INJECTOR HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 132 of 1395

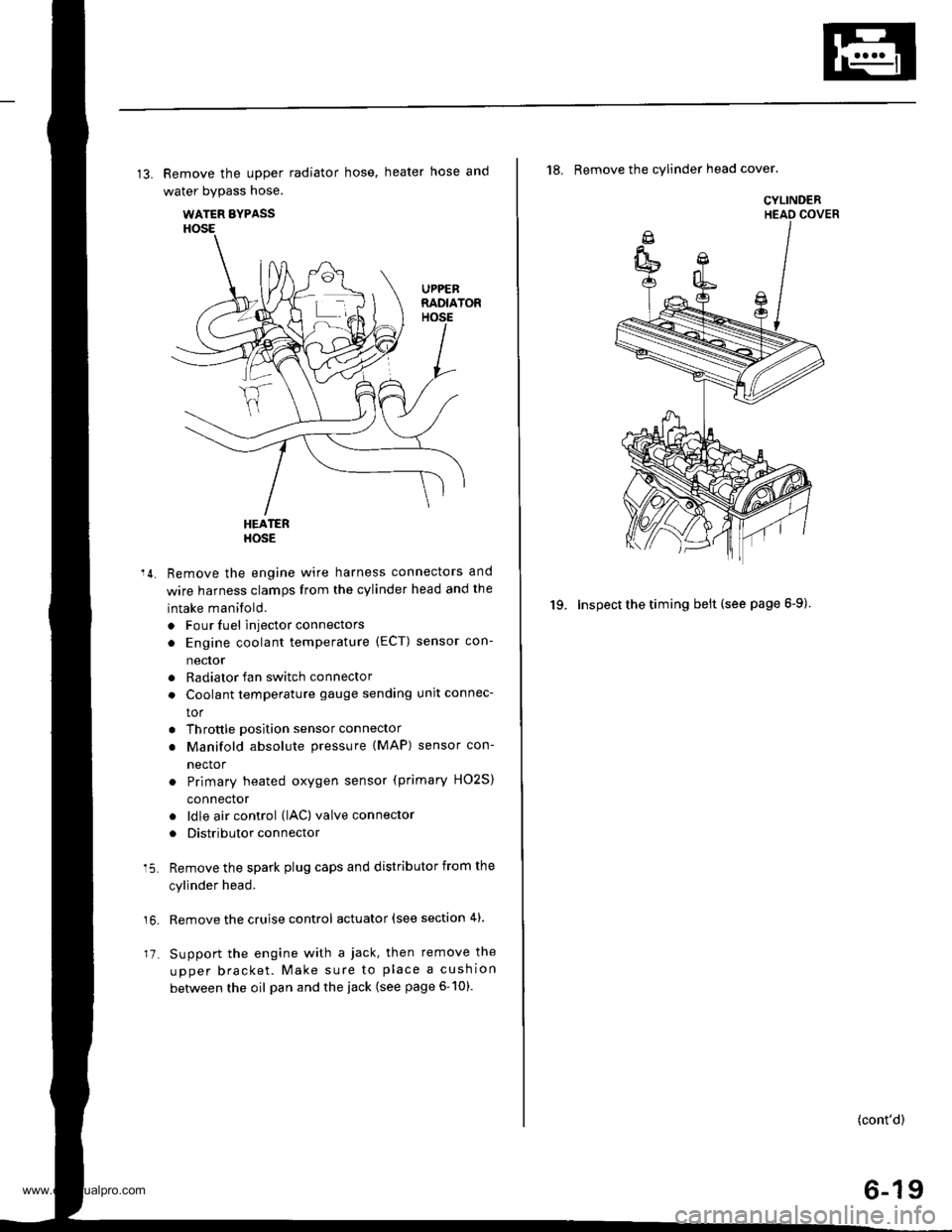

13. Remove the upper radiator hose, heater hose and

water bypass hose.

WATER BYPASS

UPPEBRADIATORHOSE

17

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

neclor

. Radiator fan switch connector

. Coolant temperature gauge sendlng unlt connec-

tor

. Throttle position sensor connector

. Manifold absolute pressure {MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

ldle air control (lAC) valve connector

Distributor connector

Remove the spark plug caps and distributor from the

cylinder head.

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil pan and the iack (see page 6-10).

a

18. Remove the cylinder head cover.

19. Inspect the timing belt (see page 6-9).

CYLINDER

(cont'd)

6-19

www.emanualpro.com

Page 210 of 1395

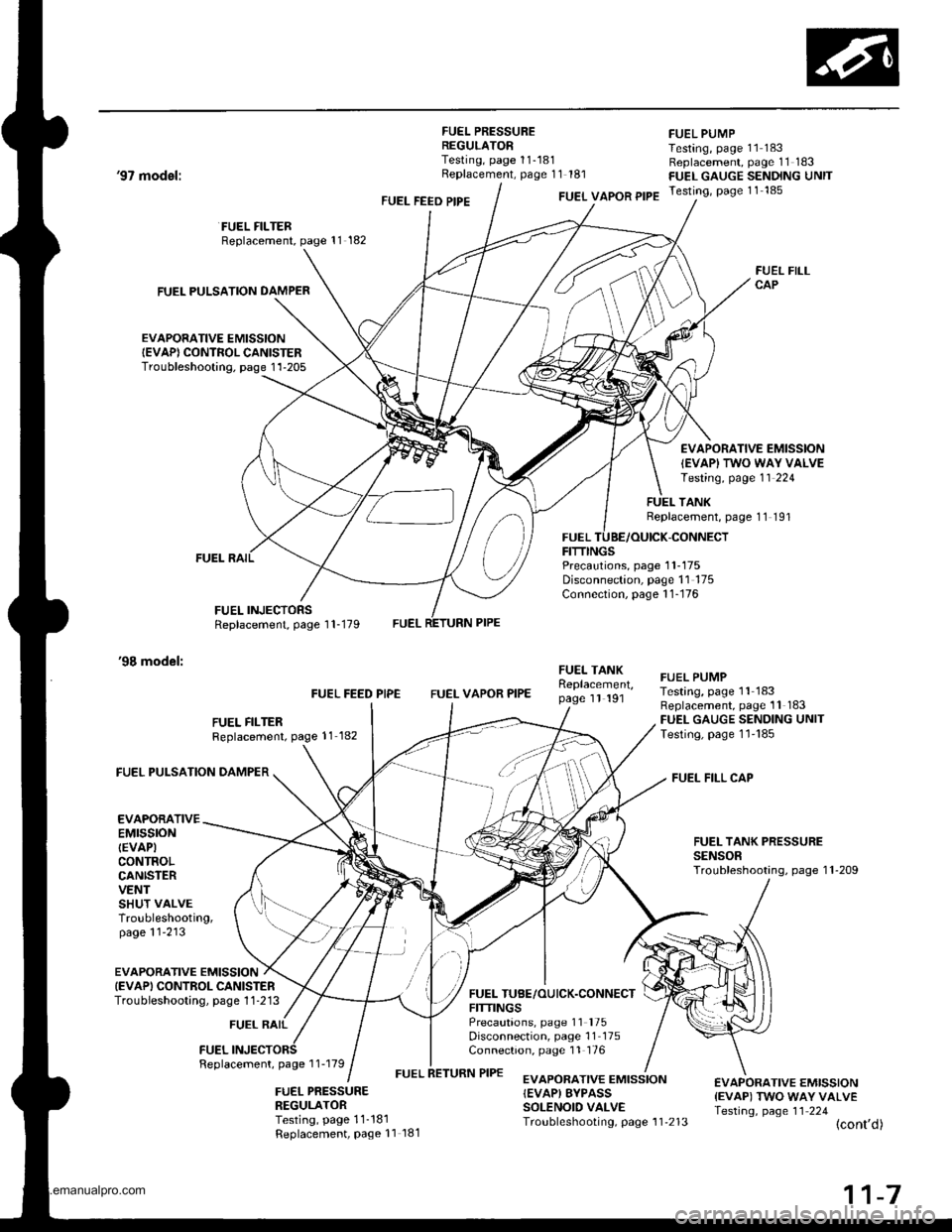

FUEL PRESSUREREGULATORTesting, page 11-181Replacement, page 11 181

FUEL PUMPTesting, page 11 183Replacement, page 11 183FUEL GAUGE SENDING UNITTesting, page 11 185

'97 model:

'98 model:

FUEL PULSATION DAMPER

EVAPORATIVE EMISSIONIEVAP) CONTROL CANISTERTroubleshooting. page 1'l-205

FUEL FILTERReplacement, page 11 182

FUEL INJECTORSReplacement, page 1 1-179

FUEL FEED PIPEFUEL VAPOR PIPE

FUELFITTINGS

FUEL FILLCAP

EVAPORATIVE EMISSION

IEVAPI TWO WAY VALVETesting, page 11 224

TANKReplacement, page 11 191

-CONNECT

Precautions, page 1 1-175Disconnection, page 11 175Connection, page 1 1-176

FUEL FILTERReplacement, page 11 182

FUEL FEED PIPEFUEL VAPOR PIPE

FUEI- TANKReplacement,page 1l 191

FUEL TUBE/OUICK.CONNECTFITTINGSPrecautions, page 11 '175

Disconnection, page 11 175Connection, page 11 176

FUEL PUMPTesting, page 11 183Replacement, page 11 183FUEL GAUGE SENDING UNITTesting, page 1l'185

FUEL FILL CAP

FUEL TANK PRESSURESENSORTroubleshooting, page 1 l-209

FUEL PULSATION DAMPER

EVAPORATIVEEMTSSTONIEVAPICONTROLCANISTERVENTSHUT VALVETroubleshooting,page 11'213

EVAPORATIVE EMISSIONIEVAPI CONTROL CANISTERTroubieshooting, page 1 1 -213

FUEL RAIL

FUELFeplacement, page 1 1-179

FUEL PRESSURENEGULATORTesting, page 11-181Replacement, Page 11 181

EVAPORATIVE EMISSION{EVAP) EYPASSSOLENOID VALVETroubleshooting, page 1 1'213

€VAPORATIVE EMISSION{EVAP) TWO WAY VALVETesting, page 11 224(cont'd)

www.emanualpro.com

Page 215 of 1395

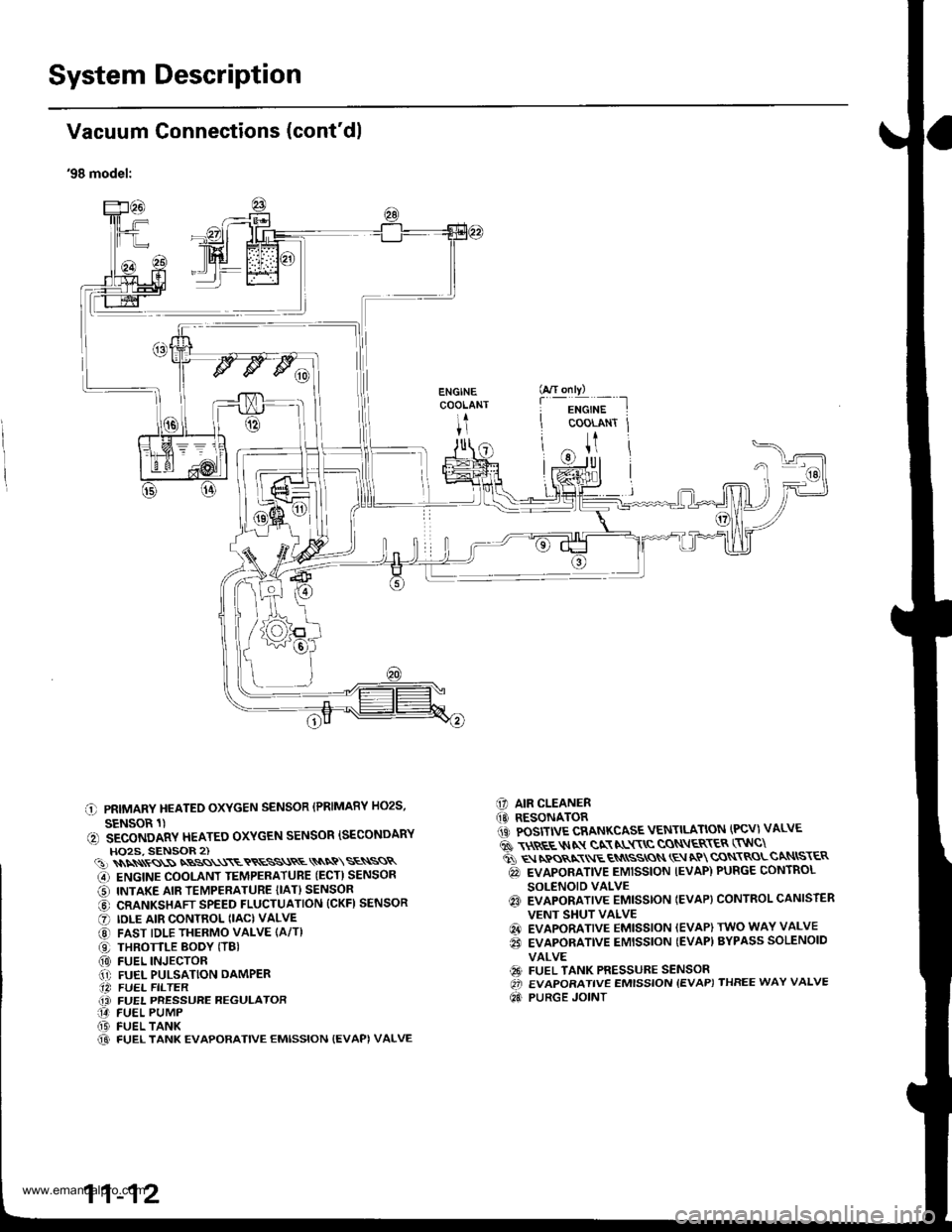

System Description

I

I

I

Vacuum Connections (cont'dl

'98 model:

C PRIMARY HEATEO OXYGEN SENSOR (PRIMARY HO2S,

SENSOR 1)(, SECONDARY HEATEO OXYGEN SENSOR ISECONDARYHO2S, SENSOR 2)(!)\\\\ss\SNBSS\\\ETRESS\RE\\NQ\SE\SSR

G) ENGINE COOLANT TEMPERATUBE (ECT) SENSOR

O INTAKE AIR TEMPERATURE {IAT} SENSOR

@ CRANKSHAFT SPEED FLUCTUATION (CKFI SENSOR

O IDLE AIR CONTROL (IAC) VALVE

@ FAST IDLE THERMO VALVE (A/T)

O THROTTLE BODY (TBI(0) FUEL INJECTOR.1' FUEL PULSATION DAMPER.14 FUEL FILTER(i FUEL PRESSURE REGULATOR14 FUEL PUMP(D FUEL TANK@ FUEL TANK EVAPORATIVE EMISSION {EVAPI VALVE

C] AIR CLEANER(O RESONATOR1iC POSITIVE CRANKCASE VENTILATION (PCV) VALVE

6 \$REE$IN gN NL$\C CON\ER\ER (TNC\

ti q rpos,xr E qN

ssros \E aP cqN\RoLcaNtsr€R

@ EVAPORATIVE EMISSION IEVAP) PURGE CONTROL

SOLENOID VALVEq3 EVAPORATIVE EMISSTON IEVAP} CONTROL CANISTER

VENT SHUT VALVE

@ EVAPORATIVE EMISSION (EVAP) TWO WAY VALVE

€i EVAPORATIVE EMISSION {EVAP) BYPASS SOLENOID

VALVE

€9 FUEL TANK PRESSURE SENSOROi EVAPORATIVE EMISSION {EVAP) THREE WAY VALVE

Qd PURGE JOINT

G/T only)

f

-i*'";-t

COOLANT Jt

U

11-12

www.emanualpro.com

Page 217 of 1395

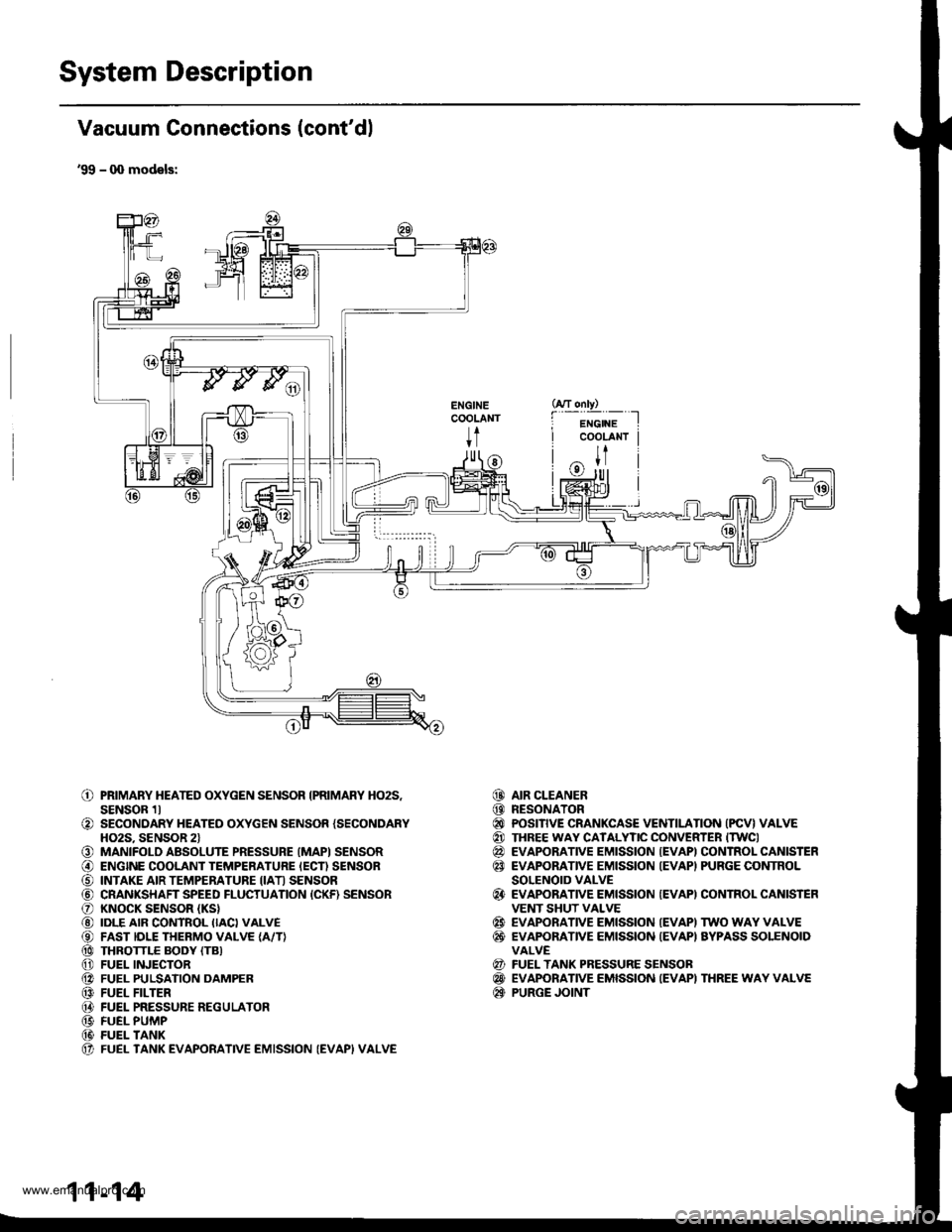

System Description

Vacuum Connections (cont'dl

'99 - q) models:

ENGINECOOLANT

t

o

o

o@

o@@@@@@@@@(t

PRIMARY HEATED OXYGEN SENSOR IPRIMARY HO2S,SENSOR 1lSECONDARY HEATED OXYGEN SENSOR {SECONDARYHO2S. SENSOR 2lMANIFOLD ABSOLUTE PRESSURE (MAPI SENSORENGINE COOLANT TEMPERATURE IECN SENSORINTAKE AIR TEMPERATURE IIATI SENSORCRANKSHAFT SPEED FLUCTUATION {CKF) SENSORKNOCK SENSOR (KS}

IDLE AIR CONTROL IIACI VALVEFAST IDLE THERMO VALVE {A/T}THROTTLE BODY (TB}

FUEL INJECTORFUEL PULSATION DAMPERFUEL FILTERFUEL PRESSURE REGULATORFUEL PUMPFUEL TANKFUEL TANK EVAPORATIVE EMISSION (EVAPI VALVE

AIR CLEANERRESONATORPOSITIVE CRANKCASE VENTILATION (PCV} VALVETHREE WAY CATALYTIC CONVERTER ITWCIEVAPORATIVE EMISSION {EVAPI CONTROL CANISTEREVAPORATIVE EMISSION IEVAPI PURGE CONTROLSOLENOID VALVEEVAPORATIVE EMISSION {EVAPI CONTROL CANISTEFVENT SHUT VALVEEVAPORATIVE EMISSION IEVAPI TWO WAY VALVEEVAPONANVE EMISSION {EVAPI AYPASS SOLENOIDVALVEFUEL TANK PRESSURE SENSOBEVAPORATIVE EMISSION IEVAPI THREE WAY VALVEPURGE JOINT

@@@@@@

@

@@

@@@

11-14

www.emanualpro.com

Page 269 of 1395

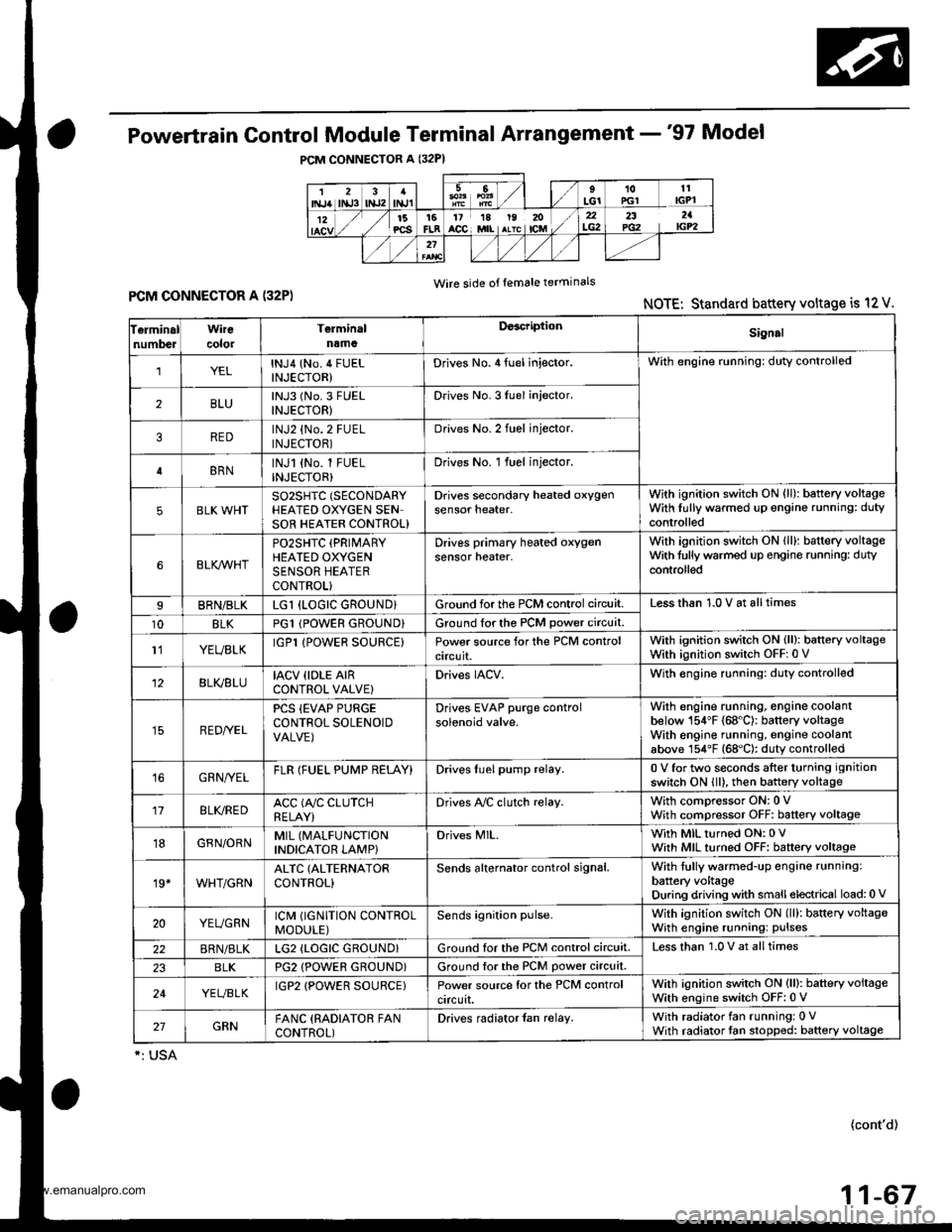

Powertrain Control Module Terminal Arrangement -'97 Model

FCM CONNECTOR A (32P)NOTE: Standard battery voltage is 12 V.

Wire side of lemale terminals

f€rminalnumlreJWirecolor

Telminalnama

DescriptionSignal

YELlNJ4 (No.4 FUELINJECTOR)Drives No. 4 {uel injector.With engine running: duty controlled

2BLUlNJ3 (No.3 FUELINJECTOR)Drives No. 3luel injector.

REDlNJ2 {No.2 FUELINJECTOR)Drives No.2 tuel injector.

BRNlNJl (No. l FUELINJECTOR)Drives No. 1 fuel injector.

5BLK WHTSO2SHIC (SECONDARY

HEATED OXYGEN SENSOR HEATER CONTROL)

D ves secondary heated oxygensensor heater.With ignition switch ON {ll): battery voltageWith fully warmed up engino running: dutycontrolled

6BLKAr'YHT

PO2SHTC (PRIMARY

HEATED OXYGENSENSOR HEATERCONTROL}

Drives primary heated oxygensensor heater,With ignition switch ON lll): battery voltagewith fully warmed up engine running: dutycontroll6d

I8RN/BLKLGl (LOGIC GROUND}Ground forthe PCM control circuit.Less than 1.0 V at all times

10BLKPG1 lPOWER GROUND}Ground for the PCM power circuit.

l1YEUELKIGPl lPOWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltageWith ignition switch OFF: 0 V

12BLI(BLUIACV {IDLE AIRCONTROL VALVE}Drives IACV.With €ngine running: duty controlled

REDryEL

PCS (EVAP PURGECONTFOL SOLENOIDVALVE)

Drives EVAP purge controlsolenoid valve.

With engine running, engine coolantbelow 154'F (68"C): battery voltageWith engine running, engine coolantabove 154"F (68"C): duty controlled

16GRN/VELFLR (FUEL PUMP RELAY)Drives Iuel pump relay.0 V for two seconds after turning ignition

switch ON lll), then battery voltage

118LI(REDACC (A,/C CLUTCHRELAY}Drives Ay'C clutch relay.With comoressor ON: 0 VWith compressor OFF: baftery voltage

18GRN/ORNMIL (MALFUNCTION

INDICATOR LAMP}Drives MlL.With MIL turned ON: 0 VWith MIL turned OFF: baftery voltage

19*WHT/GRNALTC (ALTERNATOR

CONTROL}Sends alternator control signal.With tully warmed-up engine running:

battery voltageDuring driving with smallelectrical load:0 '

20YEUGRNICM (IGNITION CONTROLMODULE)Sends ignition pulse.With ignition switch ON (ll): baftery voltageWith engine running: pulses

22BRN/BLKLG2 (LOGIC GROUND}Ground tor the PCM control circuit.Less than 1.0 V at alltimes

23BLKPG2 {POWER GROUND}Ground lor the PCM power circuit.

24YEUBLKIGP2 {POWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltage

With engine switch OFF: 0 V

27GRNFANC (RADIATOR FANCONTROL)Drives radiator {an relay.With radiator fan running: 0 VWith radiator fan stopped: baftery voltage

*: USA

{cont'd)

11-67

www.emanualpro.com

Page 274 of 1395

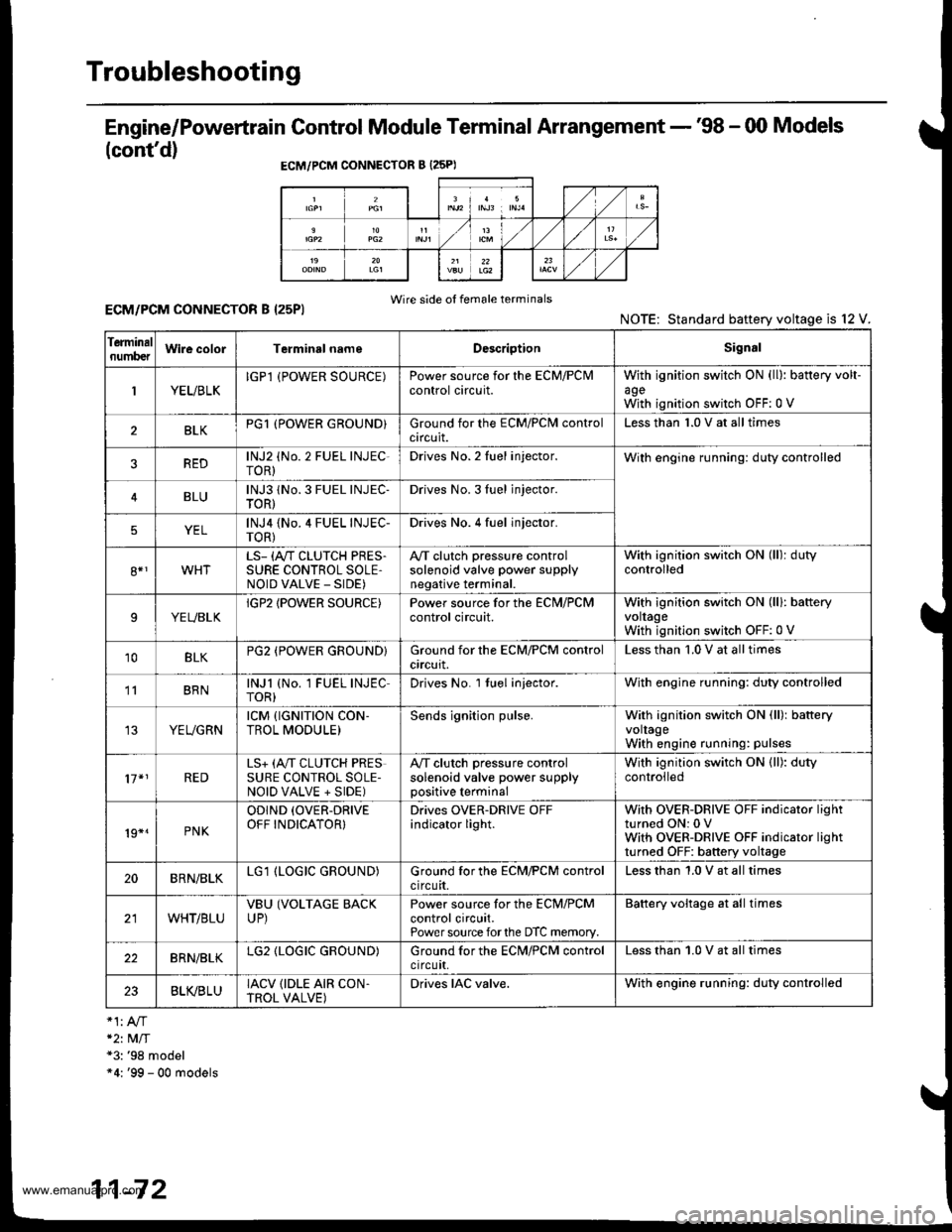

Troubleshooting

Engine/Powertrain Control Module Terminal Arrangement - '98 - 00 Models

(cont'd)

ECM/PCM CONNECTOR B {25PI

Wire side of female terminalsECM/PCM CONNECTOR B I25PI

*2t MlT*3: '98 model"4: '99 - 00 models

NOTE: Standard baftery voltage is l2

Ierminalnumb€tWire colorTerminsl nameDescriptionSignal

1YEUBLKIGPl (POWER SOURCE)Power source for the ECM/PClvlcontrol circuit.withagewith

ignition switch ON (ll): battery volt-

ignition switch OFF:0 V

BLKPG1 (POWER GROUND}Ground for the ECM/PClvl controlcircuit.Less than 1.0 V at all times

REDlNJ2 (No. 2 FUEL INJEC-roR)Drives No. 2 Iuel injector.With engine running: duty controlled

BLUlNJ3 1No. 3 FUEL INJEC-TOR)Drives No. 3Iuel jnjector.

YELlNJ4 {No.4 FUEL INJEC-TOR)Drives No. 4 fuel injector.

8*1WHTLS- (A"/T CLUTCH PRES.SURE CONTROL SOLE,NOID VALVE _ SIDE)

A,/T clutch pressure controlsolenoid valve power supplynegative terminal.

With ignition switch ON (ll): dutycontrolled

9YEUBLKIGP2 IPOWER SOURCE)Power source for the ECN,I/PCMcontrol circuit.With ignition switch ON (lll: bafteryvoltageWith ignition switch OFF:0 V

10BLKPG2 (POWER GROUND}Ground for the ECM/PCM controlcrrcurt.Less than '1.0 V at all times

' BRNlNJl (No. 1 FUEL INJECTOR)Drives No. l tuel injector.With engine running: duty controlled

YEUGRNrcM {rGNrTroN coN-TROL MODULE)Sends ignition pulse.With ignition switch ON (ll): batteryvoltageWith engine running: pulses

17*1REDLS+ (A,,IT CLUTCH PRESSURE CONTROL SOLE-NOID VALVE + SIDE)

A,/T clutch pressure controlsolenoid valve power supplypositive terminal

With ignition switch ON (ll): dutycontrolled

19*.PNK

ODIND (OVER-DRIVE

OFF INDICATOR}Drives OVER-DRIVE OFFindicator light.With OVER-DRIVE OFF indicator lightturned ON: 0 VWith OVER-DRIVE OFF indicator lightturned OFF: battery voltage

20BRN/BLKLG1 (LOGIC GROUND)Ground for the ECM/PCM controlcircuit.Less than 1.0 V at all times

WHT/BLUVBU (VOLTAGE BACKUP)Power source for the ECM/PCMcontrol circuit.Power source forthe DTC memory.

Battery voltage at all times

22BRN/BLKLG2 (LOGIC GROUND)Ground for the ECN4/PCM controlctrcutt,Less than 1.0 V at all times

23BLVBLUIACV {IDLE AIR CON.TROL VALVE)Drives IAC valve.With engine running: duty controlled

11-72

www.emanualpro.com

Page 278 of 1395

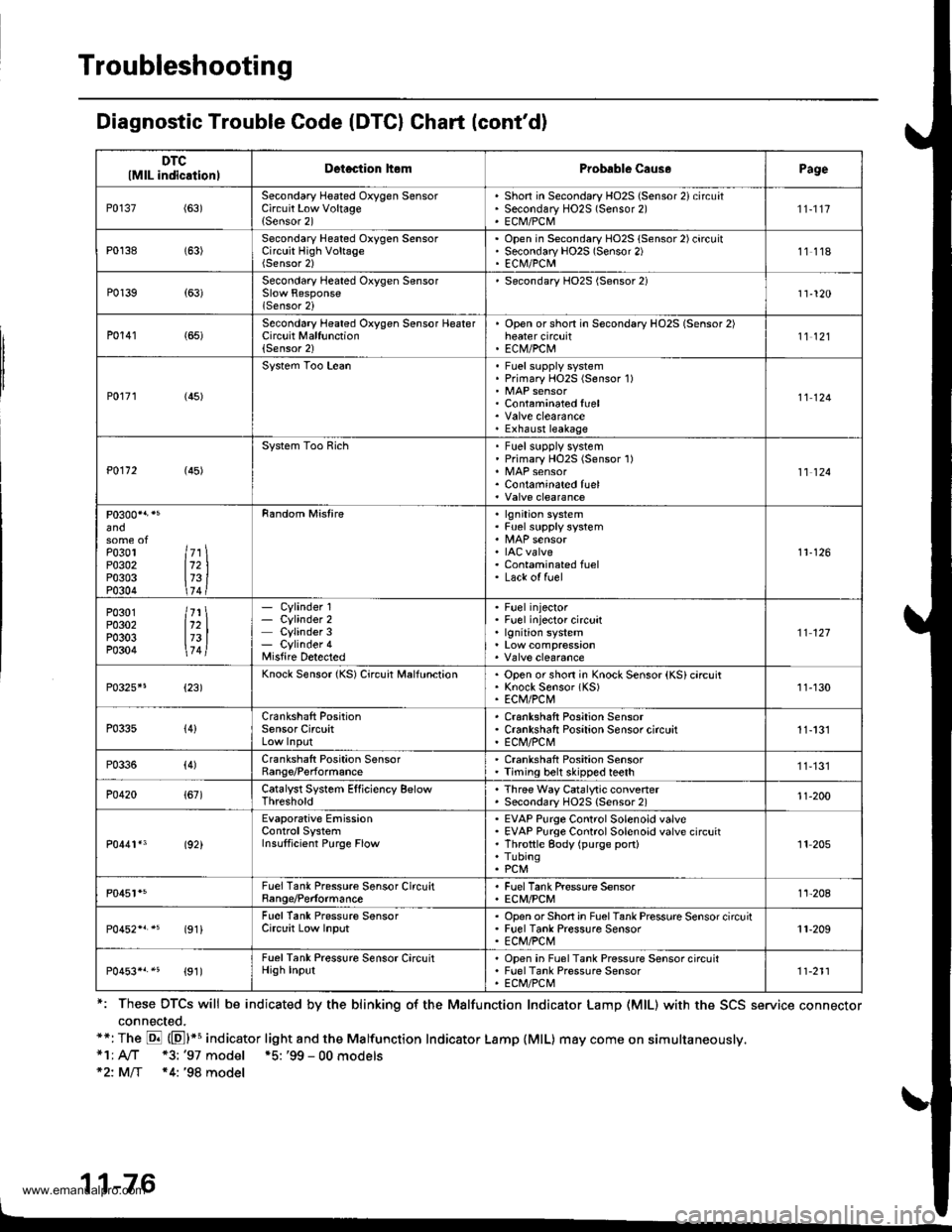

Troubleshooting

Diagnostic Trouble Code (DTCI Chart (cont'd)

*: These DTCS will be indicated by the blinking o{ the Malfunction Indicator Lamp (MlL) with the SCS service connector

connected.**: The E (El*s indicator light and the Malfunction Indicator Lamp {MlL) may come on simultaneously,*1; A/T *3: '97 model *5: '99 - 00 models*2: MlT *4: '98 model

11-76

DTClMlL indicationlDetection hemProbable Caus.Page

P0137(63)Secondary Heated Oxygen SensorCircuit Low Voltage{Sensor 2)

Shon in Secondary HO2S (Sensor 2) circuatSecondary HO2S (Sensor 2)ECM/PCM

'n-1t7

P0138 (63)Secondary Heated Oxygen SensorCircuit High VoltageOpen in Secondary HO2S (Sensor 2) circuitSecondary HO2S (Sensor 2)EC|\il/PCM11118

P0139{63)Secondary Heated Oxygen Sensor

lSensor 2i

Secondary HO2S (Sensor 2)11-120

P0141 (65)Second6ry Heated Oxygen Sensor HeaterCircuit Malfunction(Sensor 2)

Open orshon in Secondary HO2S (Sensor 2)heater circuitEC|V/PCtu11't2l

P0r71 (45)

System Too LeanFuel supply systemPrimary HOzS (Sensor 1)

Contaminated fuel

Exhaust leakage

11124

P0112 (45)

System Too RichFuel supplv systemPrimary HO2S (Sensor 1)

Contaminated fuel11 124

and

Po3ol ltr \P0302 112 |P0303 173 iP0304 \74 t

Random Mistirelgnition systemFuel supply system

IAC valveContaminated fuelLack of fuel

11-126

P0301 /71 \P0302 112 |P0303 173 |P0304 \7 4l

- Cylinder 1- Cylinder 2Cylinder 3- Cylinder 4Misfire Detected

Fuel injectorFuel injector circuitlgnition system't't 127

P0325*5{23)Knock Sensor {KS) Circuit MalfunctionOpen or shon in Knock Sensor (KS) circuitKnock Sensor (KS)ECM/PCt\411-130

P033s{4}Crankshaft PositionSensor CircuitCrankshaft Position SensorCrankshaft Positaon Sensor circuitE Cl\,l/PC l\,'!11-131

P0336(4)Crankshaft Position SensorRange/PerformanceCrankshaft Position SensorTiming belt skipped teeth11,131

P0420{67)Catalyst System Efficiency BelowThresholdThree Way Catalytic convenerSecondary HO2S {Sensor 2)'t1-200

P0441*3 (92)

Evaporative EmissionControlSystemInsulficient Purge Flow

EVAP Purge Control Solenoid valveEVAP Purge Control Solenoid valve circuitThrottle gody (purge port)TubingPCM

'It 205

P0451*5FuelTank Pressure Sensor CircuitBange/PerformanceFuel Tank Pressure SensorECM/PCMt't-208

(91iFuel Tank Pressure SensorCirclit Low InputOpsn orShort in FuelTank Pressure Sensor circuitFuel Tank Pressure SensorECM/PCt\411-209

P0453*r.5 {91)FuelTank Pressure Sensor CircuitHigh InputOpen in Fuel Tank Pressure Sensor circuitFuel Tank Pressure SensorECt /PCt\.111-211

www.emanualpro.com

Page 282 of 1395

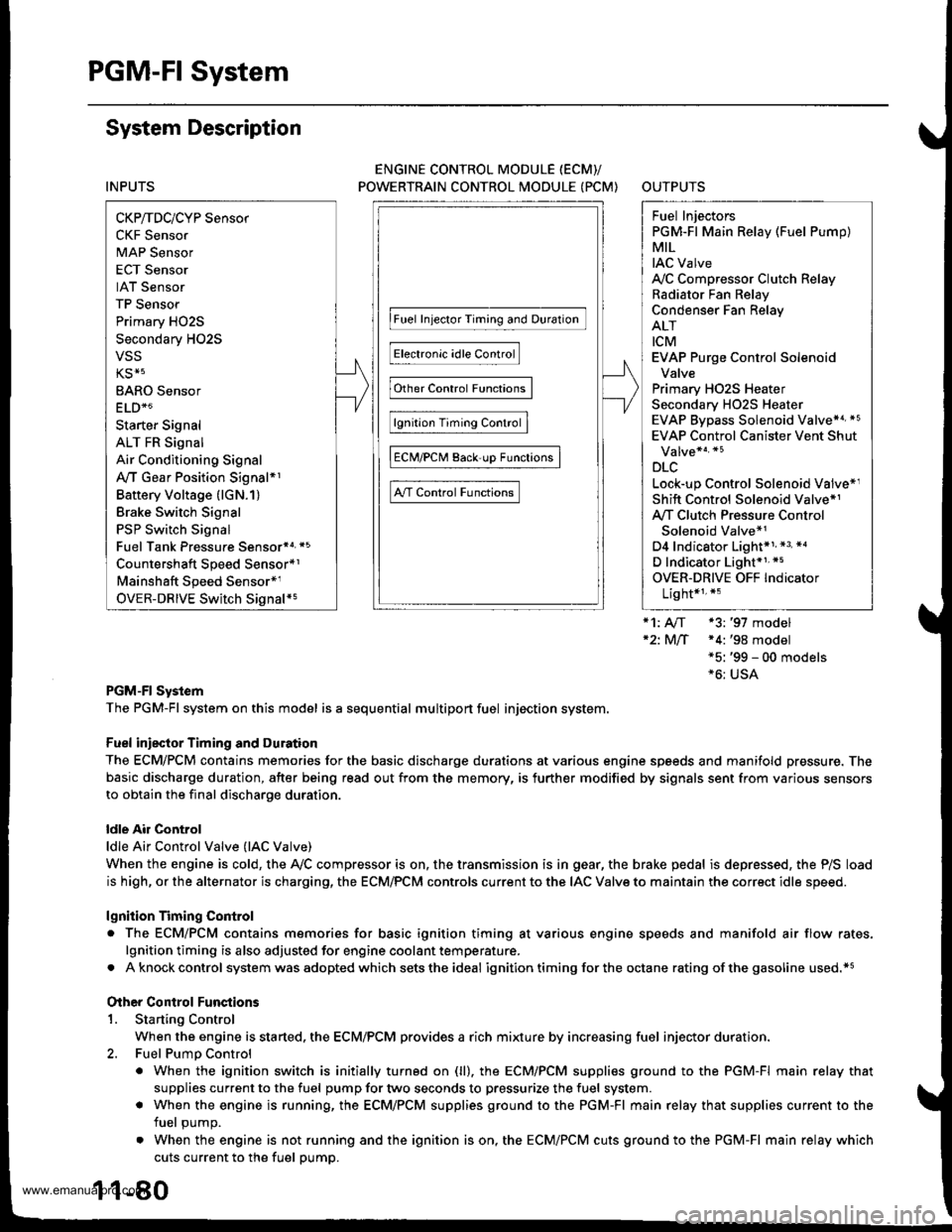

PGM-FI System

System Description

INPUTS

CKP/TDC/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

Primary HO2S

Secondary H02S

vss

KS*5

BARO Sensor

ELD*6

Starter Signal

ALT FR Signal

Air Conditioning Signal

Ay'T Gear Position Signal*1

Baftery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal

Fuel Tank Pressuae Sensor*4. *5

Countershaft Speed Sensor*1

Mainshaft Speed Sensor*r

OVER-DRIVE Switch Signal*s

ENGINE CONTROL MODULE (ECM)/

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

|iuel 1"j""- Th,rhg ""d Drrafr";-l

Et*-.nt"tdt"cont.orl

to,r*,c;;trffi;]

l.----.---:. .Lrgnrnon |lmrng Lonrror I

Ecir/PcM B*k',p Fr""il]

m;"t-ll-r*'io*l

Fuel Injectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

Ay'C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

tcM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S HeaterEVAP Bypass Solenoid Valve*a *5

EVAP Control Canister Vent Shut

DLC

Lock-up Control Solenoid Valve*l

Shift Control Solenoid Valve*1

Ay'T Clutch Pressure Control

Solenoid Valve*1

D4 Indicator Light'1 *3, *a

D Indicator Light,l *5

OVER-DRIVE OFF Indicator

Lighl*t *:

*1: A/T {3:'97 model'2: M/f +4:'98 model*5: '99 - 00 models"6: USA

PGM-Fl System

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel iniecior Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold pressure. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

o The ECM/PCM contains memories for basic ionition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. A knock control system was adopted which sets the ideal ig nition timing for the octane rating of the gasoline used.*s

Other Control Funstions

1. Starting Control

When the engine is started. the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on (ll). the ECMiPCM suppli€s ground to the PGM-FI main relay that

supplies current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM/PCM supplies ground to the PGM-FI main relay that supplies current to the

fuel oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

1 1-80

www.emanualpro.com

Page 283 of 1395

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com

Page 287 of 1395

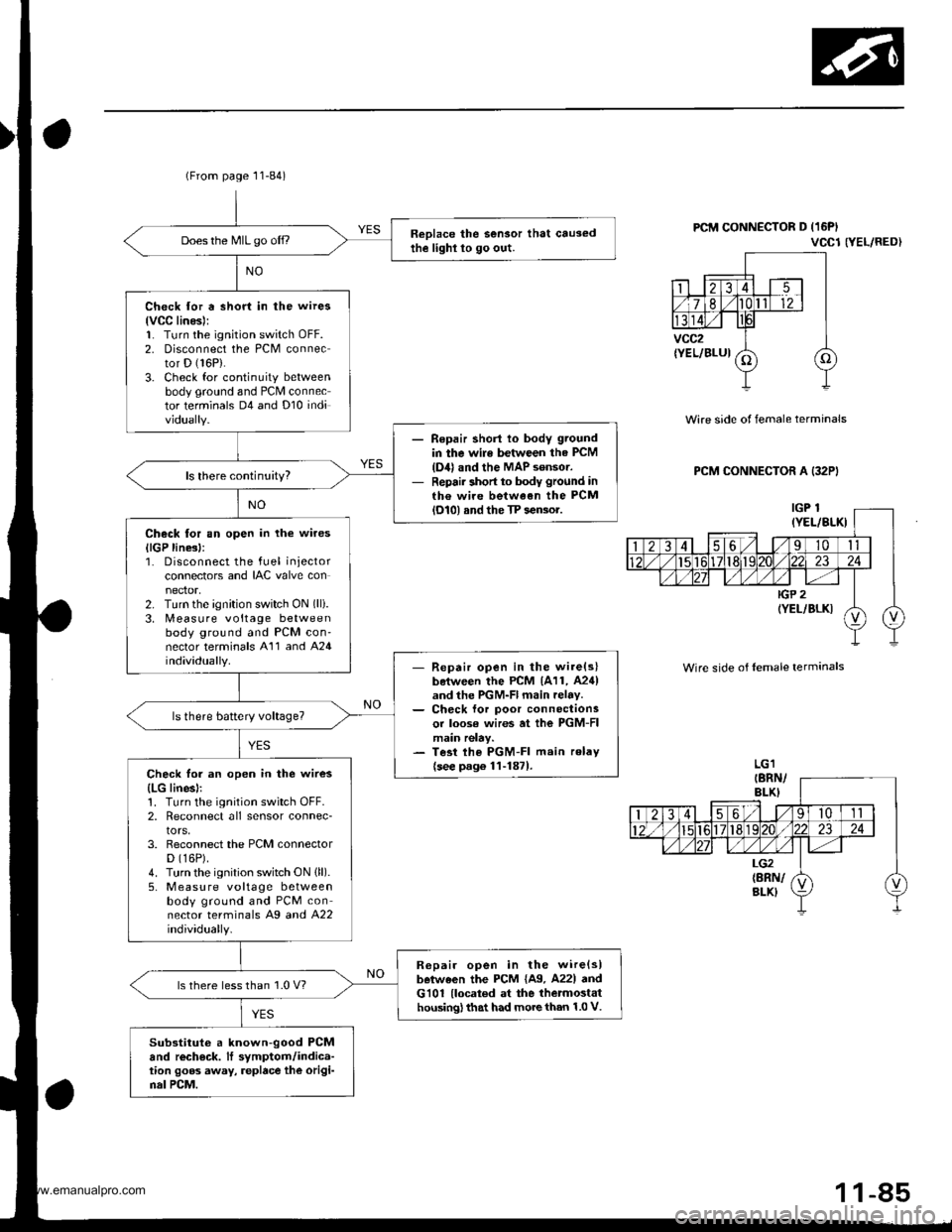

(From page 11-84)

Reolace the Sensor that causedthe lighl lo go out.Does the MIL go off.,

Check for a short in the wires

lvCC linesl:1. Turn the ignition switch oFF.2. Disconnect the PCM connector D (16P).

3. Check for continuity betweenbody ground and PCM connector terminals D4 and Dl0 individually.

Repair shorl lo body ground

in the wile between the PCM

{D4} and the MAP sensor.Repair short to body ground inth€ wire between the PCMlol0l and the TP sensor.

Check tor an open in the wires

llGP line3l:1. Disconnect the fuel injectorconnectors and IAC valve con

2. Turn the ignition switch ON (lli.

3. [,4easure voltage betweenbody ground and PCM con'nector terminals A'11 and A24individually.- Repair open in the wire(slboiween the PCM 1A11, A24)and the PGM-Fl main relav.- Ch€ck lor poor connectionsor loose wires at ihe PGM-FImain relay.- Tesi lhe PGM-FI main relav

{see p.g6 1l-1871.Check for an open in the wires

{LG linesl:1. Turn the ignition switch OFF.2, Reconnect all sensor connec-tors,3. Reconnect the PCM connectorD (16P).

4. Turn the ignition switch ON (ll).

5, M easu re voltage betweenbody ground and PCM connector terminals Ag a^d 422individually.

R6pair open in the wire{slbetween the PCM {A9. A22l andG101 {located at the thetmostathousing) that had more than 1.0 V.

ls there less than 1.0 V?

Substituto a known-good PCMand rech€ck. It symptom/indica-tion goos away, replace the origi-nal PCM.

PCM CONNECTOR D (16PI

VCCl NEL/RED}

Wire side of female terminals

PCM CONNECTOR A (32PI

Wire side of lemale terminals

1 1-85

www.emanualpro.com