sensor system HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 352 of 1395

ldle Control System

ldle Control System

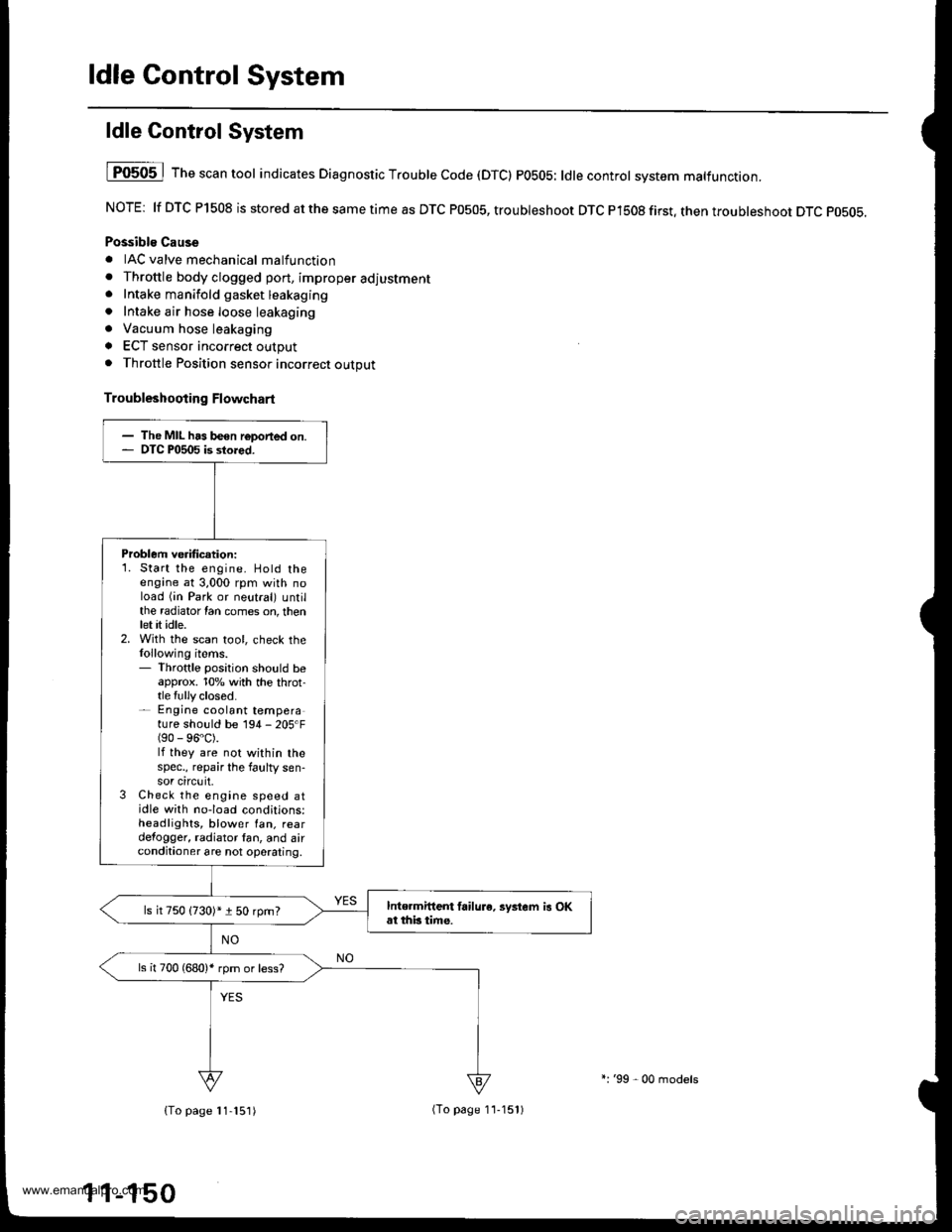

I P0505 | The scan tool indicates Diagnostic T.ouble Code (DTCI PO5O5: ldlecontrol svstem mattunction.

NOTE: lf DTC P1508 is stored at the same time as DTC P0505, troubleshoot DTC P1508 first. then troubleshoot DTC p0505.

Possibls Cause

. IAC valve mechanical malfunction. Throttle body clogged port, improper adlustment. Intake manifold gasket leakaging. Intake air hose loose leakaging. Vacuum hose leakaging

a ECT sensor incorrect output. Throttle Position sensor incorrect output

Troubleshooting Flowchart

The MIL has been reDorted on.DTC P0505 is sto.ed.

Problem verificationi1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator Ian comes on, thenlet it idle.2. With the scan tool, check thelollowing items.- Throttle position should beapprox. 10% with the throt-tle {ully closed.- Engine coolant temperature shorJld be 194 - 205'F(90 - 96"C).lf they are not within thespec., repair the faulty sen-sor circuit.3 Check the engine speed atidle with no-load conditions:headlights, blower fan. reardefogger, radiator lan, and airconditioner are not operaling,

Inte.mittent failure. syltem is OKat this time.ls it 750 {730)* i 50 rpm?

ls il 700 (680)' rpm or less?

{To page 11-151)(To page 1'l-151)

l:'99 - 00 models

www.emanualpro.com

Page 382 of 1395

Fuel Supply System

Fuel Injectors {cont'dl

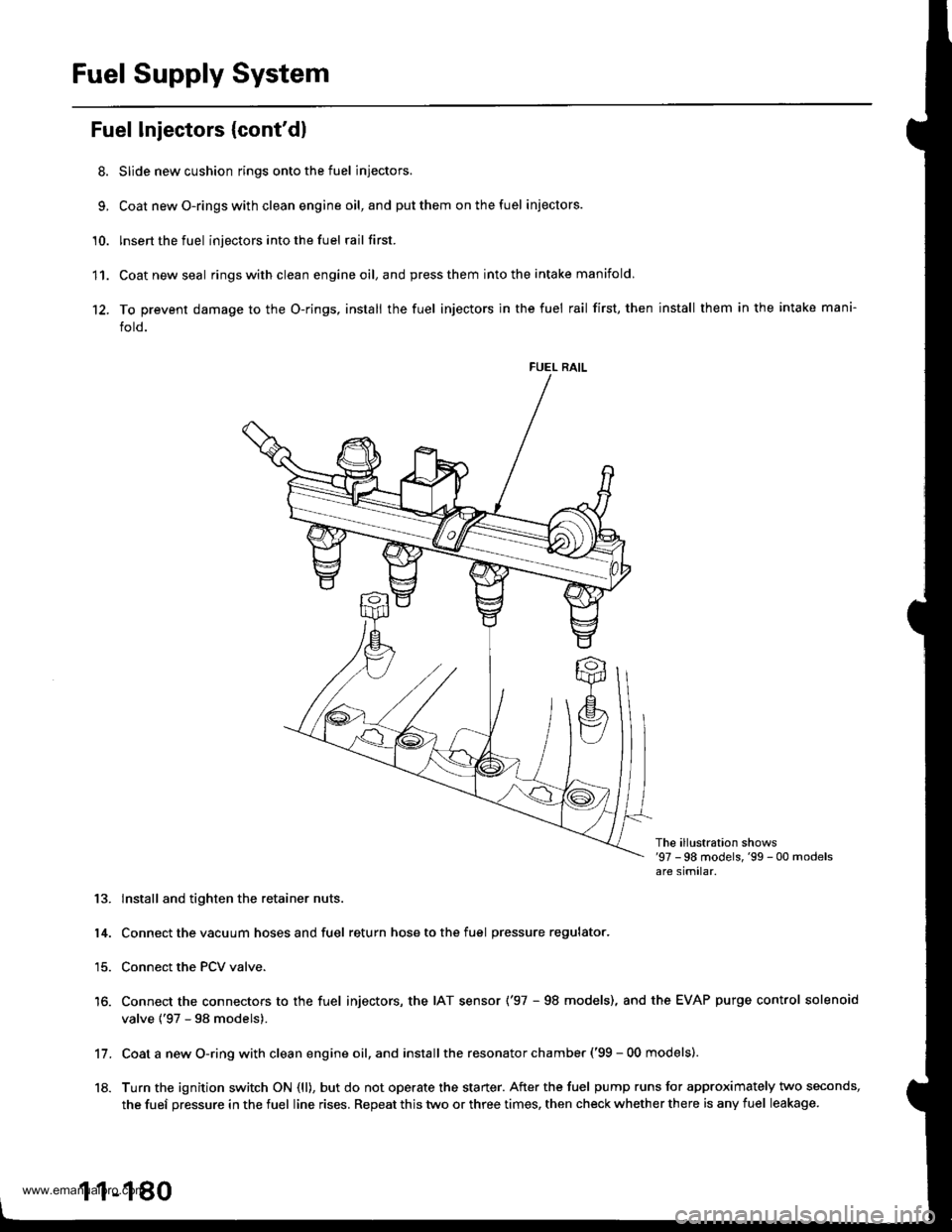

8. Slide new cushion rings onto the fuel injectors.

9, Coat newO-ringswith clean engine oil,and putthem onthefuel iniectors.

'10. lnsert the fuel injectors into the fuel rail first.

11. Coatnewseal ringswithclean engineoil,and press them into the intake manifold

12. To prevent damage to the O-rings, install the fuel injectors in the fuel rail first, then install them in the intake mani-

fold.

FUEL RAIL

The ill!stration shows'97 -98 models,'99 - 00 modelsare similar.

13. lnstall and tighten the retainer nuts.

14. Connect the vacuum hoses and fuel return hose to the fuel pressure regulator.

15. Connect the PCV valve.

16. Connect the connectors to the fuel injectors, the IAT sensor ('97 - 98 models), and the EVAP purge control solenoid

valve {'97 - 98 models).

Coat a new O-ring with clean engine oil, and install the resonator chamber ('99 - 00 models).

Turn the ignition switch ON (ll), but do not operate the starter. After the fuel pump runs for approximately two seconds,

the fuef pressure in the fuel line rises. Repeat this two or three times, then check whether there is any fuel leakage.

11.

18.

1 1-180

www.emanualpro.com

Page 395 of 1395

Intake Air System

System Description

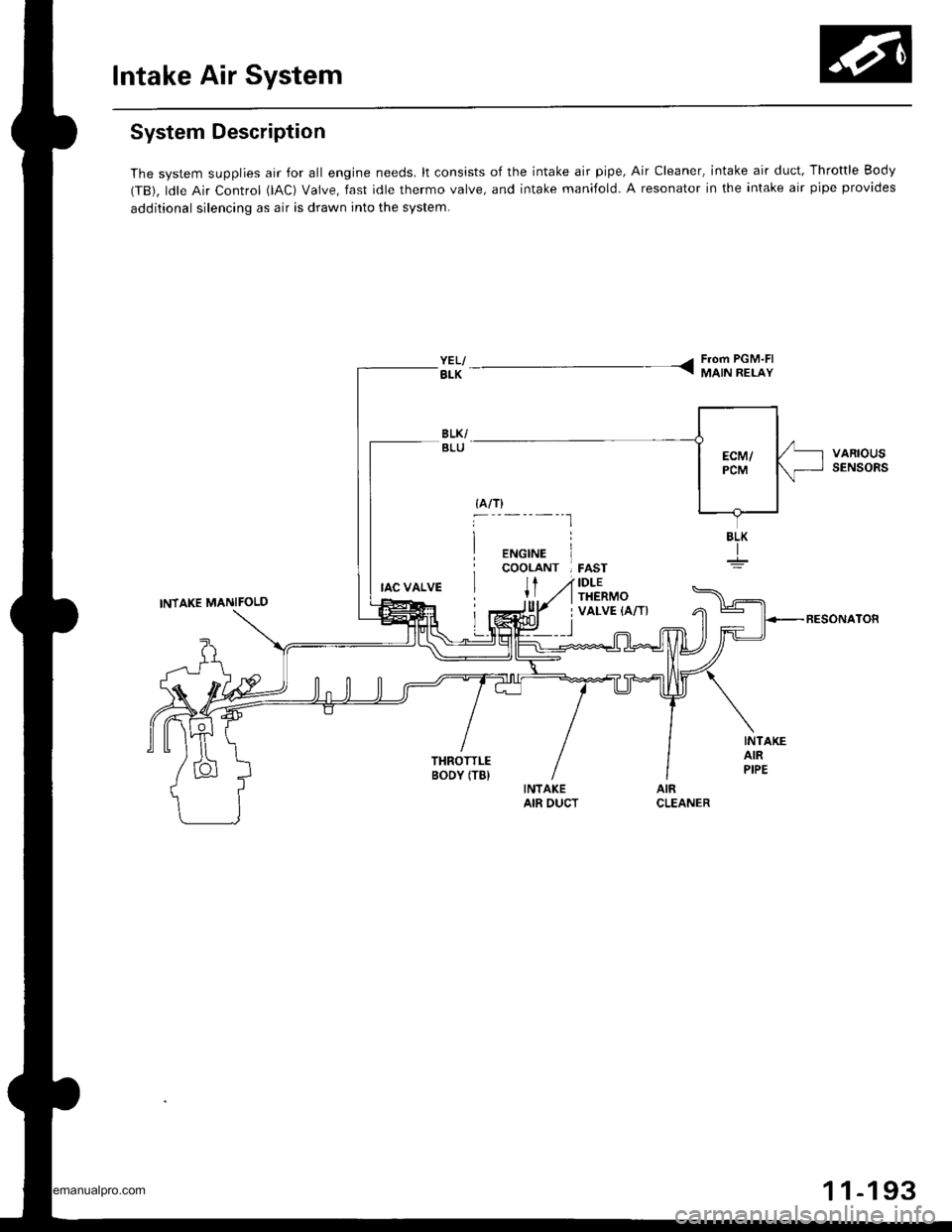

The system supplies air for all engine needs. lt consists of the intake air pipe, Air Cleaner, intake air duct, Throttle Body

(TB), ldle Air Control (lAC) Valve, fast idle thermo valve, and intake manifold. A resonator in the intake air pipe provides

additional silencing as air is drawn into the system.

INTAKE MANIFOLD

YEL| - - Fiom PGM'FI

BLK T MAIN RELAY

IDLETHERMO

lJ- _iuo'u'j"'

INTAKEAIR DUCT

vaRtousSENSORS

FESONATON

THROTTLEBODY (TB)

1 1-193

www.emanualpro.com

Page 402 of 1395

Emission Control System

Three Way Catalytic Converter {TWCI (cont'd}

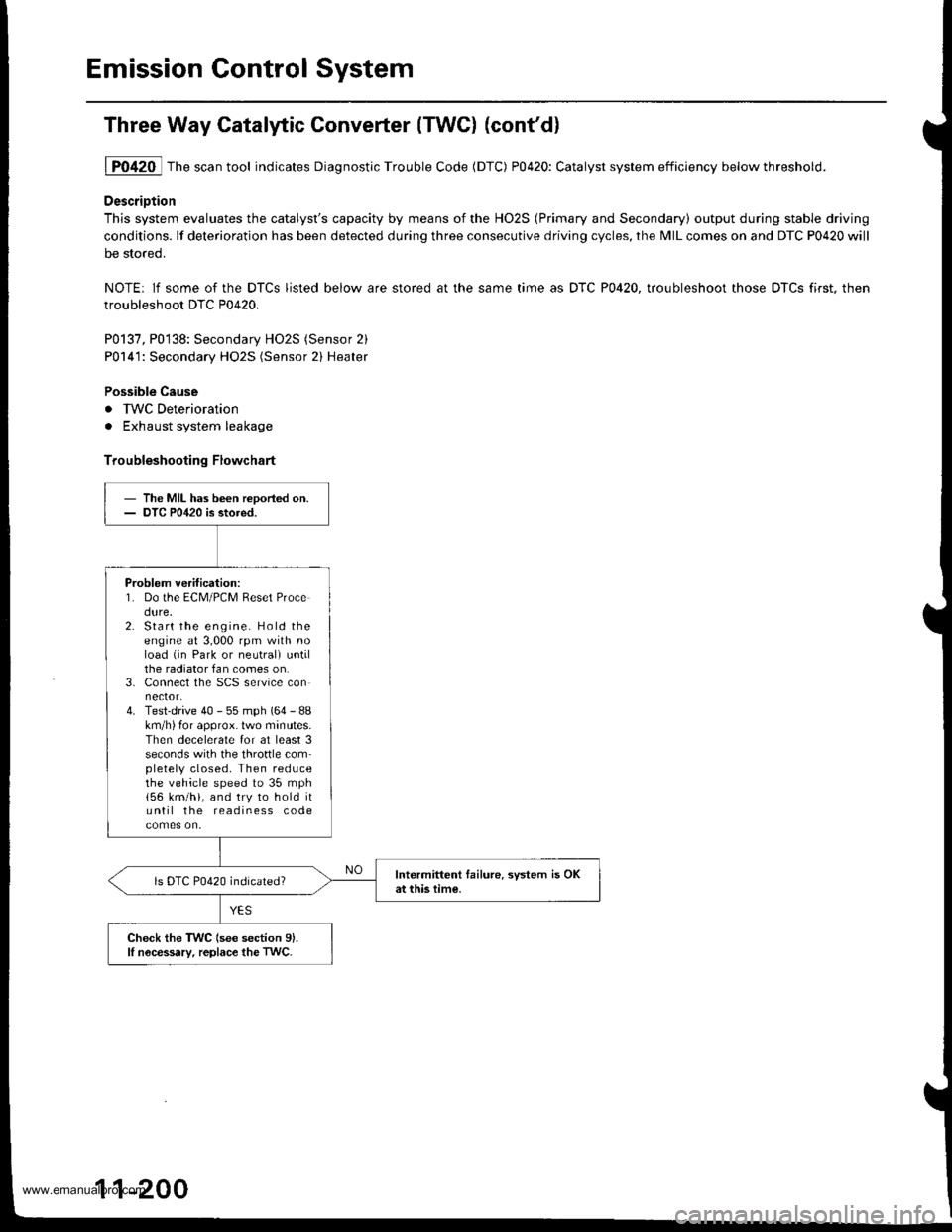

1P0420 Thescantool indicates Diagnostic Trouble Code (DTC) P0420: Catalyst system efficiency belowthreshold.

DescriDtion

This system evaluates the catalyst's capacity by means of the HO2S (Primary and Secondary) output during stable driving

conditions. lf deterioration has been detected during three consecutive driving cycles, the MIL comes on and DTC P0420 will

be stored.

NOTE: lf some of the DTCS listed below are stored at the same time as DTC P0420, troubleshoot those DTCS first. then

troubleshoot DTC P0420.

P0137, P0138: Secondary HO2S (Sensor 2)

P0141: Secondary HO2S (Sensor 2) Heater

Possible Cause

. IWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has been reDoried on.- DTC P0420 is stored.

Problem verification:1. Do the ECM/PCM Reset Procedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrali untilthe radiator fan comes on.3. Connect the SCS service connector.4. Test-drive 40 - 55 mph (64 - 88km/h) for approx. lwo minutes.Then decelerate for at least 3seconds with the throftle completely closed. Then reducethe vehicle speed to 35 mph

156 km/h), and try to hold ituntil the readiness code

Intermittent tailure. system is OKat this time.ls DTC P0420 indicated?

Check the TWC (see section 9).lI nocessary, replace the TwC.

11-200

www.emanualpro.com

Page 405 of 1395

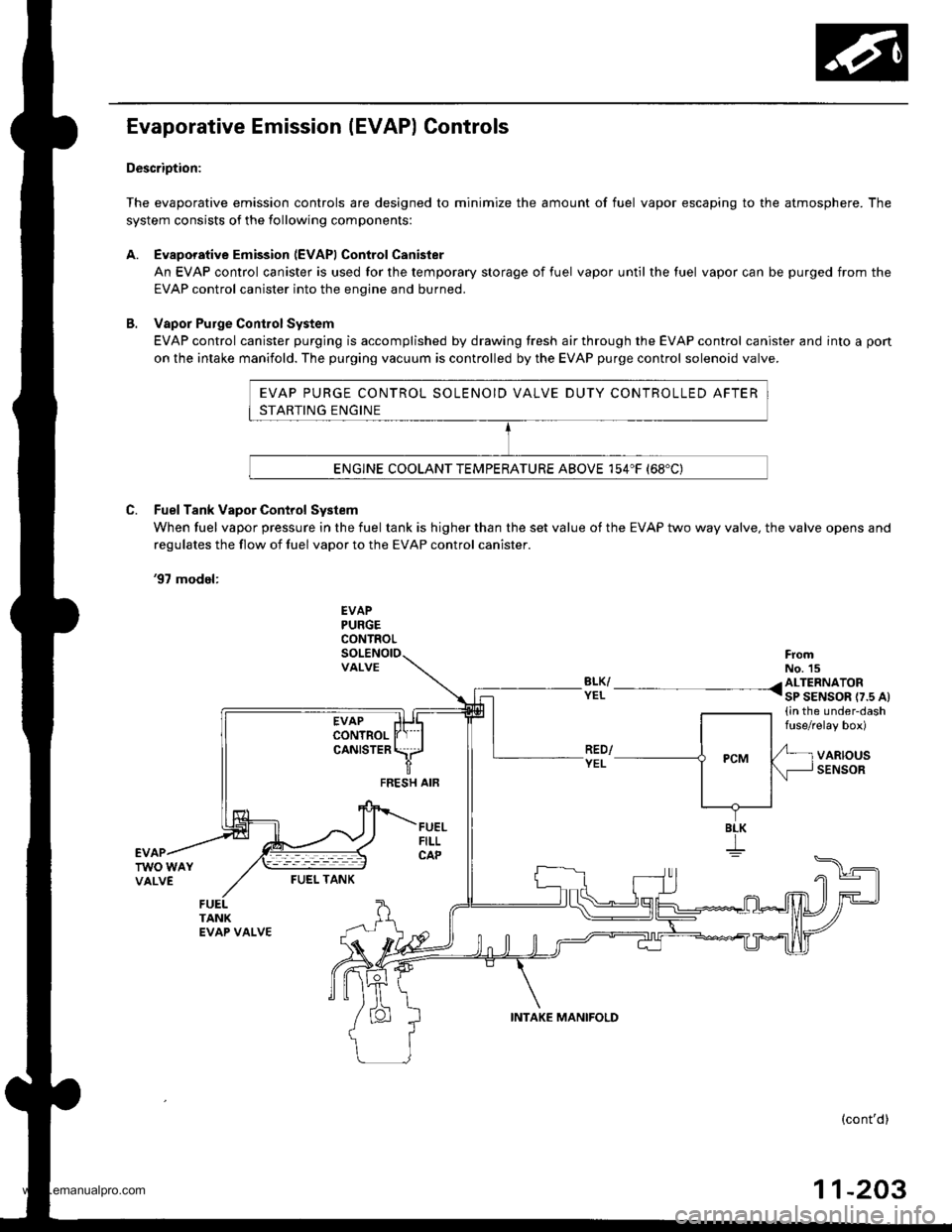

EVAP PURGE CONTROL SOLENOID VALVE DUTY CONTROLLED AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154"F (68'C)

Evaporative Emission (EVAP) Controls

Description:

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAPI Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the luel vapor can be purged from the

EVAP control canister into the enqine and burned.

B. Vapor Purge ConirolSystem

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a pon

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow ot fuel vapor to the EVAP control canister.

'97 model:

EVAPPURGECONTROL

VALVEFromNo. 15BLK/ /ALTERNATORYEL I sP SENSOR r7.s At(in the under-dashfuse/relay box)

VARIOUSSENSORFEESH AIF

BLK

I

FUEI- TANK

(cont'd)

11-203

INTAKE MANIFOLD

www.emanualpro.com

Page 406 of 1395

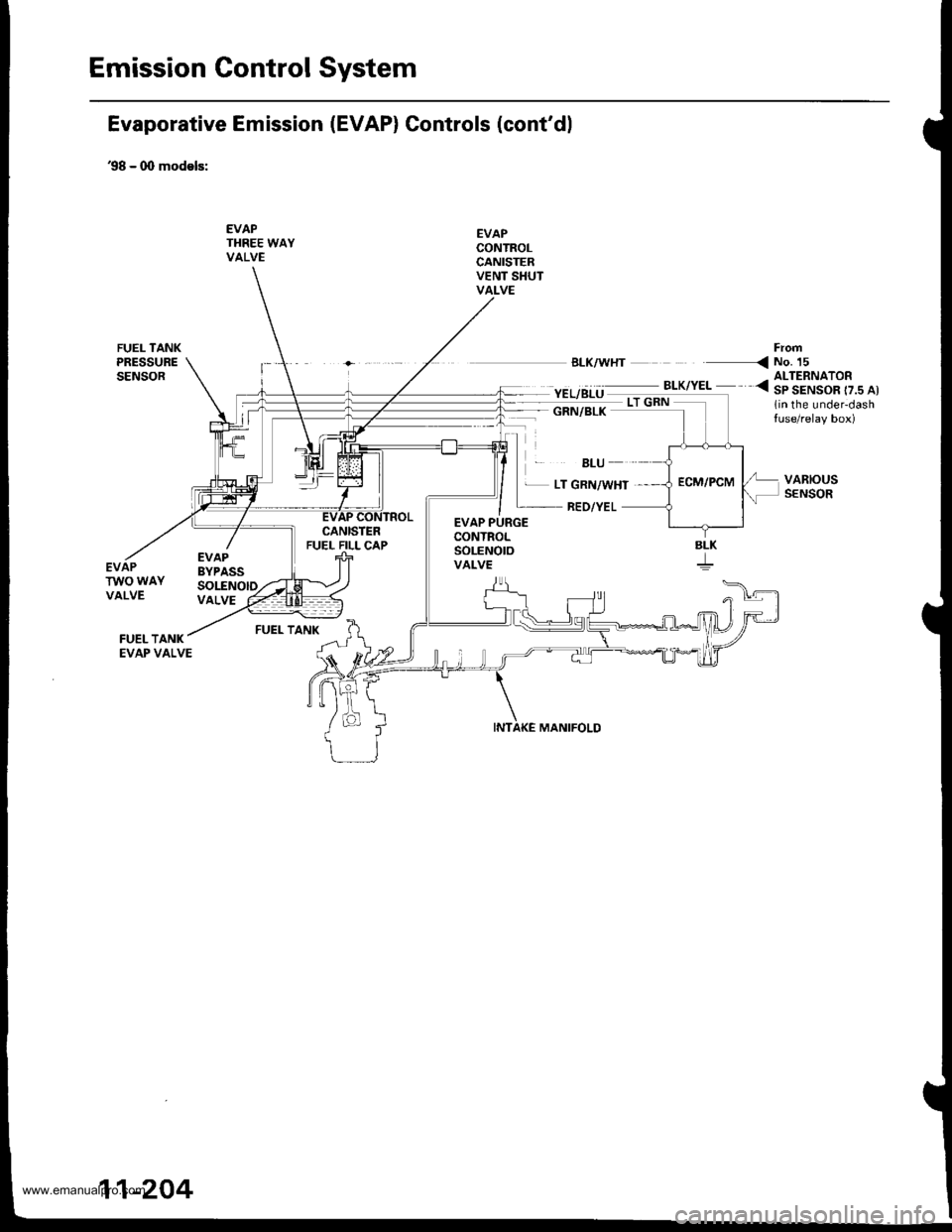

Emission Gontrol System

Evaporative Emission (EVAP) Controls (cont'dl

'98 - 0O models:

EVAPTHREE WAYVALVE

EVAPCONTROLCANISTERVENT SHUTVALVE

'EL/BLU ._^_-:.*,".. <3|ltAIS"o[..^,

1in the under-dashtuse/relay box)

FrofiBLK/WHT < NO. 15

GRN/BLK

BLU

EVAPBYPASSSOLENOID

EVAP PURGECONTROLSoLENOtOVALVE

L LT GRN/WHT ,

RED/YEL

MANIFOLD

VARIOUSSENSOR

EVAPTWO WAYVALVEVALVE

FUEL TANK

SLK

11-204

www.emanualpro.com

Page 407 of 1395

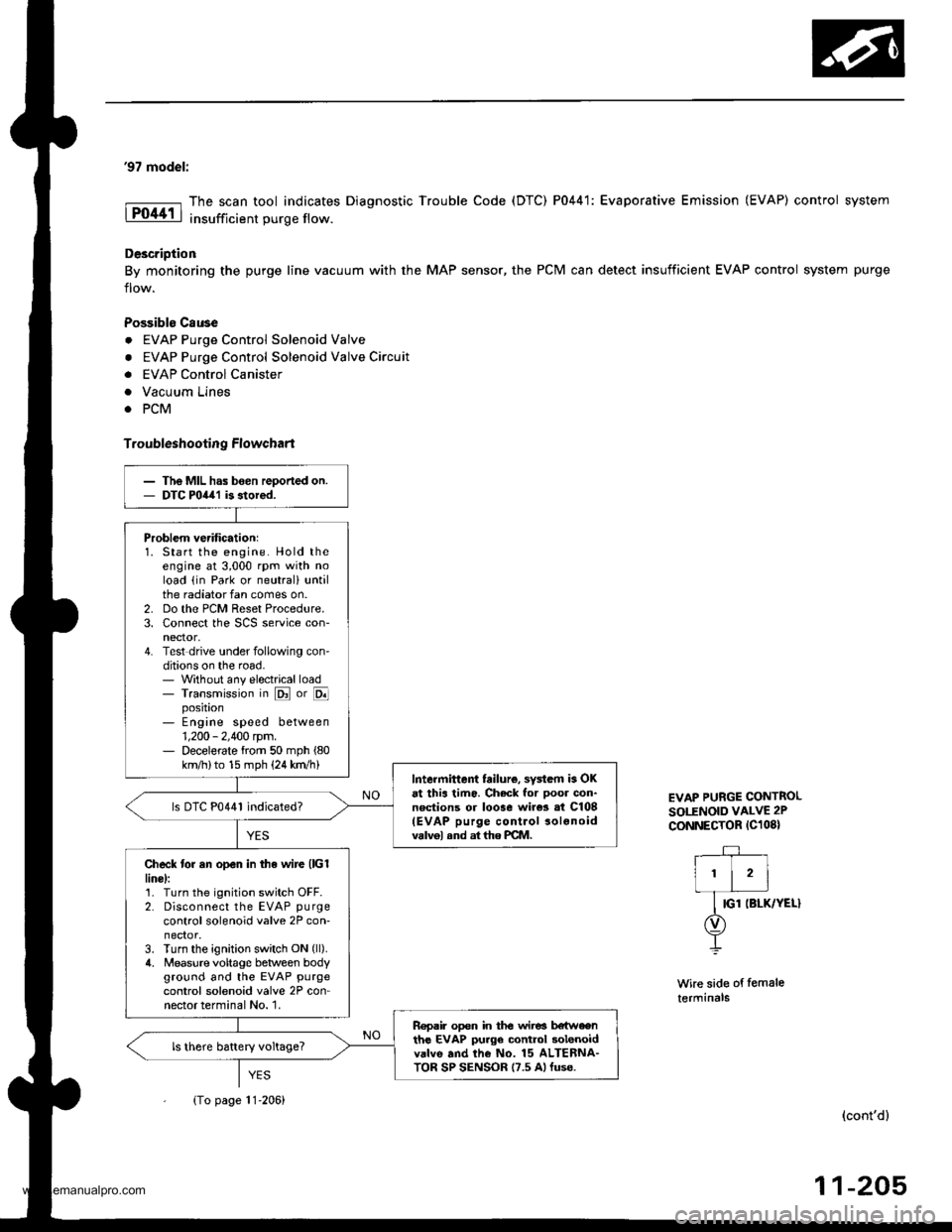

'97 model:

The scan tool indicates Diagnostic Trouble Code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the PCM can detect insufficient EVAP control system purge

flow.

Possiblo Cause

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. PCM

Troubleshooting Flowchart

EVAP PURGE CONTROL

SO1TNOID VALVE 2P

CoNNECTOR (C108)

(v)

YL

Wire side of female

termrnals

(cont'd)

11-205

Th€ MIL has b€en reooited on.DTC P0441 is .tored.

Problem verificationl1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neut.al) untilthe radiator fan comes on.2. Do the PCM Reset Procedure.3. Connect the SCS service con-nector,4. Test drive under following con'ditions on the road.- without any electrical load- Transmission in @ or @position- Engine speed between1 ,2OO - 2,4OO rpfi.- Decelerate from 50 mph (80

km/h)to 15 mph (24 km/h)Intermittent trilure, sydern is OKat this time. Check for Door con-nections or loose wir€3 at C108

IEVAP purge control solonoidvalvol .nd at the PCM.

ls DTC P0441 indicated?

Check tor an open in the wire (lcl

linel:1. Turn the ignition switch OFF.2. Disconnect the EVAP purge

control solenoid valve 2P con-nector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the EVAP purge

control solenoid valve 2P con-nector terminal No. '1,

R€pafu open in thc wir6 b€tw€enthG EVAP purge control solenoidvalve and the No. 15 ALTEBNA-TOR SP SENSOR (7.5 A)fuse.

ls there batlery voltage?

(To page 11'206)

www.emanualpro.com

Page 410 of 1395

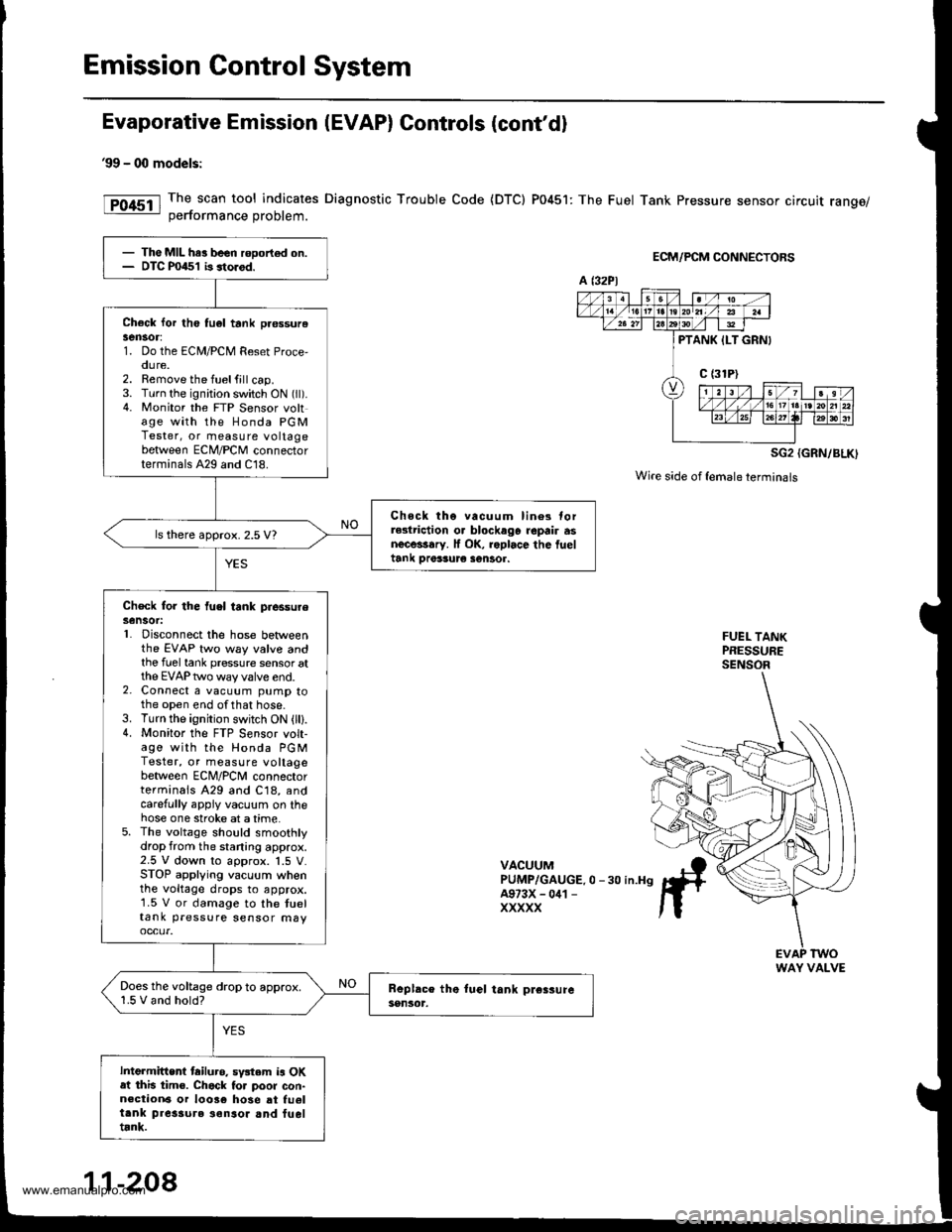

Emission Control System

Evaporative Emission (EVAP) Controls (cont'd)

99 - 00 models:

The scan tool indicates Diagnostic Trouble Code {DTC) P0451: The Fuel Tank Pressure sensor circuit range/oerformance Droblem.

ECM/PCM CONNECTORS

SG2 {GRN/BLK)

Wire side of {emaleterminals

FUEL TANKPRESSURESENSOR

VACUUMPUMP/GAUGE.0 -30 in.H9A973X - 041 -

XXXXX

- The MIL har been rooort€d on.- DTC P0451 b storod.

Check lor th6 tu6l tank pr€ssurelen30r:1. Do the ECM/PCM Reset Proce,oure.2. Remove the fuelfill cap.3. Turn the ignition switch ON (ll).4. Monitor the FTP Sensor voltage with the Honda PGMTester, or measure voltagebetween ECM/PCM connectorterminals A29 and C18.

Chock tho vacuum lin6s torrGlriction o. blockago repair asnecessary. lf OK, roplace the fueltank Drer3ur€ sentor.

ls there approx. 2.5 V?

Check for the fuel tank piessureSensot:L Disconnect the hose betweenthe EVAP two way valve andthe fuel tank pressure sensor atthe EVAP two way valve end.2. Connect a vacuum pump tothe open end ofthat hose.3. Turn the ignition switch ON (lll.4. Monitor the FTP S€nsor volt-age with the Honda PGMTester, or measure voltagebetween ECNI/PCNI connectorterminals A29 and C18, andcarefully appiy vacuum on thehose one stroke at a time.5. The voltage should smoothlydrop from the staning approx.2.5 V down to approx. 1.5 V.STOP applying vacuum whenthe voltage drops to approx.1.5 V or damage to the tueltank pressure sensor may

Does the voltage drop to approx.1.5 V and hold?

Intermittent tailuro. sv3tem is OKat this tim€. Chack to. poor con-n€ction6 or 10036 hose at fu6ltank pres3ure ionsor and fueltrnk.

a t32Pl

PTANK ILT GRNI

WAY VALVE

11-208

www.emanualpro.com

Page 411 of 1395

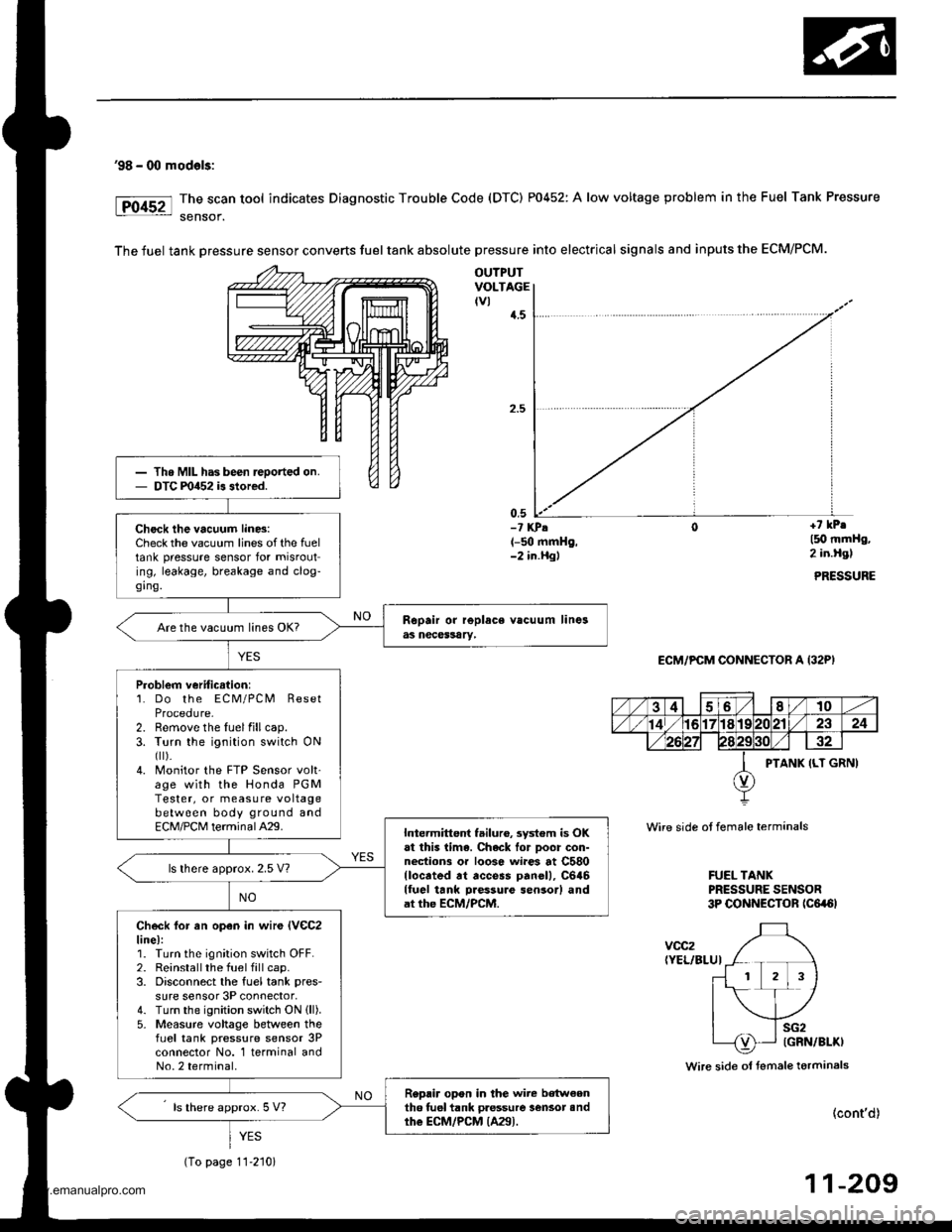

'98 - 00 mod€ls:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensof.

The fuel tank Dressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM.

OUTPUTVOLTAGEtvl{.5

0,5-? KPA(-50 mmHg,-2 in.Hgl

+7 kPr

l5O mmHg,2 in.Hgl

PRESSURE

ECM/PCM CONNECTOR A (32P)

Wire side ot female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR tc6a6l

voc2(YEL/BLUI

Wire side ol fsmale terminals

(cont'd)

11-209

Th. MIL has been reoorted on.DTC m452 is stored.

Check the vacuum lin6:Check the vacuum lines of the fueltank pressure sensor for misrouting, leakage, breakage and clog-ging.

Are the vacuum lines OK?

Problem veriticstion:1. Do the ECM/PCM ResetProcedure-2. Remove the luelfillcap.3. Turn the ignition switch ONfl r).4. Monitor the FTP Sensor volt'age with the Honda PGMTester, or measure voltagebetween body ground andECM/PCM terminalA29.Intermittent failuro, system is OKat this lima. Chack lor Door con-nections or loose wi.es at C580llocrted rt access panell, C646lluel tank Daessure sensor) andat the ECM/PCM.

ls lhere approx. 2.5 V?

Check lor an open in wir€ lVeC2line):1. Turn the ignition switch OFF.2. Reinstallthe fuel fill cap.3. Disconnect the fuel tank pres-

sure sensor 3P connector,4. Turn the ignition switch ON (ll).

5- Measure voltage between thefLrel tank pressure sensor 3Pconnector No. 1 terminal andNo.2 terminal.

Replir opon in the wire b€tw€enth6 tuel tank pressure lensot andthe ECM/PCM {A29).ls there approx. 5 V?

YES

(To page 11-210)

www.emanualpro.com

Page 412 of 1395

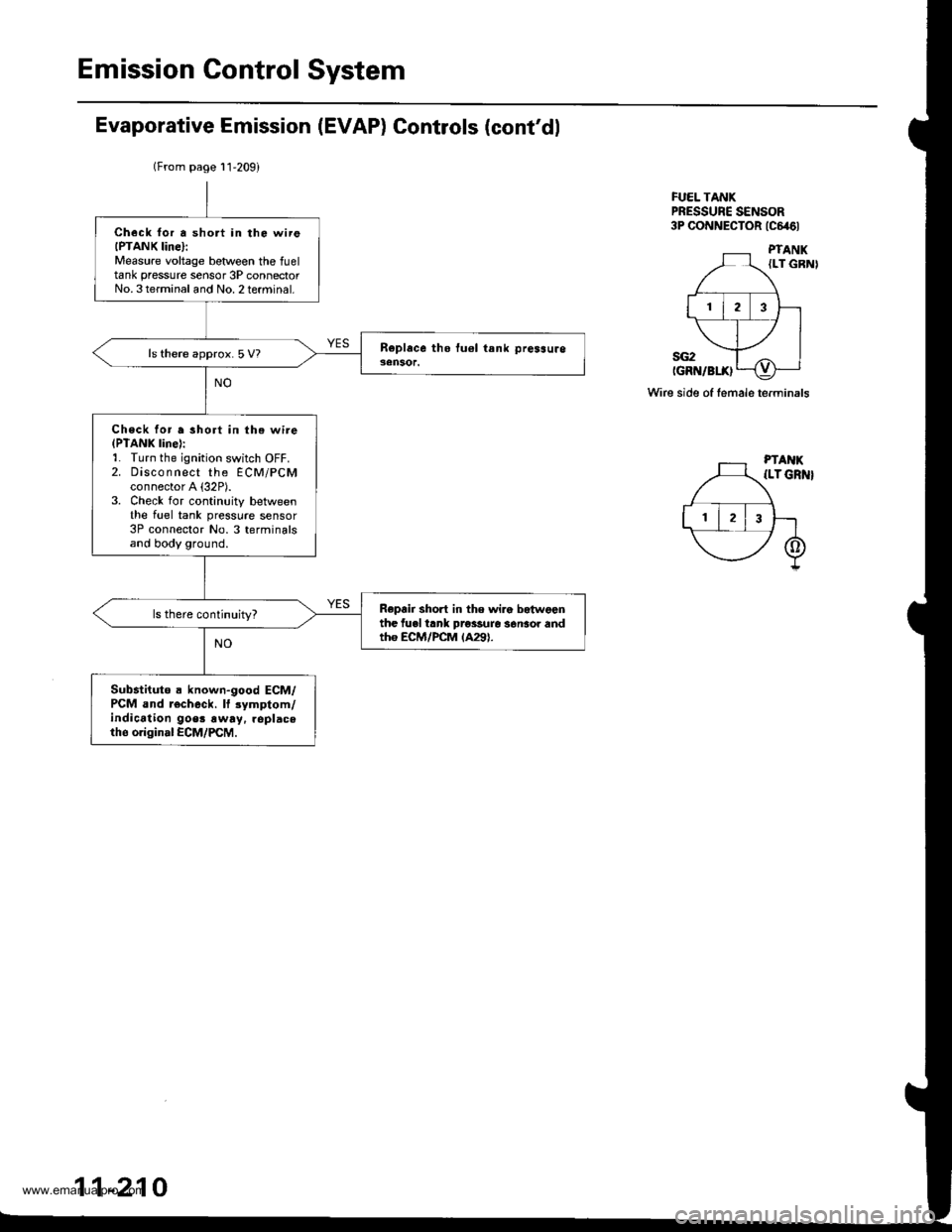

Emission Control System

Evaporative Emission (EVAP) Controls (cont'dl

FUEL TANKPRESSUNE SENSOR3P CONNECTOR tc646l

Wire side of female terminals

(From page l1'209)

Check lor a short in the wireIPTANK Iine}:Measure voltage betlveen the fueltank pressure sensor 3P connectorNo. 3terminal and No. 2terminal.

ls there approx.5 V?

Check for a short in the wire(PTANK line):1. Turn the ignition switch OFF.2. Disco n nect the ECM/PCMconnector A {32P).3. Check for continuity betweenthe fuel tank pressure sensor3P connector No. 3 terminalsand body ground.

Repair short in the wira betwgonthe fuel trnk prossure s6nsor andtho ECM/PCM lA29).

Sub.tituto a known-good ECM/PCM and r€check. lf 3ymptom/indication goer !way. replaceth6 original ECM/PCM.

11-210

www.emanualpro.com