Power steering HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 206 of 1395

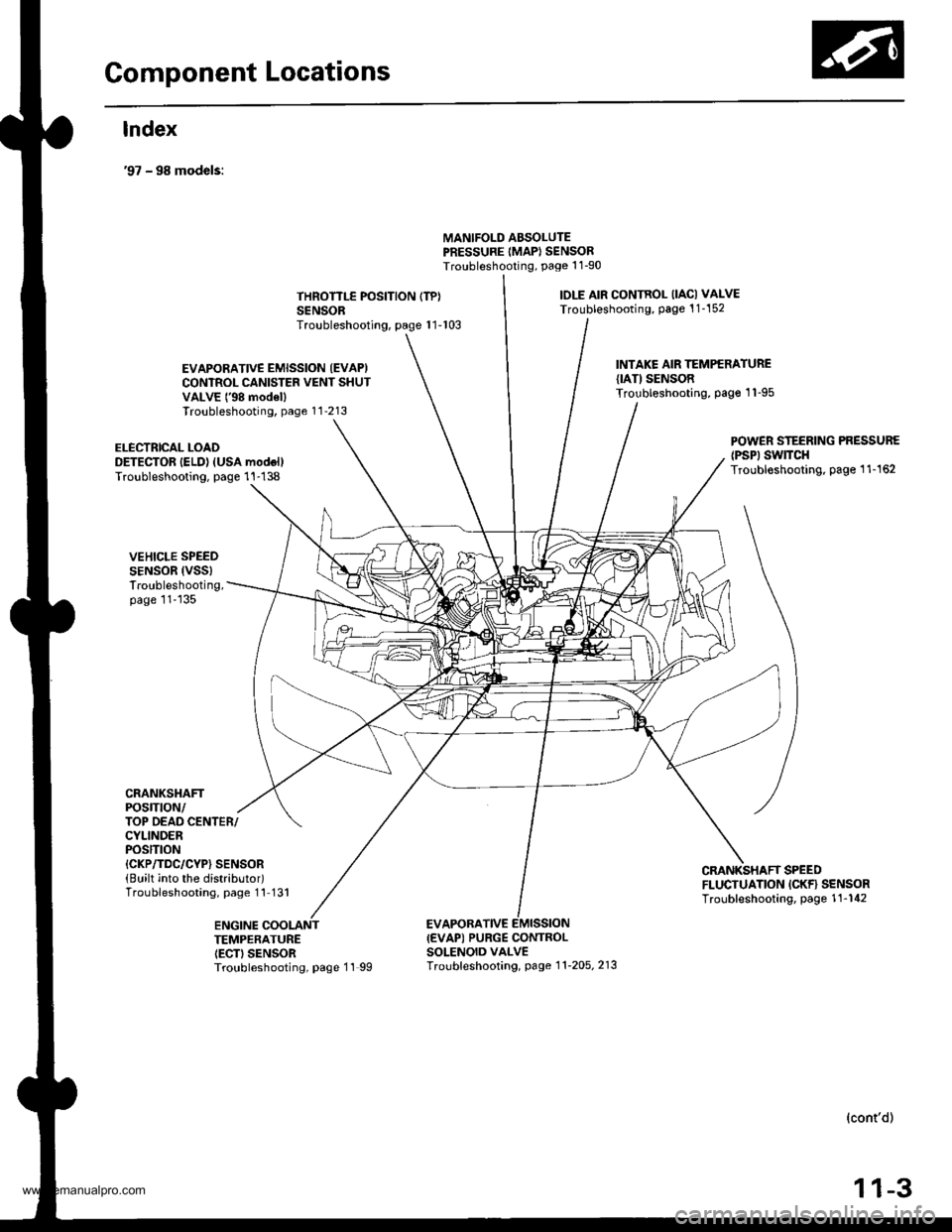

Component Locations

lndex

'97 - 98 models:

MANIFOLD ABSOLUTEPRESSURE IMAP} SENSORTroubleshooting, Page 1 1-90

THROTTLE POSITION (TP}

SENSORTroubleshooting, page 1 1-103

toLE AtR CONTROL llAcl VAI-VE

Troubleshooting, page 1 1-152

EVAPORATIVE EMISSION (EVAP)

CONTROL CANISTER VENT SHUTVALVE t'98 mod€llTroubleshooting, page 11'213

INTAKE AIR TEMPERATUREIIATI SENSORTroubleshooting. page 1 'l -95

ELECTRICAL LOADDETECTOR IELD) (USA modol)Troubleshooting, page 1 1-138

VEHICLE SPEEDSENSOR (VSS)

Troubleshooting,page 11'135

CRANKSHAFTPOSTTtON/

POWER STEERING PRESSURElPsPl swtrcHTroubloshooting, page 1 1-162

TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP} SENSOR(Built into the distributor)Troubleshooting, page 1 l-131

CMNKSHAFT SPEEDFLUCTUATION ICKF} SENSORTroubleshooting. page 1'!-142

ENGINE COOLANTTEMPERATUREIECTI SENSORTroubleshooting, page 11 99

EVAPORATIVEI€VAP) PURGE CONTROLSOLENOID VALVETroubf eshooting, page 1 1'2o5, 213

(cont'd)

11-3

www.emanualpro.com

Page 271 of 1395

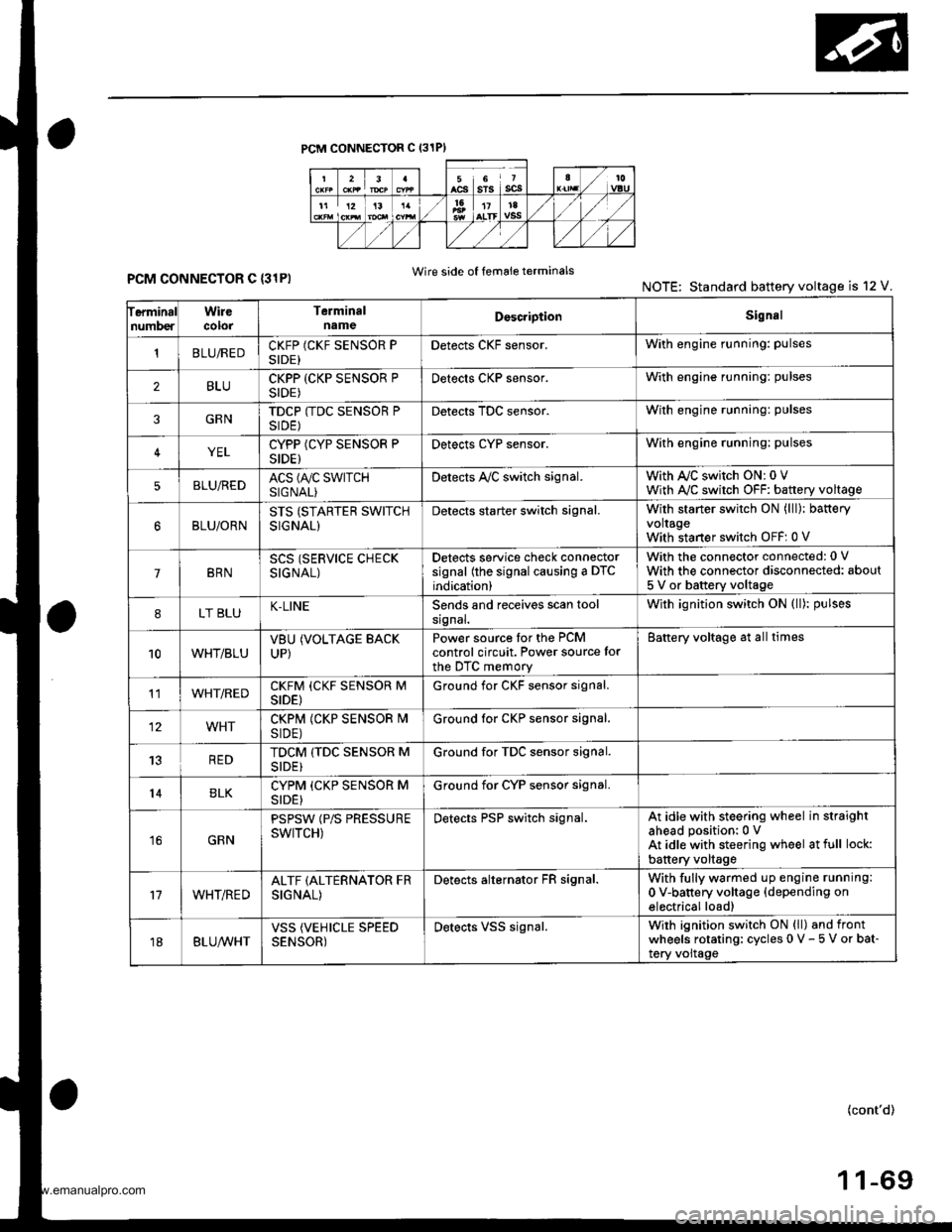

PCM CONNECTOR C (31PI

ferminalnumberWirecolorTerminalnameDoscriptionSignal

'tBLUiREDCKFP (CKF SENSOR PSIDE)Detects CKF sensor.With engine running: pulses

2BLUCKPP (CKP SENSOR PSIDE)Detects CKP sensor.With engine running: pulses

3GRNTDCP (TDC SENSOR PSIDE)Detects TDC sensor.With engine running: pulses

4YELCYPP (CYP SENSOR PSIDE)Detects cYP sensor.With engine running: pulses

5BLU,frEDACS (A/C SWTTCHSIGNAL)Detects A,/C switch signal.With AJC switch ON: 0 VWith A,/C switch OFF: battery voltage

BLU/ORNSTS (STARTER SWITCHSIGNAL)

Detects starter switch signal.With starter switch ON (lll): bafteryvoltageWith staner switch OFF: 0 V

7BRNSCS (SERVICE CHECKSIGNAL)

Detects service check connectorsignal (the signal causing a DTCindication)

With the connector connected: 0 V

With the connector disconnected: about

5 V or battery voltage

8LT BLUK-LINESends and receives scan toolsrgnal.With ignition switch ON (ll): pulses

10WHT/BLUVBUUP)

(VOLTAGE BACKPower source tor the PCMcontrol circuit. Power source for

the DTC memory

Battery voltage at all times

11WHT/REDCKFM (CKF SENSOR MSIDE)Ground for CKF sensor signal.

12WHTCKPM (CKP SENSOR I\4SIDE)Ground lor CKP sensor signal.

13REDTDCM (TDC SENSOR MSIDE}Ground for TDC sensor signal.

14BLKCYPM (CKP SENSOR MSIDE}Ground for CYP sensor signal.

16GRN

PSPSW (P/S PRESSUREswtTcH)Detects PSP switch signal.At idle with steering wheel in straightahead position:0 VAt idle with steering wheel at full lock:

battery voltage

17WHT/REDALTF (ALTERNATOR FRSIGNAL)

Detects alternator FR signal.With fully warmed up engine running:

0 V-battery voltage {depending onelectrical load)

18BLUA/VHTVSS (VEHICLE SPEEDSENSOR)Detects VSS signal.Wirh ignition switch ON (ll) and frontwheels rotating: cycles 0 V - 5 V or bat-tery voltage

Wire side of femaie terminalsPCM CONNECTOR C {31PINOTE: Standard battery voltage is 12 V.

(cont'd)

www.emanualpro.com

Page 364 of 1395

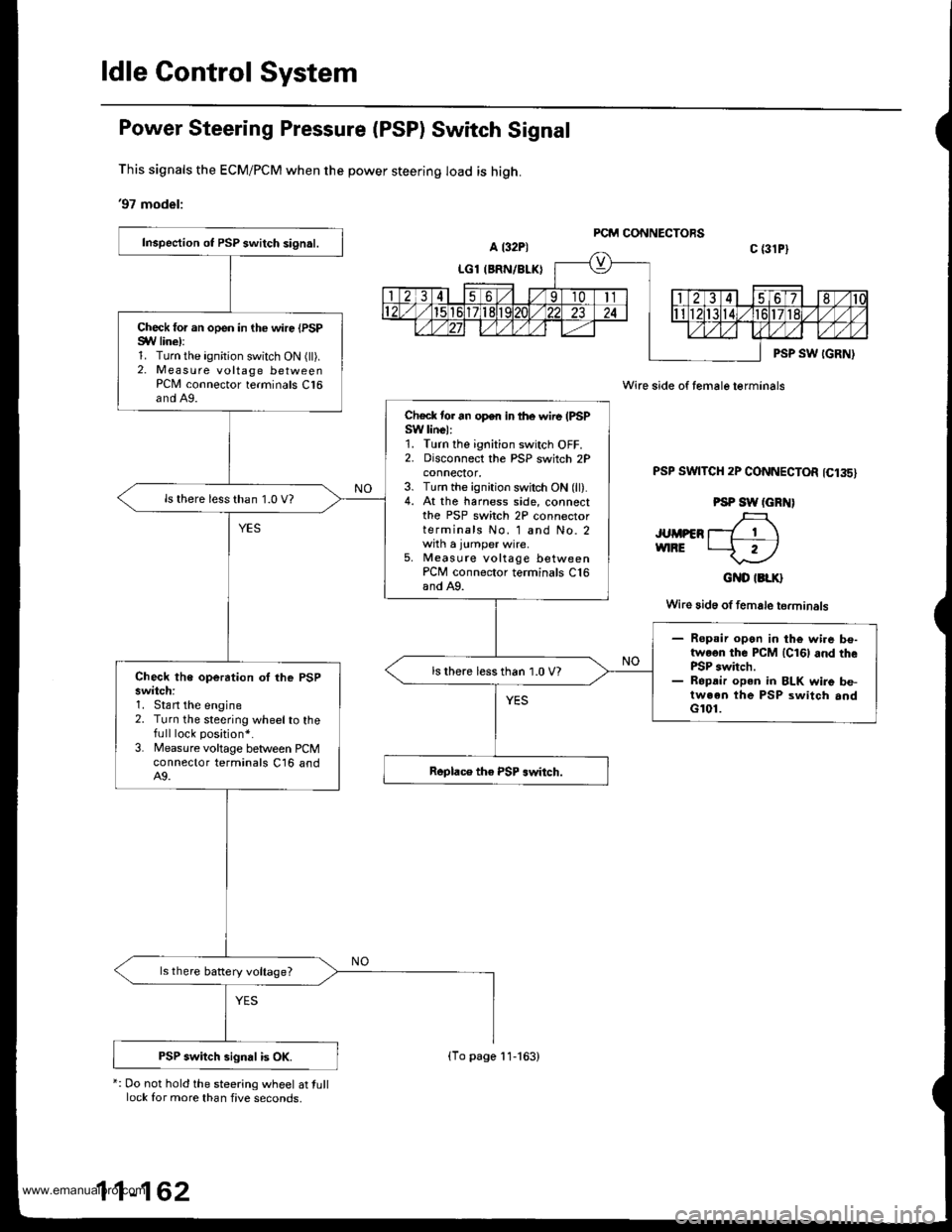

ldle Gontrol System

Power Steering Pressure (PSP) Switch Signal

This signals the ECM/PCM when the power steering load is high.

'97 model:

*: Do not hold the steering wheel at tulllock for more than five seconds,

Wire side of female terminals

PSP SWTTCH 2P CONNECTOR 1C135)

PSP SW (GRN)

JUMPER T_7 1 \vnRE t--f r)

GND IBLK}

Wire 3id6 of female terminals

Inspection ot PSP switch signal.

Check for an open in the wire {PSPSYV line):1. Turn the ignition switch ON (ll).2. Measure voltage betweenPCN4 connector terminals C16and A9.

Check tor an open in lhe wire (PSPSW linel:1. Turn the ignition switch OFF.2. Disconnect the PSP switch 2Pconnecror,3. Turn the ignition switch ON (ll).4. At the harness side, connectthe PSP switch 2P connectorterminals No. 1 and No. 2with a jumper wire.5, Measute voltage betweenPCM connector terminals C16and A9.

ls there less than 1.0 V?

- Ropsir open in the wi.e be-twoon the PCM lcl6l and thePSP switch.- Ropdir open in BLK wire be-tween the PSP switch andG101.

ls there less than 1.0 V?Check the operation oI lhe PSPswitch:1. Stan the engine2. Turn the steering wheelto thefull lock position*.

3. Measure voltage between PCMconnector terminals C16 andA9.

ls there battery voltage?

PSP switch signal is OK.(To page 11-163)

www.emanualpro.com

Page 366 of 1395

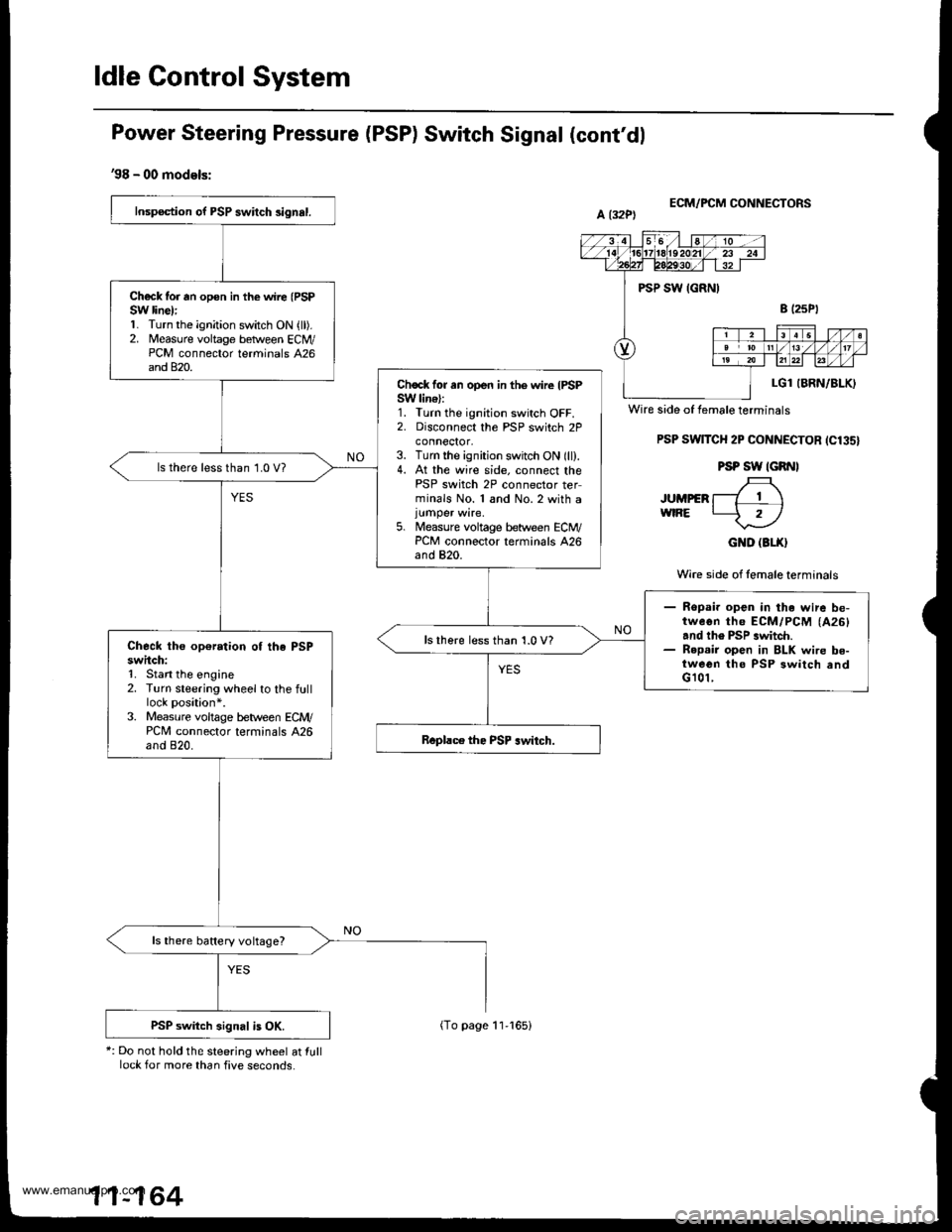

ldle Control System

Power Steering Pressure (PSP) Switch Signal (cont'dl

'98 - 00 models:

*: Do not hold the steering wheel at lulllock for more than five seconds.

ECM/FCM CONNECTORS

PSP SwlTCH 2P CONNECTOR ICl35}

PSP SW IGRNI

JUMpER f-7 T \wtRE L-5 rl

GND (3LX}

Wire side of lemale terminals

Inspection of PSP swilch 3ignal.

Ch€ck tor rn opon in the wire (PSP

SW line):1. Turn the ignition switch ON {ll).2. Measure voltage betlveen ECM/PCM connector terminals 426and 820.

Chock for an open in the wire IPSPSW lin€):1. Turn the ignition switch OFF.2. Disconnect the PSP switch 2Pconnector,3. Turn the ignition switch ON (ll).4. At the wire side. connect thePSP switch 2P connector terminals No. 1 and No.2 with a

5. Measure voltage between ECM/PCM connector terminals 426and 820.

ls there less than 1.0 V?

- Ropai. open in the wire be-tweon th6 ECM/PCM (A26)

and th6 PSP .witch.- R6p.ir open in BLK wire be-tween tho PSP 3witch andG 101,

lsthere less than 1.0 V?Check the op€ration of the PSPswitch:1. Stan the engine2. Turn steering wheel to the fulllock position*.3. Measure voltage b€tween ECM/PCM connector terminals A26and 820.

ls there battery voltage?

PSP switch signal is OK.

Wire side of female terminals

11-164

(To page 11-165)

www.emanualpro.com

Page 384 of 1395

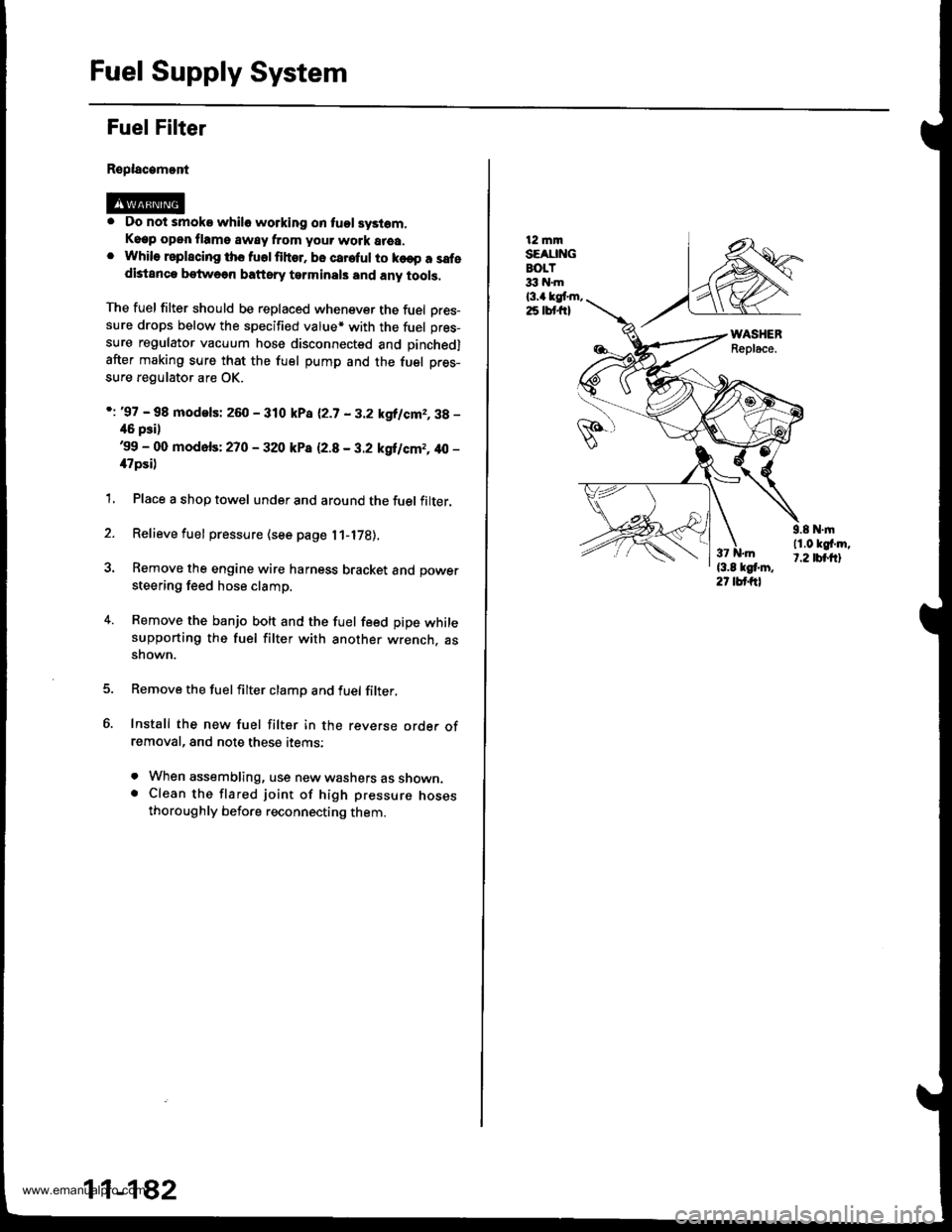

Fuel Supply System

Fuel Filter

Replacamont

. Do not smoke whilo working on tuol syslom,Keep open flame away from your work area.. While rsplscing ths fuolfihor. bo careful to ko€p a safedistanca betweon baftsry tarminals and any tools,

The fuel filter should be replaced whenever the fuel Dres-sure drops below the specified value* with the fuel pres-

sure regulator vacuum hose disconnected and pinchedl

after making sure that the fuel pump and the fuel pres-

sure regulator are OK.

i: '97 - 98 modelsi 260 - 310 kPa 12.7 - 3.2 kgllcm2,3g -

46 psil'99 - 00 mod6fs: 270 - 320 kP8 12.8 - 3.2 kgilcm2, 40 -

il7psi)

1, Place a shop towel under and around the fuel filter.

2. Relieve fuel pressure (see page l1-l7B).

3. Remove the engine wire harness bracket and power

steering feed hose clamp.

4. Remove the banjo bolt and the fuel feed pipe whilesupporting the fuel filter with another wrench. assnown.

Remove the fuelfilter clamp and fuel filter,

Install the new fuel filter in the reverse orde. ofremoval, and note these items:

. When assembling, use new washers as shown.. Clean the flared joint of high pressure nosesthoroughly before reconnecting them.

11-182

12 mmSEAUNGBOLT33 hl.m

l3.a kgt m,25 lbt frl

9.8 N.|n11.0 kgf'm,t.2 tbt.ftl

www.emanualpro.com

Page 662 of 1395

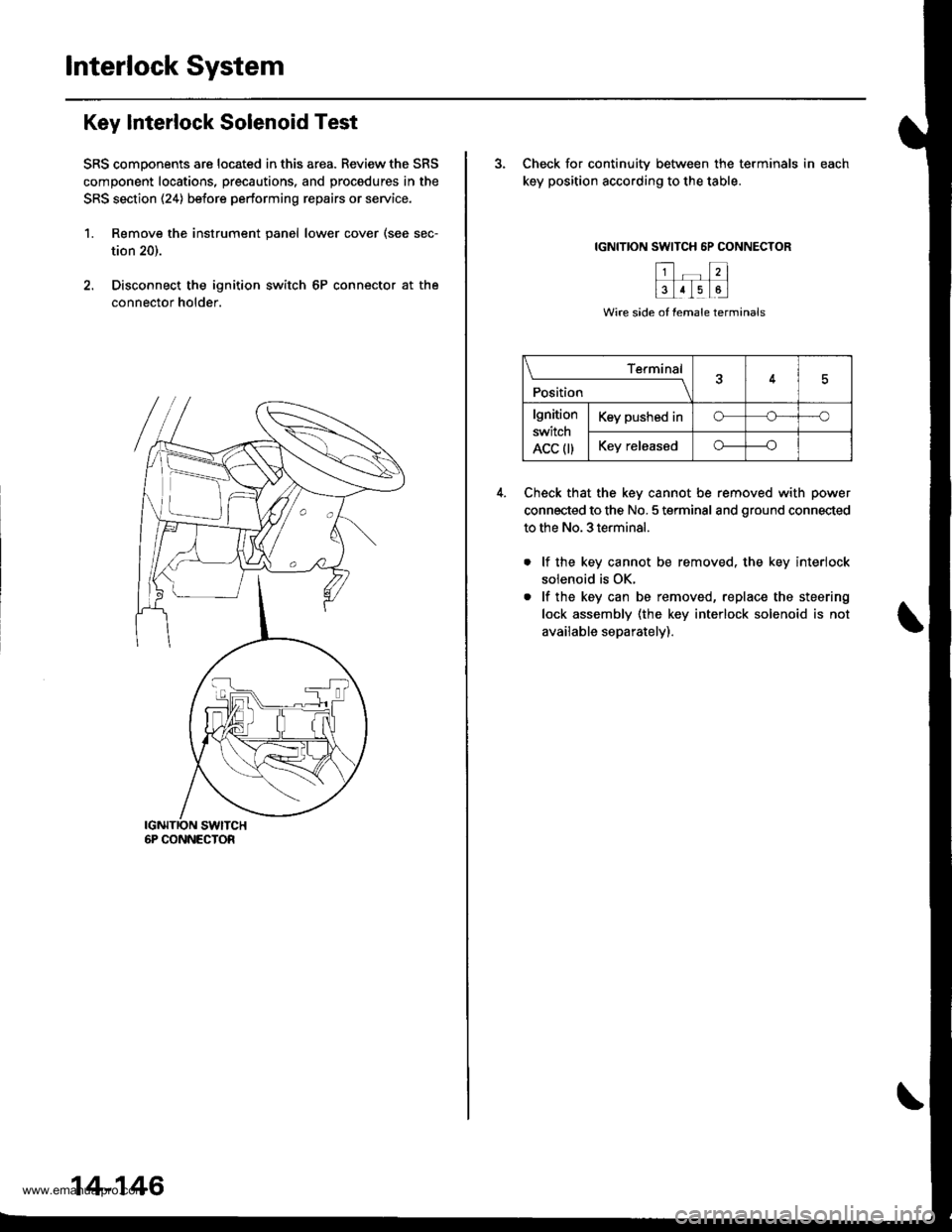

lnterlock System

Key Interlock Solenoid Test

SRS comoonents are located in this area. Review the SRS

component locations, precautions. and procedures in the

SRS section (24) before pertorming repairs or service.

1. Remove the instrument panel lower cover (see sec-

tion 20).

2. Disconnect the ignition switch 6P connector at the

connector holder.

6P CONNECTOR

14-146

3. Check for continuitv between the terminals in each

key position according to the table.

IGNITION SWITCH 6P CONNECTOR

Check that the key cannot be removed with power

connected to the No. 5 terminal and ground connected

to the No. 3 terminal.

lf the key cannot be removed. the key interiock

solenoid is OK.

lf the key can be removed, replace the steering

lock assembly (the key interlock solenoid is not

available separately).

\____________r{r4

Position

lgnition

switch

ACC 0)

Key pushed ino---'o

Key releasedo----o

www.emanualpro.com

Page 663 of 1395

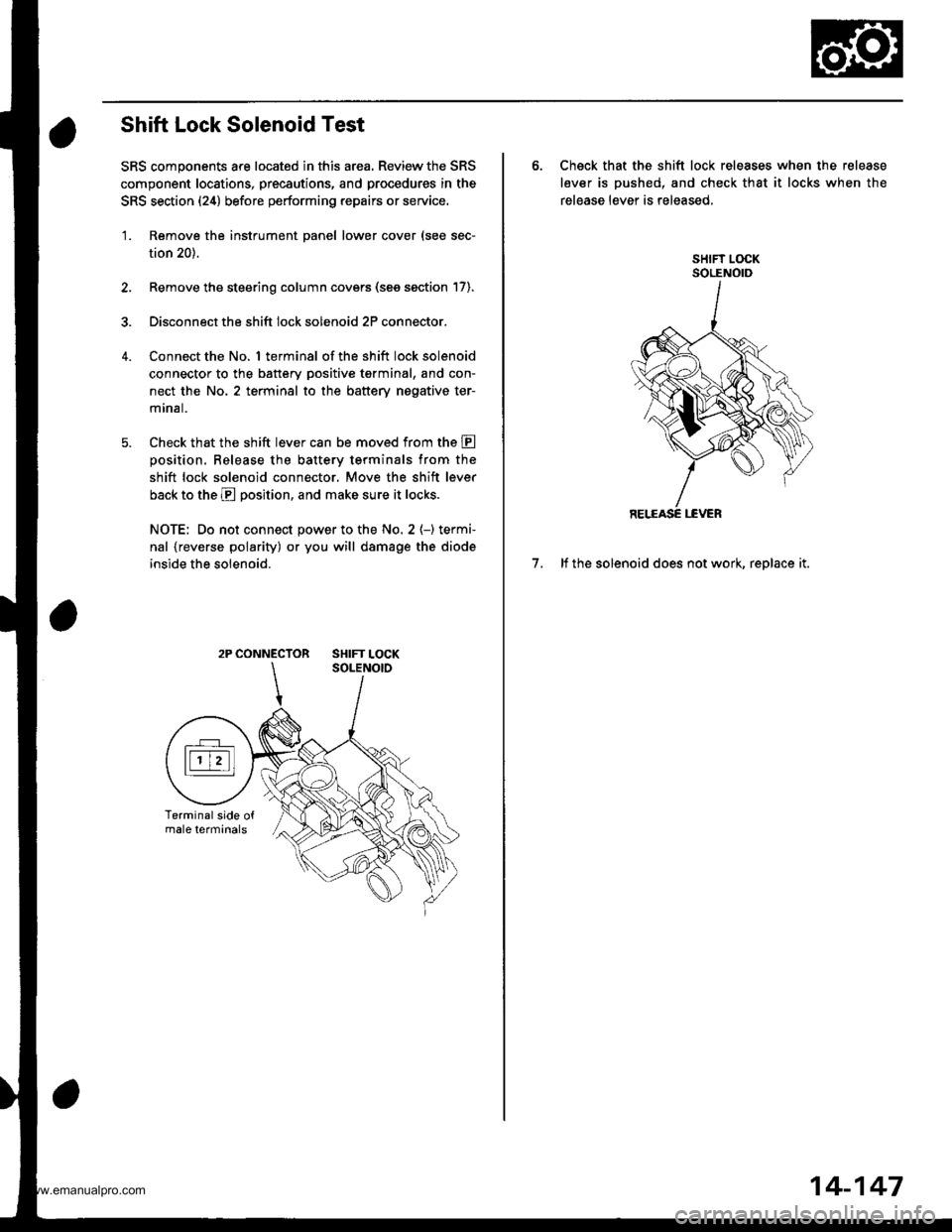

Shift Lock Solenoid Test

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service,

'1. Remove the instrument panel lower cover (see sec-

tion 20).

2. Remove the steering column covers (see section 17).

3. Disconnect the shift lock solenoid 2P connector.

Connect the No. 1 terminal of the shift lock solenoid

connector to the battery positive tgrminal, and con-

nect the No. 2 terminal to the battery nogative ter-

mrnal.

Check that the shift lever can be moved from the E

oosition. Release the batterv terminals from the

shift lock solenoid connector. Move the shift lever

back to the E position, and make sure it locks.

NOTE: Do not connect power to the No. 2 (-) termi-

nal {reverse polarity) or you will damage the diode

inside the solenoid.

2P CONNECTOR SHIFT LOCK

6. Check that the shift lock releases when the release

lever is pushed, and check that it locks when the

release lever is released,

7. lf the solenoid does not work, replace it.

14-147

www.emanualpro.com

Page 846 of 1395

Steering

Special Toofs ............. 17-2

Component Locations

Index ................ ....... 17-3

Troubleshooting

General Troubleshooting ................ 1 7-4

Noise and Vibration ......................... 17-8

Fluid Leaks ............. 17-10

Inspection and Adiustment

Steering Operation .......................... 17-12

Power Assist Check

With Vehicle Parked ....................

Steering Linkage and Gearbox .......

Pump Belt

Rack Guide Adjustment ...................

Fluid Rep|acement ...................,,.,....

Pump Pressure Check .................,,...

*Steering Wheel

Removal ................. 17-18

*Steering Column

Removal/lnstallation ................ ....... 17 -2O

lnspection .............. 17-21

Steering Lock Replacement ............ 17 -22

Power Steering Hoses, Lines

Ffuid Leakage Inspection ................. 17 -23

Repfacement .......... 17-23

Power Steering Pump

Repfacement .......... 17-24

Disassembly ...........17-25

fnspection .............. 17-26

Reassembly ............ 17-28

Power Steering Gearbox

Removal ................. 17-31

Disassembly ........... 17-34

Reassembly ............ 17-40

Ball Joint Boot Replacement .......... 17-50

Installation ............. 17-51

17-12

17-13

17-14

l7-15

17-15

17-16

Disassembly/Reassembly............... 17-18

4'%/b.......... -r'-7--a/

SUPPLEN\EN AL RES\RA(N SYSTES{ (SRS\

This model has an SRS which includes a driver's airbag in the steering wheel hub. a passenger's airbag in the dashboardabove the glove box ('97 - 00 models), and seat belt tensioners in the seat belt retractors ('98 - 00 models). Informationnecessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contentspage include, or are located near, SBS components. Servicing. disassembling or replacing these items will require specialprecautions and tools, and should only be done by an authorized Honda oearer.

To avoid rendering the SRS inoperative, which could lead to peFonal iniury or death in the event of a sevore trontalcollision. allSRS service work must be performod by an authorized Honda dealer.lmproper service procedurgs, including incorrect removal and installalion of the SRS, could lead to personal iniurycaused by unintontional deployment of th€ airbags {'97 - 00 models), and seat belt tensioners ('98 - 00 modelsl.Do not bump the SRS unit. Otherwise, the system may lail in case ot a collision, or the airbags may deploy when theignition switch is ON (lll.

SRS electrical wiring harnesses are identitied by yellow colof coding. Ralated components are located in the steeringcolumn, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-trical test equipment on these cilcuits,

www.emanualpro.com

Page 849 of 1395

Troubleshooting

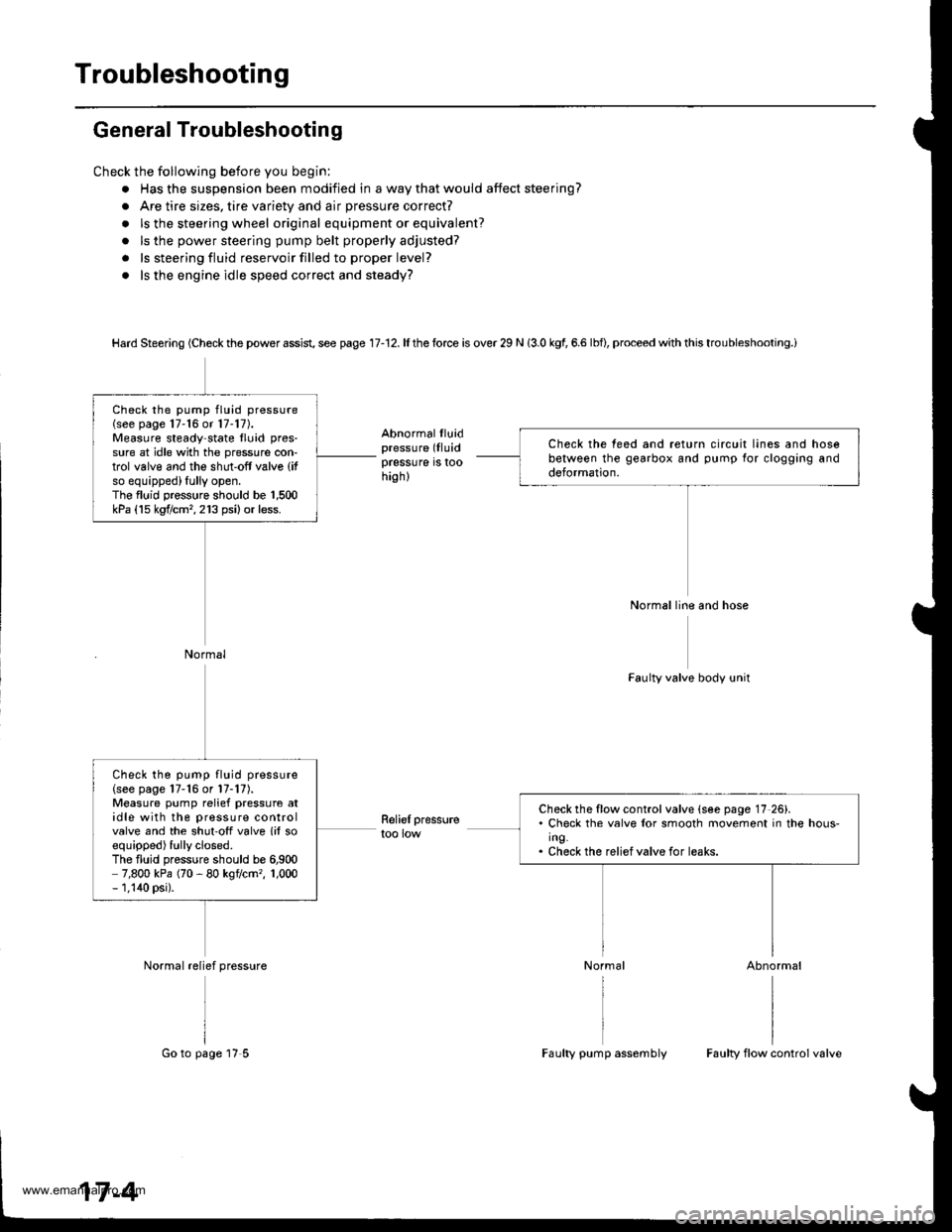

General Troubleshootin g

Check the following before you begin:

. Has the suspension been modified in a way that would affect steering?

. Are tire sizes, tire variety and air pressure correct?

. ls the steering wheel original equipment or equivalent?

. ls the power steering pump belt properly adjusted?

. ls steering fluid reservoir filled to proper level?

. ls the engine idle speed correct and steady?

Hard Steering (Check the power assist, see page 17-12. lf the force is over 29 N (3.0 kgl 6.6 lbfl, proceed with this troubleshooting.i

Abnormalthiidpressure (Iluidpressure is toohigh)

Relief pressuretoo low

Faulty valve body unit

Abnormal

Check the teed and return circuit lines and hosebetween the gearbox and pump for clogging anddeformation.

Normal line and hose

Check the pump fluid pressure(see page 17-16 or 17-17).Measure steady state lluid pres-

sure at idle with the pressure con-trol valve and the shut-off valve (it

so equipped) fully open.The fluid pressure should be 1,500kPa (15 kgf/cm,,213 psi)or less.

Normal

Check the flow control valve (see page 17 26).. Check the valv€ lor smooth movement in the hous-ing.. Check the relief valve for leaks.

Check the pump fluid pressure(see page 17-16 or l7-17).Measure pump relief pressure atidle with the pressure controlvalve and the shut'off valve lil soequipped) fully closed.The fluid pressure should be 6,9007,800 kPa (70 - 80 kgflcm,, 1,000- 1,140 psi).

Normal relief pressure

17-4

Go to page 17 5Faulty pump assemblyFaulty flow control valve

www.emanualpro.com

Page 851 of 1395

Troubleshooting

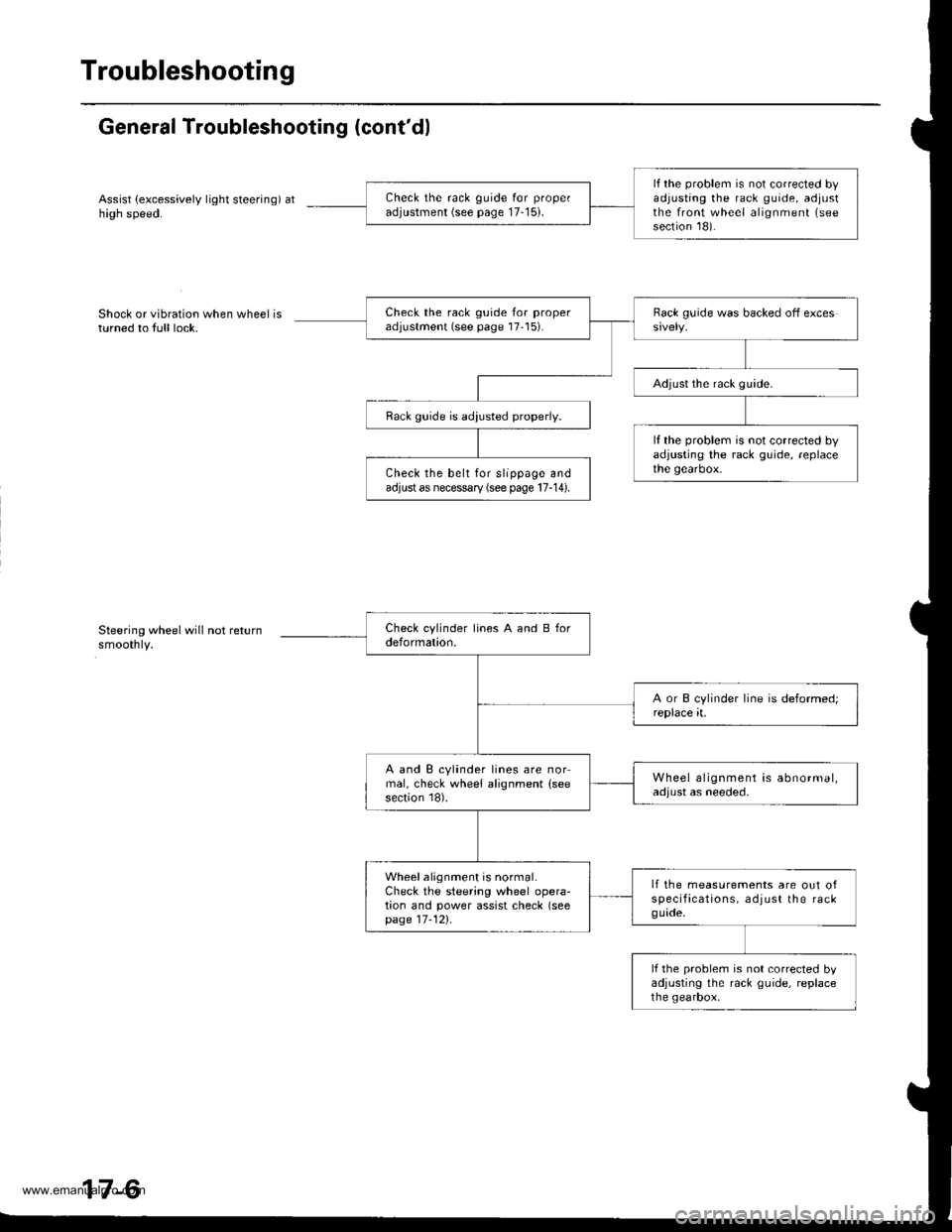

General Troubleshooting (cont'dl

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to full lock.

Steering wheel will not returnsmoothly.

lf the problem is not corrected byadjusting the rack guide, adjustthe front wheel alignment (see

section 18).

Check the rack guide for proper

adjustment (see page 17-15).

Check the rack guide for properadjustment (see page 17'15).

Adjust the rack guide.

Rack guide is adiusted properly.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox.Check the belt for slippage andadjust as necessary (see page 17-14).

A and B cylinder lines are normal, check wheel alignment (see

section 18).

Wheel alignment is abnormal,adjust as needed.

Wheel alignment is normal.Check the steering wheel opera-tion and power assist check (seepage 17-121.

lf the measurements are out ofspecifacations, adjust the rackguade.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox,

www.emanualpro.com