Cam cap HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 36 of 1395

to

l

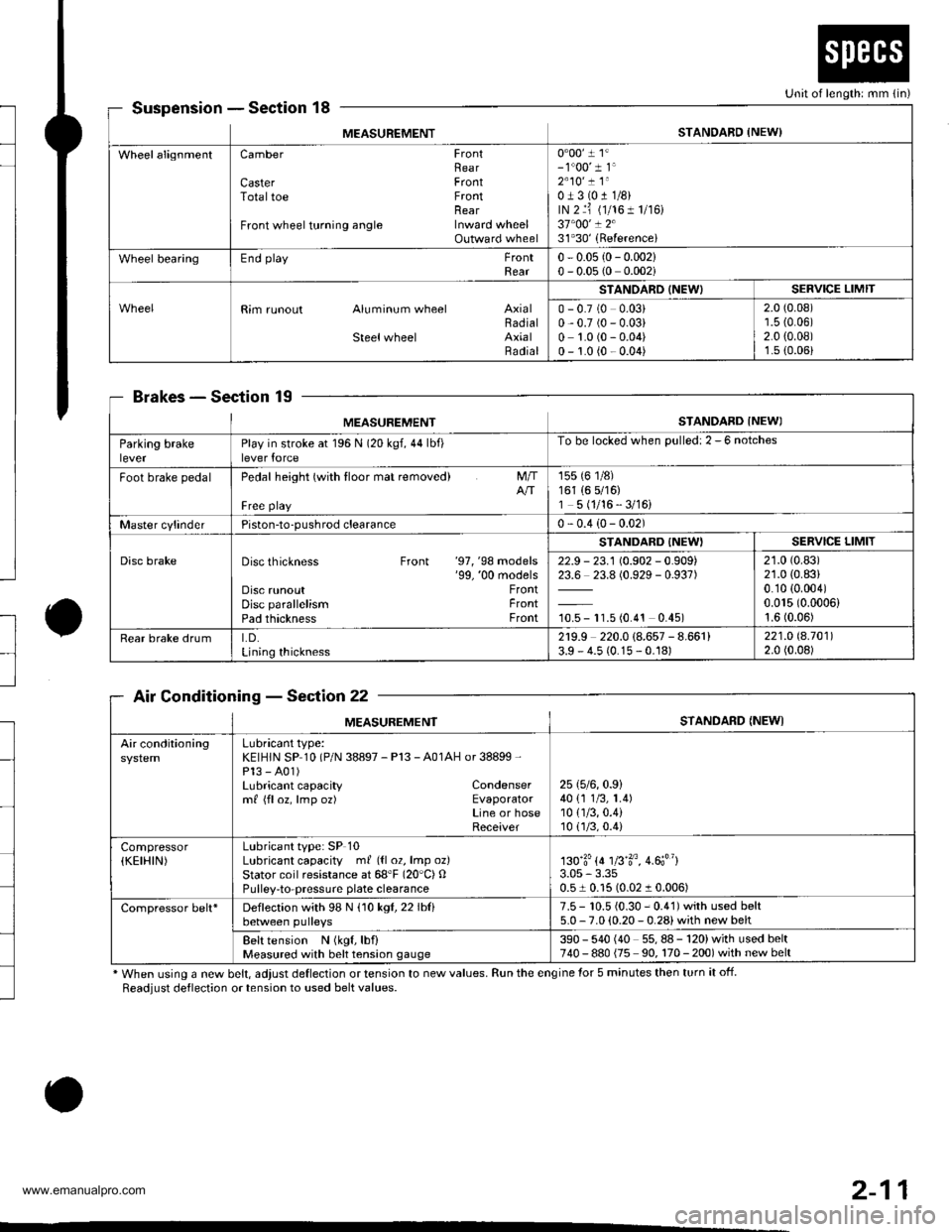

SuspensionSection 18

BrakesSec'tion 19

Air ConditioningSection 22

* When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.

Readjust deflection or tension to used belt values.

o

Unit of length: mm {in)

MEASUREMENTSTANDARD {NEW)

WheelalignmentCamber FrontRearCaster FrontTotaltoe FrontnearFront wheel turning angle Inward wheelOutward wheel

0"00' 1 1'- 1"00' 1 1'2"10' ! 1"0J3(011/8)rN 2 ri (1/161 1/r6)37"00' ! 231'30'(Referencei

Wheel bearingEnd playFrontRear0 - 0.05 {0- 0.002}0 - 0.05 (0 0.002i

Rim runout Aluminum wheel AxialBadialSteelwheel AxialRadial

STANOARD (NEW)SERVICE LIMIT

0 - 0.7 (0 0.03)0,0.7 (0 - 0.03)0 1.0 (0 - 0.04)0 - 1.0 {0 - 0.04)

2.0 (0.08)'r.5 {0.06)2.0 {0.08)1.s (0.06)

MEASUREMENTSTANDARD INEWI

Parking brakeleverPlay in stroke at 196 N (20 kgf,44lbf)lever force

To be locked when Dulled: 2 - 6 notches

Foot brake pedalPedal height (with tloor mat removed)

Free playNT

155 (6 1/8)161 (6 5/16)1 5 (1/16 - 3/16)

Master cylinderPiston-to-pushrod clearance0 - 0.4 (0- 0.02)

Disc brakeDisc thickness Front '97, '98 models'99, '00 modelsDisc runoutDisc parallelismPad thickness

FrontFrontFront

STANDARD {NEW'SERVICE LIMIT

22.9 - 23.1 (0.902 - 0.909)23.6 23.8 (0.929 - 0.937)

10.5 - 11.5 (0.4'�t 0.45)

21.0 (0.83)

21.0 (0.83)

0.10 {0.004)0.015 (0.0006)

1.6 (0.06)

Rear brake drumLD.Lining thickness

2r9.9 220.0 (8.657 - 8.661)3.9 - 4.5 (0.15 - 0.18)221.O 8.70112.0 (0.08)

MEASUREMENTSTANDARD {NEWI

Air conditioningLubricant type:KEIHIN SP 10 (P/N 38897 - Pl3 - A01AH or 38899 -

Pl3 - A01)Lubricant capacity Condensermf {floz, lmp oz) EvaporatorLine or hoseReceiver

25 (5/6,0.9)

40 {1 1/3, 1.4)10 {1/3,0.4)10(.]/3,0.4)

Compressor(KEIHIN)Lubricant type: SP 10Lubricant capacity ml ({l 02, lmp oz}Stator coil resistance at 68'F (20"C) OPulley-to-pressuae plate clearance

130'3'{4 1fi'3o, 4.6;"}3.05 - 3.350.51 0.15 (0.02 1 0.006)

Compressor belt*Deflection with 98 N (10 kgl,22lblibetween pulleys7.5 - 10.5 {0.30 - 0.41) with used belt5.0 - 7.0 (0.20 - 0.28) with new belt

Belt tension N (kgf, lbf)Measured with belt tension gauge390 - 540 (40 55,88-120)withusedbelt740 - 880 {75 90, 170 - 200) with new belt

2-11

www.emanualpro.com

Page 38 of 1395

--

-

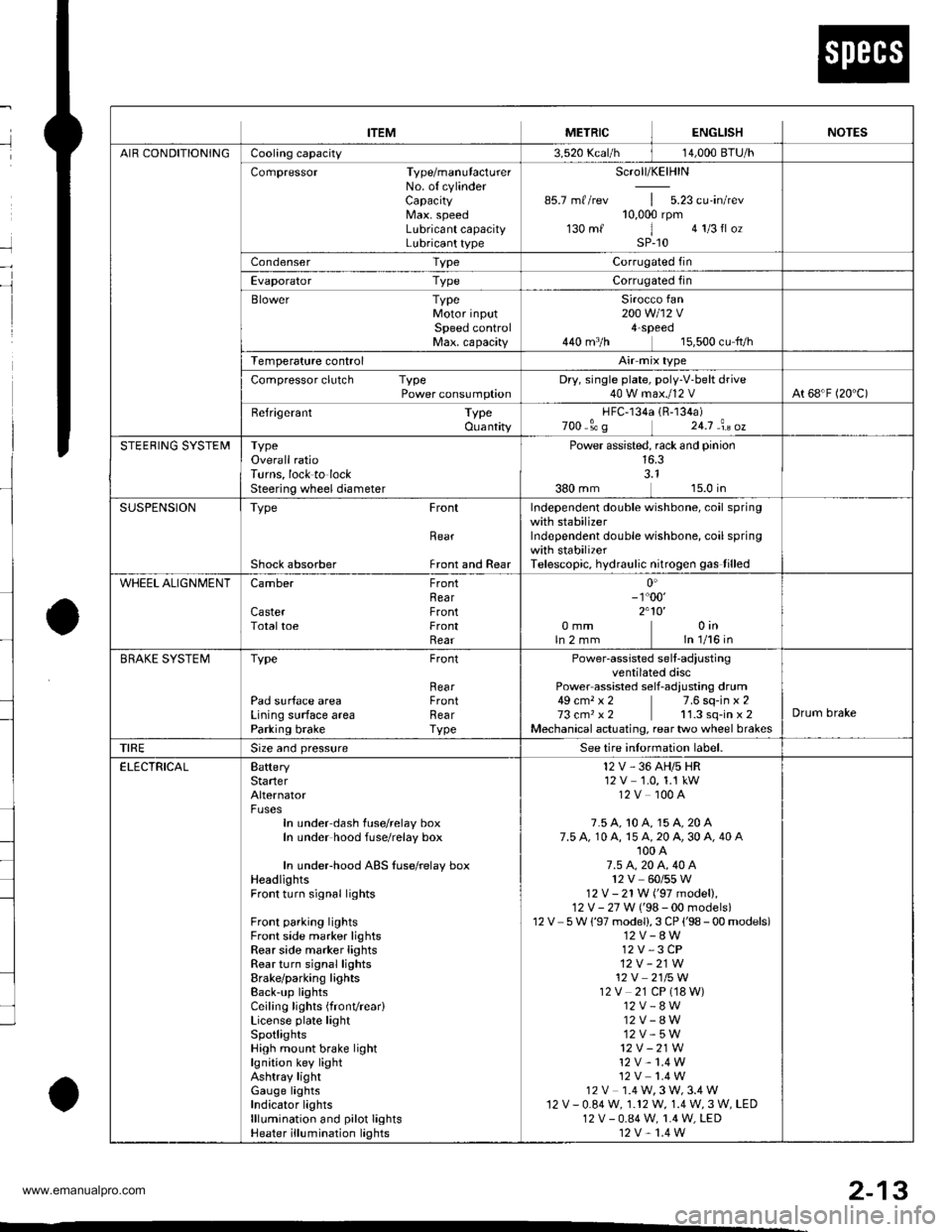

METRICITEMENGLISHNOTES

AIR CONDITIONINGCooling capacity3,520 Kcal/h j 14,000 BTU/h

Compressor Type/manutacturerNo. of cylinderCaPacityMax. speedLubricant capacityLubricant type

Scroll/KElHlN

85.7 mf/rev | 5.23 cu'in/rev10,000 rpm130mf 1 algIlozsP-10

Condenser TypeCorrugated fin

Evaporator TypeCorrugated fin

Blower TypeMotor inputSpeed controlMax. capacity

Sirocco fan200 w 112 v4-Speeo440 m3/h 15,500 cu fvh

Temperature control

Compressor clutch TypePower consumptionDry, single plate, poly-V-belt drive40 W max./12 VAt 68'F (20 C)

Befrigerant TypeOuantity

HFC-134a 1R-134a)zoo o' g 24j an oz

STEERING SYSTEMTypeOverall ratioTurns, lock to lockSteering wheel diameter

Power assisted, rack and pinion

SUSPENSIONType Front

Bear

Shock absorber Front and Rear

Independent double wishbone, coil springwith stabilizerIndependent double wishbone, coil springwith stabilizerTelescopic, hydraulic nitrogen gas tilled

WHEEL ALIGNMENTCamber

CasterTotaltoe

FronthearFrontFrontRear0inln 1/16 in0mmln2mm

0'- r"00'2.10'�

BRAKE SYSTEMTvpe

Pad surface areaLining surface areaParking brake

Front

RearFrontRearTvpe

Power-assisted selt-ad,ustingventilated discPower assisted self-adiusting drum49 cm, x 2 7.6 sq-in x 273 cm, x2 11.3 sq-in x 2Mechanical actuating, rear two wheel brakes

Drum brake

TIRESize and pressureSee tire inlormation label.

ELECTRICALBafteryStarterAlternator

In under-dash fuse/relay boxIn under hood fuse/relay box

In underhood ABS fuse/relay boxHeadlightsFront turn signal lights

Front parking lightsFront side marker lightsRear side marker lightsRear turn signal lightsErake/parking lightsBack-up lightsCeiling lights {fronvrear)License plate lightSpotlightsHigh mount brake lightlgnition key lightAshtray lightGauge lightsIndicator lightslllLrmination and pilot IightsHeater illumination lights

12 V, 36 AH/s HR12V 1.0, 1.1 kW12V 100A

7.5 A, 10 A, 15 A, 20 A7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A'100 A7.5 4,20 A. 40 A12V 60/55 W12 V- 21 W ('97 model),12 V - 27 W ('98-00 models)12V 5 W {'97 model),3 CP ('98 - 00 models)12V-8W12 V,3 CP12V-21W12 V 2115 W12V 21 CP (18 W)12V-8W12V-8W12V-5W12V -21W

12 V- 1.4 W12V 1.4 W12 V 1.4 W,3 W,3.4 W12V-0.84W, 1.12 W, 1.4 W,3 W, LED12 V - 0.84 W, 1.4 W, LED12 V,1.4 W

2-13

www.emanualpro.com

Page 67 of 1395

e

o

I'

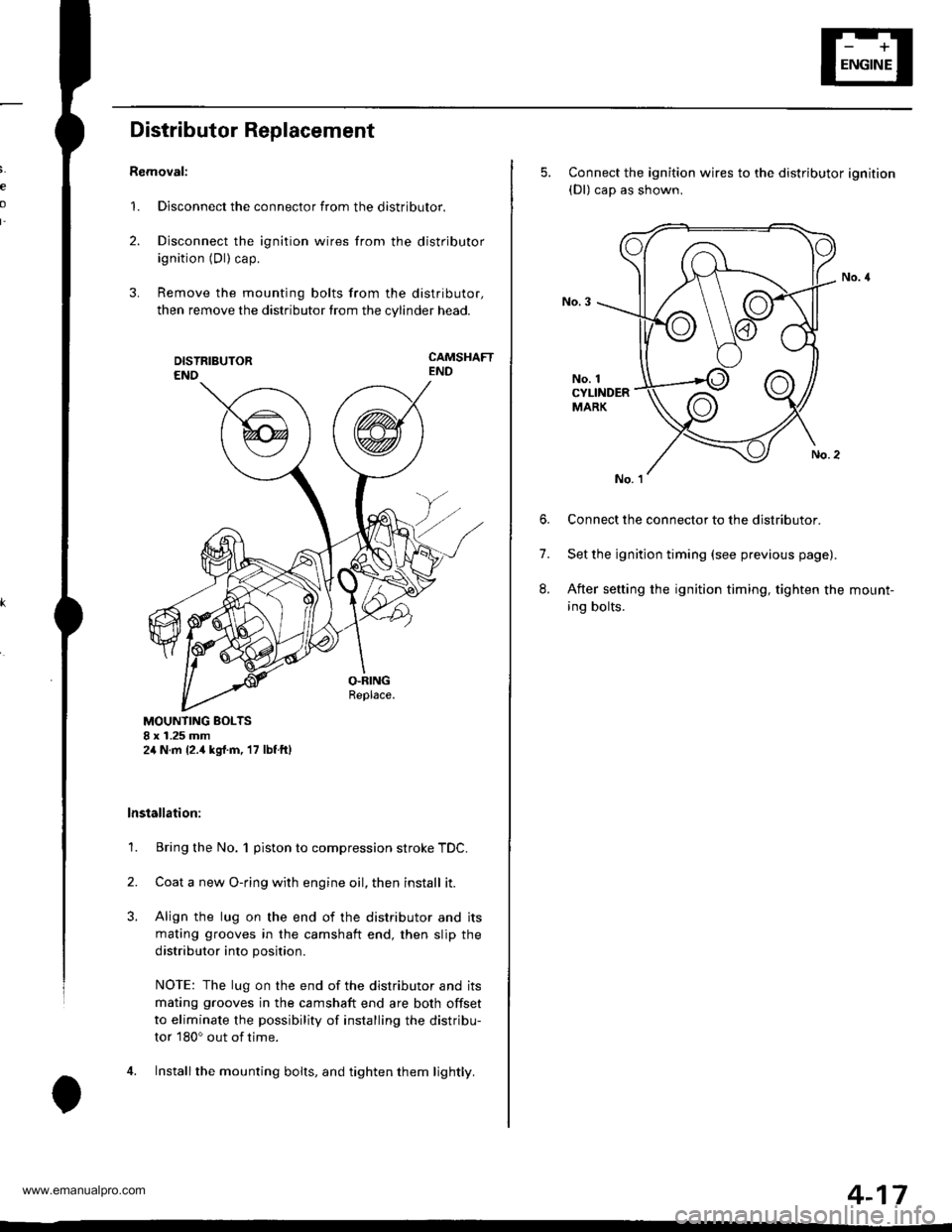

Distributor Replacement

Removal:

1. Disconnect the connector from the distributor.

2. Disconnect the ignition wires from the distributor

ignition (Dl) cap.

3. Remove the mounting bolts from the distributor,

then remove the distributor from the cylinder head.

CAMSHAFTEND

MOUNTING BOLTS8 x 1.25 mm2,1N.m {2.,1kgrf.m, 17 lbf ftl

lnstallation:

1. Bring the No. 1 piston to compression stroke TDC.

2. Coata new O-ring with engine oil, then install it.

3. Align the lug on the end of the distributor and its

mating grooves in the camshaft end, then slip the

distributor into position.

NOTE: The lug on the end of the distributor and its

mating grooves in the camshaft end are both offset

to eliminate the possibility of installing the distribu-

tor 180o out of time.

4. Installthe mounting bolts, and tighten them lightly.

5. Connect the ignition wires to the distributor ignition(Dl) cap as shown,

No. 1CYLINDERMARK

6. Connect the connector to the distributor.

7. Set the ignition timing (see previous page).

8. After setting the ignition timing, tighten the mount-

ing bolts.

4-17

www.emanualpro.com

Page 377 of 1395

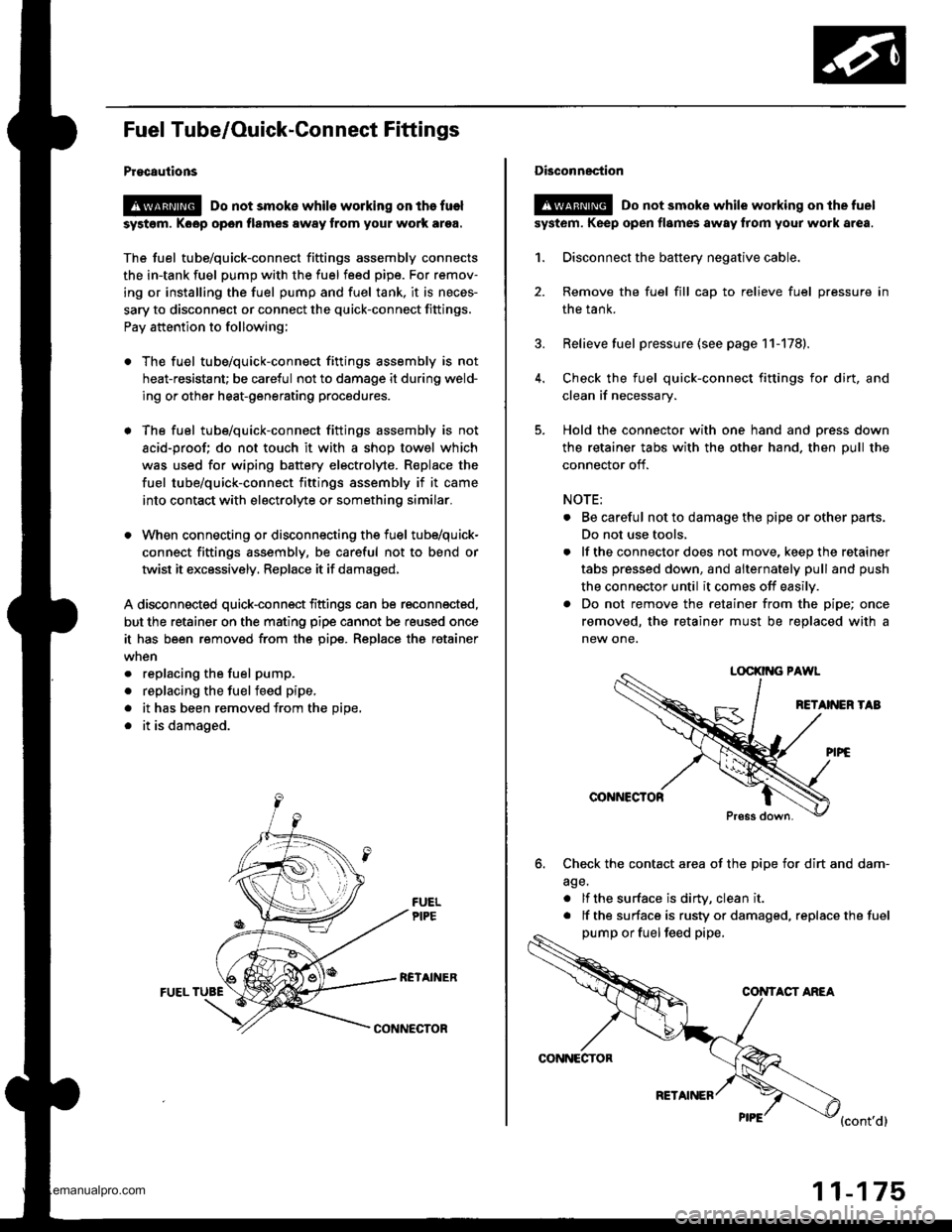

Fuel Tube/Ouick-Gonnect Fittings

Procautions

@ Do not smoke whils working on the fuel

syst6m, Koop open flames away from your work ar9a.

The fuel tube/quick-connect fittings assembly connects

the in-tank fuel pump with the fuel feed pipe. For remov-

ing or installing the fuel pump and fuel tank, it is neces-

sary to disconnect or connect the quick-connect fittings.

Pay attention to following;

. The fuel tube/quick-connect fittings assembly is not

heat-resistant; be careful not to damage it during weld-

ing or other heat-generating procedures.

. The fuel tube/quick-connect fittings assembly is not

acid-proof; do not touch it with a shop towel which

was used for wiping battery electrolyte. R€place the

fuel tube/quick-connect fittings assembly if it came

into contact with electrolyte or somethino similar.

. When connecting or disconnecting the fuel tube/quick-

connect fittings assembly, be careful not to bend or

twist it excessively, Replace it if damaged,

A disconnected quick-connect fittings can be reconnected,

but the retainer on the mating pipe cannot be reused once

it has been removed from the pipe. Replace tha retainer

. replacing the fuel pump.

. replacing the fuelfeed pipe,

. it has been removed from the Dioe,

. it is damaged.

RCTAINERFUEL TUBE

CONNECTOR

CONNECTOR

RETAINER

11-175

Disconnection

!@ Do not smoke while working on the fuel

syst6m. Keep open flames away from your work area.

1. Disconnect the battery negative cable.

2. Remove the fuel fill cap to relieve fuel pressure in

the tank.

3. Relieve fuel pressure (see page 11-178).

4. Check the fuel quick-connect fittings for dirt, and

clean if necessary.

5. Hold the connector with one hand and press down

the retainer tabs with the other hand. then pull the

connector off.

NOTE:

. Be careful not to damage the pipe or other parts.

Do not use tools,

. lf the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.

. Do not remove the retainer from the pipe; once

removed, the retainer must be replaced with a

new one.

LOCKII{G PAWL

RETANEN TAB

@NNCCTOR

Press down.

6. Check the contact area of the pipe for dirt and dam-

age.

. lf the surface is dirW, clean it

. lf the surface is rusty or damaged, replace the fuel

pump or fuel feed pipe,

CONTACT ANEA

{cont'd}

www.emanualpro.com

Page 871 of 1395

Power Steering Pump

Disassembly (cont'dl

1.

7.

9.

10.

Drain the fluid from the pump.

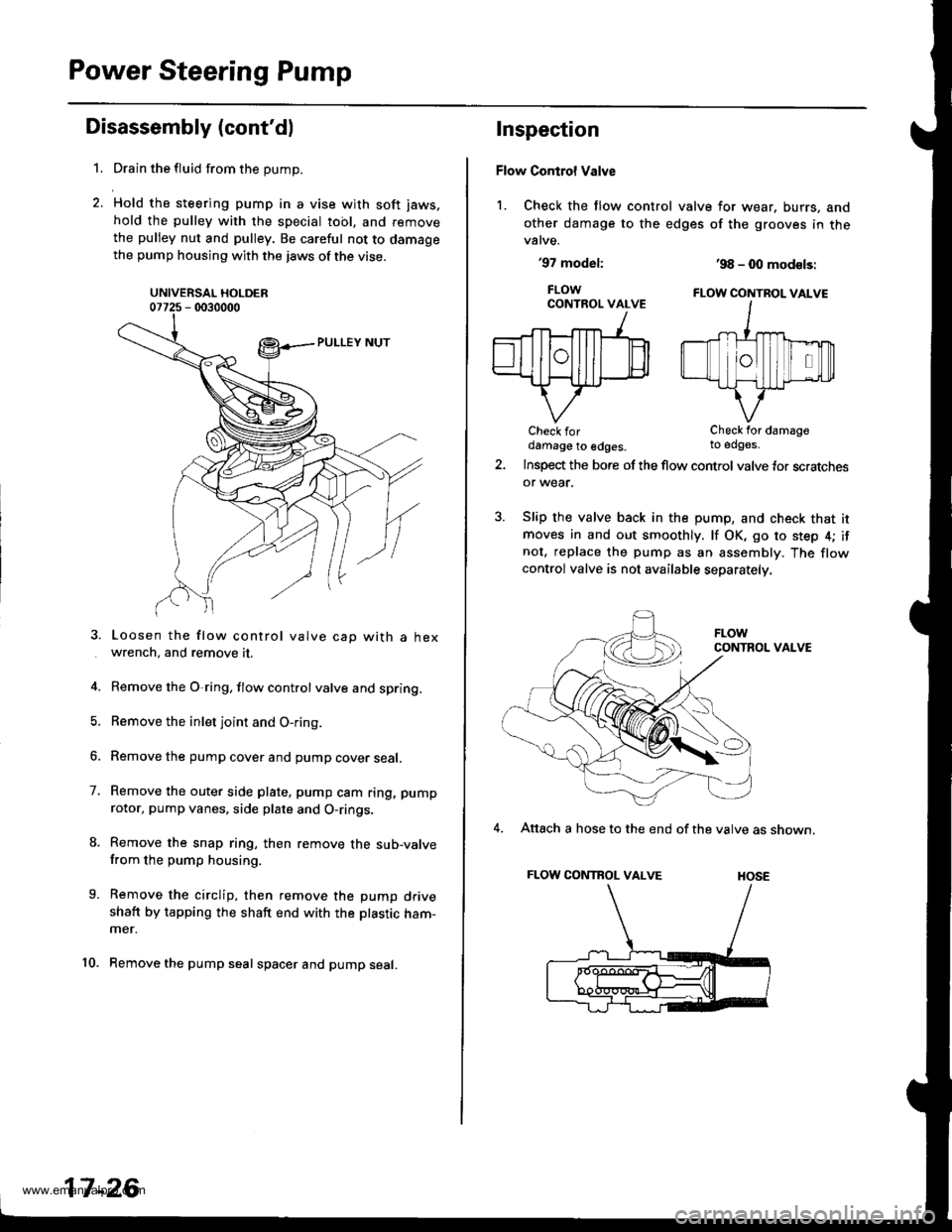

Hold the steering pump in a vise with soft jaws.

hold the pulley with the special tool, and remove

the pulley nut and pulley. Be careful not to damagethe pump housing with the jaws of the vise.

UNIVERSAL HOLDER07725 - 0030000

Loosen the flow control valve cap with a hexwrench, and remove it.

Remove the O,ring, flow control valve and spring.

Remove the inlet joint and O-ring.

Remove the pump cover and pump cover seal.

Remove the outer side plate, pump cam ring, pump

rotor, pump vanes, side plate and O-rings.

Remove the snap ring, then remove the sub-valvefrom the pump housing.

Remove the circlip, then remove the pump driveshaft by tapping the shaft end with the ptastic ham-mer.

Remove the pump seal spacer and pump seal.

17-26

Inspection

Flow Control Valve

1. Check the flow control valve for wear, burrs, and

other damage to the edges of the grooves in thevalve.

'97 model:

FLOWCONTROL VALVE

Check fordamage to edges.

'98 - 0O mod€ls:

FLOW CONTBOL VALVE

Check for damageto edges.

Insp€d the bore of the flow control valve tor scratchesor wear.

Slip the valve back in the pump, and check that itmoves in and out smoothly. lf OK, go to step 4; ifnot, replace the pump as an assembly. The flowcontrolvalve is not available separately.

CONTROL VALVE

4. Attach a hose to the end of the valve as shown.

FLOW CONTROL VALVE HOSE

www.emanualpro.com

Page 874 of 1395

8.

9.

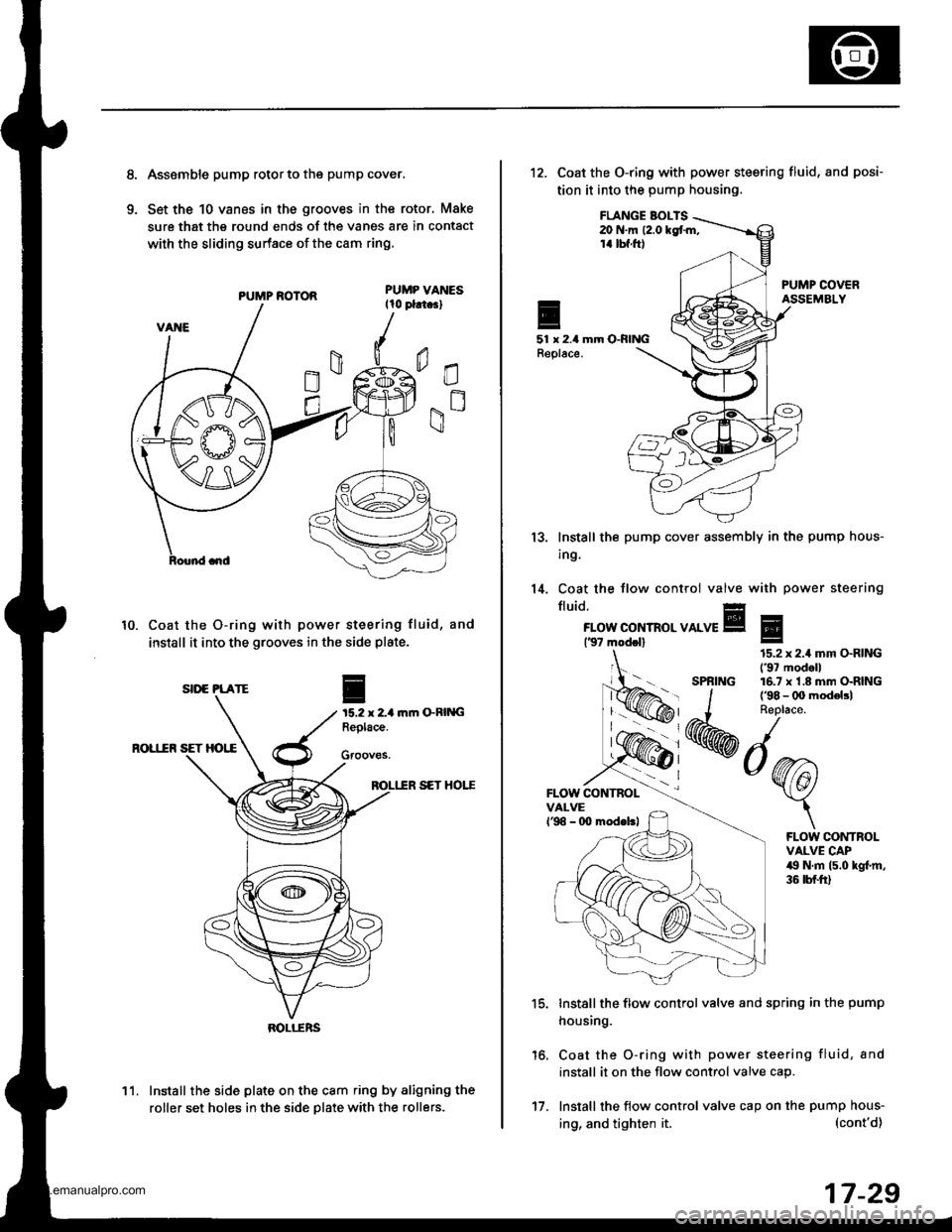

Asssmble pump rotor to the pump cover,

Set the 10 vanes in the grooves in the rotor, Make

sure that the round ends of the vanes are in contact

with the sliding surface of the cam ring.

PUMP ROTOR

Coat the O-ring with power steering fluid, and

install it into the grooves in the side plate.

ftm GRING

ROL1IR SET HOI,E

SET HOTT

Install the side plate on the cam ring by aligning the

roller set holes in the side Dlate with the rollers.

10.

I

15.2 x 2-1Replace.

Gfooves.

SII'E PLATE

BOLI-ERS

11.

17.

ing, and tighten it.

12. Coat the O-ring with power steering fluid,

tion it into the pump housing.

and posi-

FLANGE BOI-TS20 N.m (2.0 kgt m,14 tbf.ft)

51 x 2.4 mm O-RINGReplace.

13.

14.

lnstall the

ing.

Coat the

fluid.

pump cover assembly in the pump hous-

tlow control valve with power steering

FLOW CONTROL VALVE137 modol)

FLOW CONTBOLVALVEl'98 - 0O modeltl

'15.

16.

Install the flow control valve and spring in the pump

housing.

Coat the O-ring with power steering fluid, and

install it on the flow control valve cap.

Install the flow control valve cap on the pump hous-

Eg

SPRING

15.2 x 2.4 mm O.RING('97 modell16.7 x'1.8 mm O-RING

FLOW CONTROLVALVE CAP49 N.m (5.0 kgl.m,36 tbf.ft)

(cont'd)

17-29

www.emanualpro.com