Iac valve HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 356 of 1395

The MIL has boen r.ported on.DIC Pl 508 b 3tored.

Problem veritication:L Do the ECM/PCM Reset Pro-cedure.2. Start the engine, and warm itup to normal operating tem-perature.

Int€rmittent failure, systom is OKal lhis timo. Check lor poor con-nections or looro wirca at C132(lAc vrlvel and .t rho EcM/PcM.

ls DTC P1508 indicated?

Chock tor an open in the wir6llGPl linel:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector,3. Turn the ignition switch ON (ll).4. Measure voltage between bodyground and the IAC valve 2Pcon nector termina I No, 2.

Repair opon in the wira botwoonthe IAC valve and tho PGM-FImain aalay.

Check tor an open or short in thewire (IACV linel:1. Turn the ignition switch OFFand reconnect the IAC valve2P connector.2. Disconnect ECM/PCM con-nector B {25P).3. Turn the ignition switch ON {ll}.4. Measure voltage betweenbody ground and ECM/PCMconnector terminal 823.

Ropair open or short in thg wirebetween tho ECM/FCM lB23l andthe IAC valve.

ls there battery voltage?

Check the IAC valve func,tion:Momentarily connect ECM/PCMconnector terminals 823 and 82with a jumper wire several times.

Does the IAC valve click?

Subslitute . known-good ECM/PCM .nd rechock. lf symptom/indication goes aw.y, replac.th€ original ECM/PCM.

ldle Air Control (lAC) Valve {cont'd}

'98 - 00 models:

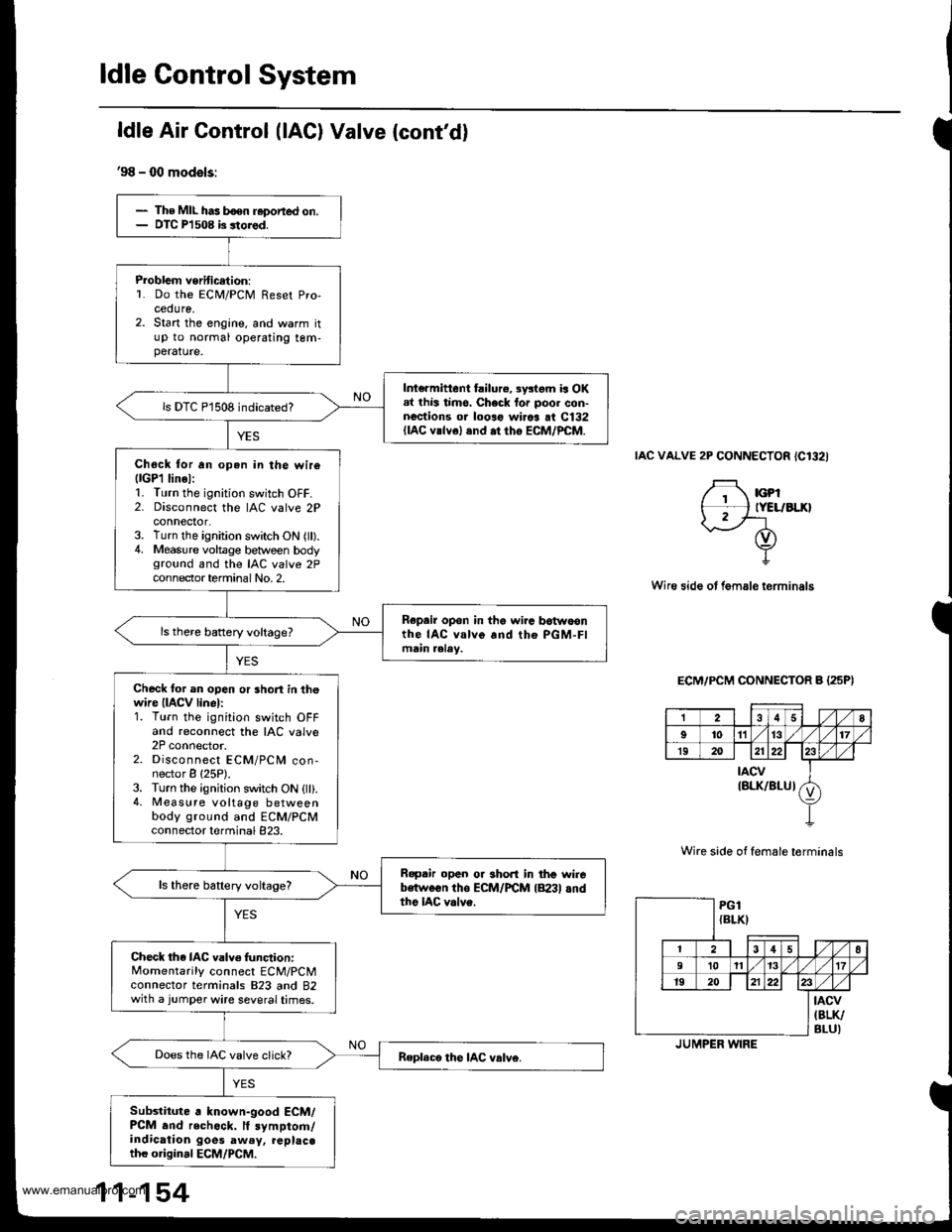

IAC VALVE 2P CONNECTOR {C132I

F rcpt*l tYELrBLxlI2/'-- rf)

Y

Wire side ot fem.le terminals

ECM/PCM CONNECTOR B (25PI

Wire side of female torminals

258

9'to1l13t7

1920212223

tAcv(BLK/BLUIv

PG1{BLKI

12 | t3 4 58

910 111317

1920 | 121)22

tAcv(BLK/

BLU)JUMPER WIRE

www.emanualpro.com

Page 371 of 1395

ldle Speed Setting

Inspoction/Adiustmont

37 modsl:

NOTE:

. Before setting the idle speed, check the following

items:- The MIL has not been reportsd on.- lgnition timing- Spark plugs

- Air cleaner- PCV system

. lcanada) Pull the parking brake lever up. Stan the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Connect a tachometer or a Honda PGM Tester.

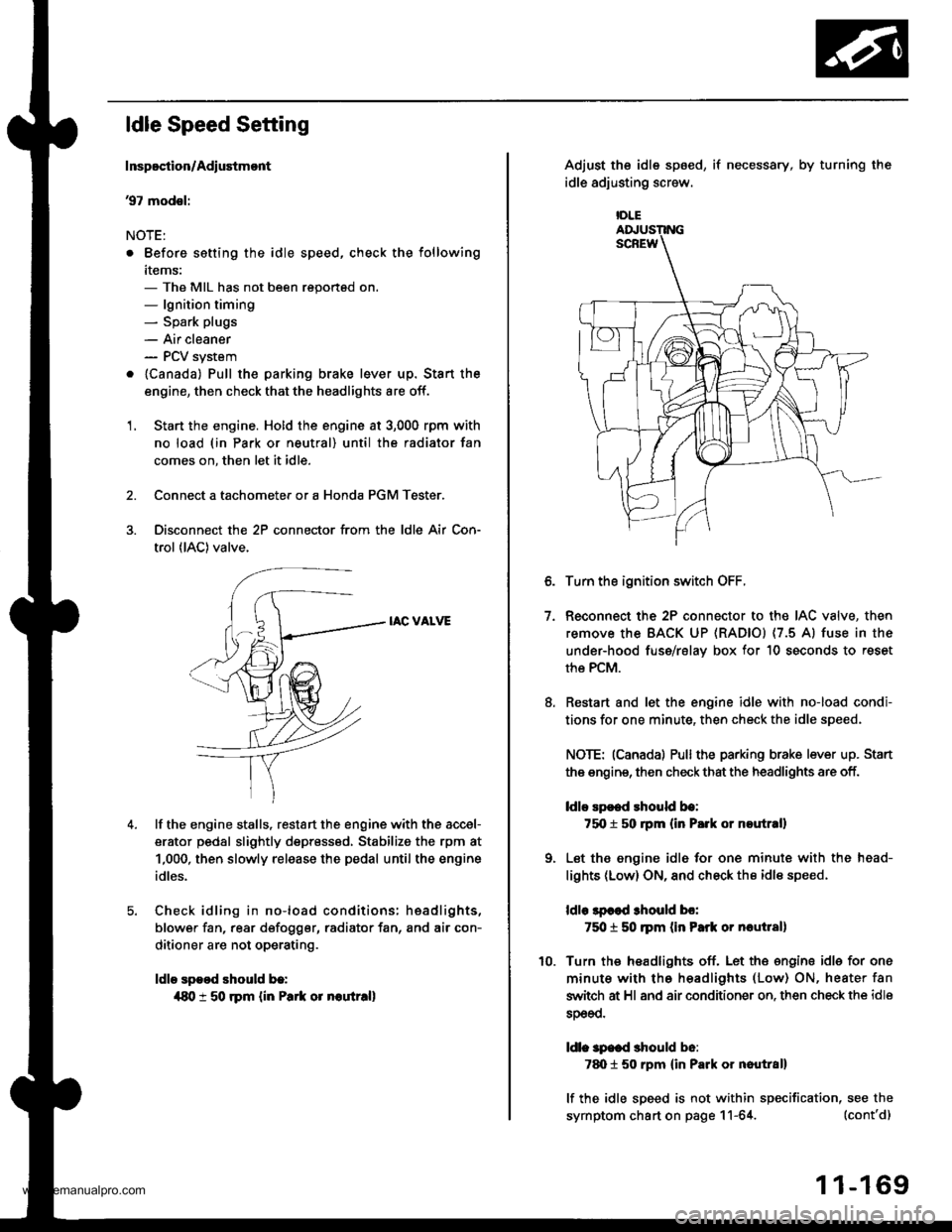

Disconnect the 2P connector from the ldle Air Con-

trol (lAC) valve.

IAC VALVE

lf the engine stalls, restart the engine with the accel-

erator pedal slightly depr6ss6d, Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: hsadlights,

blower fan, rear d€fogger, radiator fan, and air con-

ditioner are not operating.

ldle spood should b.:

{80 t 50 rpm {in Park or noutr.ll

IDLE

7.

Adjust the idle sp6ed,

idle adjusting screw.

if necessary, by turning the

Turn the ignition switch OFF.

Reconnect the 2P connector to the IAC valve, then

remove the BACK UP (RAD|Ol (7.5 Al fuse in the

under-hood fuse/rslav box for 10 seconds to reset

the PCM.

Restart and let the engine idle with no-load condi-

tions for one minute, then check the idle speed.

NOTE: (Canadal Pullthe parking brake lever up. Stan

the engine, then check that the headlights are off.

ldlo Ep€ed rhould be:

75O t 50 rpm (in P.rk or noutr.ll

Let the engine idl6 for one minute with the head-

lights (Low) ON, and check th€ idl€ speed.

ldle lpcod 3hould bo:

750 t 50 ]pm (in Park or nautlal)

Turn the headlights off. Let th€ engine idle for one

minute with the headlights (Low) ON, heater fan

switch at Hl and air conditioner on. then check the idle

sDeeo.

ldl. specd should b6:

7d) 1 50 rpm {in Park or nautral}

lf the idle speed is not within specification, see the

symptom chart on page 11-64. (cont'd)

1 1-169

www.emanualpro.com

Page 372 of 1395

ldle Control System

ldle Speed Setting (cont'd)

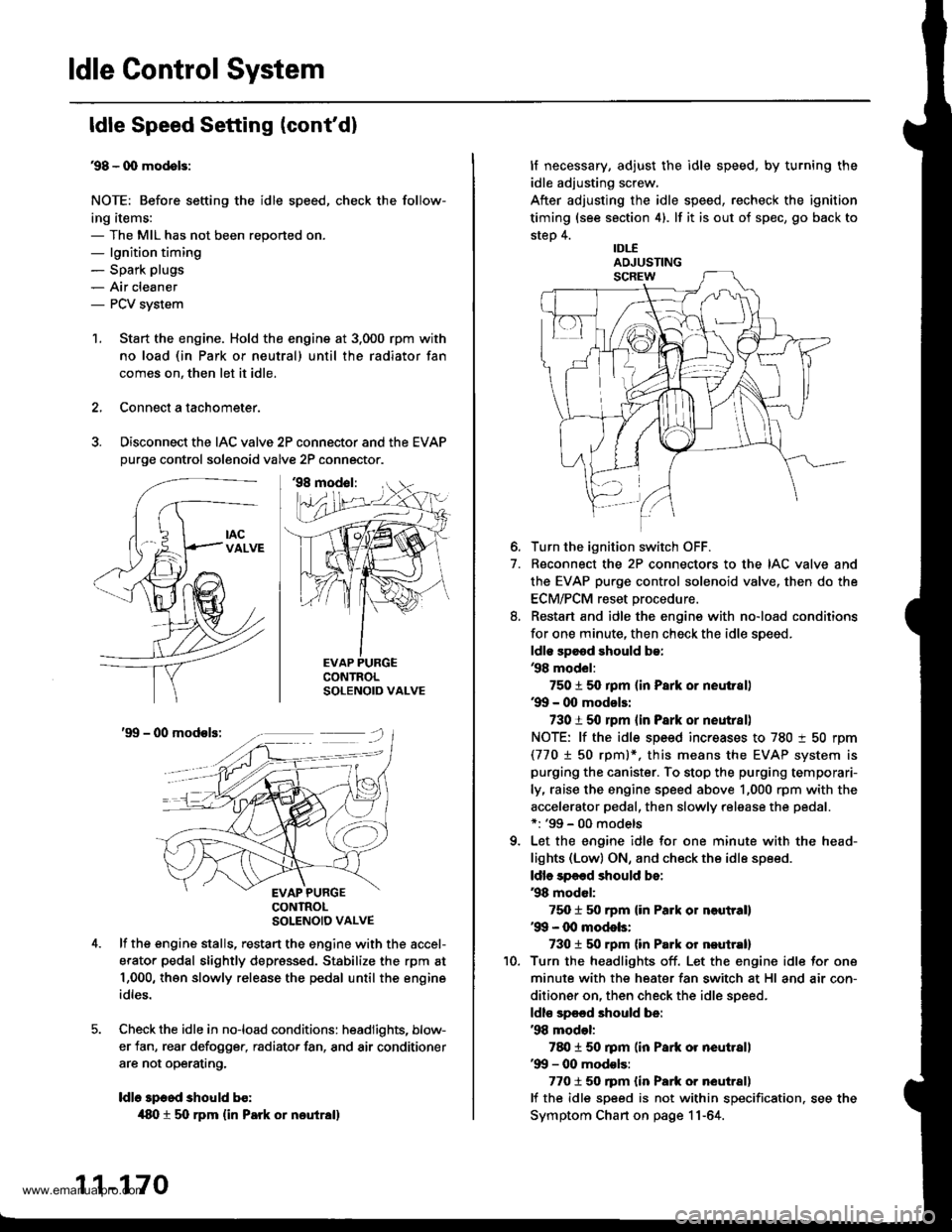

38 - 0O mod6l3:

NOTE: Before setting the idle speed, check the follow-

ing items:- The MIL has not been reported on.- lgnition timing- Spark plugs

- Air cleaner- PCV system

1. Start the engine. Hold the engine at 3.000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAP

purge control solenoid valve 2P connector.

CONTROLSOLENOID VALVE

SOLENOID VALVE

lf the engine stalls, restart the engine with the accel-

erato. pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Che€k the idle in no-load conditions: headlights, blow-

er fan, rear defogger, radiator fan, and air conditioner

are not operating,

ldle speed should bo:

480 t 50 rpm {in PErk or noutrall

11-170

lf necessary, adjust the idle speed, by turning the

idle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing (see section 4). lf it is out of spec, go back to

steo 4.tDt.E

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM/PCM reset procedure.

8. Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

ldle speod should be:,98 model:

750 t 50 rpm tin Park or neutral)'9!l - 00 modsls:

730 i 50 lpm lin Psrk or neutral)

NOTE: lf the idle speed increases to 780 t 50 rpm(770 1 50 rpml*, this means the EVAP system is

purging the canister. To stop the purging temporari-

ly, raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.*: '99 - 00 models

9. Let the engine idle for one minute with the head-

lights (Low) ON, and check the idle speed.

ldle speed should be:

38 mod6l:

750 f 50 rpm (in Palk or neutrall'99 - 00 modols:

730 t 50 rpm (in Palk or neutral)

10. Turn the headlights off. Let the engine idle for one

minute with the heater fan switch at Hl and air con-

ditioner on, then check the idle speed.

ldls spqed should be:'98 model:

780 t 50 rpm (in Park or neutrall'99 - 00 mod€ls:

7701 50 rpm lin Park or neutral)

lf the idle speed is not within specification. see the

Symptom Chart on page 11-64.

ADJUSTING

www.emanualpro.com

Page 517 of 1395

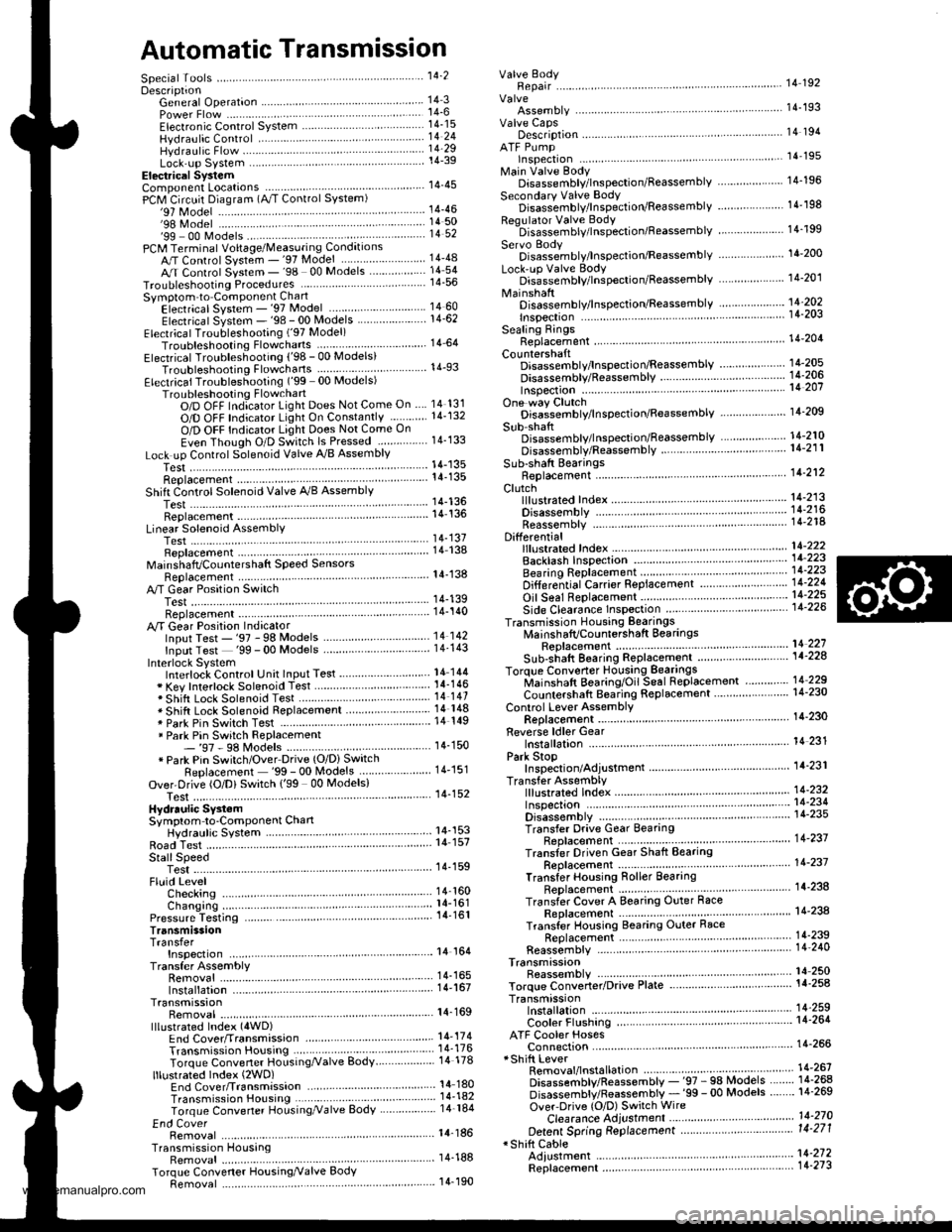

Automatic Transmission

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 685 of 1395

Transmission

Removal

@

2.

'1.

Make sure lifts. iacks, and safety stands aro placed

properly, and hoist brackets are attached to the col-

rest position on the engine lsee section 11.

Apply th€ parking brake and block the r€ar wheels,

so vehicls will noi roll off the stands and fall on you

while working under it.

NOTE: Use fender covers to avoid damaging painted

surfaces.

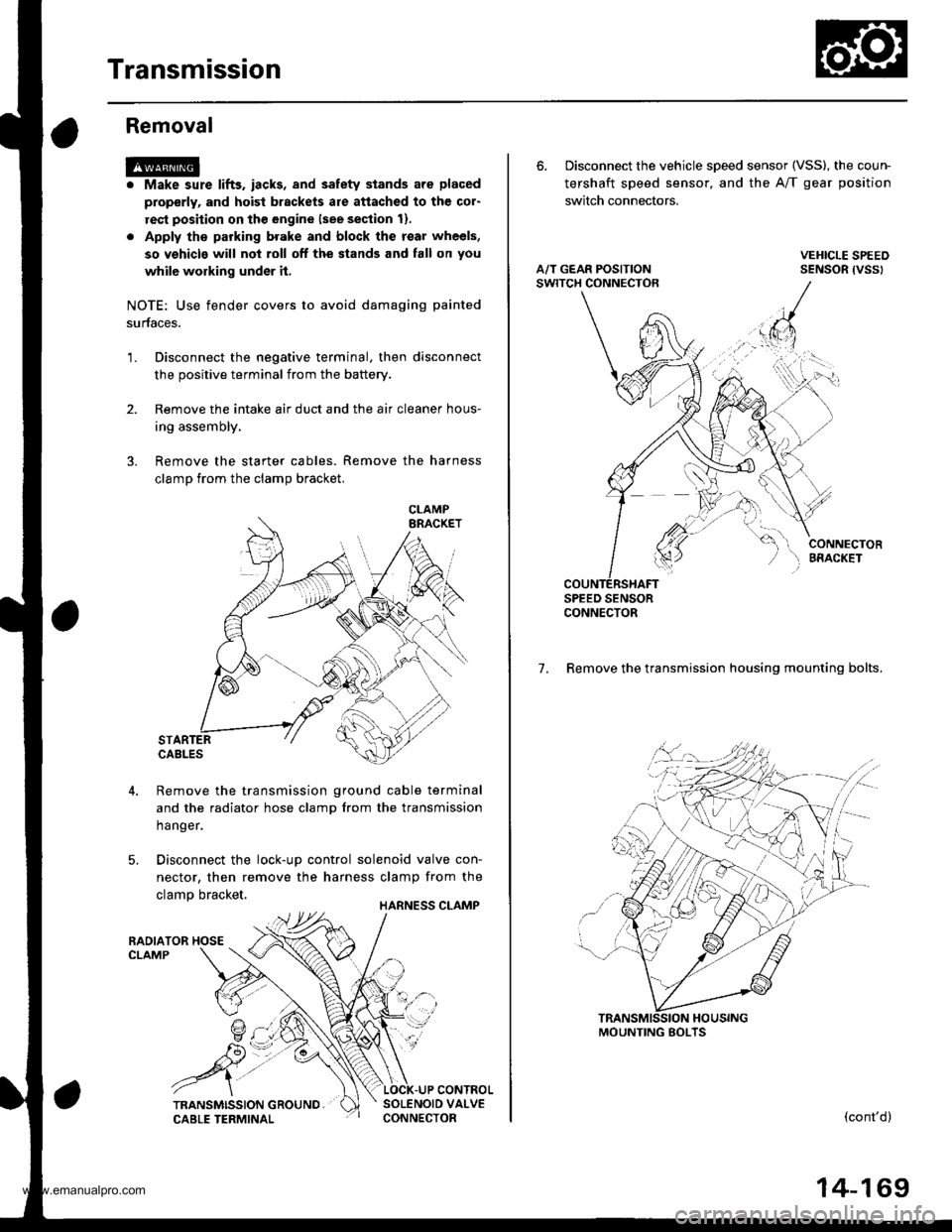

Disconnect the negative terminal, then disconnect

the positive terminal from the battery.

Remove the intake air duct and the air cleaner hous-

ing assembly,

Remove the starter cables. Remove the harness

clamp from the clamp bracket.

5.

STARTERCABLES

Remove the transmission ground cable terminal

and the radiator hose clamp lrom the transmission

hanger.

Disconnect the lock-up control solenoid valve con-

nector, then remove the harness clamp from the

clamp bracket.HARNESS CLAMP

RADIATOR HOSECLAMP

CONTROLSOLENOID VALVECONNECTOR

CLAMP

6. Disconnect the vehicle speed sensor (VSS), the coun-

tershaft speed sensor, and the A/T gear position

switch connectors.

A/T GEAR POSITIONSWITCH CONNECTOR

VEHICLE SPEEDSENSOR |VSS'

CONNECTORBfiACKET

SPEED SENSORCONNECTOR

7. Remove the transmission housing mounting bolts.

MOUNTING BOLTS

(cont'd)

14-169

www.emanualpro.com