Torque spec HONDA CR-V 1998 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 740 of 1395

Differential

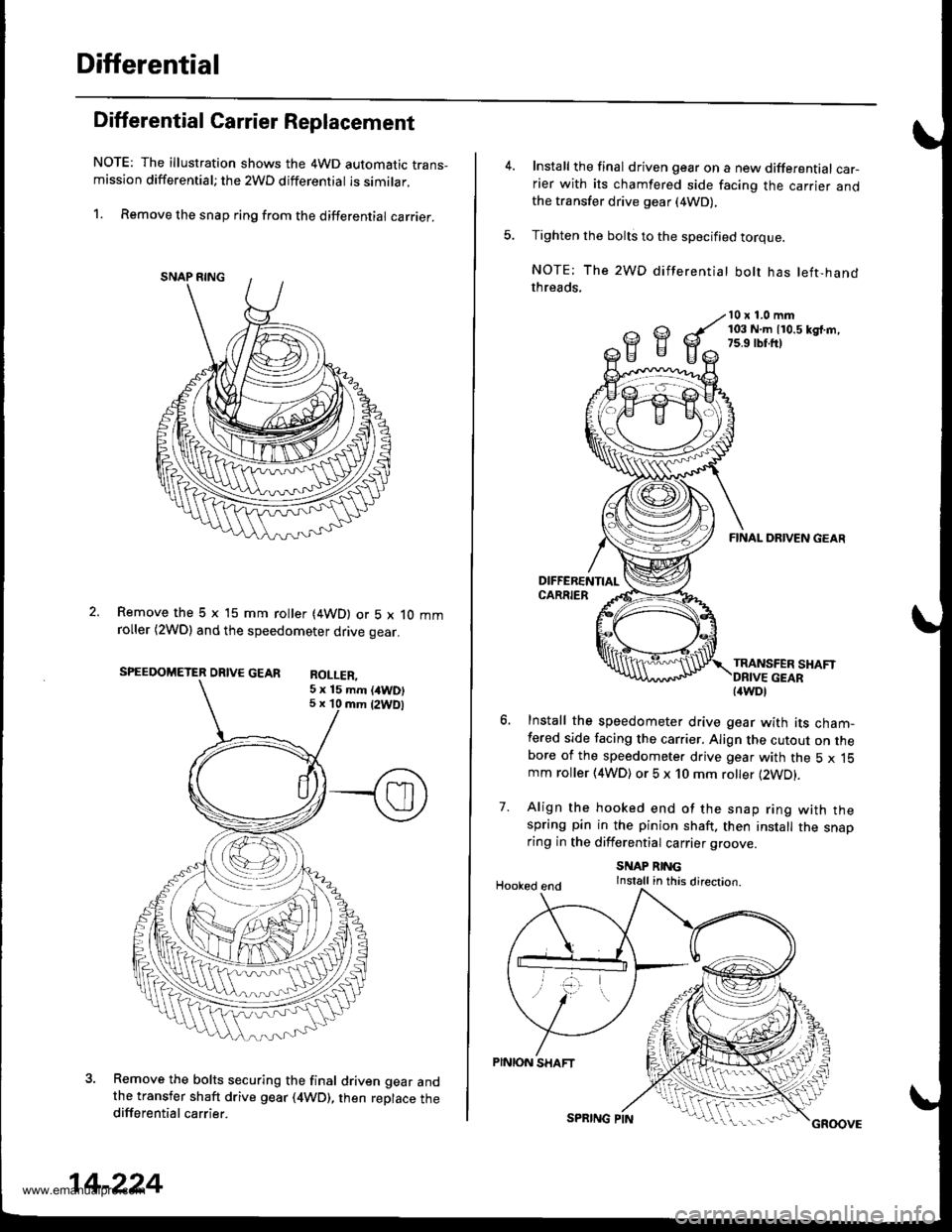

Differential Carrier Replacement

NOTE: The illustration shows the 4WD automatic trans-mission differential; the 2WD differential is similar.

1. Remove the snap ring from the differential carrier.

Remove the 5 x 15 mm roller (4WD) or 5 x 10 mmroller (2WDl and the speedometer drive gear.

SPEEDOMETER DRIVE GEAR RoI I FP

Remove the bolts securing the final driven gear andthe transfer shaft drive gear (4WD), then replace thedifferential carrier.

5 x 15 mm (/tWD)5 x 10 mm {2WDl

14-224

SPRING PINGROOVE

Install the final driven gear on a new differential car-rier with its chamfered side facing the carrier andthe transfer drive gear (4WD),

Tighten the bolts to the specified torque.

NOTE: The 2WD differentiat bolt has left-handthreads,

10 x 1.0 mm103 N.m 110.5 kd.m,7s.9 rbr.ft)

7.

FINAL DRIVEN GEAR

TRANSFER SHAFT

Install the speedometer drive gear with its cham-fered side facing the carrier. Align the cutout on thebore of the speedometer drive gear with the 5 x 15mm roller (4WD) or 5 x 10 mm roller (2WD).

Align the hooked end of the snap ring with thespring pin in the pinion shaft. then install the snaoring in the differential carrier groove

SNAP RINGInstall in this direction.Hooked end

PINION SHAFT

{4WDl

www.emanualpro.com

Page 741 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Service Manual

Oil Seal Replacement

1. Remove the oil seal from the transmission housing.

OIL SEALReplace.

Remove the oil seal from the torque converter

housing.

OIL SEALReplace.TOROUE CONVERTERHOUSING

-.].

3. lnst HONDA CR-V 1998 RD1-RD3 / 1.G Service Manual

Oil Seal Replacement

1. Remove the oil seal from the transmission housing.

OIL SEALReplace.

Remove the oil seal from the torque converter

housing.

OIL SEALReplace.TOROUE CONVERTERHOUSING

-.].

3. lnst](/img/13/5778/w960_5778-740.png)

Oil Seal Replacement

1. Remove the oil seal from the transmission housing.

OIL SEALReplace.

Remove the oil seal from the torque converter

housing.

OIL SEALReplace.TOROUE CONVERTERHOUSING

-.].

3. lnstall the oil seal in the transmission housing using

the special tools as shown.

DRIVER077a9 - 0010000

ATTACHMEMT079r? - slx[ax)

4.Install the oil seal in the torque converter housing

using the specialtools as shown.

14-225

www.emanualpro.com

Page 742 of 1395

Differential

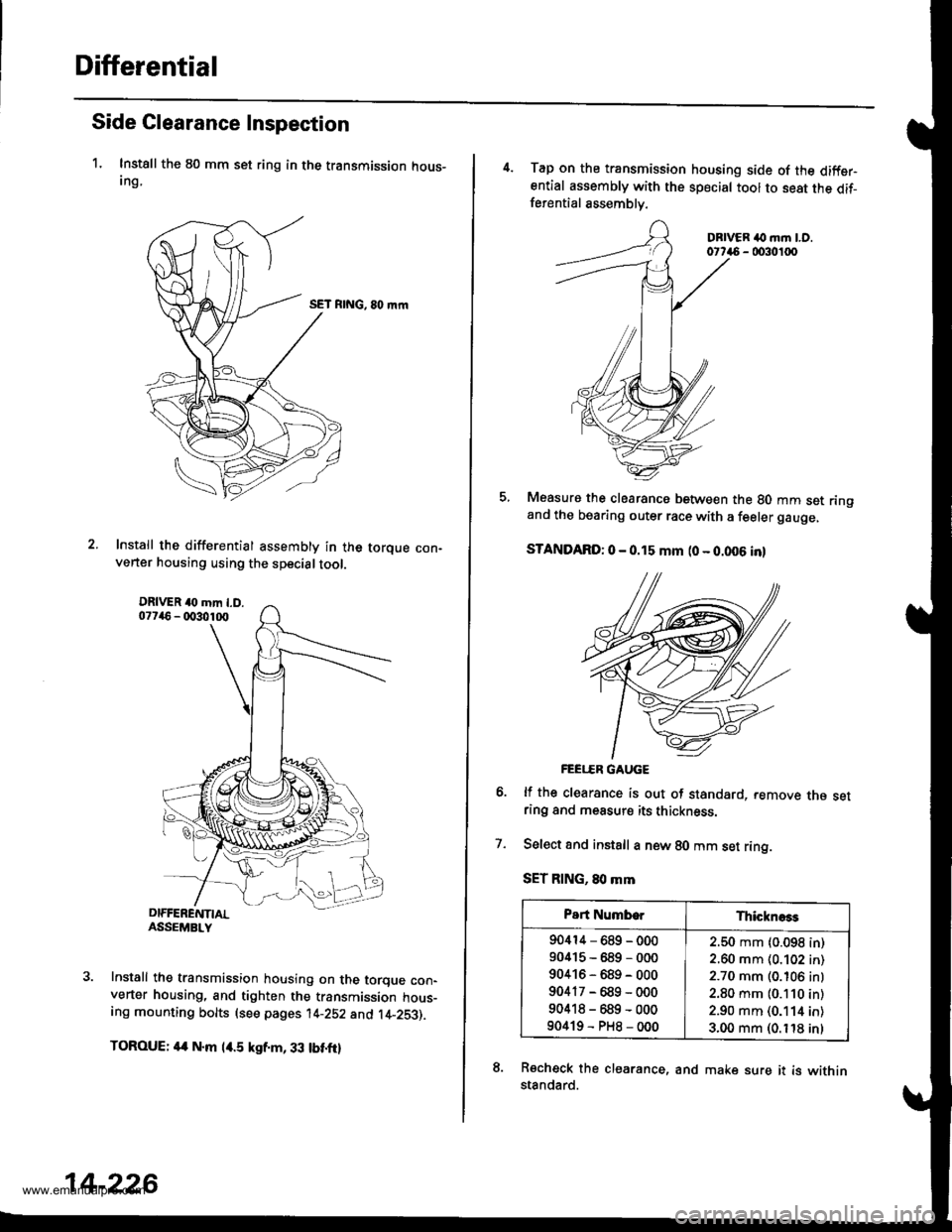

Side Clearance Inspection

1. Instsll the 80 mm set ring in the transmission hous-Ing,

SET RING, 80 mrn

Install the differential assembly in the torque con-verter housing using the specialtool.

Install the transmission housing on the torque con-verter housing, and tighten the transmission hous-ing mounting bolts (see pages 14-252 and t4-253).

TOROUE: 4a N.m l/r.5 kgf.m, 33 tbt.ftl

14-226

4. Tap on the transmission housing side of the diffsrential assembly with the special tool to seat the dif-ferential assemblv.

DBIVER ilo m.n LO.0t746 - 0030100

Measure the clearancs between the 80 mm set ringand the bearing outer race with a feeler gauge,

STANDARD: 0 - 0.15 mm (0 - 0.006 inl

FEEI..ER GAUGE

lf the clearance is out of standard, remove rne setring and measurs its thickness.

Select and instsll a new 80 mm set ring.

SET RING, 80 mm

Recheck the clearance, and make sure it is withinstandard.

7.

Part NumborThicknoss

90414-689-000

90415-689-000

90416-689-000

90417-689-000

90418-689-000

90419-PH8-000

2.50 mm (0.098 in)

2.60 mm (0.102 in)

2.70 mm (0.106 inl

2.80 mm (0.110 in)

2.90 mm (0.114 in)

3.00 mm (0. t'18 inl

www.emanualpro.com

Page 746 of 1395

Torque Gonverter Housing

BearingsGontrol Lever Assembly

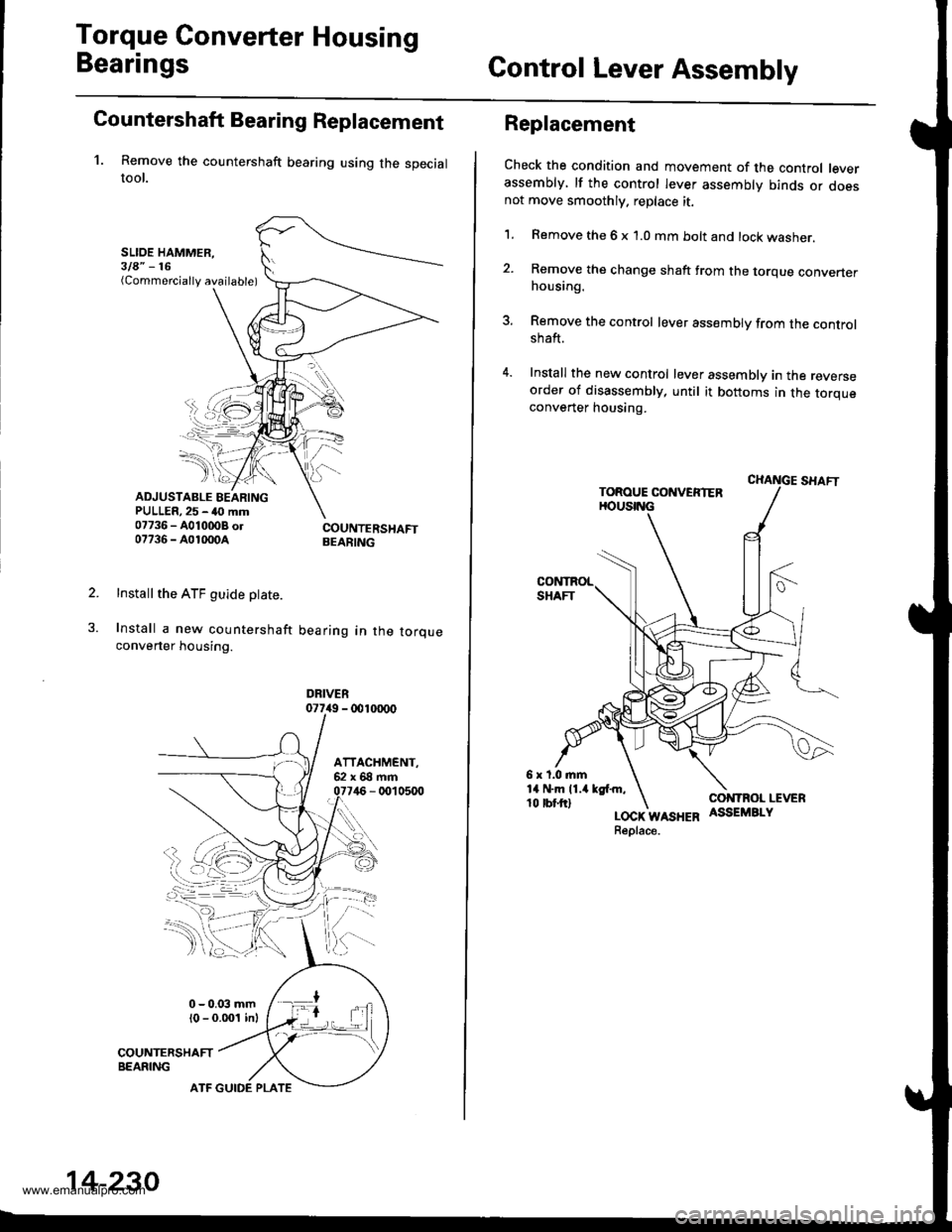

Countershaft Bearing Replacement

1. Remove the countershaft bearing using the specialtool.

SLIOE HAMMER,3la" -16(Commercially available)

ADJUSTABLE BEARINGPULLER,25 - 40 mm07736 - A0100OB ol07736 - A01m0A

Install the ATF guide ptate.

Install a new countershaft

converter housing.

COUNTERSHAFTBEARING

bearing in the torque

DRIVER077i19 - 001m00

14-230

ATF GUIDE PLATE

Replacement

Check the condition and movement of the control leverassembly, lf the control lever assembly binds or doesnot move smoothly. replace it.

1. Remove the 6 x 1.0 mm bolt and lock washer.

2. Remove the change shaft trom the torque converterhousing.

3. Remove the control lever assembly from the controlshaft.

4. Install the new control lever assembly in the reverseorder of disassembly, until it bottoms in the torqueconverter housing.

LOCK WASHERReplace.

www.emanualpro.com

Page 749 of 1395

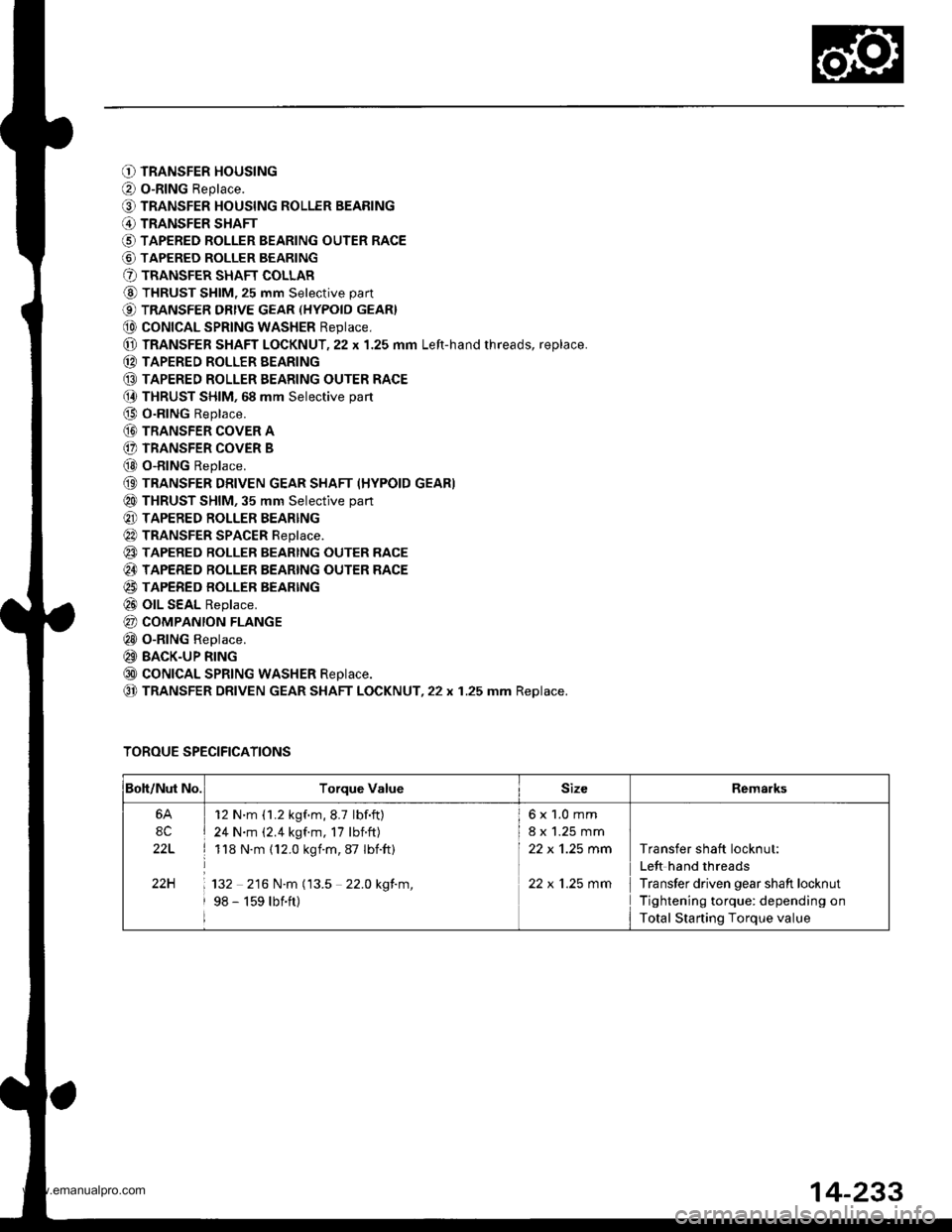

O TRANSFER HOUSING

O o-RING Replace.

O TRANSFER HOUSING ROLLER BEARING

@ TRANSFER SHAFT

O TAPERED ROLLER BEARING OUTER RACE

@ TAPERED ROLLER BEARING

O TRANSFER SHAFT COLLAR

@ THRUST SHIM, 25 mm Selective part

€) TRANSFER DRtvE GEAR (HYPoID GEAR}

@ coNtcAL SPRtNG WASHER Reptace,

@ TRANSFER SHAFT LOCKNUT,22 x 1.25 mm Left-hand rhreads, replace.

(D TAPERED ROLLER EEARING

@ TAPERED ROLLER EEARING OUTER RACE(} THRUST SHIM, 68 mm Selective part

@ O-RING Replace.

@ TRANSFER coVER A

(} TRANSFER COVER B

@ o-RING Replace.

(9 TRANSFER DRIVEN GEAR SHAFT (HYPOID GEAR)

@ THRUST SHIM, 35 mm Selective part

@ TAPERED ROLLER BEARING

@ TRANSFER SPACER Reptace.

@ TAPERED RoLLER BEARTNG OUTER RACE

@ TAPERED ROLLER BEARING OUTER RACE

@ TAPERED BOLLER BEARTNG

@ olL SEAL Replace.

@ COMPANION FLANGE

@ o-RING Replace.

@ BACK-UP RING

@ coNtcAL SPRtNG WASHER Reptace.

@ TRANSFER DRIVEN GEAR SHAFT LOCKNUT,22 x 1.25 mm Replace.

TOROUE SPECIFICATIONS

Boh/Nut No.Torque ValueSizeRemarks

6A

8C

22L

22H

12 N'm (1.2 kgf.m,8.7 lbf.ft)

24 N.m (2.4 kgf.m, 17 lbnft)

118 N.m (12.0 kgim,87 Ibift)

132 216 N.m (13.5 22.0 kgf.m,

98 - 159 lbift)

6x1.0mm

8 x 1.25 mm

22 x 'l.25 mm

22 x 1.25 mm

Transfer shaft locknut:

Left hand threads

Transfer driven gear shaft locknut

Tightening torque: depending on

Total Starting Torque value

14-233

www.emanualpro.com

Page 750 of 1395

Transfer Assembly

Inspection

NOTE: To prevent damage to the transfer housing,

always use soft jaws or equivalent materials between

the transfer housing and the vise.

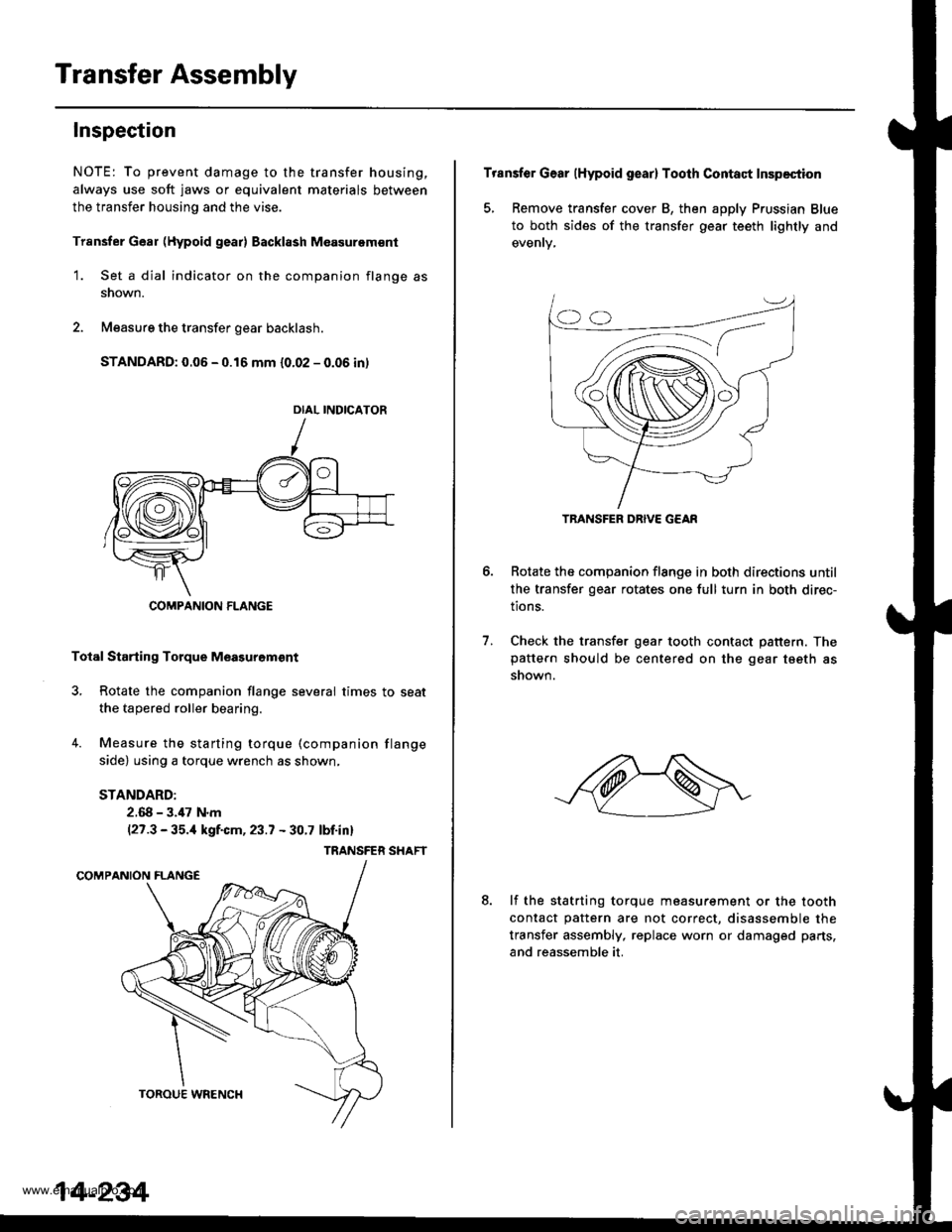

Trsnsfer Gear (Hypoid gear) Backl8sh M€asurem€nt

1. Set a dial indicator on the companion flange as

snown.

2. Measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm {0.02 - 0.06 in)

Total Starting Torque Meagurgm€nt

3, Rotate the companion flange several times to seat

the tapered roller bearing.

4. Measure the starting torque (companion flange

side) using a torque wrench as shown,

STANDARD:

2.68 - 3.,17 N.m(27.3 - 35.,1 kgf.cm, 23.7 - 30.7 lbf.inl

TRANSFER SHAFT

DIAL INDICATOR

COMPANION FLANGE

14-234

Transfer Gear (Hypoid gear) Tooth Contact Inspection

5, Remove transfer cover B, then apply Prussian Blue

to both sides of the transfer gear teeth lightly and

Rotate the companion flange in both directions until

the transfer gear rotates one full turn in both direc-

tions.

Check the transfer gear tooth contact pattern. Thepattern should be centered on the gear tseth as

snown.

6.

7.

8.lf the statrting torque measurement or the tooth

contact pattern are not correct, disassemble the

transfer assembly, replace worn or damaged parts,

and reassemble it.

TRANSFER DRIVE G€AR

www.emanualpro.com

Page 758 of 1395

Transfer Assembly

Reassembly (cont'd)

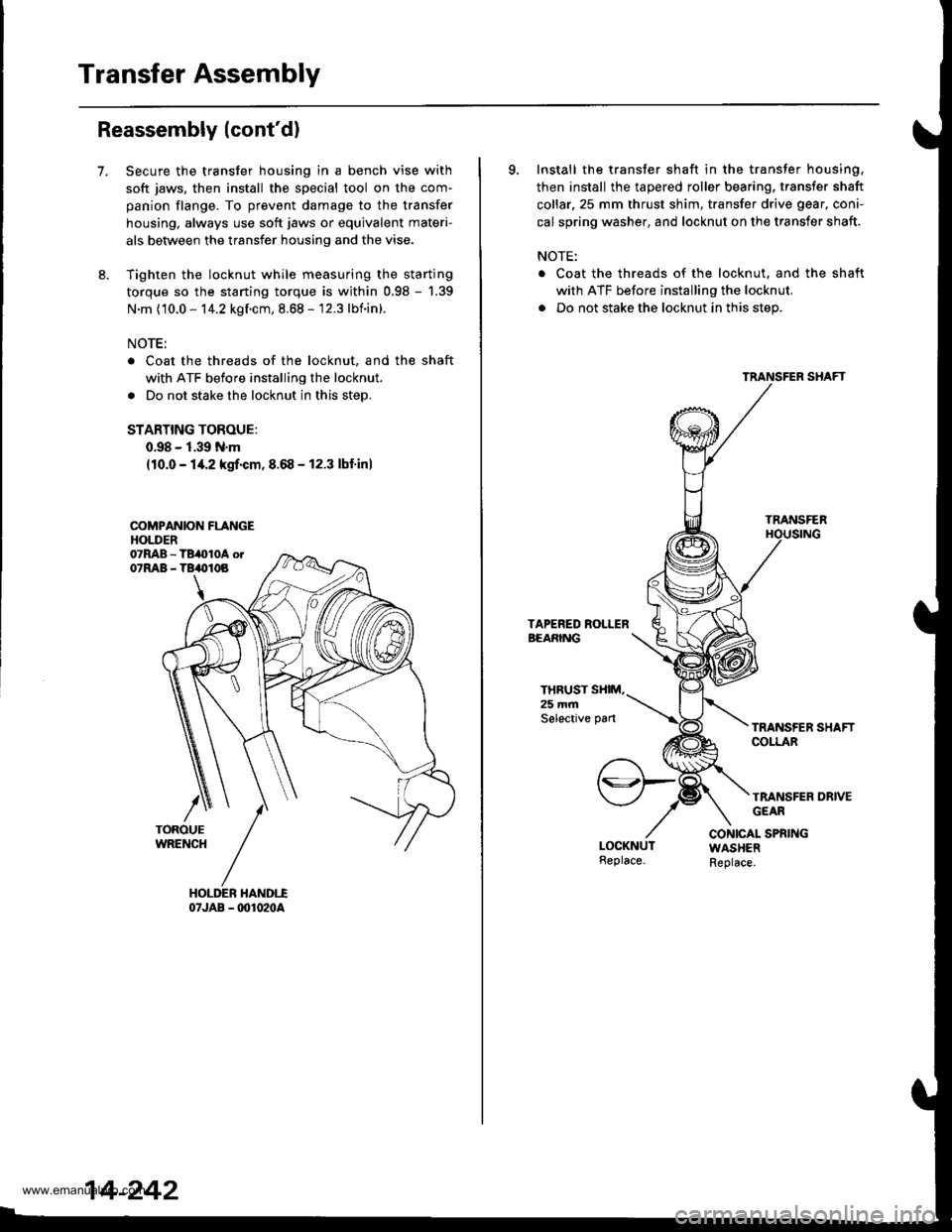

7.Secure the transfer housing in a bench vise with

soft jaws, then install the special tool on the com-

panion flange. To prevent damage to the transfer

housing, always use soft jaws or equivalent materi-

als between the transfer housing and the vise.

Tighten the locknut while measuring the starting

torque so the starting torque is within 0.98 - '1.39

N.m (10.0 - 14.2 kgf.cm, 8.68 - 12.3 lbnin).

NOTE:

Coat the threads of the locknut, and the shaft

with ATF before installing the locknut.

Do not stake the locknut in this step.

STARTING TOROUE:

0.98 - 1.39 N.m

{10.0 - 14.2 kgrf.cm,8.68 - 12.3 lbf'inl

COMPANION FLANGEHOLDER

07JAB - @1020A

14-242

9. Install the transfer shaft in the transfer housing,

then install the tapered roller bearing, transfer shaft

collar.25 mm thrust shim, transfer drive gear, coni-

cal spring washer, and locknut on the transfer shaft.

NOTE:

. Coat the threads of the locknut. and the shaft

with ATF before installing the locknut.

. Do not stake the locknut in this step.

TRANSFER

THRUST SXIM,25 mmSelective pan

TRANSFER DRIVEGEAR

CONICAL SPRINGWASHERReplace.

www.emanualpro.com

Page 761 of 1395

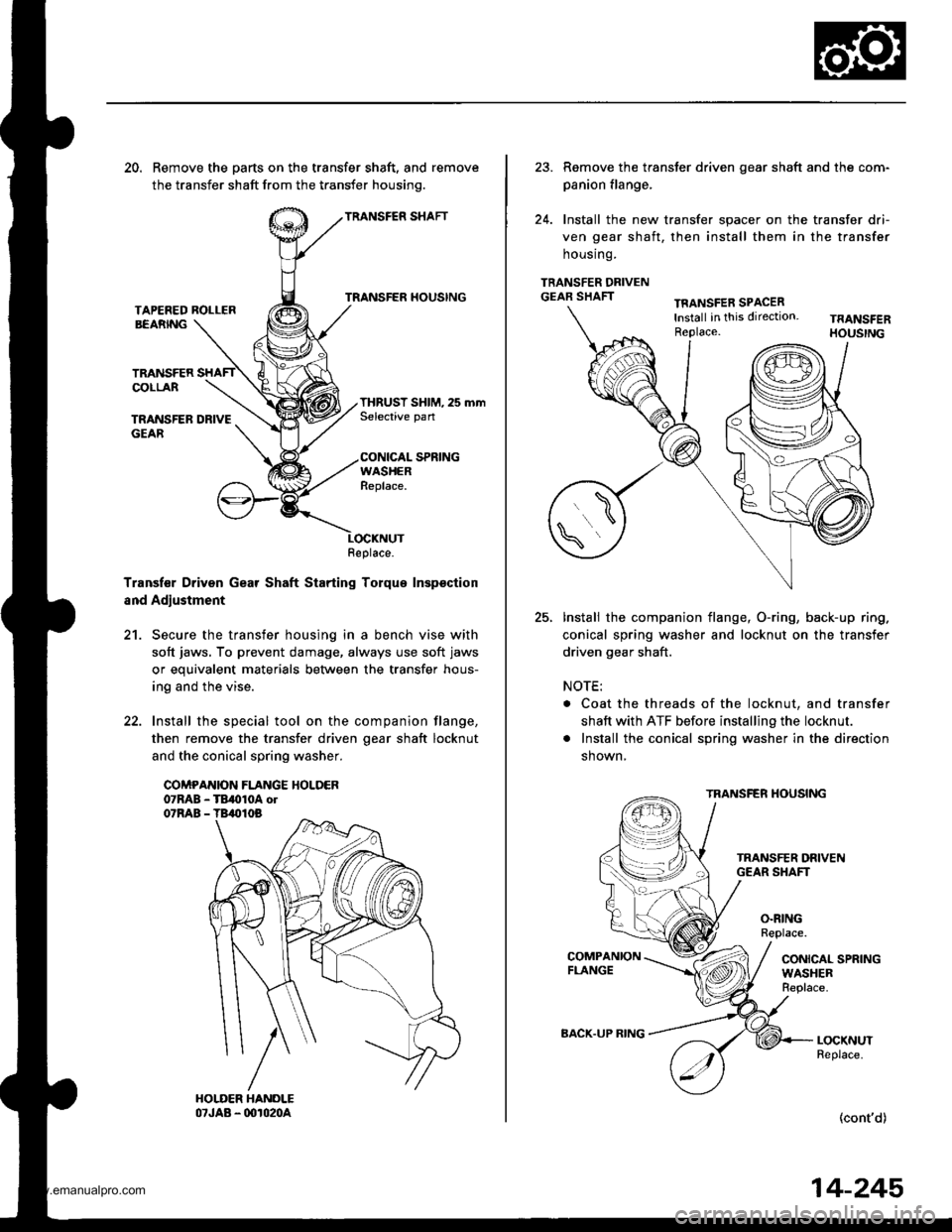

20. Remove the parts on the transfer shaft, and remove

the transfer shaft from the transfer housinq.

TRANSFER SHAFT

TRANSFER HOUSINGTAPEFED ROLLERBEARNG

TRANSFERCOLLAR

TRANSFER DRIVEGEAR

THRUST SHIM, 25 mmSelective pan

CONICAL SPRINGWASHERReplace.

Transf€r Driven Gear Shaft Starting Torque Inspsction

and Adjustment

21. Secure the transfer housing in a bench vise with

soft jaws, To prevent damage, always use soft jaws

or equivalent materials between the transfer hous-

ing and the vise.

22. Install the special tool on the companion flange,

then remove the transfer driven oear shaft locknut

and the conical spring washer.

COMPANION FLANGE HOLDER07RAB - TB,010A ol07RAB - TB,010B

Replace.

23. Remove the transter driven gear shaft and the com-

panion flange,

24. Install the new transfer spacer on the transfer dri-

ven gear shaft, then install them in the transfer

housrng.

TRANSFER DRIVENGEAR SHAFTTFANSFER SPACERlnstall in this direction.Replace.

25.Install the companion flange, O-ring, back-up ring.

conical spring washer and locknut on the transfer

driven gear shaft.

NOTE:

. Coat the threads of the locknut, and transfer

shaft with ATF before installing the locknut.

. Install the conical spring washer in the direction

shown,

TRANSFER HOUSING

O.RINGReplace.

CONICAL SPRINGWASHERReplace.

LOCKNUTReplace.

(cont'd)

BACK.UP RING

14-245

www.emanualpro.com

Page 762 of 1395

Transfer Assembly

Reassembly (cont'd)

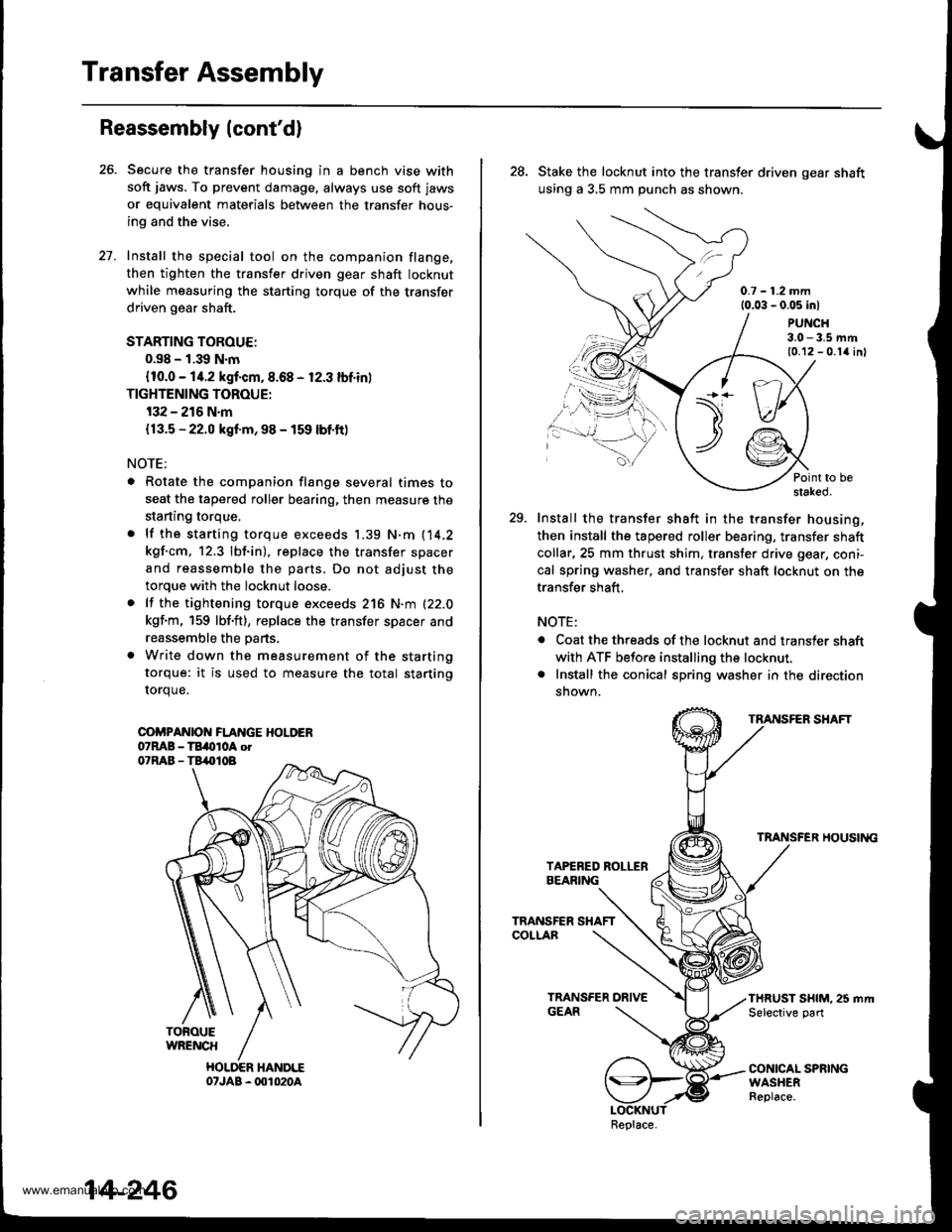

Secure the transfer housing in a bench vise with

soft jaws. To prevent damage, always use soft jaws

or equivalent materials between the transfer hous-

ing and the vise.

Install the special tool on the companion flange,

then tighten the transfer driven gear shaft locknut

while measuring the starting torque of the transfer

driven gear shaft.

STARTING TOROUE:

0.s8 - 1.39 N.m

{10.0 - 14.2 kgf.cm,8.68 - 12.3 lbf.in)

TIGHTENING TOROUE:

132 - 216 N.m

{13.5 - 22.0 kgf.m, 98 - 159 lbf.ft)

NOTE;

. Rotate the companion flange several times to

seat the tapered roller bearing, then measure the

starting torque,

. lf the starting torque exceeds 1.39 N.m (14,2

kgf.cm, 12.3 lbf.in), replace the transfer spacer

and reassemble the parts. Do not adjust the

torque with the locknut loose.

. lf the tightening torque exceeds 216 N.m (22.0

kgf.m, 159 lbf'ft), replace the transfer spacer and

reassemble the parts.

. Write down the measurement of the starting

torque: it is used to measure the total starting

rorque.

COi'PANIOI{ FLANGE HOLDER07MB - TBi(tloA otO'RAB - TB,.|}IOB

TOFOUEWRENCH

HOLDER HANDLE07JAB - 001020A

27.

14-246

28. Stake the locknut into the transfer driven gear shaft

using a 3,5 mm punch as shown.

0.7 - 1.2 mm{0.03 - 0.05 inl

PUNCH3.0 - 3.5 mm10.12 - 0.1{ inl

Point to bestaked.

29. Install the transfer shaft in the transfer housing,

then install the tapered roller bearing, transfer shaft

collar,25 mm thrust shim, transter drive gear, coni-

cal spring washer, and transfer shaft locknut on the

transfer shaft,

NOTE:

. Coat the threads of the locknut and transler shaft

with ATF before installing the locknut.. Install the conical spring washer in the direction

snown.

TRANSFER SHAFT

TRANSFER HOUSII{G

THRUST SHIM. 25 mrt|Selective part

CONICAL SPRINGWASHERReplace.

\t)t--/./

.,.-,.,\

Replace.

www.emanualpro.com

Page 764 of 1395

Transfer Assembly

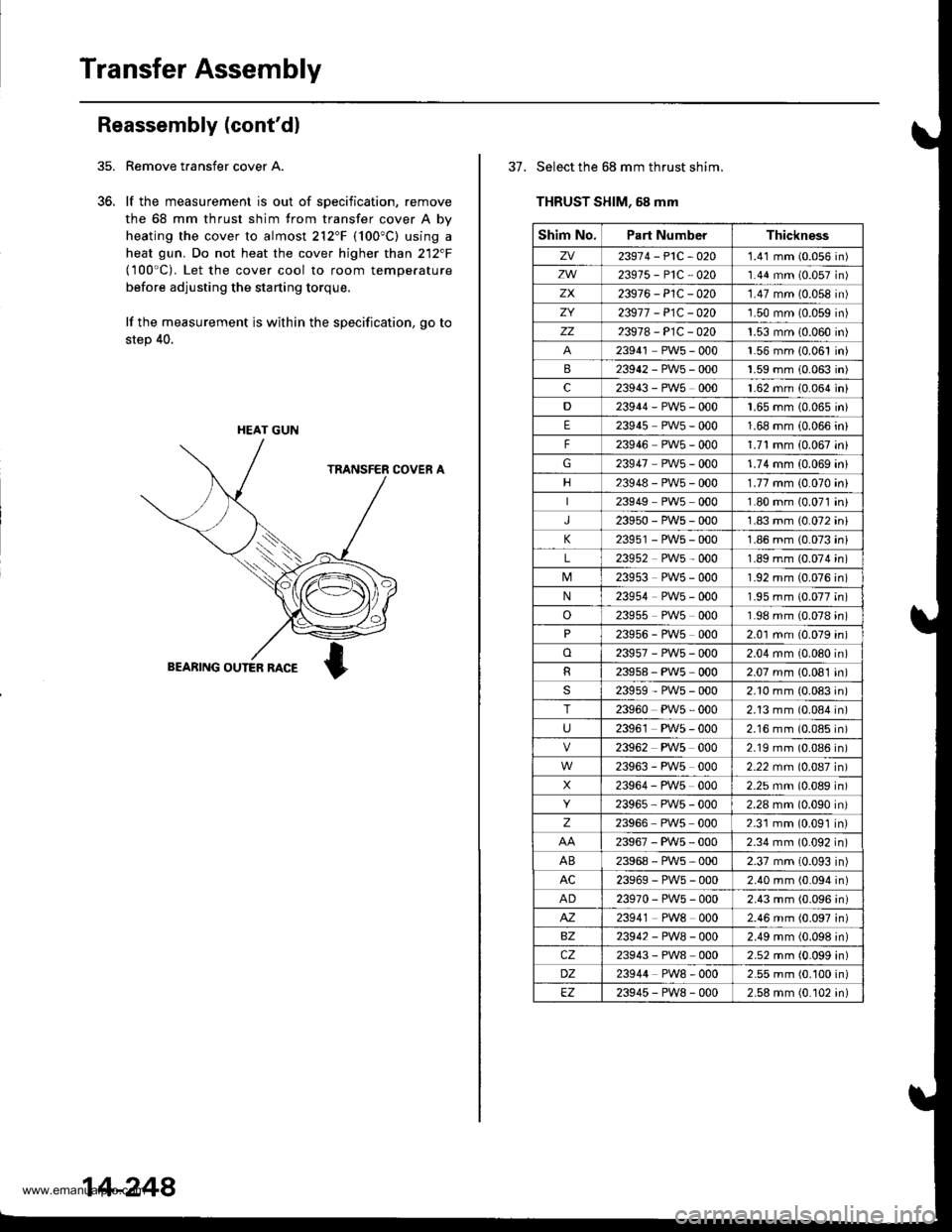

35.

Reassembly (cont'dl

36.

Remove taansfer cover A.

lf the measurement is out of specification, remove

the 68 mm thrust shim from transfer cover A by

heating the cover to almost 212"F (100"C) using a

heat gun. Do not heat the cover higher than 212"F(100'C). Let the cover cool to room temperature

before adjusting the starting torque,

lf the measurement is within the specification, go to

step 40.

HEAT GUN

14-248

37. Select the 68 mm thrust shim.

THRUST SHIM, 58 mm

Shim No.Part NumberThickness

zv23974-P1C-O201.41 mm (0.056 in)

zw23975-P1C-O201.44 mm (0.057 in)

zx23976-P1C-020'1.47 mm (0.058 in)

ZY23977 - P1C - O201.50 mm (0.059 in)

zz23978-P1C-0201.53 mm 10.060 in)

23941 PW5 - 000'1.56 mm {0.061 in)

B23942-PWs-0001.59 mm 10.063 in)

c23943 - PWs 0001.62 mm (0.064 in)

D23944-PW5-0001.65 mm {0.065 in}

E23945 PWs - 0001.68 mm (0.066 in)

F23946 PWs - 0001.71 mm (0.067 in)

G23947 PWs - 0001.74 mm (0.069 ini

23948-PW5-0001.77 mm (0.070 ini

23949 PW5 0001.80 mm (0.071 in,

J23950-PWs-0001.83 mm {0.072 ini

K23951 - PWs - 0001.86 mm (0.073 in

L23952 PW5 - 0001.89 mm (0.074 in

23953 PWs - 0001.92 mm (0.076 in

N23954 PW5 - 0001.95 mm (0.077 in

o23955 PW5 0001.98 mm (0.078 in

P23956 - PWs 0002.01 mm (0.079 in

o23957-PW5-0002.04 mm (0.080 in

R23958, PWs 0002.07 mm (0.081 in

s23959-PW5-0002.10 mm (0.083 in

T23960 PW5 - 0002.13 mm (0.084 in

U2396'1 PW5 - 0002.16 mm (0.085 in

23962 PWs 0002.19 mm (0.086 in

23963 - PW5 0002.22 mm (0.087 in

X23964 - PW5 0002.25 mm (0.089 in

23965 PW5 - 0002.28 mm (0.090 in

z23966 PWs 0002.31 mm (0.091 in

23967-PWs-0002.34 mm (0.092 in

AB23968-PWs-0002.37 mm (0.093 in)

AC23969-PWs-0002.40 mm (0.094 in)

AD23970-PW5-0002.43 mm (0.096 in)

M23941 PW8 0002.46 mm (0.097 in)

BZ23942-PW8-0002.49 mm (0.098 in)

cz23943 - PW8 0002.52 mm (0.099 in)

DZ23944 PW8 - 0002.55 mm (0.100 in)

EZ23945-PW8-0002.58 mm (0.102 in)

www.emanualpro.com