Vacuum HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 292 of 1395

PGM-FI System

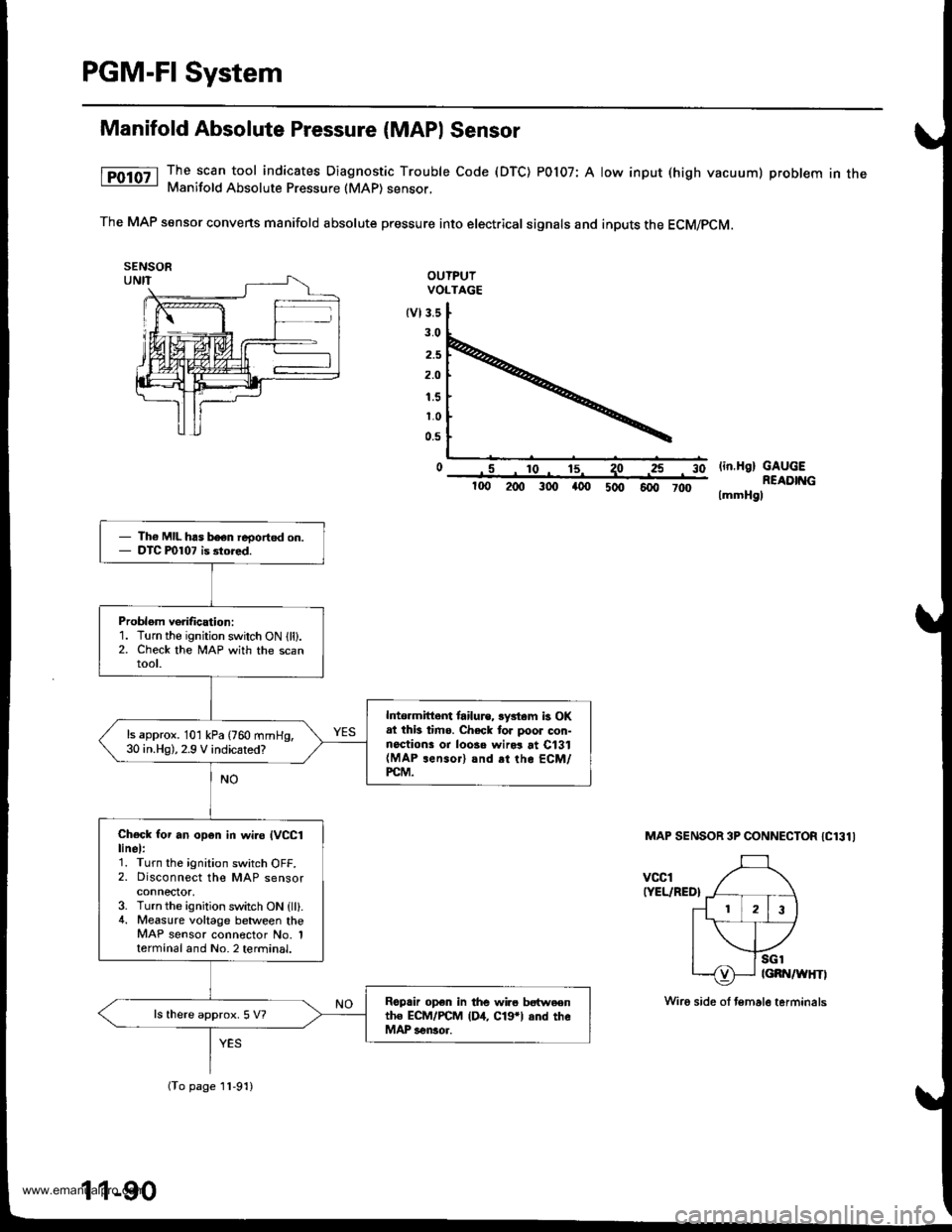

Manifold Absolute Pressure (MAPI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) POl07: A low input (high vacuum) problem in theManifold Absolute Pressure (MAP) sensor,

The MAP sensor convens manifold absolute pressure into electrical signals and inputs the ECM/pCM.

OUTPUIVOLTAGE

tvl3.s

3.0

2.5

2.O

1.5

1.0

0.5

o .5 ro- 15^ 1olin.H9) GAUGEREADIT{G

lmmHgl

3025

100 200 300 a00 5oo 6fi, 7d)

MAP SENSOR 3P CONNECTOR IC131I

vccl(YEL/RED}

Th6 MIL has b€en reoorted on.DTC P0107 is 3tored.

Problom verification:1. Turn the ignition switch ON lll).2. Check the lvlAP with the scanroot.

lrtormittem tailu.e, lystam b OKat thb timo. Check tor poor con-noctions or loosa wird at C131(MAP rensor) and rt the ECM/PCM.

ls approx. 101 kPa (760 mmHg,30 in.Hg),2.9 V indicated?

Check for an op6n in wi.o IVCC1linel:1. Turn the ignition switch OFF.2. Disconnect the MAP sensorconnector,3. Turn the ignition switch ON {ll}.4. Measure voltage between theMAP sensor connector No. 1termanal and No. 2 terminal.

Roprir op€n in the wir6 bstweentho ECM/PCM (D4, C19*l and theMAP sensor.

ls there approx. 5 V?

(To page 11-91)

11-90

Wiro side ol temale terminals

www.emanualpro.com

Page 294 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Owners Manual

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (contd)

[tn,t nn-] The scan tool indicates Diagnostic Trouble Code (DTC) P0108: A high voltage (low vacuum) problem in the|jg Manifold Absolute HONDA CR-V 1998 RD1-RD3 / 1.G Owners Manual

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (contd)

[tn,t nn-] The scan tool indicates Diagnostic Trouble Code (DTC) P0108: A high voltage (low vacuum) problem in the|jg Manifold Absolute](/img/13/5778/w960_5778-293.png)

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (cont'd)

[tn,t nn-] The scan tool indicates Diagnostic Trouble Code (DTC) P0108: A high voltage (low vacuum) problem in the|jg Manifold Absolute Pressure (MAP) sensor.

MAP SENSOR 3P CONNECTOR IC131I

Wire side of female terminals

vcclIYEL/RED}

PCM CONNECTOR D I16PI

JUMPER WIRE

sGlIGRN/WHTI

Wire side of lemale termin6ls

1

(To page 11,93)': '98 - 00 models

1-92

tcRN/wHrll IIRED/GRN|

The MIL has boen reported on.DTC m108 is slored.

Problem veritication:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on, thenlet it idle.2. Check the MAP with the scantool.

Intermittent tailuro, system i3 OKat this time. Check tor ooor con-nections or loose wires at C131IMAP s6nsor) snd the ECM/rcM.

ls 101 kPa {760 mmHg,30 in.Hg),2.9 V or higher indicated?

Check Ior an open in the MAPsensor:1. Turn the ignition switch OFF.2. Disconnect the MAP sensor3P connector.3. lnstall a jumper wire betweenthe MAP sensor 3P connectorterminals No.3 and No.2.4. Turn the ignition switch ON {ll).5. Check the MAP with the scantool.

ls 10'l kPa (760 mmHg,30 in.Hg),2.9 V or higher indicated?

Check for an open in wire (SGlliDel:1. Remove the jumper wire.2. Measure voltage between theMAP sensor 3P connector ter-minals No. 1 and No- 2.

R6p.ir open in the wire betwoenthe ECM/PCM (D12, CTrl and theMAP sensor.

ls there approx. 5 V?

Check for an open in the wire(MAP line):1. Turn the ignition switch OFF.2. lnstall a iumper wire on thePCM connectors between D3and D12.3. Turn the ignition switch ON (ll).4. Check the MAP wirh the scantool.

Ropair opon in the wire betweenthe PCM {D3, .nd the MAP son-3('t.

ls 101 kPa 1760 mmHg, 30 in.Hg),2.9 V or higher indicated?

YES

www.emanualpro.com

Page 327 of 1395

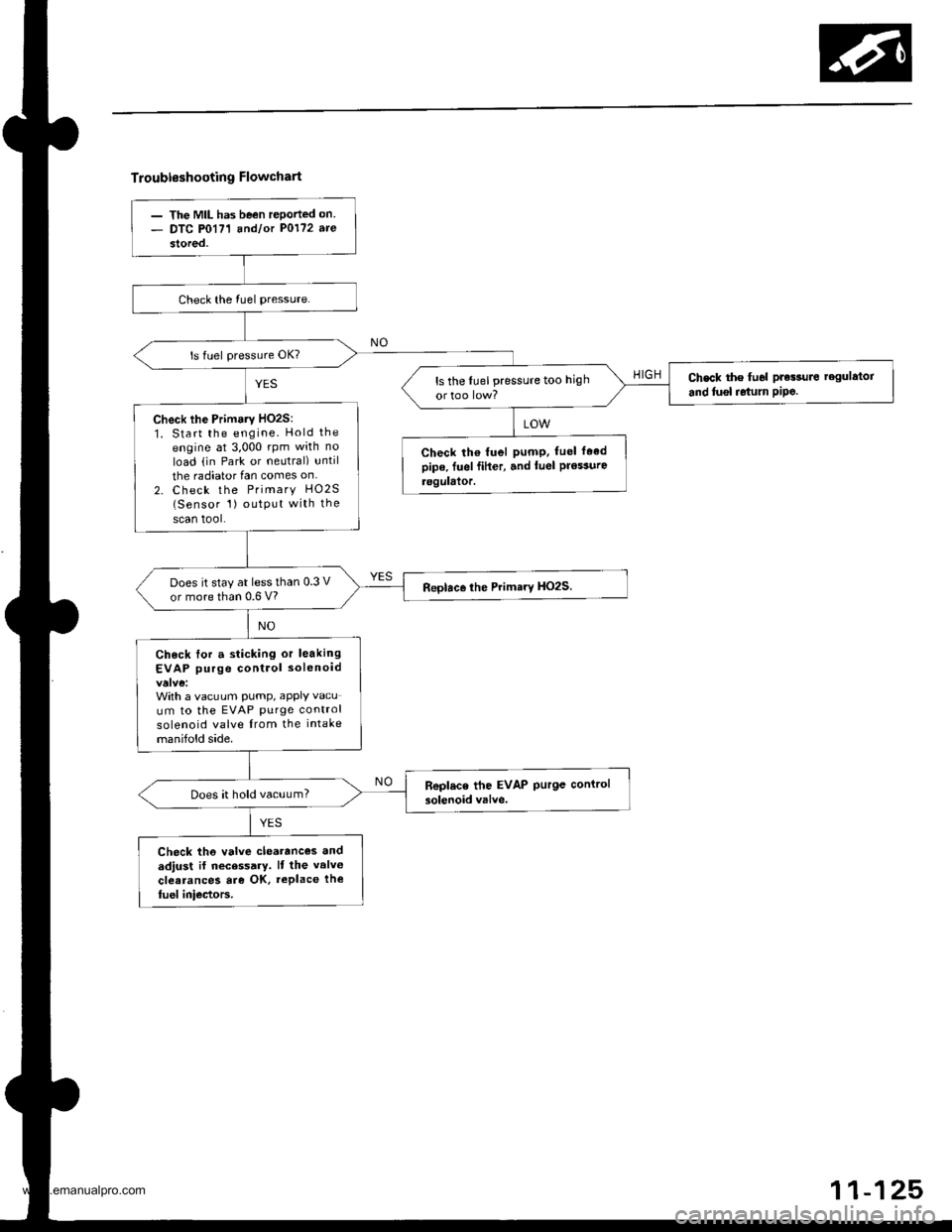

Troubleshooting Flowchart

- The MIL has been rePorted on- DTC P0171 andlot P0172 are

stored,

Check the lu6l pressuro regulator

and tusl relum PiPe.ls the lLrel pressure too high

Check lhe Primaty HO2S:1. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park ot neutral) until

the radiator fan comes on

2. Check the Primary HO2S(Sensor 1) outPut with the

scan tool.

Check lh€ fuel pumP. fuel faedpipe. fuel fiher, and luel Prossurc.eguhior.

Does it stay at lessthan 0.3 V

or more than 0.6 V?

Check for a sticking or leaking

EVAP purge control solenoid

With a vacuum pump, aPPIY vacu

um to the EVAP Purge control

solenoid valve from the intake

manifold side.

Does it hold vacuum?

Check th6 valve clearanc€s and

adjust il necessary. It the valv€

clearances are OK, replace the

fuel iniectors.

www.emanualpro.com

Page 352 of 1395

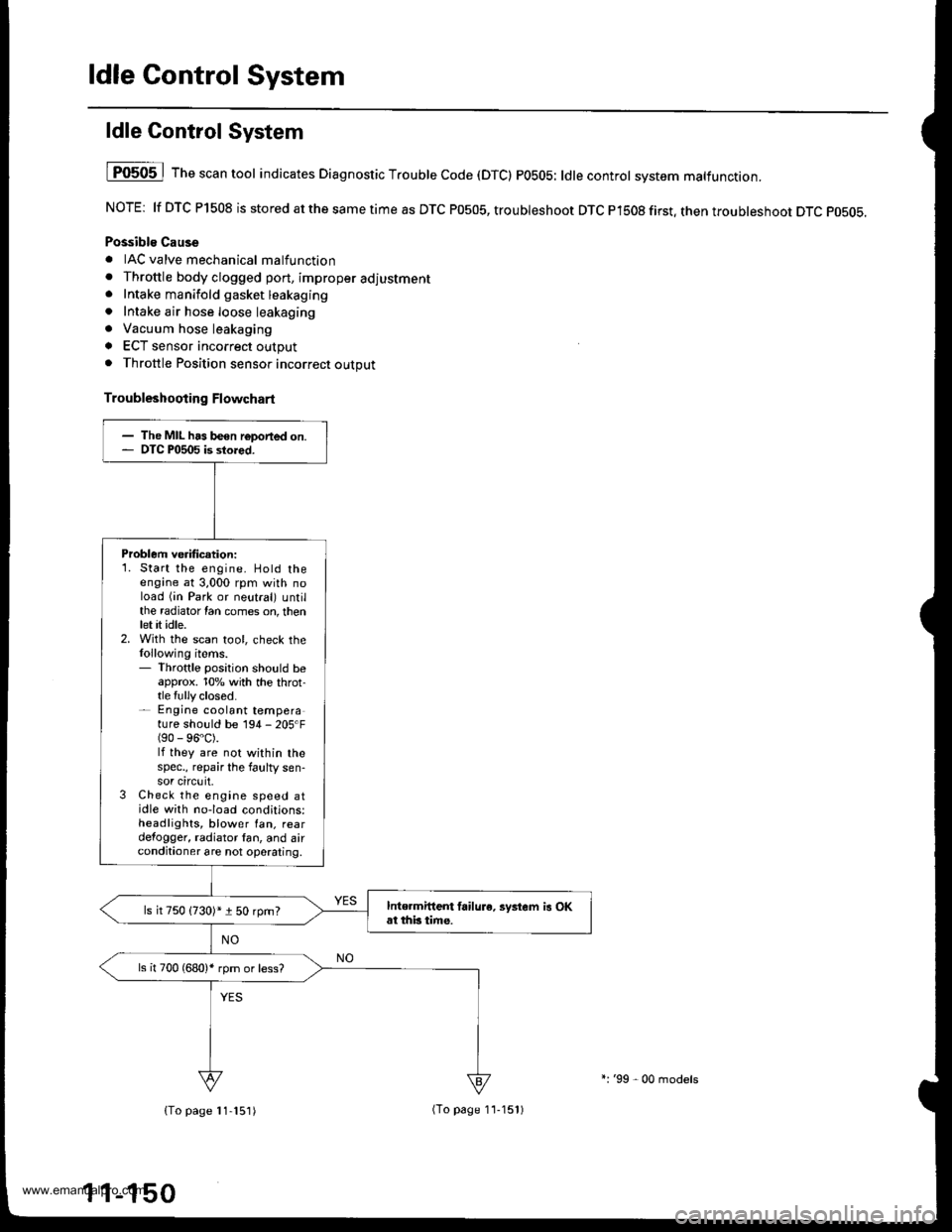

ldle Control System

ldle Control System

I P0505 | The scan tool indicates Diagnostic T.ouble Code (DTCI PO5O5: ldlecontrol svstem mattunction.

NOTE: lf DTC P1508 is stored at the same time as DTC P0505, troubleshoot DTC P1508 first. then troubleshoot DTC p0505.

Possibls Cause

. IAC valve mechanical malfunction. Throttle body clogged port, improper adlustment. Intake manifold gasket leakaging. Intake air hose loose leakaging. Vacuum hose leakaging

a ECT sensor incorrect output. Throttle Position sensor incorrect output

Troubleshooting Flowchart

The MIL has been reDorted on.DTC P0505 is sto.ed.

Problem verificationi1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator Ian comes on, thenlet it idle.2. With the scan tool, check thelollowing items.- Throttle position should beapprox. 10% with the throt-tle {ully closed.- Engine coolant temperature shorJld be 194 - 205'F(90 - 96"C).lf they are not within thespec., repair the faulty sen-sor circuit.3 Check the engine speed atidle with no-load conditions:headlights, blower fan. reardefogger, radiator lan, and airconditioner are not operaling,

Inte.mittent failure. syltem is OKat this time.ls it 750 {730)* i 50 rpm?

ls il 700 (680)' rpm or less?

{To page 11-151)(To page 1'l-151)

l:'99 - 00 models

www.emanualpro.com

Page 353 of 1395

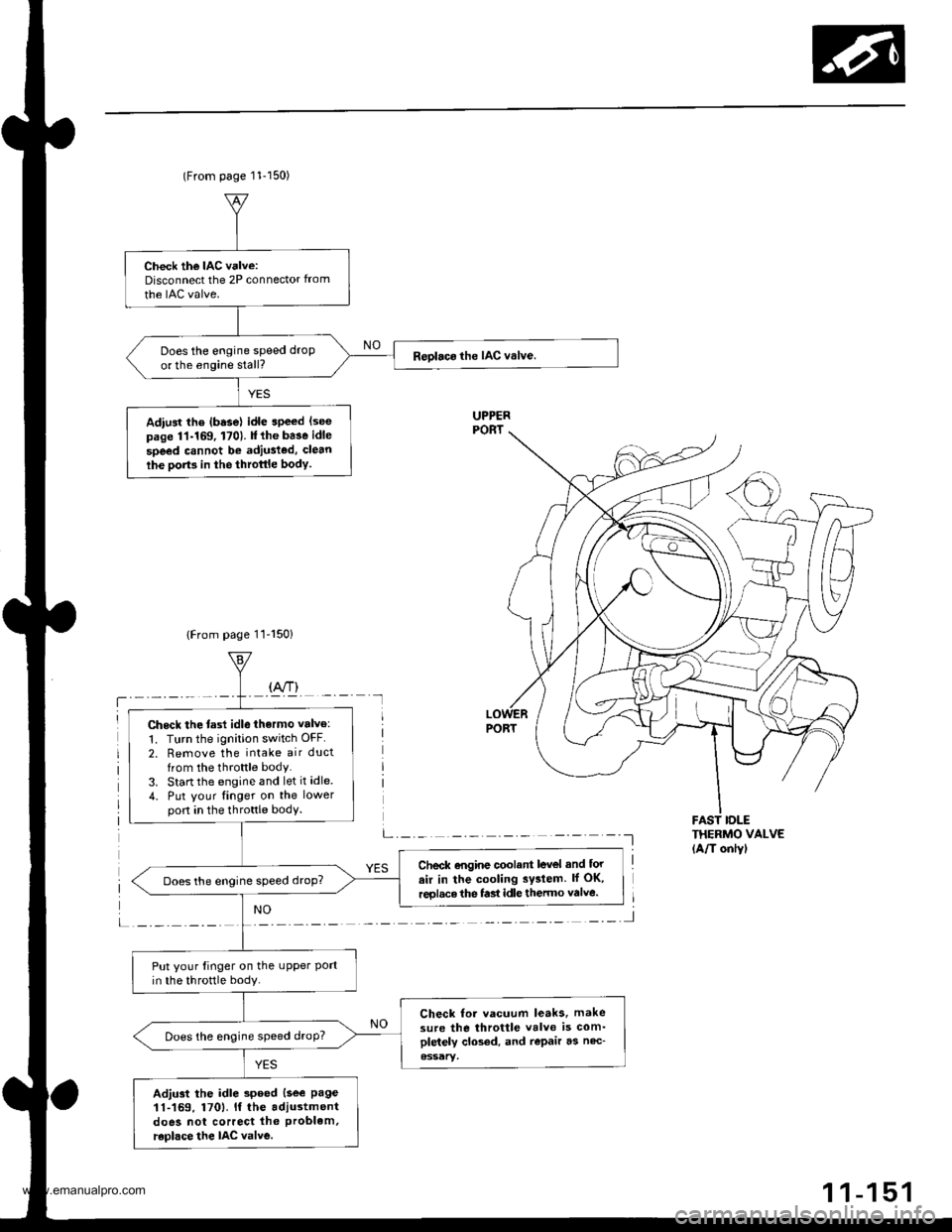

(From page 11-150)

{From page 11-150}

THERMO VALVE(A/T onlyl

Check the IAC valve:Disconnect the 2P connector from

the IAC valve.

Does the engine speed droP

or the engine stall?

Adiust the (basel idl€ speed lseepage 11-169, 1t0). Itihe ba3e idle

speed cannot be adiust€d, clean

the Dorts in the throttle body.

UPPER

Check the tast idle lhermo valve:

1. Turn the ignition switch OFF.

2. Remove the intake air ductfrom the throttle body.3. Start the engine and let it idle.

4. Put your finger on the lowerpon in the throttle body.

Check engine cool.nt level and for

air in the cooling sy3lem. lf OK,

reolace the f.st idle thermo valve.Does the engine speed drop?

Put your Iinger on the uPPer Portin the throttle body.

Check for vacuum leaks, make

sure the throttle valve is com'pletely clo3ed. and repair as nec-Does the engine speed droP?

Adjust the idle spoed lsee Page11-169. 1701. lf the adiustmentdoes not correct lhe problem,

r.olace the IAC valve.

www.emanualpro.com

Page 380 of 1395

Fuel Supply System

System Description

The fuel supply system consists of a fuel tank, in-tank

high-pressure fuel pump. PGM-Fl main relay, fuel filter,

fuel pressure regulator, fuel injectors, and fuel delivery

and return lines. This system delivers pressure-regulat-

ed fuel to the fuel injectors and cuts the fuel delivery

when the engine is not running.

Fuel Pressure

Relieving

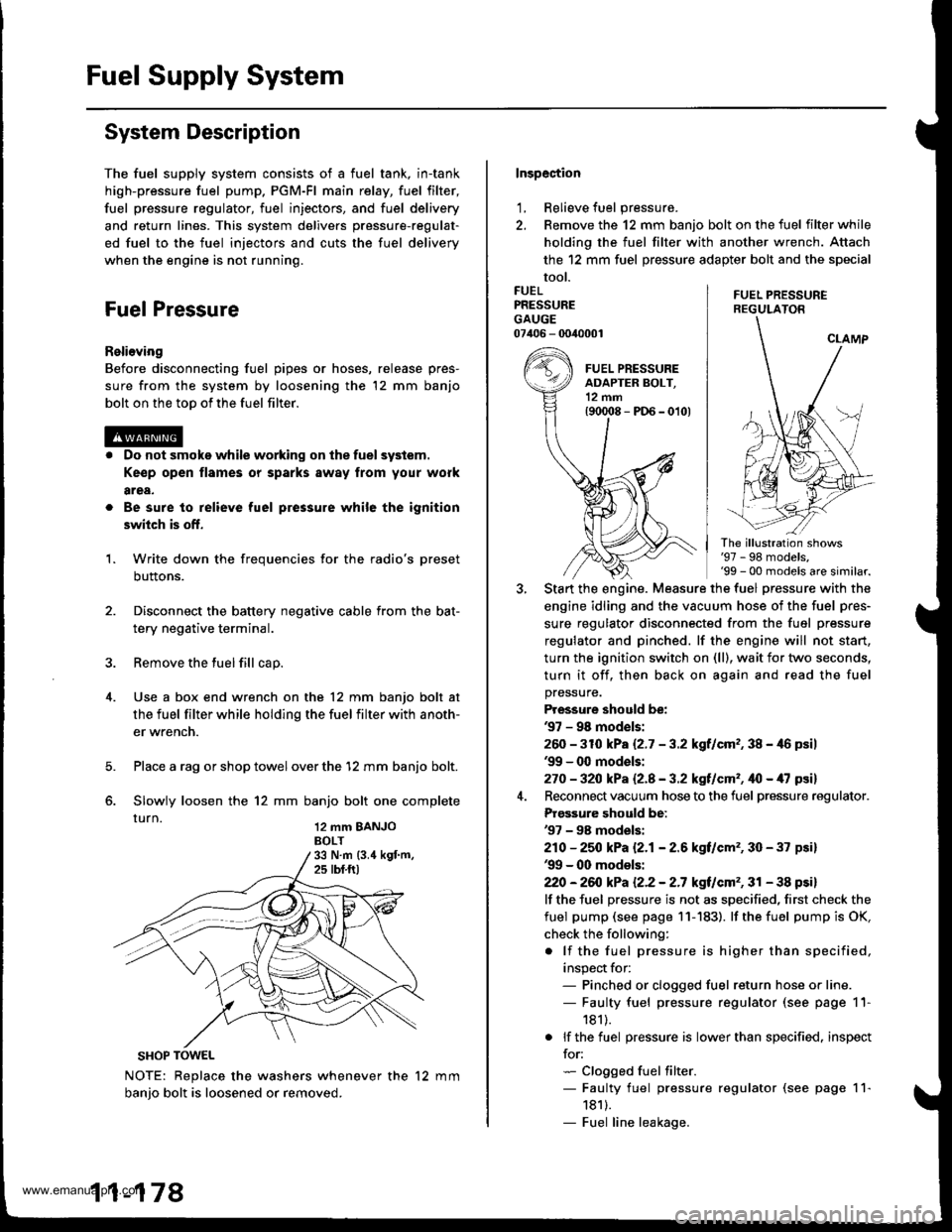

Before disconnecting fuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on the too of the fuel filter.

Do not smoke while working on the fuel system.

Ke€p open flames or sparks away from your work

area,

Be sure to relieve fuel pressure while the ignition

switch is off.

Write down the frequencies for the radio's preset

buttons.

Disconnect the battery negative cable from the bat-

tery negative terminal.

Remove the fuel fill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with anoth-

er wrench.

Place a rag or shop towel over the '12 mm banjo bolt.

Slowly loosen the 12 mm banjo bolt one complete

rurn 12 mm BANJoBOLT

1.

SHOP TOWEL

NOTE: Replace the washers whenever the 12 mm

banio bolt is loosened or removed.

11-178

Inspection

1, Relieve fuel pressure.

2. Remove the 12 mm banjo bolt on the fuel filter while

holding the fuel filter with another wrench. Attach

the 12 mm fuel pressure adapter bolt and the special

tool.

FUEL PRESSUREREGULATON

FUELPRESSUREGAUGE07406 - 0040001

The illustration shows'97 - 98 models,'99 - 00 models are similar.

Start the engine. Measure the fuel pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched. lf the engine will not start,

turn the ignition switch on (ll), wait for two seconds,

turn it off, then back on again and read the fuel

pressure.

Pressure should be:'97 - 98 mod€ls:

260 -31O kPa 12.7 - 3.2 kgf/cm,, 38 - 46 psil'99 - 0O models:

270 - 32O kPa Q.A - 3.2 kgf/cm'�, ifo - /U psil

Reconnect vacuum hose to the fuel pressure regulator.

Prgs3ure should be:'97 - 98 models:

210 - 25O kPa 12.1- 2.6 kgf/cm'�, 30 - 37 psi)'99 - 00 models:

22O -26iJ kPa 12.2 - 2.7 kgt/cm'�, 31 - 38 psi)

lf the fuel pressure is not as specified, first check the

fuel pump (see page 11- 183). lf the fuel pump is OK,

check the following:

. lf the fuel pressure is higher than specified,

inspect for:- Pinched or clogged fuel return hose or line.- Faulty fuel pressure regulator (see page 11-

181).

. lf the fuel pressure is lower than specified. inspect

for:- Clogged fuel filter.- Faulty fuel pressure regulator (see page 11-

1811.- Fuel line leakage.

www.emanualpro.com

Page 381 of 1395

Fuel Injectors

R6placomoni

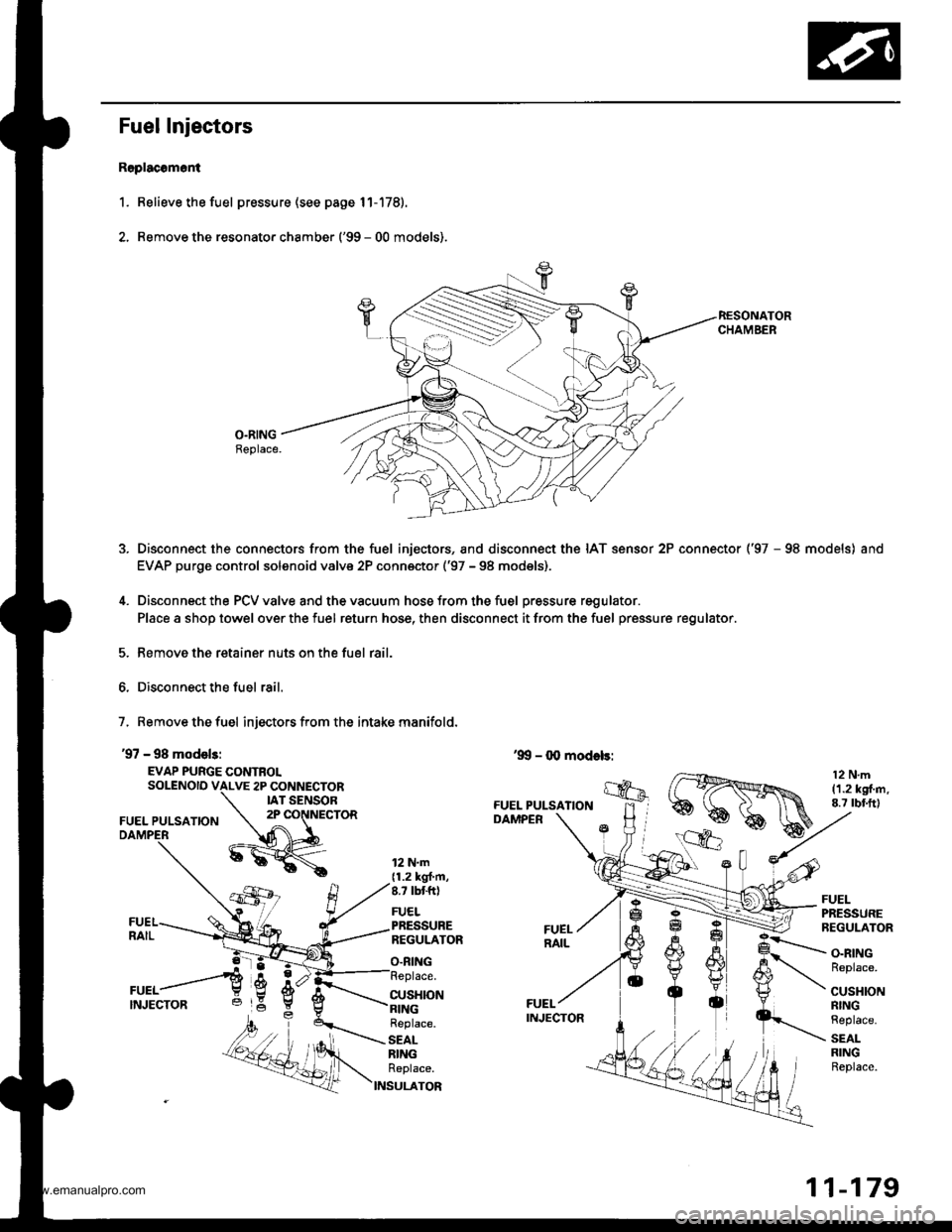

1. Relieve the fuel pressure (see page 11-178).

2. Remove the resonato. chamber ('99 - 00 models).

O.RINGBeplace.

Disconnect the connectors from the fuel injectors, and disconnect the IAT sensor 2P connector ('97 - 98 models) and

EVAP purge control solenoid valve 2P conn€ctor ('97 - 98 models),

Disconnect the PCV valve and the vacuum hose from the fuel pressure regulator.

Place a shop towel over the fuel return hose, then disconnect it from the fuel pressure regulator.

Remove the retainer nuts on the fuel rail.

Disconnect the fuel rail.

7, Remove the fuel injectors from the intake manifold.

'97 - 98 model3:

EVAP PURGE CONTROLSOLENOID VALVE 2P CONNECTORIAT SENSOR

FUEL PULSATION2P CONNECTOR

12 N.m{1.2 kgt'm,8.7 tbtft)

FUELPRESSUREREGULATOR

O.RING

FUELPRESSUREREGULATOR

CUSHION

O.RINGReplace.

CUSHIONRINGReplace.

SEALRINGReplace.

Replace.

SEALRINGReplace.

S

11-179

www.emanualpro.com

Page 382 of 1395

Fuel Supply System

Fuel Injectors {cont'dl

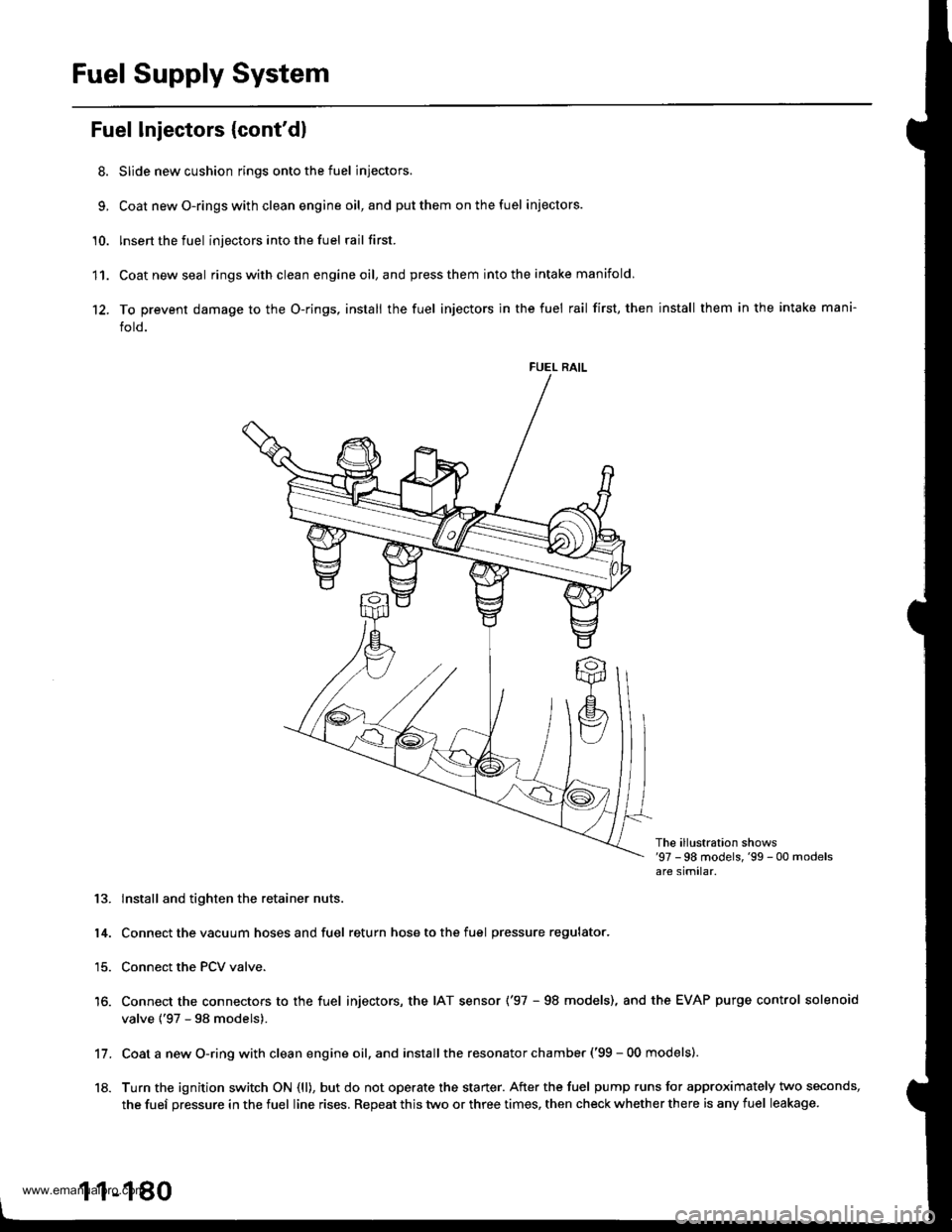

8. Slide new cushion rings onto the fuel injectors.

9, Coat newO-ringswith clean engine oil,and putthem onthefuel iniectors.

'10. lnsert the fuel injectors into the fuel rail first.

11. Coatnewseal ringswithclean engineoil,and press them into the intake manifold

12. To prevent damage to the O-rings, install the fuel injectors in the fuel rail first, then install them in the intake mani-

fold.

FUEL RAIL

The ill!stration shows'97 -98 models,'99 - 00 modelsare similar.

13. lnstall and tighten the retainer nuts.

14. Connect the vacuum hoses and fuel return hose to the fuel pressure regulator.

15. Connect the PCV valve.

16. Connect the connectors to the fuel injectors, the IAT sensor ('97 - 98 models), and the EVAP purge control solenoid

valve {'97 - 98 models).

Coat a new O-ring with clean engine oil, and install the resonator chamber ('99 - 00 models).

Turn the ignition switch ON (ll), but do not operate the starter. After the fuel pump runs for approximately two seconds,

the fuef pressure in the fuel line rises. Repeat this two or three times, then check whether there is any fuel leakage.

11.

18.

1 1-180

www.emanualpro.com

Page 383 of 1395

Fuel Pressure Regulator

Tesiing

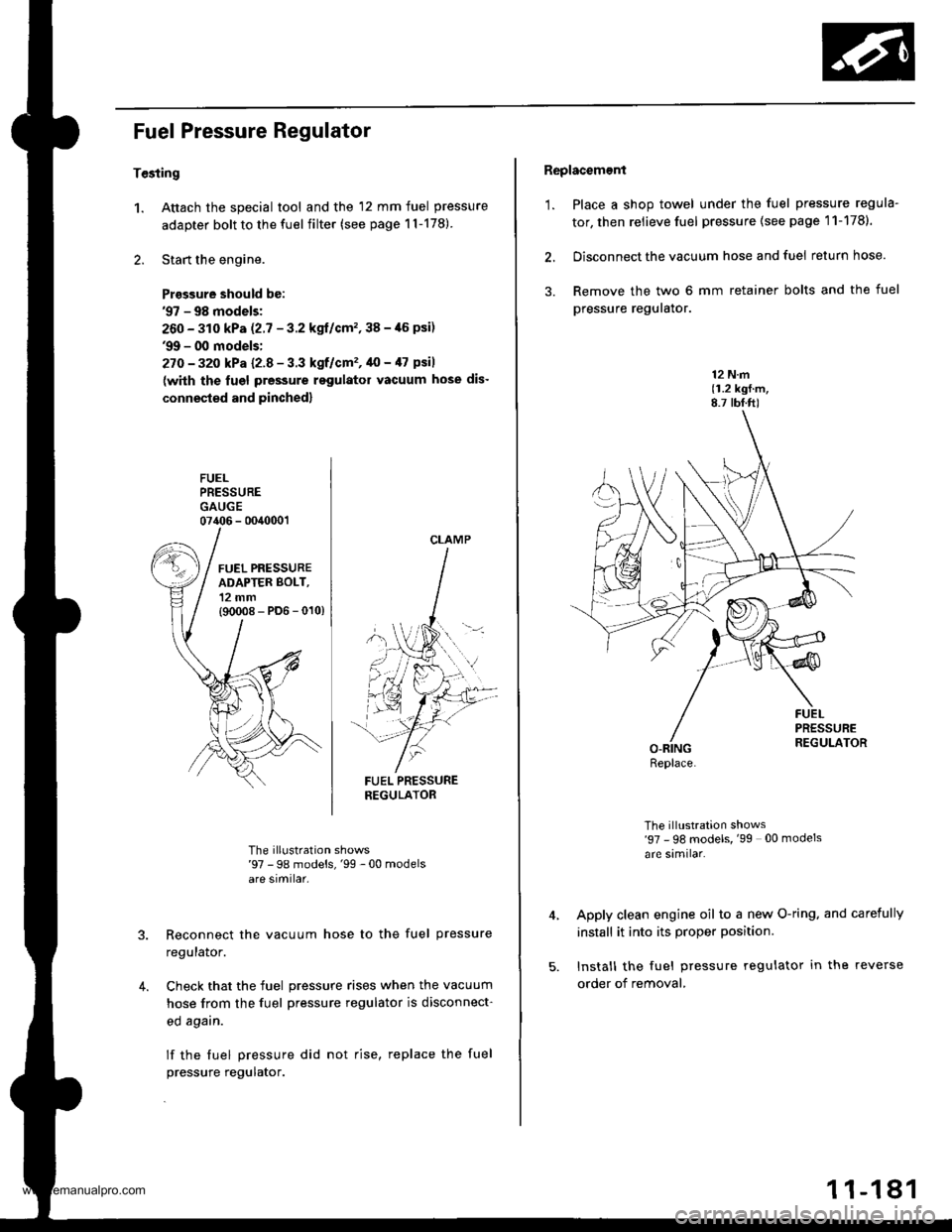

1. Attach the special tool and the 12 mm fuel pressure

adapter bolt to the fuel filter (see page 1l-178)

2. Start the engine.

Prasgure should be:'97 - 98 models;

260 - 310 kPa (2.7 - 3.2 kgl/cm'�,38 -,16 psi)'9!t - 00 models:

27O - 32o kPa l2-8 - 3.3 kgf/cm'�, 40 - /l7 psil

(with the lugl pressure rsgulator vacuum hose dis-

connested and pinched)

FUELPRESSUREGAUGE07406 - 0040001

FUEL PRESSURENEGULATOR

The illustration shows'97 - 98 models,'99 -00 modelsare similar.

Reconnect the vacuum hose to the fuel pressure

regulalor.

Check that the fuel pressure rises when the vacuum

hose from the fuel pressure regulator is disconnect-

ed agarn.

lf the fuel pressure did not rise, replace the fuel

pressure regulator.

4.

CLAMP

Replacement

'1. Place a shop towel under the fuel pressure regula-

tor, then relieve fuel pressure (see page 11-1781.

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts and the fuel

pressure reguralor.

12 N.m(1.2 kgf.m,8.7 tbf.ft)

The illustration shows'97 - 98 models, '99 00 models

are similar.

Apply clean engine oil to a new O-ring. and carefully

install it into its proper position.

Install the fuel pressure regulator in the reverse

order of removal,

Replace.

1 1-181

www.emanualpro.com

Page 384 of 1395

Fuel Supply System

Fuel Filter

Replacamont

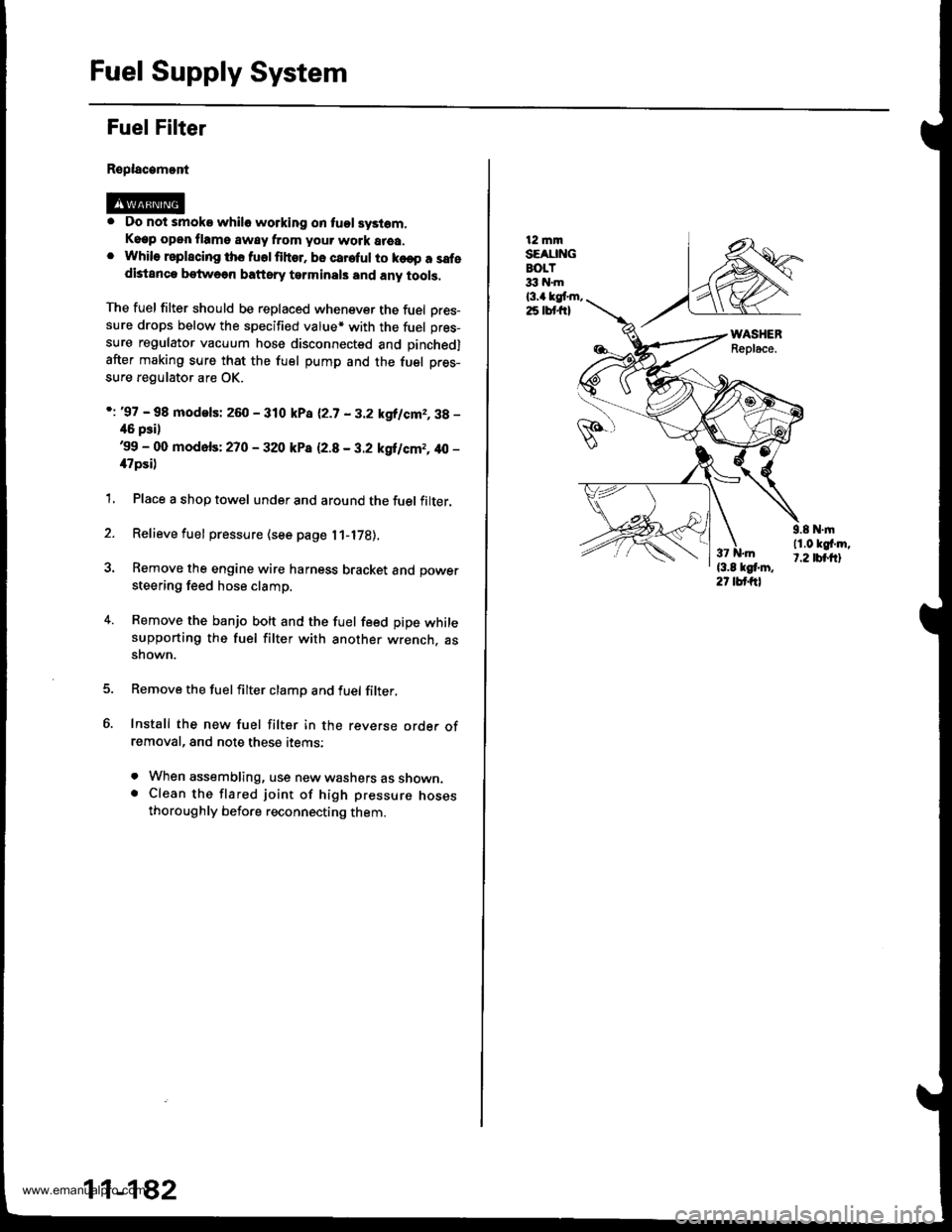

. Do not smoke whilo working on tuol syslom,Keep open flame away from your work area.. While rsplscing ths fuolfihor. bo careful to ko€p a safedistanca betweon baftsry tarminals and any tools,

The fuel filter should be replaced whenever the fuel Dres-sure drops below the specified value* with the fuel pres-

sure regulator vacuum hose disconnected and pinchedl

after making sure that the fuel pump and the fuel pres-

sure regulator are OK.

i: '97 - 98 modelsi 260 - 310 kPa 12.7 - 3.2 kgllcm2,3g -

46 psil'99 - 00 mod6fs: 270 - 320 kP8 12.8 - 3.2 kgilcm2, 40 -

il7psi)

1, Place a shop towel under and around the fuel filter.

2. Relieve fuel pressure (see page l1-l7B).

3. Remove the engine wire harness bracket and power

steering feed hose clamp.

4. Remove the banjo bolt and the fuel feed pipe whilesupporting the fuel filter with another wrench. assnown.

Remove the fuelfilter clamp and fuel filter,

Install the new fuel filter in the reverse orde. ofremoval, and note these items:

. When assembling, use new washers as shown.. Clean the flared joint of high pressure nosesthoroughly before reconnecting them.

11-182

12 mmSEAUNGBOLT33 hl.m

l3.a kgt m,25 lbt frl

9.8 N.|n11.0 kgf'm,t.2 tbt.ftl

www.emanualpro.com