front end HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1025 of 1395

lnterior Trim

Headliner Removal and Installation

CAUTION: When prying with a tlat-tip screwdriver,

wrap it with protective tape to prevent damage.

NOTE:

. Take care not to bend and scratch the headliner.o Be careful not to damage the dashboard and other

interior trim.

1. Remove:

. Front and rear door side trim (see page 20-41). Front pillartrim (see page 20-41)

. Center pillar lower trim panel (see page 20-41). Center pillar upper trim (see page 20 41). Rear seat (one side, see page 20-63). Cargo area floor and cargo storage bin

{see page 20-43)

. Rear trim panel (see page 20-421

. Rear side trim panel (oneside, see page 20-42l,

. Rear hatch glass support strut (one side, seepage 20-78)

. Ouaner pillar trim panel {one side, see page 20-

42)

. Ceiling light, interior light and trunk light(see section 23)

. Rearview mirror (see page 20-28)

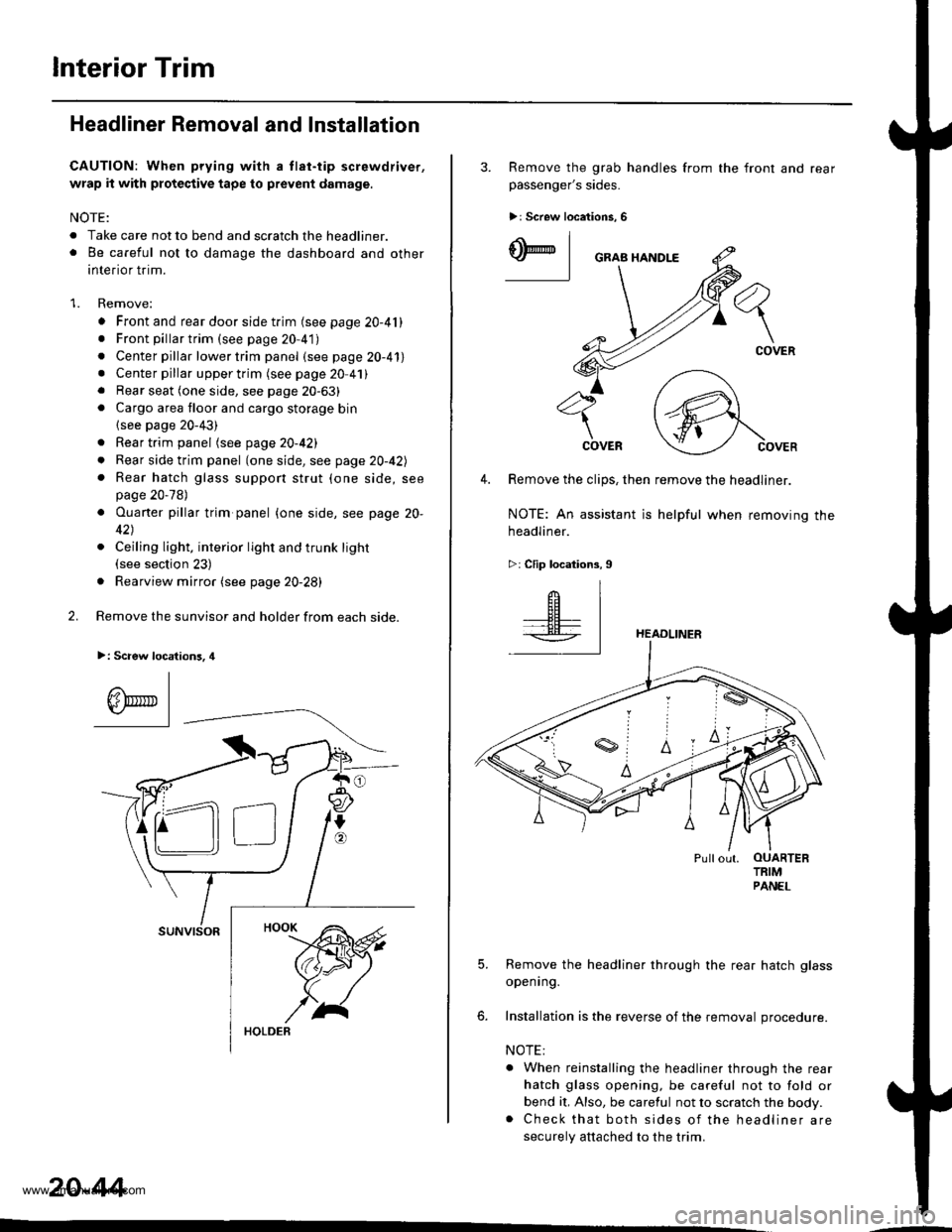

2. Remove the sunvisor and holder from each side.

>: Scaew location3, 4

I

A\"r- |Yr* || -

suNvtsoR

20-44

3. Remove the grab handles from

passenger's sides.

>r Screw locations, 6

the front and rear

ry_l

COVER

4. Remove the clips, then remove the headliner.

NOTE: An assistant is helpful when removing the

headliner.

>: Clip locations,9

HEADLINER

Pullout. OUARTERTRIMPANEL

5. Remove the headliner through the rear hatch glass

openrng.

6. Installation is the reverse of the removal procedure.

NOTE:

. When reinstalling the headliner through the rear

hatch glass opening, be careful not to fold or

bend it, Also, be careful not to scratch the body.. Check that both sides of the headliner are

securely attached to the trim.

www.emanualpro.com

Page 1038 of 1395

Front Seat Removal and Installation

CAUTION: When prying whh a tlat-tip screwdrivor, wrap

it with proteqtive tape to prevent damage.

NOTE: Take care not to scratch the bodv or tear the seat

covers.

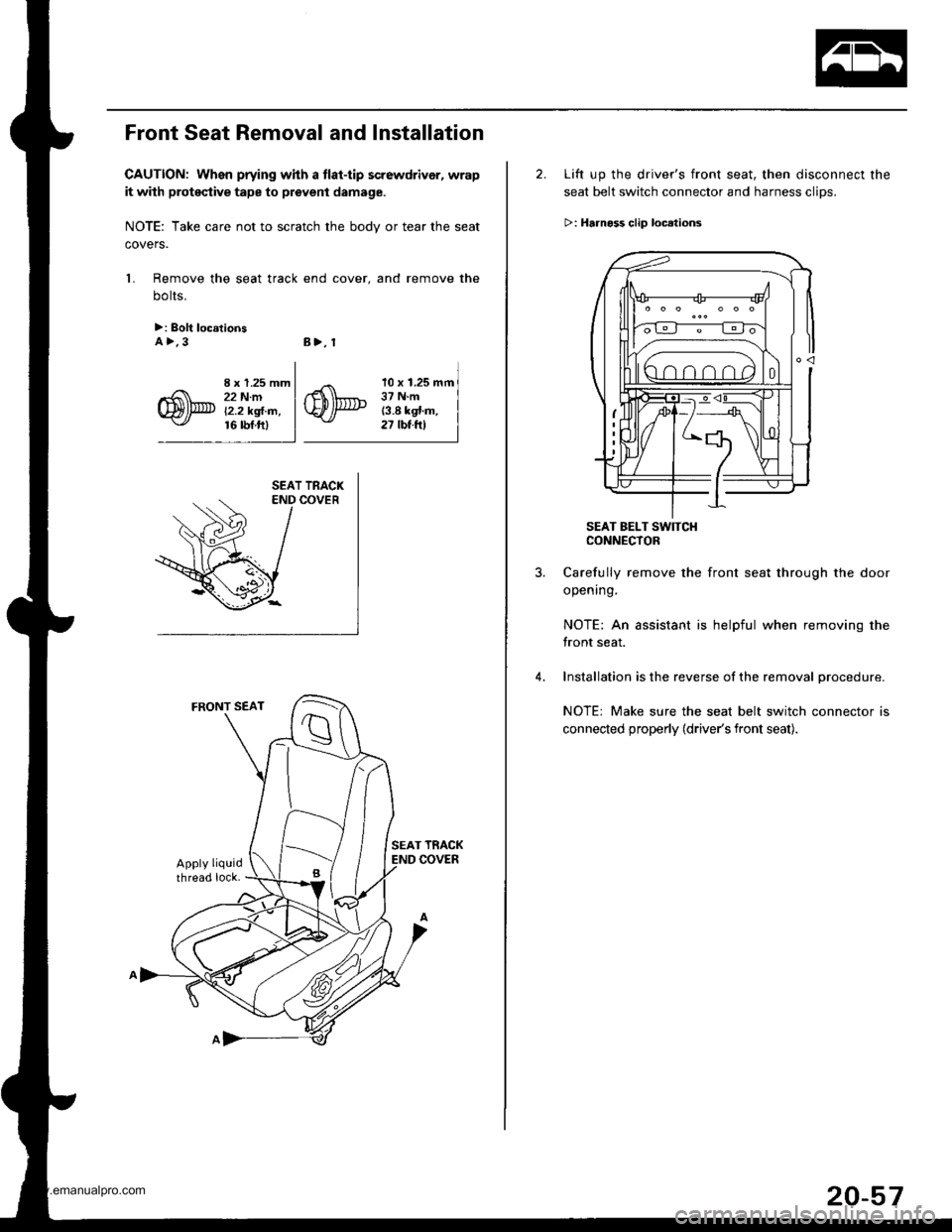

1. Remove the seat track end cover, and remove the

bolts.

>: Bolt loc.tionsA>.3B>, 1

I x 1.25 mm22 N.mi'2.2 kgl.m,16 rbf.ftl

10 x 1.25 mm37 N.m13.8 kgt.m,27 tbt.ftl

2. Lift up the driver's front seat, then disconnect the

seat belt switch connector and harness clips.

>: Hrrnoss clip loc.lions

SEAT BELT SW]TCHCONNECTOR

Carefully remove the front seat through the door

opening.

NOTE: An assistant is helpful when removing the

front seat.

Installation is the reverse of the removal procedure.

NOTE: Make sure the seat belt switch connector is

connected properly (driver's front seat).

20-57

www.emanualpro.com

Page 1053 of 1395

Bumpers

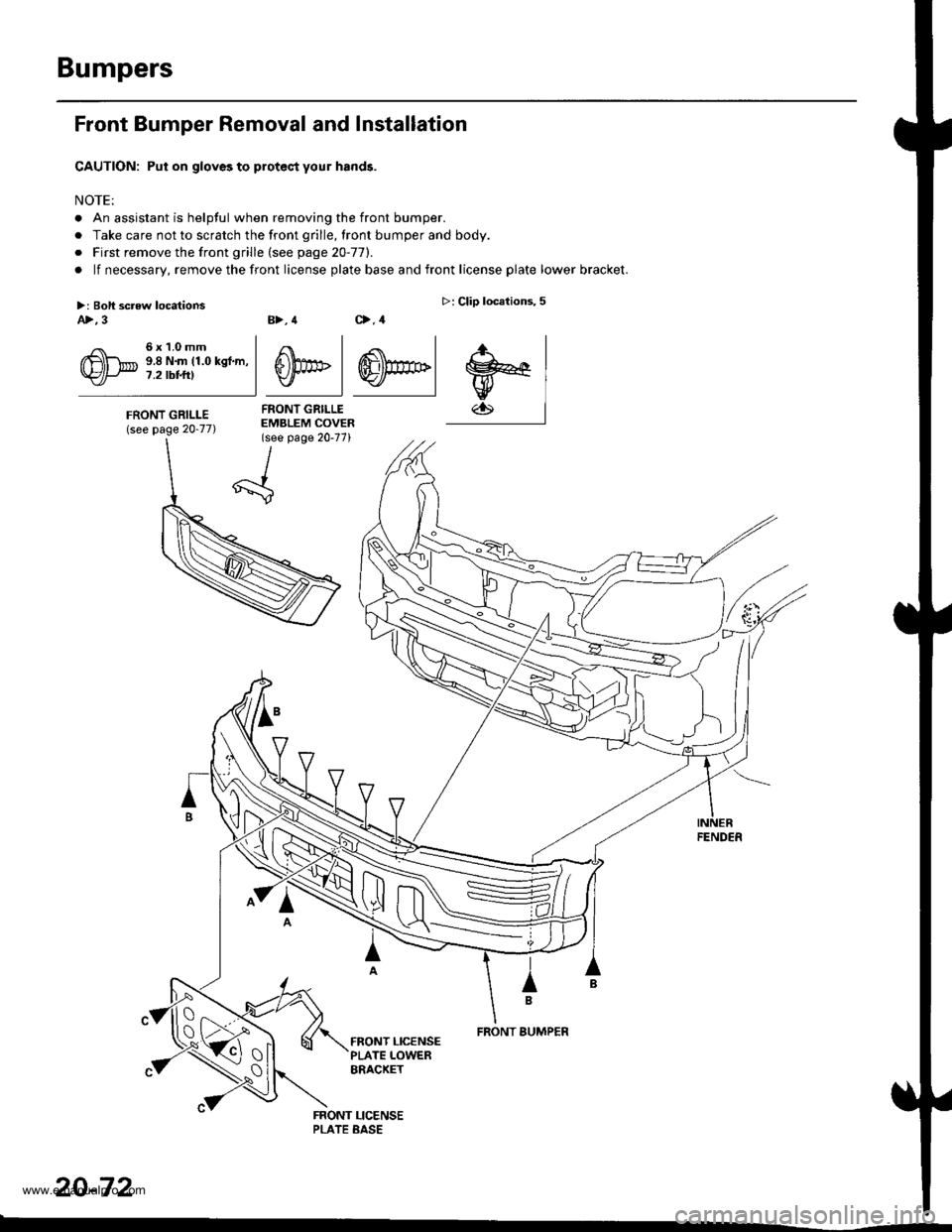

Front Bumper Removal and Installation

CAUTION: Put on gloves to protec,t your hands.

NOTE:

. An assistant is helpful when removing the front bumper.

. Take care not to scratch the front grille, lront bumper and body.

o First remove the front grille (see page 20-77).

. lf necessary, remove the front license plate base and front license plate lower bracket.

B>, 4 C>,4

4 .<\l

S))PF | ffi)m>lv I Y./ |

FRONT GRILLEEMBLEM COVER(see page 20-77)

>: Clip locations,5

.r., I

w€lw

FENDER

IB

FRONT BUMPER

20-72

>: Boli screw locationsA>,3

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbt t0

FRONT GRILLE(see page 20-77)

tx -

\{_:

www.emanualpro.com

Page 1065 of 1395

Moldings

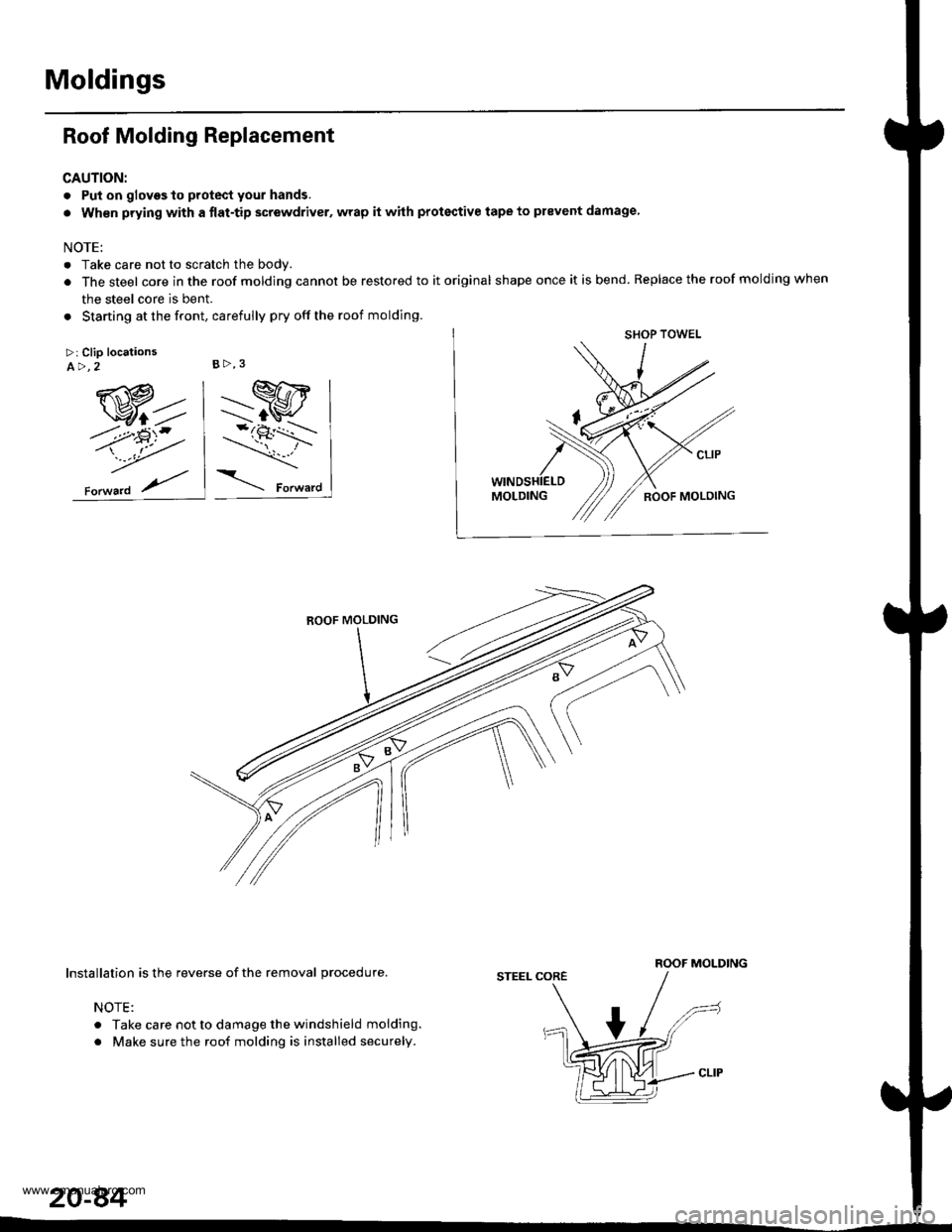

Roof Molding Replacement

CAUTION:

. Put on glovgs to protect your hands.

. Wh€n prying with a {lat-tip screwdriver, wrap it whh protective tape to prevent damage

NOTE:

. Take care not to scratch the body.

. The steel core in the roof molding cannot be restored to it original shape once it is bend. Replace the roof molding when

the steel core is bent.

. Starting at the front, carefully pry off the roof molding.

>: Clip locationsA>,2

ROOF MOLDINGInstallation is the reverse of the removal procedure.

NOTE:

. Take care not to damage the windshield molding.

. Make sure the roof molding is installed securely.

STEEL CORE

B>,3

20-84

www.emanualpro.com

Page 1067 of 1395

Moldings

Door Moldings Replacement (cont'd)

It the old molding is to be reinstalled:

The following materials and tools are required to repair

the molding.

NOTE: Followthe manufacturer's instructions.

Materials: (Reference)

. Stripe remover

3M 08907

. Stripe adhesive remover

3M 08908

. Adhesive tape

3M Super Automotive Attachment Tape

Tools:

. Protective tape

. Knife or Cutter

. Sponge or Shop towel

. Infrared dryer

. Film

. Plastic putty knife

. Alcohol

CAUTION: Put on gloves to protect your hands,

1. lf necessary, replace any damaged clips on the mold-

ang.

2. Apply the stripe remover evenly to the bonding sur-

face of the body and molding.

3. Cover the bonding surface of the body and molding

with a film, then heat to 104 - 122"F (40 - 50'C) for 5- 10 minutes with an infrared dryer.

NOTE: Use care when heating to prevent deforma-

tion of the body and molding.

4. Carefully scrape the adhesive tape with a plastic

putty knife.

For removal of adhesive tape residue, follow-up with

stripe adhesive remover, then scrape the adhesive

tape with a plastic putty knife.

Remove the protective tape, then clean the bonding

surface with a sponge dampened in alcohol.

NOTE: Make sure the bonding surface is kept free or

water, oil and grease.

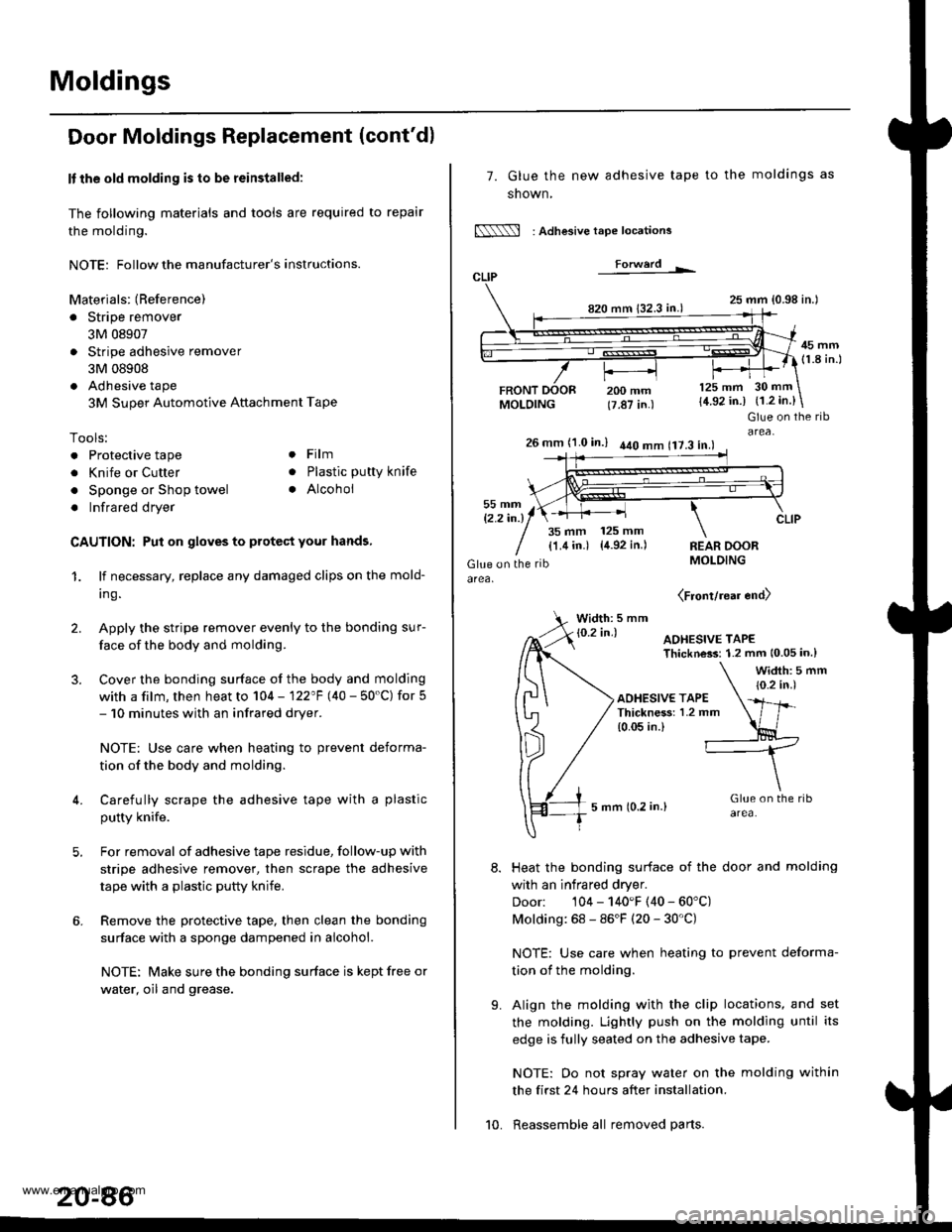

7. Glue the new adhesive tape

snown,

N : Adlesive tape locations

Forwerd L

820 mm 132.3 in.)

FRONTMOLDING

to the moldings as

25 mm {0.98 in.l

45 mm(1.8 in.l

200 mm(7.87 in.)

125 mm

{4.92 in.)30 mm

{1.2 in.}

t'.

Glue on the ribarea,26 mm (1.0 in.) 440 mm 117.3 in.l

35 mm 125 mm

{1.4 in.) {4.92 in.)REAR DOORMOLDING

(Front/rear end)

Width: 5 mm

Heat the bonding surface of the door and molding

with an infrared dryer.

Door: 104 - 140'F (40 - 60'C)

Molding: 68 - 86'F (20 - 30'C)

NOTE: Use care when heating to prevent deforma-

tion of the molding.

Align the molding with the clip locations, and set

the molding. Lightly push on the molding until its

edge is fully seated on the adhesive tape.

NOTE: Oo not spray water on the molding within

the first 24 hours after installation.

Reassemble all removed parts.10.

www.emanualpro.com

Page 1070 of 1395

Fenderwell

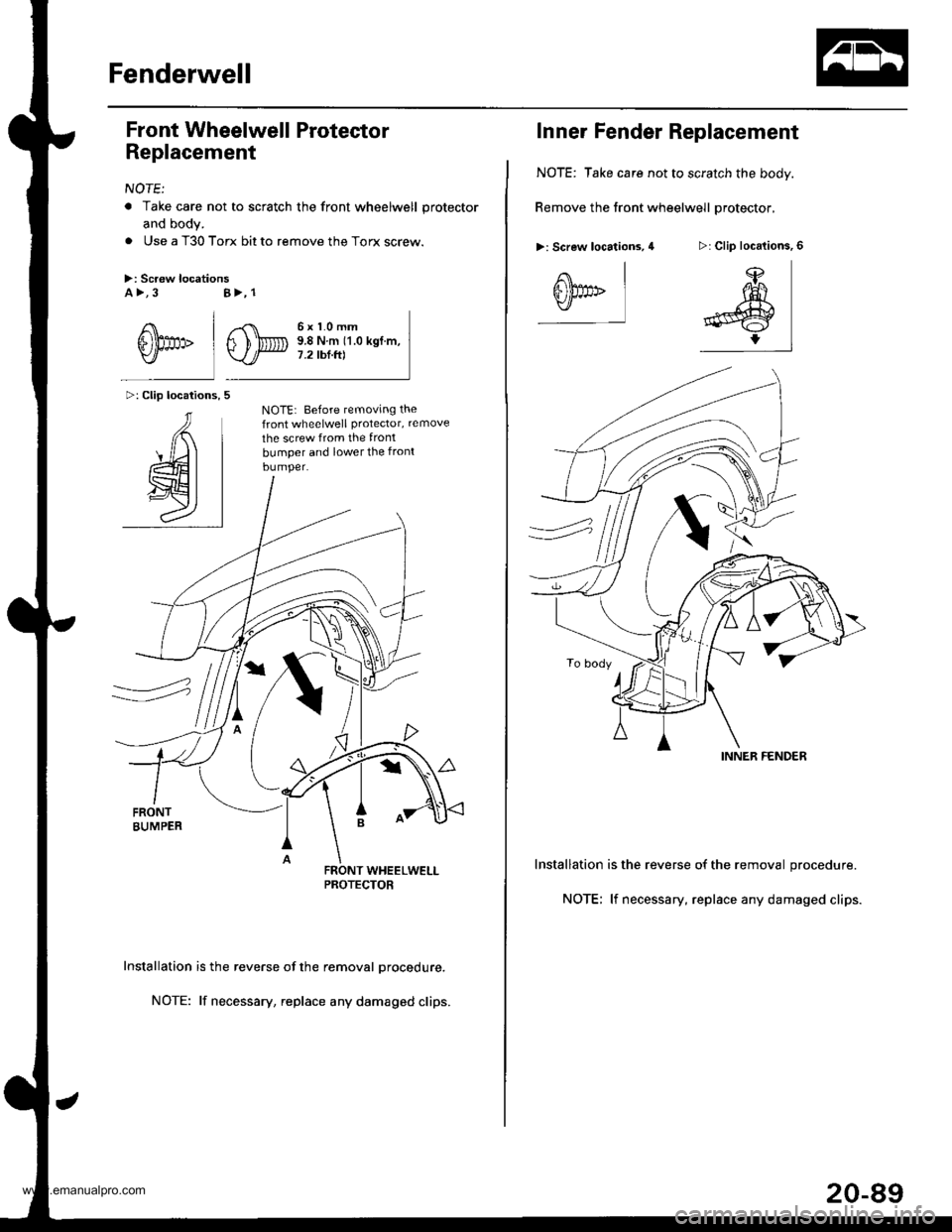

Front Wheelwell Protector

Replacement

NOTE:

a Take care not to scratch the front wheelwell protector

and body.

. Use a T30 Torx bit to remove the Torx screw.

>: Screw locationsa >,3

/\l

6'thp IY/

>: Clip locations,

AI

4t I

wt I

al

B>, 1

,,-C\

s)Dv.l/

6x1.0mm9.8Nm(1.0kgf.m,7.2 tbf.ft)

NOTE: Before temoving thefront wheelwell Protector, remove

the screw from the front

bumper and lower the front

bumper.

Installation is the reverse of the removal Drocedure.

NOTE: lf necessary, replace any damaged clips.

Inner Fender Replacement

NOTE: Take care not to scratch the body.

Remove the front wheelwell protector,

>: Screw locations, 4

Installation is the reverse of the removal procedure.

NOTE; lf necessary, replace any damaged clips.

>: Clip locations,

ffi)fl(

l#:rl

A\

s))pp>Y]

INNER FENDER

20-89

www.emanualpro.com

Page 1074 of 1395

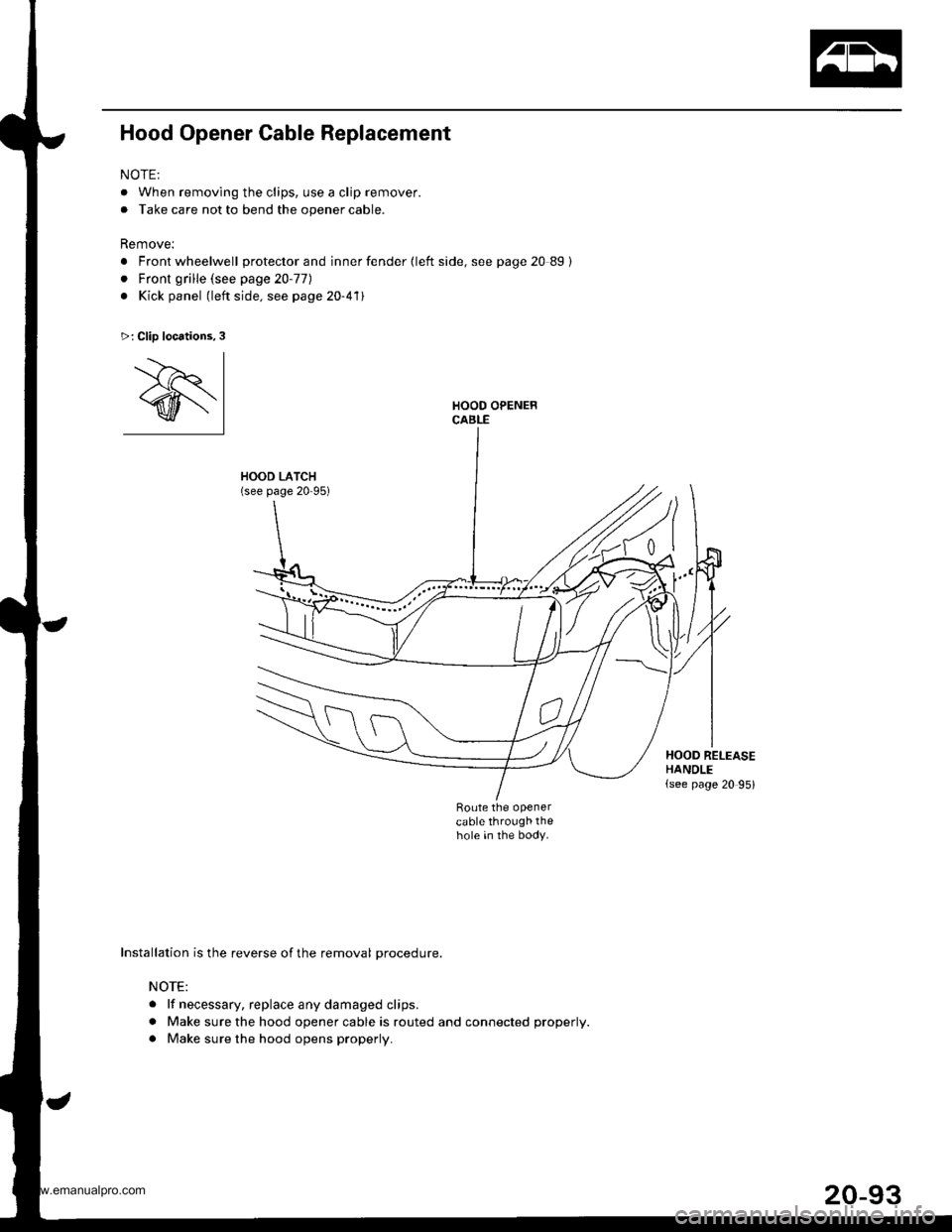

Hood Opener Cable Replacement

NOTE:

. When removing the clips, use a clip remover.

. Take care not to bend the opener cable.

Remove:

. Front wheelwell protector and inner fender {left side, see page 20 89}

. Front grille (see page 20-77)

. Kick panel (left side. see page 20-411

HOOD LATCH(see page 20-95)

Route the openercable through thehole in the body.

>: Clip locations,3

'.--)r I

@l

Installation is the reverse of the removal procedure.

NOTE:

. lf necessary. replace any damaged clips.

. Make sure the hood opener cable is routed and connected properly.

. Make sure the hood opens properly.

t"

HOOD RELEASEHANDLE(see page 20 95)

www.emanualpro.com

Page 1075 of 1395

Openers

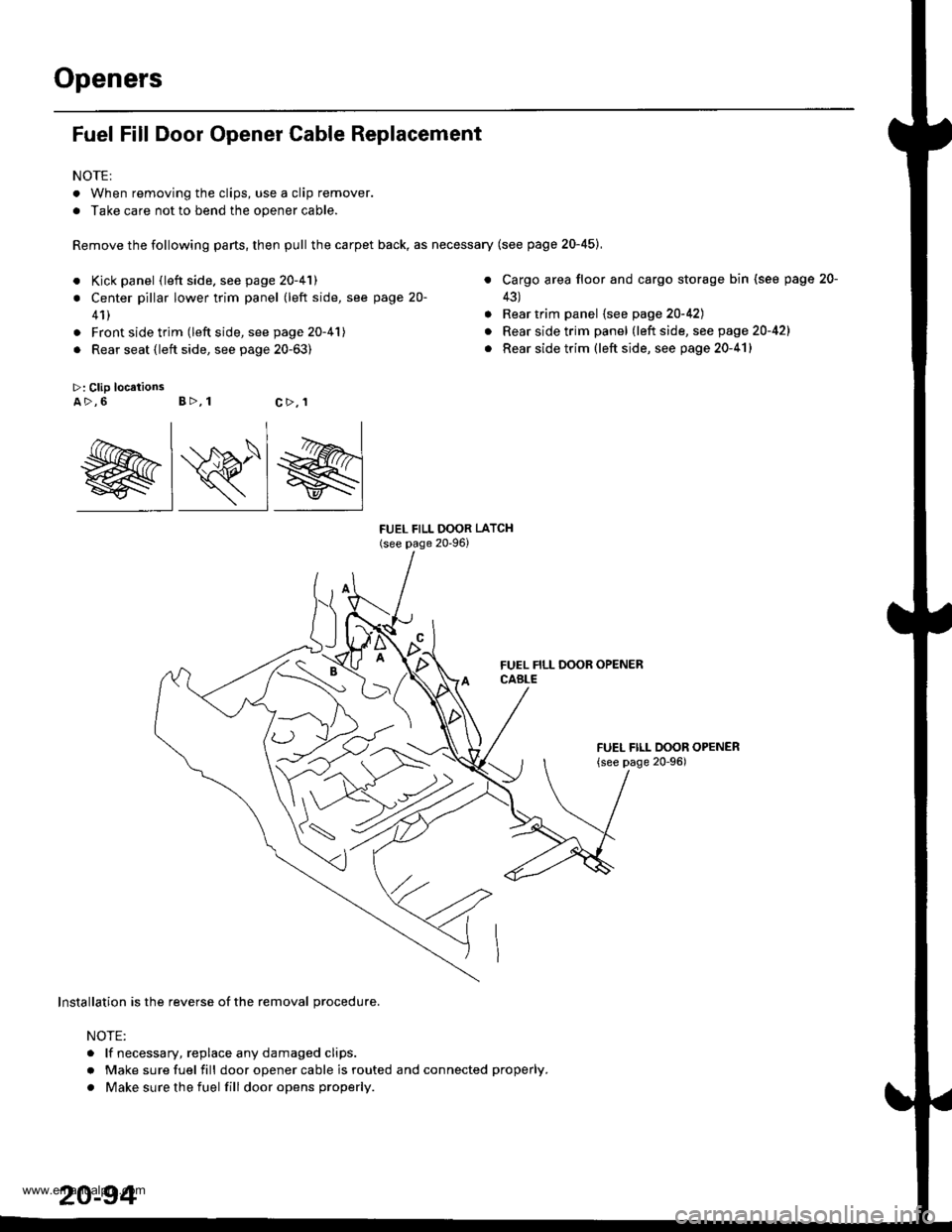

Fuel Fill Door Opener Cable Replacement

NOTE:

. When removing the clips, use a clip remover.

. Take care not to bend the opener cable.

Remove the following parts, then pull the carpet back, as necessary (see page 20-45),

a

>: Clip locationsA>,6 B>, 1

a

a

FUEL FILL OOOR LATCH(see page 20-96)

Kick panel (left side. see page 20-41)

Center pillar lower trim panel (left side, see page 20-

41)

Front side trim (left side, see page 20-41)

Rear seat (left side, see page 20-63)

Cargo area floor and cargo storage bin (see page

43)

Rear trim panel {see page 20-42)

Rear side trim panel (left side, see page 20-421

Rear side trim (left side, see page 20-41)

FUEL FILL DOOR OPENER

{see page 20-96)

20-

c>,1

@lRlg

Installation is the reverse of the removal procedure.

NOTE:

. lf necessary, replace any damaged clips.

r Make sure fuel fill door opener cable is routed and connected properly.

. Make sure the fuel fill dooropens properly.

www.emanualpro.com

Page 1076 of 1395

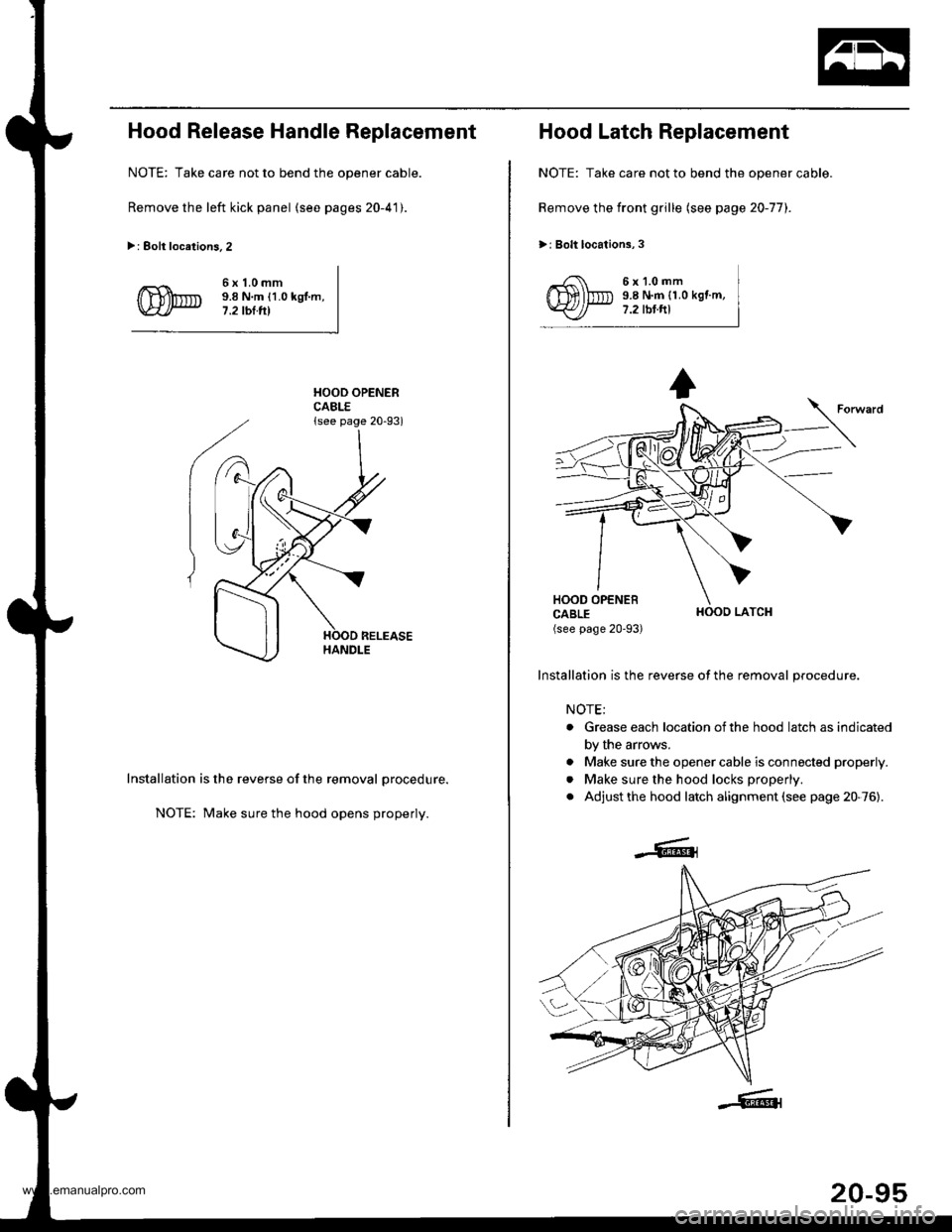

Hood Release Handle Replacement

NOTE: Take care not to bend the opener cable.

Remove the left kick panel (see pages 20-41).

>: Eolt locations.2

6x1.0mm9.8 N.m {1.0 kgl.m,7.2 tbl.tll

HOOD OPENERCABLE{see page 20-93)

Installation is the reverse of the removal procedure.

NOTE: Make sure the hood opens properly.

Hood Latch Replacement

NOTE: Take care not to bend the opener cable.

Remove the front grille (see page 20-77).

>: Bolt locations,3

6x1.0mm9.8 N.m {1.0 kgf.m,7.2 tbt.ftl

HOOO LATCH

Installation is the reverse of the removal procedure.

NOTE;

. Grease each location ofthe hood latch as indicated

by the arrows.

. Make sure the opener cable is connected properly.

. Make sure the hood locks properly.

. Adjust the hood latch alignment (see page 20-76).

20-95

www.emanualpro.com

Page 1077 of 1395

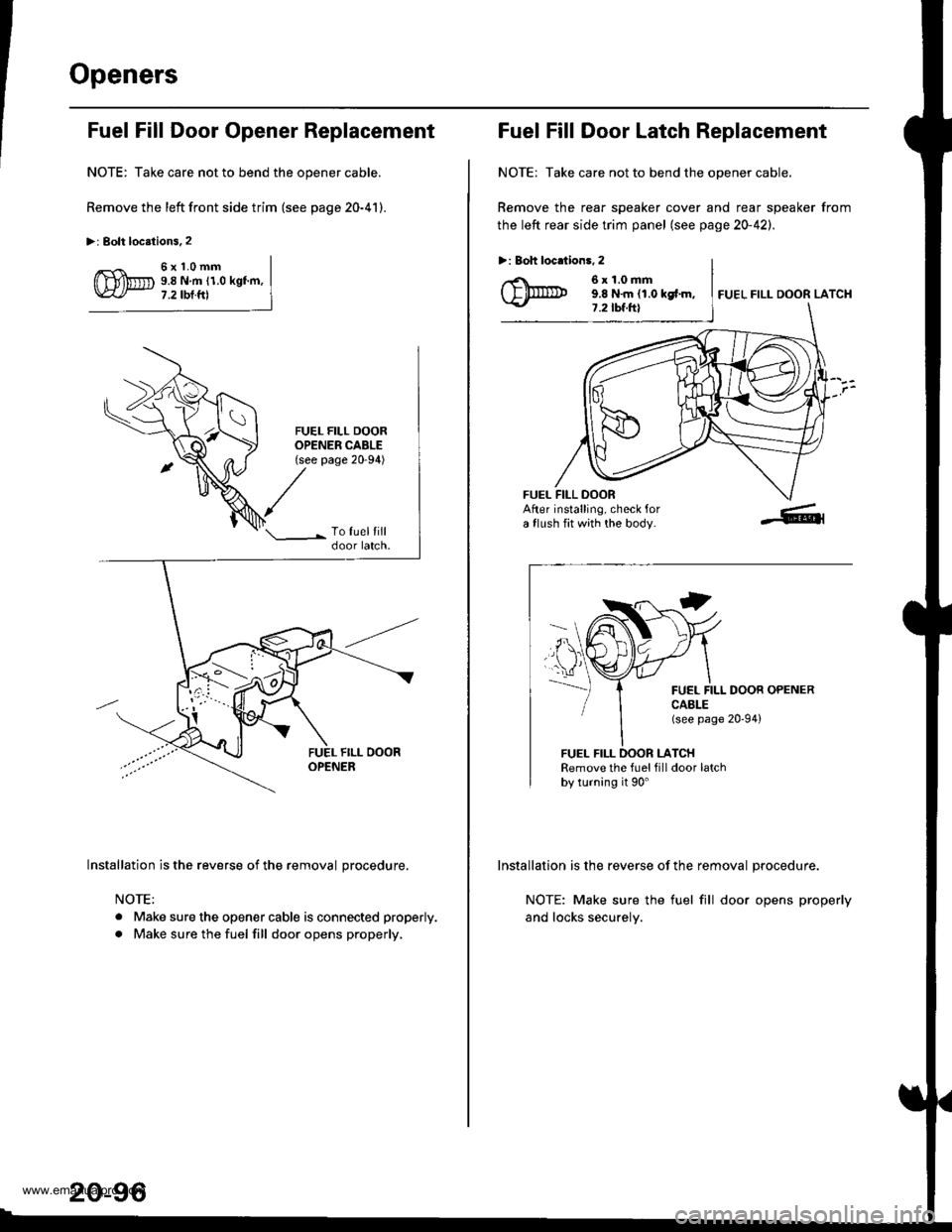

Openers

Fuel Fill Door Opener Replacement

NOTE: Take care not to bend the opener cable.

Remove the left front side trim (see page 20-41).

>: Bolt locstions.2

5x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbt.ftl

FUEL FILL DOOROPENER CABLE(see page 20-94)

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the opener cable is connected properly.

. Make sure the fuel fill door opens properly,

20-96

Fuel Fill Door Latch Reolacement

NOTE: Take care not to bend the opener cable.

Remove the rear speaker cover and rear speaker from

the left rear side trim panel (see page 20-42).

>: Boh locdions, 2

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbf.ft)FUEL FILL DOOR LATCH

FUEL FILL DOORAfter installing, check fora flush fit with the body.

CAELE(see Page

LATCH

DOOR OPENER

20,94)

FUEL

FUEL FILLRemove the fuel fill door latchby turning it 90'

Installation is the reverse of the removal procedure.

NOTE: Make sure the fuel fill door opens properly

and locks securely.

www.emanualpro.com