Transmission assembly HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 770 of 1395

Transmission

28.

Reassembly (cont'd)

PARX GEAR

ONE.WAY CLUTCH

BEARING

Install the mainshaft speed ssnsor (with new O-ring) on the transmission housing.

Install the park lever on the control shaft, theninstall the lock bolt with a new lock washer. Do notbend the lock tab of the lock washer in this step;bend it after checking the park pawl engagement instep 45.

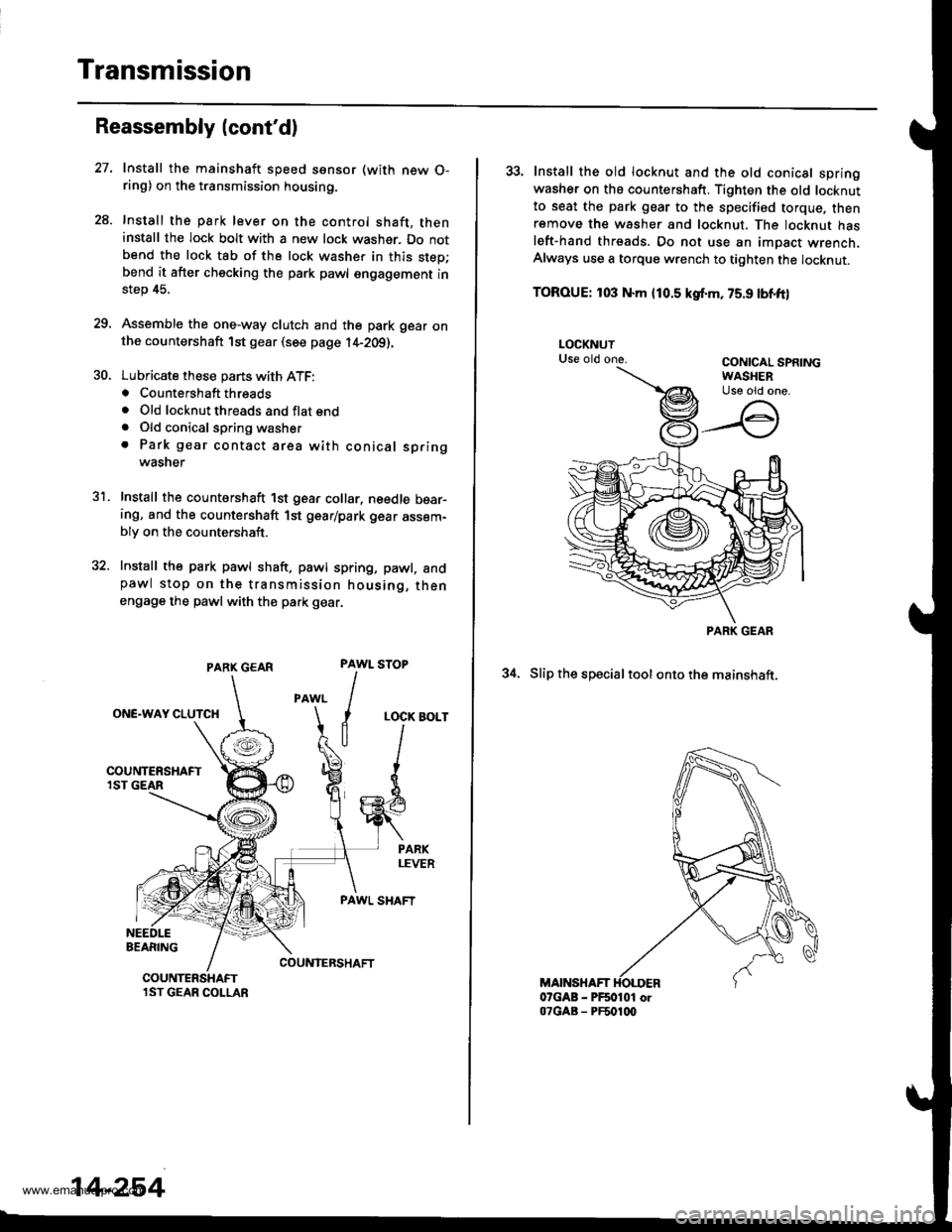

Assemble the one-way clutch and the park gear onthe countershaft 1st gear (see page l4-2Og).

Lubricate these pans with ATF:. Countershaft threads. Old locknut threads and flat end. Old conical spring washer. Park gear contact area with conical springwasner

Install the countershaft 1st gear collar, needle bear-ing, and the countershaft 1st gear/park gear assem-bly on the countershaft.

Install the park pawl shaft. pawl spring, pawl. andpawl stop on the transmission housing, thenengage the pawl with th€ park gear.

31.

PAWL

I

I

a

STOP

LOCK BOLT

PAWL SHAFT

COUNIERSHAFTCOUNTERSHAFTlST GEAR COLLAR

14-254

33. Install the old locknut and the old conical springwasher on ths countershaft. Tighten the old locknutto seat the park gear to the specified torque, thenremove th€ washer and locknut. The locknut hasleft-hand threads. Do not use an impact wrench.Always use a torque wrench to tighten the locknut.

TOROUE: 103 N.m {10.5 kgf.m, 75.9 lbnft)

34. Slip the specialtool ontothe mainshaft.

MAINSHAFT07GAB - PF50101 or07GAB - PF501q)

PARK GEAR

www.emanualpro.com

Page 772 of 1395

Transmission

Reassembly lcont'd)

44.

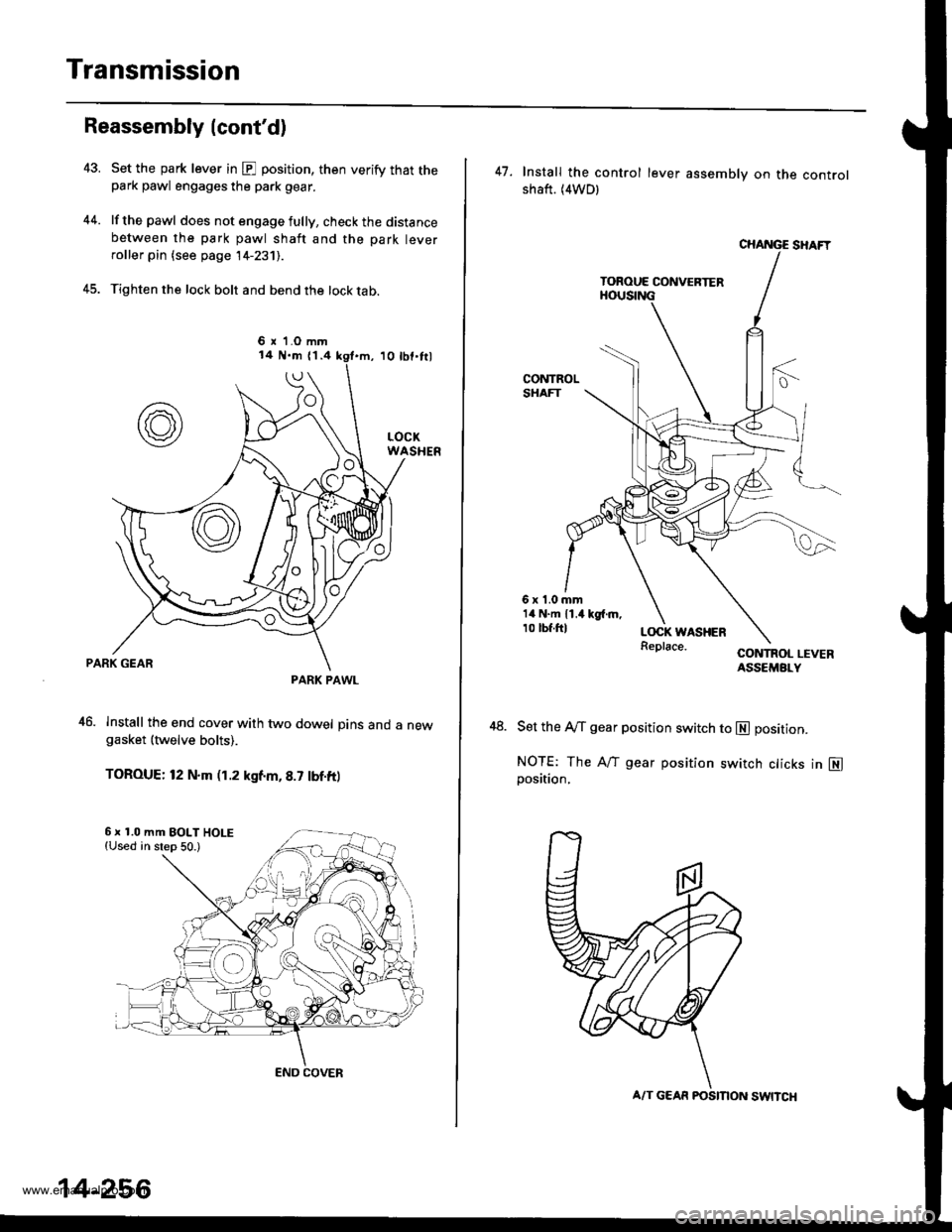

Set the park lever in @ position, then verify that thepark pawl engages the park gear.

lf the pawl does not engage fully, check the distancebetween the park pawl shaft and the park leverroller pin (see page 14-231).

Tighten the lock bolt and bend the lock tab.

1o tbf'frl

PARK GEAR

46. Install the end cover with two dowel pins and a newgasket {twelve bolts).

TOROUE: 12 N.m (1.2 kgf.m, 8.7 tbf.ft)

6 r 1.O mm

PARK PAWL

6 x 1.0 mm EOLT HOLE{Used in step 50.)

END COVER

14-256

A/T GEAR FOSMON SWNCH

47. Install the control lever assemblv on the controlshaft. (4WDl

6x1.0mm14 N.m 11.4 kg{.m,10 tbf.ftl

48.

CONTROL LEVERASSEMBLY

Set the A/f gear position switch to E] position.

NOTE: The Aff gear position switch cticks in N]position,

www.emanualpro.com

Page 773 of 1395

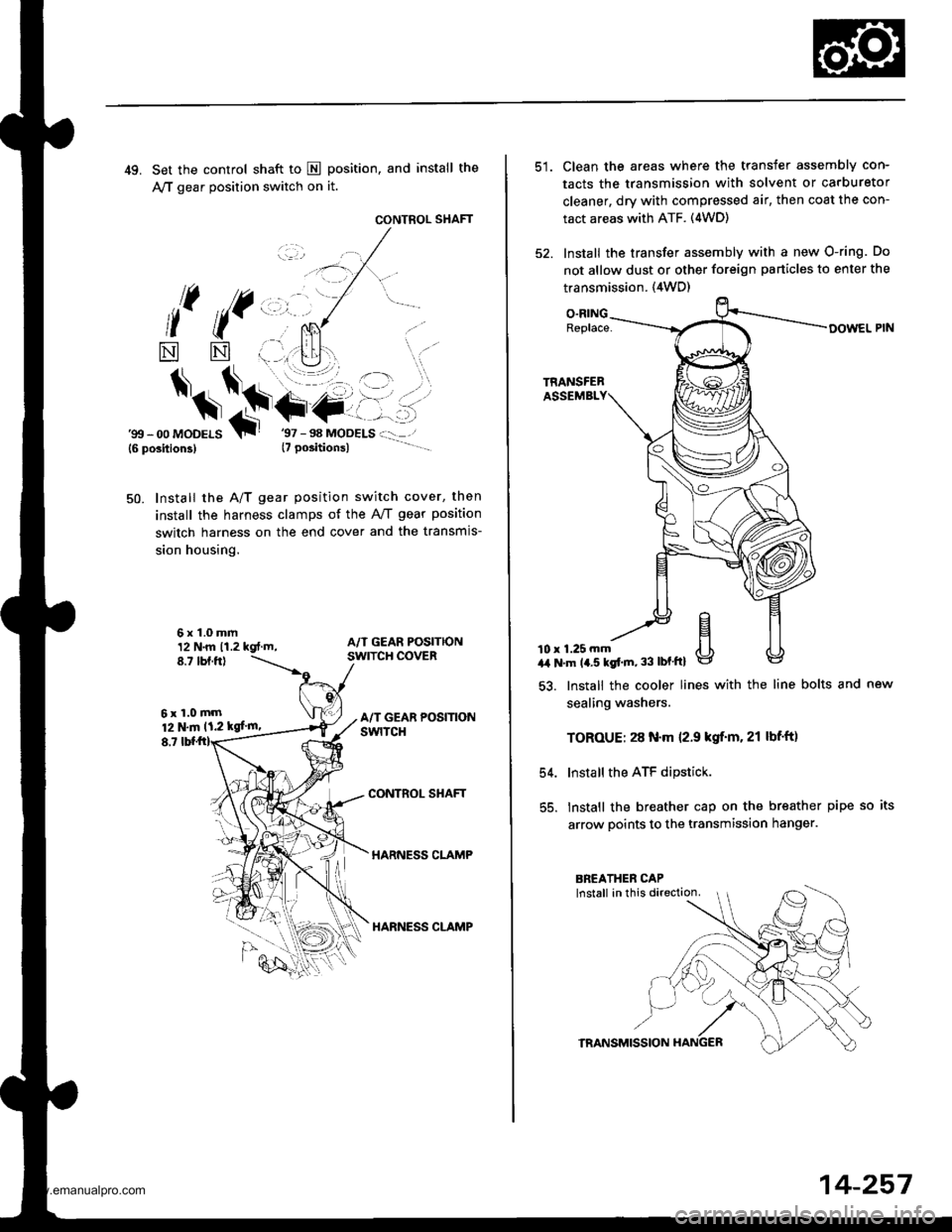

49. Set the control shaft to E position, and install the

A,/T gear position switch on it.

CONTROL SHAFT

l( ((,,, ,.

*

$*\.t+-

NN

6x1.0mm12 N.m 11.2 kgt.m,8.7 tbf.ftl

6xl.0mm12 N.m 11.2 kgf'm,

8,7

'gtt - 00 MoDELS{6 position3}T

Install the A/T gear position switch cover, then

install the harness clamps of the AviT gear position

switch harness on the end cover and the transmis-

sion housing.

50.

CONTROL SHAFT

HARNESS CLAMP

HARNESS CLAMP

Clean the areas where the transfer assembly con-

tacts the transmission with solvent or carburetor

cleaner, dry with compressed air, then coat the con-

tact areas with ATF. (4WD)

Install the transfer assembly with a new O-ring. Do

not allow dust or other foreign particles to enter the

transmission. {4WD)

O.RINGReplace-

10 r 1.25 mma,a N'm 14.5 kgt'm, 33 lbf'ftl

54.

55.

lnstall the cooler lines with the line bolts and new

sealing washers.

TOROUE: 28 N.m 12.9 kgif'm. 21 lbf'ft)

Install the ATF dipstick.

lnstall the breather cap on the breather pipe so its

arrow points to the transmission hanger.

TRANSMISSION

14-257

www.emanualpro.com

Page 775 of 1395

Transmission

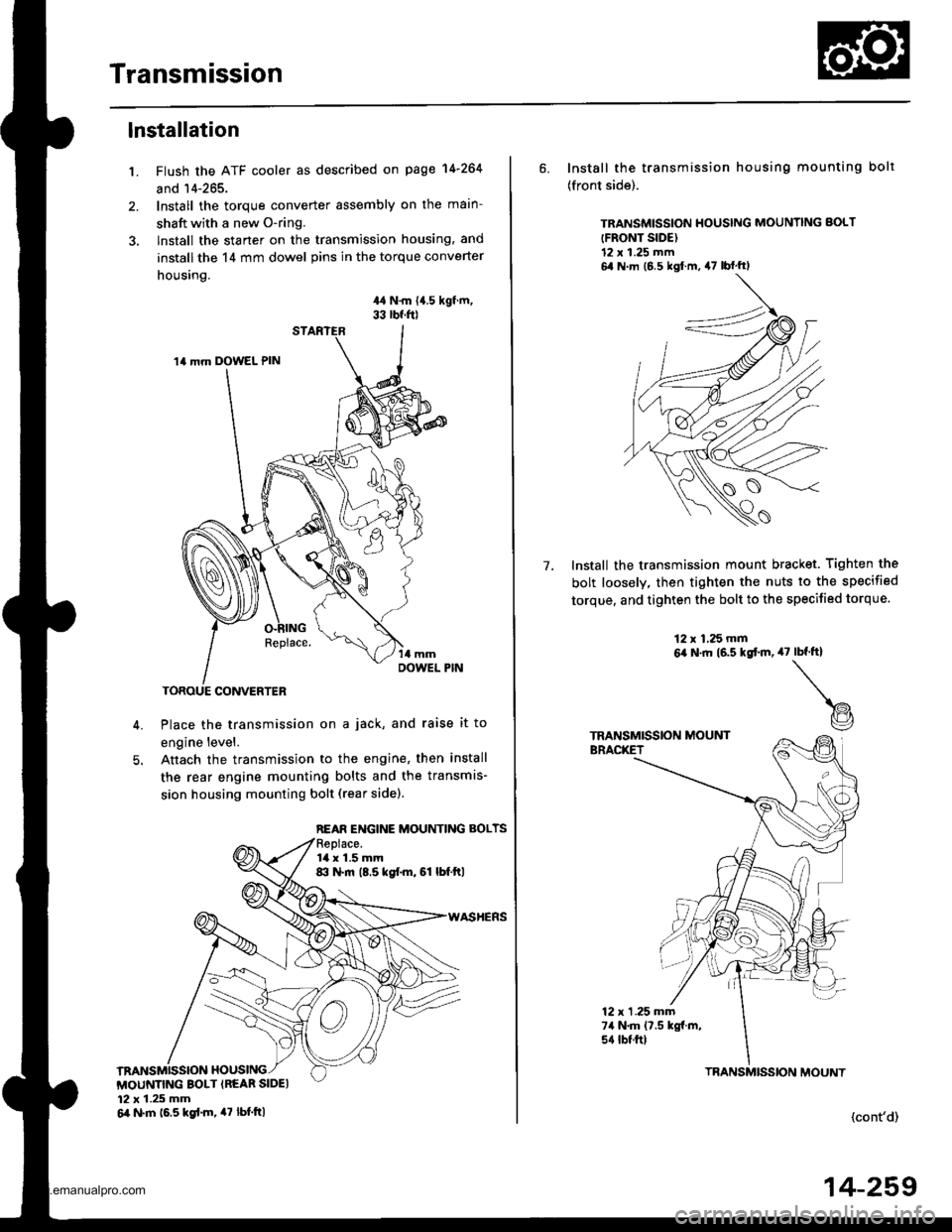

1.

lnstallation

Flush the ATF cooler as described on page 14-264

and 14-265.

Install the torque converter assembly on the main-

shaft with a new O-ring.

lnstall the starter on the transmission housing, and

install the 14 mm dowel pins in the torque converter

housing.

44 N.m {{.5 kgf.m,33 rbf.f0

Place the transmission on a jack, and raise it to

engine level.

Anach the transmission to the engine, then install

the rear engine mounting bolts and the transmis-

sion housing mounting bolt (rear sidel.

14 mm DOWEL PIN

REAR ENGINE MOUNTING BOLTS

la x 1.5 mm8:l N.m (8.5 kgf.m, 61 lbf.ftl

MOUNTING BOLT {REAR SIDEI12 x 1.25 mm6il N.m 16.5 kgd.m, 47 tbt.ttl

6. Install the transmission housing mounting bolt

(front side).

TRANSMISSION HOUSING MOUNNNG BOLT

{FRONT SIDE)12 x 1.25 mm6,1 N m (6 5 kgl m, 47 lbf'ftl

Install the transmission mount bracket. Tighten the

bolt loosely, then tighten the nuts to the specified

torque, and tighten the bolt to the specified torque.

7.

12 x 1,25 mm6,a N.ft (6.5 kgtm,47rbf.ft)

t@

TRANSMISSION MOUNTBRACKET

12 x 1 .25 mm74 N.m (7.5 kgf.m,s{ tbtftl

(cont'd)

TBANSMISSION MOUNT

14-259

www.emanualpro.com

Page 777 of 1395

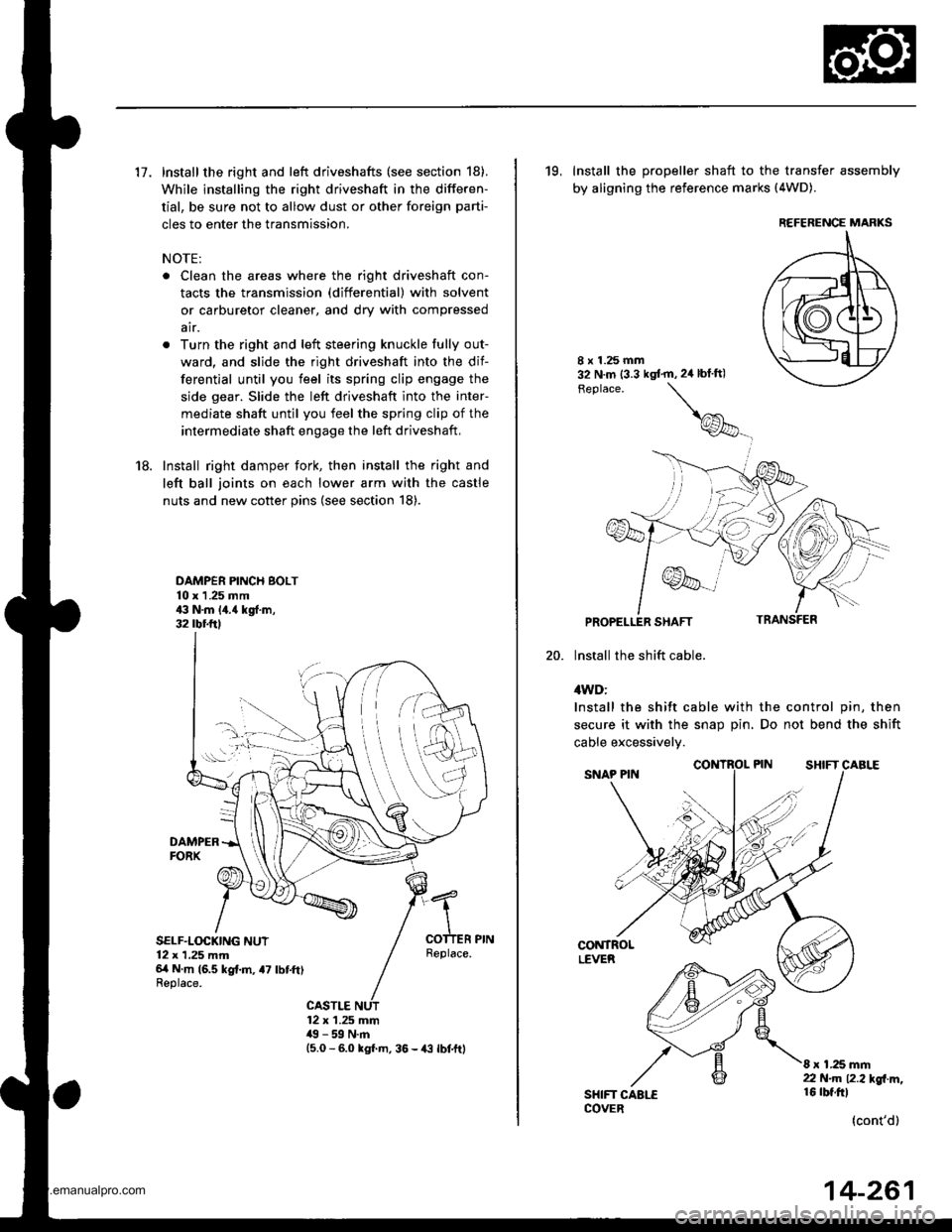

17. Install the right and left driveshafts (see section 18).

While installing the right driveshaft in the differen-

tial, be sure not to allow dust or other foreign parti-

cles to enter the transmission.

NOTE:

. Clean the areas where the right driveshaft con-

tacts the transmission (differential) with solvent

or carburetor cleaner, and dry with compressed

air.

. Turn the right and left steering knuckle fully out-

ward, and slide the right driveshaft into the dif-

ferential until you feel its spring clip engage the

side gear. Slide the left driveshaft into the inter-

mediate shaft until you feel the spring clip of the

intermediate shaft engage the left driveshaft,

18. Install right damper fork, then install the right and

left ball joints on each lower arm with the castle

nuts and new cotter pins (see section 18).

DAMPER PINCH BOLT10 x 1 .25 mm43 N.m 14.{ kgf.m,32 rbr.ftl

DAMPERFORX

SELF.LOCKING NUT12 x 1,25 mm6/t N m (6.5 kg{.m, a7 lbtft)Replace.

Replace.

CASTLE12 x 1.25 mm49 - 59 N.m15.0 - 6.0 kgl m, 36 - {3 lbtftl

19, Install the propeller shaft to the transfer assembly

by aligning the reference marks (4WD).

20.

8 x 1.25 mm32 N.m (3.3 kgt'm,2ir blft)

Feplace.

\

@_

PROPELLER SHAFT

lnstall the shift cable.

4WD:

Install the shift cable with the control pin, then

secure it with the snap Din. Do not bend the shift

cable excessivelv.

CONTROLLEVER

SHIFT CAALECOVER

8 x 1.25 mm22 N.m 12.2l'gl m,16 rbt.ftl

(cont'd)

REFERENCE MARKS

14-261

www.emanualpro.com

Page 779 of 1395

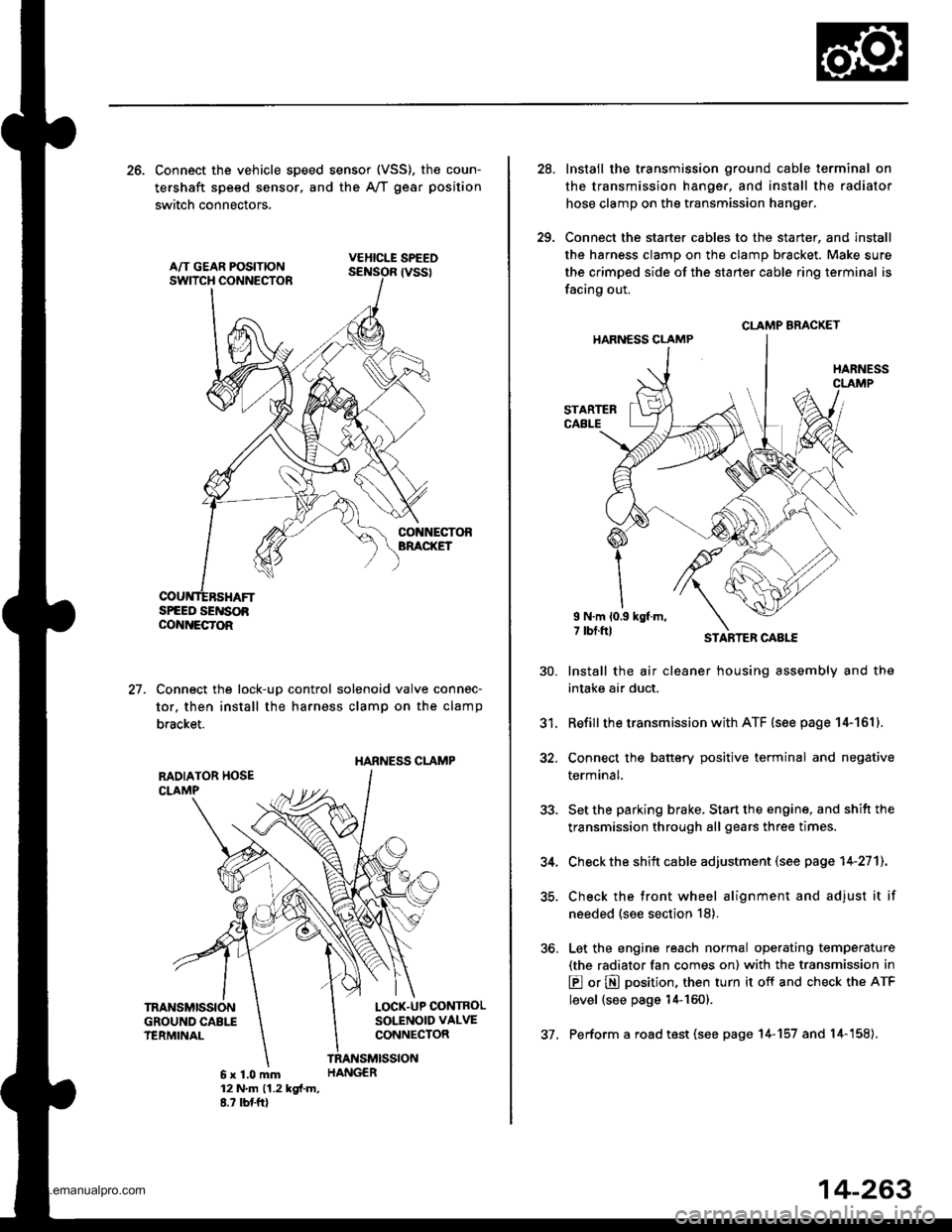

26. Connect the vehicle speed sensor (VSS). the coun-

tershaft speed sensor. and the A,/T gear position

switch connectors,

VEHICLE SPEEO

SPEED SENSOACO'{NECTOR

Connect the lock-up control solenoid valve connec-

tor, then install the harness clamp on the clamp

bracket.

HARNESS CI-AMP

27.

RADIATOR HOSECLAMP

TRANSMISSIONGROUND CAB1ITERMINAL

LOCK-UP OONTROLSOLENOID VALVECONNECTOR

6x1.0mm12 N'm (1.2 kgi.m,8.? tbtftl

28.

29.

Instail the transmission ground cable terminal on

the transmission hanger, and install the radiator

hose clamp on the transmission hanger,

Connect the starter cables to the starter, and install

the harness clamD on the clamD bracket. Make sure

the crimped side of the starter cable ring terminal is

facing out.

STARTEBCABLE

STARTER CAAtf,

Install the air cleaner housing assembly and the

intake air duct.

Refill the transmission with ATF (see page 14-161).

Connect the battery positive terminal and negative

terminal.

Set the parking brake, Start the engine, and shift the

transmission through all gears three times.

Check the shift cable adjustment (see page 14-271]-.

Check the tront wheel alignment and adjust it if

needed (see section 18).

Let the engine reach normal operating temperature

(the radiator fan comes on) with the transmission in

E or N position, then turn it off and check the ATF

level {see page 14-160).

Perform a road test (see page 14-157 and 14-158).

30.

31.

34.

CLAMP BRACKET

37.

14-263

www.emanualpro.com

Page 806 of 1395

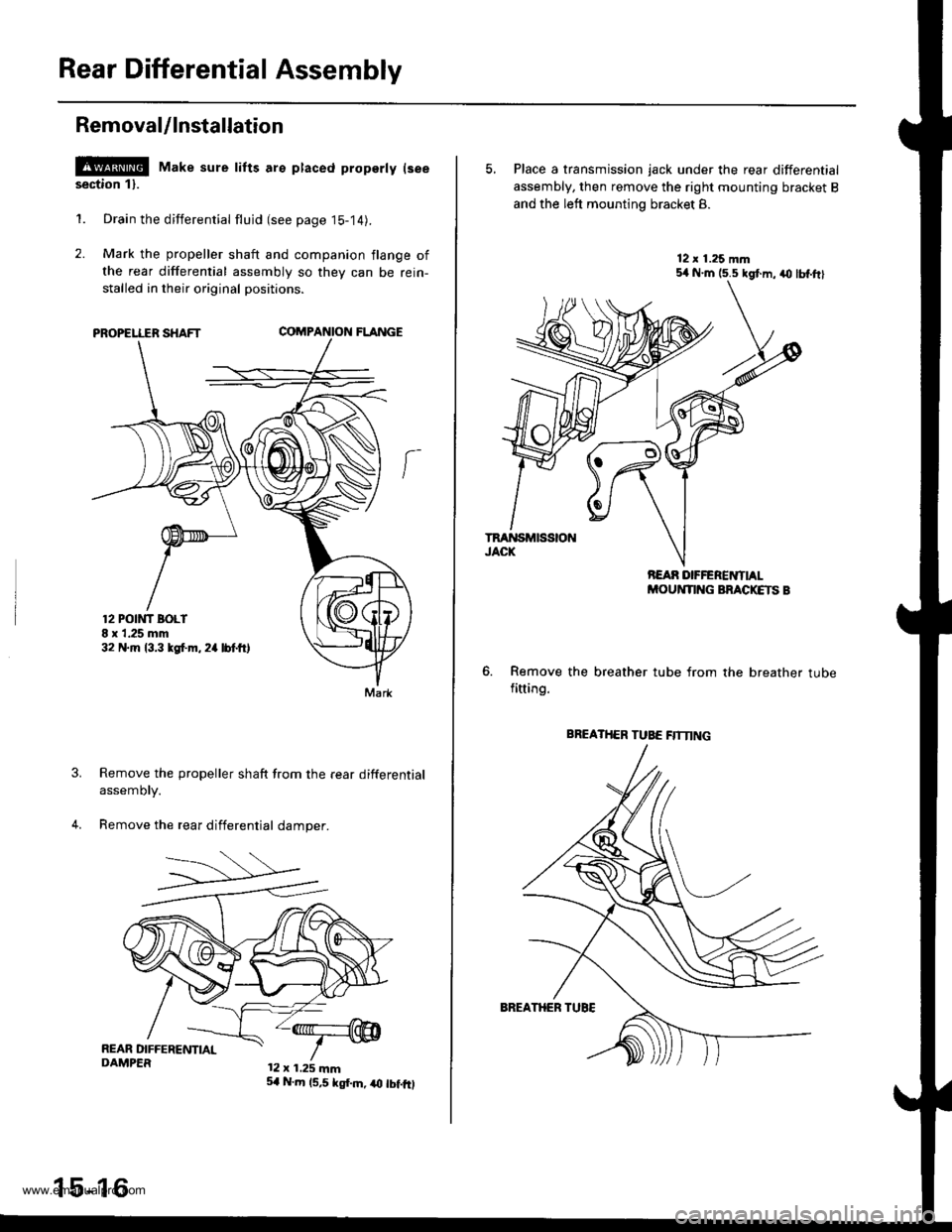

Rear Differential Assembly

Removal/lnstallation

l!!@ Make sure tifts are ptaced property lseesection 11.

1. Drain the differential flujd (see page 15-14).

2. Mark the propeller shaft and companion flange of

the rear differential assembly so they can be rein-

stalled in their original positions.

PROPELLER SHAFTCOMPA'{ION FLANGE

Remove the propeller shaft from the rear differential

assemory.

Remove the rear differential damper.

12 POtt'lT BOLI8 x 1.25 mm32 N.m 13.3 tgf.m. 2a lbtft,

Mark

12 x 1.25 mm

15-16

5,1 N.m 15,5 kgf.m, iO tbf.fO

5, Place a transmission jack under the rear differential

assembly, then remove the right mounting bracket B

and the left mounting bracket 8.

Remove the breather tube from the breather tubefitting.

BREATHER TUBE flTNNG

www.emanualpro.com

Page 836 of 1395

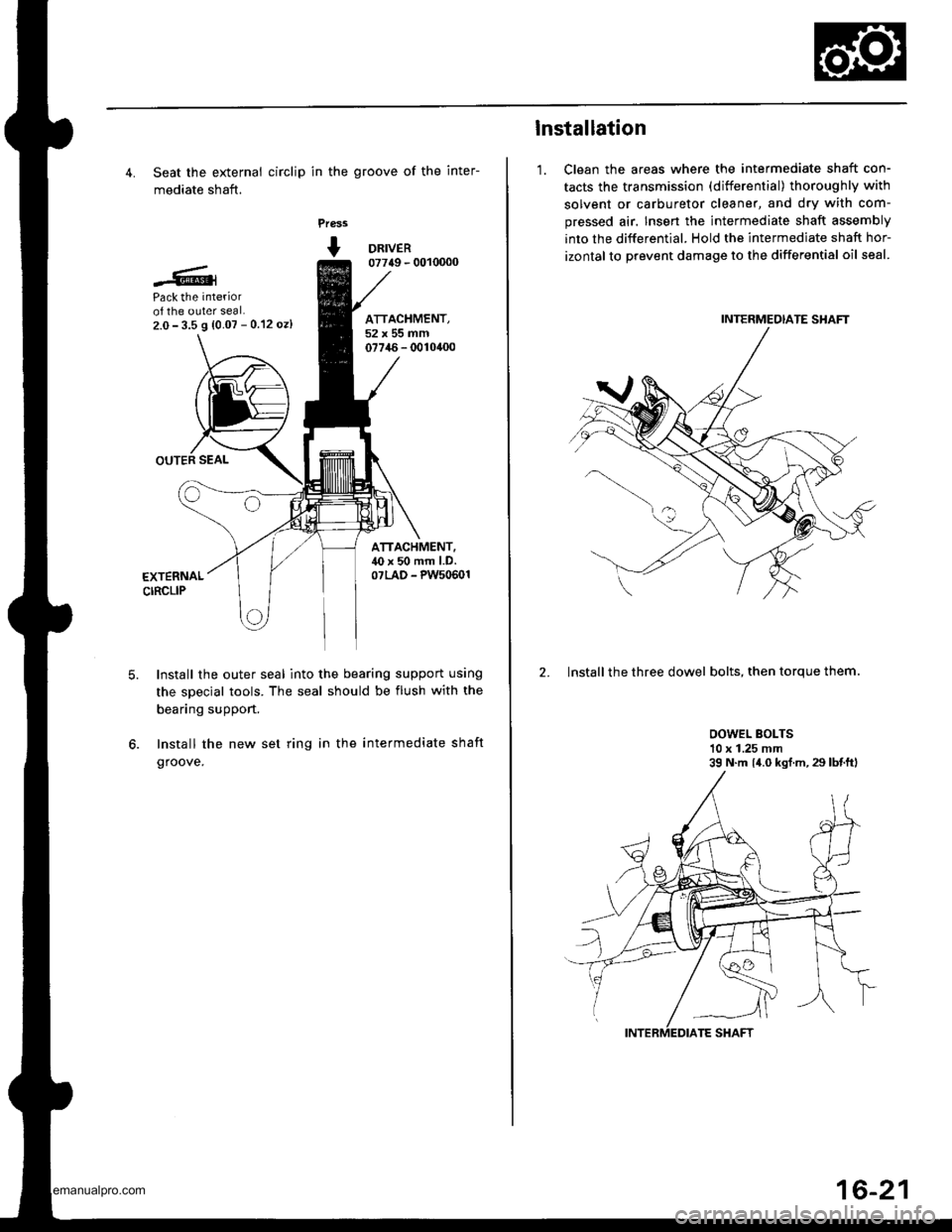

4. Seat the external circlip in the groove of the inter-

mediate shaft.

Press

+ DRNER07749 - 0010000

Pack the interiorof the outer seal.2.0- 3.5 9 {0.07 - 0.12 oz)

OUTER SEAL

ATTACHMENT,52x55mm07746- 0010400

ATTACHMENT.40 x 50 mm l.D.07LAD - PW50601EXTERNALCIRCLIP

6.

Install the outer seal into the bearing support using

the special tools. The seal should be flush with the

bearing support.

Install the new set ring in the intermediate shaft

groove.

lnstallation

1. Clean the areas where the intermediate shaft con-

tacts the transmission (differential) thoroughly with

solvent or carburetor cleaner, and dry with com-

pressed air. Insen the intermediate shaft assembly

into the differential. Hold the intermediate shaft hor-

izontal to prevent damage to the differential oil seal.

2. Install the three dowel bolts, then torque them.

OOWEL BOLTS10 x 1.25 mm39 N.m {4.0 kgf.m, 29 lbtftl

INTERMEOIATE SHAFT

16-21

www.emanualpro.com

Page 844 of 1395

Propeller Shaft

Inspection

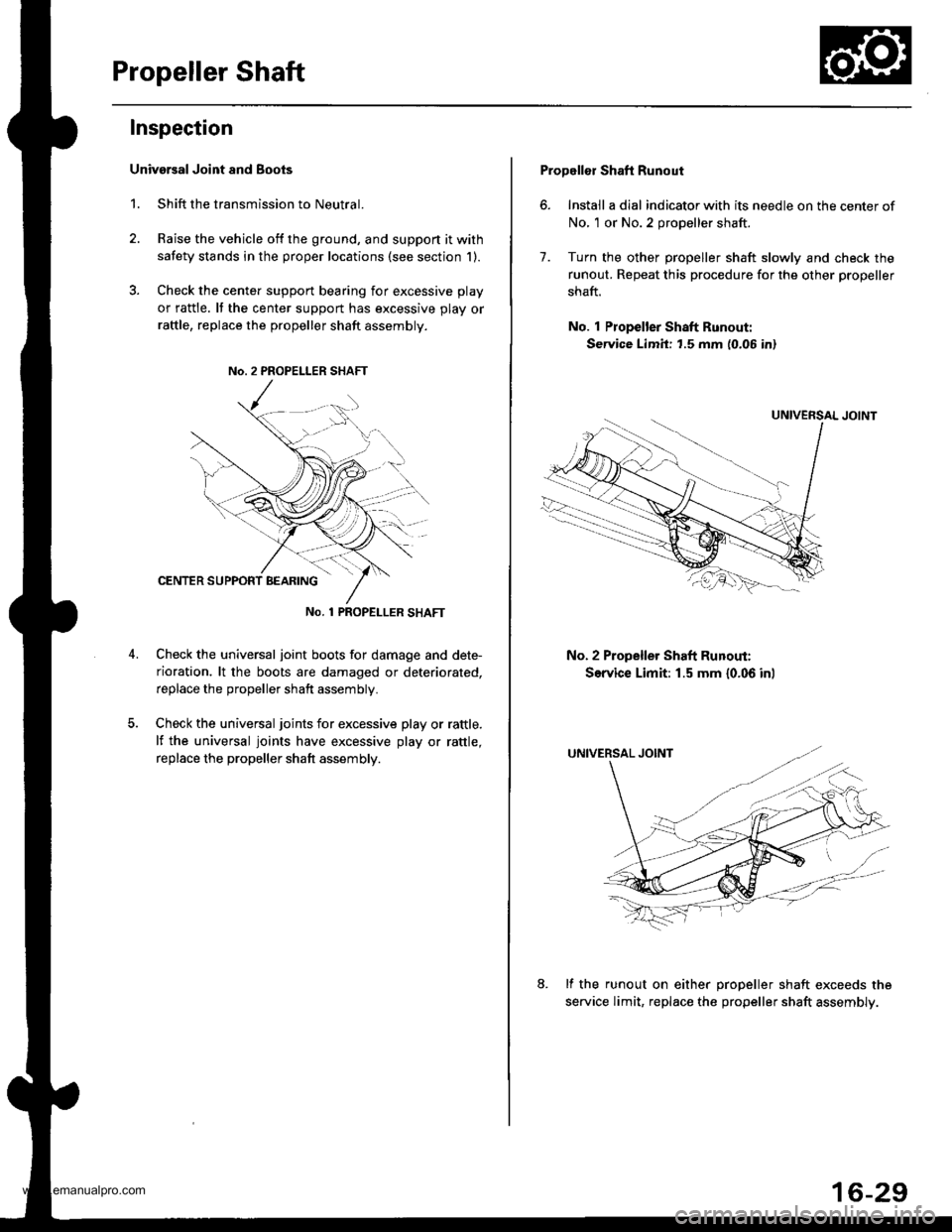

Univarsal Joint and Boots

1. Shift the transmission to Neutral.

2. Raise the vehicle off the ground, and support it with

safety stands in the proper locations (see section 1).

3. Check the cente. support bearing for excessive play

or rattle. It the center support has excessive play or

raftle, replace the propeller shaft assembly.

No. 1 PROPET_LER SHAFT

Check the universal joint boots for damage and dete-

rioration. lt the boots are damaged or deteriorated,

replace the propeller shaft assembly.

Check the universal joints for excessive play or rattle.

lf the universal joints have excessive play or rattle,

replace the propeller shaft assembly.

Propellor Shaft Runout

6. Install a dial indicator with its needle on the center of

No, 1 or No.2 propeller shaft.

7. Turn the other propeller shaft slowly and check the

runout. Repeat this procedure for the other propeller

shaft.

No. 1 Propeller Shaft Runout:

Service Limit: t.5 mm (0.06 in)

No. 2 Propeller Shaft Runout:

Service Limit: 1.5 mm {0.06 inl

lf the runout on either oroDeller shaft exceeds the

service limit, replac€ the propeller shaft assembly.

16-29

www.emanualpro.com

Page 876 of 1395

Power Steering Gearbox

Removal

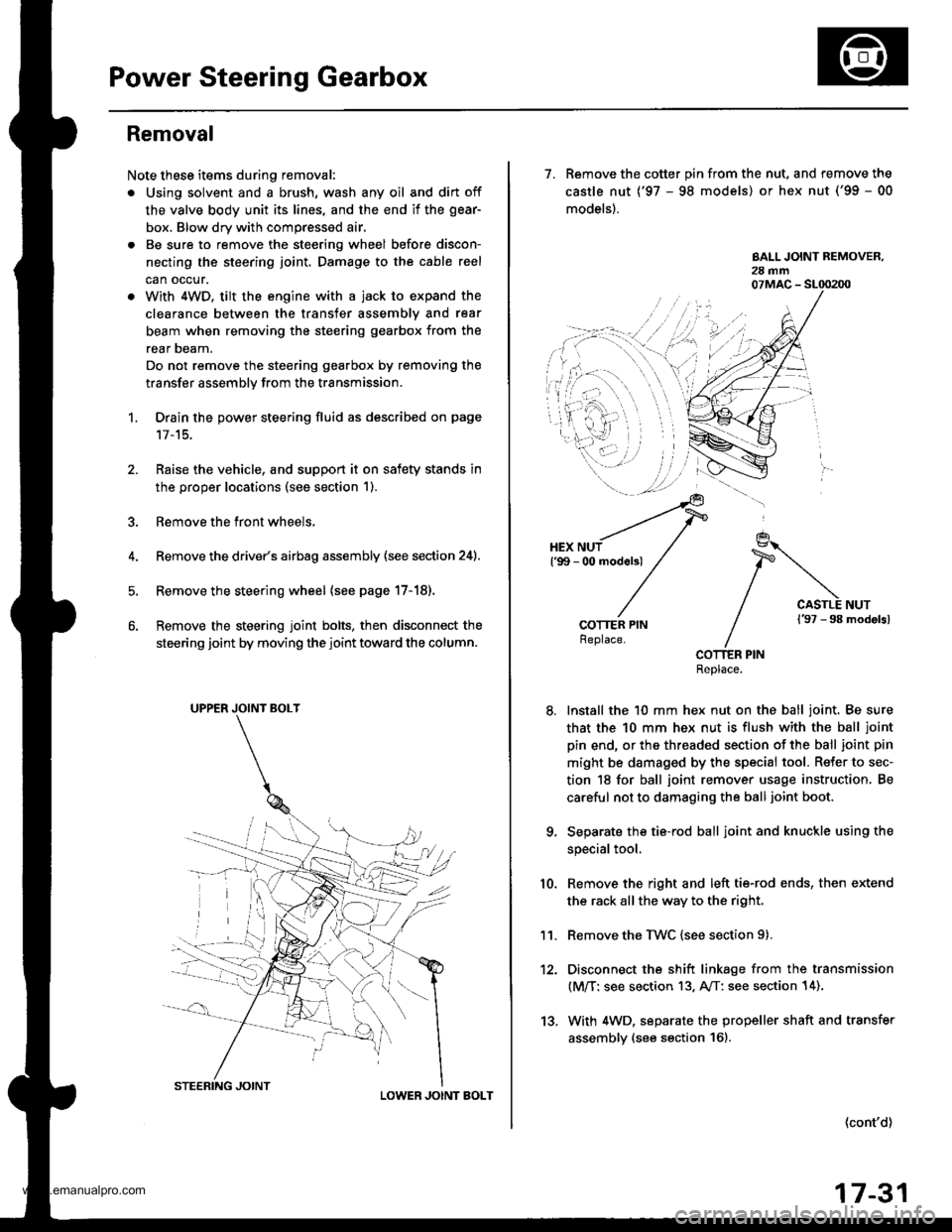

Note these items during removal:

. Using solvent and a brush, wash any oil and dirt off

the valve body unit its lines, and the end if the gear-

box. Blow dry with compressed air.

. Be sure to remove the steering wheel before discon-

necting the steering joint. Damage to the cable reel

can occur.

. With 4WD. tilt the engine with a jack to expand the

clearance between the transfer assembly and rear

beam when removing the steering gearbox from the

rear oeam.

Do not remove the steering gearbox by removing the

transfer assembly from the transmission.

1. Drain the power steering fluid as described on page'17-15.

Raise the vehicle, and suppon it on safety stands in

the proper locations (see section 1).

Remove the front wheels,

Remove the drive/s airbag assembly {see section 24).

Remove the steering wheel {see page 17-18).

Remove the steering joint bolts, then disconnect the

steering joint by moving the joint toward the column.

UPPER JOINT BOLT

LOWER JOINT BOLT

13.

7. Remove the cotter pin from the nut, and remove the

castle nut {'97 - 98 models) or hex nut ('99 - 00

models).

COTTER PINReplace.

Install the 10 mm hex nut on the ball joint. Be sure

that the 10 mm hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the special tool. Refer to sec-

tion 18 for ball joint remover usage instruction, Be

careful not to damaging the ball joint boot.

Separate the tie-rod ball joint and knuckle using the

special tool.

Remove the right and left tie-rod ends, then extend

the rack all the way to the right.

Remove the TWC (see section 9).

Disconnect the shift linkage from the transmission

(M/T: see section 13, A/T: see section 14).

With 4WD. separate the propeller shaft and transfer

assembly (see section 161.

10.

11.

(cont'd)

17-31

www.emanualpro.com