fuse HONDA CR-V 1997 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 974 of 1395

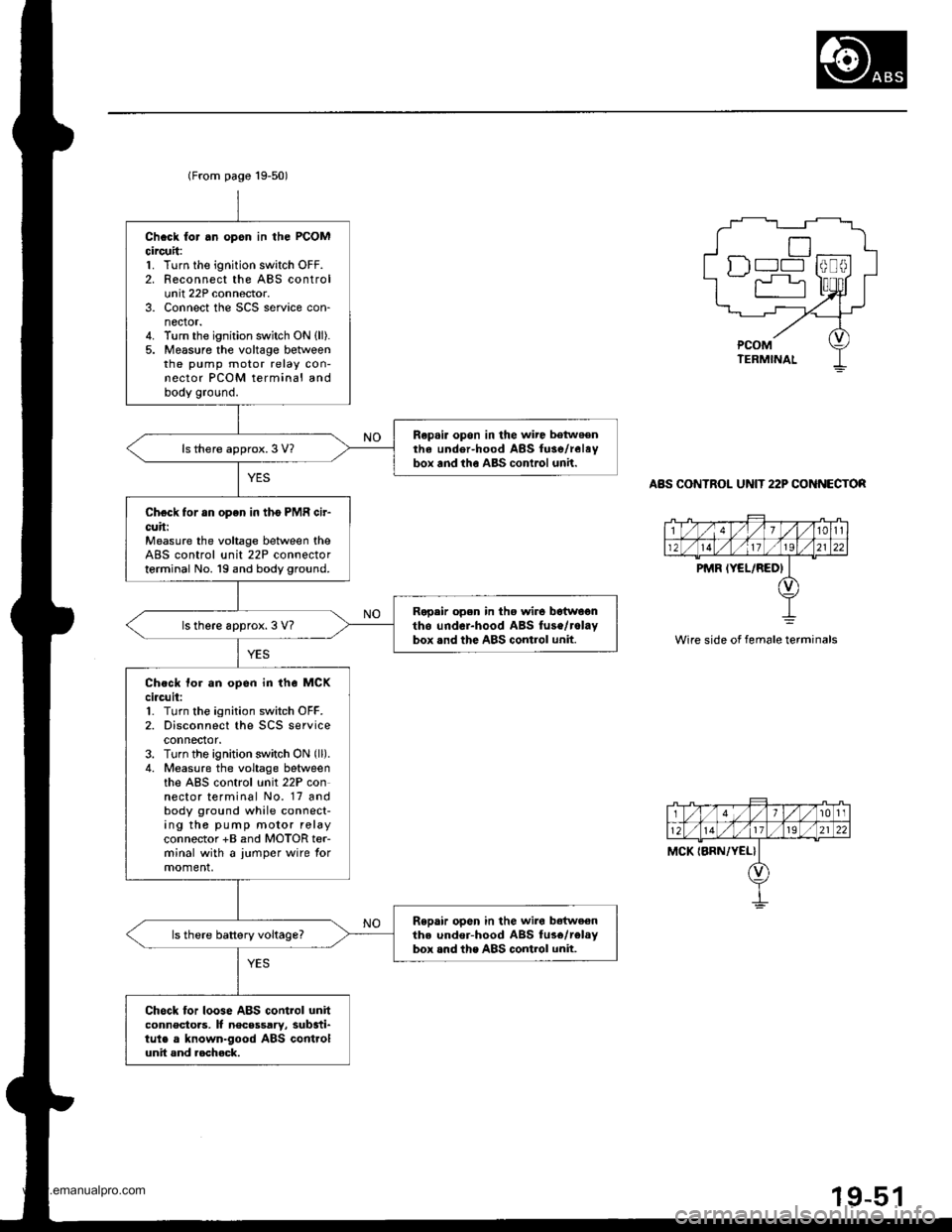

(From page 19-50)

Chcck for .n opsn in the PCOMcircuit:1. Turn the ignition switch OFF.2. Reconnect the ABS controlunit 22P connector.3. Connect the SCS service con-nector.4. Turn the ignition switch ON {ll).5. Measure the voltage betweenthe pump motor relay con-nector PCOM terminal andbody ground.

Repair opon in the wire betwoenthe under-hood ABS fuse/relaybox and tho ABS conlrol unh.ls there approx.3 V?

Check for an open in tho PMR cir-cuh:Measure the voltage between theABS control unit 22P connectorterminal No. 19 and body ground.

Ropair open in tho wir6 botwagntho undcr-hood ABS fuse/rolaybox .nd the ABS control unit.ls there approx. 3 V?

Ch.ck tor an opon in the MCKci.cuit:1. Turn the ignition switch OFF.2. Disconnect the SCS serviceconnector.3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe ABS control unit 22P connector terminal No. 17 andbody ground while connect-ing the pump motor relayconnector +B and MOTOR ter-minal with a jumper wire tormoment,

Repair open in the wiro bdtweenthe under-hood ABS fus6/telaybox .nd the ABS control unit.ls there battery voltage?

Chock for loose ABS control unitconnectoas, It necsssary, substi-tule a known-good ABS controlunit and aocheck.

tr) l--l

r"r

ABS CONTROL UNIT 22P CO NECTOR

Wire side of female terminals

1t011

MCK IBRN,/YEL}

www.emanualpro.com

Page 975 of 1395

![HONDA CR-V 1997 RD1-RD3 / 1.G Repair Manual

Troubleshooting

DTG 54: Main Relay

IWHT/GRNI

AAS CONTROL UNIT 26P CONNECTON

Wire side of female terminals

ABS COf{TROL UN]T 22P CONNECTOR

PCOMIGRN/WHTIscoM{BLK/WHTI

Wire side of female terminals

- Wi HONDA CR-V 1997 RD1-RD3 / 1.G Repair Manual

Troubleshooting

DTG 54: Main Relay

IWHT/GRNI

AAS CONTROL UNIT 26P CONNECTON

Wire side of female terminals

ABS COf{TROL UN]T 22P CONNECTOR

PCOMIGRN/WHTIscoM{BLK/WHTI

Wire side of female terminals

- Wi](/img/13/5778/w960_5778-974.png)

Troubleshooting

DTG 54: Main Relay

IWHT/GRNI

AAS CONTROL UNIT 26P CONNECTON

Wire side of female terminals

ABS COf{TROL UN]T 22P CONNECTOR

PCOMIGRN/WHTIscoM{BLK/WHTI

Wire side of female terminals

- With the ignition switch ON(lll, the ABS indicator doesnot go off.- With the SCS service connec-tor connected {see page 19-381,DTC 54 is indicatod.

Check the ABS +B 120 A) fuse inthe under-hood ABS luse/relaybox, and reinstall the fuse if it isoK.

FeDlace the tu3e and recheck.

Ch€ck tor an open in the 81, 82circuit:Measure the voltage betweenbody ground and the ABS controlunit 26P connector terminal No. 14and No. 15 individually.

Repair open in the wiro bstweonth6 ABS conirol unit and theunder-hood ABS fuse/rolay box,

ls there battery voltage?

Check for a short to body groundin the PMR circuit:L Turn the ignition switch OFF.2. Remove the pump motor relay.3. Disconnect the ABS controlunit 22P connector.4. Check lor continuity betweenterminal No. 19 and bodygrouno.

Repair short to body ground inthe wire betweon the under-hood ABS lGe/r.lay box and theABS control unit.

Check for a short to body groundin the PCOM, SCOM cilcuit:1. Disconnect the ABS controlunit 26P connector.2. Check tor continuity betweenbody ground and the ABS con-trol unit 26P terminals No- 1and No.2 individually.

. R€pair short to body ground inth€ P1COM circuit wire betweenthe ABS control unit and theund6r-hood ABS tuse/r6layoox.. R6p.ir short to body ground inthe PCOM or SCOM circuit wirebetweon th6 ABS control unitand lhe mod!lator unit.. R.Dlece tho modulrtor unit.(Short circuit inside the unitl

ls there continuity?

(To page 19-53)

www.emanualpro.com

Page 1034 of 1395

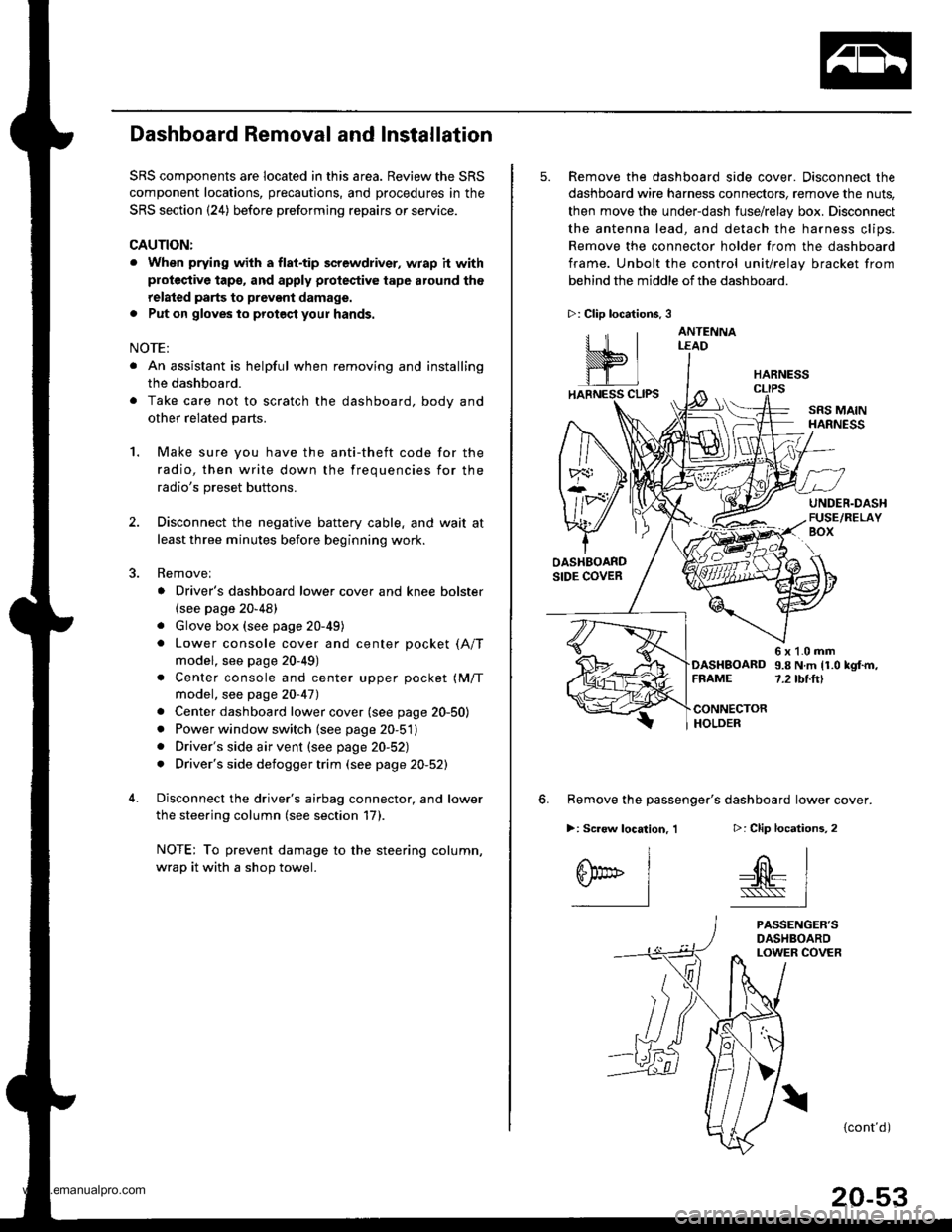

Dashboard Removal and Installation

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section {24) before preforming repairs or service.

CAUTION:

. When prying with a flat-tip screwdriver, wrap h withprotective tap€, and apply protective tape around the

related parts to prevgnt damage.

. Put on gloves to prot€ct your hands.

NOTE:

. An assistant is helpful when removing and installing

the dashboard.

. Take care not to scratch the dashboard, bodv and

other related parts.

1.Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

Disconnect the negative battery cable. and wait at

least three minutes before beginning work.

Removei

a Driver's dashboard lower cover and knee bolster(see page 20-48)

. Glove box (see page 20-49)

. Lower console cover and center pocket (A/T

model, see page 20-49)

. Center console and center upper pocket (M/T

model, see page 20-47)

. Center dashboard lower cover (see page 20-50)

. Power window switch (see page 20-51)

. Driver's side air vent (see page 20-52)

. Driver's side defogger trim (see page 20-52)

Disconnect the driver's airbag connector, and lower

the steering column (see section 17)

NOTE: To prevent damage to the steering column,

wrap it with a shop towel.

2.

5. Remove the dashboard side cover. Disconnect the

dashboard wire harness connectors, remove the nuts,

then move the under-dash fuse/relay box. Disconnect

the antenna lead, and detach the harness clips.

Remove the connector holder from the dashboard

frame. Unbolt the control unit/relay bracket from

behind the middle of the dashboard.

HARNESS

6. Remove the passenger's dashboard lower cover.

D: Clip locations,

nl

-$t- Issj

I

ANTENNALEAD

>: Clip locations.

rttl

slllll

>: Scr€w location, 1

I

SF:oo I-l

SRS MAINHARNESS

UNDER.DASHFUSE/RELAYBOX

OASHBOARDSIDE COVER

6x1.0mm9.8Nm11.0kgf.m,7.2tbt.ftlDASHBOARDFFAME

CONNECTORHOLDER

PASSENGER'SDASHBOARDLOWER COVER

{cont'd)

www.emanualpro.com

Page 1095 of 1395

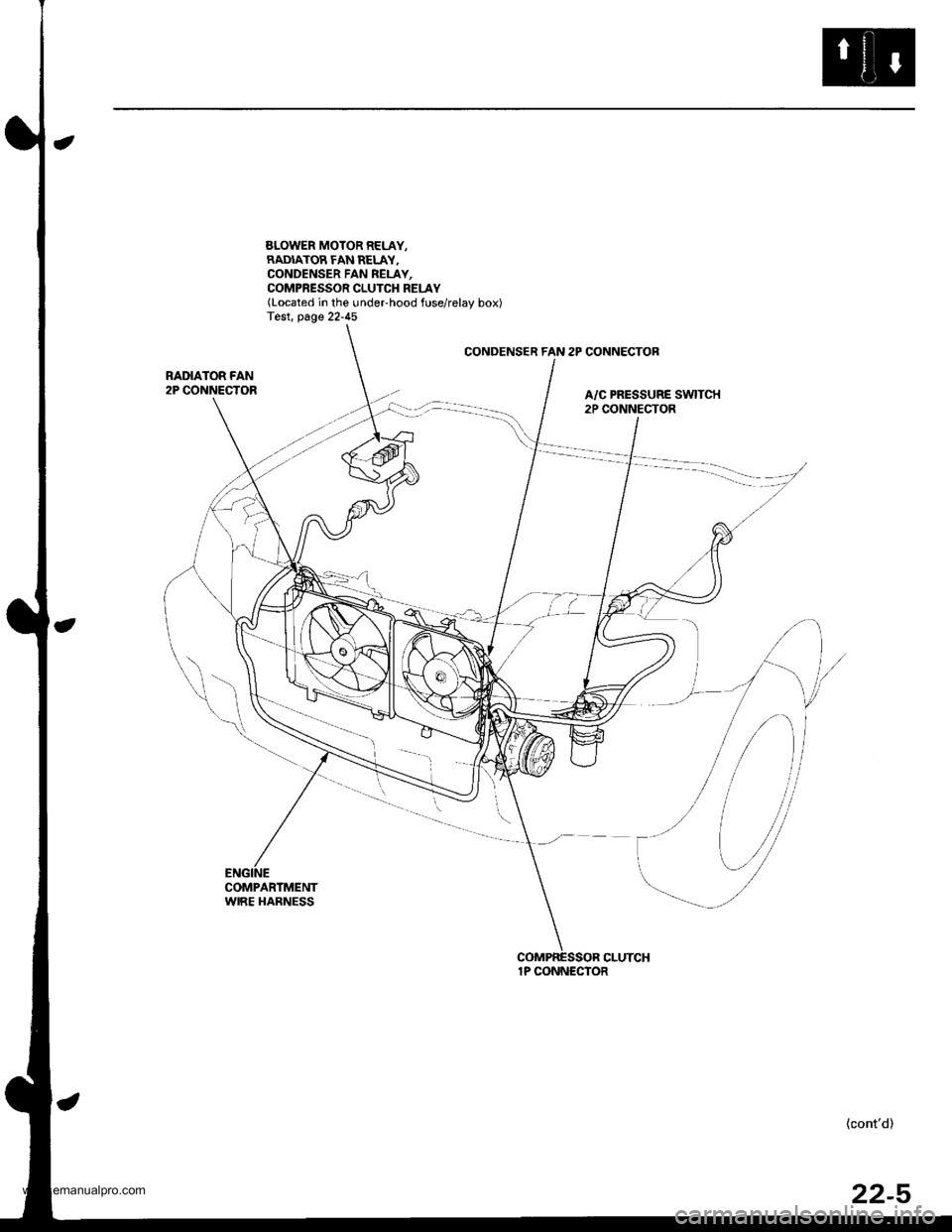

SLOWER MOTOR RELAY,RADIATOR FAN RELAY.CONDENSER FAN REI-AY,COMPRESSOR CLUTCH RELAY(Located in the undeFhood fuse/relay box)Test. page 22-45

CONDENSER FAN 2P CONNECTOB

RADIATOR FAN2P CONNECTORA/C PRESSURE SWITCH2P CONNECTOR

COMPARTMENTWIRE HARNESS

{cont'd)

1P CONNECTOR

22-5

www.emanualpro.com

Page 1097 of 1395

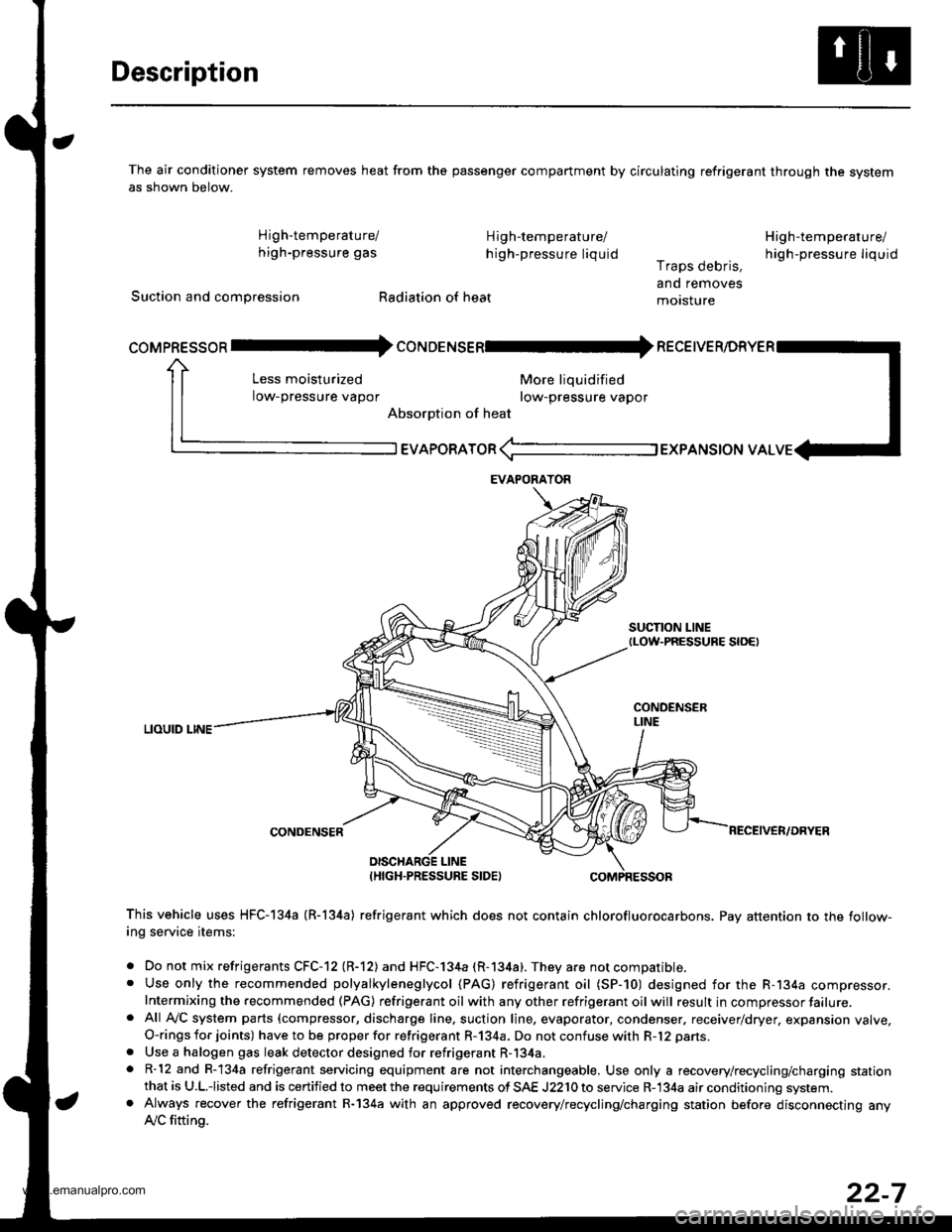

Description

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the systemas shown below.

High'temperature/ High-temperature/

high-pressure gas h igh-pressure liquid

Suction and compression Radiation of heat

High-temperature/

high-pressu re liq uidr raps oeons,

and removes

motsture

More liquidified

row-pressure vapor

EVAPoRAToR (-l EXPANSToN vAL

SUCTION LINEtLow-PRESSURE S|OEt

LIOUID LINE

CONDENSER

coMpREssoR Il- coruoerusenl* necetve

Less moisturized

low-pressure vapor

Absorption of heat

DISCHARGE LINEIHIGH.PRESSURE SIDEI

This vehicle uses HFC-I34a (R-l34a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-ing service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-l34a (R-134a). They are not compatible.. Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (SP-10) designed for the R-134a compressor.Intermixing the recommended (PAG) refrigerant oil with any other refrigerant oil will result in compressor failure.. Afl Ay'C system parts (compressor, discharge line. suction line, evaporator, condenser. receiver/dryer, expansion valve,O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a recovery/recycling/charging stationthat is U.L.iisted and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning system.. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting anylVC fitting.

EVAPORAYOR

22-7

www.emanualpro.com

Page 1098 of 1395

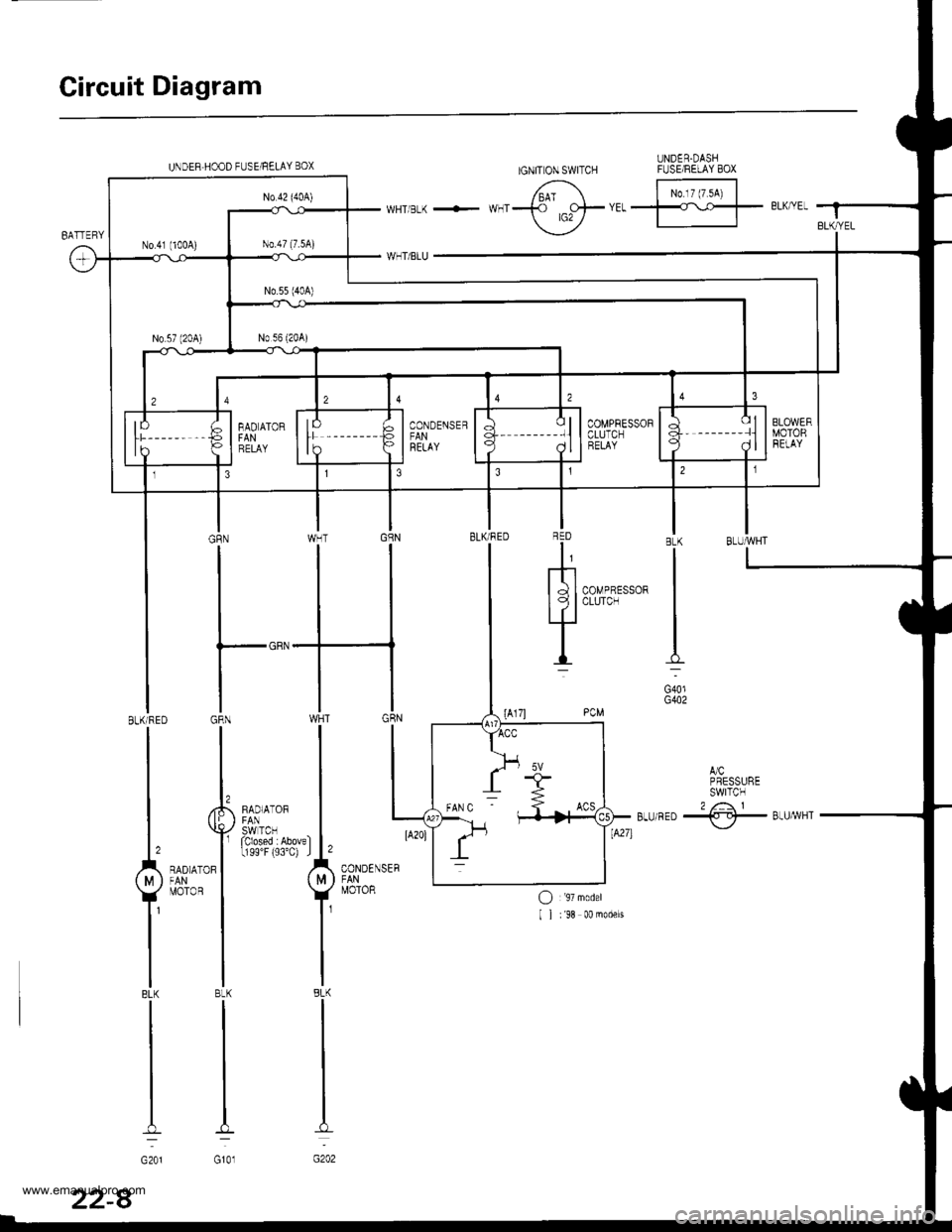

Circuit Diagram

UNDER.DASHFUSEiRELAY BOXIGNIT ON SWITCHUNDEB HOOD FUSE/RELAY BOX

/6'^' F;t"^i IwHTBLK + **f ,o+trrffl- eLK/YEI f

\_-./

,JCPRESSURESWITCN2 /: 1Btu/RED -{.-!}- Btu/yvHT\,-/

BLU'ryVHTBLK

G401G402

RED

I,

mI d I CoMPRESSORI I I CLUTCH

LIl

I

CONDENSER

MOTOR

BLK/RED GRN WHT

I I,^,^,", I

L^"^,Y**t,|

T*.'1 Y

lllBLK BLK BLK

rtl

lll---

G201 G101 G202

COMPRESSOFCLUTCHRELAY

22-8

www.emanualpro.com

Page 1100 of 1395

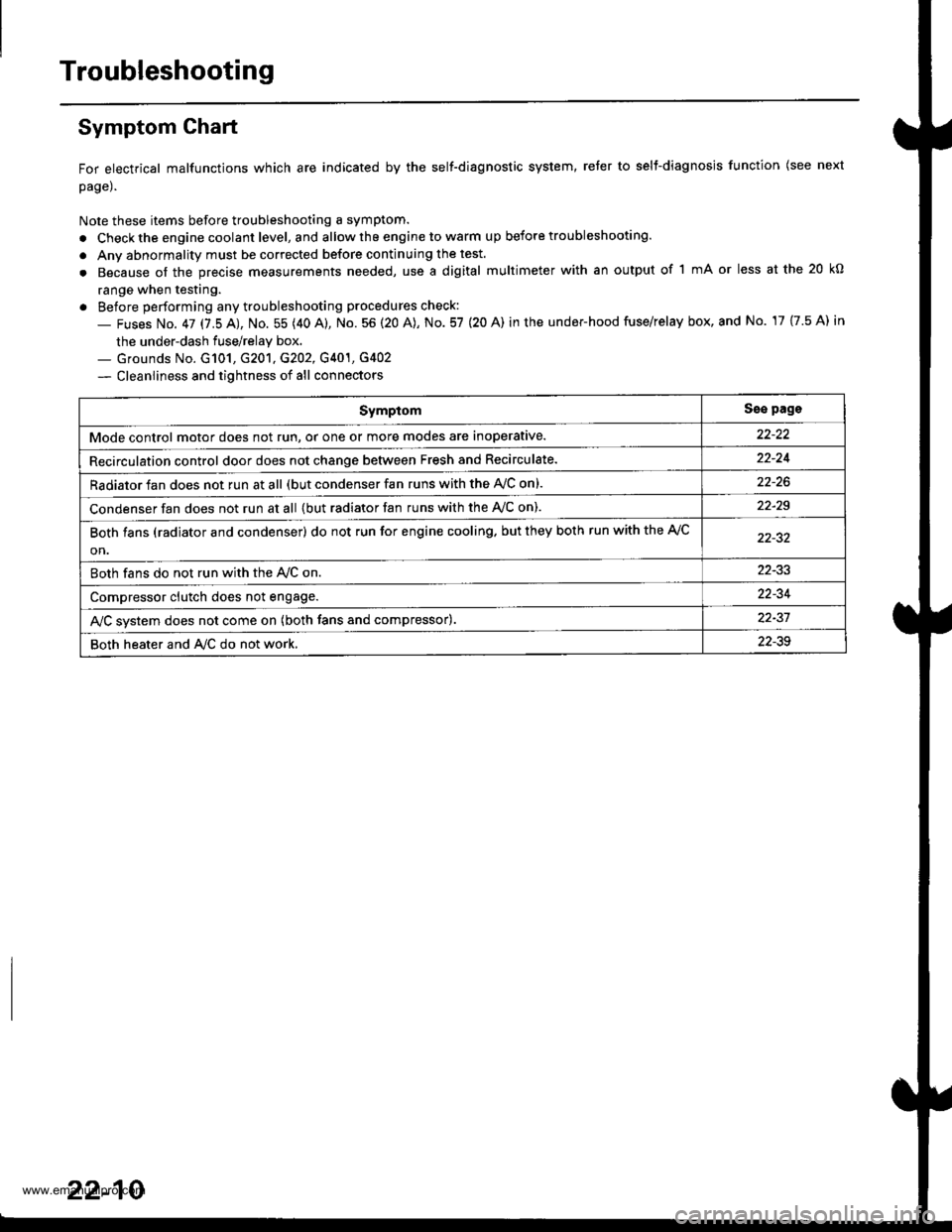

Troubleshooting

Symptom Ghart

For electrical malfunctions which are indicated by the self-diagnostic system, reter to selt-diagnosjs function (see next

page).

Note these items before troubleshooting a symptom.

. Check the engine coolant level, and allow the engine to warm up before troubleshooting.

. Anv abnormality must be corrected before continuing the test.

. Because of the precise measurements needed, use a digital multimeter with an output of 1 mA or less at the 20 kO

range when testing.

. Before performing any troubleshooting procedures check:

- Fuses No. 47 17.5 AJ, No. 55 (40 A), No. 56 (20 A), No. 57 (20 A) in the under-hood fuse/relay box, and No. 17 {7.5 A) in

the under-dash fuse/relay box.._ Grounds No. G101, G201, G202, G401, G4O2

- Cleanliness and tightness of all connectors

SymptomSse pags

Mode control motor does not run, or one or more modes are inoperative.

Recirculation control door does not change between Fresh and Recirculate.22-24

Radiator fan does not run at all (but condenser fan runs with the AVC on).

Condenser fan does not run at all {but radiator fan runs with the Ay'C on).22-29

Both fans (radiator and condenser) do not run for engine cooling. but they both run with the A,/C

on.

Both fans do not run with the Ay'C on22-33

Compressor clutch does not engage.22-34

AJC svstem does not come on (both fans and compressor).22-37

Both heater and A/C do not work,22-39

22-10

www.emanualpro.com

Page 1106 of 1395

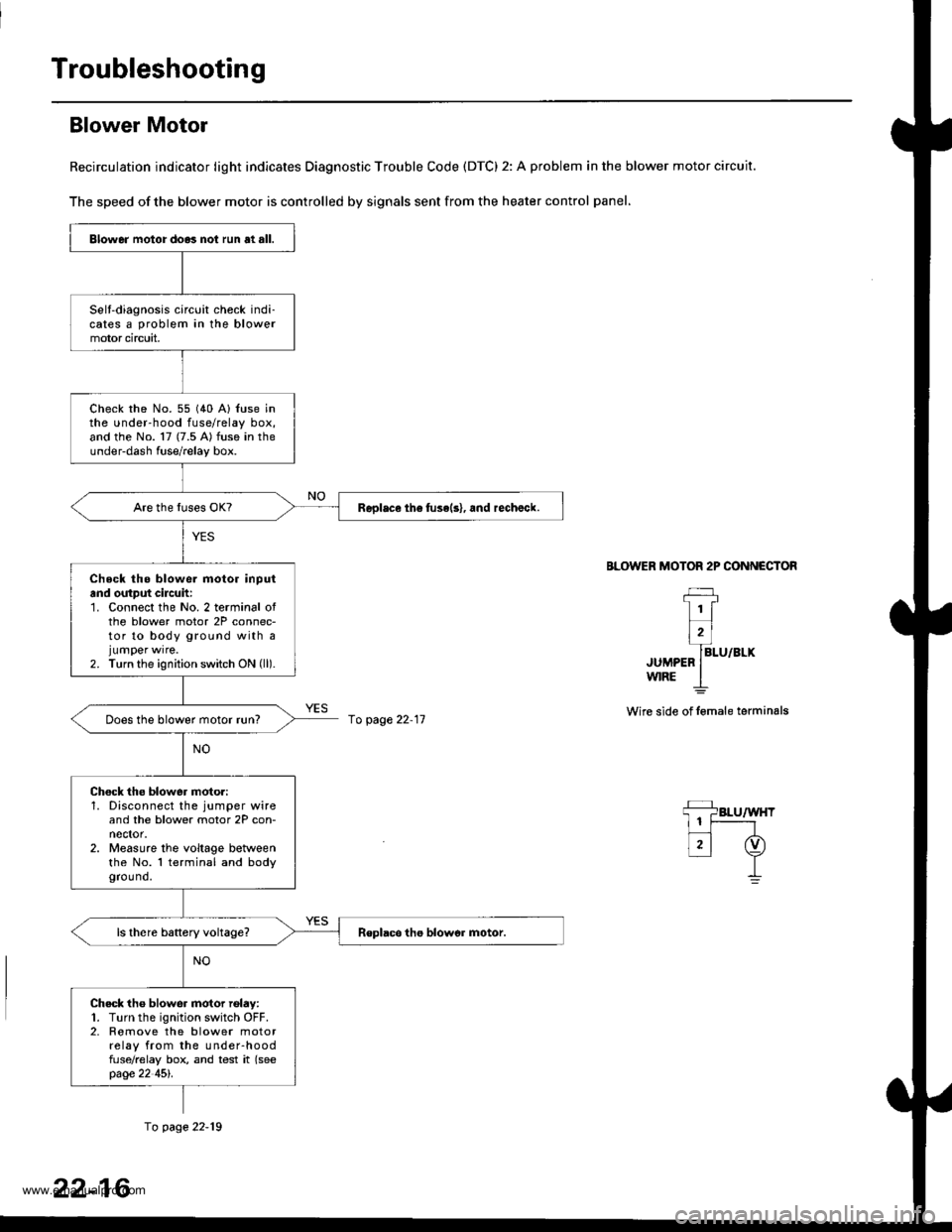

Troubleshooting

Blower Motor

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 2: A problem in the blower motor circuit.

The speed of the blower motor is controlled by signals sent from the heater control panel,

BLOWER MOTOR 2P CONNECTOR

JUMPEFw|RE

Wire side of lemale terminals

Blower motor do.3 not run at all.

Selt-diagnosis circuit check indi-cates a problem in the blowermotor circuit,

check rhe No. 55 (40 A) {use inthe under-hood fuse/relay box,and the No. 17 (7.5 A) fuse in theunder-dash fuse/relay box.

Replace th6 fuse(s), and rechalck.

Check tho blowe. motor inputand output cilcuh:1. Connect the No. 2 terminal ofthe blower motor 2P connec-tor to body ground with ajumper wrre.2. Turn the ignition switch ON (ll).

Does the blower motor run?

Chock the blower moto.:1. Disconnect the jumper wireand the blower motor 2P con-nector.2. Measure the voltage betweenthe No. l terminal and bodygrou nd.

Check tho blower motor rolay:1. Turn the ignition switch OFF.2. Romove the blower motorrelay from the under-hoodfuse/relay box, and test it (seepage 22 45l'.

fo page 22-11

fo page 22-19

22-16

www.emanualpro.com

Page 1107 of 1395

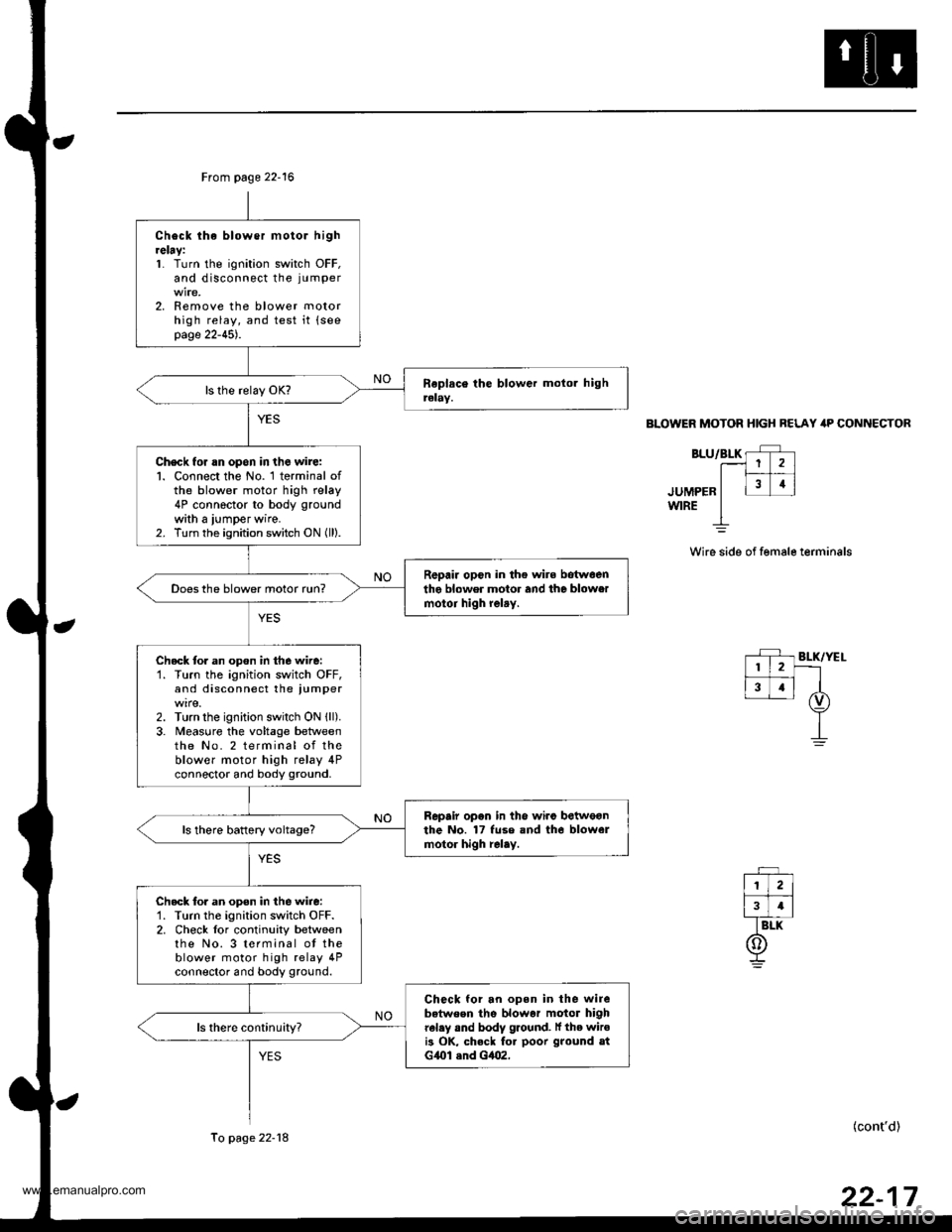

From page 22-16

Check lhe blower motor hightelay:1. Turn the ignition switch OFF,and disconnect the ju mper

2. Remove the blower motorhigh relay, and test it {seepage 22-45).

Check for rn opon in the wire:l. Connect the No. 1 terminal ofthe blower motor high relay4P connector to body ground

with a iumper wire.2. Turn the ignition switch ON (ll).

R6pair opcn in the wire botwoenthe blower motor and the blowermotoi high relry.Does the blower motor run?

Check tor an opon in the wire:'1. Turn the ignition switch OFF,and disconnect the iumper

2. Turn the ignition switch ON {ll).3. Meas0re the voltage betweenthe No. 2 terminal of theblower motor high relay 4Pconnector and body ground.

Repair opon in the wiro betweonthe No. 17 fuse and tho blowelmotor high relay.ls there battery voltage?

Check tor an open in the wire:'1. Turn the ignition switch OFF.2. Check lor continuity betweenthe No. 3 terminal ot theblower motor high relay 4Pconnector and body ground.

Check for an open in the wirebetween the blowar motor highrel.y and body ground. lf the wiroi3 OK, check fo. poor ground atG{Ol .nd Gt|()2,

To page 22-18

BLOWER MOTOR HIGH BELAY itP CONNECTOR

BLU/BLK rF r.--1 1 2 )l|_#

.ruuee" I l31i

wrRE I

Wire side of female terminals

(cont'd)

www.emanualpro.com

Page 1112 of 1395

Troubleshooting

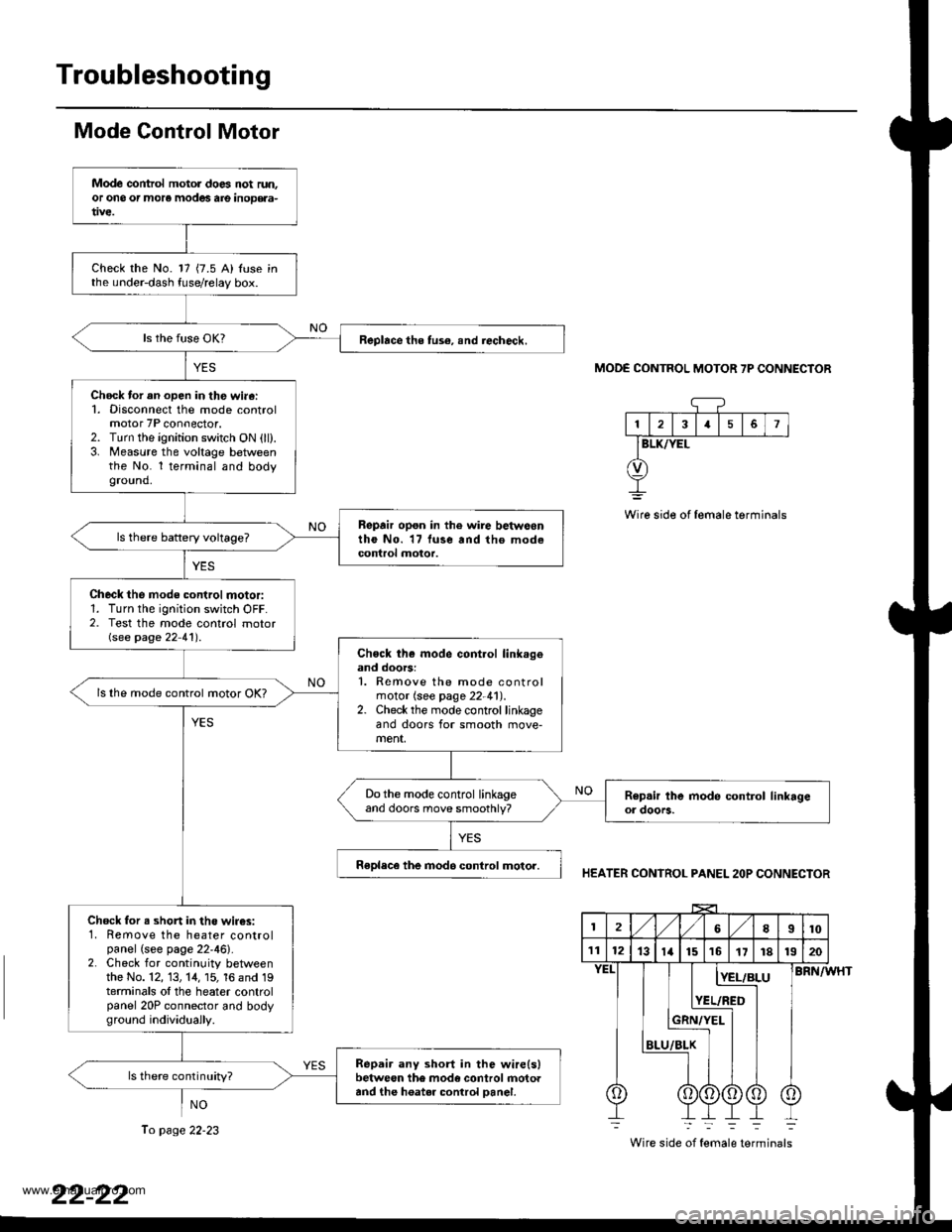

Mode Control Motor

NO

MODE CONTROL MOTOR 7P CONNECTOR

13I5

BLK/YEL

Wire side of female terminals

HEATER CONTROL PANEL 2OP CONNECTOR

BRN/WHT

Wire side of female terminals

Mode control motol does not run.or ono or more modes are inoD€aa-

Check the No. 17 {7.5 A) Iuse inthe under-dash fuse/relay box.

Replace the tus€, snd iecheck.

Chock tor an open in th€ wi.6:1. Disconnect the mode controlmotor 7P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betweenthe No. l terminal and bodyground.

Repair opon in the wire betwoontho No. 17 luse and tho modecontrol motor.

Check the mode control motor:1. Turn the ignition switch OFF.2. Test the mode control motorGee page 22 41') .

Chock th€ mode cont.ol link.geand doors:1. Remove the mode controlmotor (see page 22-41).2. Check the mode control linkageand doors for smooth move-ment,

ls lhe mode control motor OK?

Do the mode control linkageand doors move smoothly?

Replece the inod6 control motor.

Chock for s shon in the wir€s:1. Remove the heater controlpanel (see page 22'46).2. Check for continuity betweenthe No. 12, 13, 14, 15, 16 and 19terminals ol the heater controlpanel 20P connector and bodyground individuaily.

Repair any short in the wire(slbetween the mode control rnotoaand the h6ater control Danel.

ls there continuity?

2l,/1,/8I10

111213ta151617r81320

BLU

[E!r!

YEL/RED

Ii

To page 22-23

www.emanualpro.com