Motor Mount HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 38 of 1395

--

-

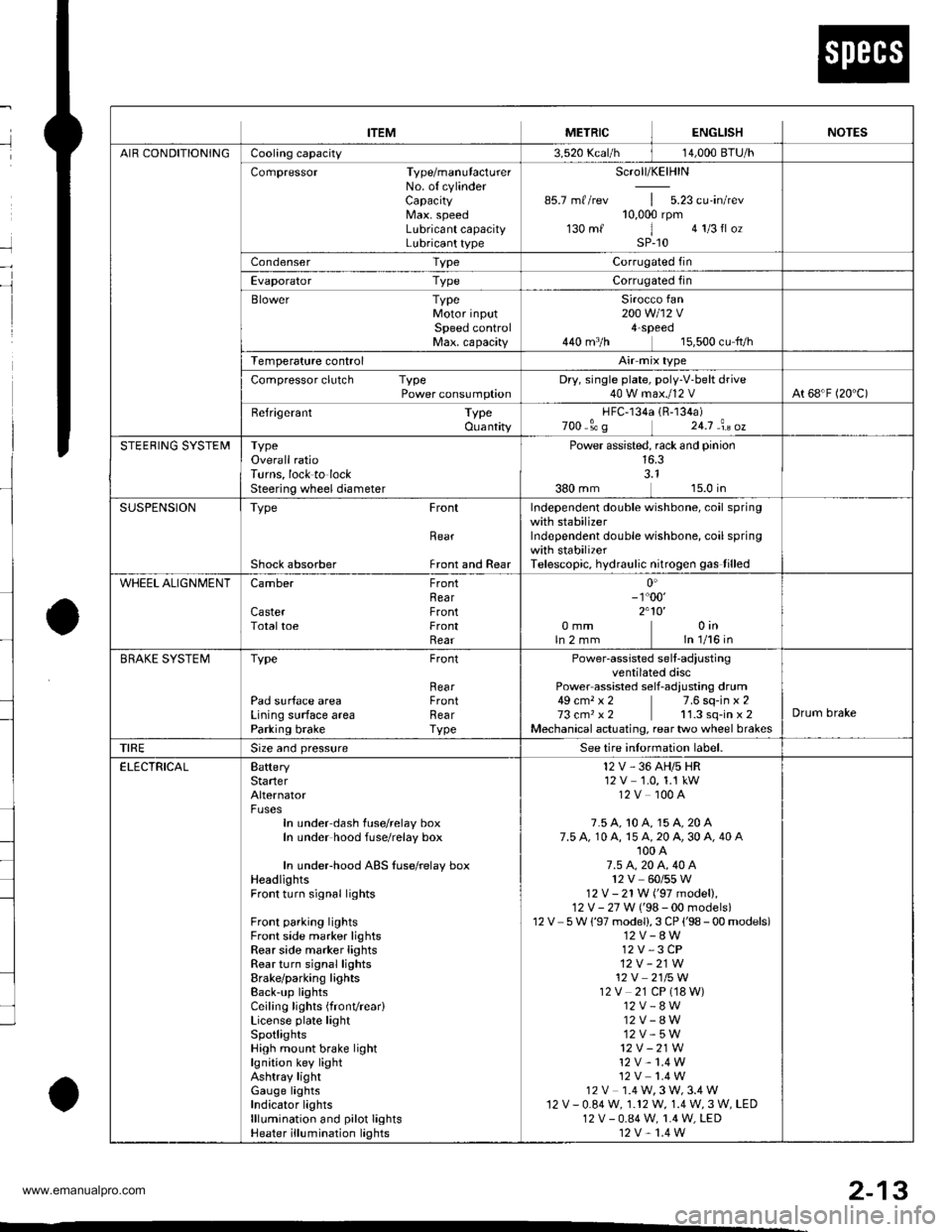

METRICITEMENGLISHNOTES

AIR CONDITIONINGCooling capacity3,520 Kcal/h j 14,000 BTU/h

Compressor Type/manutacturerNo. of cylinderCaPacityMax. speedLubricant capacityLubricant type

Scroll/KElHlN

85.7 mf/rev | 5.23 cu'in/rev10,000 rpm130mf 1 algIlozsP-10

Condenser TypeCorrugated fin

Evaporator TypeCorrugated fin

Blower TypeMotor inputSpeed controlMax. capacity

Sirocco fan200 w 112 v4-Speeo440 m3/h 15,500 cu fvh

Temperature control

Compressor clutch TypePower consumptionDry, single plate, poly-V-belt drive40 W max./12 VAt 68'F (20 C)

Befrigerant TypeOuantity

HFC-134a 1R-134a)zoo o' g 24j an oz

STEERING SYSTEMTypeOverall ratioTurns, lock to lockSteering wheel diameter

Power assisted, rack and pinion

SUSPENSIONType Front

Bear

Shock absorber Front and Rear

Independent double wishbone, coil springwith stabilizerIndependent double wishbone, coil springwith stabilizerTelescopic, hydraulic nitrogen gas tilled

WHEEL ALIGNMENTCamber

CasterTotaltoe

FronthearFrontFrontRear0inln 1/16 in0mmln2mm

0'- r"00'2.10'�

BRAKE SYSTEMTvpe

Pad surface areaLining surface areaParking brake

Front

RearFrontRearTvpe

Power-assisted selt-ad,ustingventilated discPower assisted self-adiusting drum49 cm, x 2 7.6 sq-in x 273 cm, x2 11.3 sq-in x 2Mechanical actuating, rear two wheel brakes

Drum brake

TIRESize and pressureSee tire inlormation label.

ELECTRICALBafteryStarterAlternator

In under-dash fuse/relay boxIn under hood fuse/relay box

In underhood ABS fuse/relay boxHeadlightsFront turn signal lights

Front parking lightsFront side marker lightsRear side marker lightsRear turn signal lightsErake/parking lightsBack-up lightsCeiling lights {fronvrear)License plate lightSpotlightsHigh mount brake lightlgnition key lightAshtray lightGauge lightsIndicator lightslllLrmination and pilot IightsHeater illumination lights

12 V, 36 AH/s HR12V 1.0, 1.1 kW12V 100A

7.5 A, 10 A, 15 A, 20 A7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A'100 A7.5 4,20 A. 40 A12V 60/55 W12 V- 21 W ('97 model),12 V - 27 W ('98-00 models)12V 5 W {'97 model),3 CP ('98 - 00 models)12V-8W12 V,3 CP12V-21W12 V 2115 W12V 21 CP (18 W)12V-8W12V-8W12V-5W12V -21W

12 V- 1.4 W12V 1.4 W12 V 1.4 W,3 W,3.4 W12V-0.84W, 1.12 W, 1.4 W,3 W, LED12 V - 0.84 W, 1.4 W, LED12 V,1.4 W

2-13

www.emanualpro.com

Page 450 of 1395

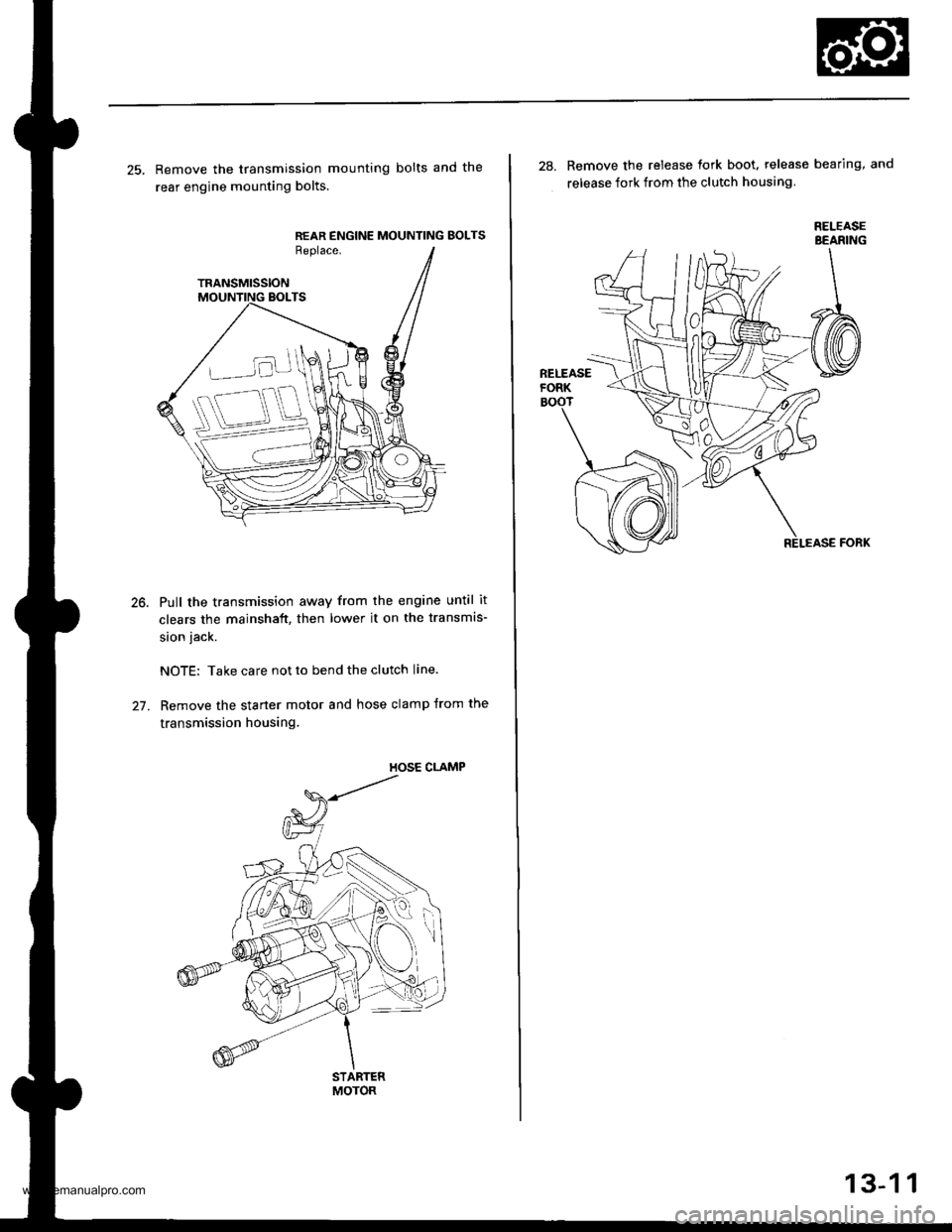

25. Remove the transmission mounting bolts and the

rear engine mounting bolts.

REAR ENGINE MOUNTING BOLTSReplace.

TRANSMISSION

Pull the transmission away from the engine until it

clears the mainshaft, then lower it on the transmis-

sion jack.

NOTE: Take care not to bend the clutch line.

Remove the starter motor and hose clamp from the

transmission housing.

STARTERMOTOR

28. Remove the release tork boot. release bearing, and

release fork from the clutch housing

RELEASEBEANING

13-1 1

www.emanualpro.com

Page 511 of 1395

Transmission Assembly

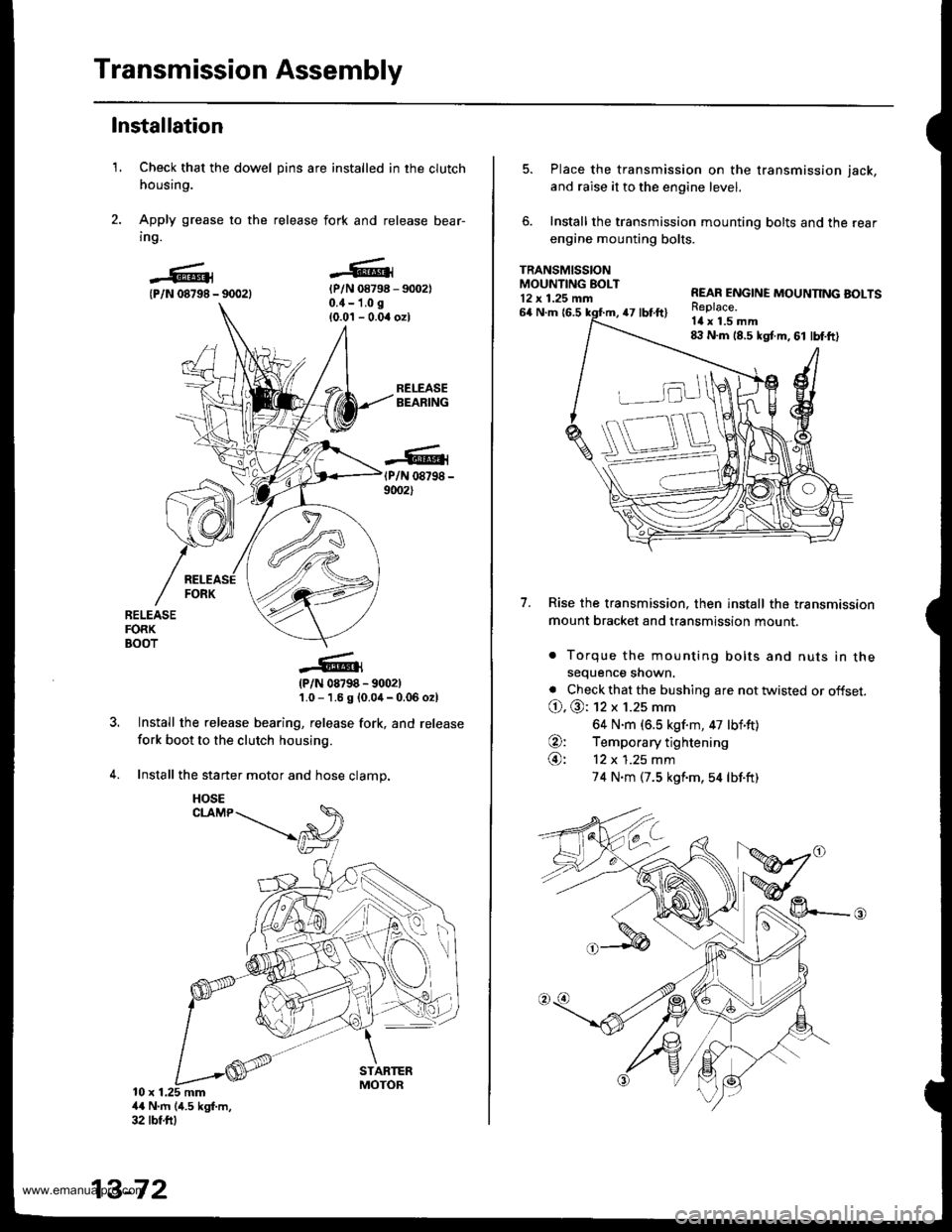

1.

Installation

Check that the dowel pins are installed in the clutch

housing.

Apply grease to the release fork and release bear-

ing.

{P/N 08798 - 90021{P/N 08798 - 9002)0.{ - 1.0 g

{0.0'l - 0.04 ozl

RELEASEBEARING

(P/N 08798 -

9002)

RELEASEFORKBOOT

?

(P/N 08798 - 9002)'1.0 - 1.6 g {0.0,1- 0.06 o2l

Install the release bearing, release fork, and release

fork boot to the clutch housing.

Install the starter motor and hose clamp.

10 x 1.25 mm4{ N'm (4.5 kgf.m,32 tbf.ftl

13-72

HOSE

5. Place the transmission on the transmission jack,

and raise it to the engine level.

6. Install the transmission mounting bolts and the rear

engine mounting bolts.

TRANSMISSIONMOUNTING EOLT12 x 1.25 mn

7.

64 N.m {6.547 tbt.ft)

REAR ENGINE MOUNNNG BOLTSReplace.Itl x 1.5 mm8:l N.m 18.5 kgt m, 61 lbf.ft)

Rise the transmission, then install the transmission

mount bracket and transmission mount.

. Torque the mounting bolts and nuts in thesequence shown.

. Check that the bushing are not twisted or offset.

O. @: 12 x 1.25 mm

64 N.m (6.5 kgf.m, 47 lbf'ft)

O: Temporary tightening

@: 12 x 1.25 mm

74 N.m (7.5 kgf'm,54 lbf.ft)

www.emanualpro.com

Page 672 of 1395

Symptom-to-Com ponent Chart

Hydraulic System (cont'd)

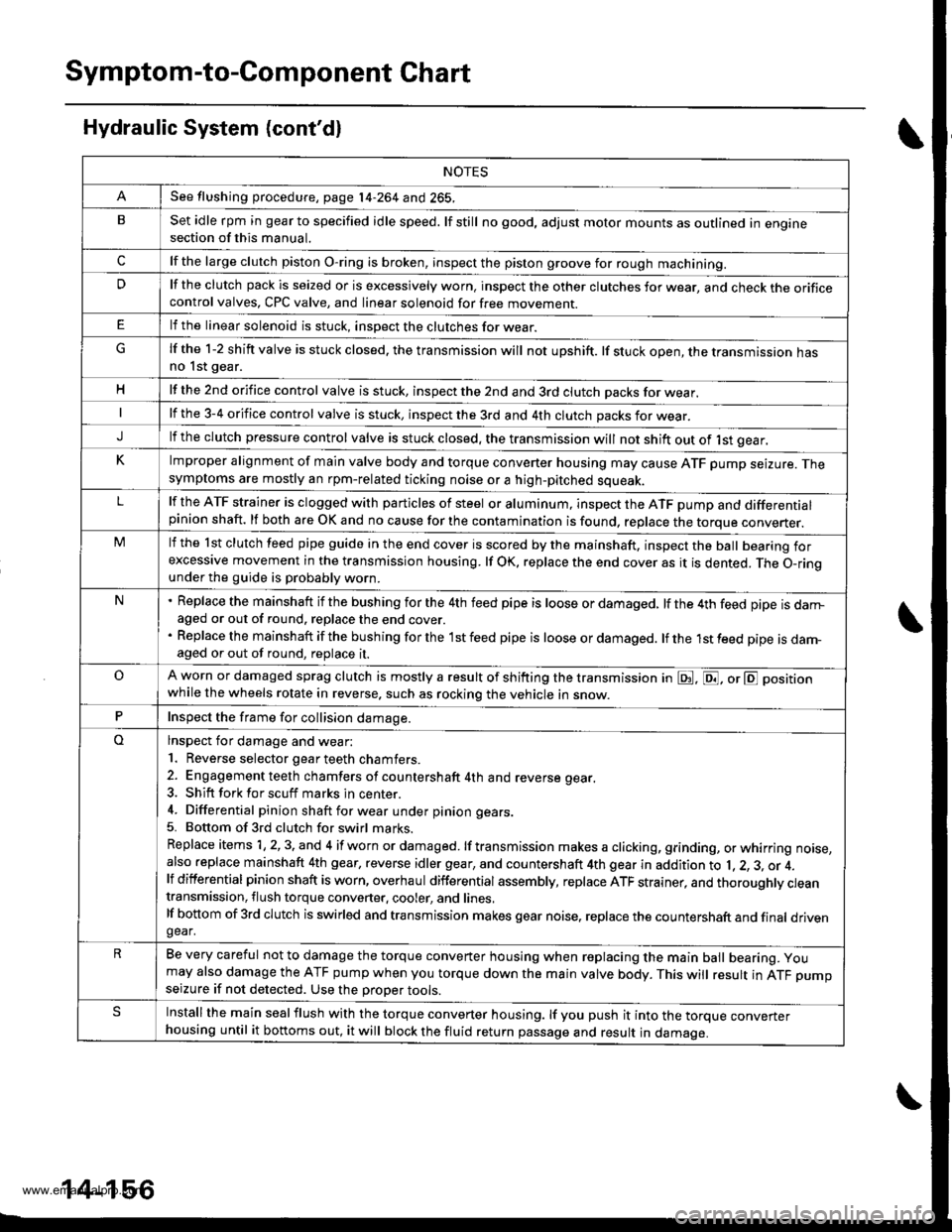

NOTES

See flushing procedure, page l4-264 and 265,

BSet idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

clf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

Dlf the clutch pack is seized or is excessively worn. inspect the other clutches fot wear, and check the orificecontrol valves, CPC valve, and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed. the transmission will not upshift. lf stuck open, the transmission hasno lst gear.

Hlf the 2nd orifice control valve is stuck, inspect the 2nd and 3rd clutch Dacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch packs for wear.

Jlf the clutch pressure control valve is stuck closed. the transmission will not shift out of lst gear.

Klmproper alignment of main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

Llf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Mlf the lst clutch feed pipe guide in the end cover is scored by the mainshaft. inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

N' Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged, lf the 4th feed pipe is darrFaged or out of round. replace the end cover.' Replace the mainshaft if the bushing for the l st feed pipe is loose or damaged. lf the 1st feed pipe is dam-aged or out of round, replace it.

oA worn or damaged sprag clutch is mostly a result of shifting the transmission in E!. E, or E positionwhile the wheels rotate in reverse. such as rocking the vehicle in snow.

PInspect the frame for collision damage.

lnspect for damage and wear:

l. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear under pinion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1, 2, 3. and 4 if worn or damaged. lf transmission makes a clicking, grinding, or whirring noise,also replace mainshaft 4th gear, reverse idler gear, and countershaft 4th gear in addition to 1,2, 3, or 4.lf differential pinion shaft is worn, overhaul differential assembly, replace ATF strainer, and thoroughly cjeantransmission, flush torque converter. cooler, and lines,lf bottom of 3rd clutch is swirled and transmission makes gear noise. replace the countershaft and final drivenoear,

Be very careful not to damage the torque converter housing when replacing the main ball bearing. you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the Drooer tools.

SInstall the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

www.emanualpro.com

Page 1060 of 1395

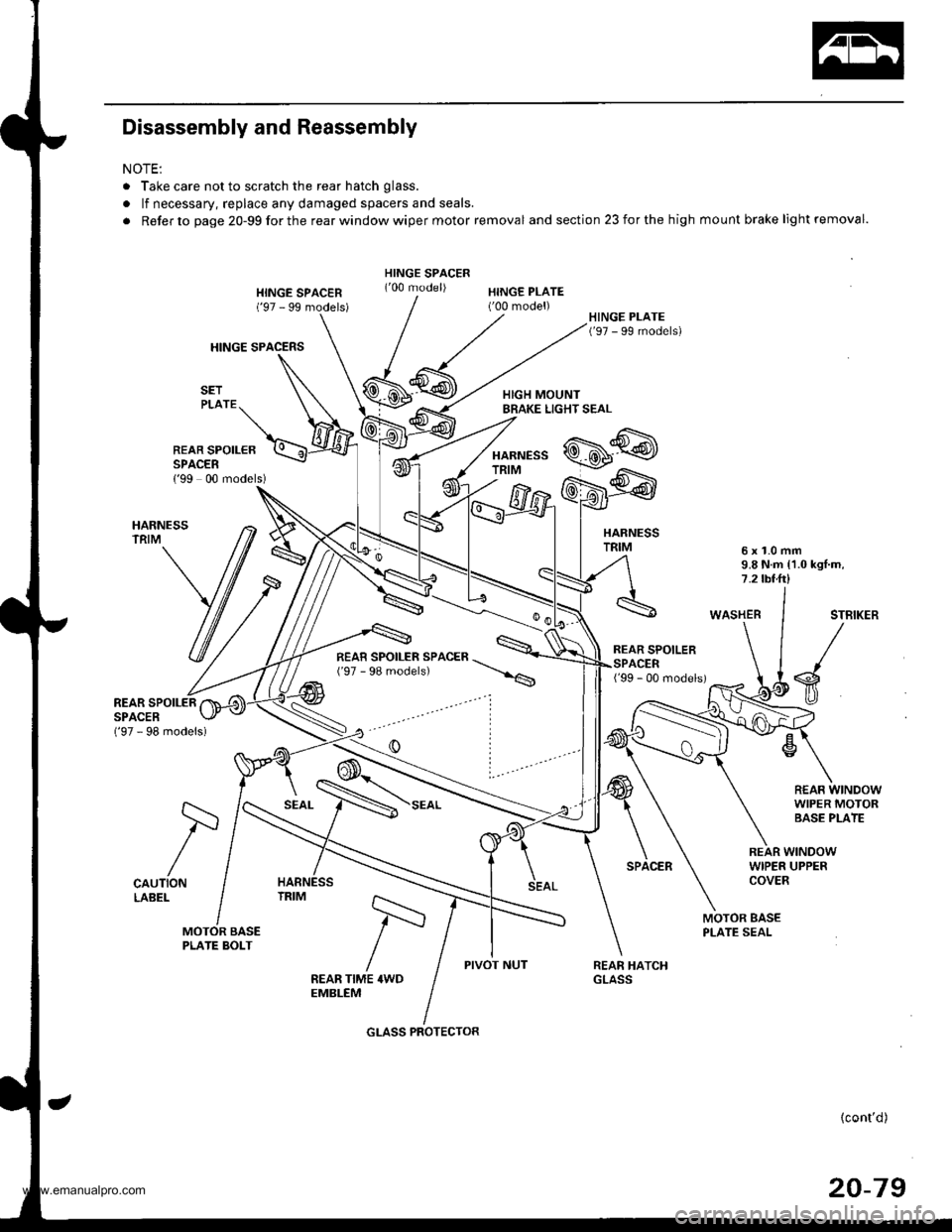

Disassembly and Reassembly

NOTE:

. Take care not to scratch the rear hatch glass.

. lf necessary, replace any damaged spacers and seals.

. Refer to page 20-99forthe rearwindowwiper motor removal and section 23 for the high mount brake light removal.

HINGE SPACERS

HINGE SPACEN('97 - 99 models)HINGE PLATE('00 model)

HARNESSTRIM

REAR SPOILEBSPACER{'99 00 models)

HARNESSTRIM6x1.0mm9.8 N.m {1.0 kgl.m,7.2 tbt.ft)

WASHERSTBIKER

s

R€AF WINDOWWIPER MOTORBASE PLATE

('97 - 98 models)

REAR SPOILERSPACER

CAUTIONLABEL

SEAL

REAR WINDOWWIPER UPPERCOVER

MOTOR BASEPLATE SEAL

PIVOT NUTFEAR TIME 4WDEMBLEM

{cont'd)

20-79

/=

GLASS PROTECTOR

www.emanualpro.com

Page 1136 of 1395

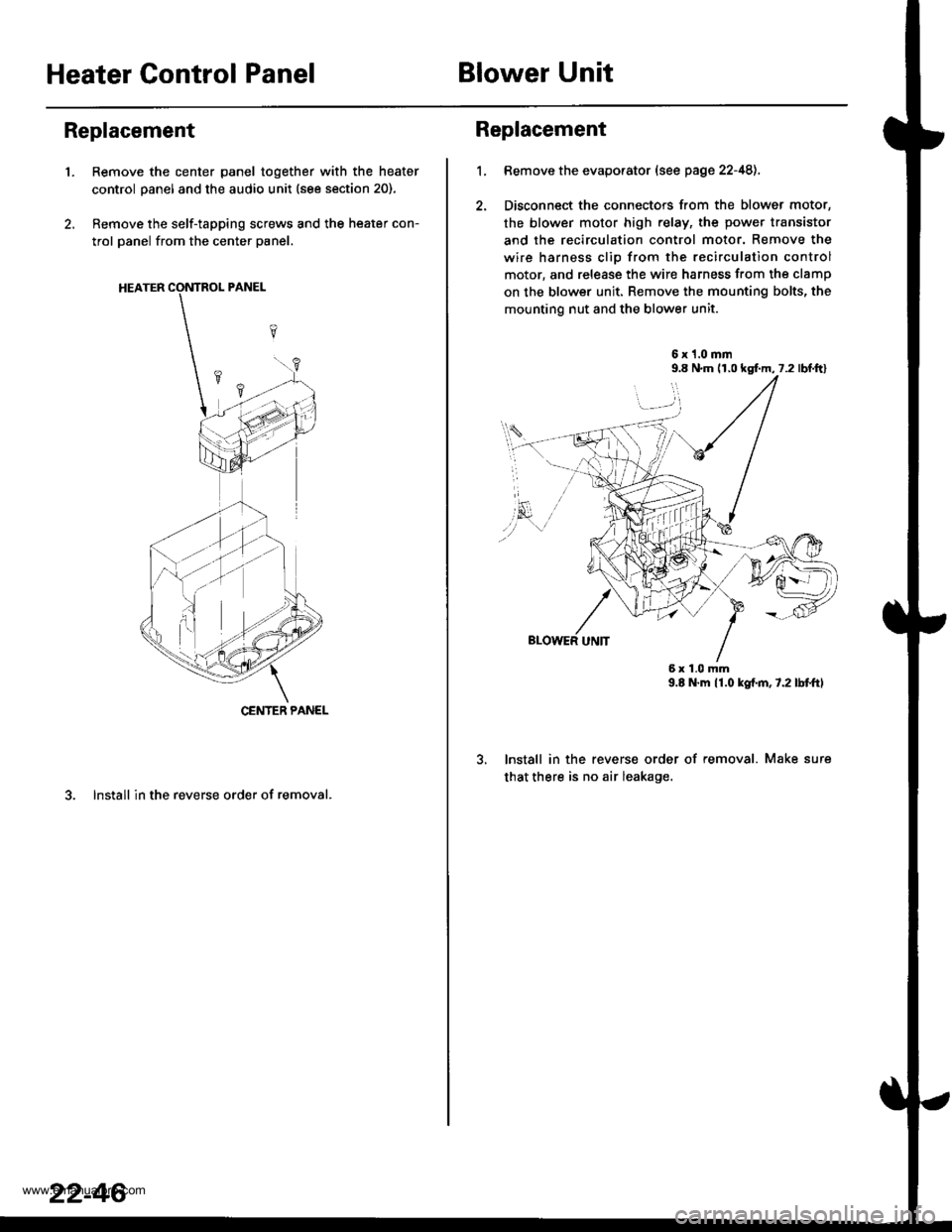

Heater Control PanelBlower Unit

Replacement

'1.Remove the center panel together with the heater

control panel and the audio unit (see section 20).

Remove the self-tapping screws and the heater con-

trol panel from the center panel.

3. lnstall in the reverse order of removal.

CENTER PANEL

22-46

1.

Replacement

Bemove the evaporator (see page 22-48),

Disconnect the connectors from the blower motor,

the blower motor high relay, the power transistor

and the recirculation control motor. Remove the

wire harness clio from the recirculation control

motor, and release the wire harness from the clamp

on the blower unit. Remove the mounting bolts, the

mounting nut and the blower unit.

6x1.0mm9.8 N.m (r,0 kgf.m, 7.2 lbl.ftl

9.E N.m 11.0 kgf.m,7.2lbtftl

lnstall in the reverse order of removal. Make sure

that there is no air leakage.

6x1.0mm

www.emanualpro.com

Page 1141 of 1395

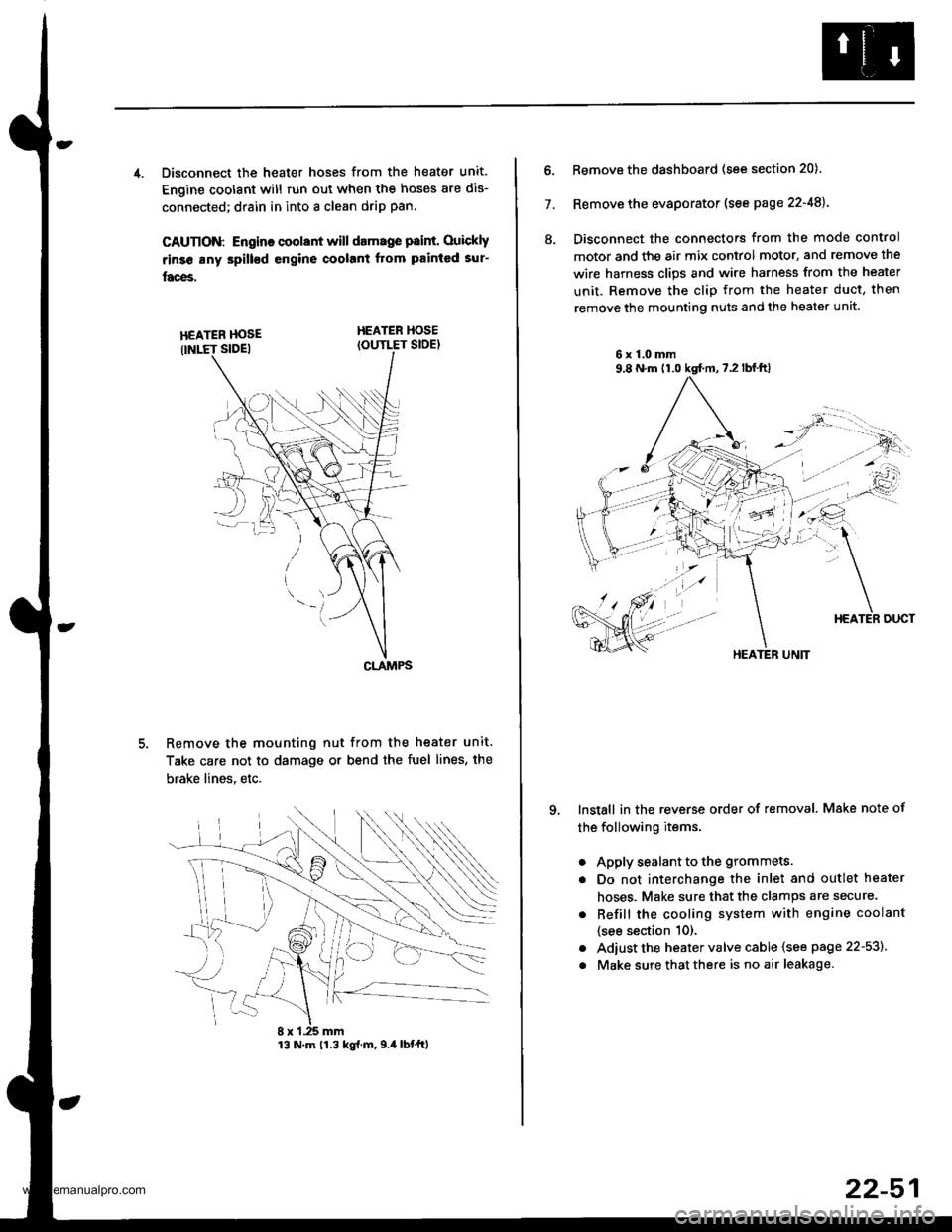

4. Disconnect the heater hoses from the heater unit.

Engine coolant will run out when the hoses are dis-

connected; drain in into a clean drip pan.

CAUTION: Engino coolant will damage p8int. Ouickly

rinse any spill€d engine coolant Itom painted sur-

faces.

HEATER HOSEIOUTLET SIDE)

Remove the mounting nut from the heater unit.

Take care not to damage or bend the fuel lines, the

brake lines. etc.

CLAMPS

13 N.m 11.3 kg{.m,9.4 lbtftl

22-51

7.

ll.

Remove the dashboard (see section 20).

Remove the evaporator (see page 22-48).

Disconnect the connectors from the mode control

motor and the air mix control motor, and remove the

wire harness clips and wire harness from the heater

unit. Remove the clip from the heater duct, then

remove the mounting nuts and the heater unit

6x1.0mm9,8 N.m (1.0 kgt m,7.2lblft)

qInstall in the reverse order of removal. Make note of

the following items.

a

a

a

a

Apply sealant to the grommets.

Do not interchange the inlet and outlet heater

hoses. Make sure that the clamps are secure.

Refill the cooling system with engine coolant

{see section 10).

Adiust the heater valve cable (see page 22-53).

Make sure that there is no air leakage.

HEATER UNIT

www.emanualpro.com

Page 1190 of 1395

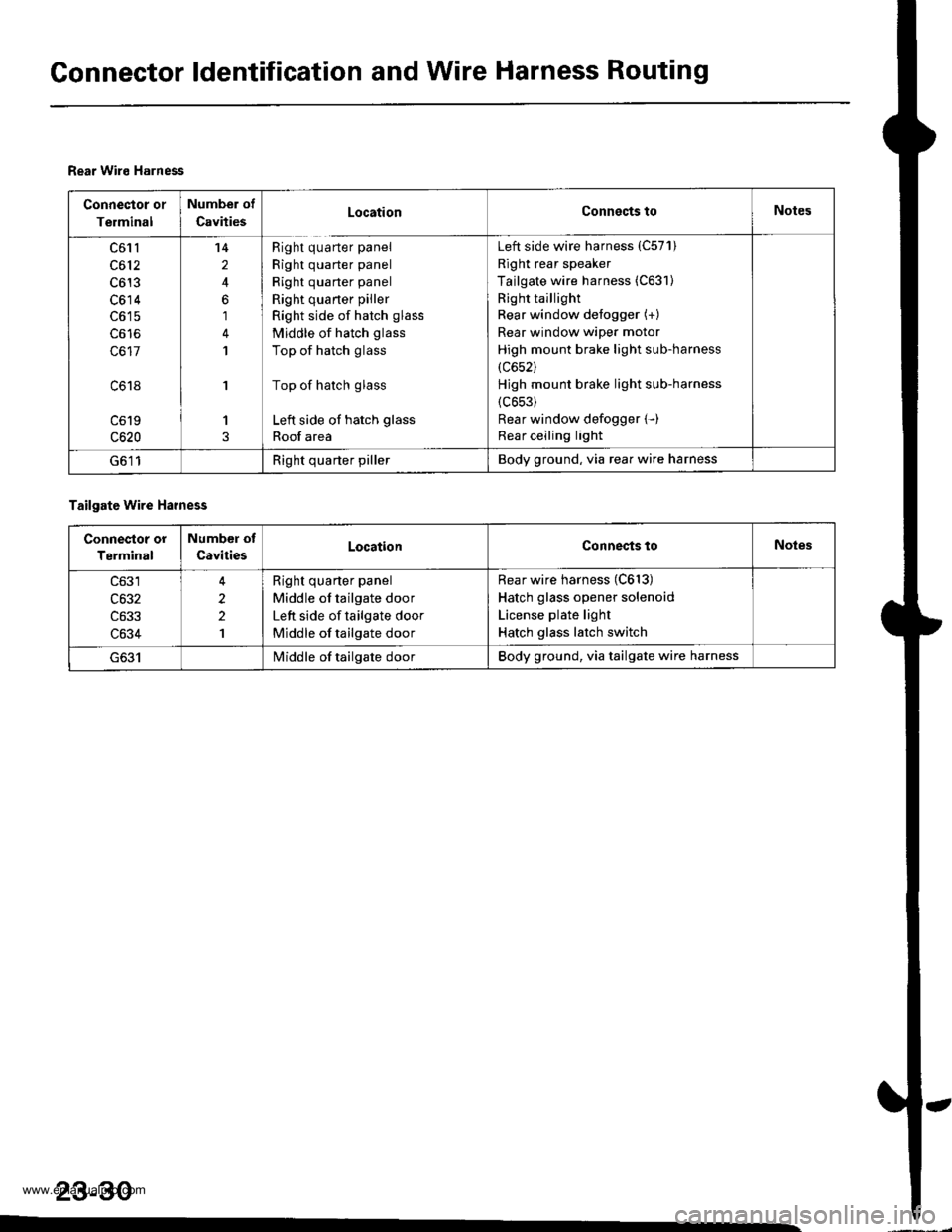

Gonnector ldentification and Wire Harness Routing

Rear Wiro Harness

Connector or

Terminal

Number of

CavitiesLocationConnects toNotes

c61l

c612

c613

c614

c617

c618

c619

c620

14

2

6

1

1

'I

1

Right quarter panel

Right quarter panel

Right quarter panel

Right quaner piller

Right side of hatch glass

Middle of hatch glass

Top of hatch glass

Top of hatch glass

Left side of hatch glass

Roof area

Left side wire harness (C57'l)

Right rear speaker

Tailgate wire harness (C631)

Right taillight

Rear window defogger (+)

Rear window wiper motor

High mount brake light sub-harness

(c652)

Hjgh mount brake light sub-harness

{c653)

Rear window defogger (-)

Rear ceiling light

G611Right quarter pillerBody ground, via rear wire harness

Tailgate wire Harness

Connestor or

Terminal

Number of

CavitiesLocationConnects toNoles

c633

c634

2

2

1

Right quarter panel

Middle of tailgate door

Left side of tailgate door

Middle of tailgate door

Rear wire harness (C613)

Hatch glass opener solenoid

License plate light

Hatch glass latch switch

I/iddle of tailgate doorBody ground, via tailgate wire harness

23-30

www.emanualpro.com

Page 1203 of 1395

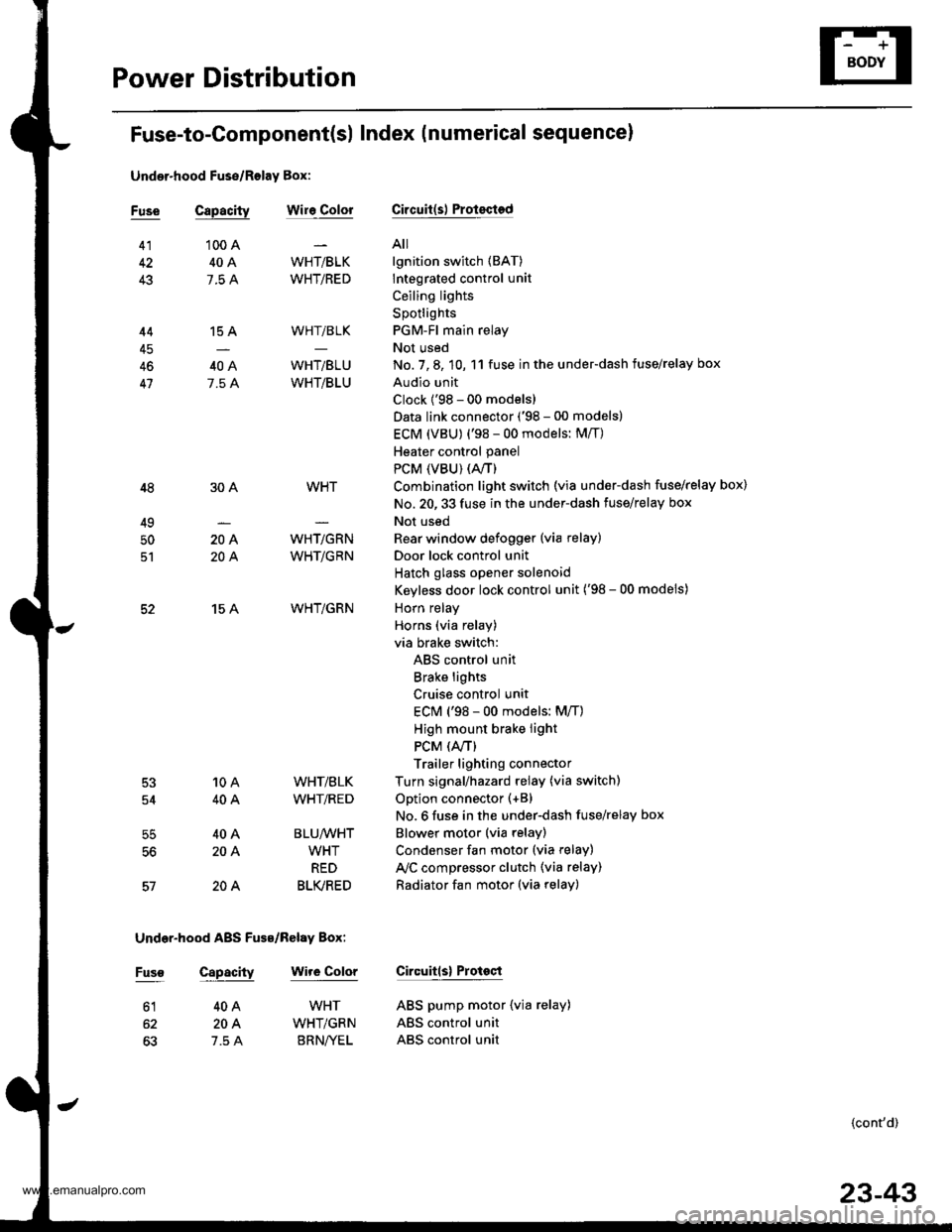

Power Distribution

Fuse-to-Gomponent(sl Index (numerical sequence)

Under-hood Fuse/Rolay Box:

41

43

44

46

47

48

49

50

52

Capacity

'100 A

40A

7.5 A

15 A

40A

7.5 A

30A

204

204

15 A

10A

40A

40A

204

20A

Capacity

40A

204

7.5 A

wiro ColorFuseCircuit(s) Prot€cted

A

lgnition switch (BAT)

lntegrated control unit

Ceiling lights

Spotlights

PGM-Fl main relay

Not used

No. 7, 8, 10, 11 fuse in the under-dash fuse/relay box

Audio unit

Clock {'98 - 00 models)

Data link connector ('98 - 00 models)

ECM (VBU) {'98 - 00 models: M/T)

Heater control panel

PCM (VBU) (A./T)

Combination light switch (via under-dash fuse/relay box)

No. 20, 33 fuse in the under-dash fuss/relay box

Not used

Rear window defogger (via relay)

Door lock control unit

Hatch glass opener solenoid

Keyless door lock control unit ('98 - 00 models)

Horn relay

Horns (via relay)

via brake switch:

ABS control unit

Brake lights

Cruise control unit

ECM ('98 - 00 models: M/T)

High mount brake iight

PCM (4./T)

Trailer lighting connector

Turn signal/hazard relay (via switch)

Option connector (+B)

No. 6 fuse in the under-dash fuse/relay box

Blower motor (via relay)

Condenser fan motor (via relay)

Ay'C compressor clutch (via relay)

Radiator fan motor (via relay)

Wire Color Circuitls) Protoct

53

54

50

WHT/BLK

WHT/RED

WHT/BLK

WHT/BLU

WHT/BLU

WHT

WHT/GRN

WHT/GRN

WHT/GRN

WHT/BLK

WHT/RED

BLU/WHT

WHT

RED

BLK/RED

Under-hood ABS Fuss/nehy Box:

Fusg

61WHT

WHT/GRN

BRN/YEL

ABS pump motor {via relay}

ABS control unit

ABS control unit

{cont'd)

23-43

www.emanualpro.com

Page 1208 of 1395

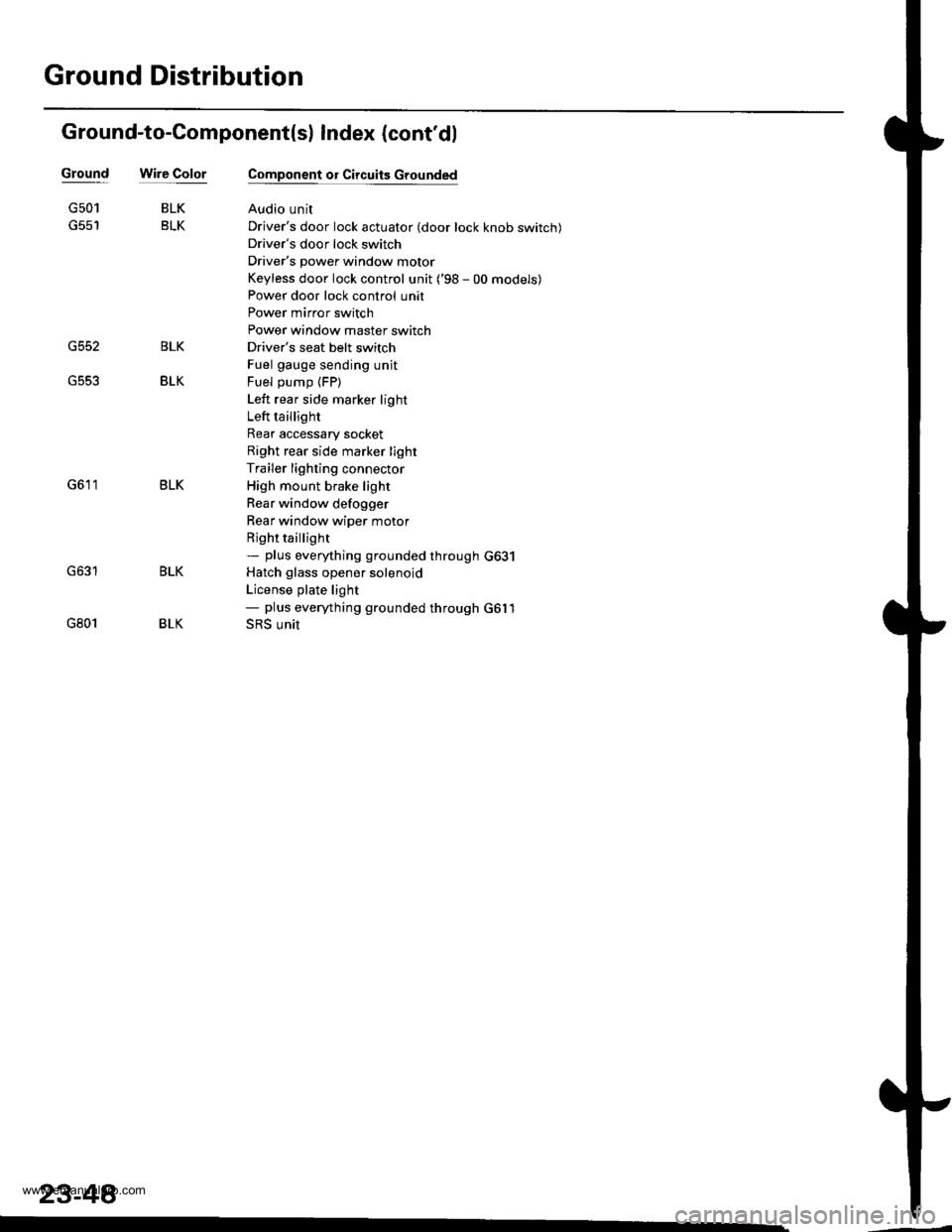

Ground Distribution

Ground-to-Component(sl Index (cont'dl

Wire ColorGround

G552

G501

G801

BLK

BLK

BLK

BLK

Component or Circuits Grounded

Audio unit

Driver's door lock actuator (door lock knob switch)

Driver's door lock switch

Driver's power window motor

Keyless door lock control unit ('98 - 00 models)

Power door lock control unit

Power mirror switch

Power window master switch

Driver's seat belt switch

Fuel gauge sending unit

Fuel pump (FP)

Left rear side marker light

Left taillight

Rear accessary socket

Right rear side marker light

Trailer lighting connector

High mount brake light

Rear window defogger

Rear window wiper motor

Rjght taillight- plus eveMhing grounded through G631

Hatch glass opener solenoid

License plate light- plus eveMhing grounded through G6l1

SRS unit

BLK

BLK

BLK

23-48�

www.emanualpro.com