Hydraulic HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 884 of 1395

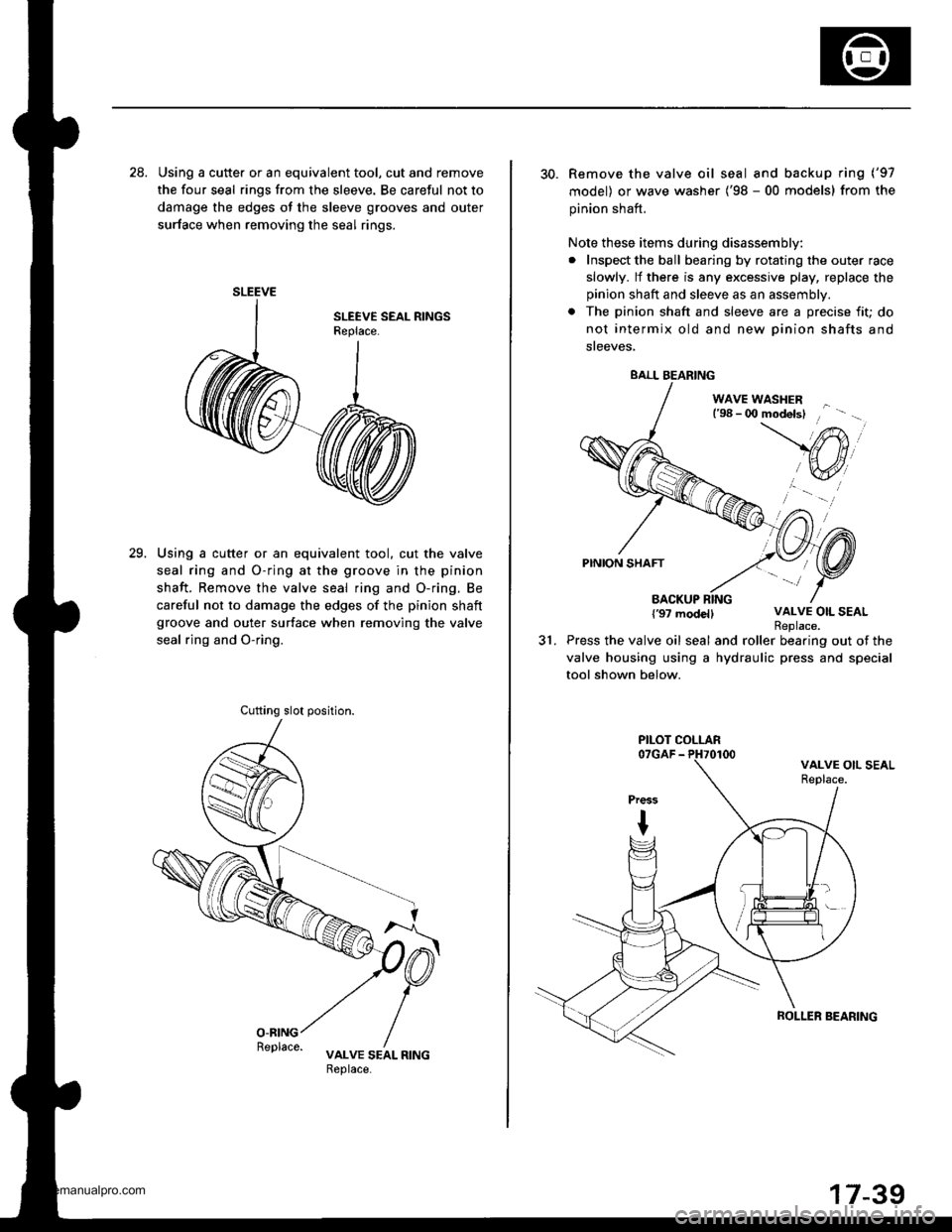

28. Using a cutte. or an equivalent tool, cut and remove

the four seal rings from the sleeve. Be careful not to

damage the edges ot the sleeve grooves and outer

surface when removing the seal rings.

Using a cutter or an equivalent tool. cut the valve

seal ring and O-ring at the groove in the pinion

shaft. Remove the valve seal ring and O-ring. Be

careful not to damage the edges of the pinion shaft

groove and outer surface when removing the valve

seal rjng and O-ring.

29.

SLEEVE

Cufting slot position.

30. Remove the valve oil seal and backup ring ('97

model) or wave washer ('98 - 00 models) from the

pinion shaft.

Note these items during disassembly:

. Inspect the ball bearing by rotating the outer race

slowly. lf there is any excessive play, replace the

pinion shaft and sleeve as an assembly.

. The pinion shaft and sleeve are a precise fit; do

not intermix old and new Dinion shafts and

sreeves,

WAVE WASHERl'98 - 0O modelsl

PINION SHAFT

BACKUP RING{'97 modellVALVE OIL SEAL

31.Replace.Press the valve oil seal and roller bearing out of the

valve housing using a hydraulic press and special

tool shown below.

BALL BEARING

PILOT COLLAR

ROLLER SEARING

www.emanualpro.com

Page 887 of 1395

Power Steering Gearbox

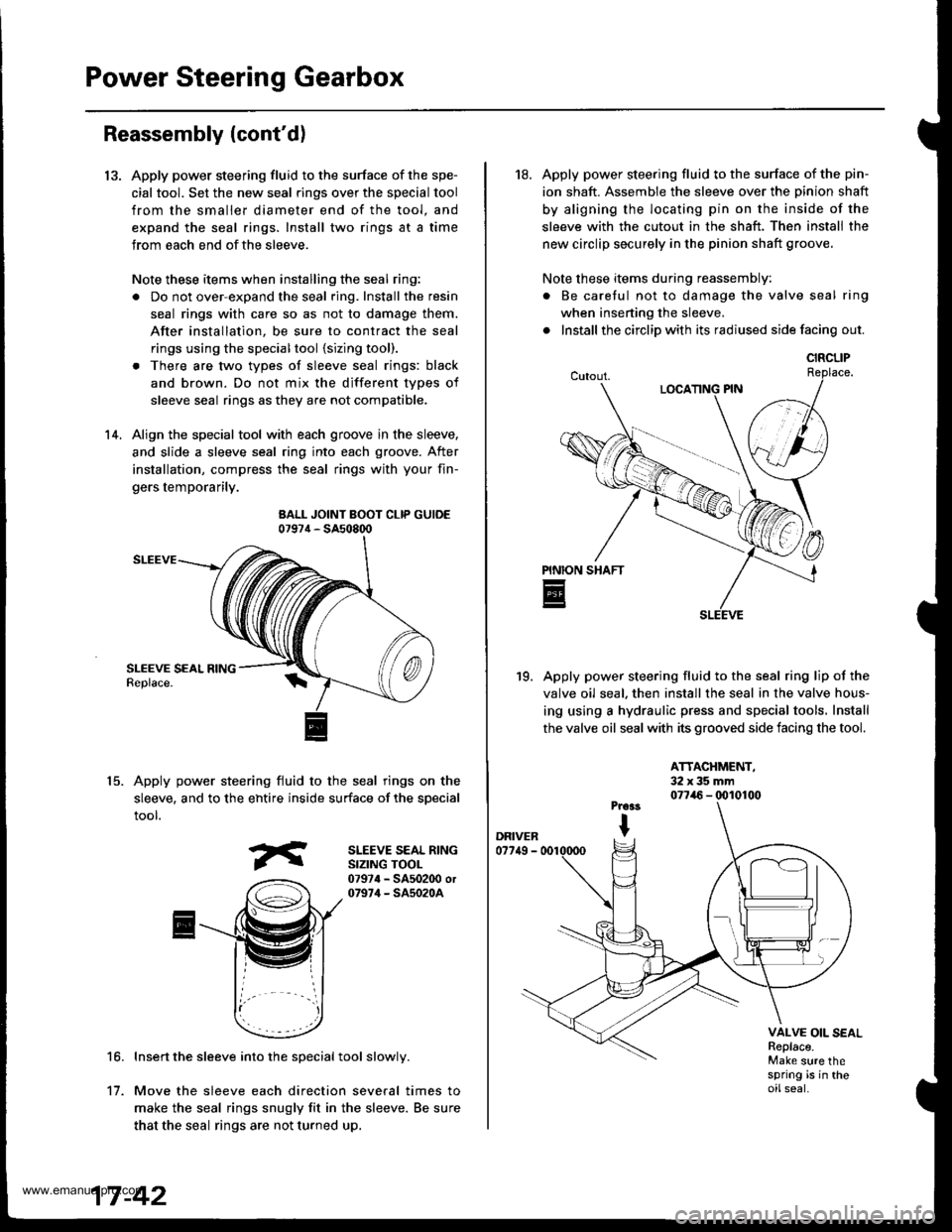

13.

Reassembly (cont'd)

Apply power steering fluid to the surface of the spe-

cial tool. Set the new seal rings over the special tool

from the smaller diameter end of the tool. and

expand the seal rings. Install two rings at a time

Jrom each end ofthe sleeve.

Note these items when installing the seal ring:

. Do not over-expand the seal ring. Install the resin

seal rings with care so as not to damage them.

After installation, be sure to contract the seal

rings using the specialtool {sizing tool).

. There are two types of sleeve seal rings: black

and brown. Do not mix the different types of

sleeve seal rings as they are not compatible.

Align the special tool with each groove in the sleeve,

and slide a sleeve seal ring into each groove. After

installation, compress the seal rings with your fin-

gers temporarily.

BALL JOINT BOOT CLIP GUIDE07974 - SA508q)

SLEEVE

Apply power steering fluid to the seal rings on the

sleeve, and to the ehtire inside surface of the special

tool.

14.

15.

SLEEVE SEAL RINGSIZING TOOL07974 - SA502O0 or07974 - SA5020A

16.Insert the sleeve into the special tool slowly.

Move the sleeve each direction several times to

make the seal rings snugly fit in the sleeve. Be sure

that the seal rings are not turned up,

't1.

18. Apply power steering fluid to the surface of the pin-

ion shaft. Assemble the sleeve over the Dinion shaft

by aligning the locating pin on the inside of the

sleeve with the cutout in the shaft. Then install the

new circlip securely in the pinion shaft groove.

Note these items during reassembly:

. Be caretul not to damage the valve seal ring

when inserting the sleeve.

. Install the circlip with its radiused side facing out.

Apply power steering fluid to the seal ring lip of the

valve oil seal. then install the seal in the valve hous-

ing using a hydraulic press and special tools. Install

the valve oil seal with its grooved side facing the tool.

19.

ATTACHMENT,32x35mm077i16 - (x)10100

VALVE OIL SEALReplace.Make sure thespring is in theoilseal.

CIRCLIP

www.emanualpro.com

Page 888 of 1395

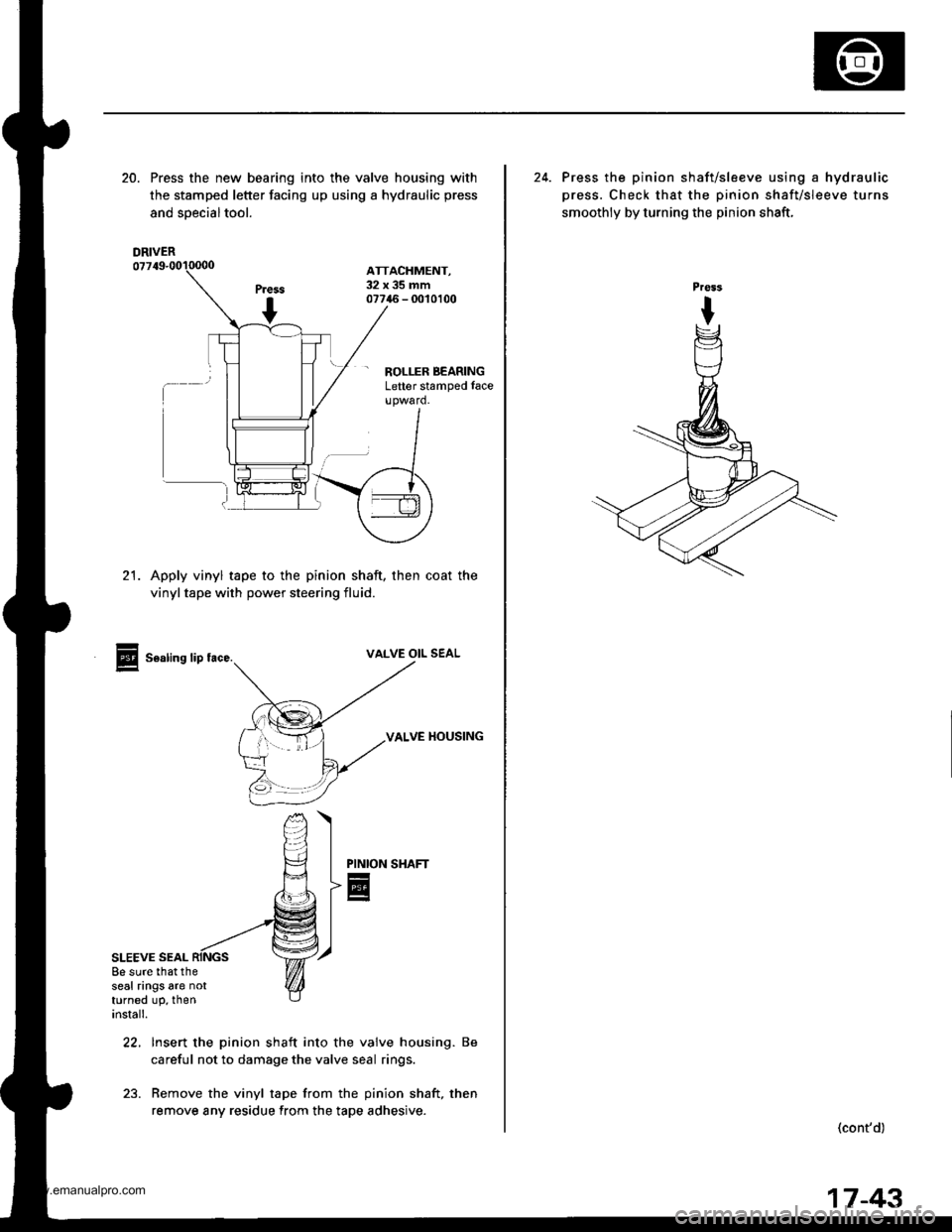

20. Press the new bearing into the valve housing with

the stamped letter facing up using a hydraulic press

and soecialtool.

ATTACHMENT,32x35mm07746 - 0010100

- ROLLER BEARINGLetter stamped face

21. Apply vinyl tape to the pinion shaft, then coat the

vinyltape with power steering fluid.

Sealing lip tace.VALVE OIL SEAL

VALVE HOUSING

SHAFT

SLEEVE SEAL

PINION

E

22, Insert the pinion shaft into the valve housing. Be

careful not to damage the valve seal rings.

23. Remove the vinyl tape from the pinion shaft, then

remove any residue from the tape adhesive.

8e sure that theseal rings are notturned up, theninstall.

DRIVER

24. Press the pinion shaft/sleeve using a hydraulic

press. Check that the pinion shaft/sleeve turns

smoothly by turning the pinion shaft,

(cont'd)

17-43

www.emanualpro.com

Page 911 of 1395

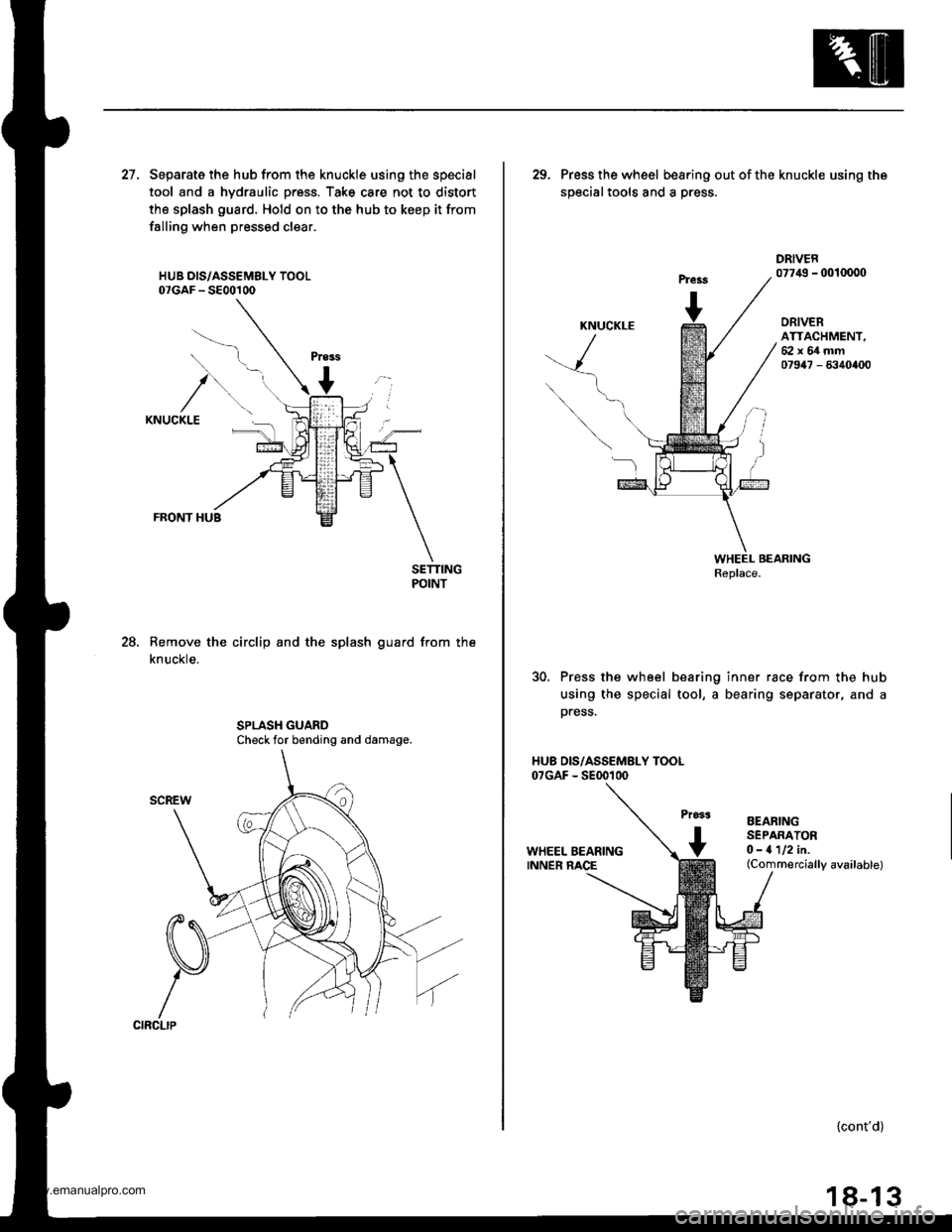

27. Separate the hub from the knuckle using the special

tool and a hydraulic press. Take care not to distort

the splash guard. Hold on to the hub to keep it from

falling when pressed clear.

HUB DIS/ASSEMELY TOOL07GAF - 5800100

FRONT HUB

SETTINGPOINT

Remove the circlip and the splash guard from the

knuckle.

28.

Check for bending and damage.

29. Press the wheel bea.ing outofthe knuckle using the

soecialtools and a Dress.

DRIVER077,19 - 0010000

ORIVERATTACHMENT,62x64mm07947 - 6340400

30. Press the wheel bearing inner race from the hub

using the special tool, a bearing separator, and a

press.

HU8 OIS/ASSEMBLY TOOL07GAF - SE00100

EEARINGSEPARATORO-1112in.(Commercially available)

{cont'd}

18-13

www.emanualpro.com

Page 912 of 1395

Front Suspension

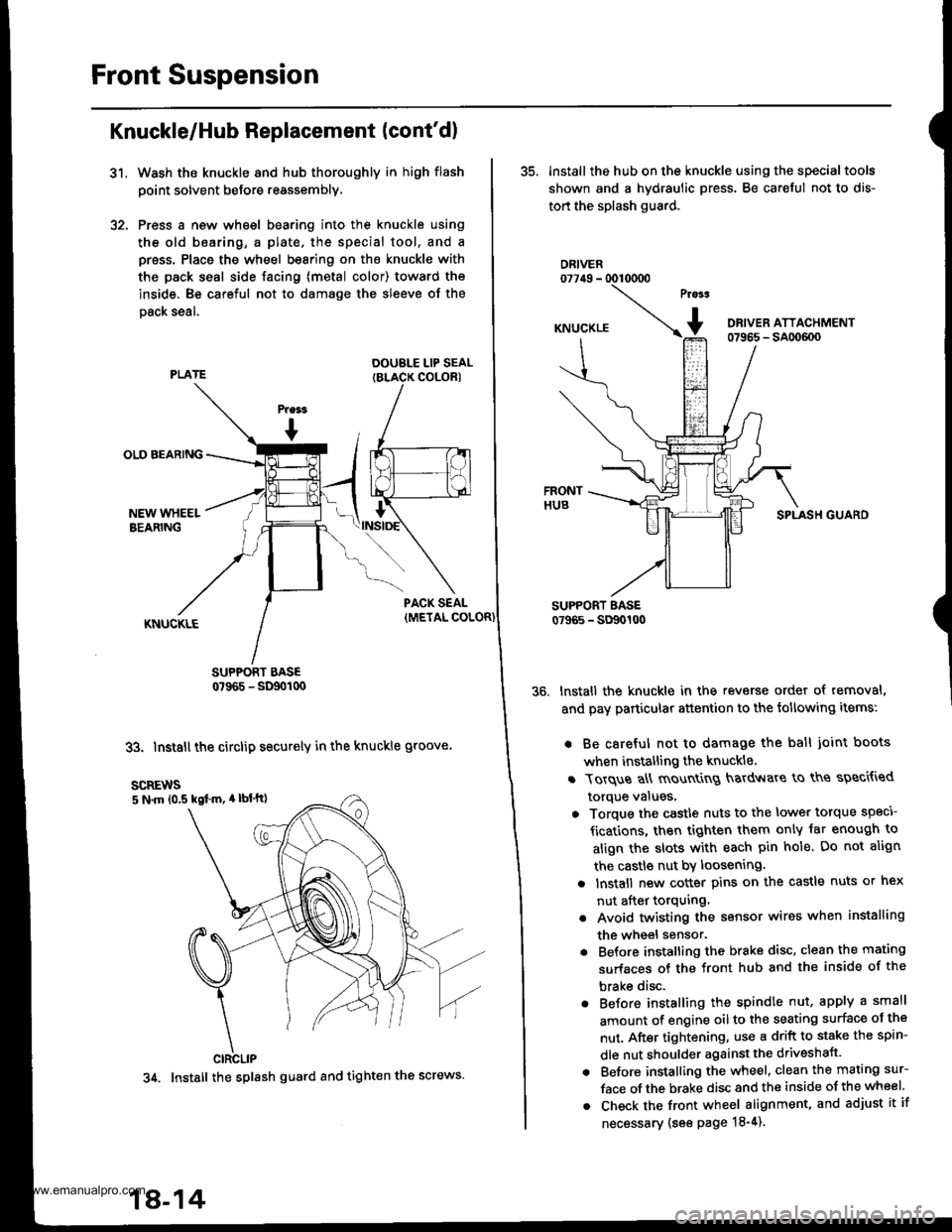

31.

Knuckle/Hub Replacement (cont'dl

Wash the knuckle and hub thoroughly in high flash

point solvent before reassembly,

Press a new wheel bearing into the knuckle using

the old b6aring, a plate. the special tool, and a

press. Place the wheel bearing on the knuckle with

the pack seal side facing (metal color) toward the

inside. Be careful not to damage the sleeve of the

Dack seal.

DOUBLE LIP SEALIBLACK COLORI

SUPPORT BASE0?965 - SD90t00

33. Install the circlip securely in the knuckle groove.

35. lnstall the hub on the knuckle using the specialtools

shown and a hydraulic press. Be careful not to dis-

tort the splash guard.

ORIVER077irg - 0010000

SPLASH GUARO

lnstall the knuckle in the reverse order of removal,

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle.

r Torque a\ mount

g hardv{are to ths speci{ied

torque values,

o Torque the castle nuts to the lower torque speci

fications, then tighten them only iat enough to

align the slots with each pin hole. Do not align

the castle nut by loosening.

a lnstall new cotter pins on the castle nuts or hex

nut after torquing.

. Avoid twisting the sensor wires when installing

the wheel sensor.

. Before installing the brake disc, clean the mating

surfaces of the front hub and the inside of the

brake disc.

. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface oJ the

nut. After tightening, use a drift to stake the spin-

dle nut shoulder against the driveshaft.

. Before installing the wheel. clean the mating sur-

face of the brake disc and the inside of the wheel.

. Check the front wheel alignment, and adjust it if

necessary {see page 18-4).

scREws5 N.m 10.5 kgl m, 4 lbl'tt)

CIRCLIP

34. Install the splash guard and tight€n the screws.

18-14

www.emanualpro.com

Page 953 of 1395

Anti-lock Brake System (ABS)

Features/Gonstruction (cont'd)

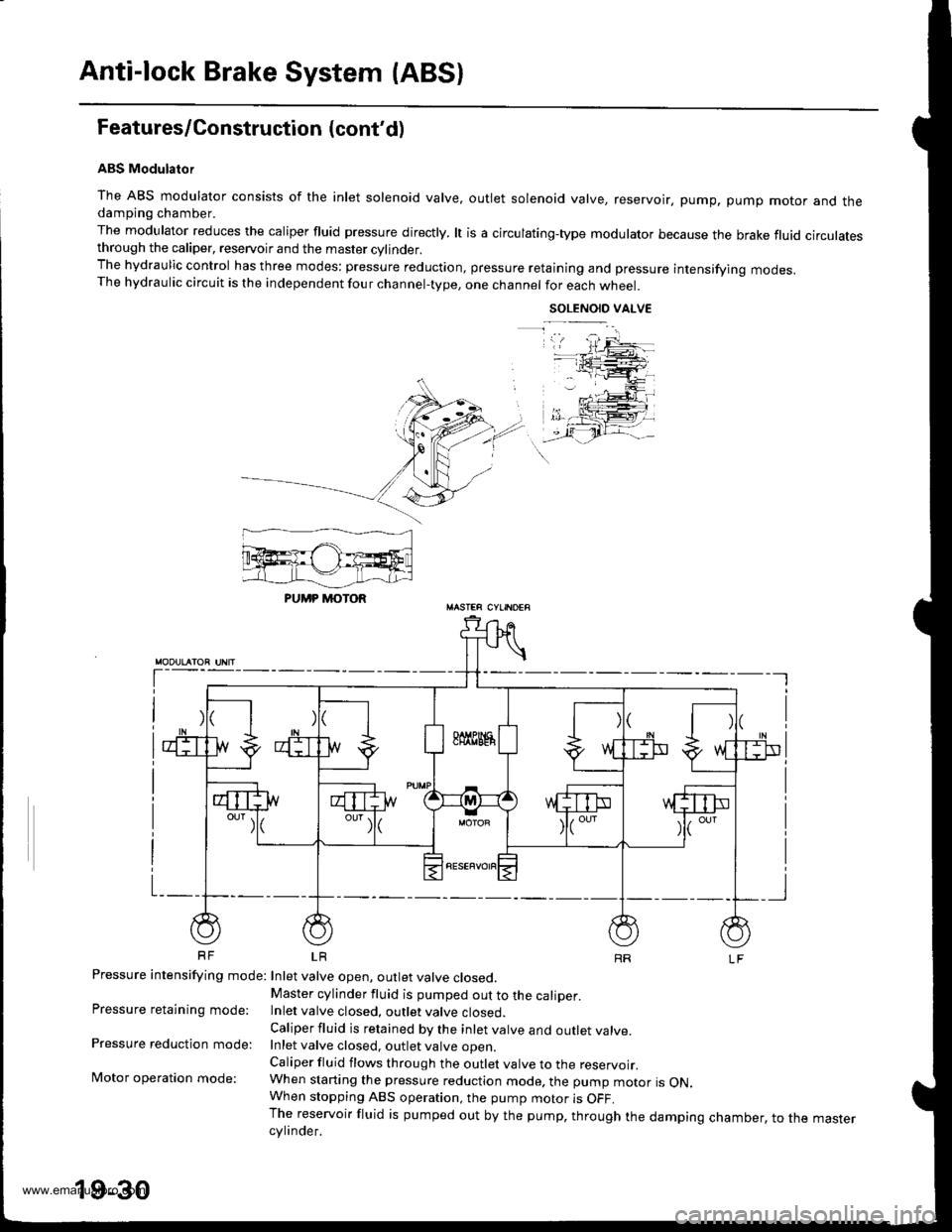

ABS Modulator

The ABS modulator consists of the inlet solenoid valve, outlet solenoid valve, reservoir, pump, pump motor and thedampjng chamber.

The modulator reduces the caliper fluid pressure directly. lt is a circulating-type modulator because the brake fluid circulatesthrough the caliper, reservoir and the master cylinder.The hydraulic control has three modes: pressure reduction, pressure retaining and pressure intensifying modes.The hydraulic circuit is the independent four channel-type, one channel for each wheel.

SOLENOID VALVE

t-

Pressure intensifying mode: Inlet valve open, outlet valve closed,

Pressure retaining mode:

Pressure reduction mode:

Motor operation mode:

Master cylinder fluid is pumped out to the caliper.Inlet valve closed, outlet valve closed.

Caliper fluid is retained by the inlet valve and outlet valve.Inlet valve closed, outlet valve ooen

Caliper fluid flows through the outlet valve to the reservoir.When starting the pressure reduction mode. the pump motor is ON.When stopping ABS operation, the pump motor is OFF.The reservoir fluid is pumped out by the pump, through the damping chamber, to the mastercylinder.

PUMP MOTOR

19-30

www.emanualpro.com