Two Way valve HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 288 of 1395

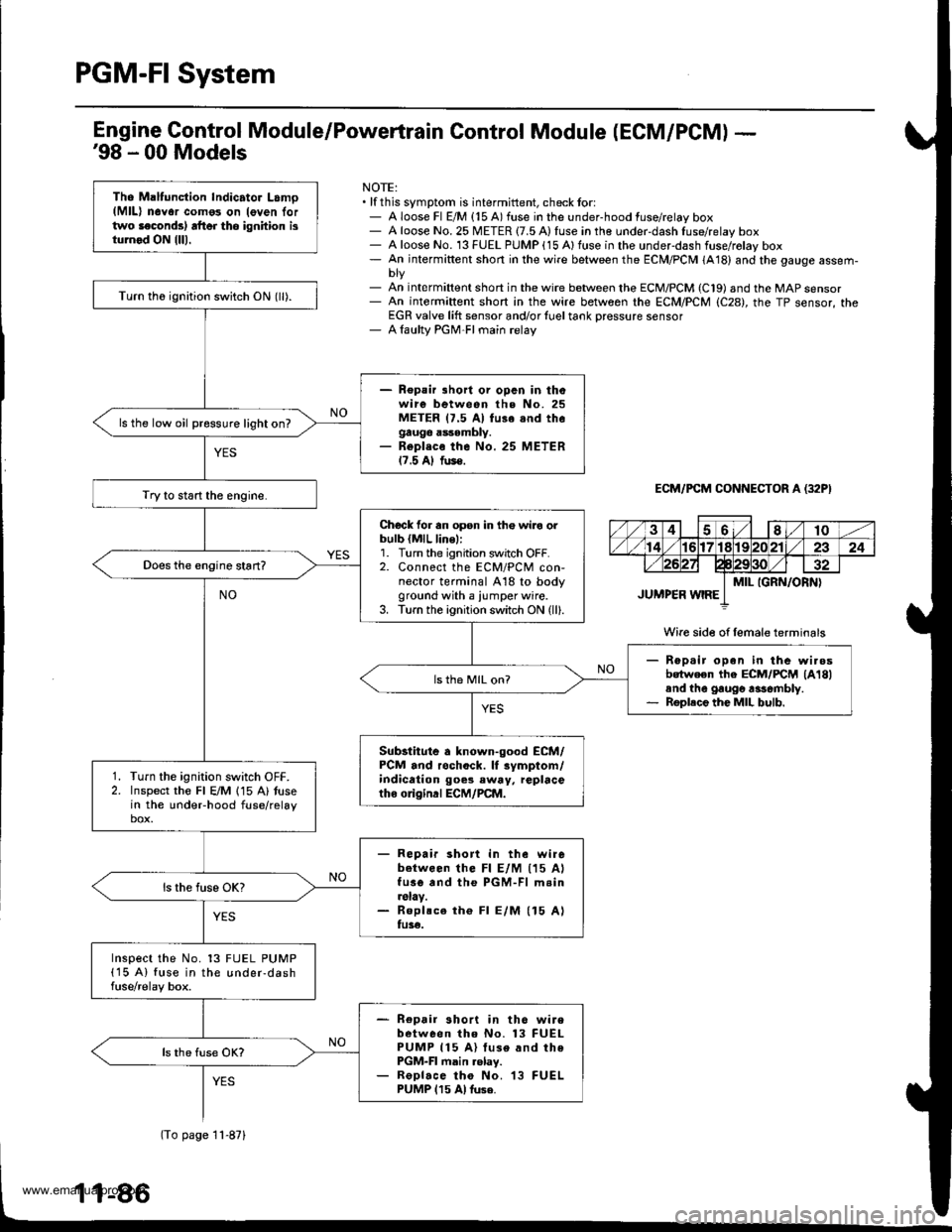

PGM-FI System

Tho Maltunction Indicator Lamo(MlL) n6Yor como3 on leven lortwo laconds) rft6r tho ignhion isturnod ON {lll.

Turn th6 ignition switch ON (ll).

- Repair lhort or opcn in thowire between the No. 25METER 17.5 Al fu3e snd thegauge assembly.- Repl.co the No. 25 METER17.5 Al fus€.

ls the low oil pressure light on?

Try to start the engine.

Chock for an opsn in th€ wiro orbulb {MlL line,:1. Turn the ignition switch OFF.2. Connect the ECM/PCM con-nector terminal A18 to bodyground with a iumper wire.3. Turn the ignition switch ON (ll).

Rep.ir open in the wi.osbotween the ECM/FCM lA18land the gaugo rasombly.Roplece the MIL bulb.

ls th6 MIL on?

Substitute a known-good ECM/PCM and rochock. lf rymptom/indication goes eway, replacetho o gind ECM/PCM.

Turn the ignition switch OFF.Inspect the Fl E/M 115 A) tusein the undeFhood fuse/relaybox.

- Repair short in the wirebetween lhe Fl E/M (15 AlfusG and the PGM-Fl m.in.slay.- Roplsce th€ Fl E/M (15 Alfu3€.

Inspect the No. 13 FUEL PUMP(15 A) fuse in the under-dashfuse/relay box.

- Repair short in th6 wirebetween tho No. 13 FUELPUMP 115 A) luse and thePGM-FI main .elay.- ReDlace tho No. 13 FUELPUMP 115 Al tuse.

Engine Gontrol Module/Powertrain Control Module (ECM/PCM) -'98 - 00 Models

NOTE:. lf this symptom is intermittent, check tor:- A loose Fl E/M {15 A) fuse in the under-hood fuse/relay box- A loose No. 25 METER {7.5 A) fuse in the under-dash fuse/relay box- A loose No. 13 FUEL PUMP (15 Alfuse in the underdash fuse/rolay box- An intermiftent short in the wire between the ECM/PCM (A18) and the gauge assem-

- An int€rmiftent short in the wire between the ECM/PCM (C19) and the MAP sensor- An intermiftent short in the wire between rhe ECM/PCM (C28), the TP sensor, theEGR valve lift sensor and/or {uel tank Dressure sensor- A laulty PGM-FI main relay

ECM/PCM CONNECTOR A (32P}

Wire side of female terminals

(To page 11-871

www.emanualpro.com

Page 289 of 1395

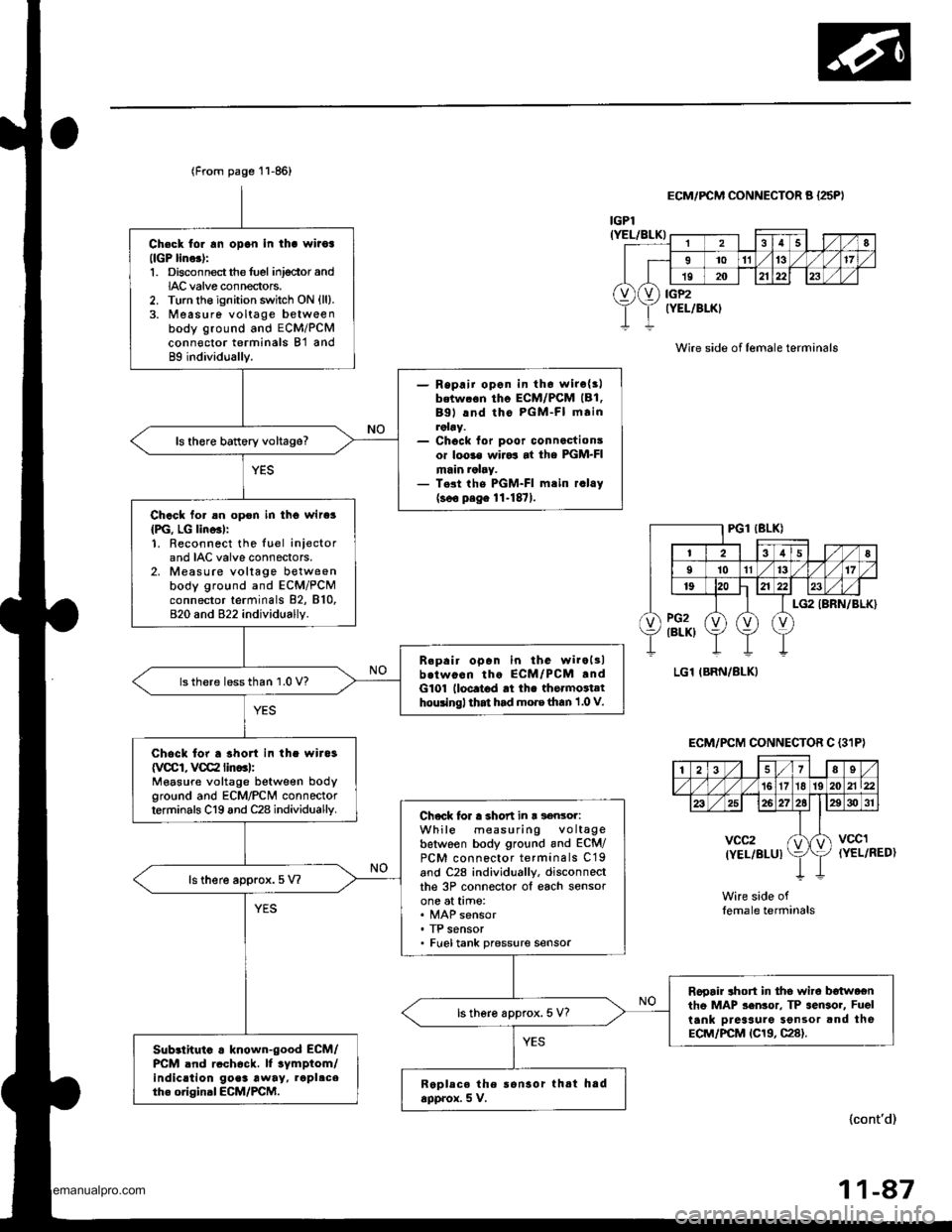

Ch€ck tor rn opon in tha wiioa(lGP lino.):1. Disconnectthe fuel inj€ctor andIAC valve connectors.2. Turn the ignition switch ON {ll}.3. Measure voltage betweenbody ground and ECM/PCMconn€ctor terminals B'l and89 individually.

- Repaii opon in th6 wirc{3lbetw.6n tho ECM/PCM (B1.

Bgl lnd tho PGM-FI mainroby.- Chock for poor connactionsor loo3€ wiJo3 at the PGM-FImain ralry.- T.st the PGM-FI mtin r.lay(soo p.ge 11-1871.

ls there battery voltage?

Chack for an opon in tho wire3

{PG, LG lino3l:1. Reconnect the luel iniectorand IAC valve connectors.2. Measure voltage betweenbody ground and ECM/PCMconnector terminals 82, 810,820 and 822 individually.

B.pair open in the wiroltlb.twocn tho ECM/PCM .ndG101 lloc.t6d rt th. thormoiathouingl that had mo.e than 1 .0 V.

lsthere lessthan 1.0 V?

Chock for a shon in the wira3

{VCCI, VCC2 lin..l:Measure voltage between bodyground and ECM/PCN4 connectorterminals C19 and C28 individuallv.Chock lor a short in r s€nsor:While measuring voltagebetwoen body ground and ECM/PCM connector terminals C19and C28 individually, disconneclthe 3P connector ol each sensorone at time:

. TP sensor. Fueltank pressure sensor

ls there approx.5 V?

Rooair ahort in tho wire b€twoentho MAP sen3or. TP sensor, Fuel

tank Dreaaure Sonsor and theECM/PCM tC19, C28).

ls there approx. 5 V?

Sub3lhuio . known-good ECM/PCM .nd rcch6ck. lf tymptom/indic.tion go.3 away, rapl.ceth. original ECM/PCM.Replece the ronsor thtt hadapprox. 5 V.

(From page 11-86)

lcont'd)

r

28

I1011't317

19202123

vXv) iiP2rELlBLK)

IGPl(YEL/BLK)

ECM/FCM CONNECTOR A {25PI

Wire side of lemale terminals

(YEL/RED)

Wire side oflemale terminals

ECM/PCM CONNECTOR C {3'IP}

| 2i37Es/'t61718 192021\22

26272elE30 31

vcc2(YEL/BLUIktvccl

11-47

www.emanualpro.com

Page 405 of 1395

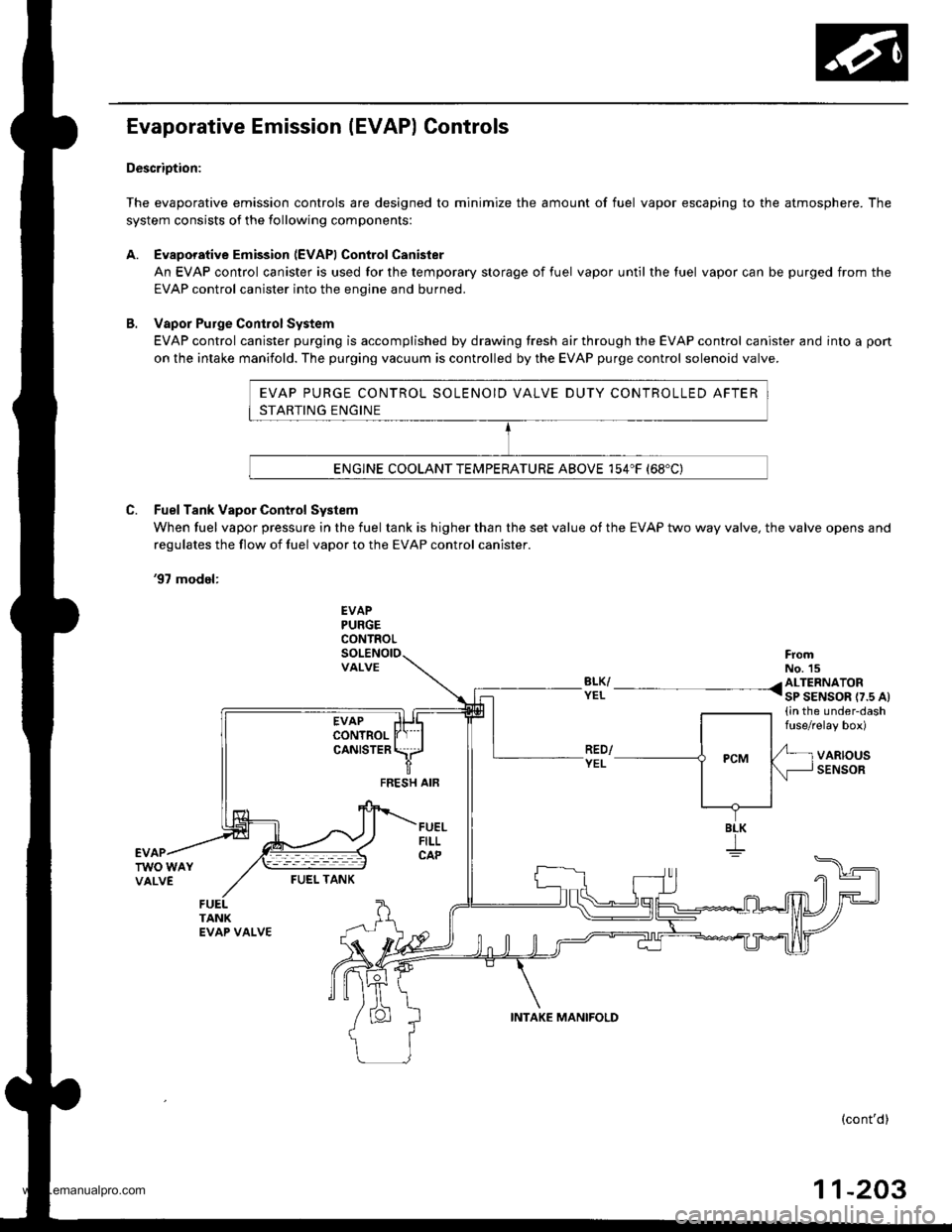

EVAP PURGE CONTROL SOLENOID VALVE DUTY CONTROLLED AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154"F (68'C)

Evaporative Emission (EVAP) Controls

Description:

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAPI Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the luel vapor can be purged from the

EVAP control canister into the enqine and burned.

B. Vapor Purge ConirolSystem

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a pon

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow ot fuel vapor to the EVAP control canister.

'97 model:

EVAPPURGECONTROL

VALVEFromNo. 15BLK/ /ALTERNATORYEL I sP SENSOR r7.s At(in the under-dashfuse/relay box)

VARIOUSSENSORFEESH AIF

BLK

I

FUEI- TANK

(cont'd)

11-203

INTAKE MANIFOLD

www.emanualpro.com

Page 406 of 1395

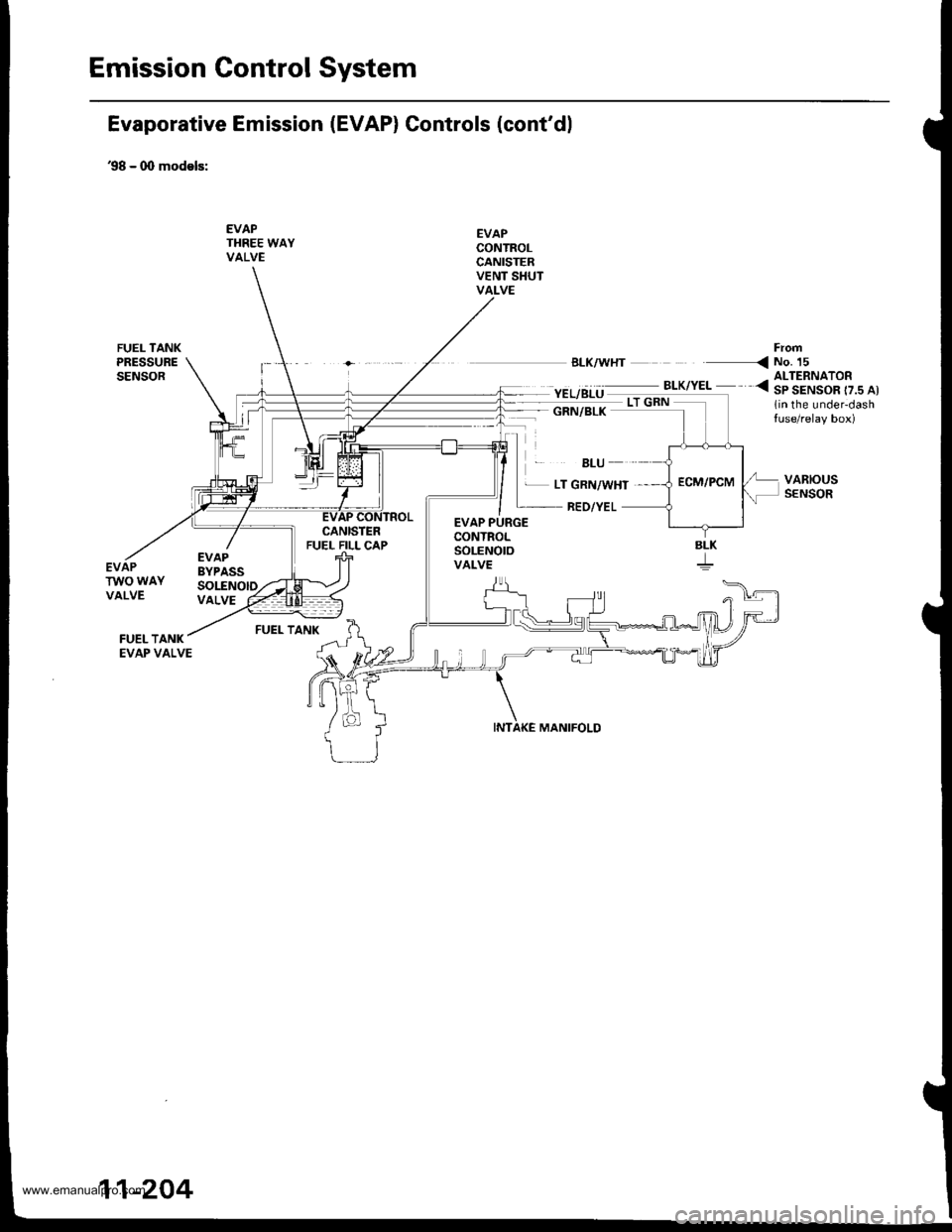

Emission Gontrol System

Evaporative Emission (EVAP) Controls (cont'dl

'98 - 0O models:

EVAPTHREE WAYVALVE

EVAPCONTROLCANISTERVENT SHUTVALVE

'EL/BLU ._^_-:.*,".. <3|ltAIS"o[..^,

1in the under-dashtuse/relay box)

FrofiBLK/WHT < NO. 15

GRN/BLK

BLU

EVAPBYPASSSOLENOID

EVAP PURGECONTROLSoLENOtOVALVE

L LT GRN/WHT ,

RED/YEL

MANIFOLD

VARIOUSSENSOR

EVAPTWO WAYVALVEVALVE

FUEL TANK

SLK

11-204

www.emanualpro.com

Page 409 of 1395

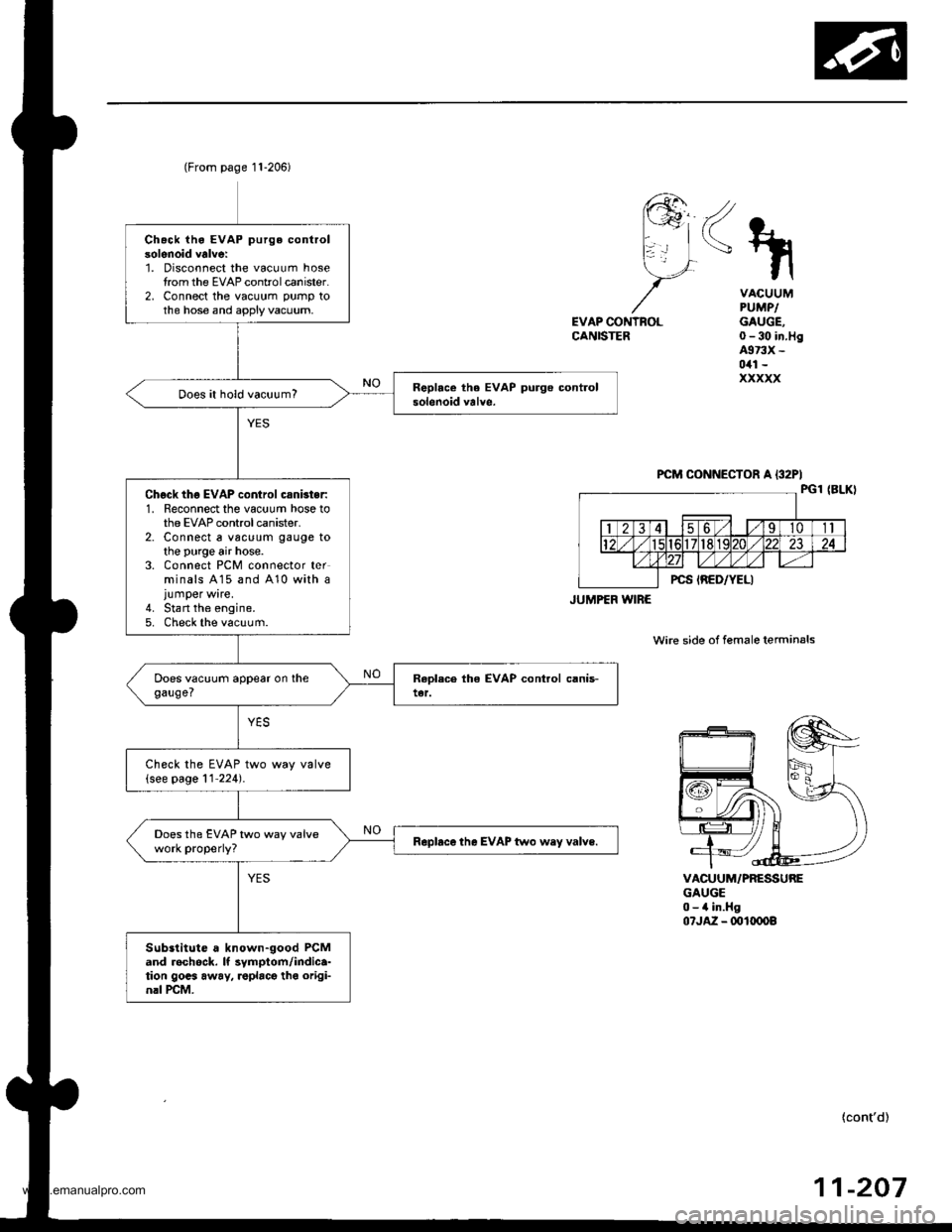

Chack iho EVAP purge controlsolenoid valve:1. Disconnect the vacuum hosetrom the EVAP controlcanister.2, Connect the vacuum pump tothe hose and apply vacuum,

Does it hold vacuum?

Chgck thg EVAP control csnbter:1. Reconnect the vacuum hose tothe EVAP control canister.2. Connect a vac!um gauge tothe purge air hose.3. Connect PCM connector terminals A15 and 410 with ajumper wire.4. Stan the engine.5. Check the vacuum.

Check the EVAP two way valve(see page 11'224).

Does the EVAP two way valvework properly?Rapbce the EVAP two wey valve.

Substitute a known-good PCMand rechock. It symptom/indica-tion gocs away, roplacg tho origi-nrl rcM.

(From page 11-206)

JUMPEF WIRE

<\

EVAP CONTNOLCANISTER

VACUUMPUMPIGAUGE,0-30 in.Hg4973X -

0il1 -

xxxxx

VACUUM/PRESSUREGAUGE0-4 in.Hg07JA2 - ml(x)o8

wire side of female terminals

{cont'd)

-20711

www.emanualpro.com

Page 410 of 1395

Emission Control System

Evaporative Emission (EVAP) Controls (cont'd)

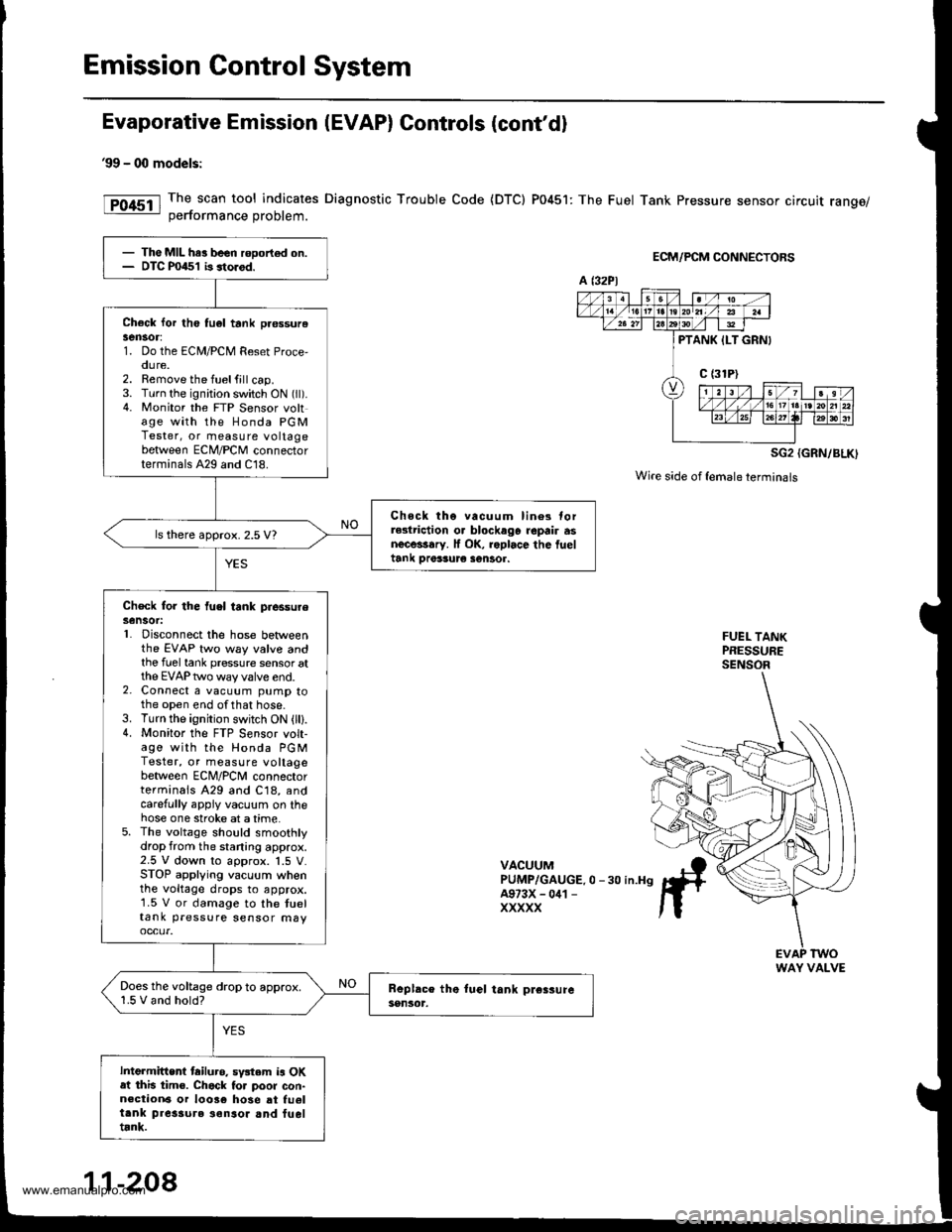

99 - 00 models:

The scan tool indicates Diagnostic Trouble Code {DTC) P0451: The Fuel Tank Pressure sensor circuit range/oerformance Droblem.

ECM/PCM CONNECTORS

SG2 {GRN/BLK)

Wire side of {emaleterminals

FUEL TANKPRESSURESENSOR

VACUUMPUMP/GAUGE.0 -30 in.H9A973X - 041 -

XXXXX

- The MIL har been rooort€d on.- DTC P0451 b storod.

Check lor th6 tu6l tank pr€ssurelen30r:1. Do the ECM/PCM Reset Proce,oure.2. Remove the fuelfill cap.3. Turn the ignition switch ON (ll).4. Monitor the FTP Sensor voltage with the Honda PGMTester, or measure voltagebetween ECM/PCM connectorterminals A29 and C18.

Chock tho vacuum lin6s torrGlriction o. blockago repair asnecessary. lf OK, roplace the fueltank Drer3ur€ sentor.

ls there approx. 2.5 V?

Check for the fuel tank piessureSensot:L Disconnect the hose betweenthe EVAP two way valve andthe fuel tank pressure sensor atthe EVAP two way valve end.2. Connect a vacuum pump tothe open end ofthat hose.3. Turn the ignition switch ON (lll.4. Monitor the FTP S€nsor volt-age with the Honda PGMTester, or measure voltagebetween ECNI/PCNI connectorterminals A29 and C18, andcarefully appiy vacuum on thehose one stroke at a time.5. The voltage should smoothlydrop from the staning approx.2.5 V down to approx. 1.5 V.STOP applying vacuum whenthe voltage drops to approx.1.5 V or damage to the tueltank pressure sensor may

Does the voltage drop to approx.1.5 V and hold?

Intermittent tailuro. sv3tem is OKat this tim€. Chack to. poor con-n€ction6 or 10036 hose at fu6ltank pres3ure ionsor and fueltrnk.

a t32Pl

PTANK ILT GRNI

WAY VALVE

11-208

www.emanualpro.com

Page 416 of 1395

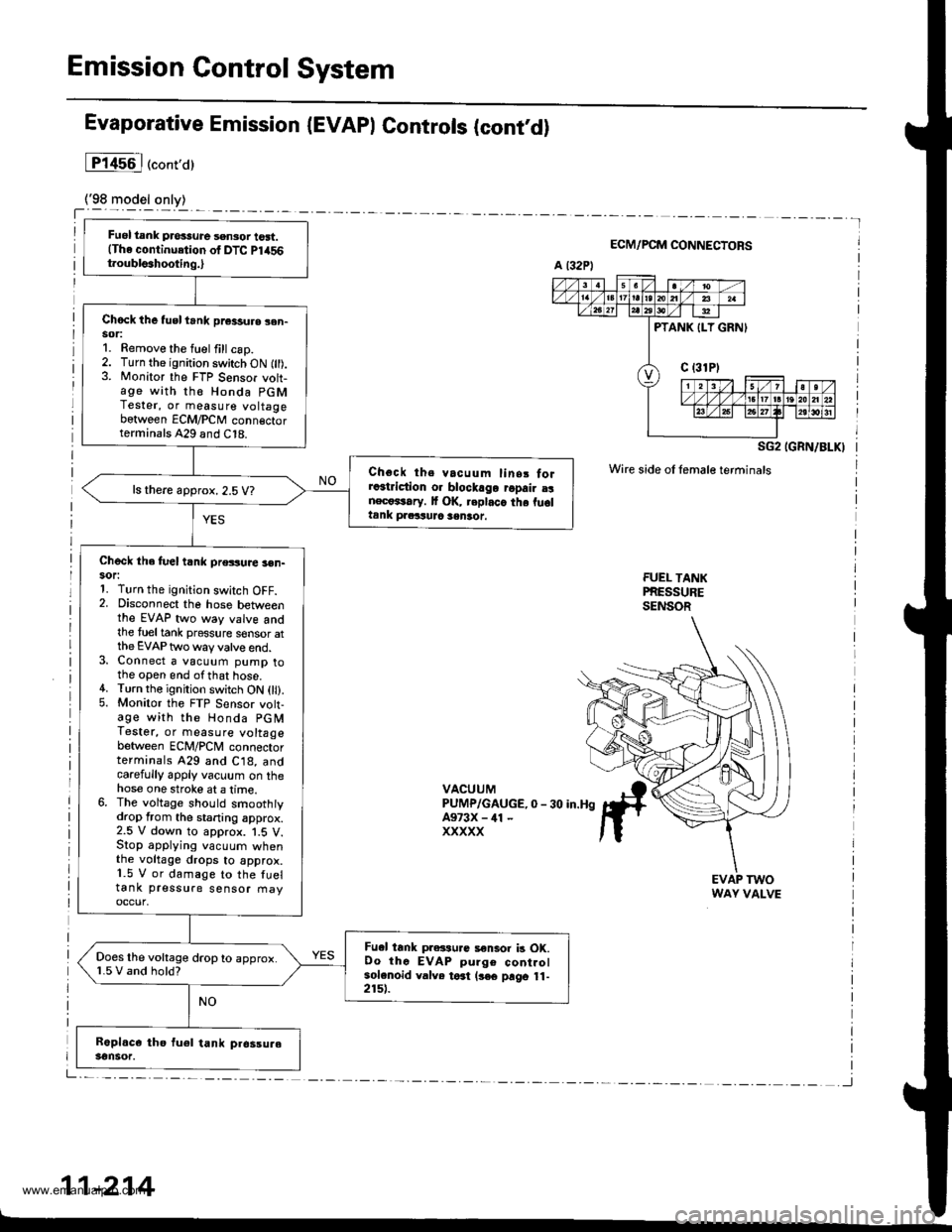

Emission Control System

Fuel tank pros3ure sensor tost.(The continuetion of DTC Pl456t.oubls3hooting.,

Chock the tusl trnk pr€3sure sen-sor:1. Remove the fuel fill csp.2. Turn the ignition switch ON fll).3. Monitor the FTP Sensor voh-age with th€ Honda PGMTester, or measure voltagebetween ECM/PCM conn€ctorterminals A29 and C18.

Choct ths vacuum linsr forra3triction o. blockago ropair a!nect*rary. It OK, replaca the fu6ltank praituJc sentot.

ls there approx. 2.5 V?

Check the fuel t nk pressuae 3en-sor:1. Turn the ignition switch OFF.2. Disconnect the hose betweenthe EVAP two way valve andthe tueltank pressure sensor atthe EVAP two way valve end.3. Connect a vacuum pump tothe open end ofthat hose.4. Turn the ignition switch ON 0l).5. Monitor the FTP Sensor volt-age with the Honda PGMTestet, or measure voltagebetween ECM/PCM connectorterminals 429 and C18, andcarefully apply vacuum on thehose one stroke at a lime.6. The voltage should smoothtydrop from the staning approx.2.5 V down to approx. 1.5 V.Stop applying vacuum whenthe voltage drops to approx.1.5 V or damage to the fueltank pressure sensor fiayoccur,

Fu.l tank pressu.c a€nlor b OK.Oo thc EVAP pulge controlsolenoid valve toat (3€€ prgo 11-2151.

Does the voltage drop to approx.1.5 V and hold?

Evaporative Emission (EVAPI Controls (contd)

lP14s6l("ont,a)

ECM/PCM CONNECTORS

SG2 IGRN/BLKI

Wire side oI female terminals

FUEI- TANKPRESSURESENSOR

VACUUMPUMP/GAUGE,0 - 30 in.HgA973X - ill -

xxxxx

EVAP TWOWAY VALVE

11-214

www.emanualpro.com

Page 418 of 1395

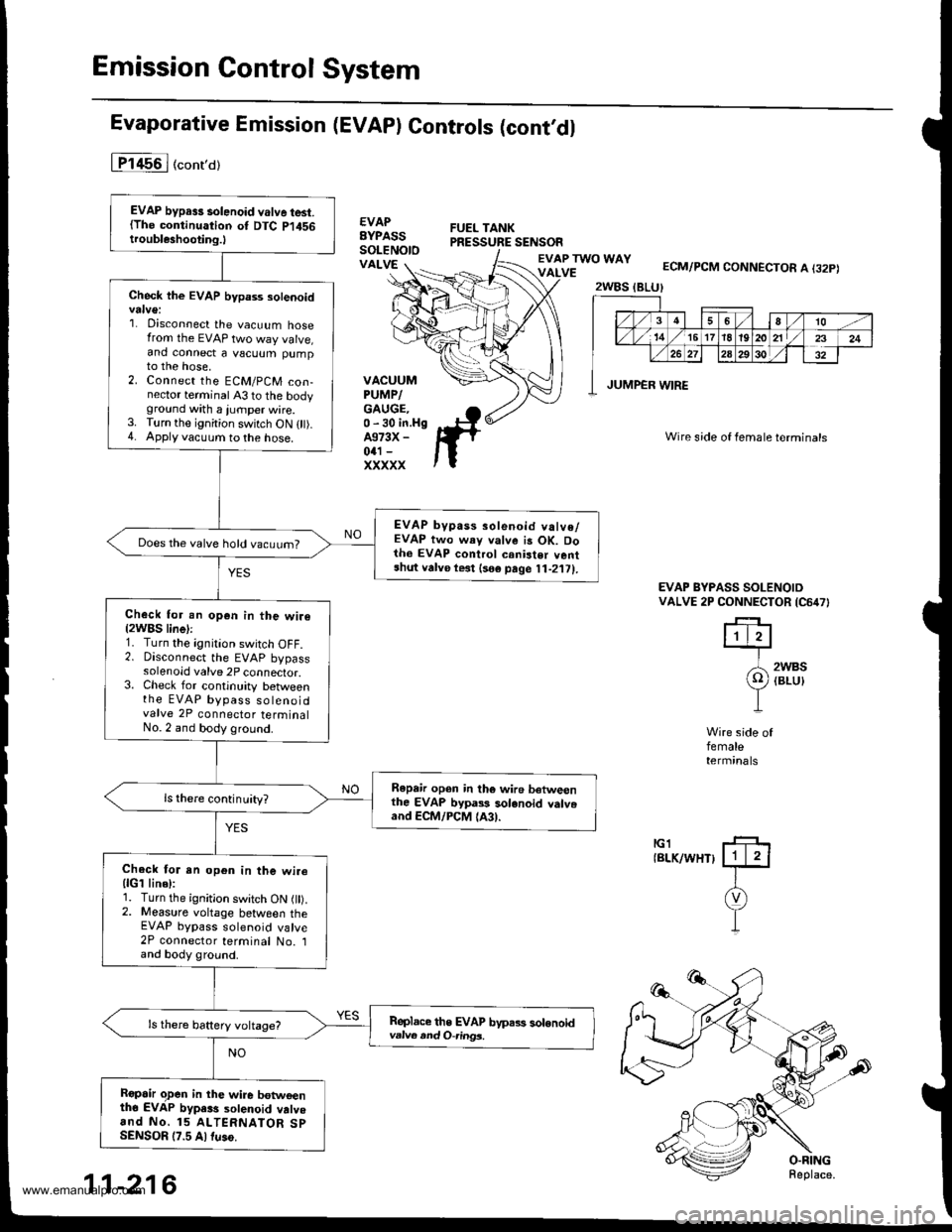

Emission Control System

Evaporative Emission (EVAPI Controls (cont,dl

1T1456I (conro)

€VAPBYPASSSoLENOtOVALVEECM/PCM CONNECTOR A I32P)

Wire side of female terminals

VACUUMPUMP/GAUGE.0 -30 in.HgA373X -

041 -

xxxxx

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR lcorlTl

2WBS(BLU}

II

Wire side offemaletermrnats

tGlIBLK/WHT}

EVAP bypa3s solenoid valve test.(The continuation ot DTC P1456troubleshooting.l

Check the EVAP bypass sotenoid

1. Disconnect the vacuum hosefrom the EVAP two way valve,and connect a vscuum pumpto the hose,2. Connect the ECM/PCM con-nector terminal 43 to the bodyground with a jurnper wire.3. Turn the ignition switch ON 0t).4. Apply vacuum to the hose.

EVAP bypass solenoid valve/EVAP two way valve is OK. Doth6 EVAP control crnister ventshut vafve le3t lso€ page 11-2'111.

Does the valve hold vacuurn?

Check for an op€n in the wir€(2WBS line):1. Turn the ignition switch OFF.2. Disconnect the EVAP bypasssolenoid valve 2P connector.3. Check for continuity betweenthe EVAP bypass so teno idvalve 2P connector terminalNo. 2 and body ground.

Repair open in the wire betweenthe EVAP bypass solenoid valv.and ECM/PCM lA3).

Chack tor an op6n in the wirellcl line):1. Turn the ignition switch ON l).2. Measure voltage between theEVAP bypass solenoid valve2P connector terminal No. land body ground.

Replace the EVAP byps.,s solonoidvatus and O-ring3.

Ropair o,pen in the wire botwoenth6 EVAP bypa$ sotenoid vatvoand No. 15 ALTERNATOR SpSENSOR (7.5 Altuso.

2WBS (BLU}

/3

7,x

4l6o/to -/

,/ 16 1718't920 211/z3

26 272A29solT32

JUMPER WIRE

11-216

www.emanualpro.com

Page 420 of 1395

Emission Control System

Evaporative Emission IEVAPI Controls (cont'd)

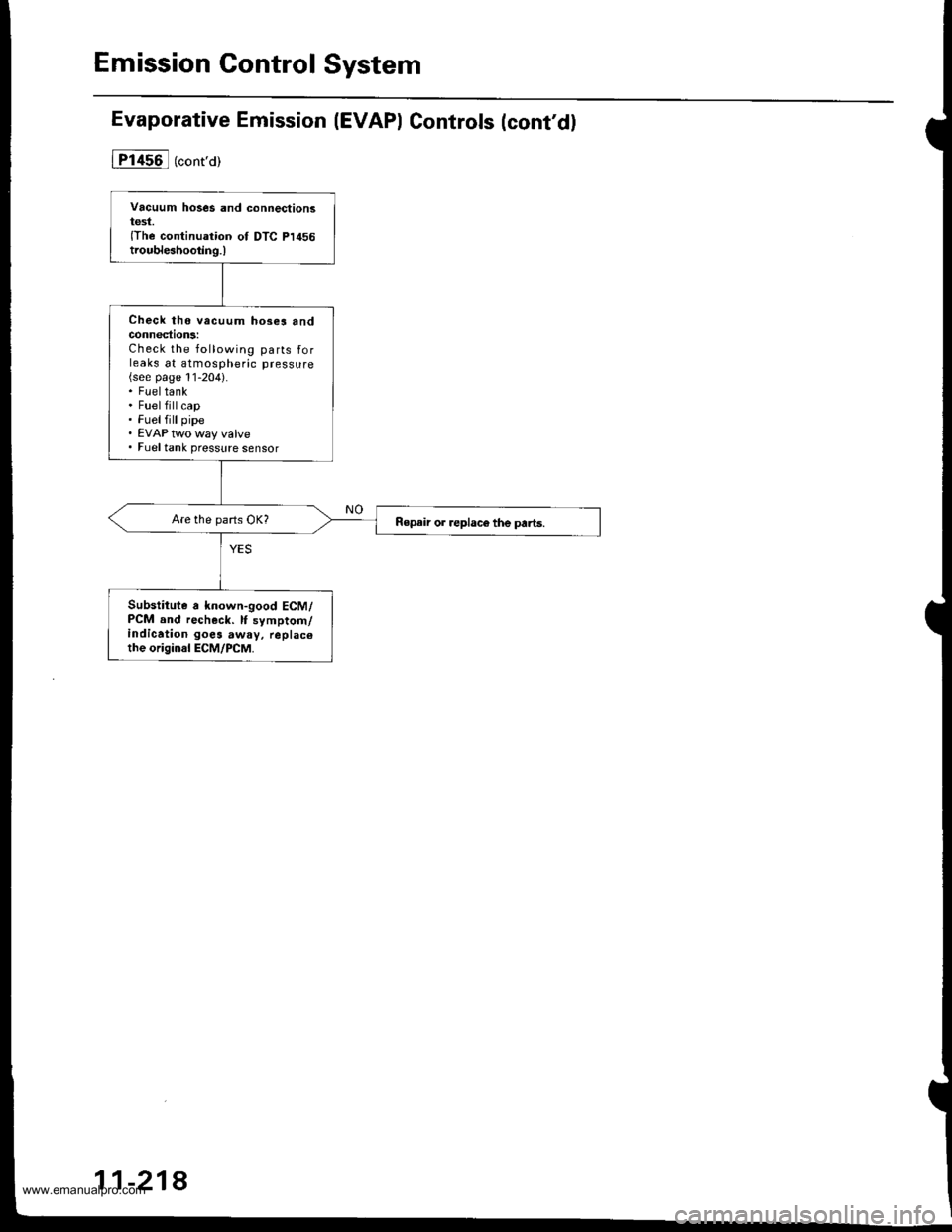

lTi,t56l ("onto)

Vacuum hoses and connectionstelit.(The continuarion of DTC P1456troubleshooiing.l

Check the vacuum ho3es andconnect|ons:Check the following parts forleaks at atmospheric p ressu re{see page 11-204).. Fueltank. Fuel fill cap. Fuelfill pipe. EVAP two way valve. Fueltank pressure sensor

Repair or replaco the parts.

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goes away, replac€the original ECM/PCM.

11-218

www.emanualpro.com

Page 423 of 1395

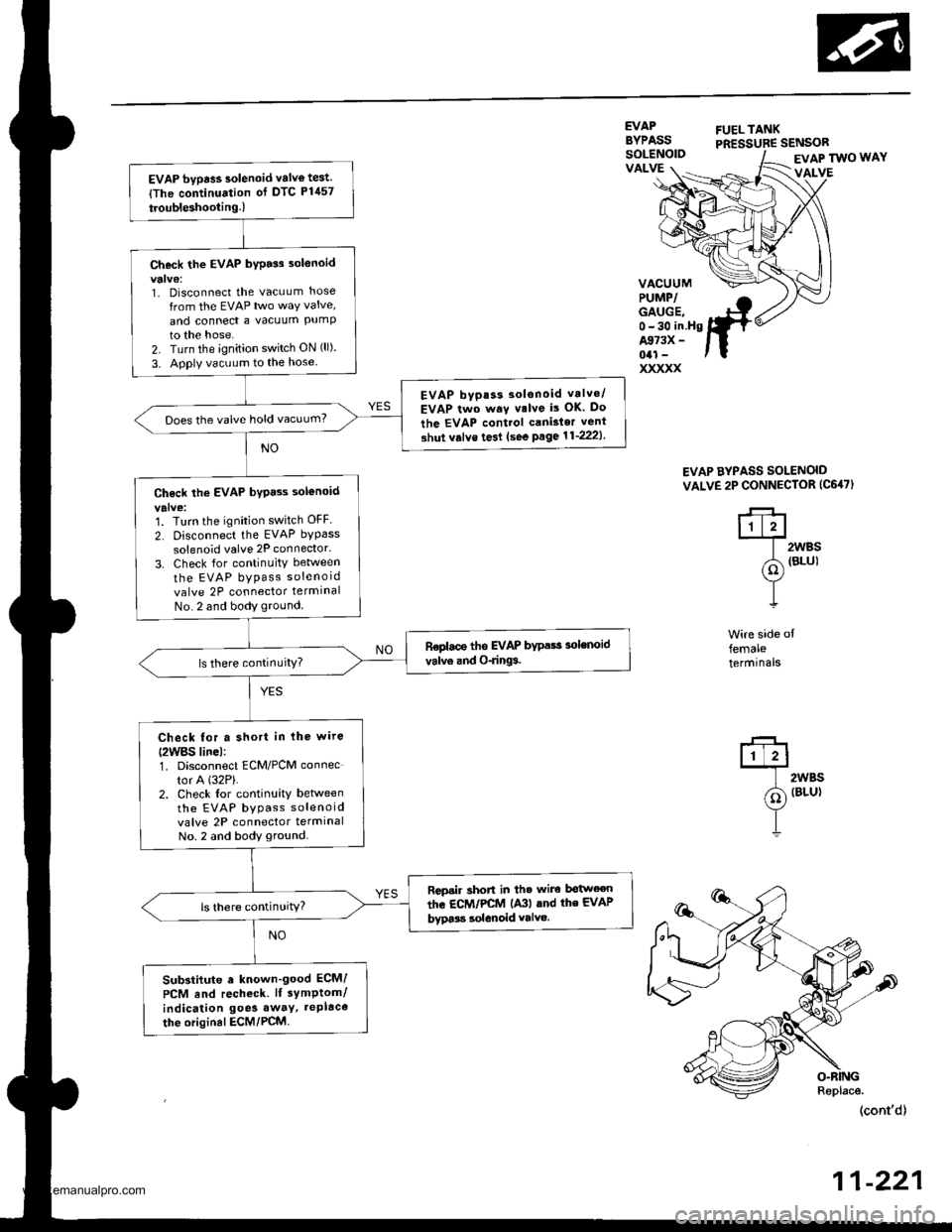

EVAP bypass solenoid valv€ test.

{The continuation of DTC P1457

troubleshooting.l

Check the EVAP bypass 3olenoid

1. Disconnect the vacuLlm hose

from the EVAP two way valve,

and conned a vacuum PUmPto the hose.2. Turn the ignition switch ON (ll).

3. Apply vacuum to the hose

EVAP bvpas3 30lsnoid vrlvo/

EVAP two way v.lve is OK. Do

the EVAP control canisler vent

3hut v.lve te3l (see Psge11'2221.

Does the valve hold vacuum?

Ch6ck the EVAP byp.ss solenoid

'1. Turn the ignition switch OFF

2. Disconnect the EVAP bypass

solenoid valve 2P connector.

3. Check {or continuity between

the EVAP bypass soleno id

valve 2P connector termlnal

No. 2 and body ground

ReDlace the EVAP bypass 3olenoid

valve and O-rings.

Check for a short in lhe wire

{2WBS linel:1. Disconnect ECM/PCM connec

tor A (32P).

2. Check lor continuity betlveenthe EVAP bypass soleno id

valve 2P connector termrnalNo. 2 and body ground.

Rcpsir short in th. wire bgtwoen

the EcM/PCtrl lA3l lnd the EVAP

bypa$ solenoid valvo.ls there continuitY?

Sub3tiiute . known'good ECM/

PCM End recheck. lI sYmptom/

indication goe3 away, tePlace

the original ECM/PCM.

EVAPBYPASSFUELTANKPRESSUBE SENSORSOLENOIDVALVEEVAP TWO WAY

VALVE

VACUUMPUMP/GAUGE,0-30 in.HgA973X -

041 -

xxxxx

EVAP AYPASS SOLENOID

VALVE 2P CONNECTOR (C647}

q

@)

T

t.'-+lt1t?l

| 2wBs

(d1 terul

Y-L

Wire side offemaleterminals

2WBS(BLU}

(cont'd)

11-221

www.emanualpro.com