troubleshoot HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 276 of 1395

Troubleshooting

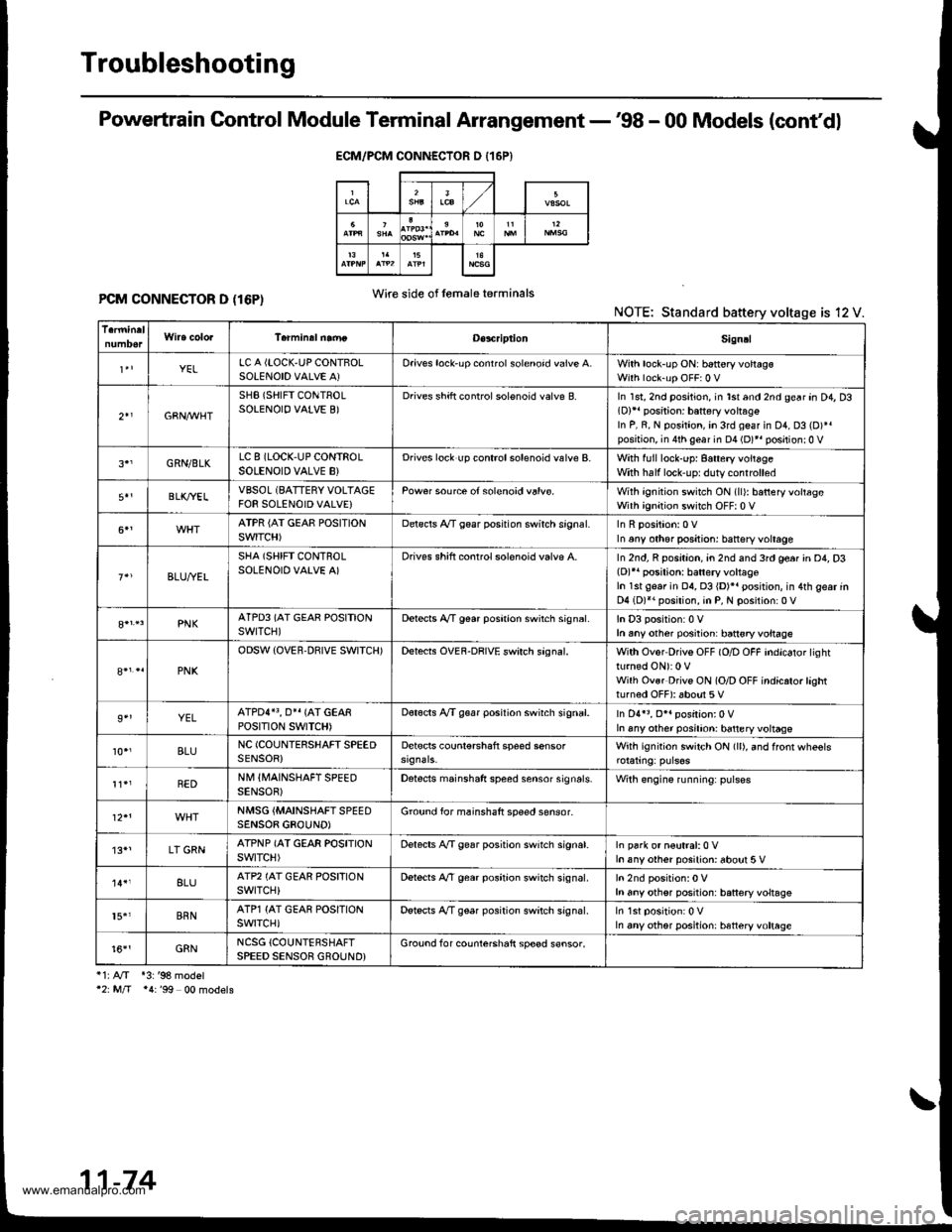

Powertrain Control Module Terminal Arrangement -'98 - 00 Models (cont'dl

PCM CONNECTOR D (16P)NOTE: Standard battery voltage is 12 V.

i1:A/T *3:'98 model'2: M/T *4:'99 00 models

ECM/PCM CONNECTOR D {16P}

Wire side of lemaleterminals

D€s4riptionSign!l

YELLC A {LOCK,UP CONTBOLSOLENOID VALVE A)Oriv€s lock'up conrrol solenoid valve A.With lock-up ON: b6ttery voltagsWith lock-up OFF:0 V

2+1GBN,M/HT

SHB (SHIFT CONTROLSOLENOIO VALVE B)Drives shift controlsolenoid valve B.In 1st, 2nd position, in lst and 2nd gear an D4, D3(D)11 position: battery vohag€In P, R, N position, in 3rd geaf in D1, D3 (D)*.position, in 4th gear in D4 (D)*r positionr0 V

GRN/BLKLC 8 (LOCK,UP CONTROLSOLENOID VALVE B}Drives lock up controlsolenoid valve B.With full lock-up: 8attery voitageWith half lock'uprduty controlled

BLK/YELVBSOL (BATTERY VOLTAGEFOR SOLENOID VALVE}Pow€r source of solenoid valvs.With ignition switch ON (ll): batteryvoltageWith ignition switch OFF| 0 V

ATPR {AI GEAE POSITIONSWITCH)Delscls A/T gear posrtion swirch srgnal.In any other positjon: battsry voltage

BLU,ryEL

SHA (SHIFT CONTROLSOLENOID VALVE A)Drives shift conrrol solenoid valvp A.In 2nd, R position, an 2nd and 3rd ge6r in D4, D3(D)r' posilion: batlery voltageIn 1st gear in 04, 03 {D)}. position, in 4th gear inD4 (D)*. position, in P, N position:0 V

PNKATPD3 (AT GEAR POSITIONswrTcH)Detects A,/T g€ar poshion swirch sign6l.In D3 position:0 Vh any other posiiion: ban€ryvoltage

PNK

ODSW (OVER.DBIVE SWITCH)Detects OVEF-DRIVE swirch sagnal.With Ovor Drivs OFF (O/D OFF indicator lightturned ON): 0 VWilh Ovsr Drivs ON (O/D OFF indicrto.lashtturned OFF): about 5 V

9''YELATPDI}3, O}I {AT GEARPOStTtON SWTTCH)Dot€cts A/T g€ar position swirch signal.In D4r3, O*. position:0 VIn any other posilion: battery voltage

10.,BLUNC (COUNIERSHAFT SPEEDSENSOR)Detscts counl€rshaft speed sensorWith ignition switch ON (ll), and ffonr wheels

REDNM IIVAINSHAFT SPEEDSENSOB)Detects mainshaft speed sensor sign6ls.Wilh engine running: pulses

NMSG {MAINSHAFTSPEEDSENSOB GBOUND)Ground for mainshaft speed sensor-

'13*1LT GRNATPNP (AT GEAR POSITIONswtTcH)Delects A,/T gear position switch signat.In park or n€utral:0 Vh any other posilion: about 5 V

8LUATP2 (AT GEAR POSFIONswrTcH)Dstects A,/T gear position switch signal.h any othsr position: battery voltsgs

15.'BRNATP1 {AT GEAR POSITIONswrTcH)Detscts A/T gear position switch signal.In any other position: htteryvoltage

t6''GRNNCSG {COUNTERSHAFTSPEED SENSOR GROUND}Grouod for counterchaft sp€ed s€nsor.

11-74

www.emanualpro.com

Page 278 of 1395

Troubleshooting

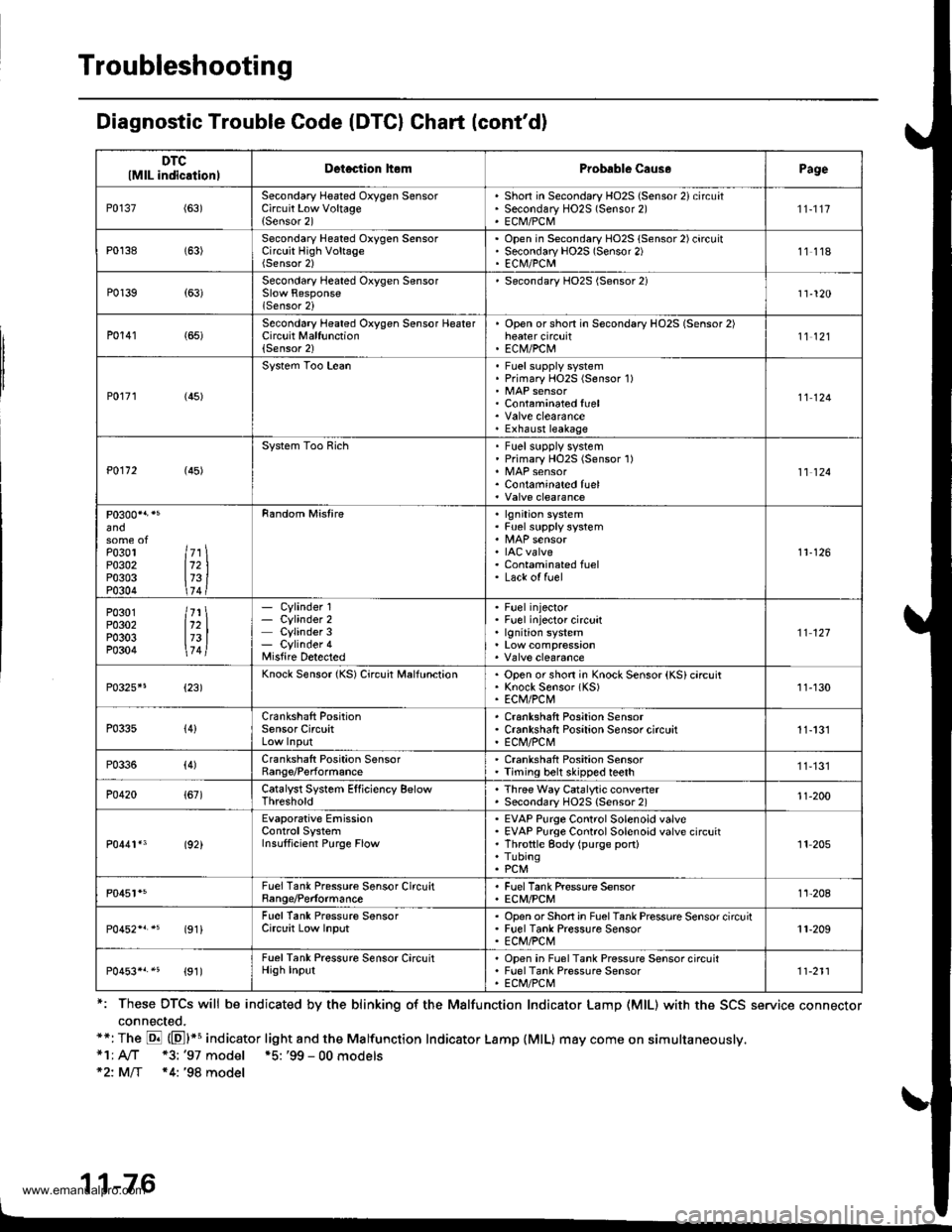

Diagnostic Trouble Code (DTCI Chart (cont'd)

*: These DTCS will be indicated by the blinking o{ the Malfunction Indicator Lamp (MlL) with the SCS service connector

connected.**: The E (El*s indicator light and the Malfunction Indicator Lamp {MlL) may come on simultaneously,*1; A/T *3: '97 model *5: '99 - 00 models*2: MlT *4: '98 model

11-76

DTClMlL indicationlDetection hemProbable Caus.Page

P0137(63)Secondary Heated Oxygen SensorCircuit Low Voltage{Sensor 2)

Shon in Secondary HO2S (Sensor 2) circuatSecondary HO2S (Sensor 2)ECM/PCM

'n-1t7

P0138 (63)Secondary Heated Oxygen SensorCircuit High VoltageOpen in Secondary HO2S (Sensor 2) circuitSecondary HO2S (Sensor 2)EC|\il/PCM11118

P0139{63)Secondary Heated Oxygen Sensor

lSensor 2i

Secondary HO2S (Sensor 2)11-120

P0141 (65)Second6ry Heated Oxygen Sensor HeaterCircuit Malfunction(Sensor 2)

Open orshon in Secondary HO2S (Sensor 2)heater circuitEC|V/PCtu11't2l

P0r71 (45)

System Too LeanFuel supply systemPrimary HOzS (Sensor 1)

Contaminated fuel

Exhaust leakage

11124

P0112 (45)

System Too RichFuel supplv systemPrimary HO2S (Sensor 1)

Contaminated fuel11 124

and

Po3ol ltr \P0302 112 |P0303 173 iP0304 \74 t

Random Mistirelgnition systemFuel supply system

IAC valveContaminated fuelLack of fuel

11-126

P0301 /71 \P0302 112 |P0303 173 |P0304 \7 4l

- Cylinder 1- Cylinder 2Cylinder 3- Cylinder 4Misfire Detected

Fuel injectorFuel injector circuitlgnition system't't 127

P0325*5{23)Knock Sensor {KS) Circuit MalfunctionOpen or shon in Knock Sensor (KS) circuitKnock Sensor (KS)ECM/PCt\411-130

P033s{4}Crankshaft PositionSensor CircuitCrankshaft Position SensorCrankshaft Positaon Sensor circuitE Cl\,l/PC l\,'!11-131

P0336(4)Crankshaft Position SensorRange/PerformanceCrankshaft Position SensorTiming belt skipped teeth11,131

P0420{67)Catalyst System Efficiency BelowThresholdThree Way Catalytic convenerSecondary HO2S {Sensor 2)'t1-200

P0441*3 (92)

Evaporative EmissionControlSystemInsulficient Purge Flow

EVAP Purge Control Solenoid valveEVAP Purge Control Solenoid valve circuitThrottle gody (purge port)TubingPCM

'It 205

P0451*5FuelTank Pressure Sensor CircuitBange/PerformanceFuel Tank Pressure SensorECM/PCMt't-208

(91iFuel Tank Pressure SensorCirclit Low InputOpsn orShort in FuelTank Pressure Sensor circuitFuel Tank Pressure SensorECM/PCt\411-209

P0453*r.5 {91)FuelTank Pressure Sensor CircuitHigh InputOpen in Fuel Tank Pressure Sensor circuitFuel Tank Pressure SensorECt /PCt\.111-211

www.emanualpro.com

Page 280 of 1395

Troubleshooting

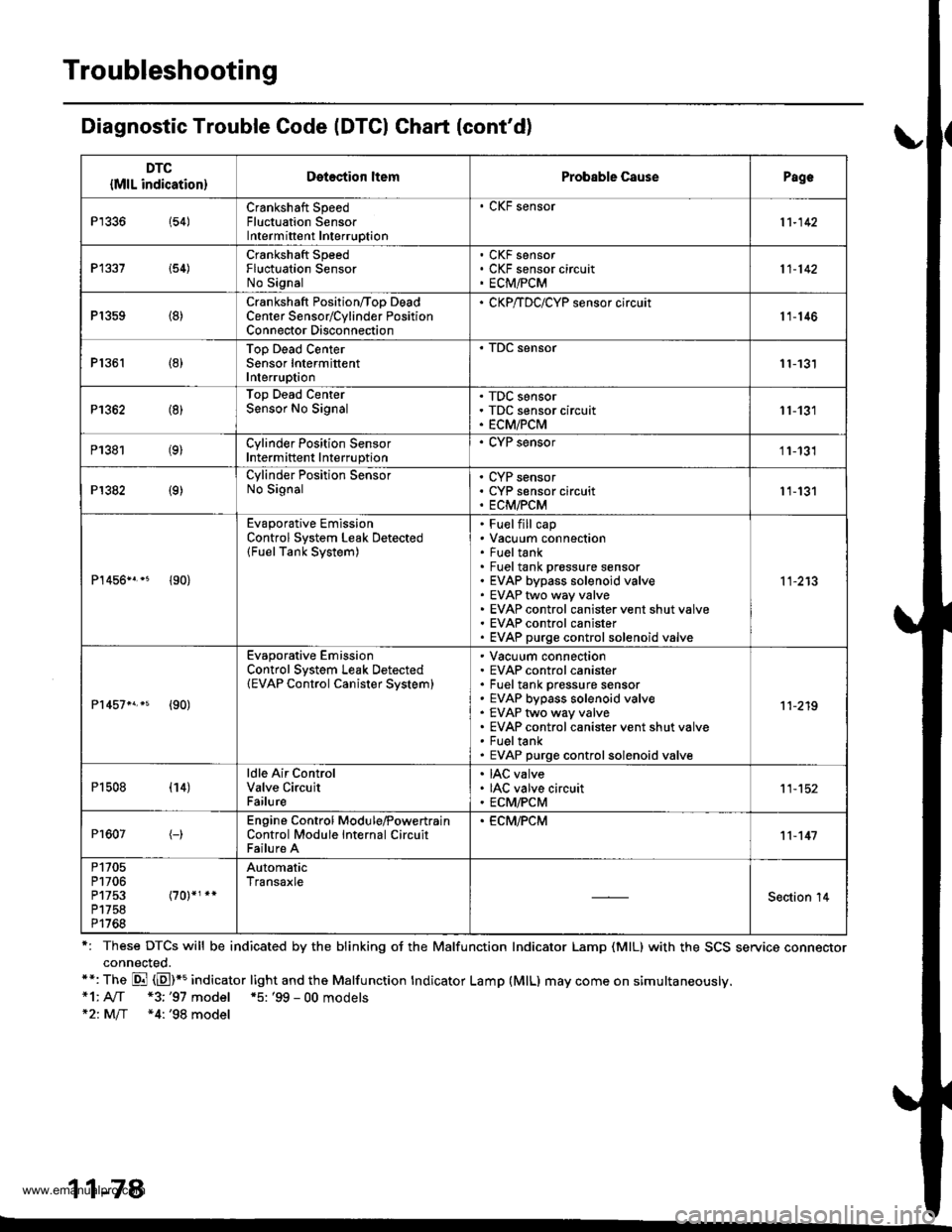

Diagnostic Trouble Code (DTCI Ghart (cont'd)

r: These DTCS will be indicated by the blinking oJ the Malfunction Indicator Lamp (MlL) with the SCS service connectorconnected.**: The Di (E)*5 indicator light and the Malfunction tndicator Lamp (MlL) may come on simultaneously.*1: A[f *3;'97 model *5: '99 - 00 models*21M/f *4: '98 model

11-78

DTC

{MlL indication}Detection ltemProbable CausePagc

P1336 154)Crankshaft SpeedFluctuation SensorIntermittent Interruption

. CKF sensor

11-142

P1337 i54)Crankshaft SpeedFluctuation SensorNo Signal

CKF sensorCKF sensor circuitECM,FCM11-142

P1359 (8)Crankshaft Position/Too DeadCenter Sensorrcylinder PositionConnector Disconnection

' CKP/TDC/CYP sensor circuit11-146

P1361 (8)Top Dead CenterSensor IntermittentInterruption11-131

P1362 (8)Top Dead CenterSensor No SignalTDC sensorTDC sensor circuitECM/PCM11-131

P1381 (9)Cylinder Position SensorIntermittent Interruption

. CYP sensor11-131

P1382 (9)Cylinder Position SensorNo SignalCYP sensorCYP sensor circuitECM/PCM11-131

P1456n.* {90}

Evaporative EmissionControl System Leak Detected(FuelTank System)

Fuelfill capVacuum connectionFueltankFuel tank prossure sensorEVAP bypass solenoid valveEVAP two way valveEVAP control canister vent shut valveEVAP control canisterEVAP purge controlsolenoid valve

11-213

Pr457n.s {90)

Evaporative EmissionControl System Leak Detected(EVAP Control Canister Svstem)

Vacuum connectionEVAP control canisterFuel tank pressure sensorEVAP bypass solenoid valveEVAP two way valveEVAP control canister vent shut valveFueltankEVAP purge controlsolenoid valve

11-219

P1508 (14)ldle Air ControlValve CircuitFailure

IAC valveIAC valve circuitECM/PCM11-152

Pr607(-)Engine Control Module,PowertrainControl Module Internal CircuitFailure A

. ECM,FCM11-147

P1705P1706P1753P1758P1768

AutomaticTransaxle

Section '14

www.emanualpro.com

Page 281 of 1395

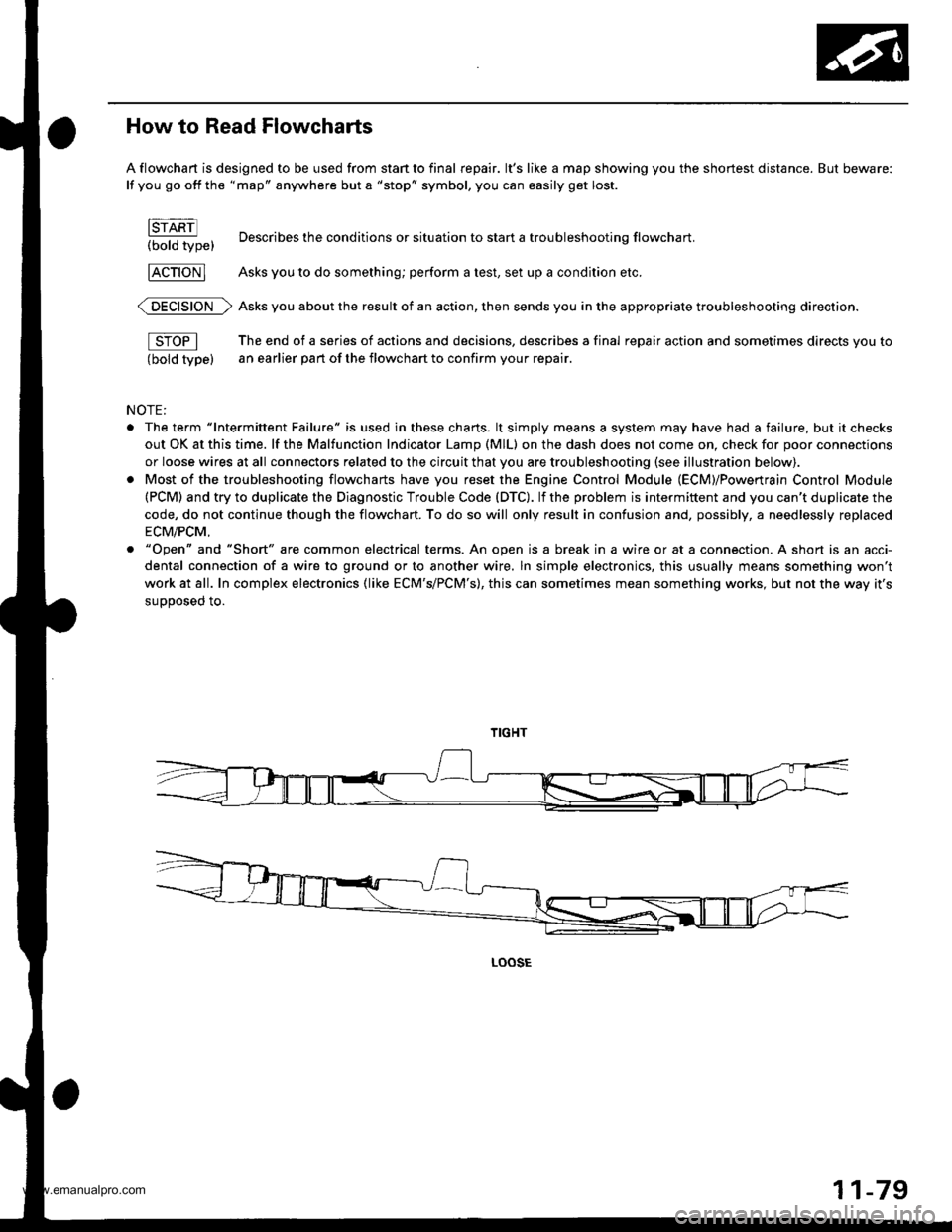

How to Read Flowcharts

A flowchart is designed to be used from start to final repair. lt's like a map showing you the shortest distance. But beware:

lf you go off the "map" anywhere but a "stop" symbol, you can easily get lost.

brARn

t.-OotO tw"t Describes the conditions or situation to start a troubleshooting flowchart.

FcTloNl Asks you to do something; perform a test, set up a condition etc.

@ Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

fS-OPl The end of a series of actions and decisions, describes a final repair action and sometimes directs you to

(bold type) an earlier part of the flowchart to confirm your repair.

NOTE:

. The term "lntermittent Failure" is used in these charts. lt simply means a system may have had a failure, but it checks

out OK at this time. lf the Malfunction Indicator Lamp (MlL) on the dash does not come on, check for poor connections

or loose wires at all connectors related to the circuit that you are troubleshooting (see illustration below).

. Most of the troubleshooting flowcharts have you reset the Engine Control Module (EcM)/Powertrain Control Module(PCM) and try to duplicate the Diagnostic Trouble Code (DTC). lf the problem is intermittent and you can't duplicate the

code, do not continue though the flowchart. To do so will only result in confusion and, possibly, a needlessly replaced

ECM/PCM,

o "Open" and "Short" are common electrical terms. An open is a break in a wire or at a connection. A short is an acci-

dental connection of a wire to ground or to another wire. ln simple electronics, this usually means something won't

work at all. In complex electronics (like ECM'S/PCM'S), this can sometimes mean something works, but not the way it's

suooosed to.

LOOSE

11-79

www.emanualpro.com

Page 283 of 1395

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com

Page 285 of 1395

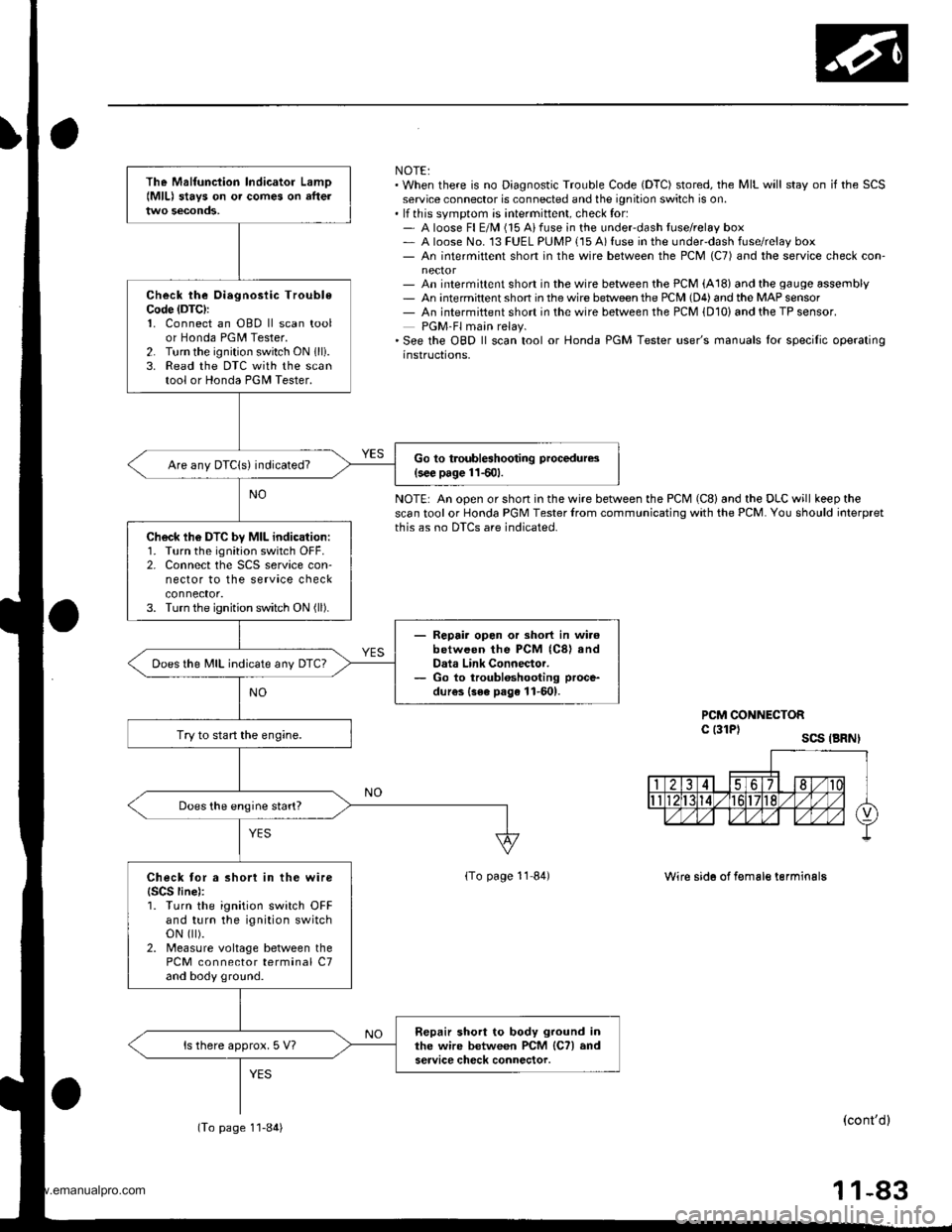

NOTE:. When there is no Diagnostic Trouble Code (DTC) stored, the MIL will stay on if the SCSservice connector is connected and the ignition switch is on.. lf this svmotom is intermittent, check for:- A loose Fl E/M (15 Aifuse in the underdash tuse/relay box- A loose No. 13 FUEL PUMP {15 A) fuse in the under-dash fuse/relay box- An intermittent short in the wire between the PCM (C7) and the service check con-

- An intermittent short in the wire between the PCM (A18) and the gauge assembly- An intermittent shon in the wire betlveen the PCM (D4) and the MAP sensor- An intermiftent short in the wire between the PCM {D10) and the TP sensor.PGM-Fl main relay.'See the OBD ll scan tool or Honda PGM Tester user's manuals lor specilic operatinginstructions,

NOTE: An open or short in the wire between the PCM (C8) and the DLC will keep thescan tool or Honda PGM Tester lrom communicating with the PCM. You should ioterpretthis as no DTCS are indicated.

PCM CONNECTORc l3lPl scs .BRNI

lTo page 11 84)Wire sid6 of f€male terminalg

(cont'dl

11-83

The Malfunciion lndicator Lamo{MlL) stavs on o. comes on afteltwo seconds,

Check the Oiegnosiic TroubleCode (DTC):

1. Connect an OBD ll scan toolor Honda PGM Tester.2. Turn the ignition switch ON 1lli.3. Read the DTC with the scantool or Honda PGII Tester.

Go to troubleshooting procedures(s€€ page 11501.Are any DTCIs) indicated?

Ch6ck lh6 DTC by MIL indication:1. Turn the ignition switch OFF.2. Connect the SCS service con-nector to the service checkconnector.3. Turn the ignition switch ON (ll).

- Repair opon or short in wi.6between the PCM (C8) andData Link Connector.- Go to troubloshooting proce-

dur€s {3ee page 11-601.

Does the MIL indicate any DTc?

Try to start the engine.

Does the engine start?

Check tor a short in the wire{SCS line):1. Turn the ignition switch OFFand turn the ignition switchoN flt).2. Measure voltage between thePCM connector terminal C7and body ground.

Repair short to body ground inthe wire between PCM lCTl andservice check connector.ls there approx. 5 V?

(To page 1'l-84)

www.emanualpro.com

Page 301 of 1395

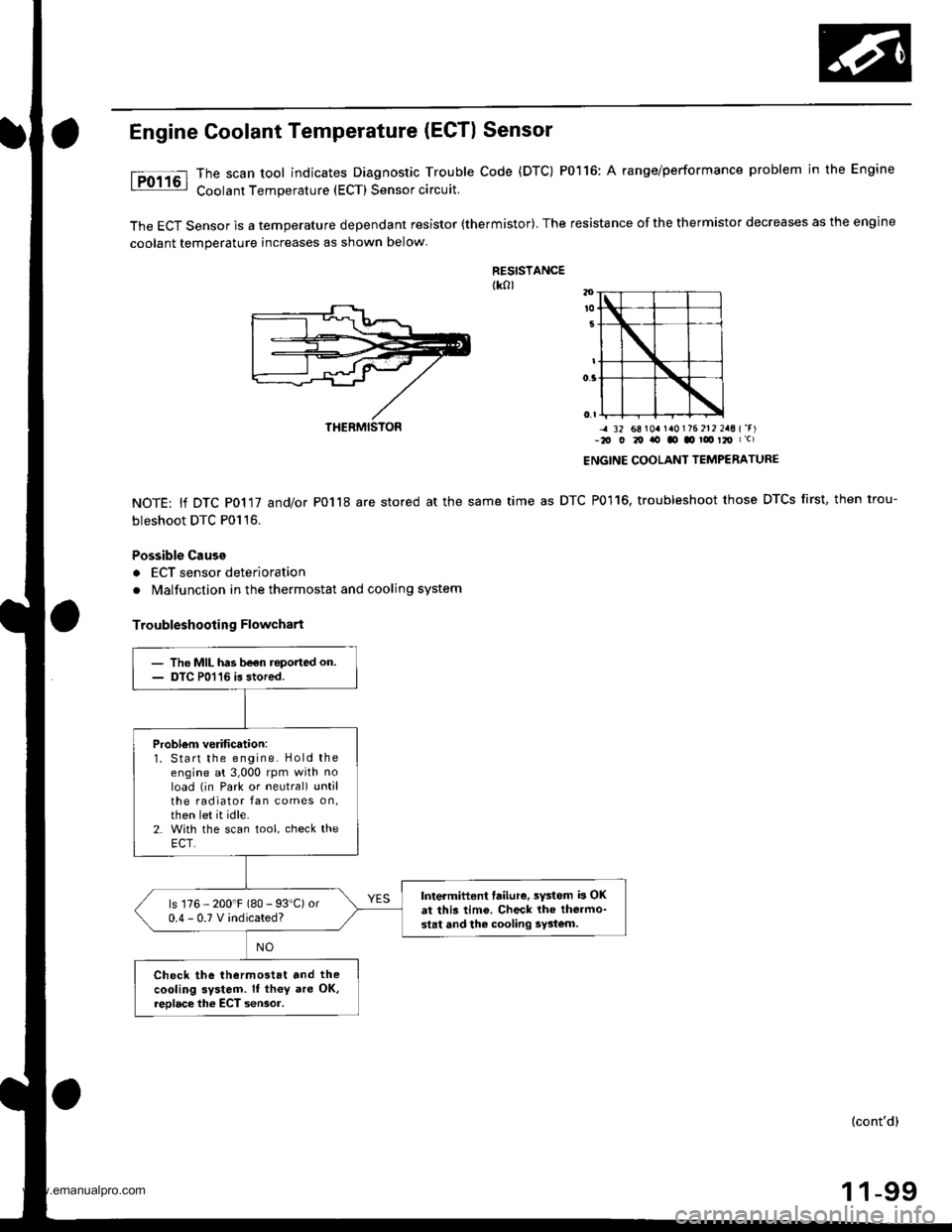

Engine Goolant Temperature (ECTI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0116: A range/performance problem in the Engine

Coolant Temperature (ECT) Sensor circuit.

The ECT Sensor is a temperature dependant resistor (thermistor). The resistance of the thermistor decreases as the engine

coolant temperature increases as shown below

RESISTANCEtk0l

NOTE: lf DTC P0117 and/or P0118 are stored at the same

bleshoot DTC P0116.

Possible Cause

a ECT sensor deterioration

. Malfunction in the thermostat and cooling system

Troubleshooting Flowchart

-4 32 68 r0a r a0176 212 2aE {'r)-2O O 20 ito tO .o ! t2O I c)

ENGINE COOLANT TEMPERATURE

time as DTC P0116, troubleshoot those DTCS first, then trou-

THERMISTON

- The MIL has be€n roported on.- DTC P01'16 is stored.

Probl6m verification:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on,then let it idle.2. With the scan tool, check theECT.

Intermittent failure, sYstem b OKat this tim6. Check lhe thermo-stat and the cooling 5y3tom.

ls 176 - 200'F (80 - 93"C) or0.4-0.TVindicated?

Check the thermostat and the

cooling system. It th€y are OK,reolace the ECT seNor.

(cont'd)

1 1-99

www.emanualpro.com

Page 318 of 1395

PGM-FI System

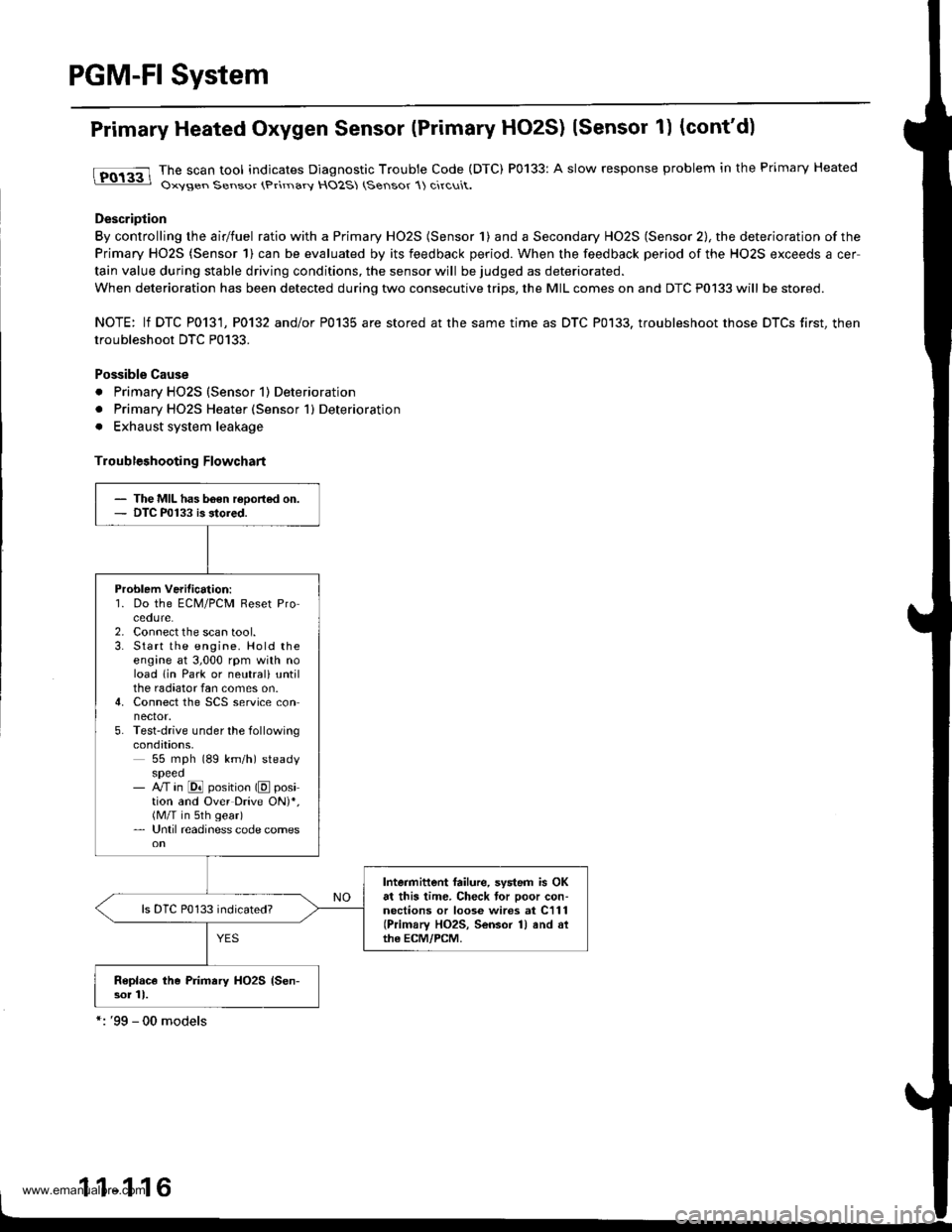

Primary Heated Oxygen Sensor (Primary HO2S) lSensor 1) (cont'd)

tFO133 lhe scan tool indicates Diagnostic Trouble Code (DTC) P0133: A slow response problem in the Primary Heated: Oxysen Sensor (Primarv HO2S (Sensor 1) circuit.

Description

By controlling the airlfuel ratio with a Primary HO2S (Sensor 1) and a Secondary HO2S (Sensor 2), the deterioration of the

Primary HO2S (Sensor 1) can be evaluated by its feedback period. When the feedback period of the HO2S exceeds a cer

tain value during stable driving conditions, the sensor will be judged as deteriorated.

When deterioration has been detected during two consecutive trips, the MIL comes on and DTC P0133 will be stored.

NOTE: lf DTC P0131, P0132 and/or P0135 are stored at the same time as DTC P0133. troubleshoot those DTCS first, then

troubleshoot DTC P0133.

Possible Cause

. Primary HO2S (Sensor 1) Deterioration

. Primary HO2S Heater (Sensor 1) Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has b6€n reoorted on.- DTC P0133 is stored.

Problem Verilication:'1. Do the ECM/PCM Reset Procedure.2. Connect the scan tool.3. Start the engine. Hold theengine at 3,000 rpm with noload lin Park or neutrali untilthe radiator fan comes on.4. Connect the SCS service connector.5. Test-drive under the followingcondations,55 mph (89 km/h) steadyspeed- M in @ position (E position and Over Drive ON)*,(M/T in sth gear)- Until readiness code comes

Intermittent failure, system is OKat this time. Check tor poor con-nections or loose wires at C111(Primary HO2S, Sensor 1) and althe ECM/PCM.

Replace the Primary HO2S {Sen-sor 11.

1 1-1 16

www.emanualpro.com

Page 326 of 1395

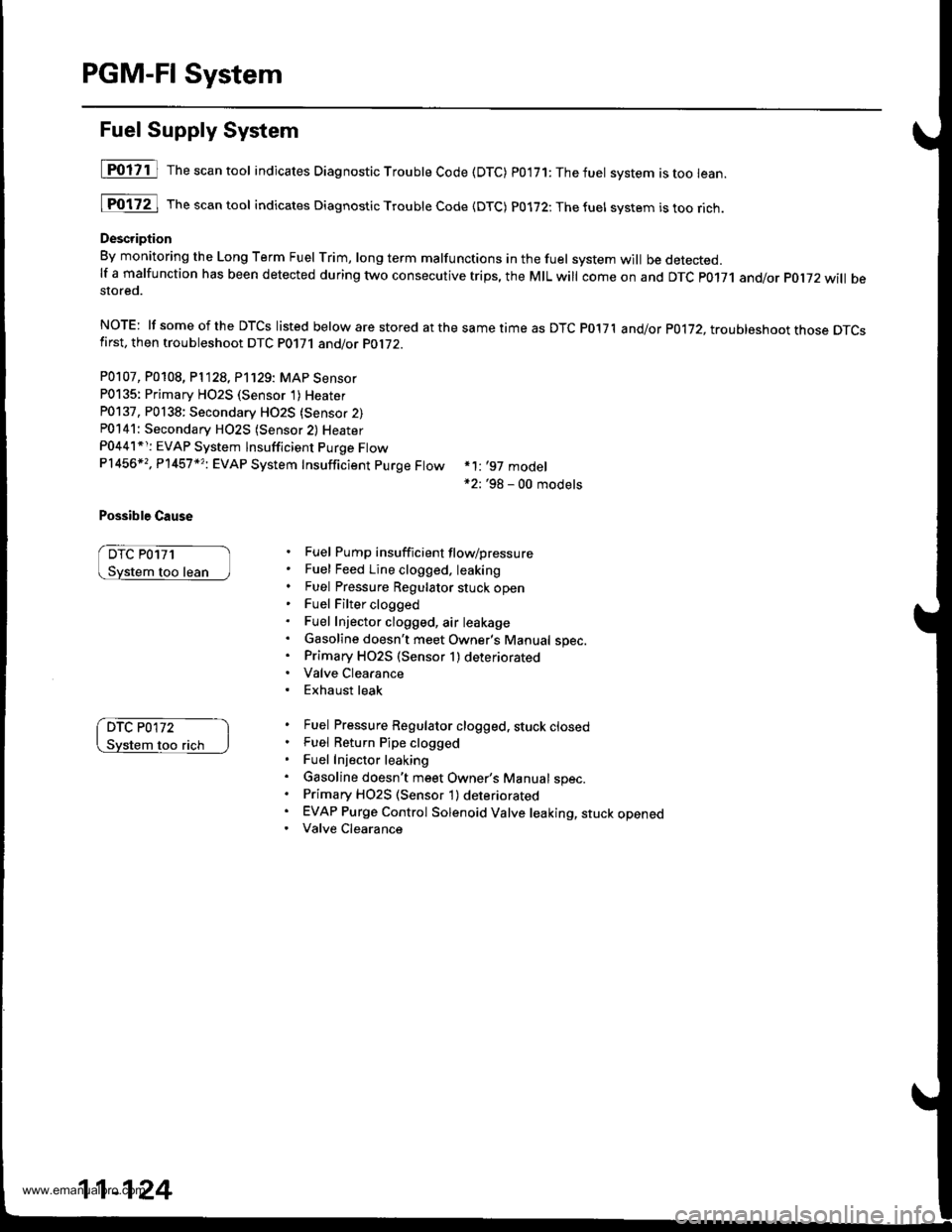

PGM-FI System

Fuel Supply System

[POliil The"""ntool indicates Diagnostic Troubte Code (DTC) p0'171:Thefuet system istoo lean.

[Fo17ZJ rh""""ntool indicates Diagnostic Troubte code {DTc) p0172:Thefuel svstem istoorich.

Description

By monitoring the Long Term Fuel rrim, long term malfunctions in the fuel system will be detected.lf a malfunction has been detected during two consecutive trips, the MIL will come on and DTc p0171 and/or pol72 will bestored.

NOTE: lf someof the DTCS listed below are stored atthesametimeas DTC P017'l and/or p0172, troubleshoot those DTcsfirst, then troubleshoot DTC P0171 and/or PO1i2.

P0107, P0108, P1128, P'1129: MAP Sensor

P0135: Primary HO2S (Sensor 1)Heater

P0137, P0138: Secondary HO2S {Sensor 2)P0141: Secondary H02S (Sensor 2) Heater

P0441*r: EVAP System lnsufficient Purge FtowP1456*,, P'l457 *?i EVAP System Insufficient purge Ftow

Possible Cause

DTC P0171

too lean

*1: '97 model*2: '98 - 00 models

Fuel Pump insufficient flow/pressure

Fuel Feed Line clogged. leaking

Fuel Pressure Regulator stuck openFuel Filter clogged

Fuel Injector clogged, air leakage

Gasoline doesn't meet Owner's Manual spec.Primary HO2S (Sensor 1) deteriorated

Valve Clearance

Exhaust leak

Fuel Pressure Regulator clogged, stuck closedFuel Return Pipe clogged

Fuel Injector leaking

Gasoline doesn't meet Owner's Manual spec.Primary H02S (Sensor 1) deteriorated

EVAP Purge Control Solenoid Valve leaking, stuck openedValve Clearance

DTC P0172

flch

11-124

www.emanualpro.com

Page 327 of 1395

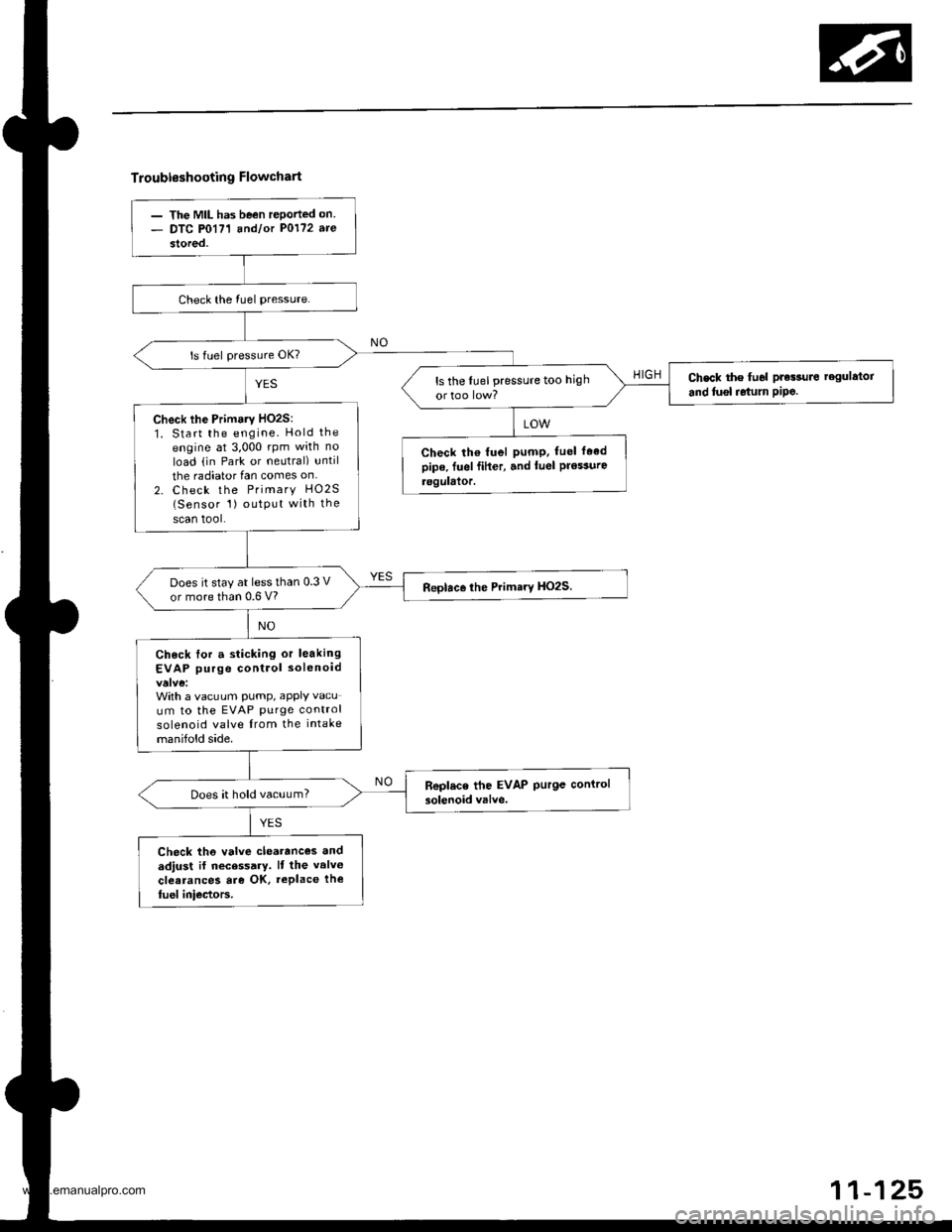

Troubleshooting Flowchart

- The MIL has been rePorted on- DTC P0171 andlot P0172 are

stored,

Check the lu6l pressuro regulator

and tusl relum PiPe.ls the lLrel pressure too high

Check lhe Primaty HO2S:1. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park ot neutral) until

the radiator fan comes on

2. Check the Primary HO2S(Sensor 1) outPut with the

scan tool.

Check lh€ fuel pumP. fuel faedpipe. fuel fiher, and luel Prossurc.eguhior.

Does it stay at lessthan 0.3 V

or more than 0.6 V?

Check for a sticking or leaking

EVAP purge control solenoid

With a vacuum pump, aPPIY vacu

um to the EVAP Purge control

solenoid valve from the intake

manifold side.

Does it hold vacuum?

Check th6 valve clearanc€s and

adjust il necessary. It the valv€

clearances are OK, replace the

fuel iniectors.

www.emanualpro.com