front HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1043 of 1395

Seats

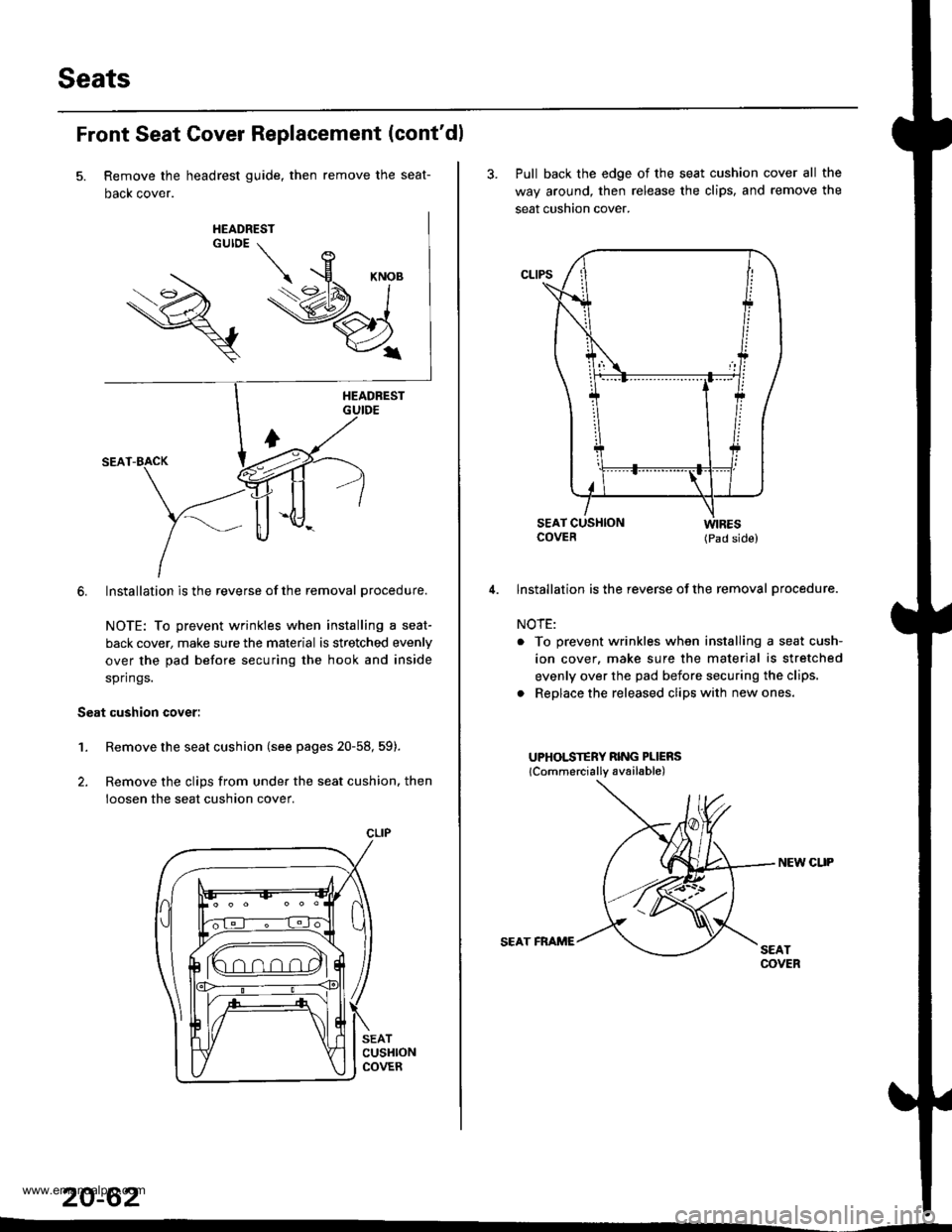

Front Seat Cover Replacement (cont'dl

Remove the headrest guide, then remove the seat-

Dacx cover.

6. Installation is the reverse of the removal procedure.

NOTE: To prevent wrinkles when installing a seat-

back cover, make sure the material is stretched evenly

over the pad before securing the hook and inside

springs.

Seat cushion cover:

1.Remove the seat cushion (see pages 20-58, 59).

Remove the clips from under the seat cushion. then

loosen the seat cushion cover.

SEATCUSHIONCOVER

20-62

CLIP

3. Pull back the edge of the seat cushion cover all the

way around, then release the clips. and remove the

seat cushion cover.

COVER (pad side)

lnstallation is the reverse of the removal procedure.

NOTE:

. To prevent wrinkles when installing a seat cush-

ion cover. make sure the material is stretched

evenly over the pad before securing the clips.

. Replace the released clips with new ones.

UPHOLSTERY RING PLIERS

lCommercially available)

NEW CUP

SEAT FRAME

www.emanualpro.com

Page 1053 of 1395

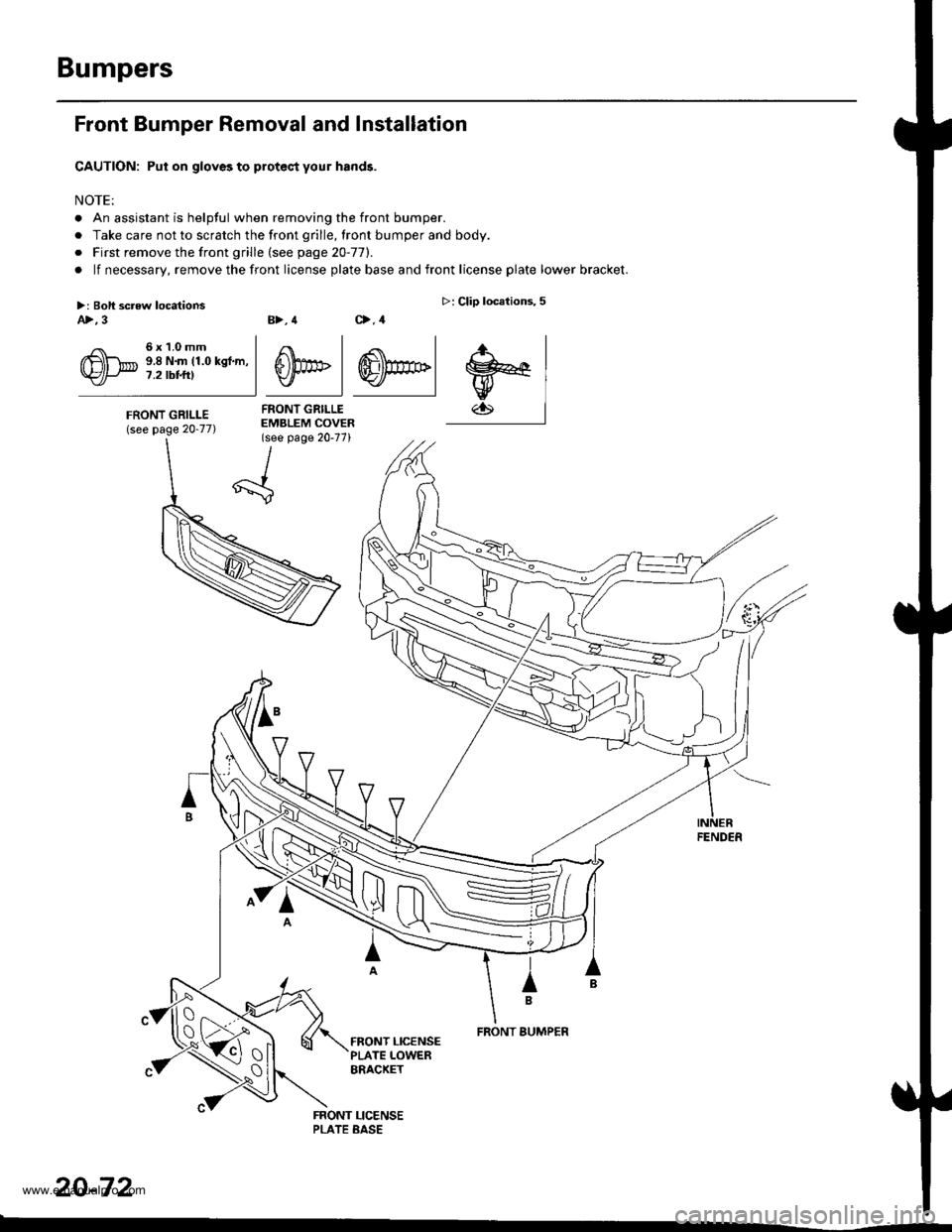

Bumpers

Front Bumper Removal and Installation

CAUTION: Put on gloves to protec,t your hands.

NOTE:

. An assistant is helpful when removing the front bumper.

. Take care not to scratch the front grille, lront bumper and body.

o First remove the front grille (see page 20-77).

. lf necessary, remove the front license plate base and front license plate lower bracket.

B>, 4 C>,4

4 .<\l

S))PF | ffi)m>lv I Y./ |

FRONT GRILLEEMBLEM COVER(see page 20-77)

>: Clip locations,5

.r., I

w€lw

FENDER

IB

FRONT BUMPER

20-72

>: Boli screw locationsA>,3

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbt t0

FRONT GRILLE(see page 20-77)

tx -

\{_:

www.emanualpro.com

Page 1054 of 1395

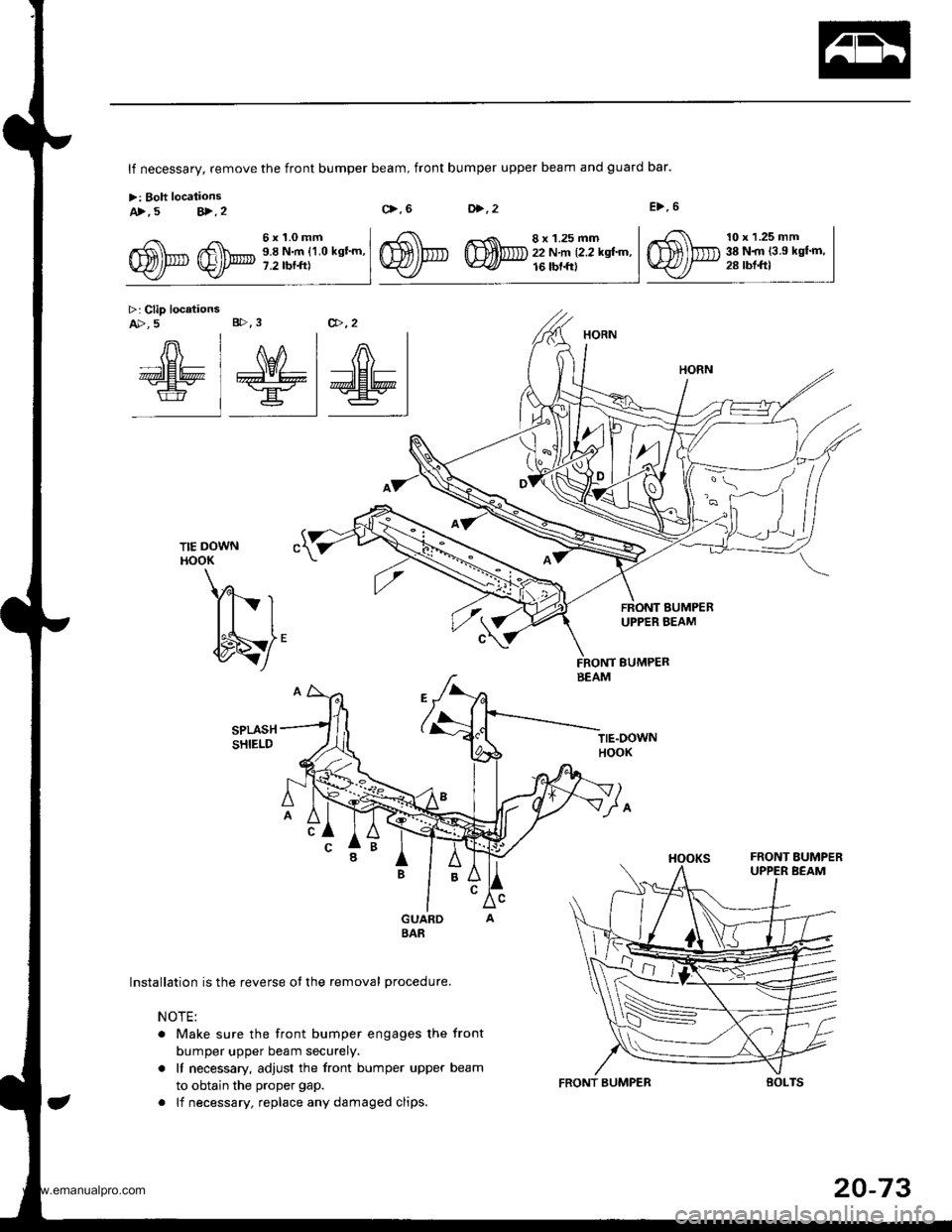

A>, 5 V.2

>: Clip locationsA>, 5 B>.3

lf necessary, remove the front bumper beam, front bumper upper beam and guard bar.

>: Boh locationsc>.6D>,2E>,6

TIE DOWNHOOK

Yl- r

{to/

Installation is the reverse ot the removal procedure.

NOTE:

. Make sure the front bumper engages the front

bumper upper beam securely.

. It necessary, adjust the front bumper upper beam

to obtain the proper gap.

. lf necessary, replace any damaged clips.

Gfu @p;i,li',ll-"-'

TIE.DOWNHOOK

v1

10 x 1.25 mm38 N.rn {3.9 kgf.m,28 rbl.ftl

@,,2

nln-nlznr I

dE6 I #\Er+ | ;lHl= |€ =.=r t:Wl

BEAM

FRONT BUMPEB

20-73

www.emanualpro.com

Page 1057 of 1395

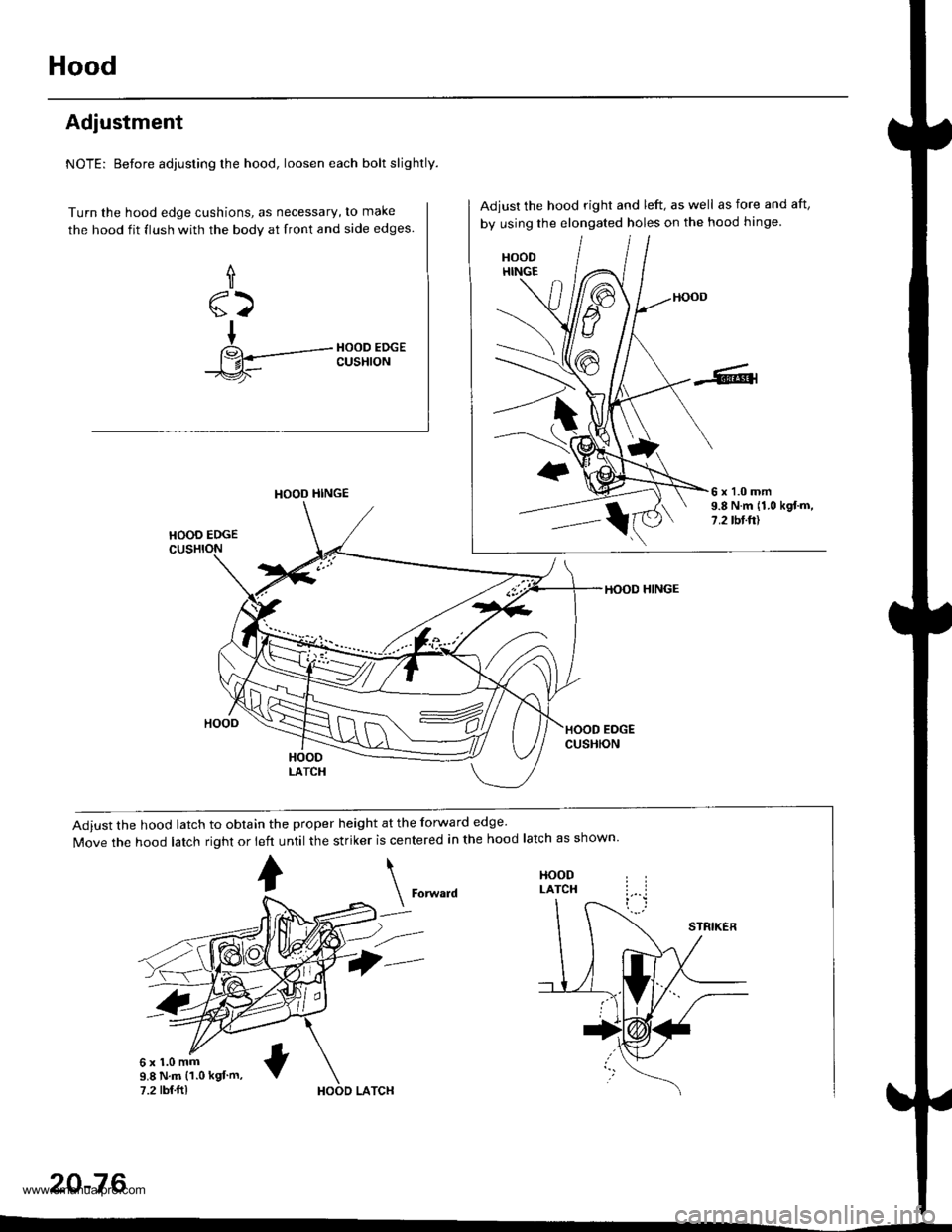

Hood

Adjustment

NOTE: Before adjusting the hood, loosen each bolt slightly.

Turn the hood edge cushions, as necessary, to make

the hood fit flush with the bodv at front and side edges.

f

sz

+

14---+ik-

HOOD EDGECUSHION

Adiust the hood latch to obtain the proper height at the forward edge'

Move the hood latch right or left until the striker is centered in the hood latch as shown

HOOD HINGE

\

?--

HOODLATCH

9.8 N.m (1.0 kgf m,

7.2 rbf.ftlHOOD LATCH

20-76

Adjust the hood right and left, as well as fore and aft,

by using the elongated holes on the hood hinge

6x1.0mm9.8 N.m (1.0 kgtm,7 .2 tbt.ttl

HOOD HINGE

www.emanualpro.com

Page 1058 of 1395

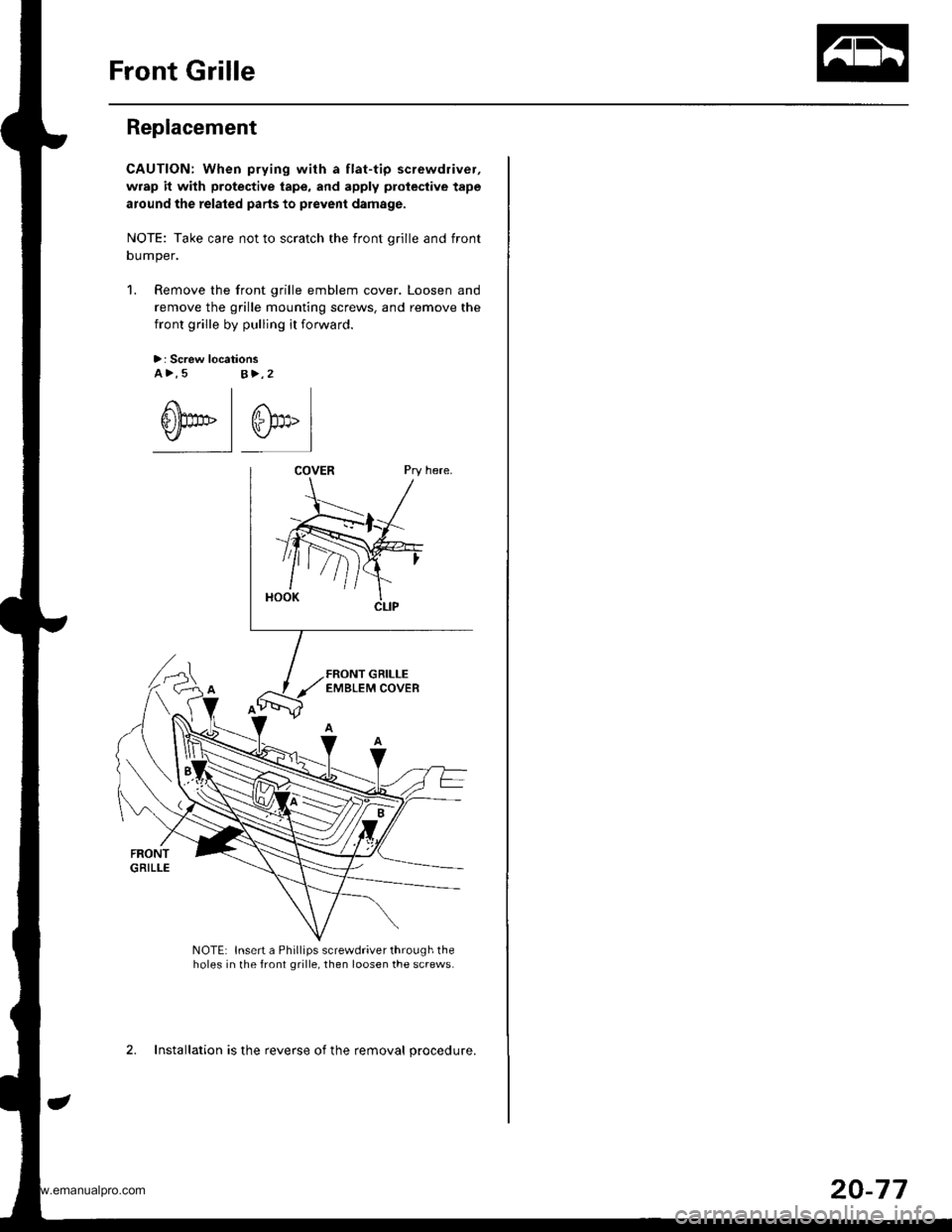

Front Grille

Replacement

CAUTION: When prying with a flat-tip screwdriver,

wrap it with protective tape, and apply protective tape

around the related parts to prevent damage.

NOTE: Take care not to scratch the front orille and front

oumper.

1. Remove the front grille emblem cover. Loosen and

remove the grille mounting screws. and remove the

front grille by pulling it forward.

>: Screw locationsa>,5s>,2

@-l @,"l

NOTE: Insert a Phillips screwdriver through theholes in the front grille, then loosen the screws.

2. Installation is the reverse of the removal procedure.

20-77

www.emanualpro.com

Page 1065 of 1395

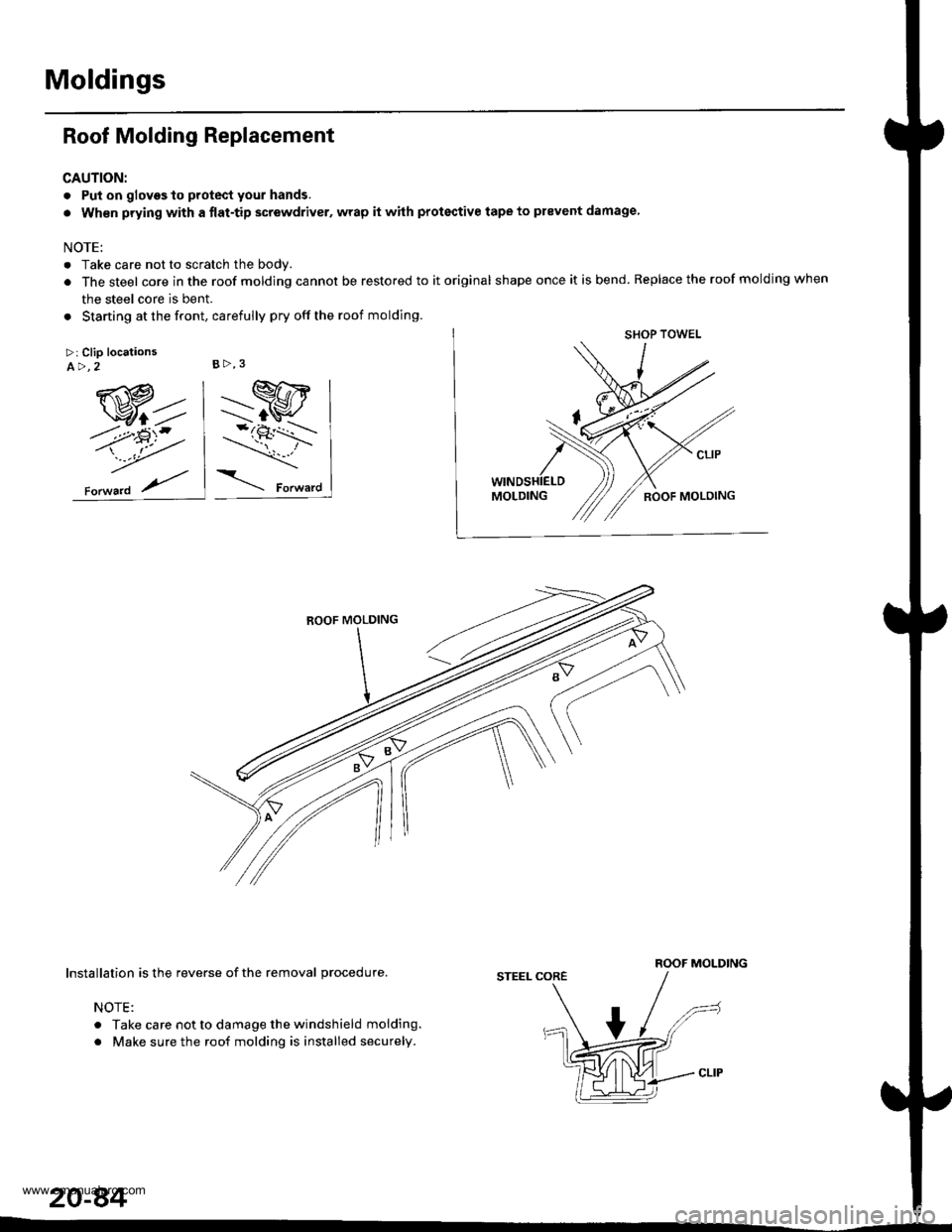

Moldings

Roof Molding Replacement

CAUTION:

. Put on glovgs to protect your hands.

. Wh€n prying with a {lat-tip screwdriver, wrap it whh protective tape to prevent damage

NOTE:

. Take care not to scratch the body.

. The steel core in the roof molding cannot be restored to it original shape once it is bend. Replace the roof molding when

the steel core is bent.

. Starting at the front, carefully pry off the roof molding.

>: Clip locationsA>,2

ROOF MOLDINGInstallation is the reverse of the removal procedure.

NOTE:

. Take care not to damage the windshield molding.

. Make sure the roof molding is installed securely.

STEEL CORE

B>,3

20-84

www.emanualpro.com

Page 1066 of 1395

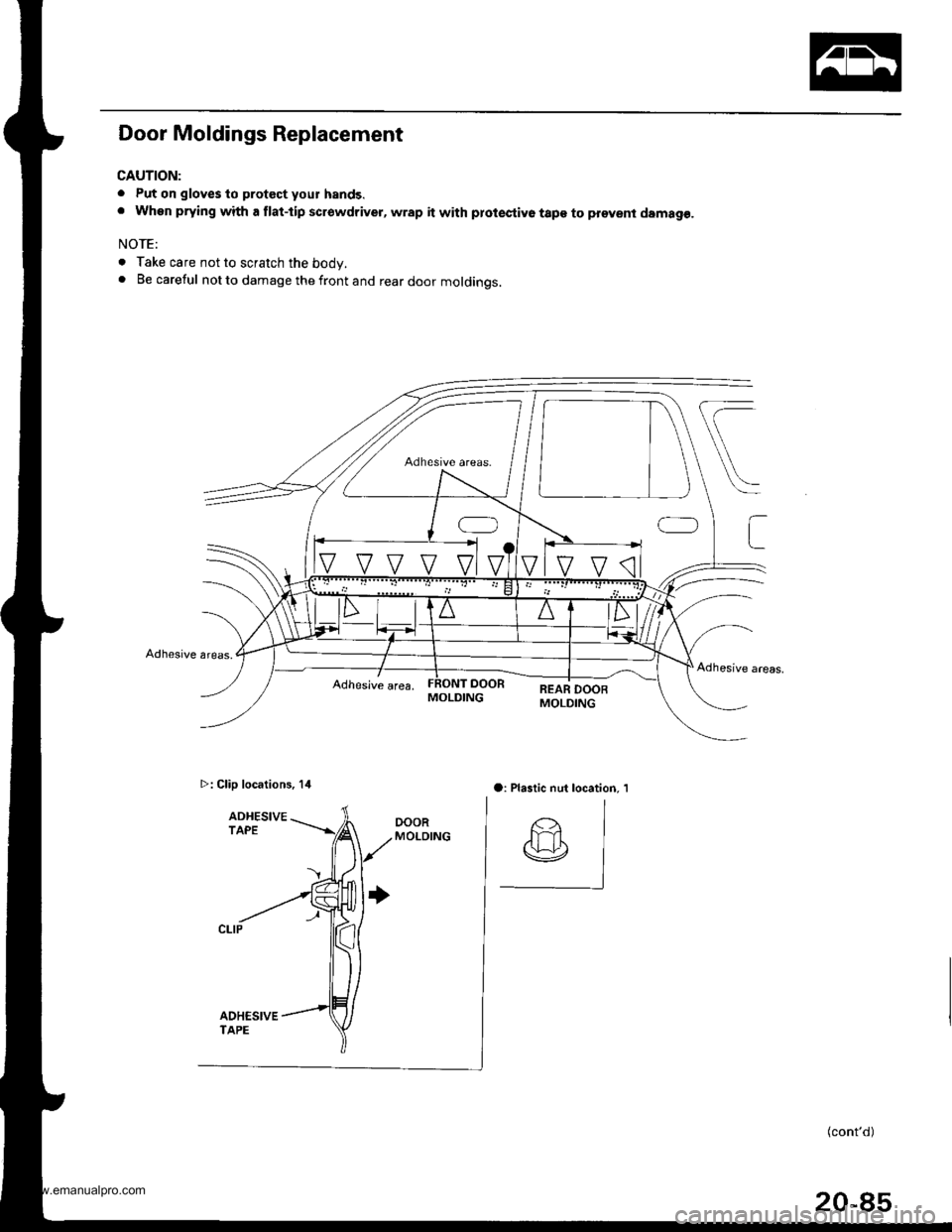

Door Moldings Replacement

CAUTION:

. Put on gloves to protect your hands.. When prying with a flat-tip scrowdriver, wrap it with prot€stive tape to provent damag€.

NOTE:

. Take care not to scratch the body.. Be careful not to damage the front and rear door moldings.

t

Adhesive aleas,

Adhesive area.FRONT DOORMOLDINGREAR DOOBMOLDING

a: Plastic nut location, 1

(cont'd)

20-85

>: Clip locations, 14

www.emanualpro.com

Page 1067 of 1395

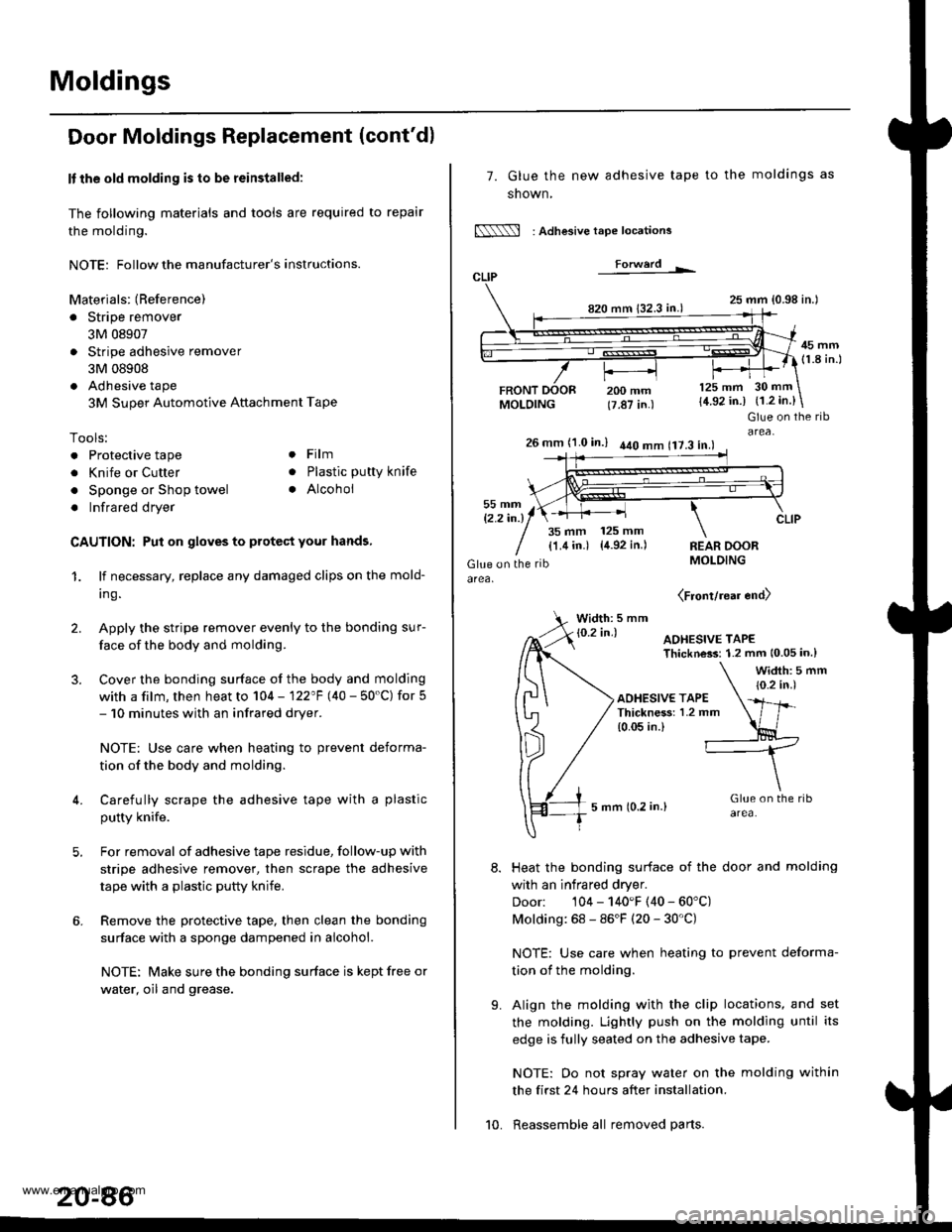

Moldings

Door Moldings Replacement (cont'd)

It the old molding is to be reinstalled:

The following materials and tools are required to repair

the molding.

NOTE: Followthe manufacturer's instructions.

Materials: (Reference)

. Stripe remover

3M 08907

. Stripe adhesive remover

3M 08908

. Adhesive tape

3M Super Automotive Attachment Tape

Tools:

. Protective tape

. Knife or Cutter

. Sponge or Shop towel

. Infrared dryer

. Film

. Plastic putty knife

. Alcohol

CAUTION: Put on gloves to protect your hands,

1. lf necessary, replace any damaged clips on the mold-

ang.

2. Apply the stripe remover evenly to the bonding sur-

face of the body and molding.

3. Cover the bonding surface of the body and molding

with a film, then heat to 104 - 122"F (40 - 50'C) for 5- 10 minutes with an infrared dryer.

NOTE: Use care when heating to prevent deforma-

tion of the body and molding.

4. Carefully scrape the adhesive tape with a plastic

putty knife.

For removal of adhesive tape residue, follow-up with

stripe adhesive remover, then scrape the adhesive

tape with a plastic putty knife.

Remove the protective tape, then clean the bonding

surface with a sponge dampened in alcohol.

NOTE: Make sure the bonding surface is kept free or

water, oil and grease.

7. Glue the new adhesive tape

snown,

N : Adlesive tape locations

Forwerd L

820 mm 132.3 in.)

FRONTMOLDING

to the moldings as

25 mm {0.98 in.l

45 mm(1.8 in.l

200 mm(7.87 in.)

125 mm

{4.92 in.)30 mm

{1.2 in.}

t'.

Glue on the ribarea,26 mm (1.0 in.) 440 mm 117.3 in.l

35 mm 125 mm

{1.4 in.) {4.92 in.)REAR DOORMOLDING

(Front/rear end)

Width: 5 mm

Heat the bonding surface of the door and molding

with an infrared dryer.

Door: 104 - 140'F (40 - 60'C)

Molding: 68 - 86'F (20 - 30'C)

NOTE: Use care when heating to prevent deforma-

tion of the molding.

Align the molding with the clip locations, and set

the molding. Lightly push on the molding until its

edge is fully seated on the adhesive tape.

NOTE: Oo not spray water on the molding within

the first 24 hours after installation.

Reassemble all removed parts.10.

www.emanualpro.com

Page 1070 of 1395

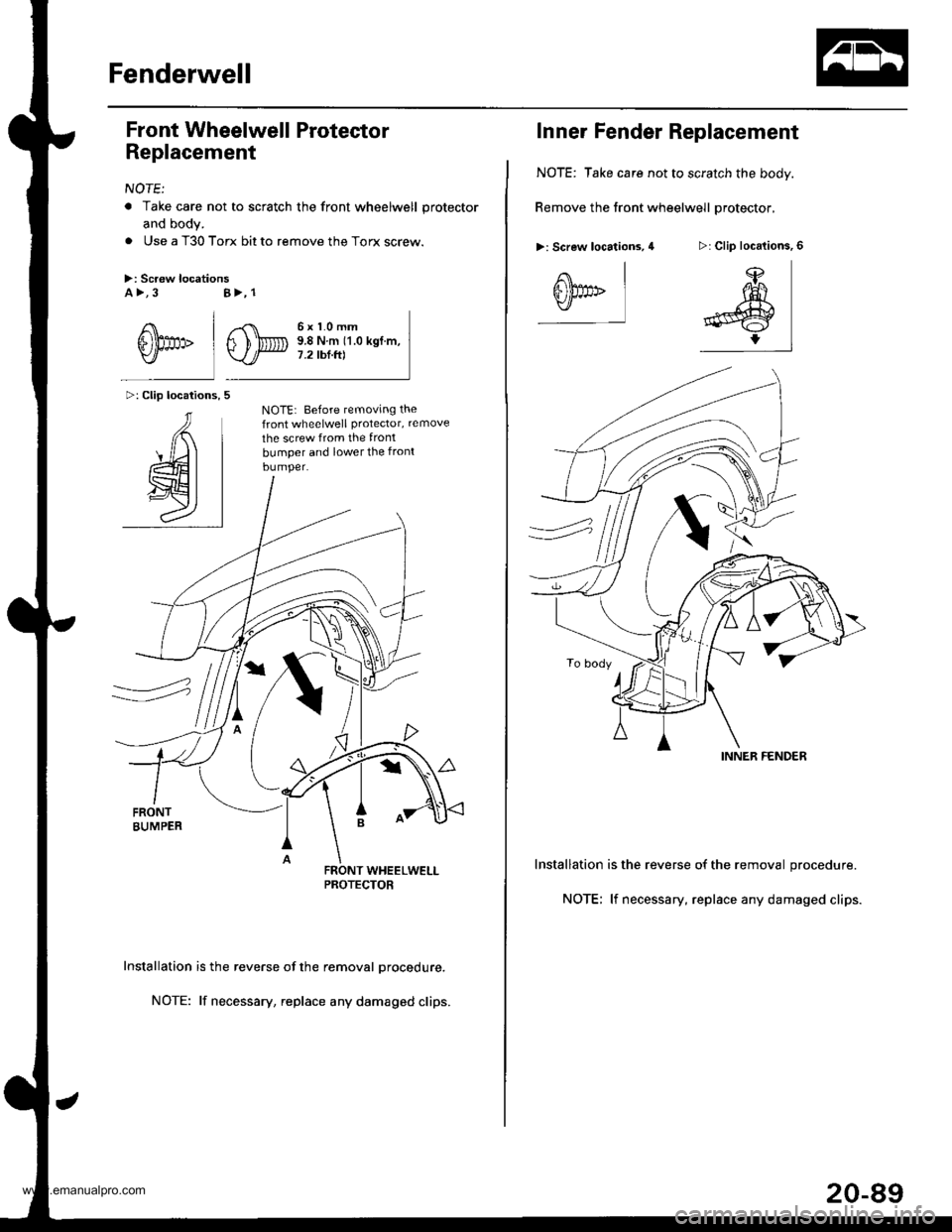

Fenderwell

Front Wheelwell Protector

Replacement

NOTE:

a Take care not to scratch the front wheelwell protector

and body.

. Use a T30 Torx bit to remove the Torx screw.

>: Screw locationsa >,3

/\l

6'thp IY/

>: Clip locations,

AI

4t I

wt I

al

B>, 1

,,-C\

s)Dv.l/

6x1.0mm9.8Nm(1.0kgf.m,7.2 tbf.ft)

NOTE: Before temoving thefront wheelwell Protector, remove

the screw from the front

bumper and lower the front

bumper.

Installation is the reverse of the removal Drocedure.

NOTE: lf necessary, replace any damaged clips.

Inner Fender Replacement

NOTE: Take care not to scratch the body.

Remove the front wheelwell protector,

>: Screw locations, 4

Installation is the reverse of the removal procedure.

NOTE; lf necessary, replace any damaged clips.

>: Clip locations,

ffi)fl(

l#:rl

A\

s))pp>Y]

INNER FENDER

20-89

www.emanualpro.com

Page 1074 of 1395

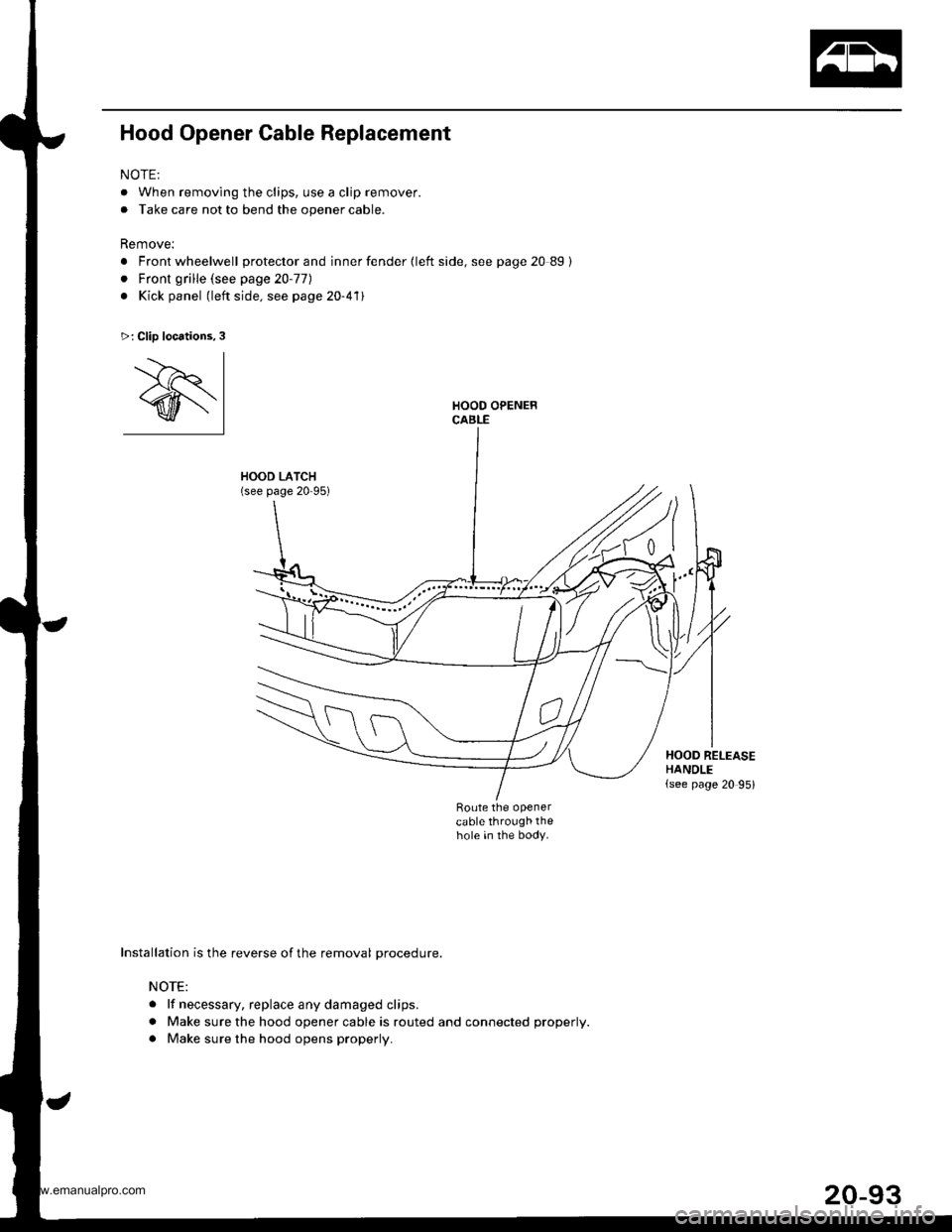

Hood Opener Cable Replacement

NOTE:

. When removing the clips, use a clip remover.

. Take care not to bend the opener cable.

Remove:

. Front wheelwell protector and inner fender {left side, see page 20 89}

. Front grille (see page 20-77)

. Kick panel (left side. see page 20-411

HOOD LATCH(see page 20-95)

Route the openercable through thehole in the body.

>: Clip locations,3

'.--)r I

@l

Installation is the reverse of the removal procedure.

NOTE:

. lf necessary. replace any damaged clips.

. Make sure the hood opener cable is routed and connected properly.

. Make sure the hood opens properly.

t"

HOOD RELEASEHANDLE(see page 20 95)

www.emanualpro.com