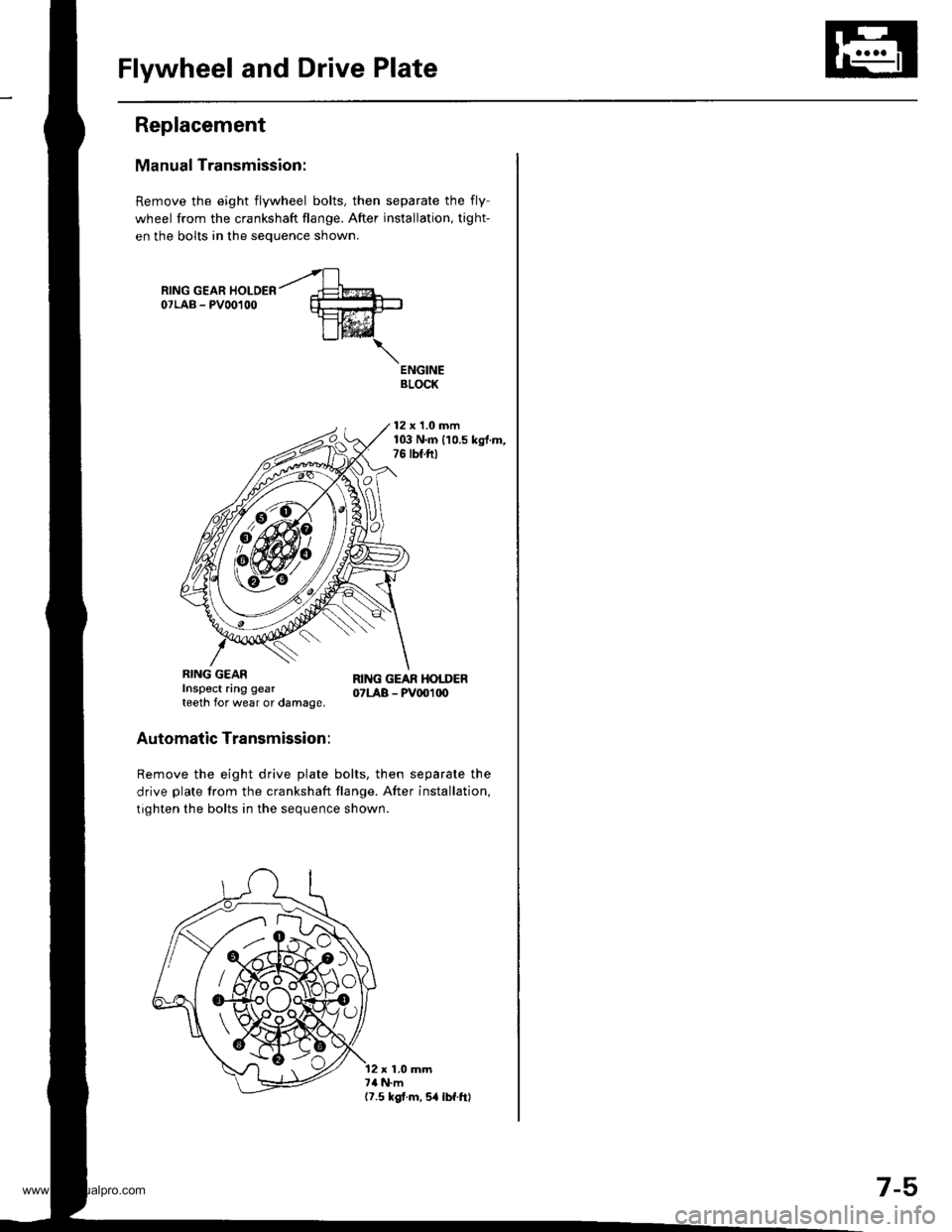

Flywheel and Drive Plate

Replacement

Manual Transmission:

Remove the eight flywheel bolts, then separate the fly-

wheel from the crankshaft flange. After installation, tight-

en the bolts in the sequence shown.

ENGINEBLOCK

12 x 1.0 mm103 N.m 110.5 kgf.m,76 lbf.ft)

Automatic Transmission:

Remove the eight drive plate bolts, then separate the

drive plate from the crankshaft flange. After installation,

tighten the bolts in the sequence shown.

RING GEARInspect ring gearteeth for wear or damage,

RI G GEAR HOTDER07LAB - PV001|X)

12 x 1.0 mm7a N.m(7.5 kgt.m,5a lbf.ftl

/ AzXi{'jA\Ao

7-5,

www.emanualpro.com