Compressor

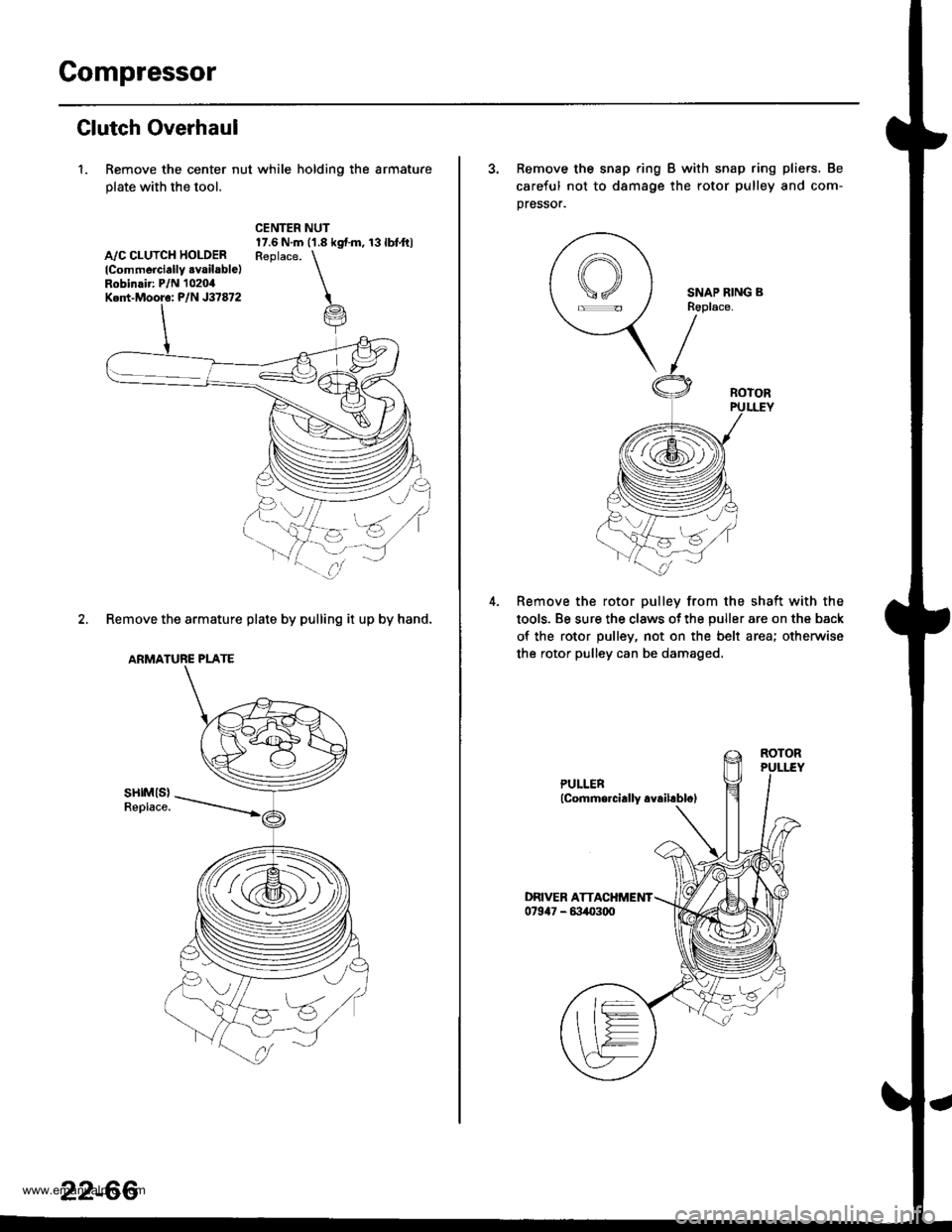

Glutch Overhaul

1. Remove the center nut while holding the armature

plate with the tool.

A,/C CLUTCH HOLOERlCommerciallY .vailable)Robinair: P/N 1020,0Ked-Mooro: P/N J37872

CENTER NUT17.6 N.m ('1.8 kgf.m, 13lbfft)Reolace. \

i

2. Remove the armature plate by pulling it up by hand.

ARMATURE PLATE

sHtMls)Replace.

za:s

(i@,

22-66

3. Remove the snap ring B with snap ring pliers. Be

careful not to d8mage the rotor pulley and com-

pressor.

SNAP RING BR6place.

Remove the rotor pulley from the shaft with the

tools. Be sure the claws ot the puller are on the back

of the rotor pulley, not on the belt area; otherwise

the rotor pulley can be damaged.

www.emanualpro.com

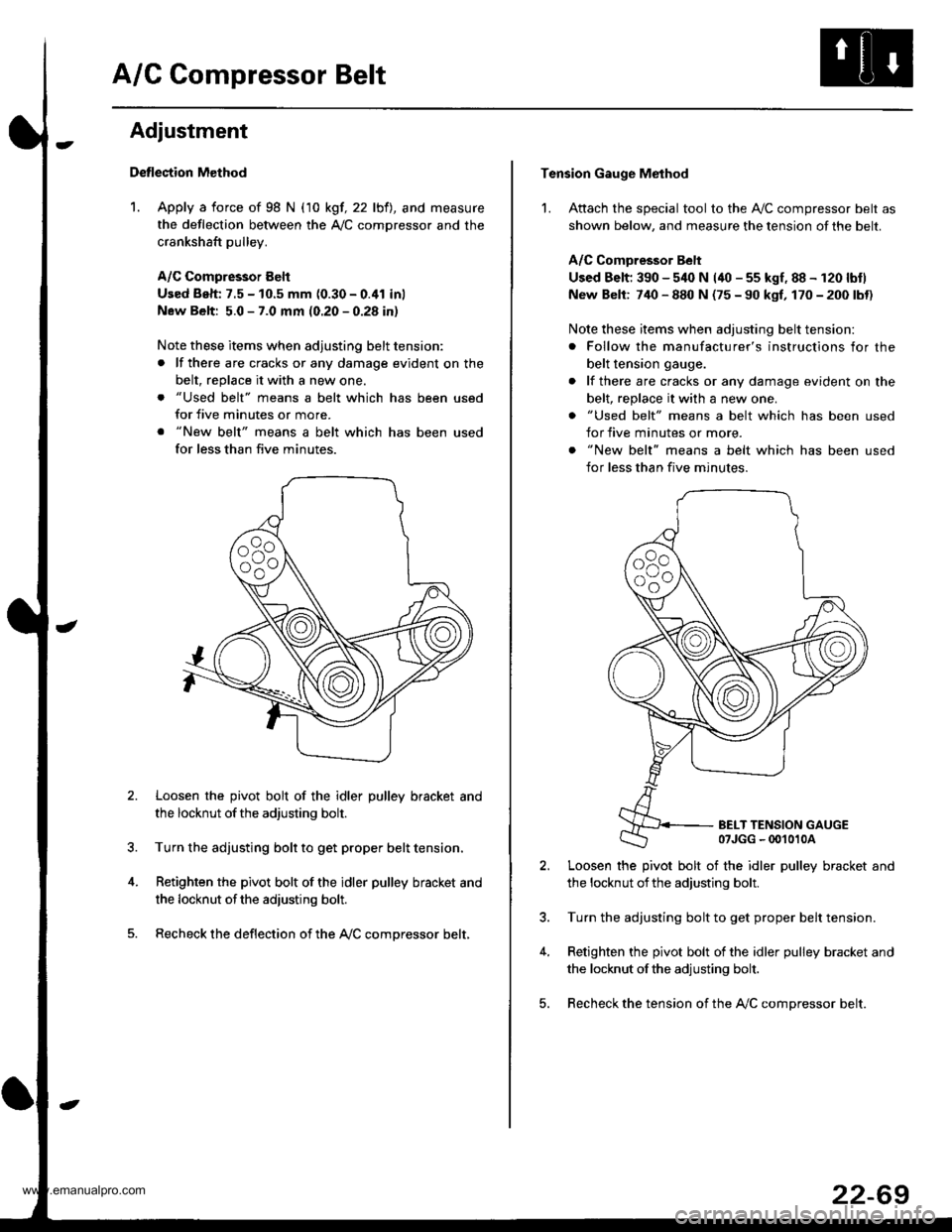

A/C Compressor Belt

Adjustment

Detlection Method

1. Apply a force of 98 N (10 kgf, 22 lbfl, and measure

the deflection between the A,/C comDressor and the

crankshaft pulley.

A/C Compressor Eelt

Used Beh: 7.5 - 10.5 mm (0.30 - 0.41 inl

New Belt: 5.0 - 7.0 mm (0.20 - 0.28 in)

Note these items when adjusting belt tension:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes.

Loosen the pivot bolt of the idler pulley bracket and

the locknut ofthe adjusting bolt.

Turn the adjusting bolt to get proper belt tension,

Retighten the pivot bolt of the idler pulley bracket and

the locknut ofthe adiusting bolt.

Recheck the deflection of the A,/C compressor belt,

Tension Gauge Method

1. Attach the special tool to the Ay'C compressor belt as

shown below, and measure the tension of the belt.

A/C Comoressor Belt

Used Belt; 390 - 540 N (40 - 55 kgf, 88 - 120 lbtl

New Belt: 740 - 880 N (75 - 90 kgf, 170 - 200 lbt)

Note these items when adjusting belt tension:

. Follow the manufacturer's instructions for the

belt tension gauge.

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes.

BELT TENSION GAUGE07JGG - 00't010A

Loosen the pivot bolt of the idler pulley bracket and

the locknut ofthe adjusting bolt.

Turn the adjusting bolt to get proper belt tension.

Retighten the pivot bolt of the idler pulley bracket and

the locknut ofthe adjusting bolt.

Recheck the tension of the A,/C compressor belt.

22-69

www.emanualpro.com