ECU HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1130 of 1395

Troubleshooting

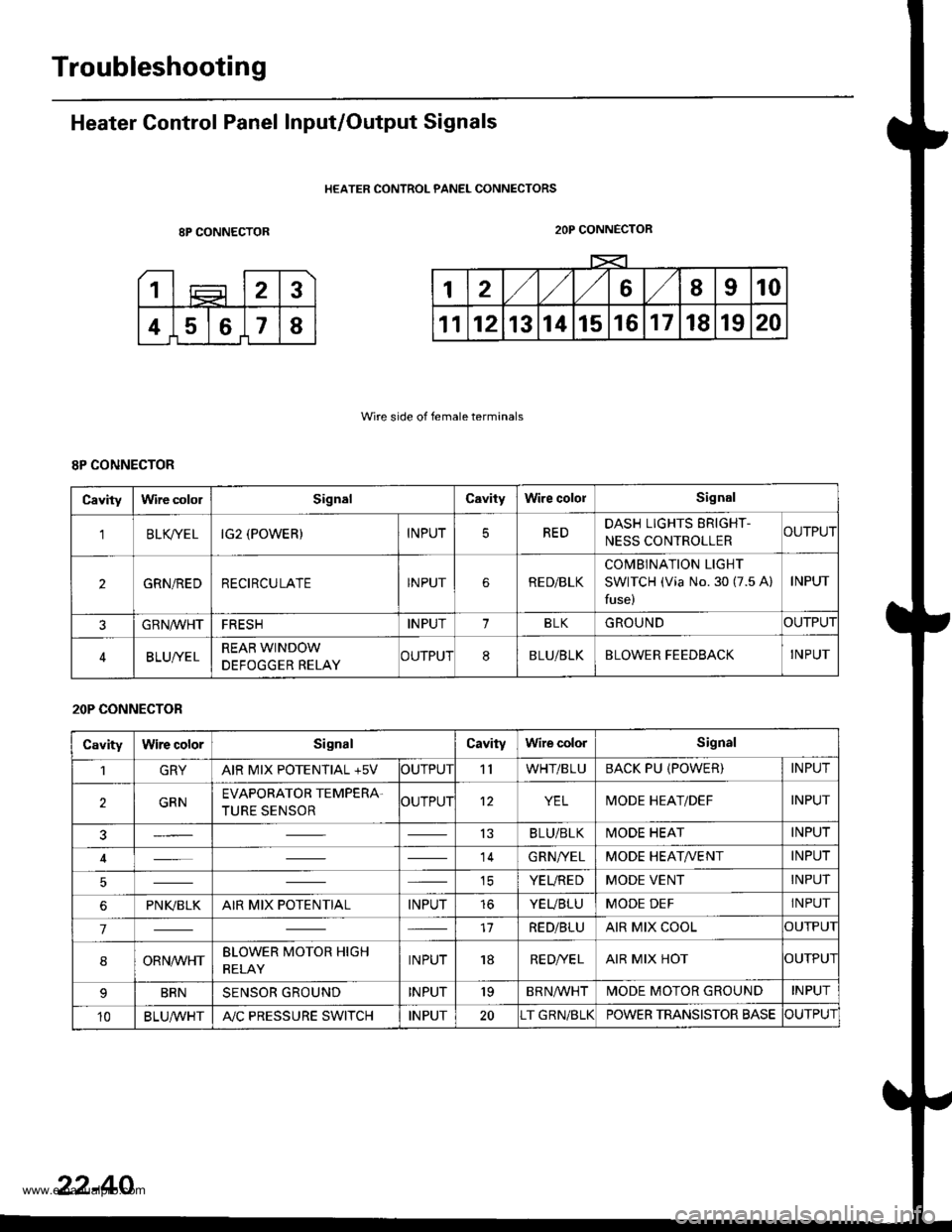

Heater Control Panel Input/Output Signals

HEATER CONTROL PANEL CONNECTORS

8P CONNECTOR

Wire side of female terminals

2OP CONNECTOR

8P CONNECTOR

Cavitylrvire cololSignalCavityWire cololSignal

'lBLK/TE LIG2 (POWER)INPUTREDDASH LIGHTS ERIGHT-

NESS CONTROLLERCUTPUT

2GRN/REDRECIRCULATEINPUTRE D/BLK

COMBINATION LIGHT

SWITCH (Via No. 30 (7.5 A)

fuse)

INPUT

GRN/VVHTFRESHINPUT1BLKGROUNDOUTPUT

BLUI/ELREAR WINDOW

DEFOGGER RELAYCUTPUT8BLU/BLKBLOWER FEEDBACKINPUT

20P CONNECTOR

CavityWire colorSignalCavityWire colorSignal

1GRYAIR MIX POTENTIAL +5VOUTPUT'llWHT/BLUBACK PU (POWER)INPUT

2GRNEVAPORATOR TEMPERA.

TURE SENSOROUTPUT12YELMODE HEAT/DEFINPUT

13BLU/BLKMODE HEATINPUT

14GRN/YELMODE HEAT/VENTINPUT

ICYEUREDMODE VENTINPUT

6PNI(BLKAIR MIX POTENTIALINPUTtoYEUBLUMODE DEFINPUT

717RED/BLUAIR MIX COOLOUTPUI

8ORNrur'HTBLOWER MOTOR HIGH

RELAYINPUT18RE D/VE LAIR MIX HOTOUTPUI

BRNSENSOR GROUNDINPUT'19BRNA/VHTIVIODE MOTOR GROUNDINPUT

10BLU,ryVHTA"/C PRESSURE SWITCHINPUT20T GRN/BLKPOWER TRANSISTOR BASECUTPUT

22-40

www.emanualpro.com

Page 1141 of 1395

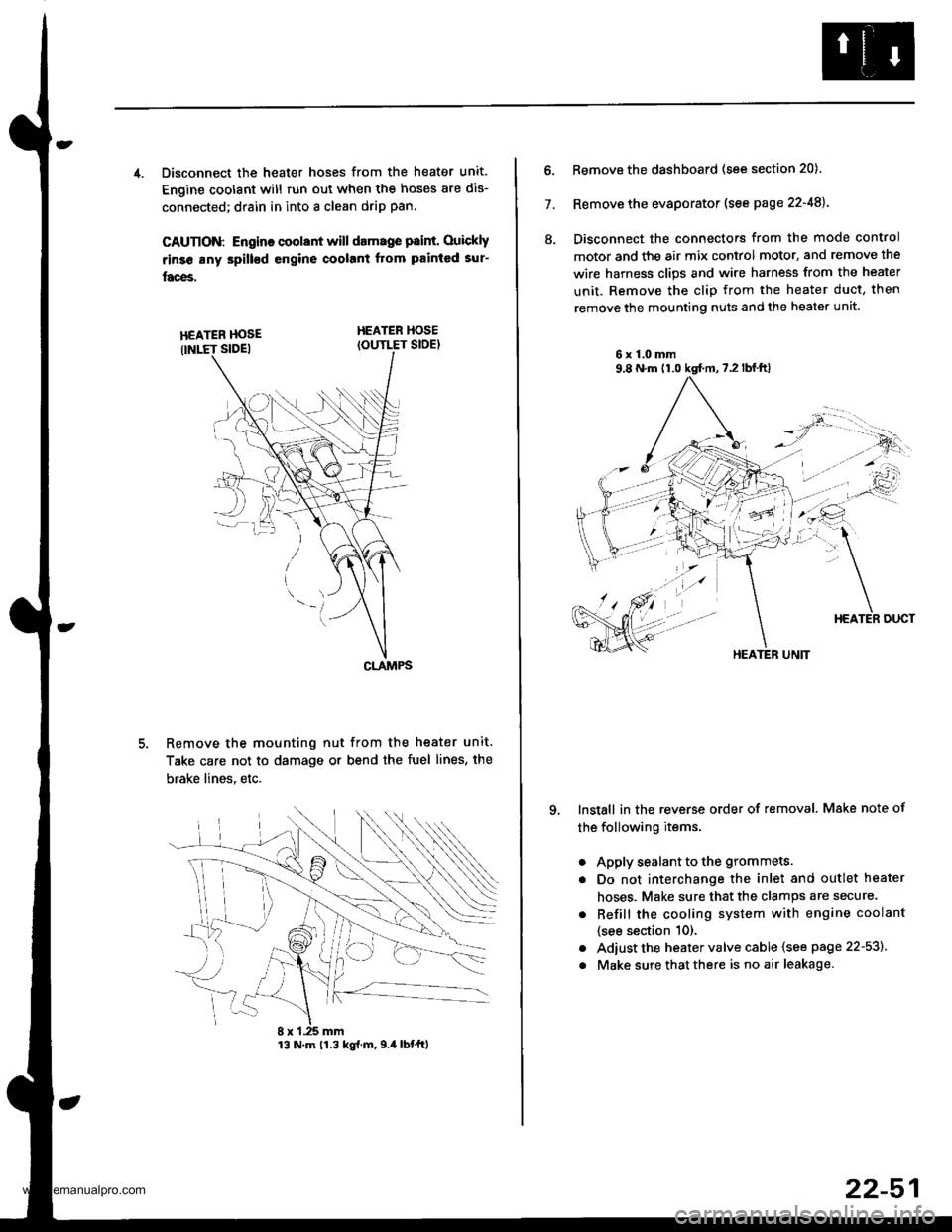

4. Disconnect the heater hoses from the heater unit.

Engine coolant will run out when the hoses are dis-

connected; drain in into a clean drip pan.

CAUTION: Engino coolant will damage p8int. Ouickly

rinse any spill€d engine coolant Itom painted sur-

faces.

HEATER HOSEIOUTLET SIDE)

Remove the mounting nut from the heater unit.

Take care not to damage or bend the fuel lines, the

brake lines. etc.

CLAMPS

13 N.m 11.3 kg{.m,9.4 lbtftl

22-51

7.

ll.

Remove the dashboard (see section 20).

Remove the evaporator (see page 22-48).

Disconnect the connectors from the mode control

motor and the air mix control motor, and remove the

wire harness clips and wire harness from the heater

unit. Remove the clip from the heater duct, then

remove the mounting nuts and the heater unit

6x1.0mm9,8 N.m (1.0 kgt m,7.2lblft)

qInstall in the reverse order of removal. Make note of

the following items.

a

a

a

a

Apply sealant to the grommets.

Do not interchange the inlet and outlet heater

hoses. Make sure that the clamps are secure.

Refill the cooling system with engine coolant

{see section 10).

Adiust the heater valve cable (see page 22-53).

Make sure that there is no air leakage.

HEATER UNIT

www.emanualpro.com

Page 1160 of 1395

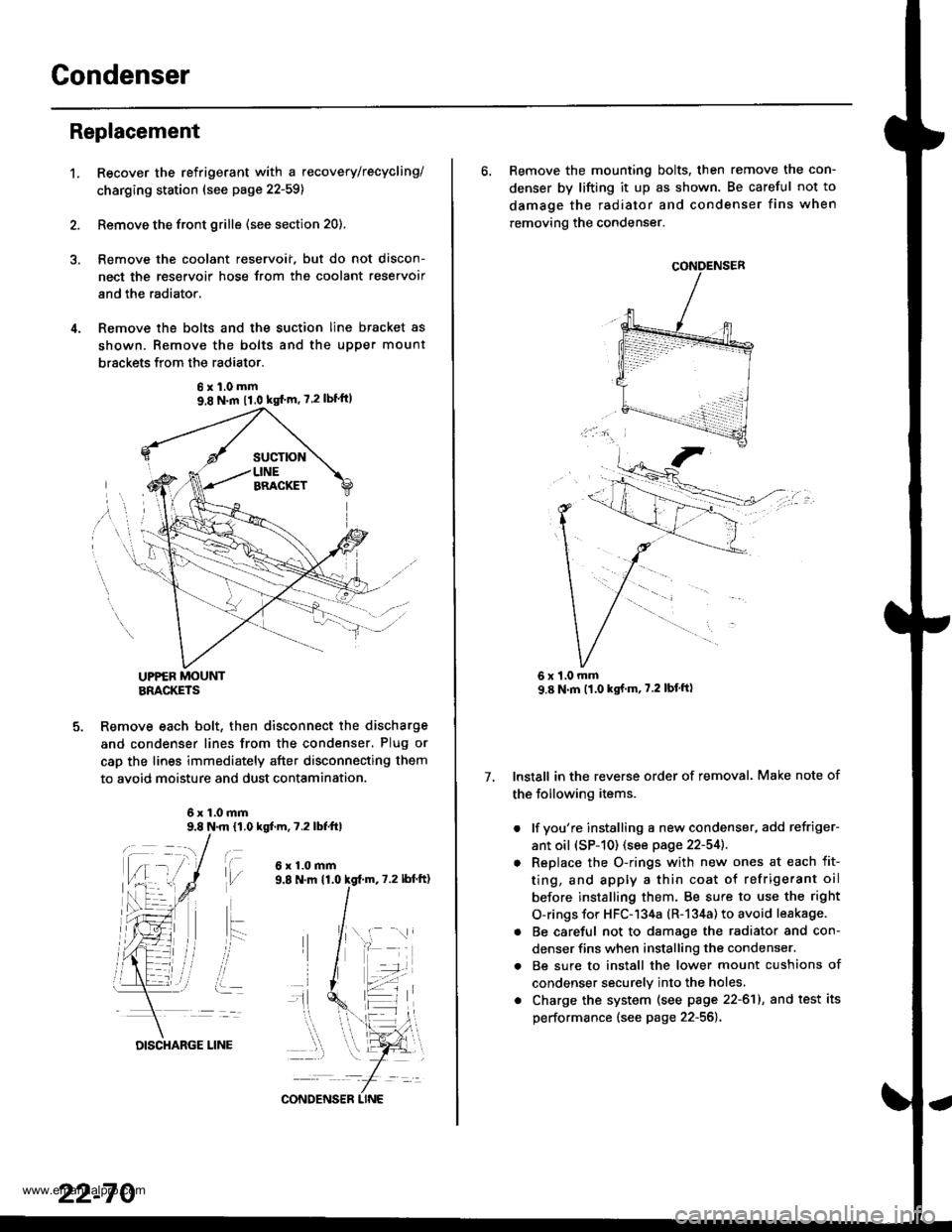

Gondenser

't.

Replacement

Recover the refrigerant with a recovery/recycling/

charging ststion (see page 22-59)

Remove the front grille (see section 20).

Remove the coolant reservoii, but do not discon-

nect the reservoir hose Jrom the coolant reservoir

and the radiator.

Remove the bolts and the suction line bracket as

shown. Remove the bolts and the upper mount

brsckets from the radiator.

UPPER MOUNTBRACKETS

Remove each bolt, then disconnect the discharge

and condenser lines from the condenser, Plug or

cap the lines immediately after disconnecting them

to avoid moisture and dust contamination.

6x1.0mm9.8 N.m 11,0 kgf.m, 7.2 lbfttl

t\,l/

ait- -:

i..

6x1.0mm

6xl.0mm9,8 N.m 11.0 kgf'm' 7.2lbf'ft)

22-70

DISCHARGE LINE

CONDENS€R LINE

6. Remove the mounting bolts, then remove the con-

denser by lifting it up as shown. Be careful not to

damage the radiator and condenser fins when

removing the condenser.

Install in the reverse order of removal. Make note of

the following items.

. lf you're installing a new condenser, add refriger-

ant oil (sP-10) (see page 22-54]..

o Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them. Be sure to use the right

O-rings for HFC-134a (R-134a) to avoid leakage.

. Be careful not to damage the radiator and con-

denser fins when installing the condenser.

. Be sure to install the lower mount cushions of

condenser securely into the holes,

. Charge the system (see page 22-61), and test its

performance (see page 22-56).

7.

1,0 mm

www.emanualpro.com

Page 1164 of 1395

Troubleshooting

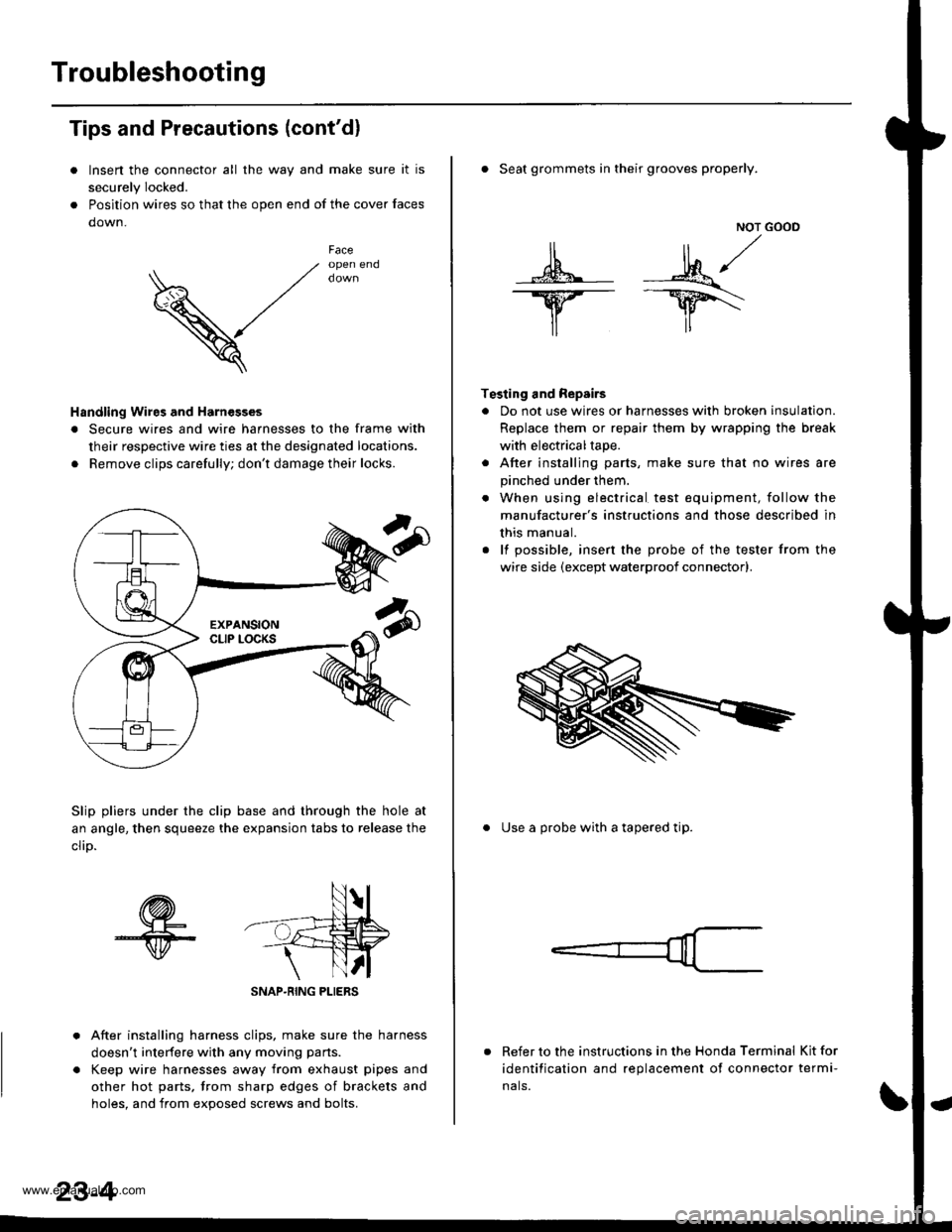

Tips and Precautions (cont'dl

Insen the connector all the way and make sure it is

securely Iocked.

Position wires so that the open end of the cover faces

down.

V

Faceopen end

Handling Wires and Harnesges

. Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

. Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clrD.

After installing harness clips, make sure the harness

doesn't interfere with any moving pans.

Keep wire harnesses away from exhaust pipes and

other hot parts, trom sharp edges of brackets and

holes. and from exoos€d screws and bolts.

NOT GOOD

A -M/

lr lr*

T€sting and Repairs

. Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electricaltape.

. After installing parts, make sure that no wires are

pinched under them.

. When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

. lf possible, insert the probe of the tester from the

wire side (except waterproof connector).

. Seat grommets in their grooves properly.

. Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nals.

www.emanualpro.com

Page 1165 of 1395

Five-step Troubleshooting

1.

3.

Verify The Complaint

Turn on all the components in the problem circuit to

verify the customer complaint. Note the symptoms.

Do not begin disassembly or testing until you have

narrowed down the problem area.

Analyze The Schematic

Look up the schematic for the problem circuit.

Determine how the circuit is supposed to work by

tracing the current paths from the power feed

through the circuit components to ground. lf several

circuits fail at the same time, the fuse or ground is a

likely cause,

Based on the symptoms and your understanding of

the circuit operation, identify one or more possible

causes of the problem.

lsolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis you made

in step 2. Keep jn mind that a logical, simple proce-

dure is the key to efficient troubleshooting. Test for

the most likely cause of failure first. Try to make

tests at points that are easily accessible,

Fix The Problem

Once the specific problem is identified, make the

repair. Be sure to use proper tools and safe proce-

dures.

Make Sure The Circuit Works

Turn on all components in the repaired circuit in all

modes to make sure you've fixed the entire prob-

lem. lf the problem was a blown fuse, be sure to

test all of the circuits on the fuse. lvlake sure no new

problems turn up and the original problem does nol

recur.

4.

O

Wire Color Codes

The following abbreviations are used to identify wire

colors in the circuit schematics:

WHT ............................. White

YEL,.............................. Yellow

BLK ..........,................... Black

BLU .............................. Blue

GRN .............................Green

RED .............................. Red

ORN .............................Oran9e

PNK.....,........................ Pink

BRN .............................. Brown

GRY .............................. Gray

PUR .........,.................... Purple

LT BLU ..................,...... Light Blue

LT GRN ........................ Light Green

The wire insulation has one color or one color with

another color stripe. The second color is the stripe.

WHT/BLK

www.emanualpro.com

Page 1180 of 1395

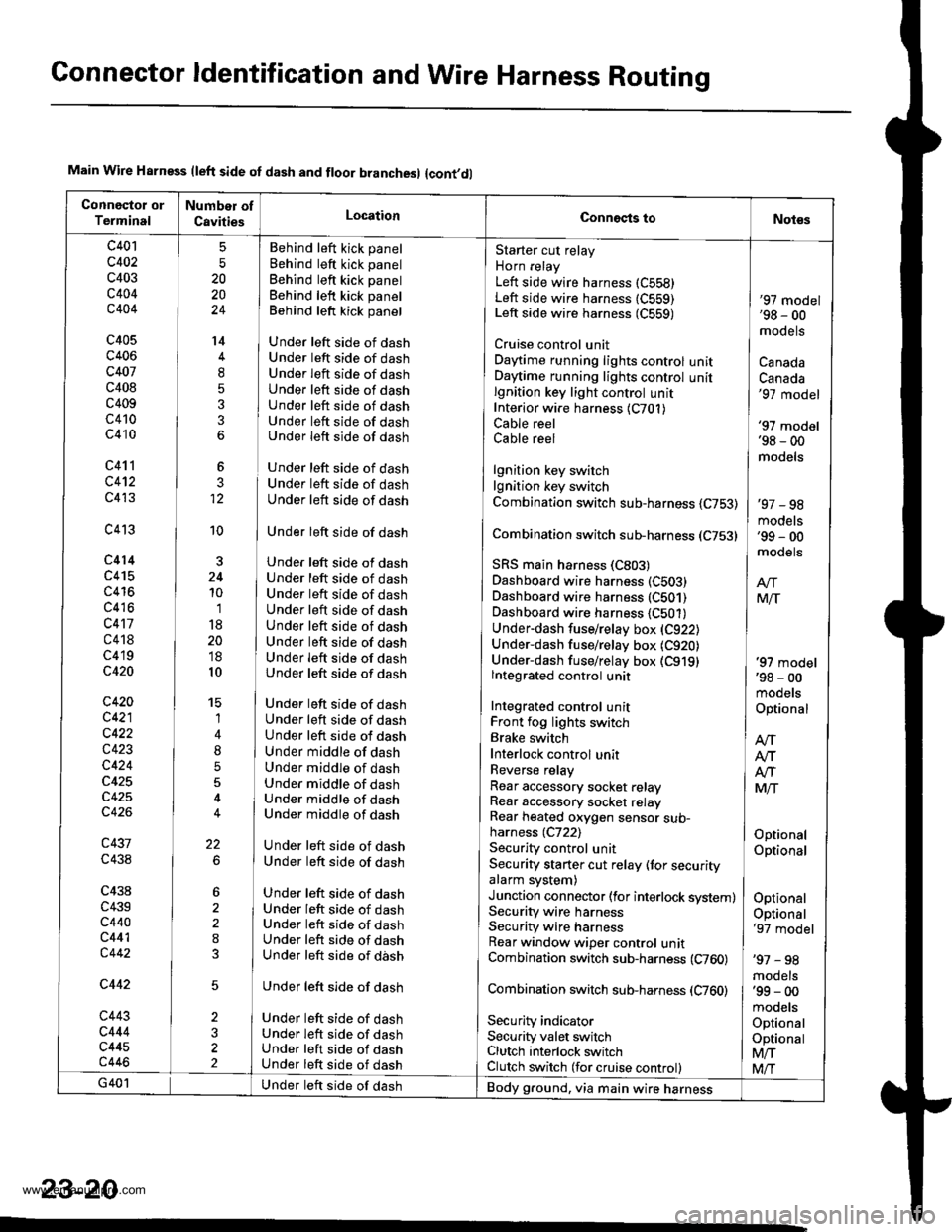

Connector ldentification and Wire Harness Routing

Main Wire Harn€ss (left side of dash and floor branchesl {cont,dl

c401

c402

c403

c404

c404

c405

c406

c407

c408

c409

c410

c410

c411

c412

c413

c413

c414

c415

c416

c416

c417

c418

c419

c420

c420

c421

c422

c423

c424

c425

c42A

c426

c437

c438

c438

c439

c440

c441c442

5

20

20

24

't4

8

5

3

12

10'1

18

20'18

10

15

1

4

8

5

5

22

Behind left kick panel

Behind left kick panel

Behind left kick panel

Behind left kick panel

Behind left kick panel

Under left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dash

Under left side of dashUnder left side of dashUnder left side of dash

Under left side of dash

Under left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dash

Under left side of dashUnder left side of dashUnder left side of dashUnder middle of dashUnder middle of dashUnder middle of dashUnder middle of dashUnder middle of dash

Under left side of dashUnder left side of dash

Under left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dash

Under left side of dash

Under left side of dashUnder left side of dashUnder left side of dashUnder left side of dash

Starter cut relay

Horn relay

Left side wire harness (C558)

Left side wire harness (C559)

Left side wire harness (C559)

Cruise control unitDaytime running lights control unitDaytime running lights control unitlgnition key light control unitInterior wire harness {C701)Cable reel

Cable reel

lgnition key switchlgnition key switch

Combination switch sub-harness {C753)

Combination switch sub-harness (C753)

SRS main harness (C803)

Dashboard wire harness (C503)

Dashboard wire harness (C501)

Dashboard wire harness {C501)Under-dash fuse/relay box (C922)

Under-dash fuse/relay box (C920)

Under-dash fuse/relay box (C919)

lntegrated control unit

Integrated control unitFront fog lights switchBrake switch

Interlock control unitReverse relay

Rear accessory socket relayRear accessory socket relayRear heated oxygen sensor sub-harness (C722)

Security control unitSecurity starter cut relay (for securityalarm system)

Junction connector (for interlock system)Security wire harnessSecurity wire harnessRear window wiper control unitCombination switch sub-harness (C760)

Combination switch sub-harness (C760)

Securlty indicatorSecurity valet switchClutch interlock switchClutch switch (for cruise control)

'97 model'98 - 00mooets

Canada

Canada'97 model

'97 model'98 - 00models

'97 - 98models'99 - 00

moqets

'97 model'98 - 00mooets

Optional

Optional

Optional

Optional

Optional'97 model

'97 - 98mooels'99 - 00models

OptionalOptional

Mfi

Mlr

Under left side of dashBody ground, via main wire harness

23-20

www.emanualpro.com

Page 1186 of 1395

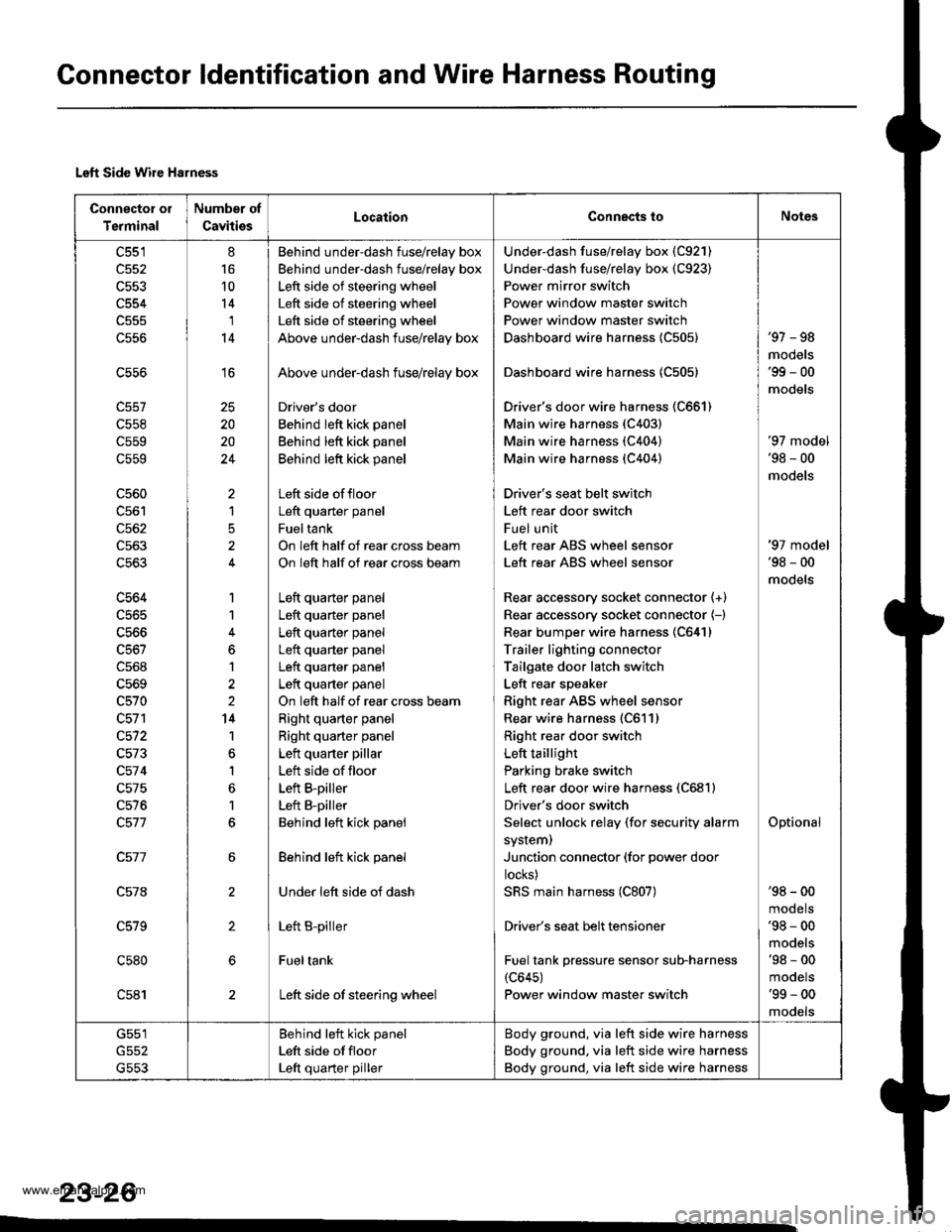

Connector ldentification and Wire Harness Routing

Left Side Wire Harness

Connector oI

Terminal

Number of

CavitiesLocaiionConnects toNot6s

c551

c552

c554

c556

c558

c559

c559

c560

c562

c563

c563

c564

c565

c566

c568

c569

c570

c572

c573

c57 4

c575

c576

c578

c579

c580

c581

8

16

10

14'I

14

16

20

20

24

)

1

5

1

1

6

1

2

14

1

1

6

1

6

Behind under-dash fuse/relay box

Behind under-dash fuse/relay box

Left side of steering wheel

Left side of steering wheel

Left side of steering wheel

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Driver's door

Behind left kick panel

Behind left kick panel

Behind left kick panel

Left side offloor

Left quaner panel

Fueltank

On left half of rear cross beam

On left half of rear cross beam

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

On left half of rear cross beam

Right quarter panel

Right quarter panel

Left quarter pillar

Left side of floor

Left B-piller

Left B-piller

Behind left kick panel

Behind left kick panel

Under left side of dash

Left B-piller

Fueltank

Left side of steering wheel

Under-dash fuse/relay box (C921)

Under-dash fuse/relay box (C923)

Power mirror switch

Power window master switch

Power window master switch

Dashboard wire harness {C505)

Dashboard wire harness 1C505)

Driver's door wire harness (C661)

Main wire harness (C403)

Main wire harness (C404)

Main wire harness (C404)

Driver's seat belt switch

Left rear door switch

Fuel unit

Left rear ABS wheel sensor

Left rear ABS wheel sensor

Rear accessory socket connector {+}

Rear accessory socket connector (-)

Rear bumper wire harness 1C641)

Trailer lighting connector

Tailgate door latch switch

Left rear speaker

Right rear ABS wheel sensor

Rear wire harness (C611)

Right rea. door switch

Left taillight

Parking brake switch

Left rear door wire harness (C681)

Driver's door switch

Select unlock relay (for security alarm

system)

Junction connector (for power door

locks)

SRS main harness (C807)

Driver's seat belt tensioner

Fuel tank pressure sensor sub-harness(c645)

Power window master switch

'97 - 98

mooets'99 - 00

models

'97 model'98 - 00

models

Optional

'97 model'98 - 00

models

'98 - 00

mooets'98 - 00

models'98 - 00

mooets'99 - 00

mooets

G551

G553

Behind left kick panel

Left side ot floor

Left quarter piller

Body ground, via left side wire harness

Body ground, via left side wire harness

Body ground, via left side wire harness

23-26

www.emanualpro.com

Page 1301 of 1395

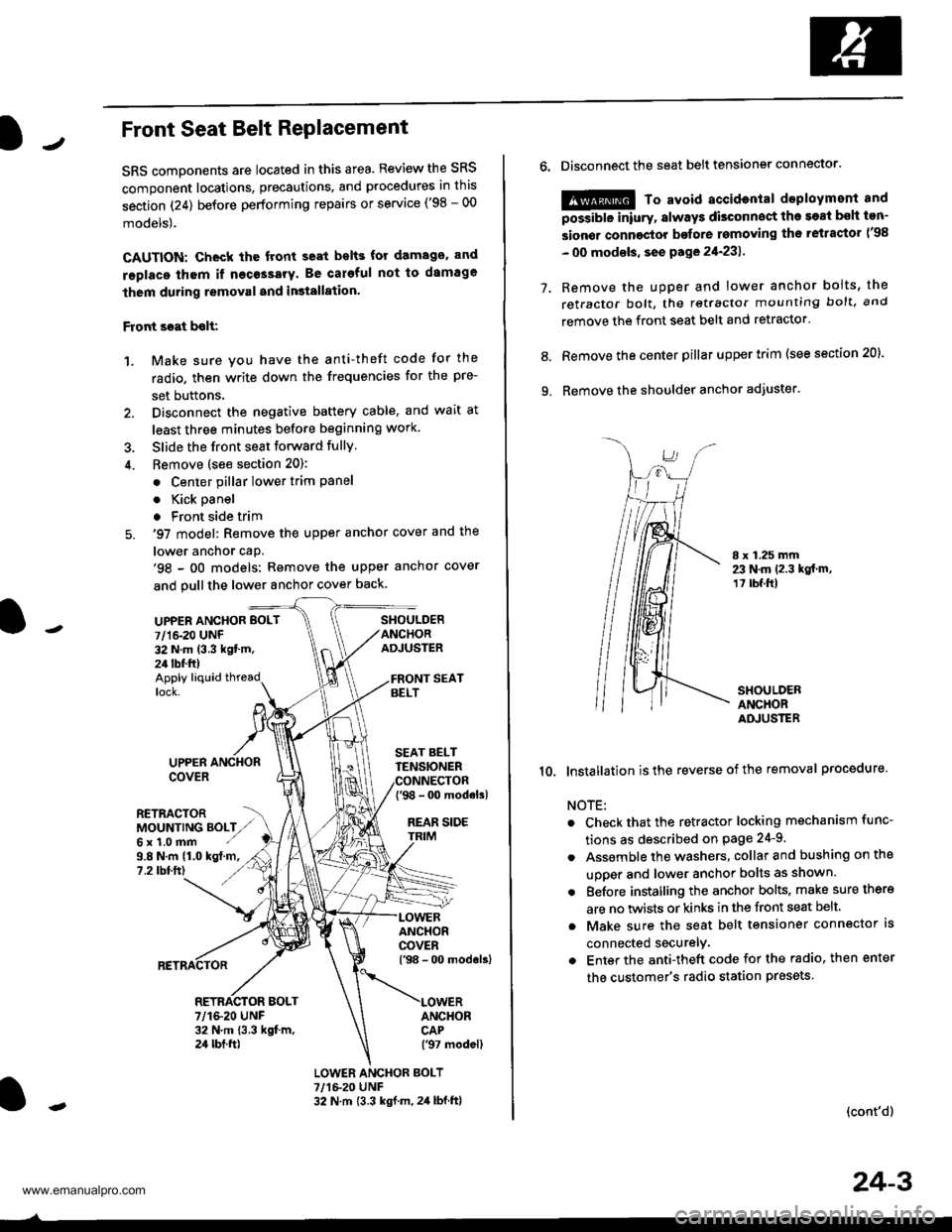

JFront Seat Belt RePlacement

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in this

section (24) before performing repairs or service ('98 - 00

models).

CAUTION: Check the front seat bslts for damago. and

replaco thom if necessary. Be careful not to damage

them during removal and in3tallation'

Front scat bolt:

1. Make sure you have the anti-theft code for the

radio, then write down the frequencies for the pre-

set buttons.

2. Disconnect the negative battery cable, and wait at

least three minutes before beginning work.

3. Slide the front seat forward fully.

4. Bemove (see section 20):

. Center pillar lower trim Pane

. Kick oanel

. Front side trim

5. '97 model: Remove the upper anchor cover and the

lower anchor caP.'98 - oO models: Remove the upper anchor cover

and pull the lower anchor cover back.

UPPEN ANCHOR BOLT

7/1&20 UNF32 N.m (3.3 kgt'm.24 tbf.ft)

SHOULDERANCHORADJUSTER

Apply liquid threadlock.

9.8 N.m (1.0 kgt.m,?.2 tbtft)

UPPERCOVER

RETRACTORMOUNTING BOLTZ,,Gx1.0mm ./

SEAT BELTTENSIONER

{'98 - 0o modols)

REAR SIDE

ANCHORCOVERl'98 - 00 models)

ANCHORCAP('97 modell

RETRACTOR BOLT7/1&20 UNF32 N.m 13.3 kgt m,24 tbt.ft)

LOWER ANCHOR BOLT?,/1&20 UNF32 N.m {3.3 kgf.m, 2,1 lbf.ftl

o.Disconnect the seat belt tensiongr connector.

@ To avoid accidontal deployment and

possibte inlury, always disconnect the soat bsh ton-

sion€r connoctor bofore rsmoving th6 retractor l'98

- 00 modsls, se€ pa ge 21-231 .

Remove the uDDer and lower anchor boits, the

retractor bolt, the retractor mounting bolt, and

remove the front seat belt and retractor.

Remove the center pillar upper trim (see section 20).

Remove the shoulder anchor adjuster.

7.

9.

8.

I x 1.25 mm23 N.m 12.3 kgt.m,1? tbf.ft)

SHOULDERANCHORADJUSTER

10. lnstallation isthe reverse of the removal procedure.

NOTE:

Check that the retractor locking mechanism func-

tions as described on Page 24-9.

Assemble the washers, collar and bushing on the

uooer and lower anchor bolts as shown.

Eefore installing the anchor bolts, make sure there

are no twists or kinks in the front seat belt.

Make sure the seat belt tensioner connector ls

connected securelv.

Enter the anti-theft code for the radio, then enter

the customer's radio station presets

(cont'd)

24-3

www.emanualpro.com

Page 1308 of 1395

Seat Belts

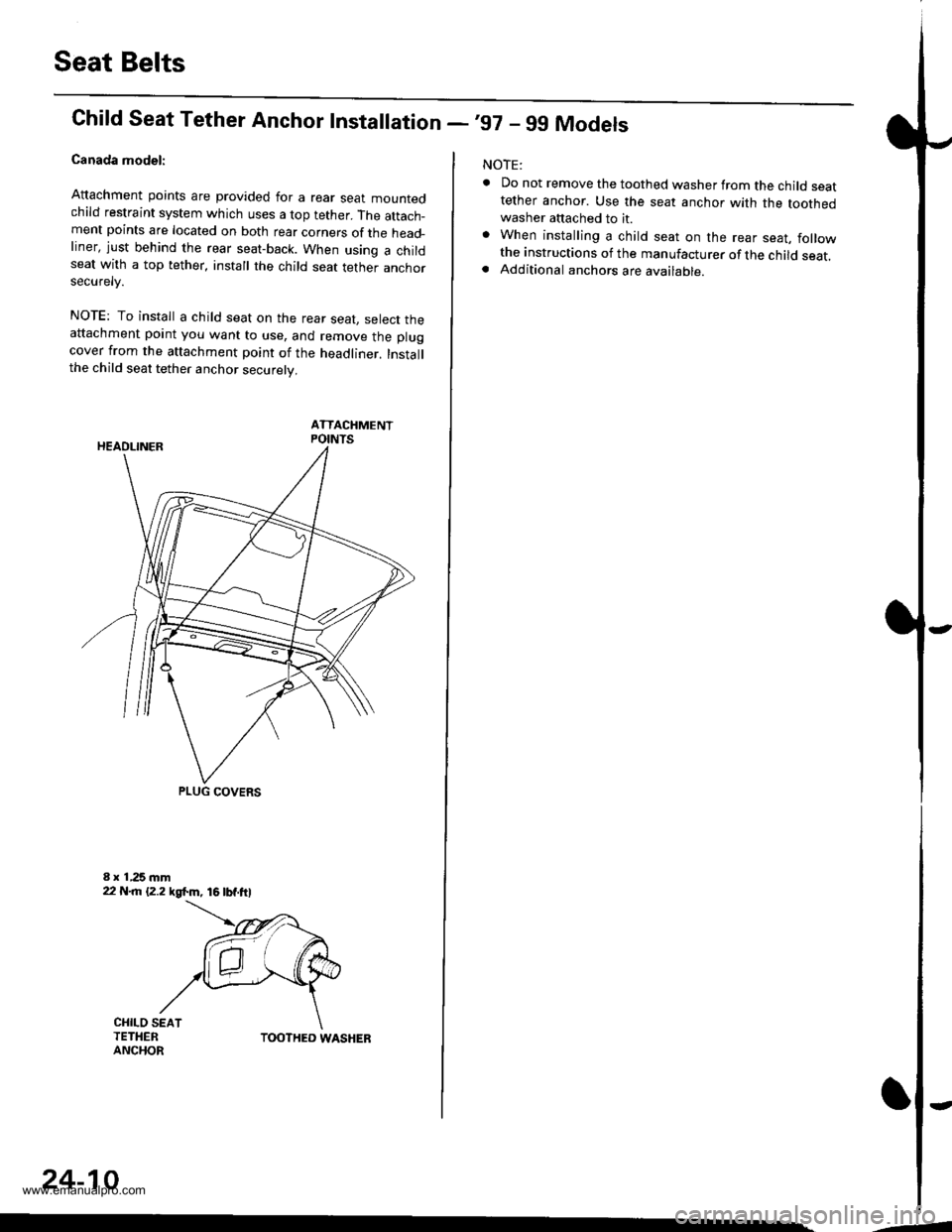

Chifd Seat Tether Anchor Installation -,97 - 99 Models

Canada model:

Attachment points are provided for a rear sear mountedchild restraint system which uses a top tether. The attach_ment points are located on both rear corners of the head_liner, just behind the rear seat-back. When using a childseat with a top tether, install the child seat tether anchorsecurelv.

NOTE: To install a child seat on the rear seat, select theattachment point you want to use, and remove the plugcover from the attachment point of the headliner. Installthe child seat tether anchor securely.

ATTACHMENTPOINTS

PLUG COVERS

CHILO SEATTETHERANCHORTOOTHED WASHER

24-10

-4

NOTE:

. Do not remove the toothed washer from the child seattether anchor. Use the seat anchor with the toothedwasher attached to it.. When installing a child seat on the rear seat, followthe instructions of the manufacturer of the child seat.. Additional anchors are available.

-

www.emanualpro.com

Page 1314 of 1395

Description

J)

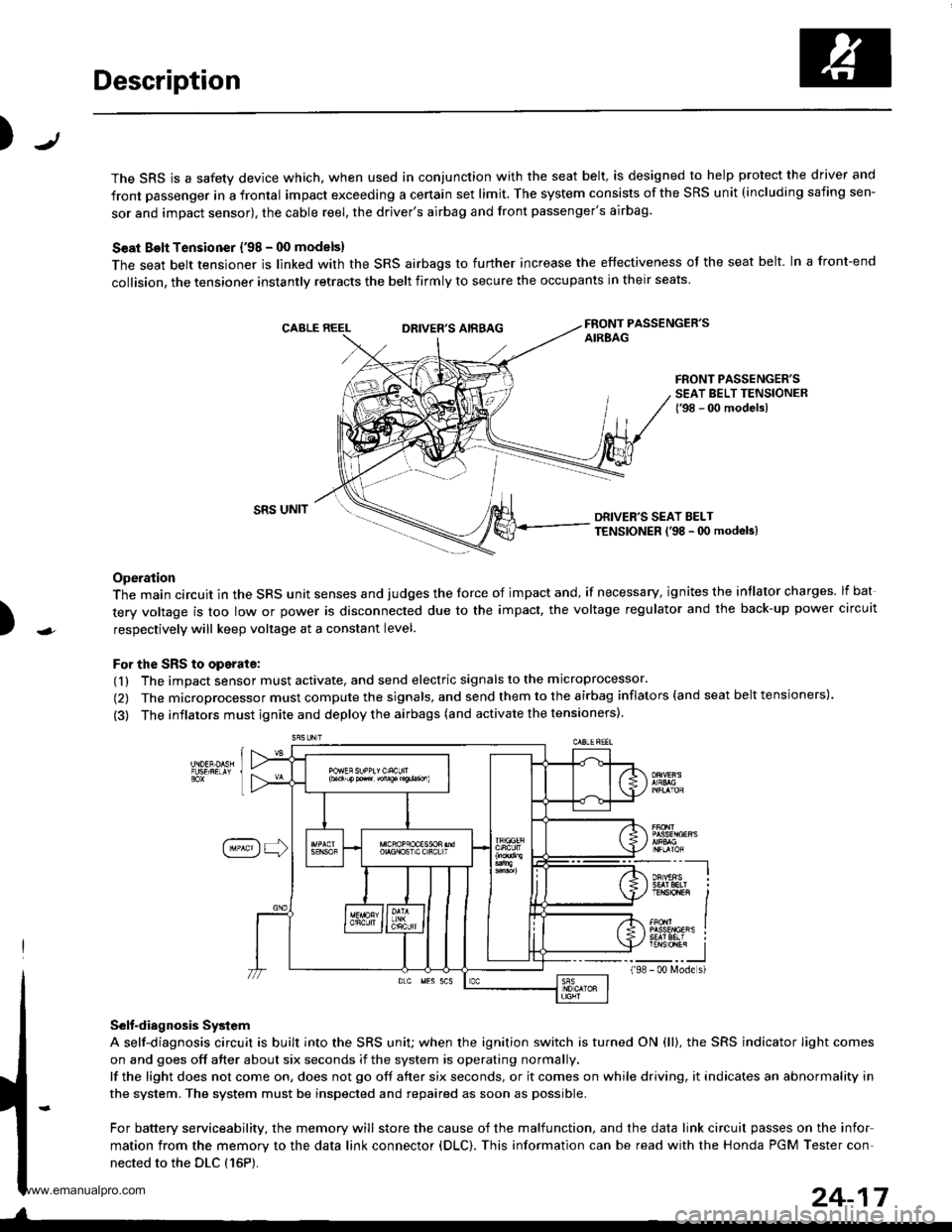

The SRS is a safety device which, when used in conjunction with the seat belt, is designed to help protect the driver and

front passenger in a frontal impact exceeding a certain set limit. The system consists of the SRS unit (including safing sen-

sor and impact sensor), the cable reel, the driver's airbag and front passenger's airbag.

Seat Bolt Tensioner {'98 - 00 models}

The seat belt tensioner is linked with the SRS airbags to further increase the effectiveness of the seat belt. In a front-end

collision, the tensioner instantly retracts the belt firmly to secure the occupants in their seats

FRONT PASSENGER'SAIREAGDRIVER'S AIRBAG

FRONT PASSENGER'SSEAT BELT TENSIONER{'98 - 00 modelsl

)

SRS UNITDRIVER'S SEAT BELTTENSIONER l'98 - 0O modeb)

Operation

The main circuit in the SRS unit senses and judges the force of impact and, if necessary, ignites the intlator charges. lf bat

tery voltage is too low or power is disconnected due to the impact, the voltage regulator and the back-up power circuit

respectively will keep voltage at a constant level.

For the SRS to operate:

(1) The impact sensor must activate, and send electric signals to the microprocessor.

(2) The microprocessor must compute the signals, and send them to the airbag inflators (and seat belt tensioners).

(3) The inflators must ignite and deploy the airbags (and activate the tensioners).

Selt-diagnosis System

A self-diagnosis circuit is built into the SRS uniU when the ignition switch is turned ON (ll), the SRS indicator Iight comes

on and goes off after about six seconds if the system is operating normally.

lf the light does not come on, does not go off after six seconds, or it comes on while driving, it indicates an abnormality in

the system. The system must be inspected and repaired as soon as possible.

For battery serviceability, the memory will store the cause of the malfunction, and the data link circuit passes on the infor

mation from the memory to the data link connector (DLC). This information can be read with the Honda PGM Tester con-

nected to the DLC {16P).

198

---__-l

TENSTO1En II

_-___J- 00 N4ode s)

24-17

www.emanualpro.com