Door HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1073 of 1395

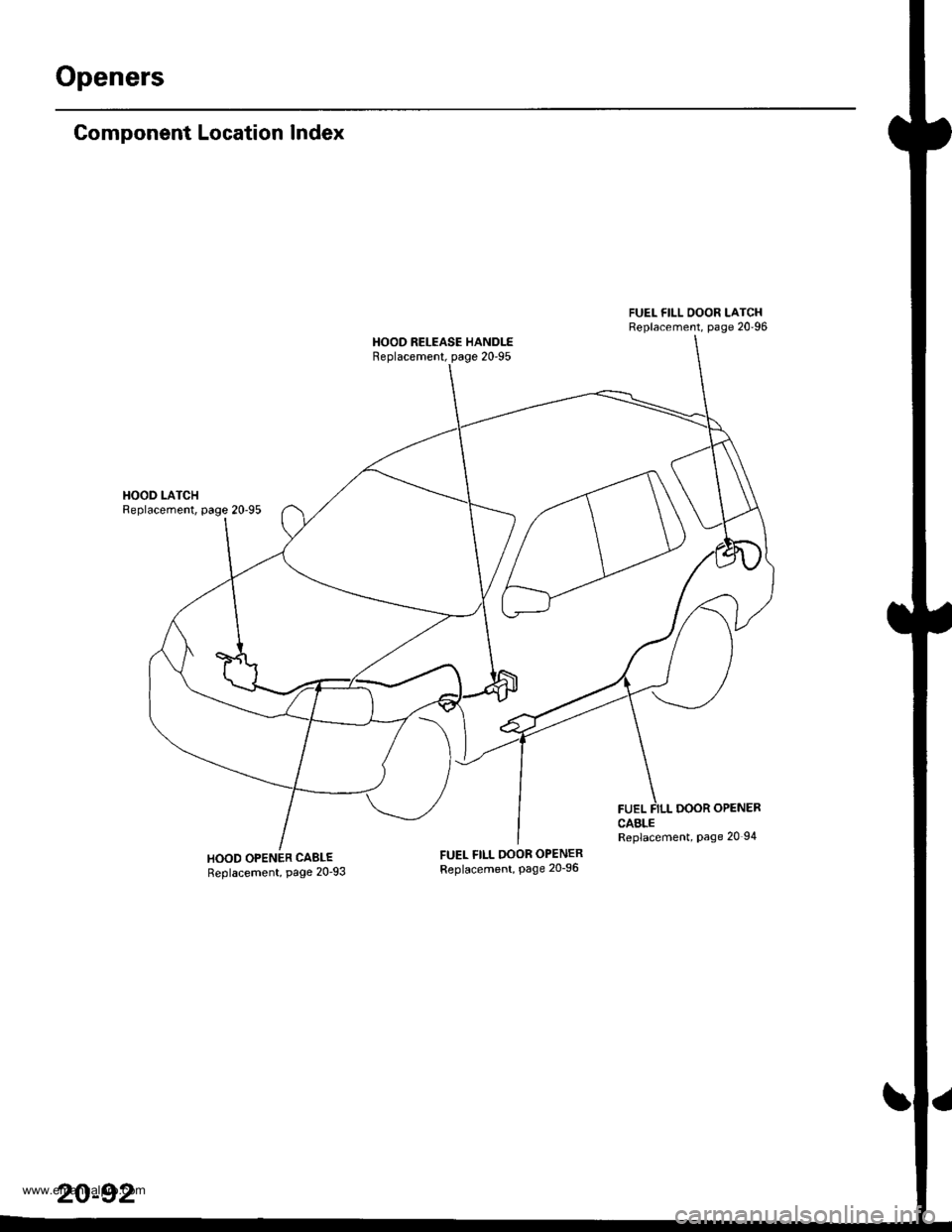

Openers

Component Location Index

HOOD LATCHReplacement, page 20'95

HOOD OPENER CABLEReplacement, page 20'93

FUEL FILL OOOR LATCHReplacement, page 20'96

HOOD RELEASE HANDLEReplacement, page 20'95

FUELDOOR OPENERCABLEReplacement, Page 20 94

FUEL FILL OOOR OPENERReplacement, Page 20_96

20-92

www.emanualpro.com

Page 1075 of 1395

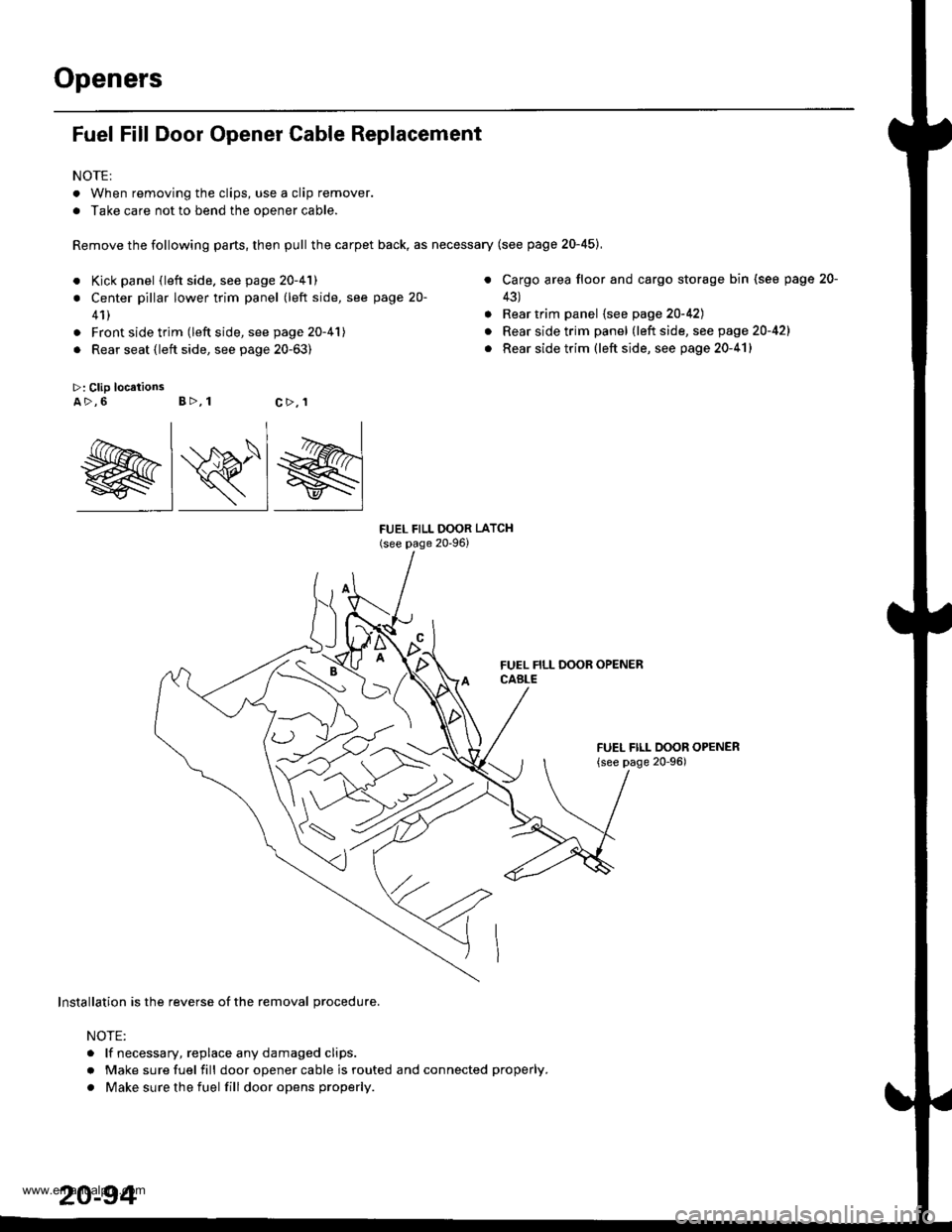

Openers

Fuel Fill Door Opener Cable Replacement

NOTE:

. When removing the clips, use a clip remover.

. Take care not to bend the opener cable.

Remove the following parts, then pull the carpet back, as necessary (see page 20-45),

a

>: Clip locationsA>,6 B>, 1

a

a

FUEL FILL OOOR LATCH(see page 20-96)

Kick panel (left side. see page 20-41)

Center pillar lower trim panel (left side, see page 20-

41)

Front side trim (left side, see page 20-41)

Rear seat (left side, see page 20-63)

Cargo area floor and cargo storage bin (see page

43)

Rear trim panel {see page 20-42)

Rear side trim panel (left side, see page 20-421

Rear side trim (left side, see page 20-41)

FUEL FILL DOOR OPENER

{see page 20-96)

20-

c>,1

@lRlg

Installation is the reverse of the removal procedure.

NOTE:

. lf necessary, replace any damaged clips.

r Make sure fuel fill door opener cable is routed and connected properly.

. Make sure the fuel fill dooropens properly.

www.emanualpro.com

Page 1077 of 1395

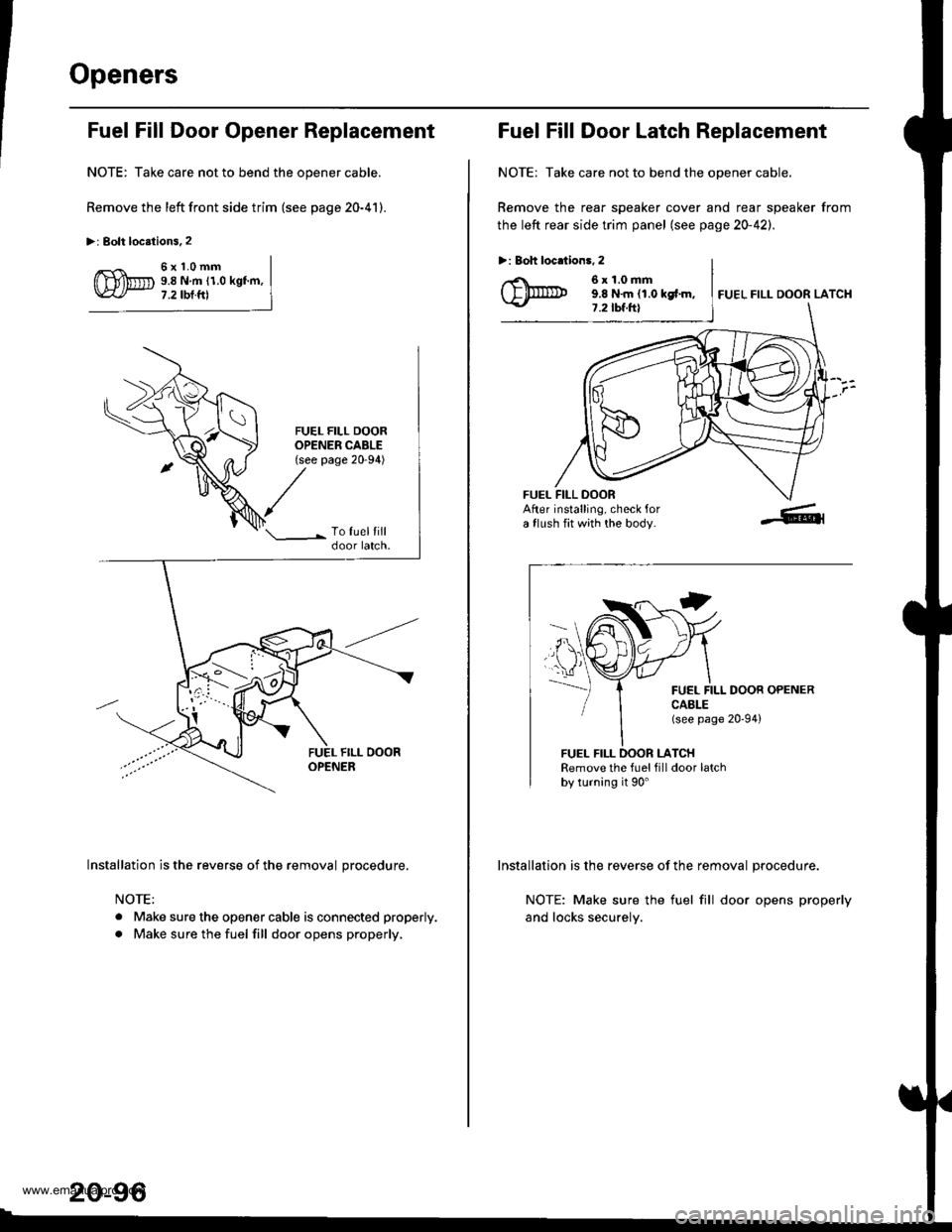

Openers

Fuel Fill Door Opener Replacement

NOTE: Take care not to bend the opener cable.

Remove the left front side trim (see page 20-41).

>: Bolt locstions.2

5x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbt.ftl

FUEL FILL DOOROPENER CABLE(see page 20-94)

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the opener cable is connected properly.

. Make sure the fuel fill door opens properly,

20-96

Fuel Fill Door Latch Reolacement

NOTE: Take care not to bend the opener cable.

Remove the rear speaker cover and rear speaker from

the left rear side trim panel (see page 20-42).

>: Boh locdions, 2

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbf.ft)FUEL FILL DOOR LATCH

FUEL FILL DOORAfter installing, check fora flush fit with the body.

CAELE(see Page

LATCH

DOOR OPENER

20,94)

FUEL

FUEL FILLRemove the fuel fill door latchby turning it 90'

Installation is the reverse of the removal procedure.

NOTE: Make sure the fuel fill door opens properly

and locks securely.

www.emanualpro.com

Page 1100 of 1395

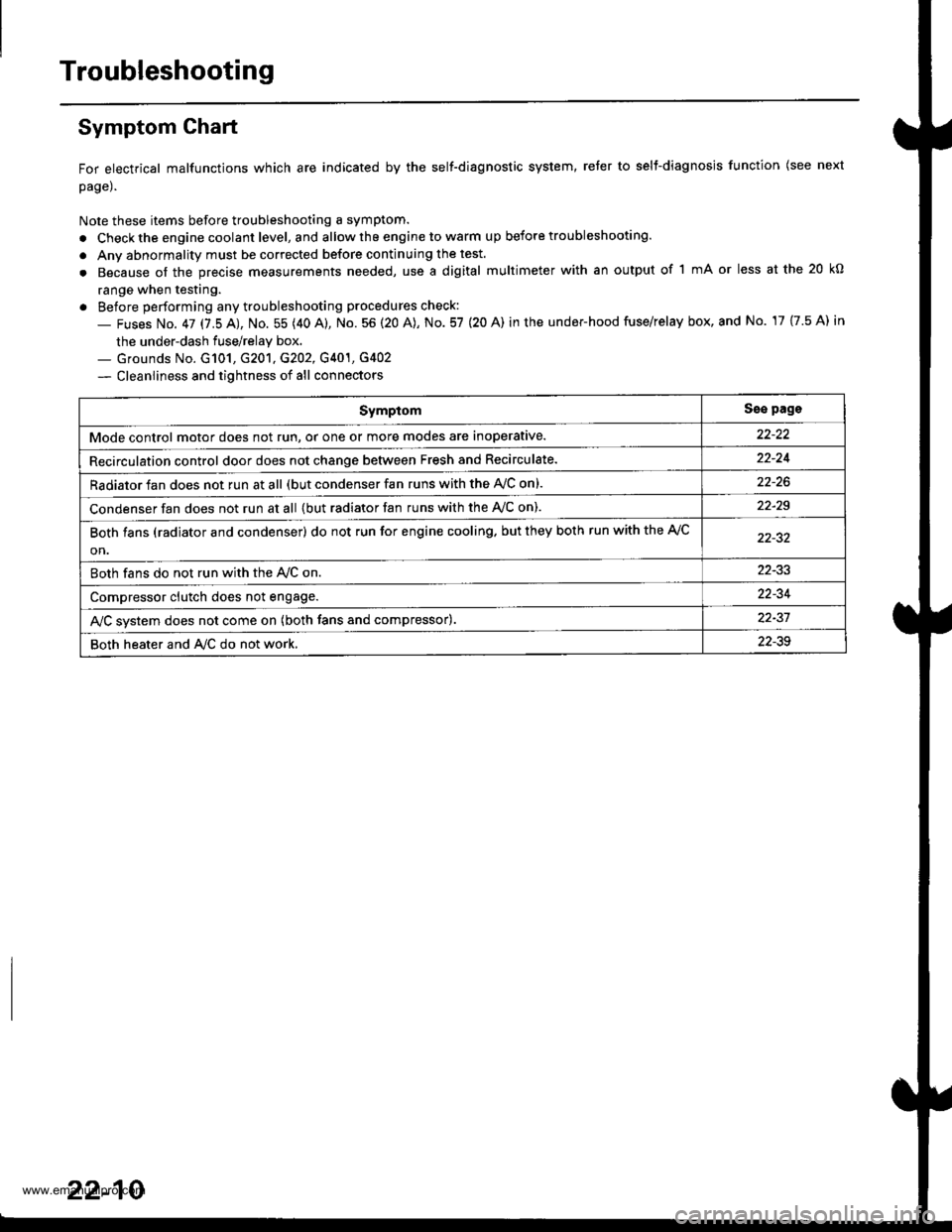

Troubleshooting

Symptom Ghart

For electrical malfunctions which are indicated by the self-diagnostic system, reter to selt-diagnosjs function (see next

page).

Note these items before troubleshooting a symptom.

. Check the engine coolant level, and allow the engine to warm up before troubleshooting.

. Anv abnormality must be corrected before continuing the test.

. Because of the precise measurements needed, use a digital multimeter with an output of 1 mA or less at the 20 kO

range when testing.

. Before performing any troubleshooting procedures check:

- Fuses No. 47 17.5 AJ, No. 55 (40 A), No. 56 (20 A), No. 57 (20 A) in the under-hood fuse/relay box, and No. 17 {7.5 A) in

the under-dash fuse/relay box.._ Grounds No. G101, G201, G202, G401, G4O2

- Cleanliness and tightness of all connectors

SymptomSse pags

Mode control motor does not run, or one or more modes are inoperative.

Recirculation control door does not change between Fresh and Recirculate.22-24

Radiator fan does not run at all (but condenser fan runs with the AVC on).

Condenser fan does not run at all {but radiator fan runs with the Ay'C on).22-29

Both fans (radiator and condenser) do not run for engine cooling. but they both run with the A,/C

on.

Both fans do not run with the Ay'C on22-33

Compressor clutch does not engage.22-34

AJC svstem does not come on (both fans and compressor).22-37

Both heater and A/C do not work,22-39

22-10

www.emanualpro.com

Page 1101 of 1395

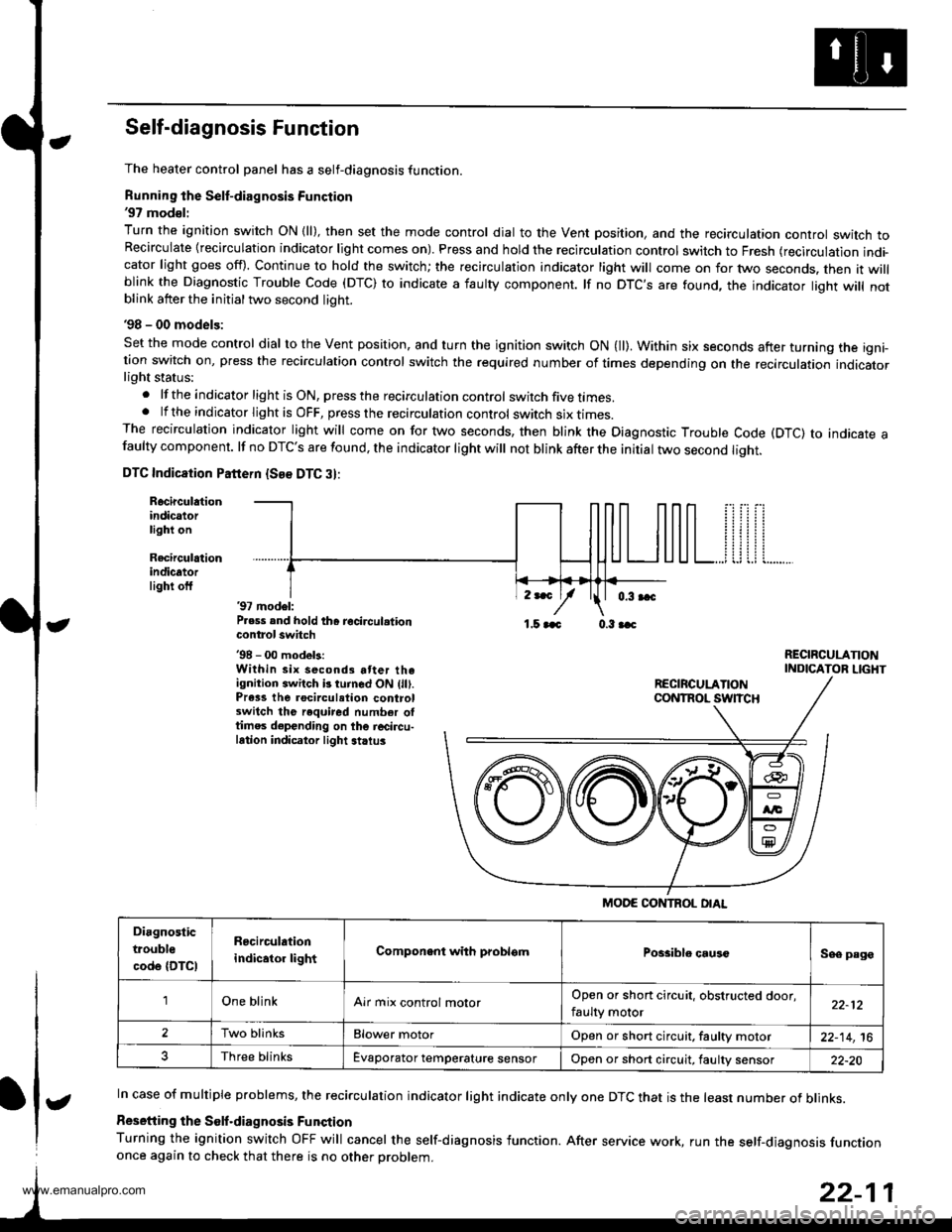

Self-diagnosis Function

The heater control panel has a self-diagnosis function.

Running the Self-diagnosis Function'97 mod€l:

Turn the ignition switch ON {ll), then set the mode control dial to the Vent position, and the recirculation controt switch toRecirculate {recirculation indicator light comes on). Press and hold the recirculation control switch to Fresh (recirculation indi-cator light goes off). Continue to hold the switch; the recirculation indicator light will come on for two seconds. then it willblink the Diagnostic Trouble Code (DTC) to indicate a iaulty component. lf no DTC'S are found, the indicator liqht will notblink atter the initial two second light.

'98 - 00 models:

Set the mode control dial to the Vent position, and turn the ignition switch ON (ll). Within six seconds after turning the igni-tion switch on, press the recirculation control switch the required number of times depending on the recirculation indicatorlight status:

.lftheindicatorlightisON,presstherecirculationcontrol switch five times..lftheindicatorlightisOFF,presstherecirculationcontrol switch six I|mes.The recirculation indicator light will come on for two seconds, then blink the Diagnostic Trouble Code (DTC) to indicate afaulty component. lf no DTC'S are found, the indicator light will not blink after the initial two second liqht.

DTC Indicaiion Pattern {See DTC 3}:

Rocirculationindicatorlight on

Recirculrtionindicatorlighi off'97 model:P.ess and hold th6 recircul.tioncontrol switch'98 - 00 modek:Within six second3 atter theignition switch b turned ON (lll.Prass the rocirculation controlswitch the required number oltimes depending on the r6circu-lation indicator light striu3

,r*

/1.5 aaa 0.3 aac

RECIRCULANONINDICATOR LIGHT

In case of multiple problems, the recirculation indicator light indicate only one DTC that is the least number of blinks.

Resetiing the Solf.diagnosis Funqtion

Turning the ignition switch OFF will cancel the self-diagnosis function. After service work, run the self-diaqnosis functiononce again to check that there is no other Droblem.

MODE CONTROL OIAL

Diagnostic

trouble

code {DTCI

R6circulation

indicator lightComponent with problsmPossiblo causcSee page

'lOne blinkAir mix control molorOpen or short circuit, obstructed door,

faulty motor22-12

2Two blinksElower motorOpen or short circuit, faultv motor22-14,16

Three blinksEvaporator temperature sensorOpon or short circuit, faulty sensor22-20

t

www.emanualpro.com

Page 1102 of 1395

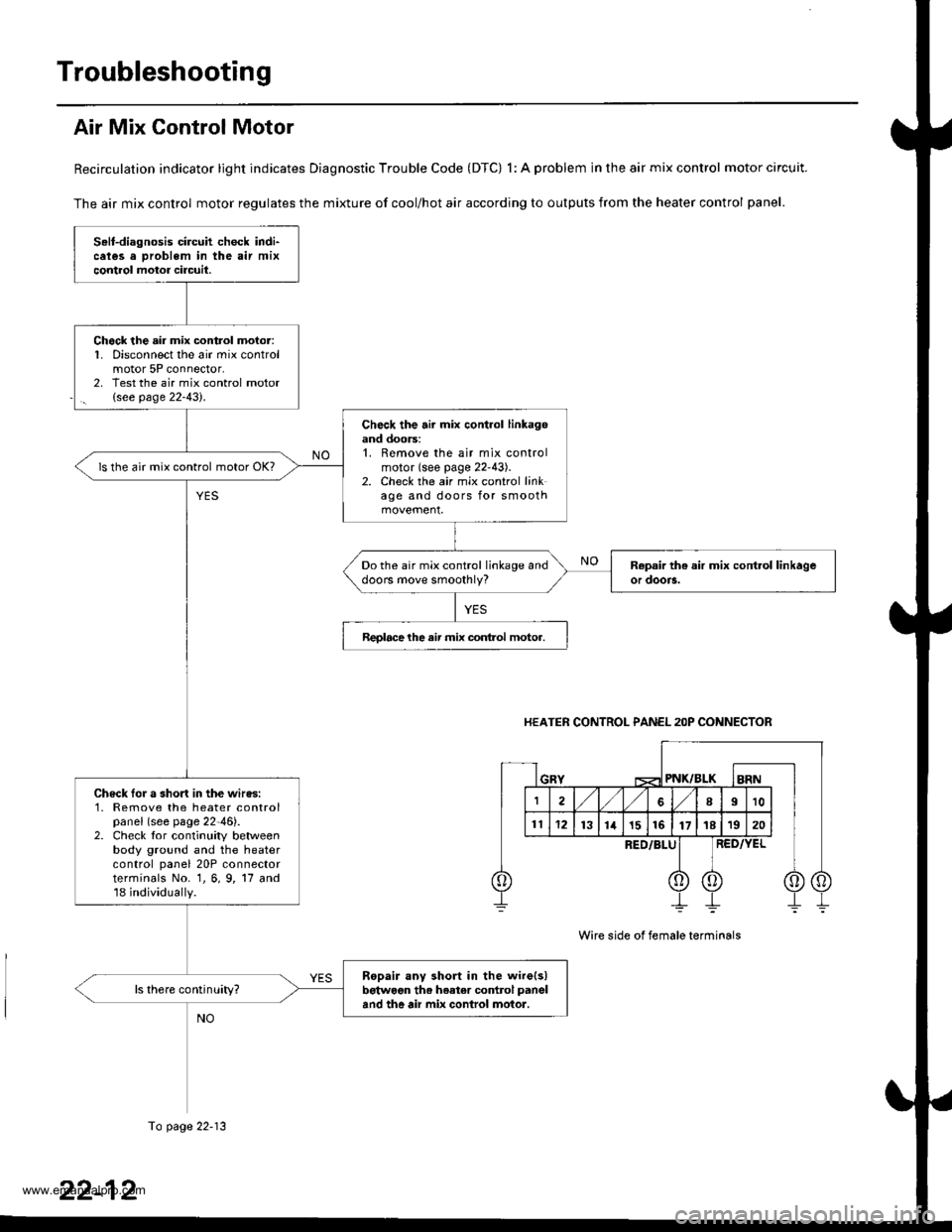

Troubleshooting

Air Mix Control Motor

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 1: A problem in the air mix control motor circuit.

The air mix control motor regulates the mixture of cool/hot air according to outputs from the heater control panel.

Selt-diagnosis circuit check indi-cates a Droblem in the air mixcontrol motor circuil.

Chock the air mix control moior:1. Disconnect the air mix controlmotor 5P connector,2, Test the air mix control motor(see page 22-43).

Check the air mix control linkagoand doors:1. Remove the air mix controlmotor (see page 22'43).2. Check the air mix control linkage and doors for smooth

ls the air mix control motor OK?

Do the air mix control linkage anddoors move smoothly?

Reolacelhe air mix conlrol motor.

Check Ior a short in the wires:1- Remove the heater controlpanel (see page 22-46).2. Check tor continuity betweenbody ground and the heatercontrol panel 20P connectorterminals No. 1, 6, 9, 17 and18 individually.

Ropair any short in the wire(s)betwoon th. heater co.rtrol panel

and the air mix conlrol motor.

HEATER CONTROL PANEL 2OP CONNECTOR

PNK/BLK

RED/BLU

Wire side of female terminals

To page 22-13

www.emanualpro.com

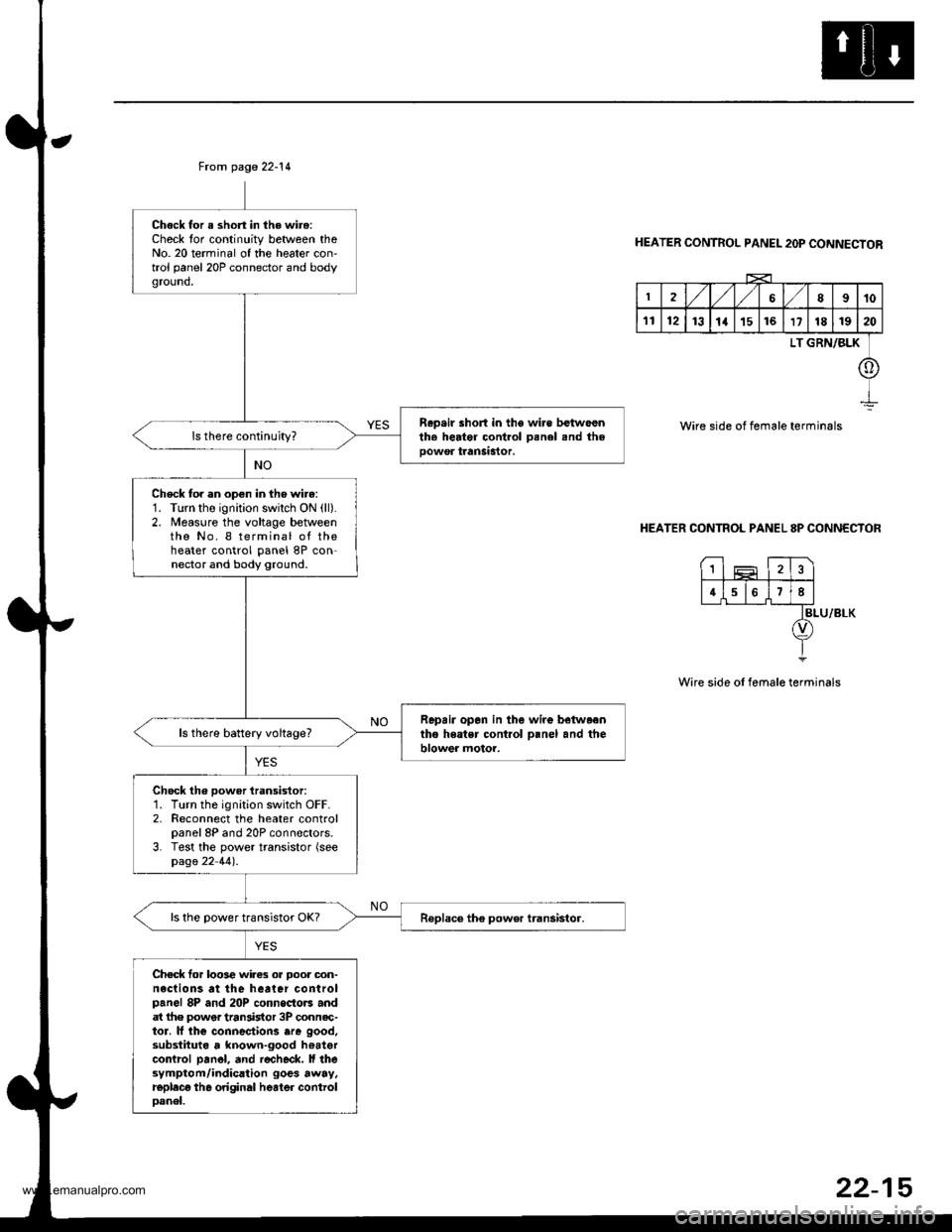

Page 1105 of 1395

From page 22-14

Chock for a short in the wire:Check tor continuity between theNo. 20 terminal of the heater con'trol panel 20P connector and bodyground,

R.p.ir short in the wire betwoenth. herter control Denel snd theoowor tranSastor.

Check to. an open in the wire:1. Turn the ignition swilch ON (ll).

2. Measure the voltage betweenthe No. I terminal of theheater control panel 8P con-nector and body ground.

Repair opan in the wire betwaentho heatsr cont.ol o.nel and theblower motor.ls there battery voltage?

Chock th6 power iransistor:1. Turn the ignition switch OFF.2. Reconnect the heater controlpanel 8P and 20P connectors.3. Test the power transistor (seepage 22 44).

ls the power transistor OK?

Chec* for loo3e wires or Door oon-neclions at the heater controlpanel 8P and 20P connoctors andat lhe power tran3istor 3P connec-tor. lf lhe connectiorc are good,substituta , known-good hoatercontrcl pan6l, and r€check. ll thesymptom/indication goes away.replecg th6 original heater controloanel.

HEATER CONTROL PANEL 2OP CONNECTOR

2,/1,/l/68910

1112131a151617181920

LT GRN/BLK

o

Wire side of female terminals

HEATER CONTROL PANEL 8P CONNECTOR

BLU/8LK

Wire side of female terminals

1

4678

22-15

www.emanualpro.com

Page 1112 of 1395

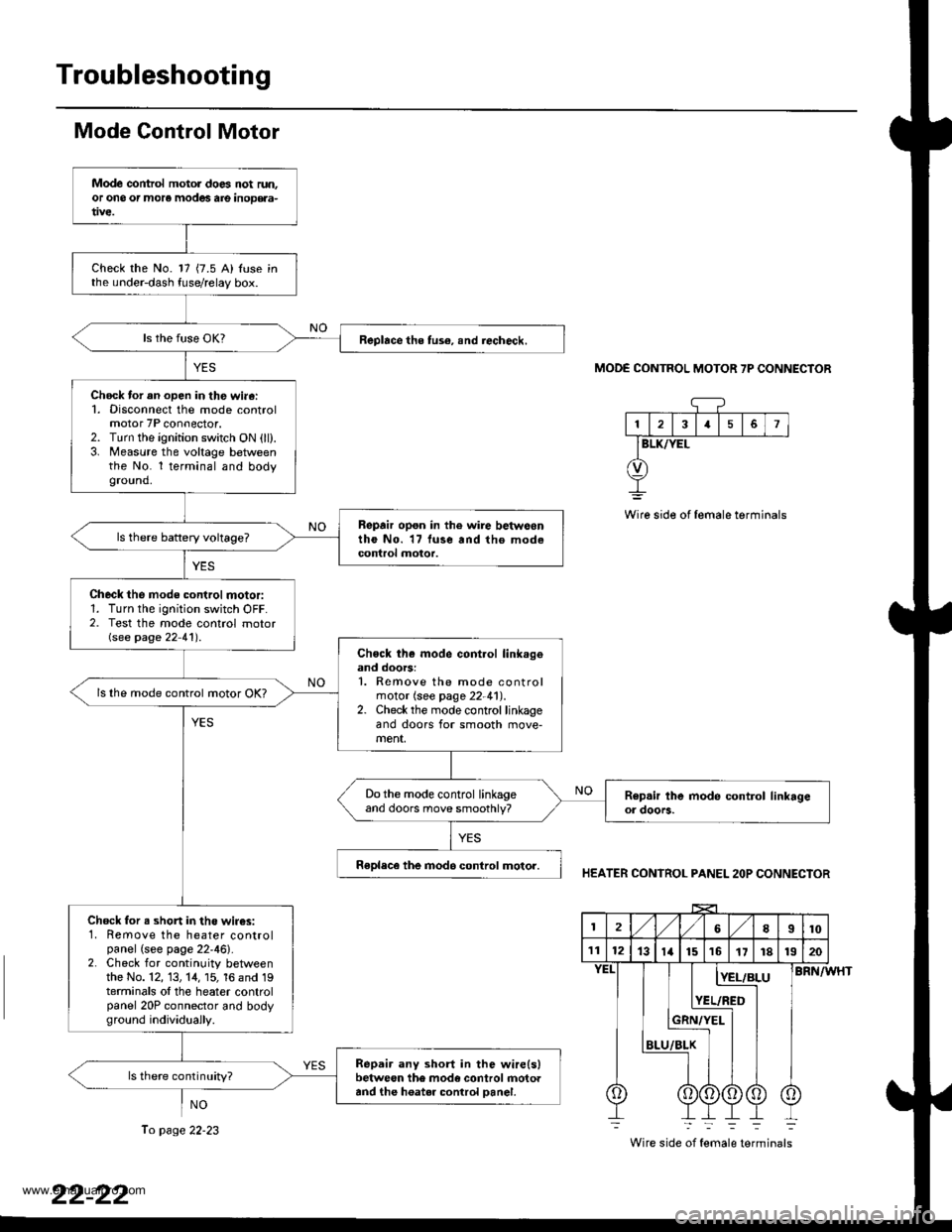

Troubleshooting

Mode Control Motor

NO

MODE CONTROL MOTOR 7P CONNECTOR

13I5

BLK/YEL

Wire side of female terminals

HEATER CONTROL PANEL 2OP CONNECTOR

BRN/WHT

Wire side of female terminals

Mode control motol does not run.or ono or more modes are inoD€aa-

Check the No. 17 {7.5 A) Iuse inthe under-dash fuse/relay box.

Replace the tus€, snd iecheck.

Chock tor an open in th€ wi.6:1. Disconnect the mode controlmotor 7P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betweenthe No. l terminal and bodyground.

Repair opon in the wire betwoontho No. 17 luse and tho modecontrol motor.

Check the mode control motor:1. Turn the ignition switch OFF.2. Test the mode control motorGee page 22 41') .

Chock th€ mode cont.ol link.geand doors:1. Remove the mode controlmotor (see page 22-41).2. Check the mode control linkageand doors for smooth move-ment,

ls lhe mode control motor OK?

Do the mode control linkageand doors move smoothly?

Replece the inod6 control motor.

Chock for s shon in the wir€s:1. Remove the heater controlpanel (see page 22'46).2. Check for continuity betweenthe No. 12, 13, 14, 15, 16 and 19terminals ol the heater controlpanel 20P connector and bodyground individuaily.

Repair any short in the wire(slbetween the mode control rnotoaand the h6ater control Danel.

ls there continuity?

2l,/1,/8I10

111213ta151617r81320

BLU

[E!r!

YEL/RED

Ii

To page 22-23

www.emanualpro.com

Page 1114 of 1395

Troubleshooting

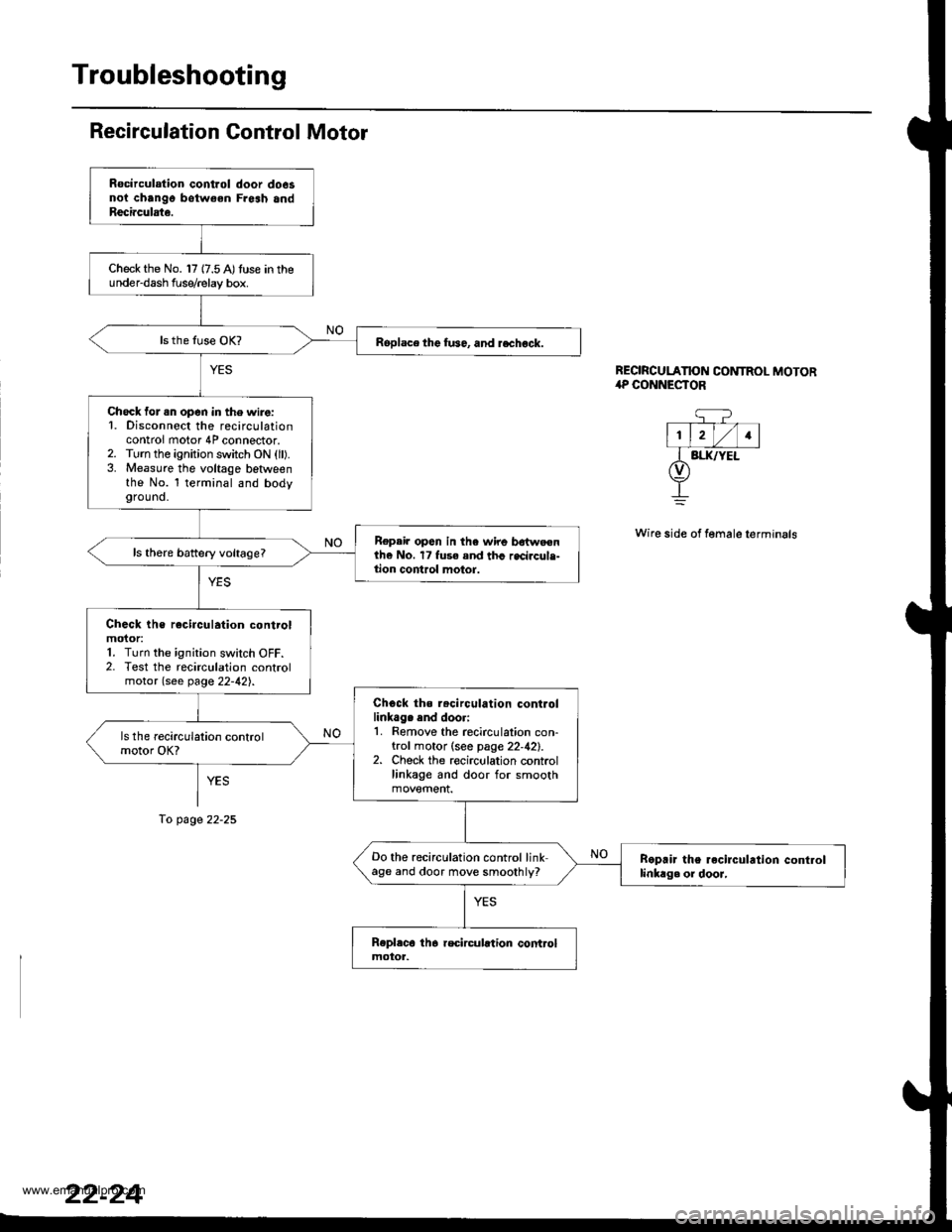

Recirculation Gontrol Motor

YES

To page 22-25

REORCULATION CONTROL MOTOR,rP CONNESTOR

q?- T--- V-l

l1, lrl/l1lI BI.IUYEL(v)

+

Wire side of female terminals

Rocirculation control door do6snoi chango botw€en Fresh andReci.culate.

Check the No. 17 {7.5 A)tuse in theunder-dash f use/relay box.

Roplace the fu36, and rechock.

Check for .n open in the wire:1. Disconnect the recirculationcontrol motor 4P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betlveenthe No. l terminal and bodyground.

Repair op6n in the wire bdtweenthe No. 17 fuse and thc recircule-tion control motor.

Check the rocirculation controlmoior:1. Turn the ignition switch OFF.2. Test the recirculation controlmotor (see page 22-42).

Chock ths r.circulation controllinkag. end doori1. Remove the recirculation con-trol motor (see page 22,42).2. Check the recirculation controllinkage and door for smooth

Do the recirculation control linkage and door move smoothly?Boprir the recirculrtion controllinkag. or dooJ,

www.emanualpro.com

Page 1126 of 1395

Troubleshooting

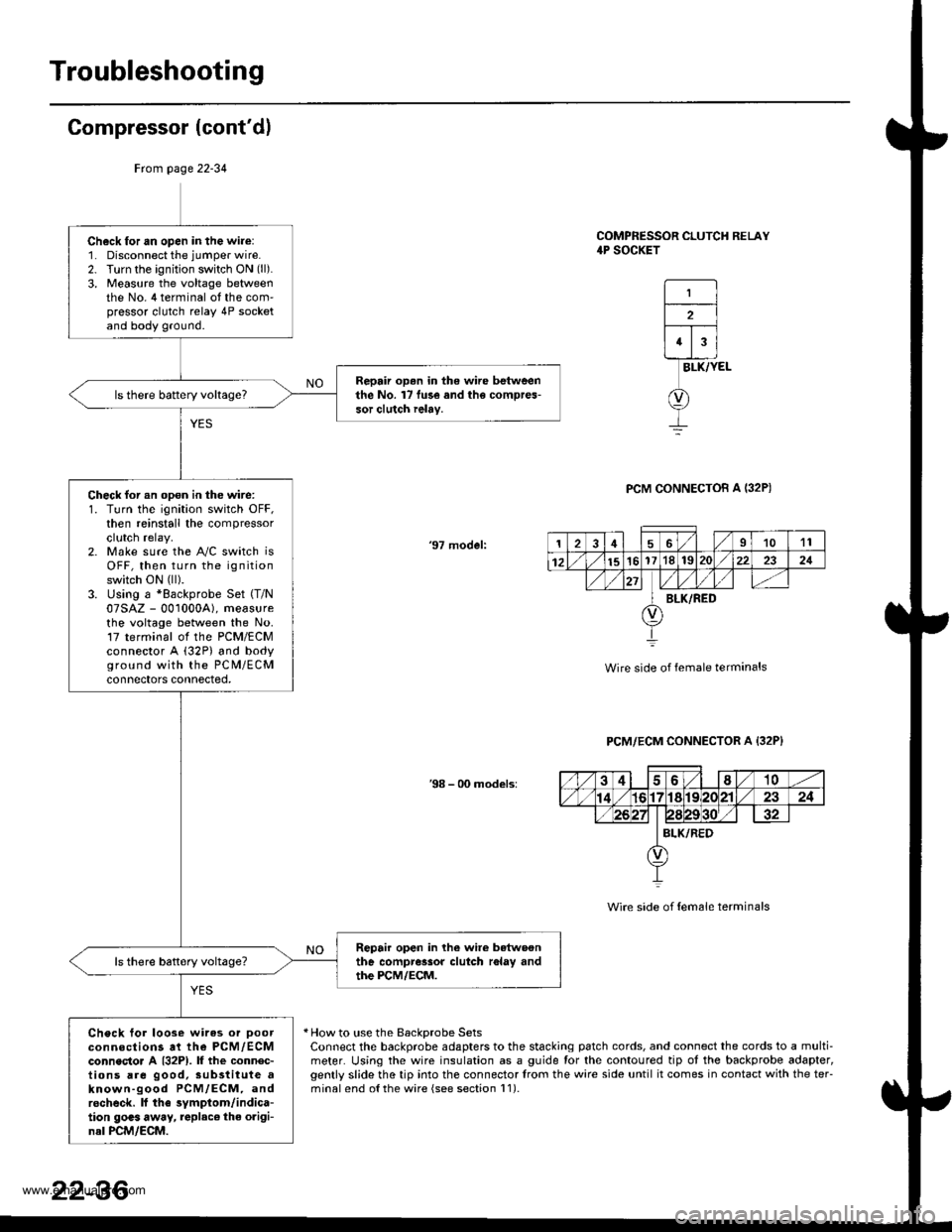

Compressor (cont'dl

COMPRESSOR CLUTCH RELAY4P SOCKET

1

2

43

BLK/YEL

PCM CONNECTOB A I32P)

'97 model:

Wire side of female terminals

PCM/ECM CONNECTOR A {32P}

38 - 00 models:

Wire side of {em6le terminals

* How to use the BackDrobe SetsConnect the backprobe adapters to the stacking patch cords, and connect the cords to a multi-meter. Using the wire insulation as a guide for the contoured tip ot the backprobe adapter,gently slide the tip into the connector trom the wire side until it comes in contact with the teFminalend o{the wire {see section l1).

Frcm page 22-34

Ch6ck for an open in the wire:1. Disconnect the jumper wire.2. Turn the ignition switch ON (ll).

3, Measure the voltage betweenthe No. 4 terminal ot the com'pressor clutch relay 4P socketand body ground.

Repair op.n in the wire betweenthe No. l7 fu3e and the compres-sor clutch ielay.

Check for an opon in the wire:1. Turn the ignition switch OFF,then reinstall the compressorclutch relay.2. Make sure the A"/C switch isOFF, then turn the ignitionswitch ON (ll).

3. Using a *Backprobe Set (T/N

07SAZ - 001000A), measurethe voltage between the No.17 terminal ol the PCM/ECMconnector A (32P) and bodyground with the PC M/ECMconnectors connected,

Repair open in lhe wire betwoonthe compressor clutch r6lay andthe PCM/ECM.

Check tor loose wires or Doorconnections at the PCM,/ECMconnecto. A {32P1. lf the connec-tions are good, sub3titute aknown-good PCM/ECM, androcheck. lf the symptom/indica-tion goas away, replac€ the origi-nal PCM/ECM.

126I1011

12151617'181S222321

BLK/RED

22-36

www.emanualpro.com