Rear seat HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 15 of 1395

G: FRONT SEAT PASSENGER AIRBAG MODULE DANGEN

A DANGEREXPLOSIVE/FLAMMABLECONTACT WITH ACID, WATER. OR I{EAVY METALS SUCH

AS COPPER. T.EAD. OR MERCURY MAY PRODUCE HARMFUL

AND IRRITATING GASES OR EXPLOSIVE COMPOUNDS.

STORAGE TEMPERATURES MUST NOT EXCEED 2OO"F

IlOO'C). FOR PROPER HANDLING, STORAGE, AND

DISPOSAL PROCEDURES REFER TO THE SERVICE MANUAL,

SRS SUPPLEMENT.POTSONCONTAINS POTSONOUS SODIUM AZIDE ANO POTASSIUM

NITRATE.FIRST AIDIF CONTENTS ARE SWALLOWED, INDUCE VOMITING. FOR

EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES. IF GASES (FROM ACID OR WATEN CONTACT)

ARE INHALEO. SEEK FRESH AIR. IN EVERY CASE, GET

PROMPT MEDICAL ATTENTION.KEEP OUT OF REACH OF CHILDREN.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND, IF

ACCIDENTALLY DEPLOYED, CAN SERIOUSLY HURT OR

KILL YOU.. DO NOT USE ELECTRICAL TEST EOUIPMENT OR

PROBING DEVICES,THEY CAN CAUSE ACCIDENTAL DEPLOYMENT.. NO SERVICEABI-E PARTS lNSlDE. DO NOT DISASSEMBII.

. PLACE AIRBAG UPRIGHT WHEN REMOVEO.

. FOLLOW SERVIC€ MANUAL INSTRUCTIONS CAREFULLY

H: PASSENGER INFORMATION lU S.A. modell

{U.S.A.'97 model}

AIEBAG SEE OTHER SIDE,

{U.S.A.'98 - 00 modelsl

AIRBAG WARNINGFLIP VISOR OVER.

l: SRS INFORMATION

lU.s.A.'97 model ilcanada '97 - 00 mod€ls I

CAUTIONTO AVOID SERIOUS INJURY:. FOR MAXIMUM SAFEW PROTECTION lN ALL TYPES OF

CRASHES, YOU MUST ALWAYS WEAR YOUR SAFETY

8ELT.o OO NOT INSTALL REARWARD-FACING CHILO SEATS lN

ANY FRONT PASSENGER SEAT POSITION.. DO NOT SIT OR LEAN UNNECESSARILY CLOSE TO THE

AIRBAG.. DO NOT PLACE ANY OBJECTS OVER THE AIRBAG OR

BETWEEN THE AIRBAG AND YOURSELF.. SEE THE OWNER'S MANUAL FOR FURTHER

INFORMATION AND EXPLANATIONS. THE SRS MUST BE INSPECTED TEN YEARS AFTER lT lS

INSTALLED.. THE DATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

lU.S.A.'98 - 00 models)

WARNINGDEATH OR SERIOUS INJURY CAN OCCUR'

. CHILDREN 12 ANO UNDER CAN BE KILLED BY THE

AIRBAG.. THE BACK SEAT lS THE SAFEST PLACE FOR CHILDREN.

. NEVER PUT A REAR-FACING CHILD SEAT lN THE

FRONT.o SIT AS FAR BACK AS POSSIBLE FROM THE AIRBAG

. ALWAYS USE SEAT BELTS AND CHll-D RESTRAINTS.

. THE SRS MUST BE TNSPECTED TEN YEAnS AFTER lT lS

INSTALLED.. THE OATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

J: FRONT PASSENGER AIRBAG WARNING

lU.S.A.'98 - 00 models)

WARNINGCHILDREN CAN BE KILLED OR INJURED 8Y THE

PASSENGER AIRBAG.THE BACK SEAT IS THE SAFEST PLACE FOR CI{ILDREN 12

AND UNDER.MAKE SURE ALL CHILDREN USE SEAT BELTS OR CHILD

SEATS.

K: FRONT SEATBELT TENSIONER WARNING

WABNINGEXPLOSIVE MATERIAL INSIDEYOU CAN BE SERIOUSLY HURT OR BURNED,

. DO NOT TAMPER OR DISASSEMBLENO SERVICEABLE PARTS INSIDE.. REFER TO SERVICE MANUAL FOR COMPLETE

INSTRUCTIONS.

(cont'd)

1-13

www.emanualpro.com

Page 37 of 1395

Design Specifications

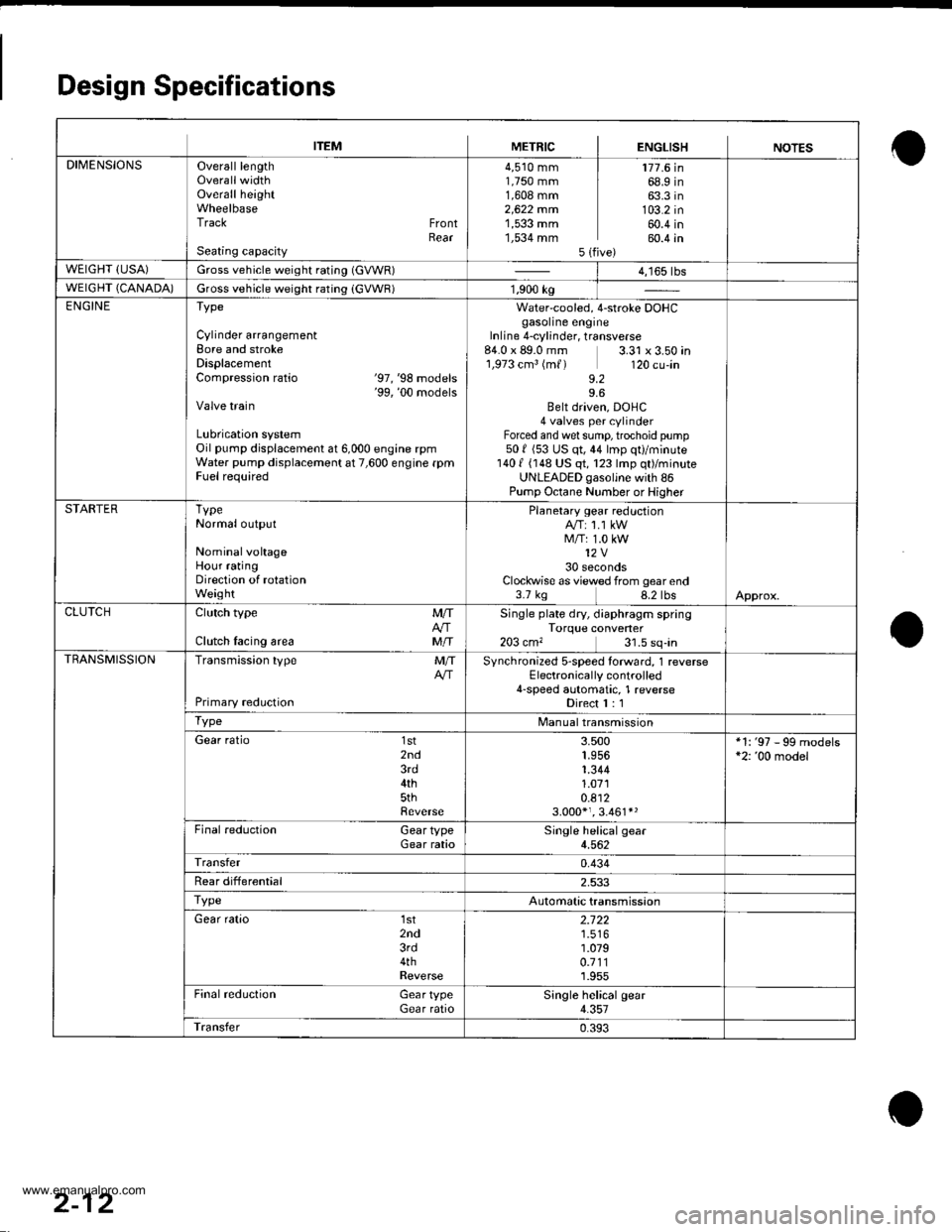

ITEMMETRICENGLISHNOTES

DIMENSIONSOverall lengthOverallwidthOverall heightWheelbaseTrack FrontRearSeating capacity

4,510 mm1,750 mm1,608 mm2,622 mrn1,533 mm1,534 mm5lf

177.6 in68.9 in63.3 in103.2 in60.4 in60.4 in

WEIGHT (USA)Gross vehicle weight rating (GVWR)| 4,165 tbs

WEIGHT (CANADA)Gross vehicle weight rating (GVWR)1,900 kg

ENGINEType

Cylinder arrangementBore and strokeDisplacementCompression ratio '97,'98 mooers'99, '00 modelsValve train

Lubrication systemOil pump displacement at 6,000 engine rpmWater pump displacement at 7,600 engine rpmFuel required

Water-cooled, 4-stroke DOHCgasoline engineInline 4-cylinder, transverse84.0 x 89.0 mm.1,973 cm3 (m{)

9.2

3.31 x 3.50 in120 cu-in

9.6Belt driven, DOHC4 valves per cylinderForced and wet sump, trochoid pump501 (53 US qt,44 lmp qt)/minute1401 (148 US qt, 123 lmp qt)/minuteUNLEADED gasoljne with 86Pump Octane Number or Higher

STARTERTypeNormal output

NominalvohageHour ratingDirection of rotationWeight

Planetary gear reductionA/T: 1.1 kWM/T: 1.0 kW12V30 secondsClockwise as viewed from gear end3.7 kg 8.2 lbsApprox.

CLUTCHClutch type

Clutch lacing area

MIT

MIT

Single plate dry, diaphragm springTorque converter203 cm, 31.5 sq-in

TRANSMISSIONTransmission type

Primary redLrction

MITSynchronized s-speed torward, 1 reverseElectronically controlled4-speed automatic, 1 reverseDirect I : 1

TypeManualtransmission

Gear ratio 1st2nd3rd4th5thReverse

3.5001.9561.3441.0710.8123.000*,. 3.461*'

*1: '97 - 99 models*2: '00 model

Final reduction Gear typeGear rataoSingle helical gear4.562

Transfer0.434

Rear differential2.533

TypeAutomatic transmission

Gear ratio 1st2nd3rd4thReverse

2.722

1.0790.7111.955

Final reduction Gear typeGear ratioSingle helical gear4.357

Transfer0.393

2-12

www.emanualpro.com

Page 385 of 1395

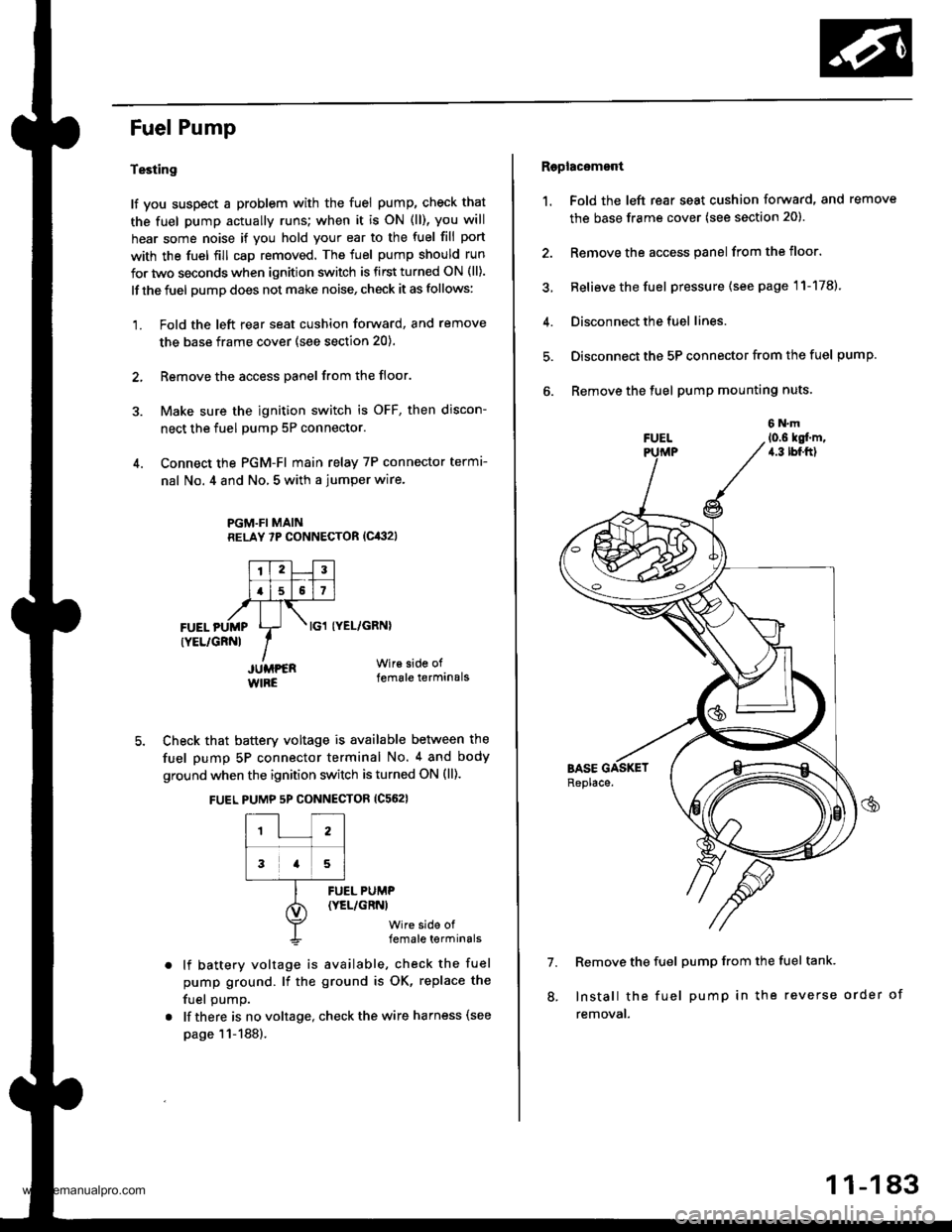

Fuel Pump

Testing

lf you suspect a problem with the fuel pump, check that

the fuel pump actually runs; when it is oN (ll), you will

hear some noise if you hold your ear to the fuel fill port

with the fuel fill cap removed. The fuel pump should run

for two seconds when ignition switch is first turned ON (ll).

lf the fuel pump does not make noise, check it as follows:

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2, Remove the access panel from the floor.

3. Make sure the ignition switch is OFF, then discon-

nect the fuel pumP 5P connector.

4. Connect the PGM-FI main relay 7P connector termr-

nal No. 4 and No, 5 with a jumper wire.

PGM.FI MAINRELAY 7P CONNECTOR (Cit:}2l

I'TtlJilt f -r'-r ll.l5l517l,frTt-,at\FUEL pUMp Lr- . tcl tyEL/cRNl

rYEL/cRNl IIJUMPER Wir€ side of

WIRE female terminals

5. Check that battery voltage is available between the

fuel pump 5P connector terminal No. 4 and body

ground when the ignition switch is turned ON (ll).

FUEL PUMP 5P CONNECTOR {C562}

12

3a5

lf battery voltage is available, check the fuel

pump ground. lf the ground is OK, replace the

fuel oumo.

lf there is no voltage, check the wire harness (see

page 11-188).

FUEL PUMP(YEL/GRNI

wire side offemale terminals

Raplac6mont

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2. Remove the access panel from the floor.

3, Relieve the fuel pressure (see page 11-178).

4. Disconnect the fuel lines.

5. Disconnect the 5P connector from the fuel pump.

6. Remove the fuel pump mounting nuts.

7. Remove the fuel pump from the fuel tank.

Install the fuel pump in the reverse order of

removal.

8.

11-183

www.emanualpro.com

Page 386 of 1395

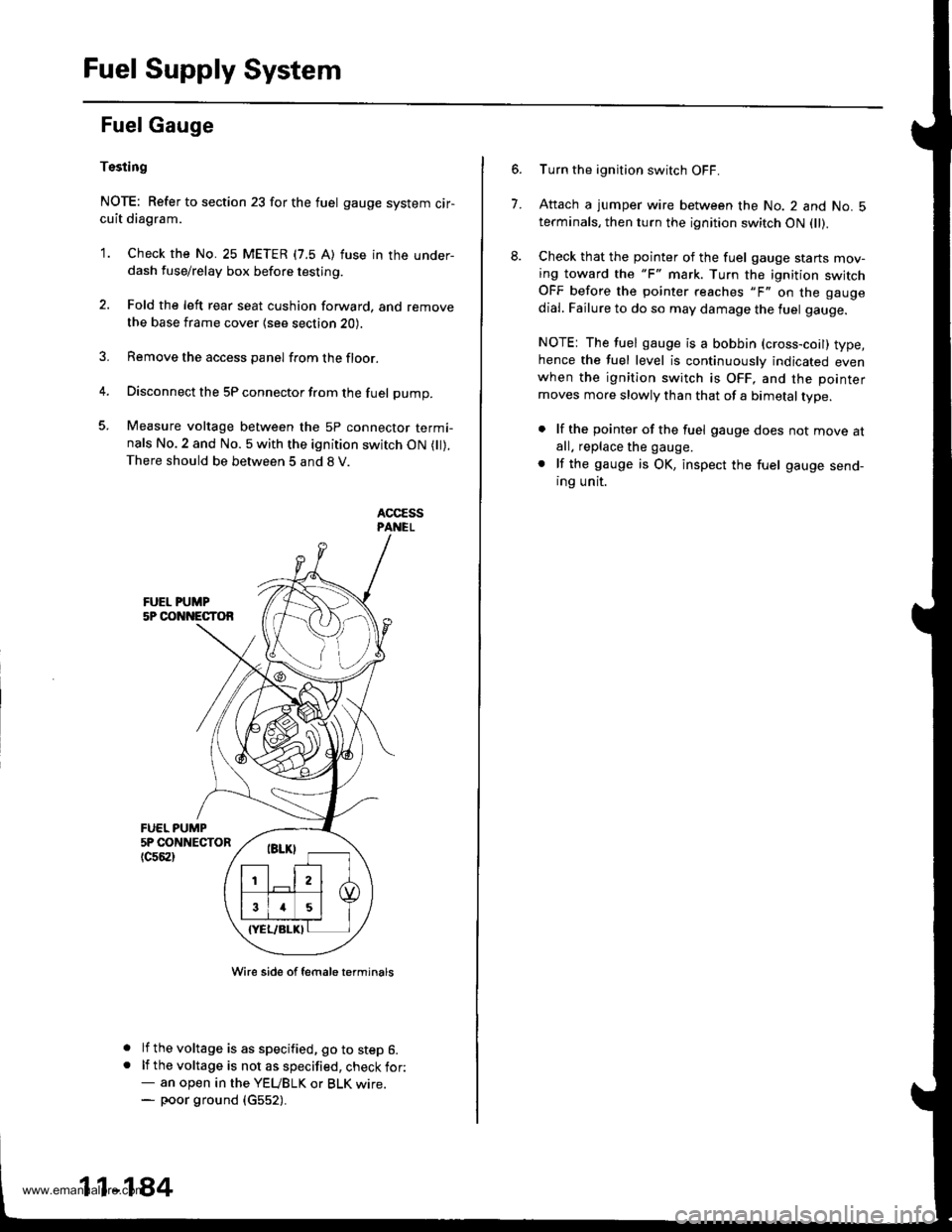

Fuel Supply System

Fuel Gauge

Tssting

NOTE: Refer to section 23 for the fuel gauge system cir-cuit diagram.

'1. Check the No. 25 METER (7.5 A) fuse in the under-dash fuse/relay box before testing.

2. Fold the left rear seat cushion forward, and remove

the base frame cover {see section 20).

3. Remove the access panel from the floor.

4. Disconnect the 5P connector from the fuel pump.

5. Measure voltage between the 5P connector termi-nals No.2 and No. 5 with the ignition switch ON ( ).There should be between 5 and 8 V.

FUEL PUMP5P CONNECTOR

tc56al

a

a

Wire side of female t€rminals

lf the voltage is as specified, go to step 6.lf the voltage is not as specified, check for:- an open in the YEUBLK or BLK wrre.- poor ground (c552).

11-184

7.

Turn the ignition switch OFF.

Attach a jumper wire between the No. 2 and No. 5terminals, then turn the ignition switch ON fll).

Check that the pointer of the fuel gauge starts mov-ing toward the "F" mark. Turn the ignition switchOFF before the pointer reaches "F" on the gauge

dial. Failure to do so may damage the luel gauge.

NOTE: The fuel gauge is a bobbin (cross-coil) type,hence the fuel level is continuously indicated evenwhen the ignition switch is OFF, and the pointer

moves more slowly than that of a bimetal type.

. lf the pointer of the fuel gauge does not move atall. replace the gauge.

. lf the gauge is OK, inspect the fuel gauge send-ing unit.

www.emanualpro.com

Page 387 of 1395

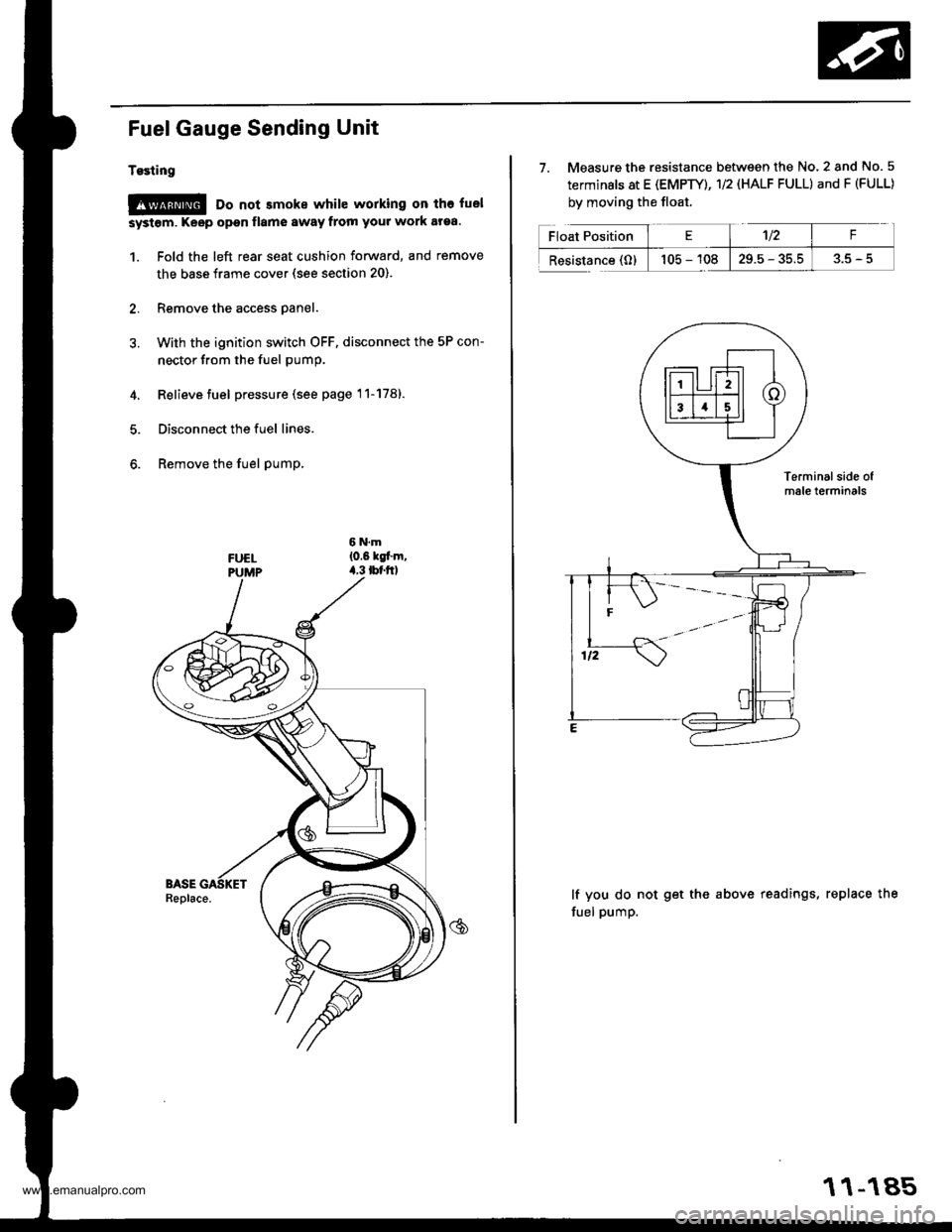

Fuel Gauge Sending Unit

Tgsting

@ Do not smoke while working on tho fuel

systom. Keop open flamo 8waY from your work araa.

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2. Remove the access panel.

3. With the ignition switch OFF. disconnect the 5P con-

nector from the fuel pump.

4. Relieve fuel pressure (see page 11-178).

5. Disconnect the fuel lines.

6. Remove the fuel pump,

7. Measure the resistance between the No. 2 and No. 5

terminals at E (EMPTY), 1/2 (HALF FULL) and F (FULL)

by moving the float.

lf you do not get the above readings, replace the

fuel pump.

11-185

www.emanualpro.com

Page 393 of 1395

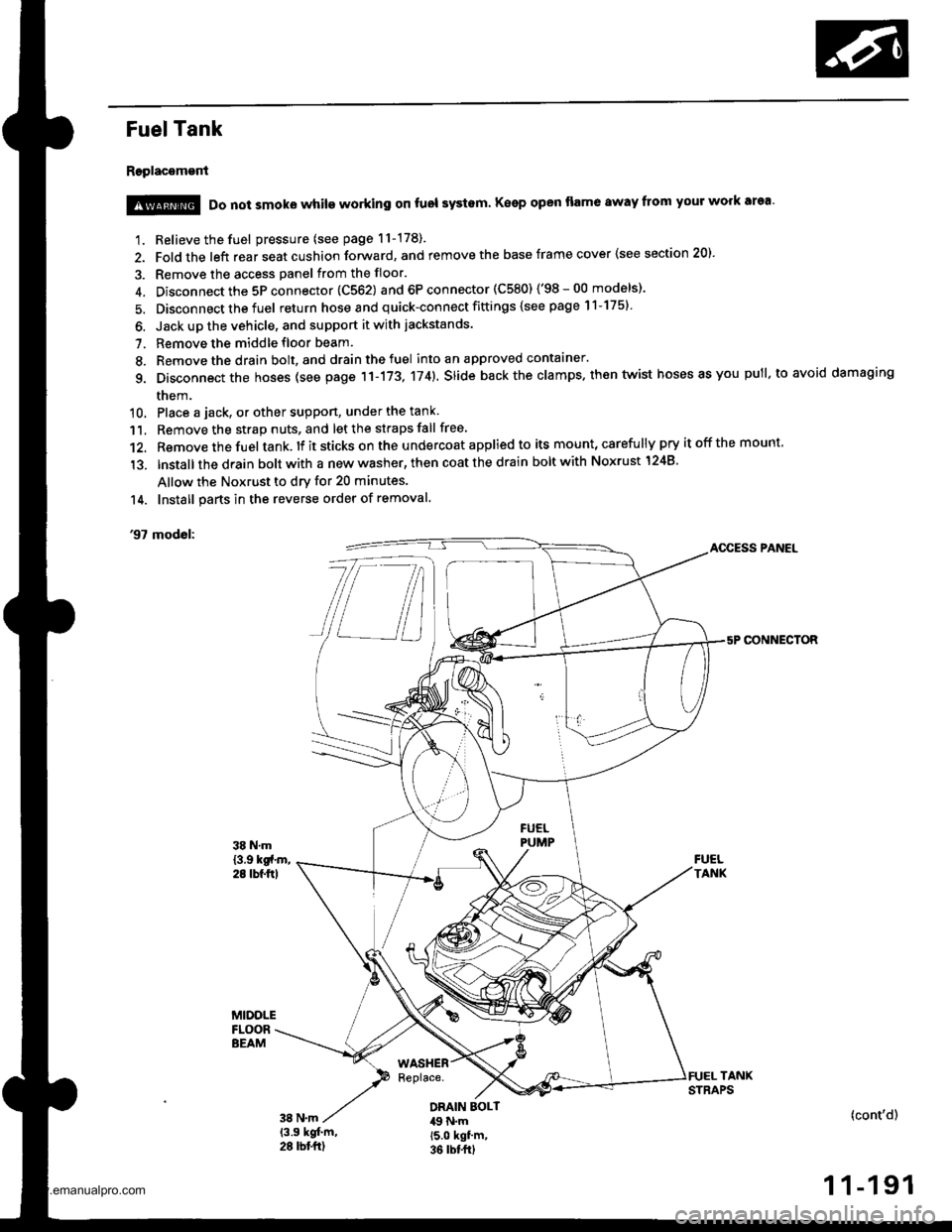

Fuel Tank

Replacement

1. Relieve the fuel pressure (see page 11-178).

2. Fold the left rear seat cushion forward, and remove the base frame cover {see section 20).

3. Remove the access panel from the floor.

4. Disconnect the 5P connector 1C562) and 6P connector (C580) ('98-00 models)'

5. Disconnect the fuel return hose and quick-connect fittings {see page 11-175}

6. Jack up the vehicle, and support it with jackstands.

7. Remove the middle floor beam.

8. Remove the drain bolt, and drain the fuel into an approved contaaner.

g. Disconnect the hoses (see page 11-173, 174). slide back the clamps. then twist hoses as you pull, to avoid damaging

them.

10. Place a jack, or other suppon, under the tank

11. Remove the strap nuts, and let the straps fall free

12. Remove the fuel tank. lf it sticks on the u ndercoat applied to its mount, carefu lly pry it off the mount,

'13. lnstallthe drain bolt with a new washer, then coat the drain bolt with Noxrust 1248'

Allow the Noxrust to dry for 20 minutes.

14. Install parts in the reverse order of removal.

'97 modol:AOCESS PANEL

CONNECTOR

@ Do not smoke while working on fuol systam Keep open flame away from your work area'

DRAIN EOLT49 N.m15.0 kgf'm,36 rbt frl

(cont'd)

1 1-191

www.emanualpro.com

Page 841 of 1395

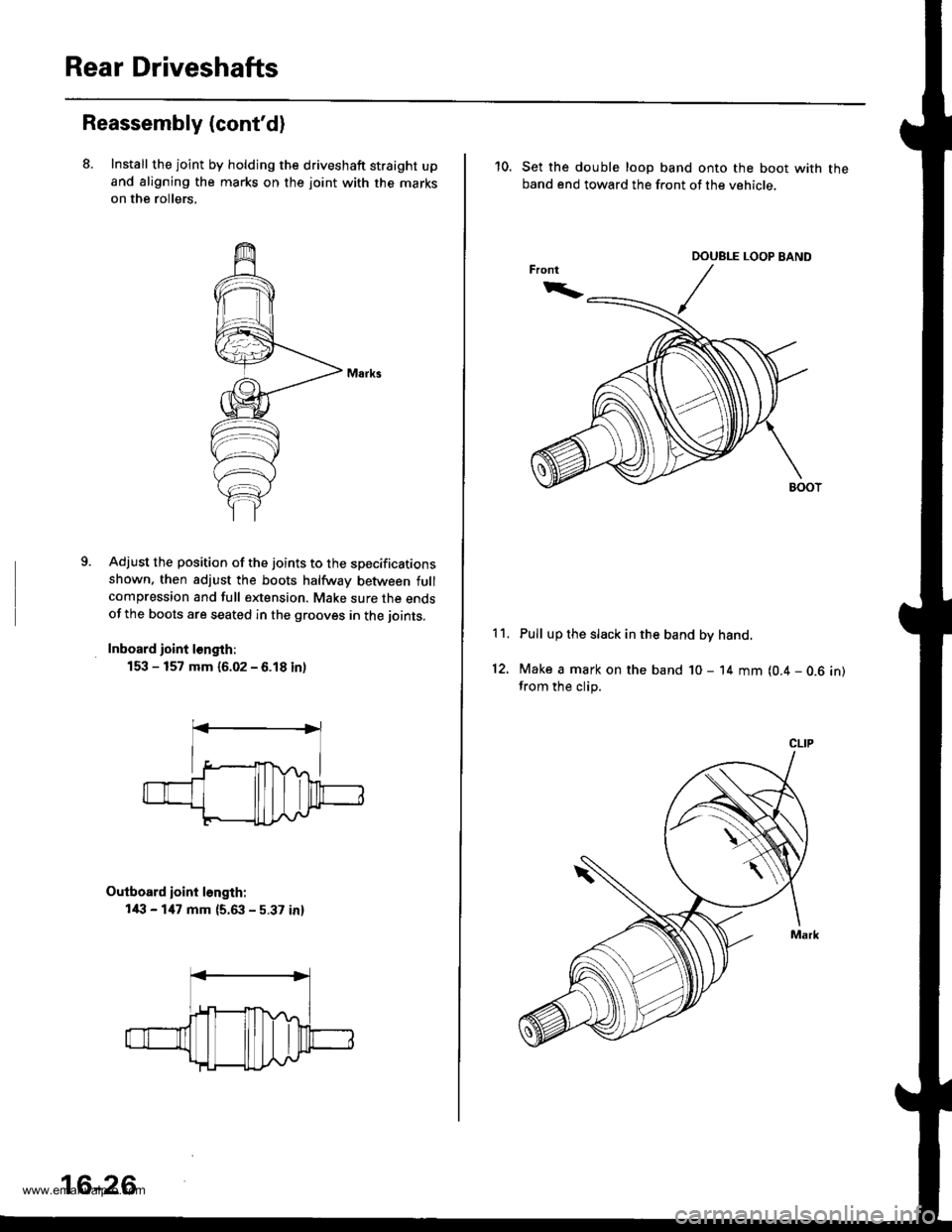

Rear Driveshafts

Reassembly (cont'd)

8. Install the joint by holdjng the driveshaft straight upand aligning the marks on the joint with the marks

on the rollers,

9.Adjust the position of the joints to the specificationsshown. then adjust the boots halfway between fullcompression and full extension. Make sure the endsof the boots are seated in the grooves in the joints.

Inboard ioint l€ngth:

153 - 157 mm {6.02 - 6.18 inl

Outboard ioint l6ngth:

l/l:' - 147 mm {5.63 - 5.37 in}

16-26

10. Set the double loop band onto the boot with theband end toward the front of the vehicle,

Pull up the slack in the band by hand.

Make a mark on the band 10 - 14 mm (0.4 - 0.6 in)from the clip.

11.

12.

CLIP

www.emanualpro.com

Page 843 of 1395

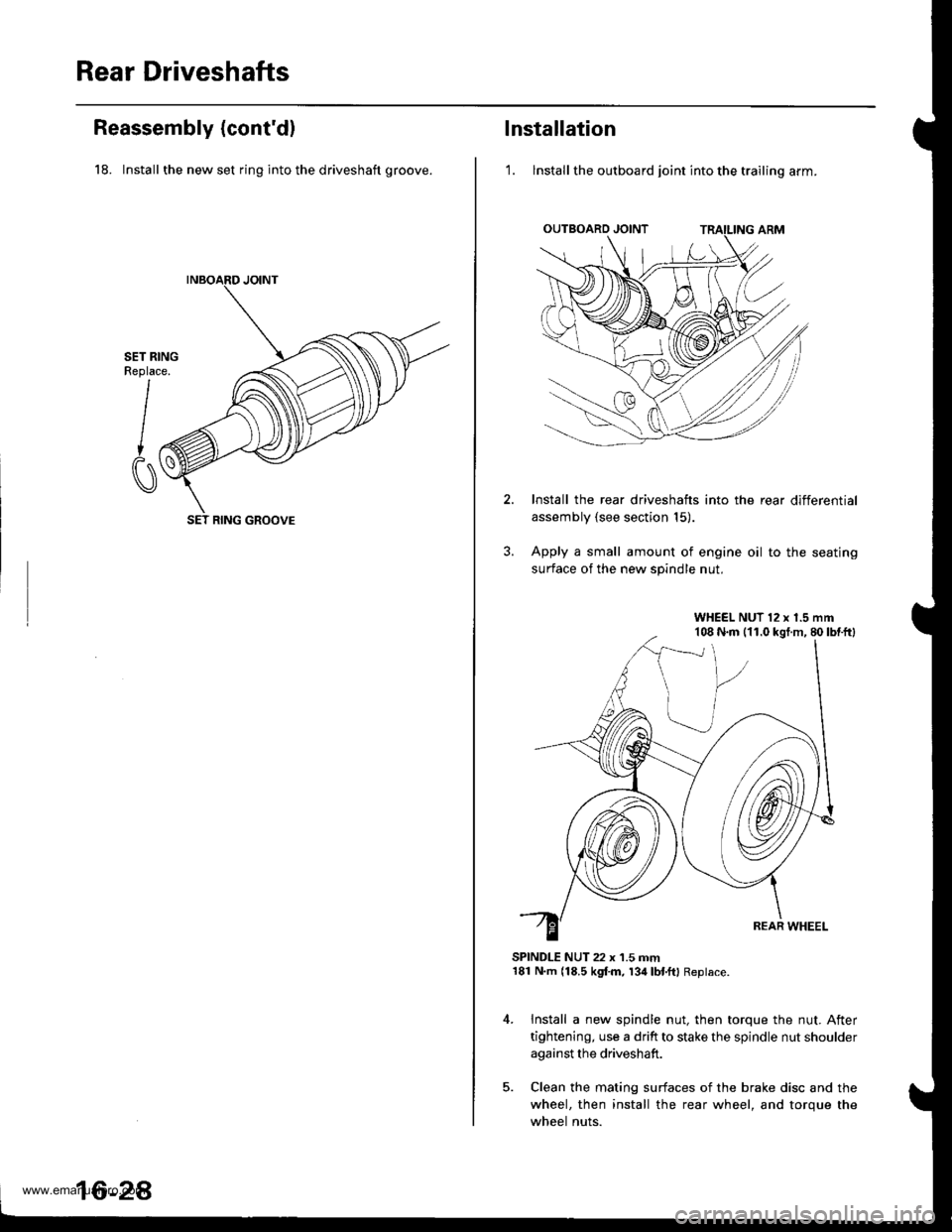

Rear Driveshafts

Reassembly (cont'd)

18. Install the new set ring into the driveshaft groove.

SET RINGReplace.

I

CI

SET RING GROOVE

16-2A

lnstallation

'1. lnstall the outboard joint into the trailing arm.

Install the rear driveshafts into the rear differential

assembly (see section 15).

Apply a small amount of engine oil to the seating

surface of the new spindle nut.

SPINDLE NUT 22 x 1.5 mm181 N.m (18.5 kgf.m, 134lbl.ftl Replace.

Install a new spindle nut, then torque the nut. After

tightening, use a drift to stake the spindle nut shoulder

against the driveshaft.

Clean the mating surfaces of the brake disc and the

wheel, then install the rear wheel, and torque the

wheel nuts.

WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgt.m, 80lbtftl

www.emanualpro.com

Page 920 of 1395

Rear Suspension

Hub Bearing Unit Replacement (cont'd)

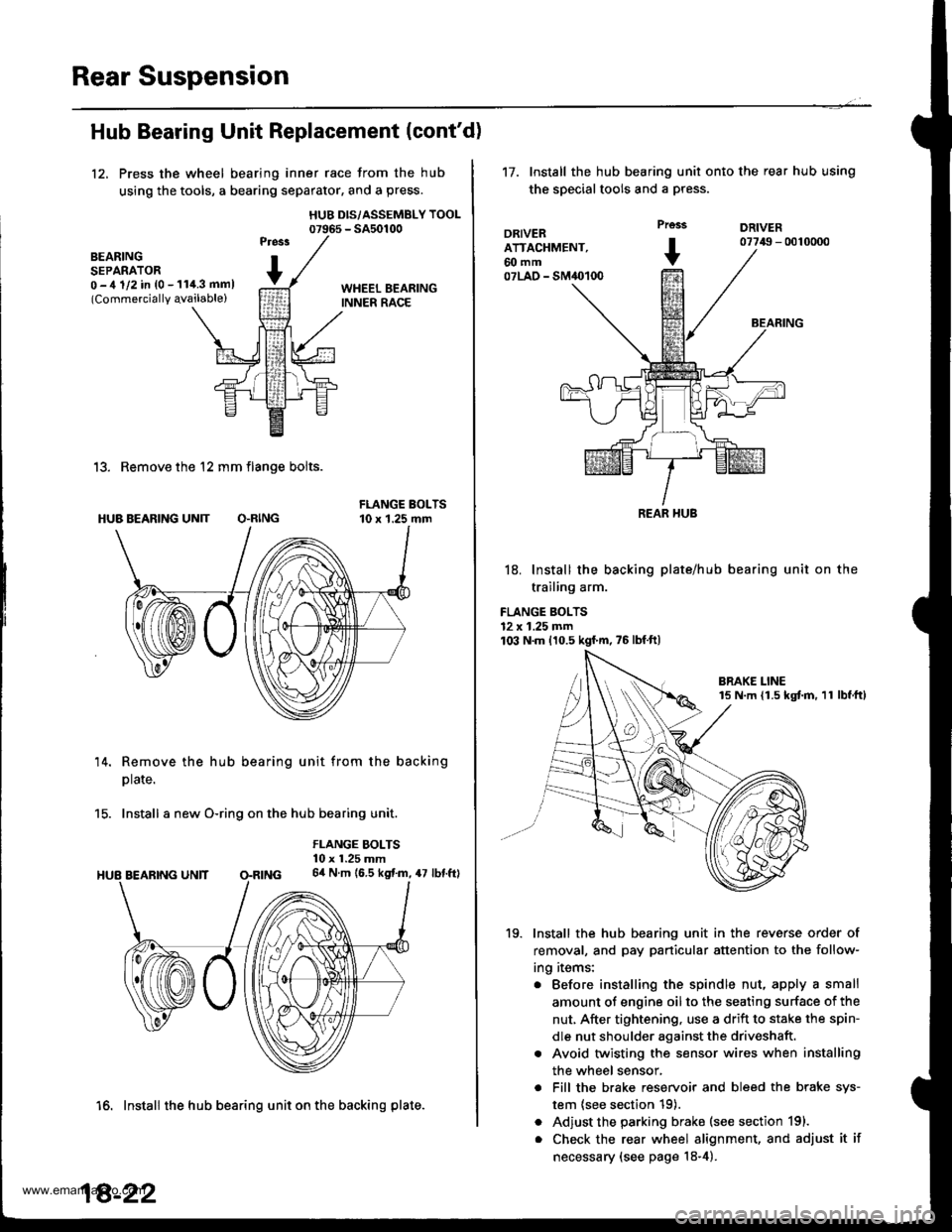

12, Press the wheel bearing inner race from the hub

using the tools, a bearing separator, and a press.

HUB DIS/ASSEMBLY TOOL07965 - SA50100

BEARINGSEPARATOR0 -,t 1/2 in {0 - 11i1.3 mml(Commercially qvailable)

13. Remove the 12 mm flange bolts.

HUB BEARING UN]T O.RING

14. Remove the hub bearing unit from the backing

plate.

15. Install a new O-ring on the hub bearing unit.

FLANGE BOLTS10 x 1.25 mm64 N.m (6.5 kgf.m, 47 lbf.ftl

16. Install the hub bearing unit on the backing plate.

18-22

't7.Install the hub bearing unit onto the rear hub using

the special tools and a press.

DRIVERATTACHMENT,60 mm07LAO - SM40100

Prcss

+

DRIVER07749 - 0010000

BEARING

18. Install the backing plate/hub

trailing arm.

FLANGE BOLTS12 x 1.25 mm103 N.m 110.5 kgf'm,75lbfft)

bearing unit on the

19. Install the hub bearing unit in the reverse order of

removal, and pay particular attention to the follow-

ing items:

. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface of the

nut, After tightening, use a drift to stake the spin-

dle nut shoulder against the driveshaft.

. Avoid twisting the sensor wires when installing

the wheel sensor,

. Fill the brake reservoir and bleed the brake sys-

tem {see section 19).

. Adjust the parking brake (see section 191.

. Check the rear wheel alignment, and adjust it if

necessary (see page 18-4).

REAR HUB

www.emanualpro.com

Page 923 of 1395

Reassembly

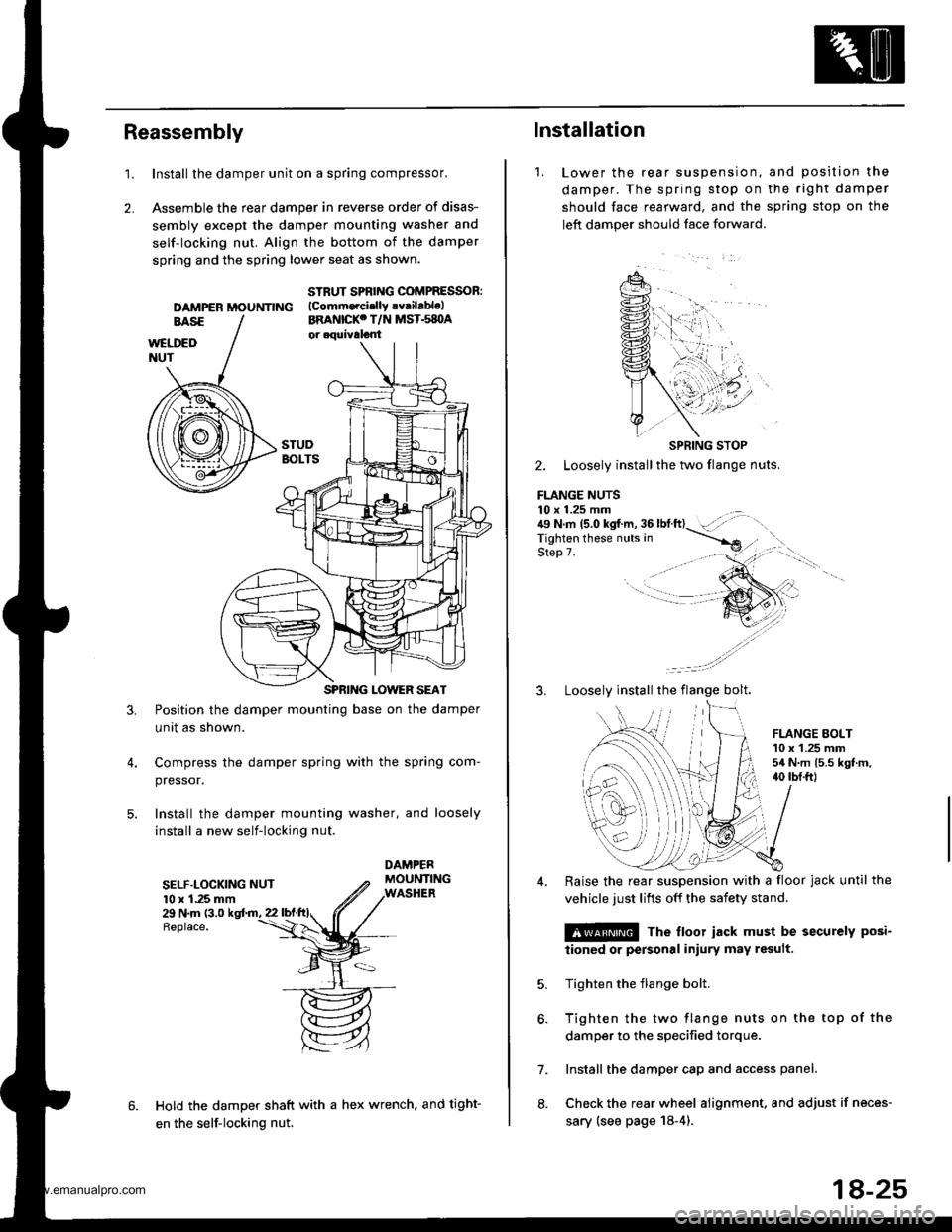

1.Install the damper unit on a spring compressor,

Assemble the rear damper in reverse order of disas-

sembly except the damper mounting washer and

self-locking nut. Align the bottom of the damper

spring and the spring lower seat as shown.

2.

DAMPER MOUNNNG

STRUT SPBING COMPRESSOR:(Commorcislly !v.ilablelBRANICKC T/N MST.s8OA

3.Position the damper mounting base on the damper

unit as shown.

Compress the damper spring with the spring com-

pressor.

Install the damper mounting washer, and loosely

install a new self-locking nut.

SELF.LOCKING NUT10 x 1.25 mm29 N.m (3.0

Replace.

Hold the damper shaft with a hex wrench, and tight-

en the self-locking nut.

1.

lnstallation

Lower the rear suspenston,

damper. The spring stop on

should face rearward, and the

left damper should face forward.

and position the

the right damper

sprang stop on the

SPRING STOP

2. Loosely install the two flange nuts.

FLANGE NUTS10 x 1.25 mm . .:{9 N.m 15.0 kgf.m, 36 lbtft}- :',,-rigf't"n if'"""_nrr. in ----.-*

qla^ 7Step 7.

3. Loosely install the flange bolt.

FLANGE EOLT10 x 1.25 mm54 N.m 15.5 kgt.m,40 tbI.ft)

6.

7.

8.

Raise the rear suspension with a floor jack until the

vehicle just lifts off the safety stand.

@ The floor iack must be securely posi-

iioned or personal iniury may result.

Tighten the flange bolt.

Tighten the two flange nuts on the top of the

damper to the specified torque.

Install the damper cap and access panel.

Check the rear wheel alignment. and adjust if neces-

sary (see page 18-4).

18-25

www.emanualpro.com