engine cover HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 66 of 1395

lgnition System

5.

lgnition Timing Inspection and Setting

2.

1.Check the idle speed, and adjust it if necessary (see

section 1 1).

Pull out the service check connector 2P (BRN and

BLK wires) from the connector holder located under

the dash on the front passenger side, then connect

the scs service connector (P/N 07PAz - 0010100) to

it.

Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in N or E, Mff in neutral) until the

radiator fan comes on, then let it idle.

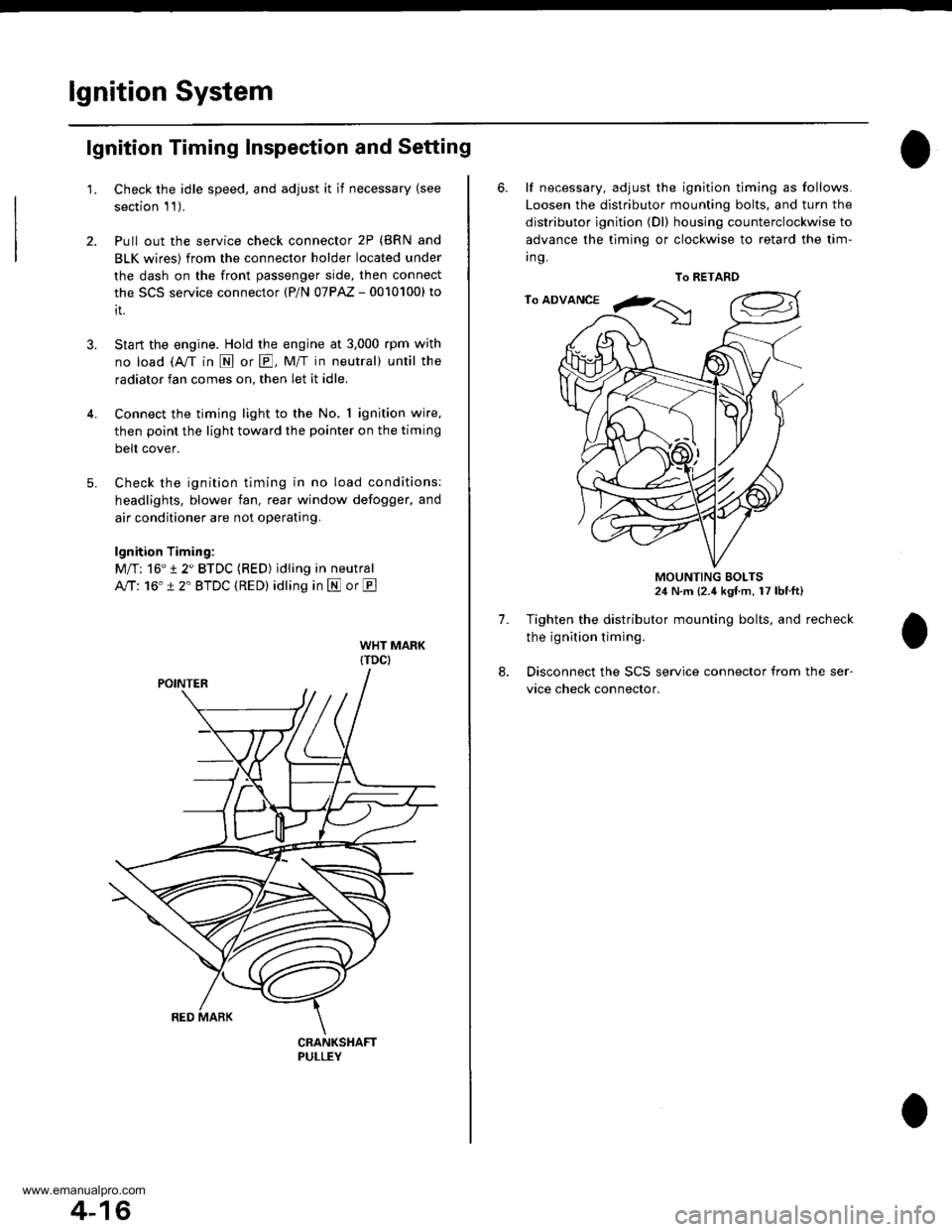

Connect the timing light to the No. I ignition wire,

then point the light toward the pointer on the timing

belt cover.

Check the ignition timing in no load conditions:

headlights, blower fan, rear window defogger, and

air conditioner are not operating.

lgnition Timing:

M/T: 16" 12" BTDC (RED) idling in neutral

AlTt'16" !2" BTDC (RED) idling in E or E

CRANKSHAFTPULLEY

4-16

6. lf necessary, adjust the ignition timing as follows.

Loosen the distributor mounting bolts, and turn the

distributor ignition (Dl) housing counterclockwise to

advance the timing or clockwise to retard the tim-

t no,

7.

8.

MOUNTING BOLTS24 N.m {2.4 kgf m, 17 lbtft}

Tighten the distributor mounting bolts, and recheck

the ignition timing.

Disconnect the SCS service connector from the ser-

vice check connector.

To RETARD

www.emanualpro.com

Page 79 of 1395

From previous page

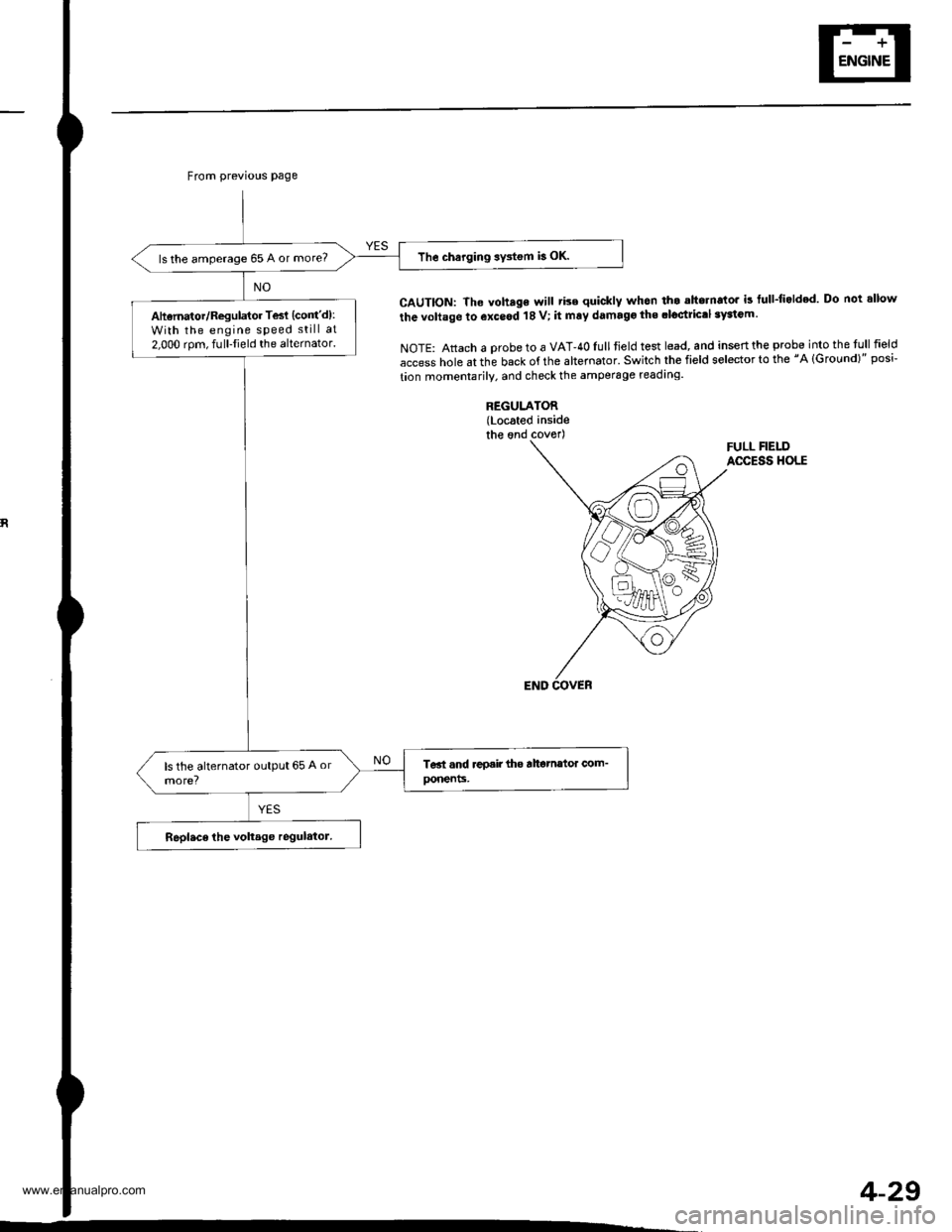

The charging sy3tem b OK.ls the amperage 65 A or more?

Aharnator/Regulator Tesl (cont'd):

With the engine speed still at

2.000 rom, fulllield the alternator.

CAUTION: The voh.ge will tise quickly whon th. ahornato. is tull-li.lded Do not allow

the voltage to exceod 18 V; it mry damago the .loctrictl 3yaiGm.

NOTE: Attach a probe to a VAT-40Iull tield test lead, and inseft the probe into the tull field

access hole at the back of the altemator' Switch the field selector to the "A lGround)" posi-

tion momentarily. and check the amperage readrng.

REGULATOR(Located insidethe ond coverlFULL FIELDACCESS HOLE

4-29

www.emanualpro.com

Page 98 of 1395

Engine RemovaUlnstallation

Removal

@a Make sure iacks and safety stands are placed properly

and hoist brackets are attached to the correct oosi-

tions on the engine.

. Make sure the vehicle will not roll oft stands and fall

while you are working under it.

NOTEI

. Use fender covers to avoid damaging painted sur-

faces.

o To avoid damage. unplug the wiring connectors care-

fully while holding the connector portion.

lvlark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

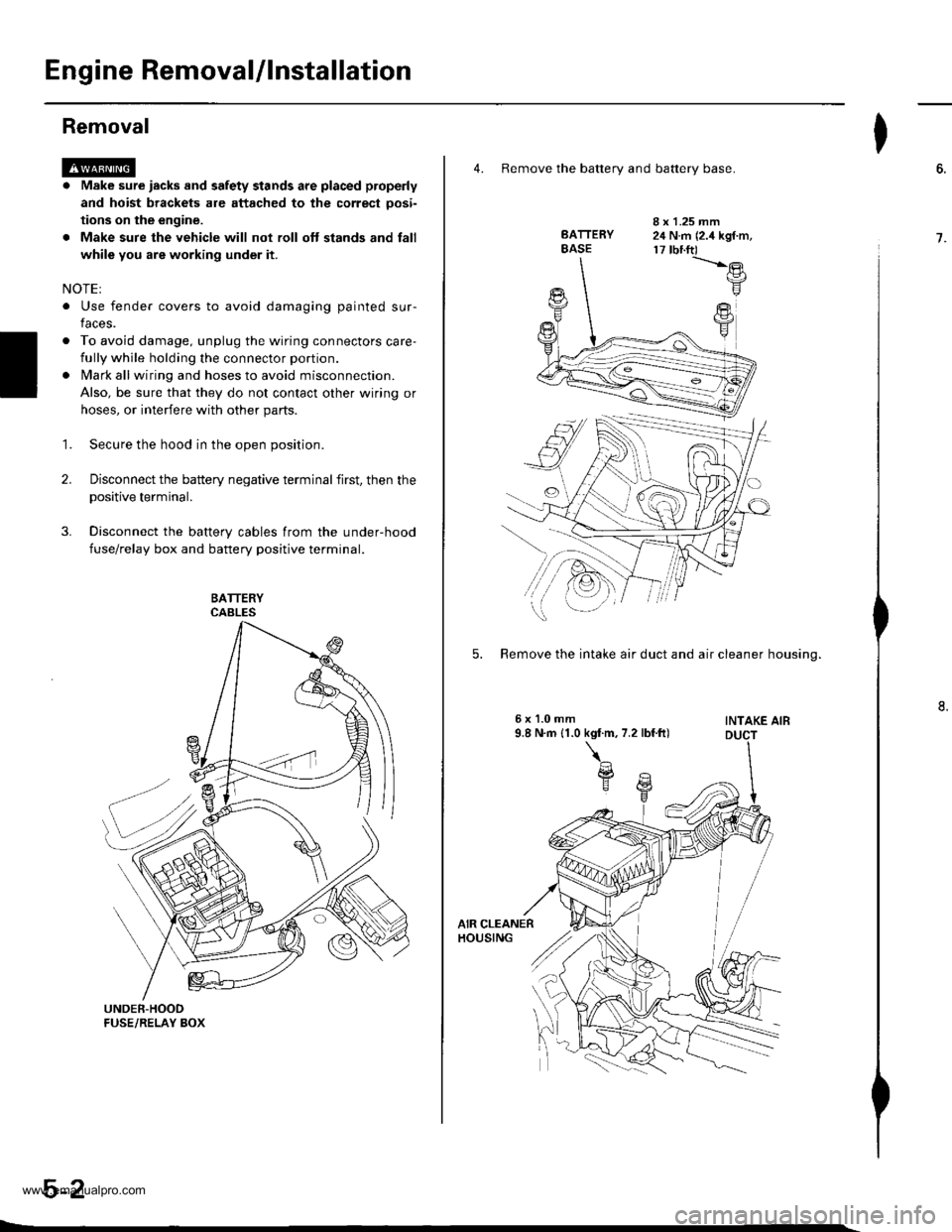

Secure the hood in the open position.

Disconnect the battery negative terminal first, then the

positive terminal.

Disconnect the battery cables from the under-hood

fuse/relay box and battery positive terminal.

1.

2.

4. Remove the batterv and batterv base.

BATTERYBASE

I x 1.25 mm24 N.m (2.4 kgf.m,17 tbnft)-t'.-e

F

FY

5. Remove the intake air duct and air cleaner housino.

INTAKE AIB

I

6.

7.

www.emanualpro.com

Page 122 of 1395

1.

2.

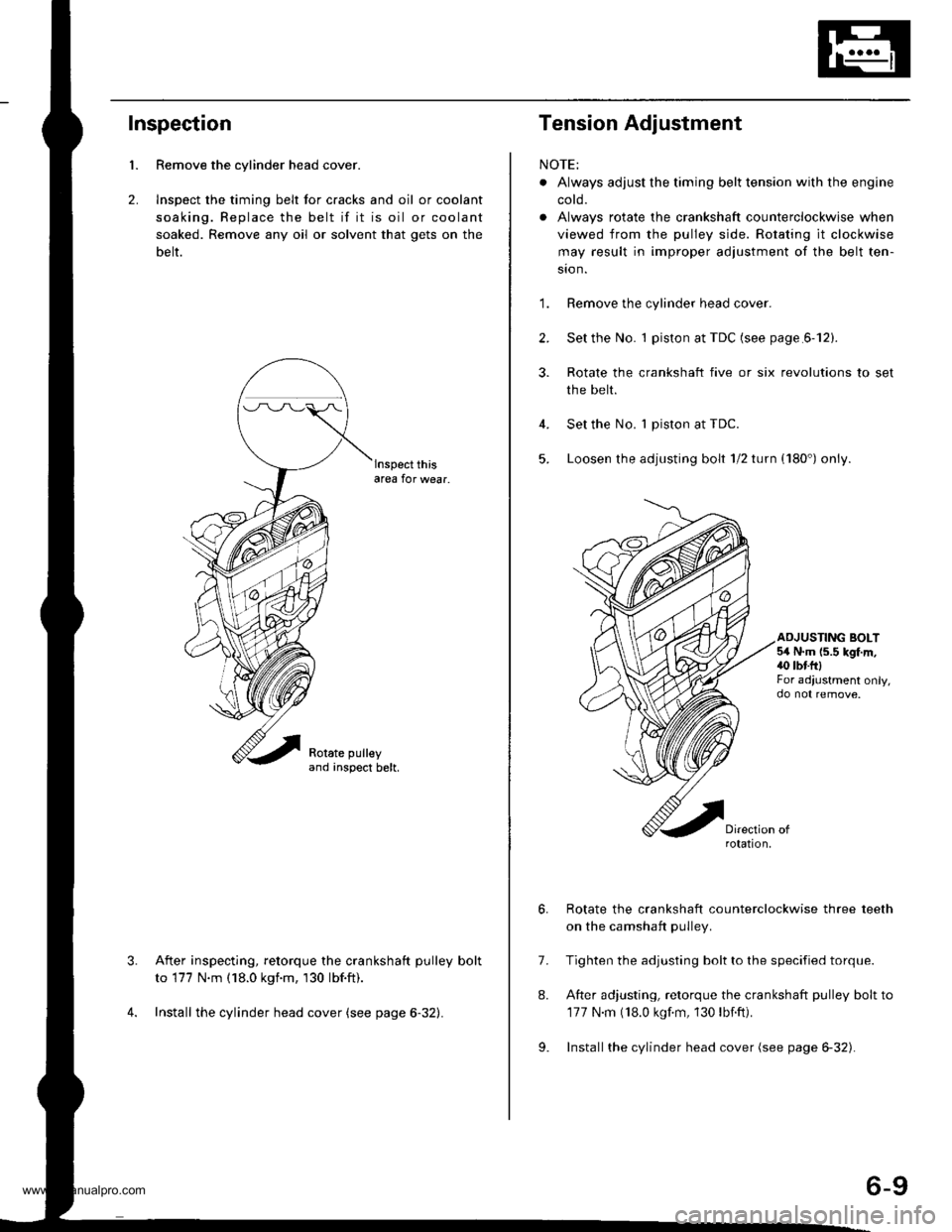

Inspection

Remove the cylinder head cover.

lnspect the timing belt for c.acks and oil or coolant

soaking. Replace the belt if it is oil or coolant

soaked. Remove any oil or solvent that gets on the

belt.

lnspect thisarea for wear.

After inspecting, retorque the crankshaft pulley bolt

to 177 N.m (18.0 kgnm, 130 lbf.ft).

Install the cylinder head cover (see page 6-32).

3.

Tension Adjustment

NOTE:

. Always adjust the timing belt tension with the engine

coto.

. Always rotate the crankshaft counterclockwise when

viewed from the pulley side. Rotating it clockwise

may result in improper adiustment of the belt ten-

sion.

'1. Remove the cylinder head cover

2. Set the No. 1 piston at TDC (see page.6-12).

3. Rotate the crankshaft five or six revolutions to set

the belt.

Set the No. 1 piston at TDC.

Loosen the adjusting bolt 1/2 turn (180') only.

4.

5.

ADJUSTING BOLT5,4 N.m (5.5 kgf.m,40 tbtftlFor adiustment only,

7.

8.

Rotate the crankshaft counterclockwise three teeth

on the camshaft pulley.

Tighten the adjusting bolt to the specified torque.

After adjusting, retorque the crankshaft pulley bolt to

177 N.m (18.0 kgf.m, 130 lbf.ft).

Installthe cylinder head cover (see page 6-32).9.

rotation,

6-9

www.emanualpro.com

Page 127 of 1395

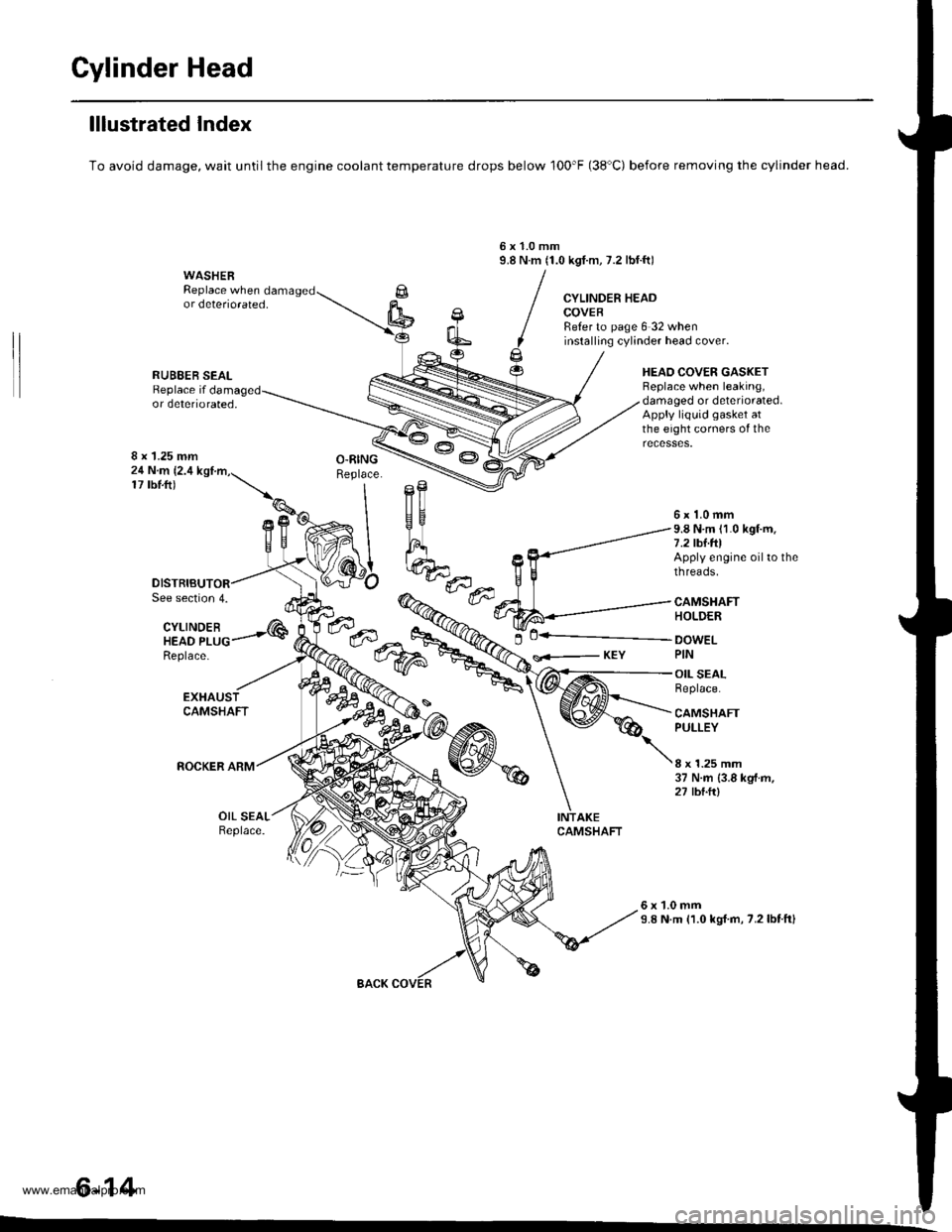

Gylinder Head

lllustrated Index

To avoid damage, wait until the engine coolant temperature drops below 100'F (38'C) before removing the cylinder head.

6x1.0mm9.8 N.m (1.0 kgI.m, 7.2 lbf.ft)WASHERReplace when damagedor deteriorated,CYLINDER HEADCOVEBReter to page 6 32 wheninstalling cylinder head cover.

HEAO COVER GASKETBeplace when leaking,damaged or deteriorated.Apply liquid gasket atthe eight corners of the

RUBEER SEALReplace ifor deteriorated,

8 x 1.25 mm24 N.m (2.4

17 tbtft)

See section 4.

CYLINDEBHEAD PLUGReplace-

---..-@0+---.."...-

s<-- KEY

6x1.0mm9.8 N.m (1.0 kgf.m.7.2 tbf.foApply engine oil to thethreads.

CAMSHAFTHOLDER

DOWELPIN

OIL SEALReplace.

CAMSHAFTPULLEY

8 x 1.25 mm37 N.m {3.8 kgf.m,27 tbtft)

OIL SEALReplace.

6x1.0mm9.8 N.m (1.0 kgl.m, 7.2lbtftl

6-14

www.emanualpro.com

Page 129 of 1395

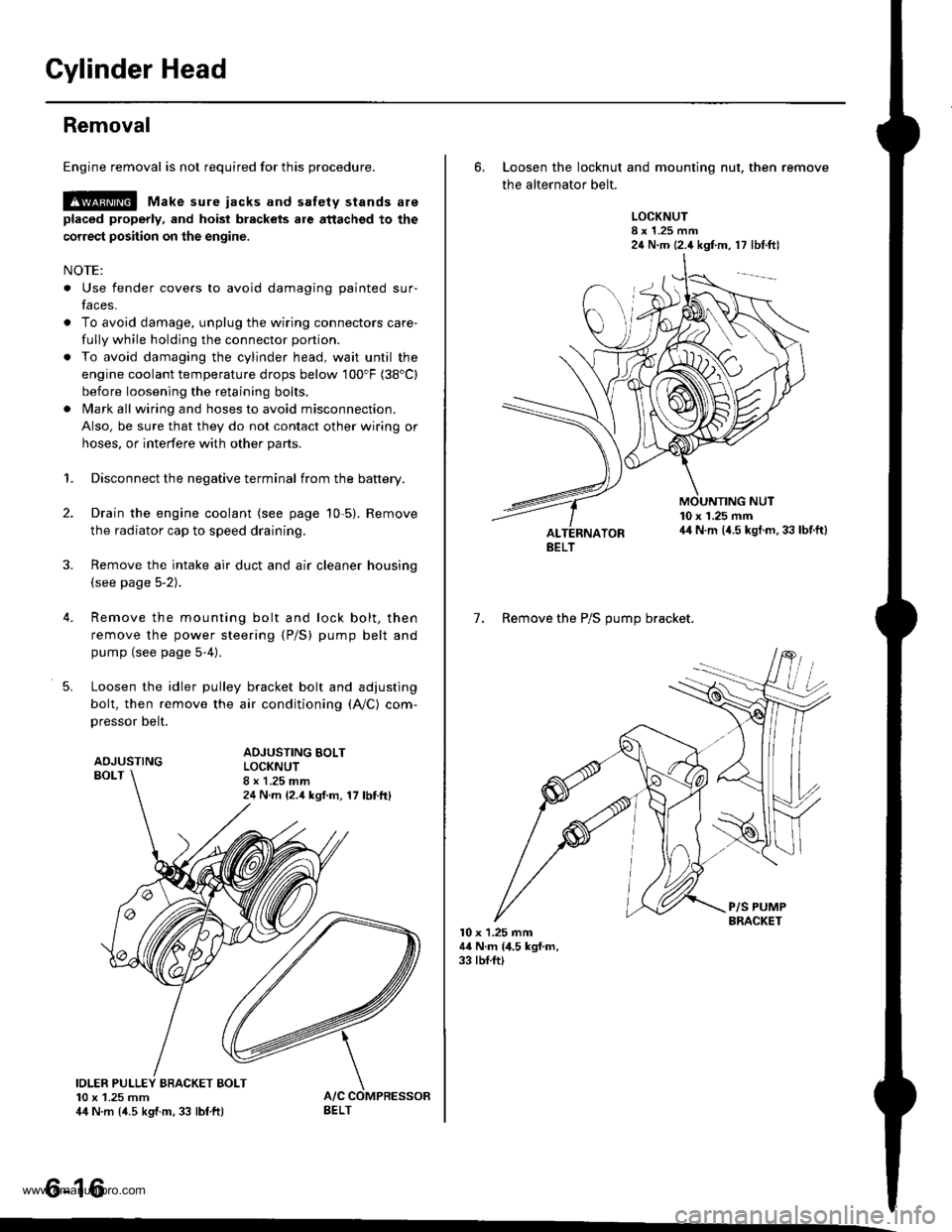

Gylinder Head

Removal

Engine removal is not required for this procedure.

l!@ Make sure iacks and safety stands are

placed properly, and hoist blackels ale attachgd to the

correct position on the engine.

NOTE:

o Use fender covers to avoid damaging painted sur-

faces.

o To avoid damage, unplug the wiring connectors care-

fully while holding the connector portion.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F (38'C)

before loosening the retaining bolts.

. Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

2.

4.

5.

1.Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5). Remove

the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing(see page 5-2).

Remove the mounting bolt and lock bolt, then

remove the power steering (P/S) pump belt and

pump (see page 5-4).

Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A,/C) com,

pressor belt.

ADJUSTINGBOLT

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N m {2.4 ksf.m, 17 lbttt}

IOLER PULLEY BBACKET BOLT10 x 1.25 mm44 N.m {4.5 kgtm, 33 lbf ft)

tt aAo-Io

6. Loosen the locknut and mounting nut, then remove

the alternator belt.

LOCKNUT8 x 1.25 mm24 N.m (2.4 kgf.m, 17 lbt.ftl

10 x 1.25 mm44 N.m (4.5 kgt.m. 33 lbf.ft)

7. Remove the P/S OUmo bracket.

l0 x 1.25 mm44 N.m (4.5 kgf.m,33 rbf.ft)

BELT

www.emanualpro.com

Page 132 of 1395

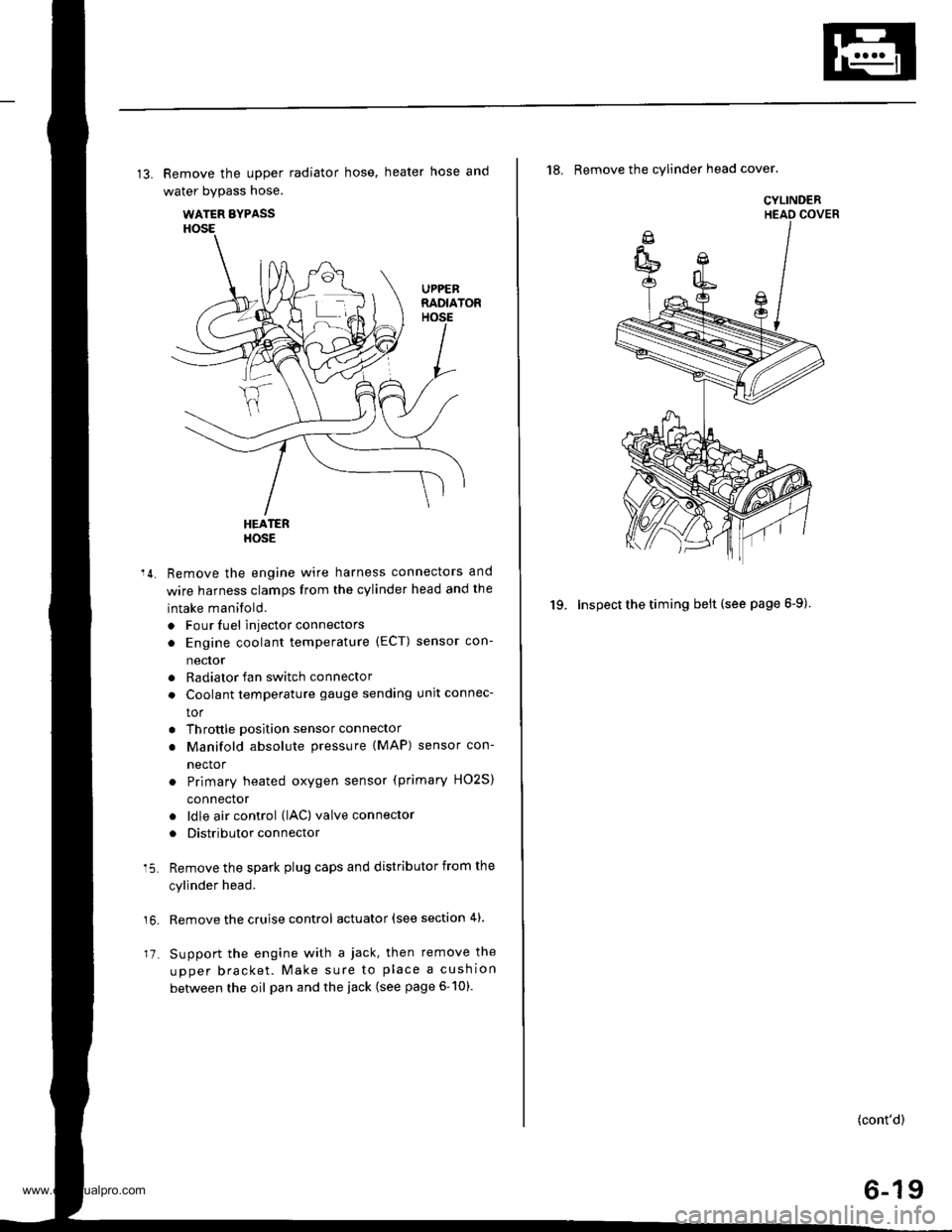

13. Remove the upper radiator hose, heater hose and

water bypass hose.

WATER BYPASS

UPPEBRADIATORHOSE

17

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

neclor

. Radiator fan switch connector

. Coolant temperature gauge sendlng unlt connec-

tor

. Throttle position sensor connector

. Manifold absolute pressure {MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

ldle air control (lAC) valve connector

Distributor connector

Remove the spark plug caps and distributor from the

cylinder head.

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil pan and the iack (see page 6-10).

a

18. Remove the cylinder head cover.

19. Inspect the timing belt (see page 6-9).

CYLINDER

(cont'd)

6-19

www.emanualpro.com

Page 146 of 1395

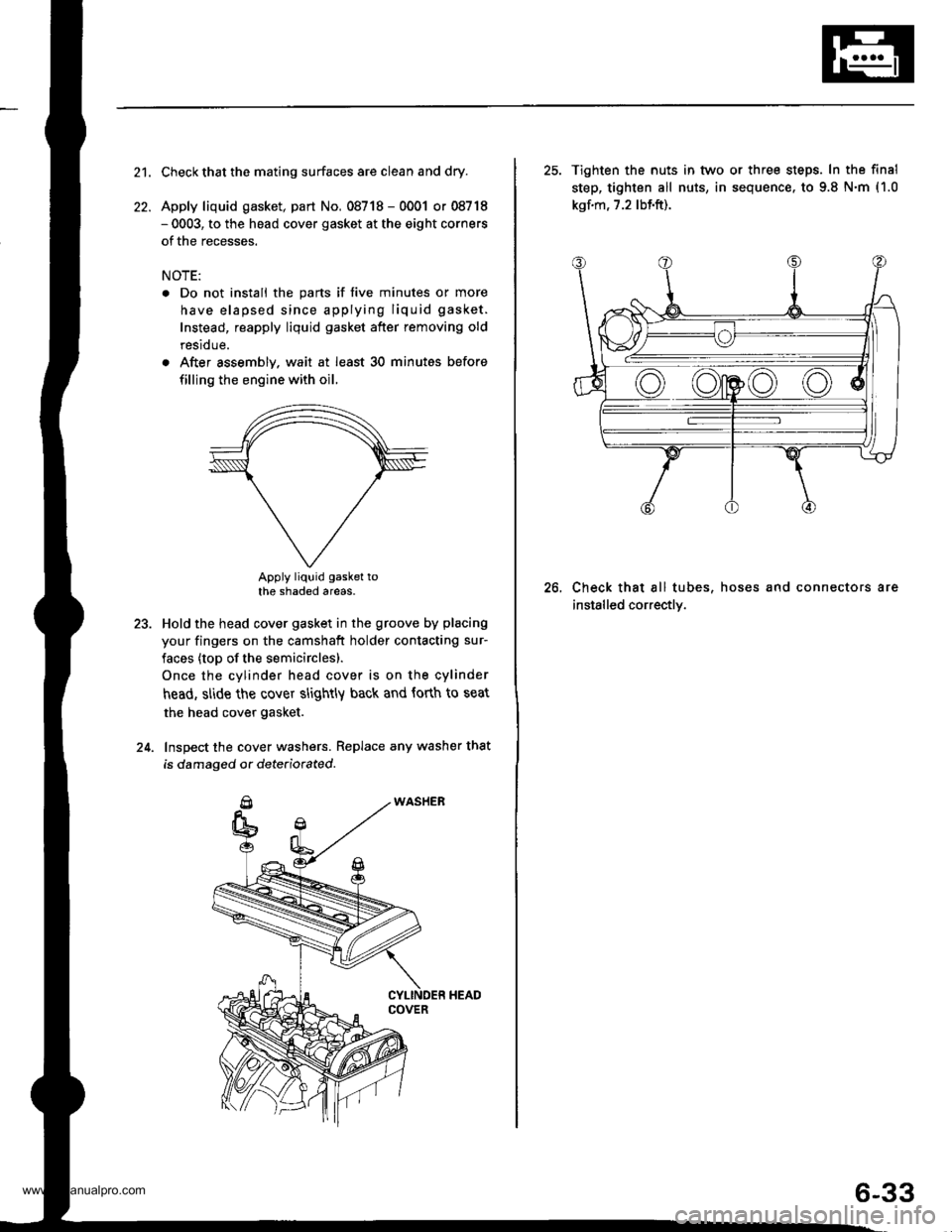

21.

22.

Check that the mating surfaces are clean and dry.

Apply liquid gasket, part No. 08718 - 0001 or 08718- 0003, to the head cover gasket at the eight corners

of the recesses.

NOTE:

. Do not install the parts if five minutes or more

have elapsed since applying liquid gasket.

Instead, reapply liquid gasket after removing old

residue.

. After assembly. wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket tothe shaded areas.

Hold the head cover gasket in the groove by placing

your fingers on the camshaft holder contacting sur-

faces (top of the semicirclesl.

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

Inspect the cover washers. Replace any washer that

is damaged or dete(iorated.

23.

24.

25. Tighten the nuts in tvvo or three steps. In the final

step, tighten all nuts, in sequence. to 9.8 N.m (1.0

kgf.m, 7.2 lbf.ft).

Check that all tubes, hoses and connectors are

installed correctly.

26.

6-33

www.emanualpro.com

Page 149 of 1395

lllustrated lndex

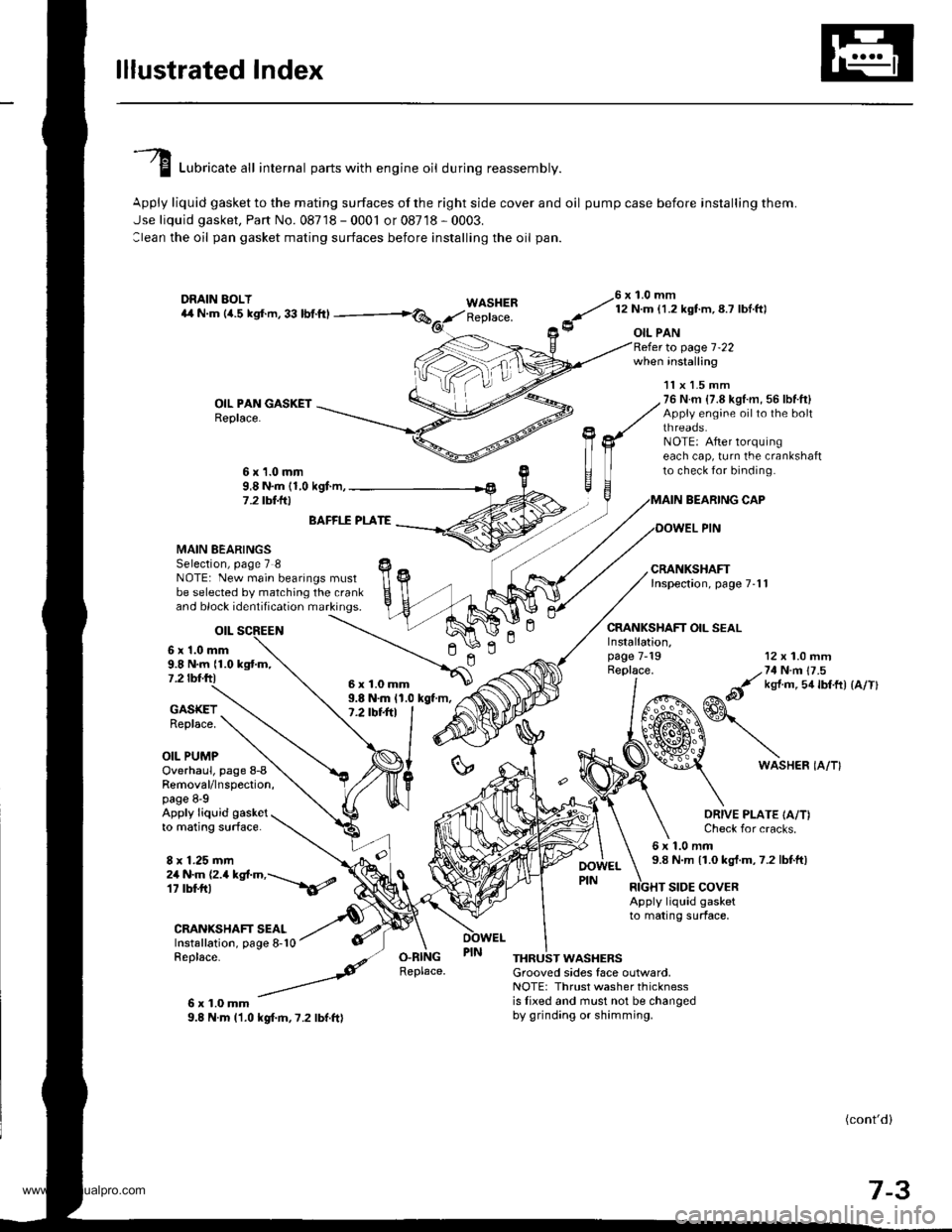

I Luori""t" "tl internal parts with engine oil during reassembly.

Apply liquid gasket to the mating surfaces of the right side cover and oil pump case before installing them.

Jse liquid gasket, Part No. 08718 - 0001 or 08718 - 0003.

:lean the oil pan gasket mating surfaces before installing the oil pan.

WASHERReplace.

76 x 1.0 mm

y' t:n- l.zxstm, 8.7 lbl ftl

9 oIL PAN

OIL PAN GASKETReplace.

to page 1-22when installing

BEARING CAP

OOWEL PIN

CRANKSHAFT OIL SEAL

11x 1.5 mm76 N.m {7.8 kgl.m, 56 lbf.ft}Appiy engine oilto the boltthreaos.NOTE: After lorquingeach cap, turn the crankshaftto check for binding.6x1.0mm9,8 N.m (1,0 kgf.m,7 .2 tbt.lrl

n

MAIN BEARINGSSelection, page 7 8NOTE: New main bearings mustbe selected by matching the crankand block identification markings.

otL

6 x'1.0 mm9.8 N.m {1.0 kgtm,7.2 tbf.ftl

BAFFI.f PLATE

9.8 N.m 11.0 kgt m,7.2 tbt+tl

12 x 1.0 mm

/,71N n 17 .5

&it ks{ m 5a lbtft) {a/Tl

GASKETReplace.

OIL PUMP

Installation,page 7-19Replace.

ln

6WASHER IA/T}Overhaul, page 8-8Removal/lnspection,page 8-9Apply liquid gasketto mating surface.

8 x 1.25 mm

ORIVE PLATE IA/T)Check for cracks.

6x1.0mm9.8 N.m 11.0 kgt.m,7.2 lbtft)2a N.m (2.a kgt.m,---\6/

CRANIGHAFT SEALInstallation, page 8-10Replace-

6x1.0mm9.8 N.m l'1.0 kgf.m,7.2 lbf.ft)

RIGHT SIDE COVERApply liquid gasketto mating surface,

O.RINGReplace.THRUST WASHERSGrooved sides face outlvard,NOTE: Thrust washer thicknessis lixed and must not be changedby grinding or shimming.

(cont'd)

7-3

6x1.0mm

www.emanualpro.com

Page 167 of 1395

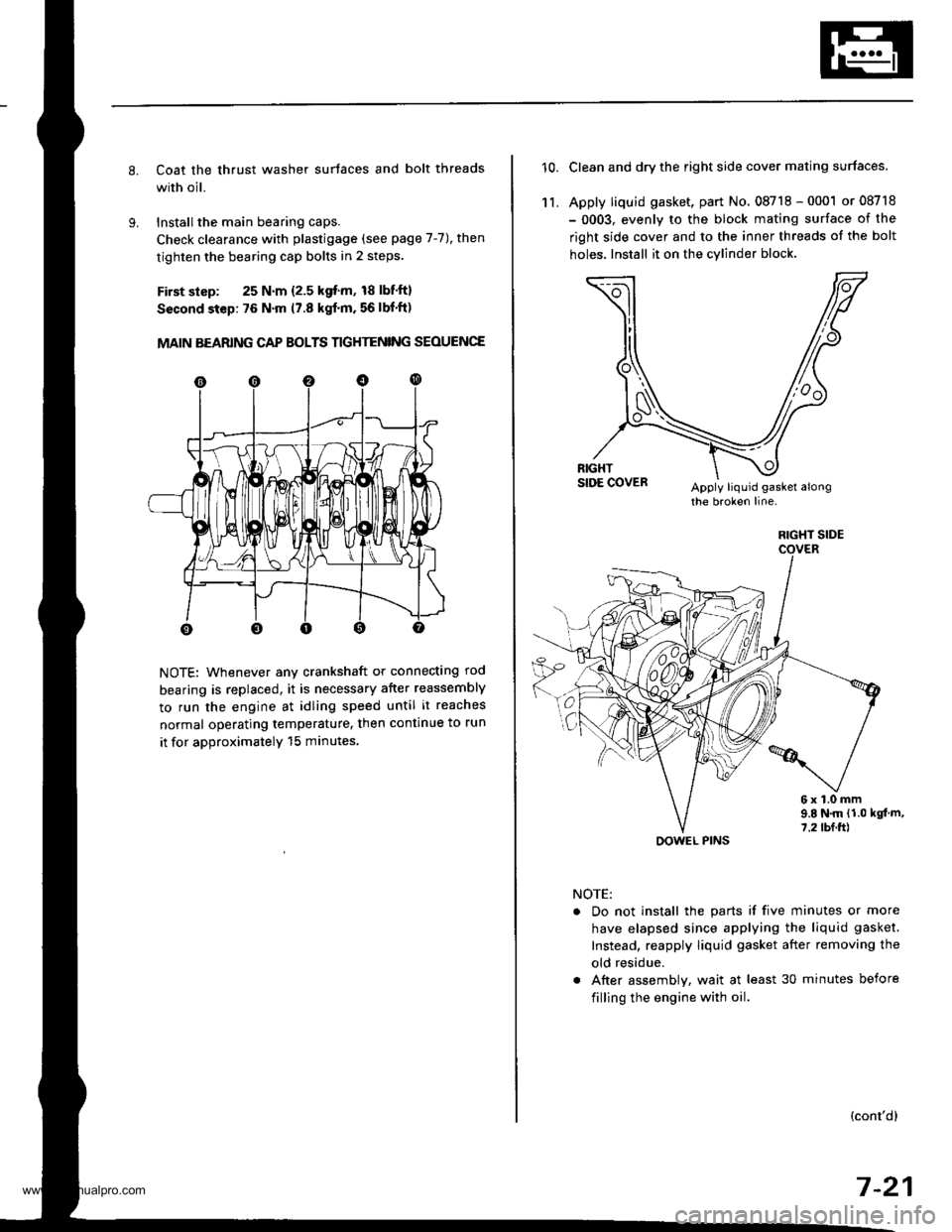

Coat the thrust washer surtaces and bolt threads

with oil.

Installthe main bearing caps.

Check clearance with plastigage (see page 7-7), then

tighten the bearing cap bolts in 2 steps.

First slsp: 25 N.m {2.5 kgf'm, 18 lbf'ft}

Sscond step: 76 N'm (7.8 kgf'm. 56 lbf'ft)

MAIN BEARING CAP BOLTS TIGHTENING SEOUENCE

NOTE: Whenever any crankshaft or connecting rod

bearing is replaced, it is necessary after reassembly

to run the engine at idling speed until it reaches

normal operating temperature, then continue to run

it for approximatelY 15 minutes.

10.Clean and dry the right side cover mating surfaces.

Apply liquid gasket, part No. 08718 - 0001 or 08718

- 0003, evenly to the block mating surface of the

right side cover and to the inner threads of the bolt

holes. Install it on the cylind€r block

11,

6x1.0mm9.E N.m {1.0 kgt m,7.2 tbf.ft)

NOTE:

. Do not install the parts if five minutes or more

have elapsed since applying the liquid gasket.

Instead, reapply liquid gasket after removing the

old residue.

. After assembly, wait at least 30 minutes before

filling the engine with oil.

(cont'dl

7-21

RIGHT SIDE

OOWEL PINS

www.emanualpro.com