ECU HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1316 of 1395

Precautions/Procedures

)General Precautions

Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being drop-

ped or improperly handled, such as dents, cracks or

deformation:

- Airbags- Cable reel- SRS unit- Seat belt tensioners

N

)-

Use only a digital multimeter to check the system, lf

it's not a Honda multimeter, make sure its output is

10 mA (0,01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

Do not install used SRS Dans from another vehicle,

When making SRS repairs, use only new pans.

Except when performing electrical inspections,

always disconnect both the negative cable and posi-

tive cable from the batterv. and wait at least three

minutes before beginning work.

Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiper/washer switch replace-

ment {see section 231.- Cruise control sevresume switch replacement (see

section 41.

Whenever the ignition switch is ON {ll}, or has been

turned OFF for less than three minutes, be careful not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries.

Whenever the airbag has been activated, replace the

SRS unit.

The original radio has a coded theft protection circuit.

Be sure to get the customer's code number before dis-

connecting the battery cables.

)

Airbag/Seat Belt Tensioner

Handling and Storage

Do not try to disassemble an airbag or a seat belt ten-

sioner. They have no serviceable parts. Once an airbag

or a seat belt tensioner have been deployed. they cannot

be repaired or reused.

For temporary storage of an airbag or a seat belt ten-

sioner during service, please observe the following pre-

cautons:

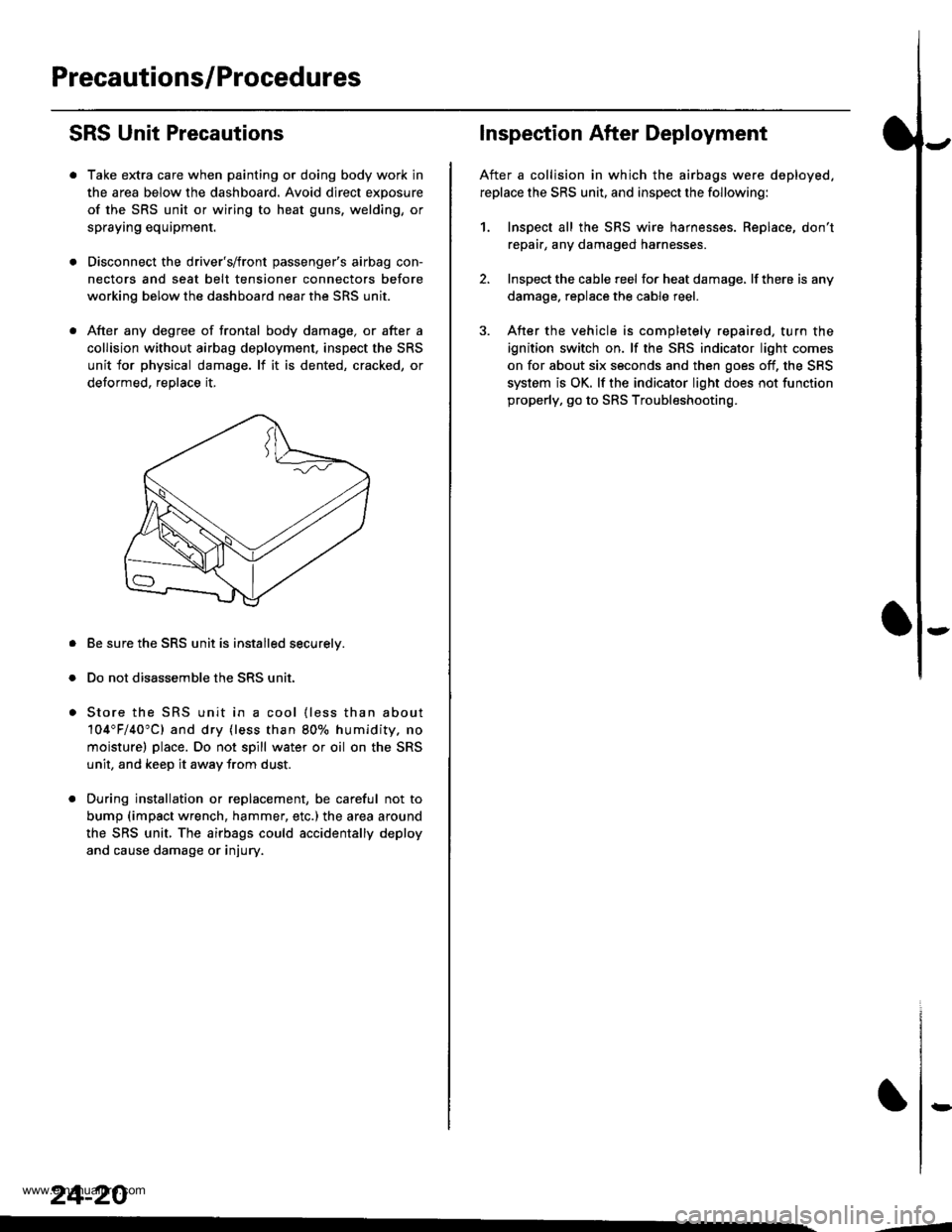

. Store the removed airbag with the pad surface up.

The driver's/front passenger's airbag connectors and

seat belt tensioner connectors have a built-in short

contact (see page 24-211.

@ r th€ airb.g is impropcrty stor€d face down,

accidental deployment could propel the unit with enough

forc€ to caus6 serious iniury,

Store the removed on a secure flat surface awav from

any high heat source (exceeding 212"F/100'C) and

free of any oil, grease. detergent or water.

lmproper handling or storage can internally damage

the airbag and seat belt tensioner. making them inop-

erative.

lf you suspect the airbag and seat belt tensioner have

been damaged, install new units and refer to the

Deploymenvoisposal Procedures for disposing of the

damaoed units.

AIRBAG CONNECTORS

www.emanualpro.com

Page 1317 of 1395

Precautions/Procedures

SRS Unit Precautions

Take extra care when painting or doing body work in

the area below the dashboard. Avoid direct exposure

of the SRS unit or wiring to heat guns, welding, or

spraying equipment.

Disconnect the driver's/front passenger's airbag con-

nectors and seat belt tensioner connectors before

working below the dashboard near the SRS unit.

After any degree of frontal body damage, or after a

collision without airbag deployment, inspect the SRS

unit for physical damage. lf it is dented, cracked, or

detormed, reolace it,

Be sure the SRS unit is installed securelv.

Do not disassemble the SRS unit.

Store the SRS unit in a cool {less than about

104"F/40"C) and dry {less than 80o/o humidity. no

moisture) place. Do not spill water or oil on the SRS

unit, and keep it awav from dust.

During installation or replacement, be careful not to

bump (impact wrench, hammer, etc.) the area a[ound

the SRS unit, The airbags could accidentally deploy

and cause damage or injury.

24-20

,..4

Inspection After Deployment

After a collision in which the airbags were deployed.

replace the SRS unit, and inspect the following:

1. Inspect all the SRS wire harnesses. Replace, don't

repair, any damaged harnesses

2. Inspect the cable reel for heat damage, lf there is any

damage. replace the cable reel.

3. After the vehicle is completely repaired, turn the

ignition switch on. lf the SRS indicator light comes

on for about six seconds and then goes off, the SRS

system is OK. lf the indicator light does not function

properly, go to SRS Troubleshooting.

rD

www.emanualpro.com

Page 1318 of 1395

JWiring Precautions

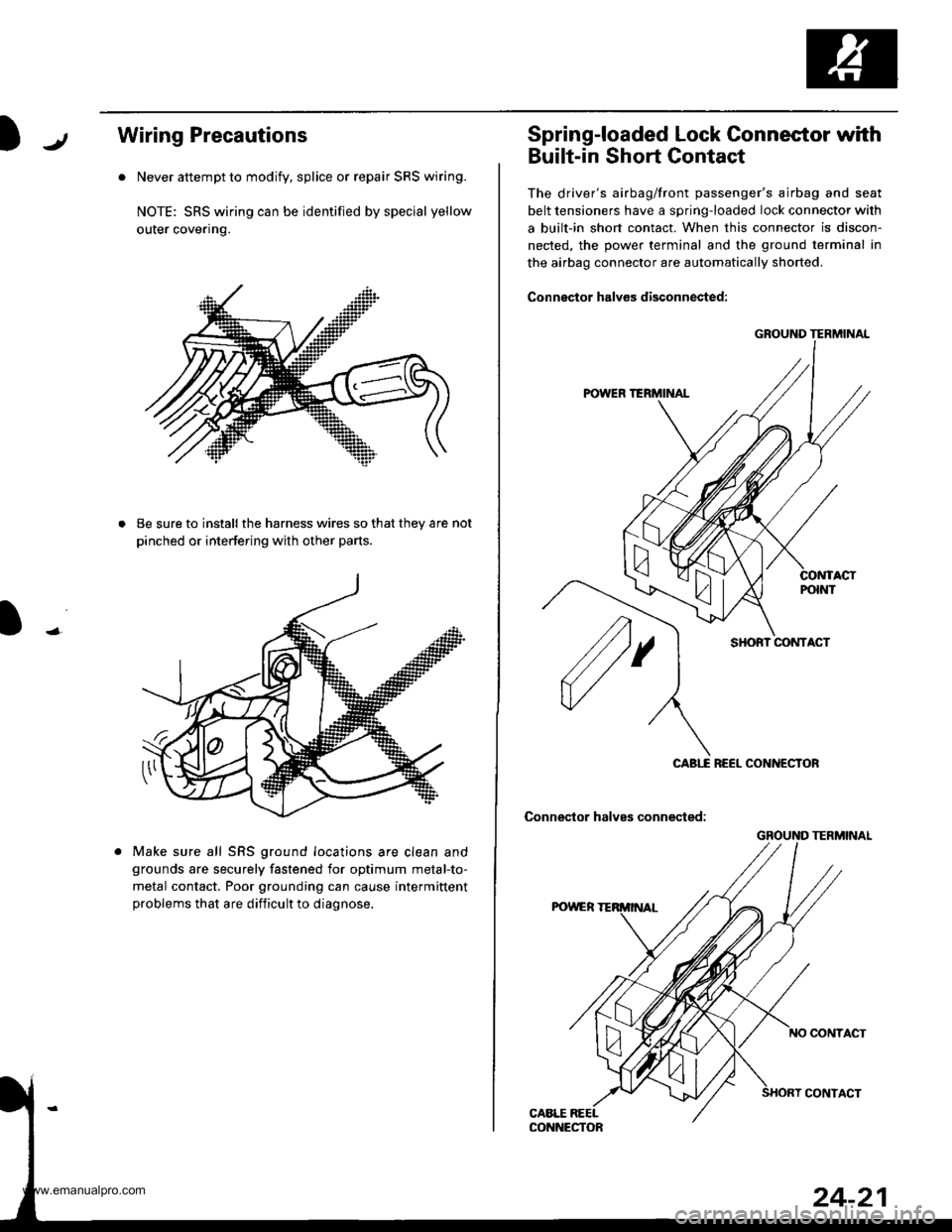

. Never attempt to modify, splice or repair SRS wiring.

NOTE: SRS wiring can be identified by special yellow

outer coveflng.

Be sure to install the harness wires so that they are

pinched or interfering with other parts.

Make sure all SRS ground locations are clean and

grounds are securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent

problems that are difficult to diagnose.

GROUND TERMINAL

CONTACT

CONTACT

24-21

Spring-loaded Lock Connestor with

Built-in Short Gontact

The driver's airbag/front passenger's airbag and seat

belt tensioners have a spring-loaded lock connector with

a built-in short contact. When this connector is discon-

nected, the power terminal and the ground terminal in

the airbag connector are automatically shorted.

Conngctor halvcs diSconnested:

GROUND TERMINAL

SHORT CONTACT

CABIf REEL CONNECTOR

Connector halves connected;

ACT

www.emanualpro.com

Page 1325 of 1395

Troubleshooting

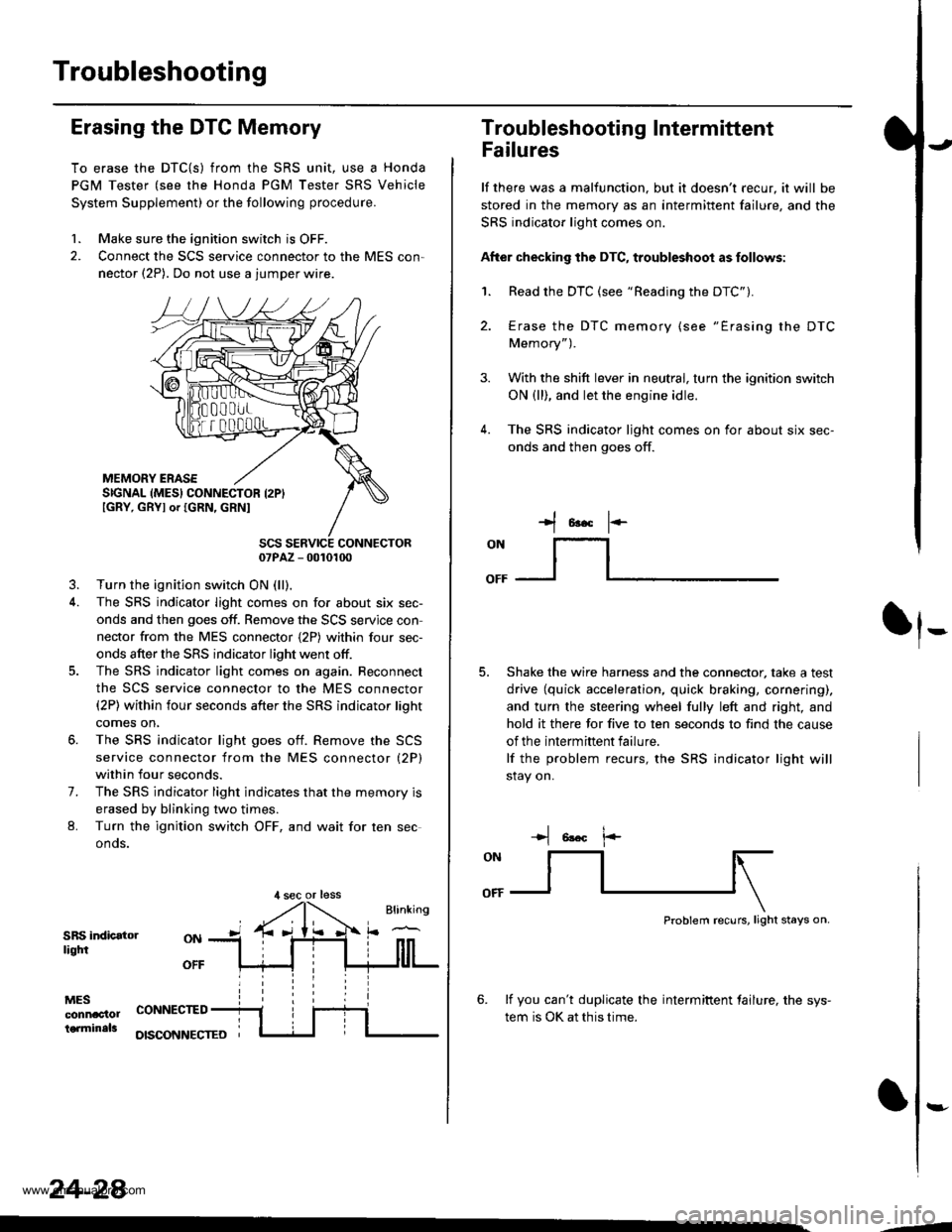

Erasing the DTC Memory

To erase the DTC{S) from the SRS unit, use a Honda

PGM Tester (see the Honda PGM Tester SRS Vehicle

System Supplement) or the following procedure.

1. Make sure the ignition switch is OFF.

2. Connect the SCS service connector to the MES con,

nector (2P). Do not use a jumper wire.

MEMORY ERASESIGNAL (MES} CONNECTOR I2PIIGRY, GRYI or IGRN, GRNI

SCS SERVICE CONNECTOR07PAZ - 0010100

3. Turn the ignition switch ON (ll),

4. The SRS indicator light comes on for about six sec-

onds and then goes off. Remove the SCS servjce con

nector from the MES connector {2P) within four sec-

onds after the SRS indicator light went otf.

5. The SRS indicator light comes on again. Reconnect

the SCS service connector to the MES connector(2P) within four seconds after the SRS indicator lioht

comes on,

6. The SRS indicator light goes otf. Remove the SCS

service connector from the MES connector (2P)

within four seconds.

7. The SRS indicator light indicates that the memory is

erased by blinking two times.

L Turn the ignition switch OFF, and wait for ten sec

onos.

SRS indicatorliqtfi

MESconnac'lolterminals

OFF

CONNECTED

OISCONNECTEO

24-28

,l sec or less

3.

Troubleshooting Intermittent

Failures

lf there was a malfunction. but it doesn't recur, it will be

stored in the memory as an intermittent failure, and the

SRS indicator light comes on.

After checking the DTC, troubleshoot as follows:

1. Read the DTC (see "Reading the DTC").

4.

Erase the DTC memory (see "Erasing the DTC

Memory").

With the shift lever in neutral, turn the ignition switch

ON (ll), and let the engine idle.

The SRS indicator ljght comes on for about six sec-

onds and then goes off.

t*F

ON

lt--- _l

Shake the wire harness and the connector, take a test

drive (quick acceleration, quick braking, cornering),

and turn the steering wheel fully left and right, and

hold it there for five to ten seconds to find the cause

of the intermittent failure.

lf the problem recurs, the SRS indicator light will

stay on.

-+t 6!.c l.-

Problem recurs, light stays on.

6. lf you can't duplicate the intermiftent tailure, the sys-

tem is OK at this time.

:-

-4

www.emanualpro.com

Page 1385 of 1395

Driver's Airbag

Replacement lcont'd)

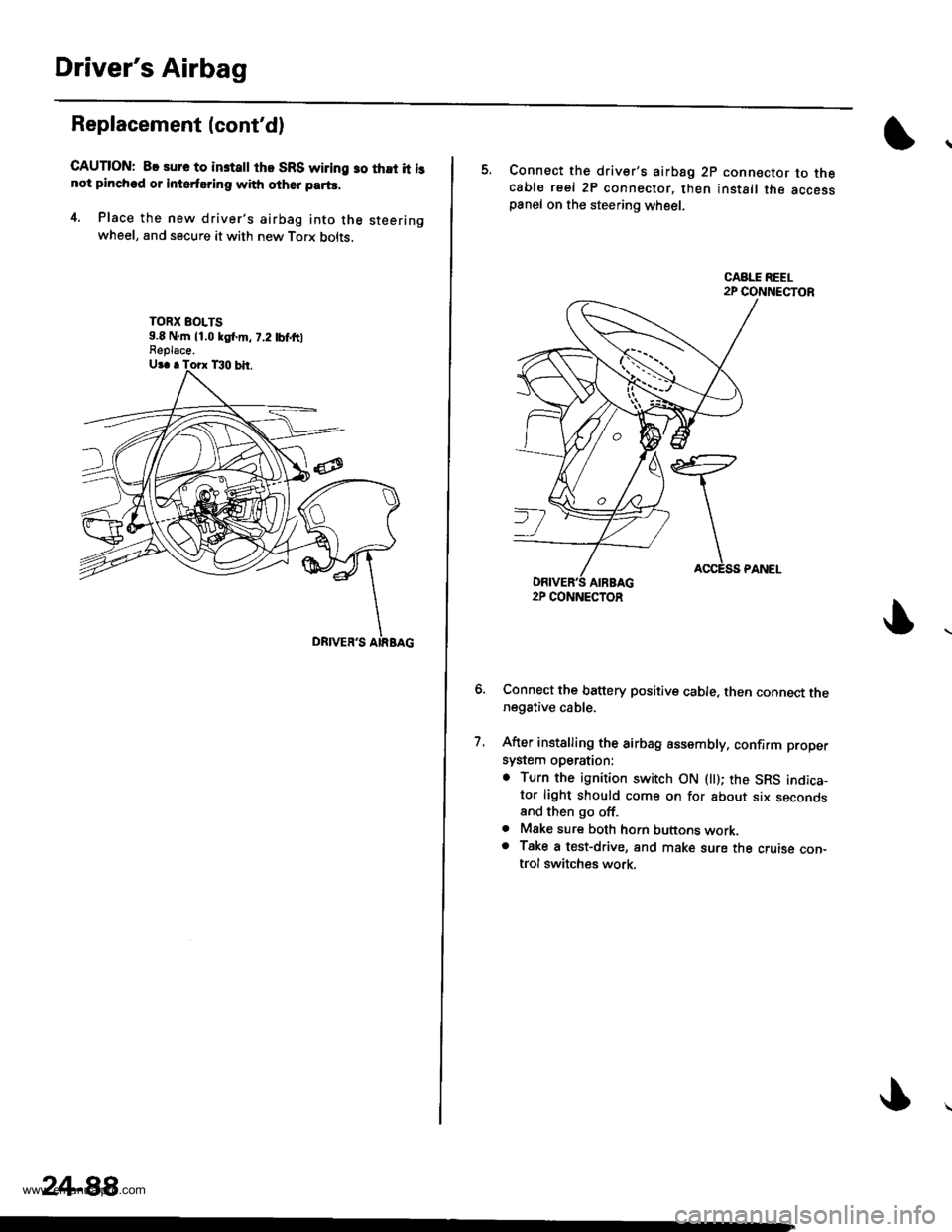

CAUTION: 8. sure to instattthe SRS wiring so that it isnot plnched or inlerfsring with other parts.

4. Place the new driver's airbag into the steeringwheel, and secure it with new Torx bolts.

TORX EOLTS9.8 N,m 11.0 kgl.m, 7.2 tbf,ftlFeplace.

24-88,

5. Connect the driver's airbsg 2p connector to thecable reel 2P connector, then install the accesspanel on the steering wheel.

Connect the battery positive cable. then connect thenegative cable.

After installing the airbag assembly, confirm proper

system operation:

. Turn the ignition switch ON llt); the SRS indica-tor light should come on for about six secondsand then go off.. Mske sure both horn buttons work.o Take a test-drive, and make sure the cruise con-trol switches work.

7.

2P CONNECTOR

www.emanualpro.com

Page 1395 of 1395

Airbag/Seat Belt Tensioner

1.

Disposal (cont'dl

Connect a 12 volt battery to the tool'

. It the green light on the tool comes on, the air-

bag igniter circuit is defective and cannot deploy

the airbag. Go to Damaged Airbag Special

Procedure.

.lftheredlightonthetool comes on, the airbag is

ready to be deployed.

Push the tool's deployment switch. The airbag

should deploy (deployment is both highly audible

and visible; a loud noise and rapid inflation of the

bag, followed by slow deflation).

. lf the airbags deploy and the green light on the

tool comes on, continue with this procedure.

. lf an airbag doesn't deploy, yet the green light

comes ON, its igniter is defective. Go to Dam-

aged Airbag Special Procedure.

. During deployment, the airbag can become hot

enough to burn you, Wait thirty minutes after

deployment before touching the airbag.

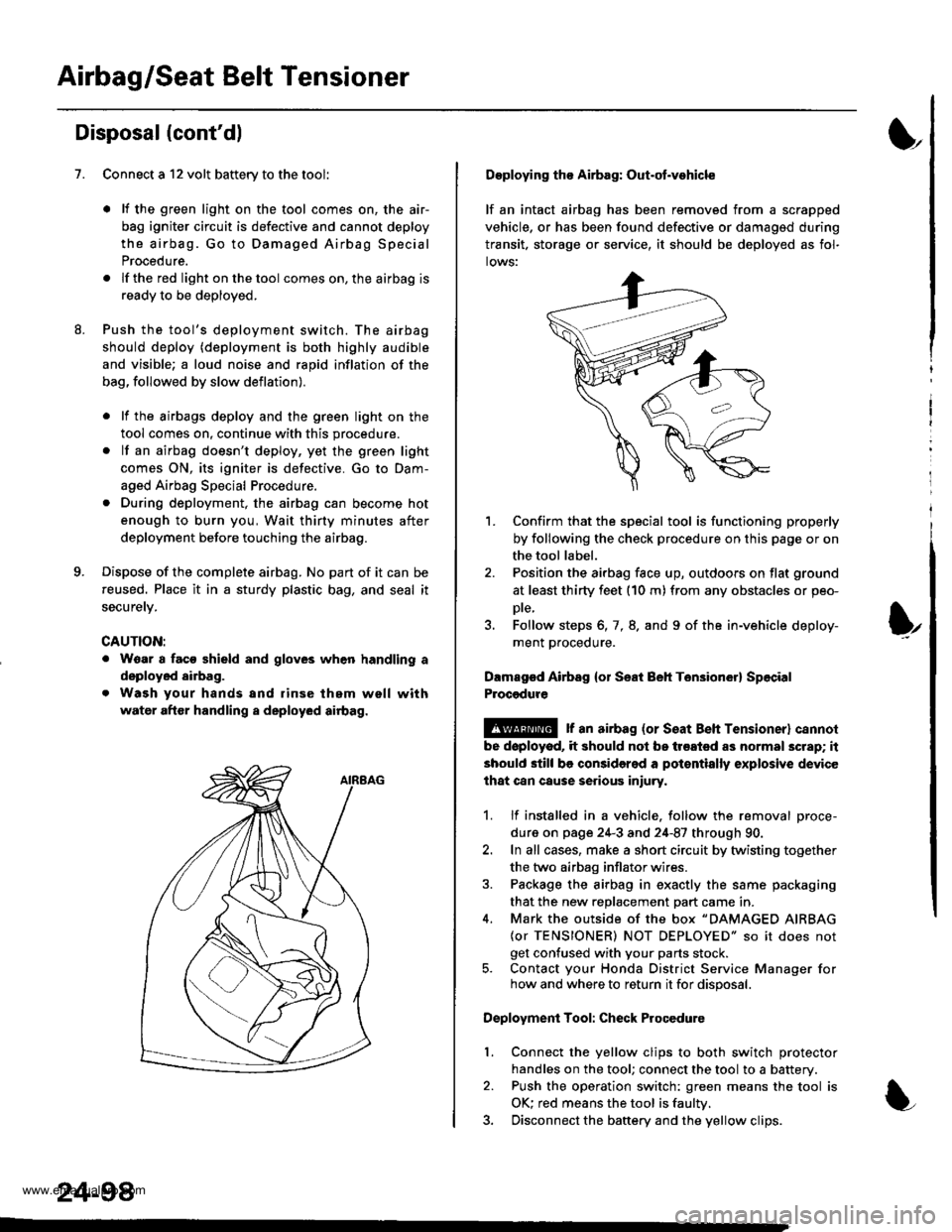

Dispose of the complete airbag. No part of it can be

reused. Place it in a sturdy plastic bag, and seal it

securety.

CAUTION:

. Wear a faco shield and gloves when handling a

deployed airbag.

. Wash your hands and rinse them well with

water after handling a deployed airbag.

24-98

Deploying tho Airbag: Out-ot.vohicle

lf an intact airbag has been removed from a scrapped

vehicle, or has been found defective or damagsd during

transit. storage or seryice, it should be deployed as fol-

lows:

'L Confirm that the special tool is functioning properly

by following the check procedure on this page or on

the tool label.

2. Position the airbag face up, outdoors on flat ground

at least thirty feet (10 m) from any obstacles or peo-

Dte,

3. Follow steps 6, 7, 8. and 9 of the in-vehicle deploy-

ment proceoure.

Dlmaged Airbsg {or Seat Beh Ten3ion6r} Sp6cial

Procgdure

!@ r an airbag {or seat Beh rensioner} cannol

be doployod, it should not be treated as normal scrap; it

should still be considered a pot€ntially explosive device

lhat can cause serious iniury.

1. lf installed in a vehicle. follow the removal proce-

dure on page 24-3 and 24-87 through 90.

2. In all cases, make a short circuit by twisting together

the two airbag inflator wires.

3. Package the airbag in exactly the same packaging

that the new reDlacement Dart came in.

4. Mark the outside of the box "DAMAGED AIRBAG

{or TENSIONER) NOT DEPLOYED" so it does not

get confused with your parts stock.5. Contact your Honda District Service Manager forhow and where to return it for disposal.

Deployment Tool: Check Procedure

Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

Push the operation switch: green means the tool is

OK: red means the tool is faultv.

Disconnect the baftery and the yellow clips.

I

t

l.

www.emanualpro.com