cv joint HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 902 of 1395

Wheel Alignment

Caster

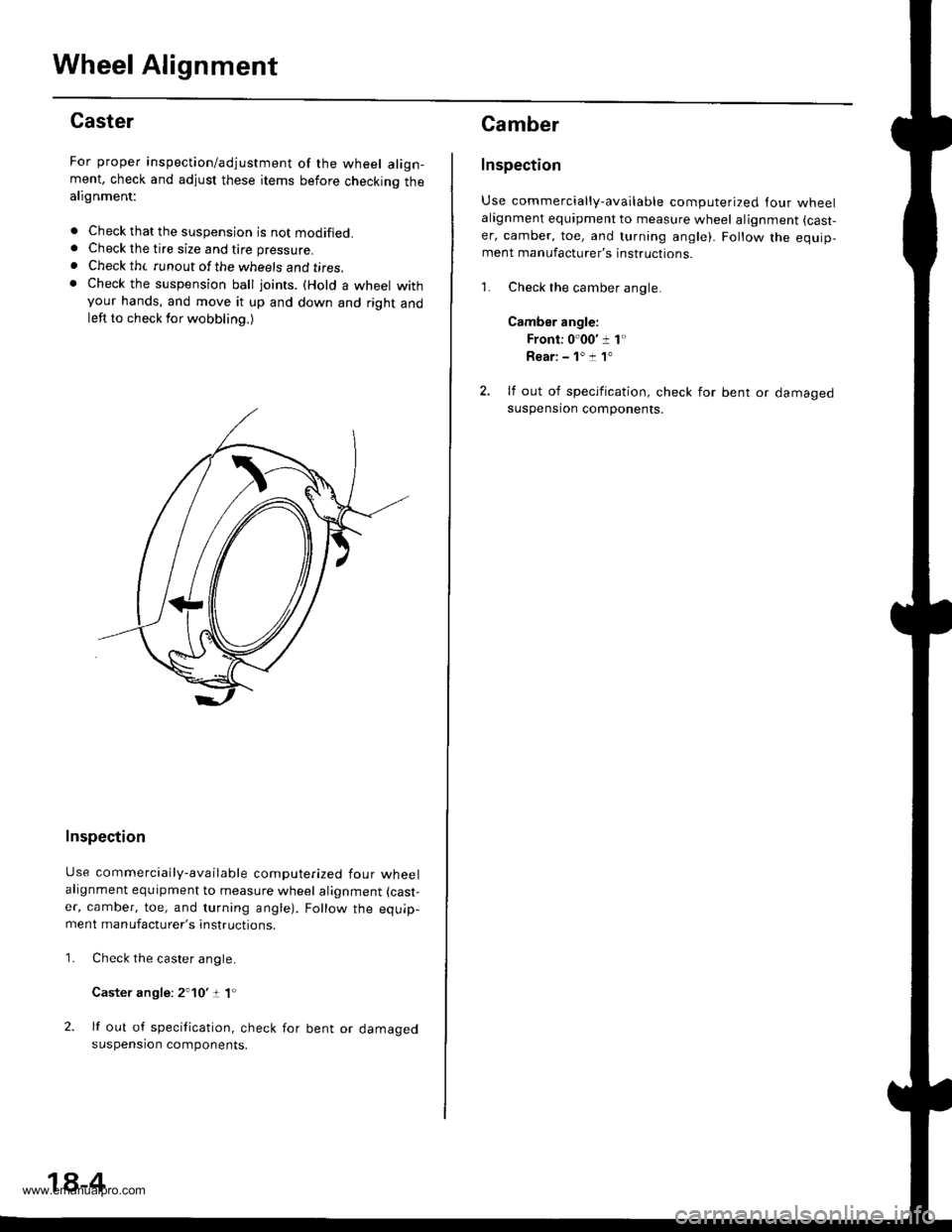

For proper inspection/adjustment of the wheel align-ment, check and adjust these items before checkinq thealignment:

. Check that the suspension is not modified.. Check the tire size and tire pressure.

. Check th( runout of the wheels and t;res,. Check the suspension ball joints. (Hold a wheel withyour hands, and move it up and down and right andleft to check for wobbling.)

Inspection

Use commercially-available computerized four wheelalignment equipment to measure wheel alignment (cast-

er, camber, toe, and turning angle). Follow the equip-ment manufacturer's instructions.

Check the caster angle.

Caster angle: 2'10':t 1"

lf out of specification, check for bent or damagedsuspension components.

1.

18-4

Camber

Inspection

Use commercially-available computerized lour wheelalagnment equipment to measure wheel alignment (cast,

er, camber, toe, and turning angle). Follow the equip,ment manufacturer's instructions.

1. Check the camber angle.

Camber angle:

Front: 0'00' 1 1"

Rear: - 1' :! 1"

2. lf out of specification, check for bent or damagedsuspensron components.

www.emanualpro.com

Page 906 of 1395

Front Suspension

Suspension Arms Replacement

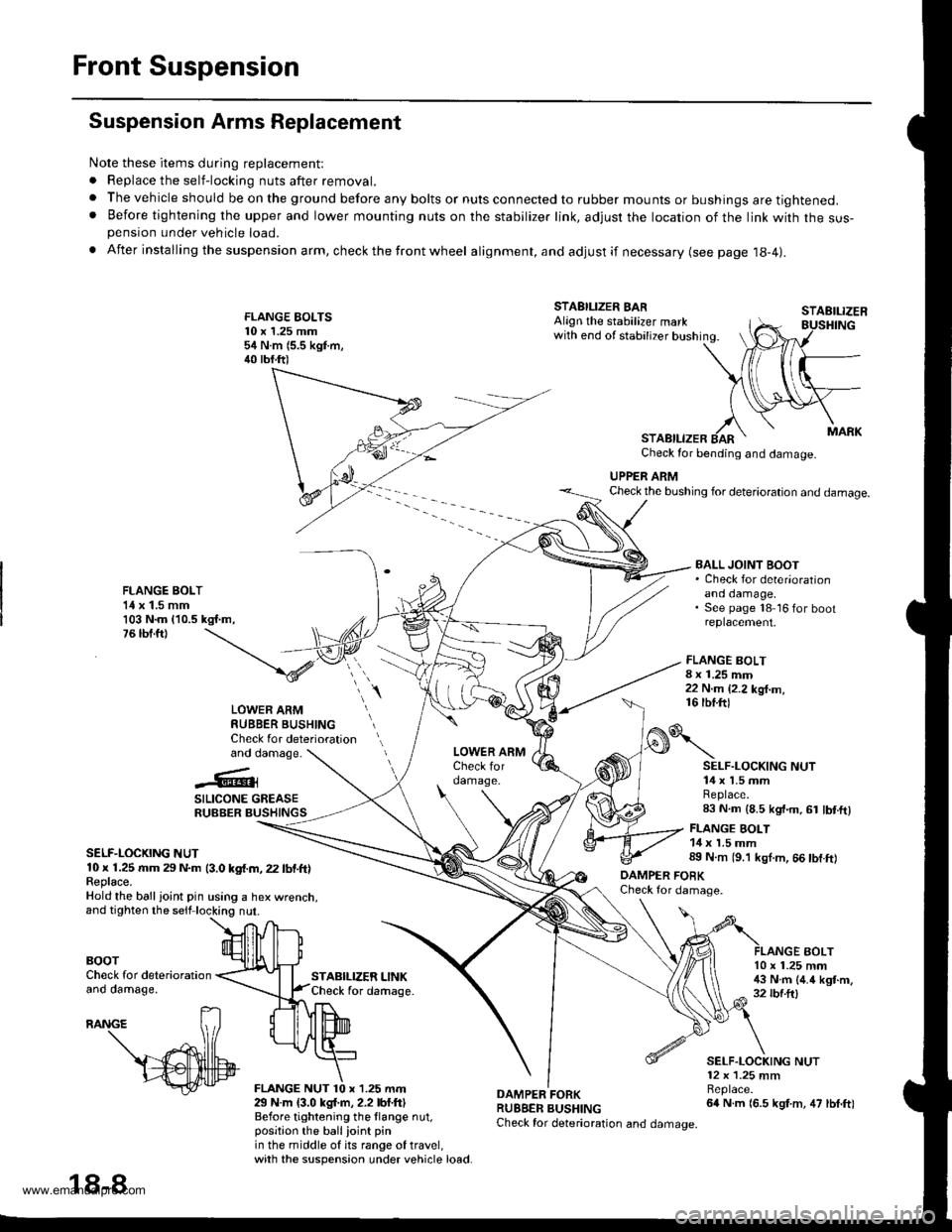

Note these items during replacement:

. Replace the self-locking nuts after removal.

. The vehicle should be on the ground before any bolts or nuts connected to rubber mounts or bushings are tightened.. Before tightening the upper and lower mounting nuts on the stabilizer link, adjusr the location of the link with the sus-pension under vehicle load.

. After insta lling the suspension arm, check the front wheel alignment, and adjust if necessary (see page 18-4|.

FLANGE EOLTS10 x 1.25 mm54 N.m (5.5 kgf.m,40 tbf.ft)

STABILIZER LINKCheck for daftage.

FLANGE BOLT8 x 1.25 mm22 N.m {2.2 kg{.m,16 tbf.ftl

STAEILIZER

AOLT

STABILIZER BARAlign the stabilizer markwith end of stabilizer bushing.

STABILIZERCheck for bending and damage.

UPPER ARMCheck the bushing for deterioration and damage.

FLANGE BOLT1{ x 1.5 mm103 N.m {10.5 kgf.m,76 tbf.ft)

BALL JOINT BOOT. Check for deter'orationano oamage,See page 18 16 for bootreplacement.

LOWER ARMRUBBER BUSHINGCheck for deteriorationand damage.

..'.{l@3

SILICONE GREASERUBBER BUSHINGS

SELF-LOCKING NUT10 x 1.25 rr|m 29 N.m (3.0 kgf.m, 22 lbf.ft)Feplace.Hold the ball ioint pin using a hex wrenct

BOOTCheck for deteriorationano oamage,

29 N.m {3.0 kgl.m, 2.2 lbf.ftlBefore tightening the llange nut,position the ballioint pinin the middle of its range of travel,with the suspension under vehicle load.

DAMPER FORKRUBBER BUSHINGCheck for deterioration and damage.

o\

DAMPER FOBKCheck for damage.

SELF.LOCKING NUT14 x 1.5 mmReplace.83 N.m (8.5 kgt.m, 61 lbt.ftl

FLANGE BOLT14 x 1.5 mm89 N.m (9.'l kgl.m, 66 tbf.ft)

10 x 1.25 mm!$ N.m (4.4 kgt.m,32 rbf.ftl

SELF.LOCKING NUT12 x 1.25 mmBeplace.64 N.m (6.5 kgt.m, 47 lbf.ft)

18-8

www.emanualpro.com

Page 907 of 1395

Knuckle/Hub Replacement

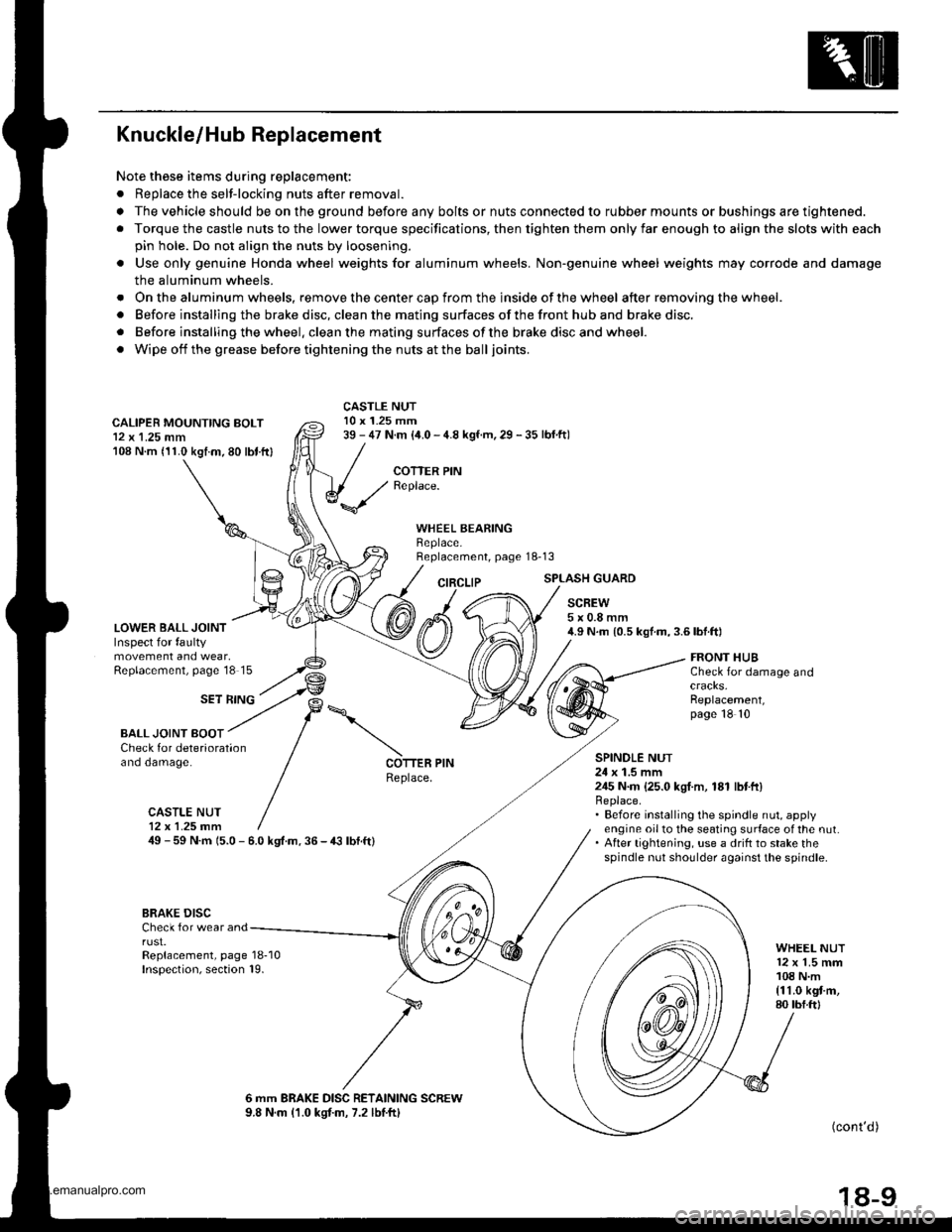

Note these items during replacement:

. Replace the selt-locking nuts after removal.

. The vehicle should be on the ground before any bolts or nuts connected to rubber mounts or bushings are tightened.

. Torque the castle nuts to the lower torque specifications, then tighten them only far enough to align the slots with each

pin hole. Do not align the nuts by loosening.

o Use only genuine Honda wheel weights for aluminum wheels. Non'genuine wheel weights may corrode and damage

the aluminum wheels.

. Onthealuminum wheels, remove the center cap from the inside of the wheel after removing the wheel.

. Before installing the brake disc, clean the mating surfaces of the front hub and brake disc.

. Before installing the wheel. clean the mating surfaces ofthe brake disc and wheel.

. Wipe off the grease before tightening the nuts at the balljoints.

CALIPER MOUNTING BOLT12 x 1.25 mm108 N.m (11.0 kgtm.80 lbt.ftl

LOWER BALL JOINTInspect for faultymovement and wear,Replacement, page'18 15

CASTLE NUT10 x 1.25 mm39 - 47 N.m (i1.0 - 4.8 kgf.m, 29 - 35 lbf.ftl

COTTER PINReplace.

WHEEL BEARINGBeplace.Replacement, page 18-13

CIRCLIPSPLASH GUARD

SCREW5x0.8mm4.9 N.m {0.5 kgf.m,3.6lbf.ft)

SET RING

FRONT HUBCheck for damage and

Replacement,page 18 10

BALL JOINT BOOTCheck for deteriorationano oamage.SPINOLE NUT24 x 1.5 mm245 N.m {25.0 kgI.m, 181 lbtft}Replace.. Before installing the spindle nut, applyengine oil to the seating surface of the nut.. After tightening, use a drift to stake thespindle nut shoulder against the spindle.

COTTER PINReplace.

CASTLE NUT12x 1.25 fim49 - 59 N.m 15.0 - 6.0 kgt.m. 36 - € lbf.ft)

BRAKE DISCCheck for wear andrust.Replacement, page 18-10Inspection, section 19.

WHEEL NUT12 x 1.5 mm108 N.m{11.0 kgt m,80 tbf.ftl

6 mm BRAKE DISC RETAINING SCREW9.8 N.m (1.0 kgtm, 7.2 lbtftl(cont'd )

18-9

www.emanualpro.com

Page 909 of 1395

12.

13.

14.

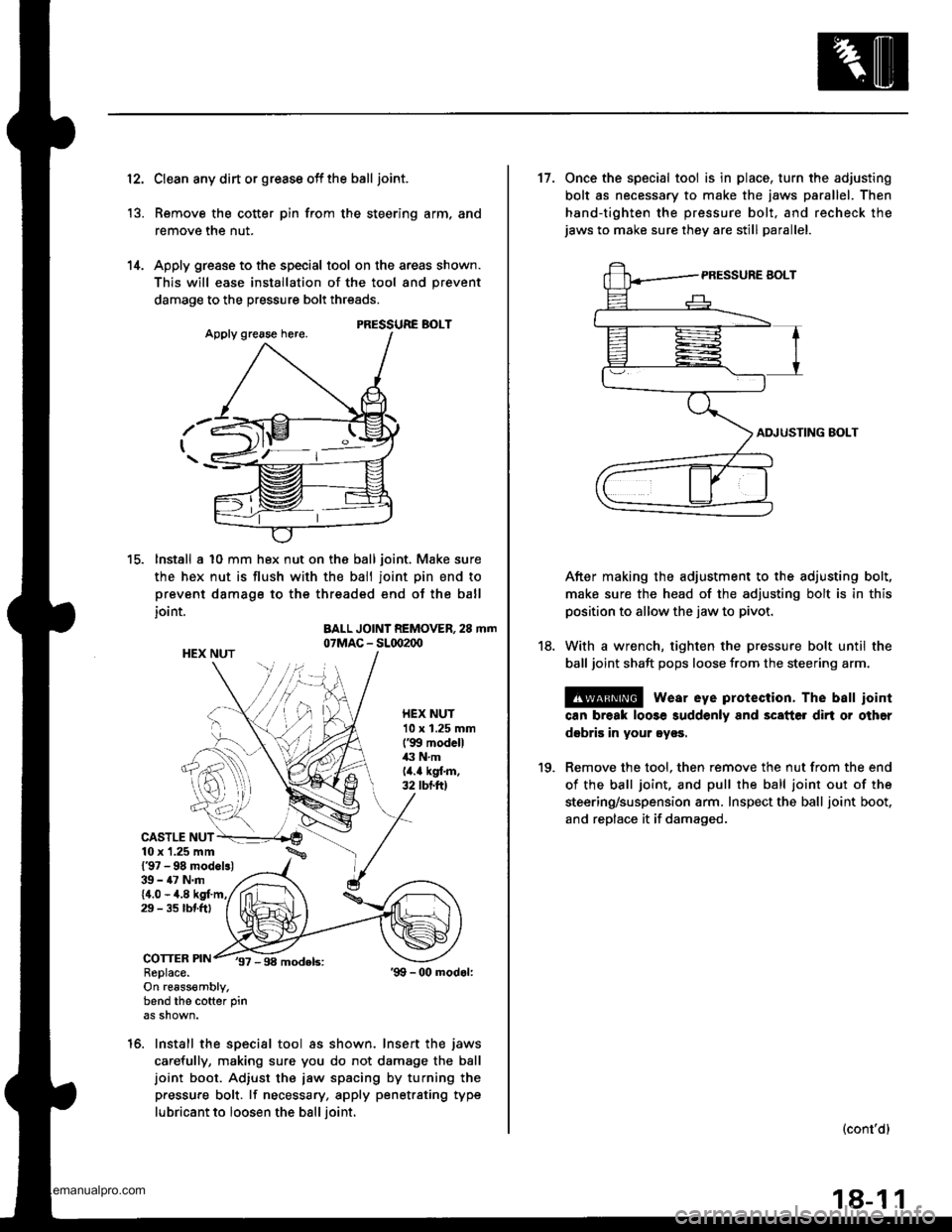

Clean any dirt or grease off the ball joint.

Remove the cotter pin from the steering arm, and

remove the nut.

Apply grease to the special tool on the areas shown.

This will ease installation of the tool and prevent

damage to the pressure bolt threads.

PRESSURE BOLT

lnstall a 10 mm hex nut on the ball joint. Make sure

the hex nut is flush with the ball joint pin end to

prevent damage to the threaded end of the ball

joint.

BALL JOINT REMOVER, 28 mm07MAC - SL(x)2(x)HEX NUT

HEX NUT10 x 1.25 mm('99 modcll43 N.mlit.a kgl.m.32 tbtft)

37 -98 models:

tc.

6:)

CASTLE NUT10 x '1.25 mm

l'97 - 98 modcls)39 - 47 N.m{4.0 - 4.829 - 3s rbtftt

COTTERReplace.On re6ss€mbly,bend the cofter pin

16. Install the special tool as shown. Insert the jaws

carefully, making sure you do not damage the balljoint boot. Adiust the jaw spacing by turning the

pressure bolt. lf necessary, apply penetrating type

lubricant to loosen the ball ioint.

'99 -00 modol:

18.

17. Once the special tool is in place, turn the adjusting

bolt as necessary to make the jaws parallel. Then

hand-tighten the pressure bolt, and recheck thejaws to make sure they are still parallel.

ADJUSTING BOLT

After making the adjustment to the adjusting bolt,

make sure the head of the adjusting bolt is in this

position to allow the jaw to pivot.

With a wrench, tighten the pressure bolt until the

ball joint shaft pops loose from the steering arm.

@ wear eye protection. The balt iointcan break loose suddenly and scatter dirt or other

dsbris in your ey€s.

Remove the tool, then remove the nut from the end

of the ball joint, and pull the ball joint out of the

steering/suspension arm. Inspect the ball joint boot.

and replace it if damaged.

(cont'dl

1(|

18-1 1

www.emanualpro.com

Page 910 of 1395

Front Suspension

Knuckle/Hub Replacement (cont'd)

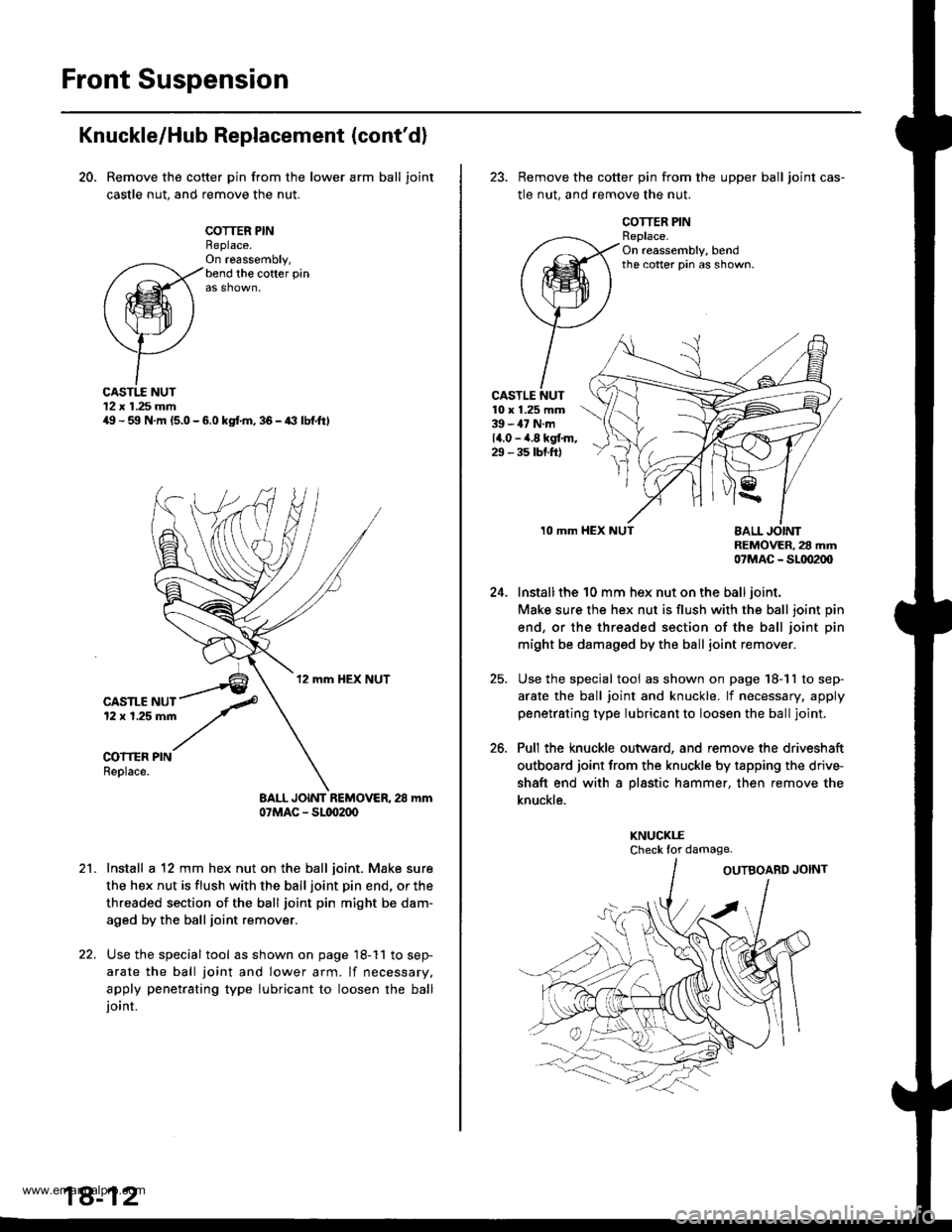

20. Remove the cotter pin from the lower arm ball joint

castle nut, and remove the nut.

COTTER PINReplace.On ra6ssembly,bend the cofter pin

CASTI.E NUT12 x 1.25 mmilg - 59 N.m (5.0 - 6.0 kgf.m, 36 - a3 lbf.ftl

CASTLE NUT12 x 1.25 mm

COITER PINReplace.

BALL JOINT REMOVER, 28 mm07MAC - Sl(xr2(x,

Install a 12 mm hex nut on the ball joint. Make sure

the hex nut is flush with the ball joint pin end, or the

threaded section of the ball joint pin might be dam-

aged by the ball joint remover.

Use the special tool as shown on page 18-11 to sep-

arate the ball joint and lower arm. lf necessary,

apply penetrating type lubricant to loosen the balljoint.

18-12

23. Remove the cotter pin from the upper ball joint cas-

tle nut, and remove the nut.

COTTER PINReplace.On reassembly, bendthe cotter pin as shown.

CASTLE NUT10 x 1.25 mm39 - 47 N.m14.0 - ,4.8 kgt m,29 - 35 tbt.ftl

24.

25.

26.

10 mmnEMOVER, 28 mm07MAC _ SLtD2(xl

Install the 10 mm hex nut on the ball joint.

Make sure the hex nut is flush with the ball joint pin

end, or the threaded section of the ball joint pin

might be damaged by the ball joint remover.

Use the special tool as shown on page 18-11 to sep-

arate the ball joint and knuckle. lf necessary, apply

penetrating type lubricant to loosen the ball joint.

Pull the knuckle outward, and remove the driveshaft

outboard joint from the knuckle by tapping the driv+

shaft end with a pl8stic hammer, then remove the

knuckle.

KNUCKI.ECheck lor damage.

www.emanualpro.com

Page 912 of 1395

Front Suspension

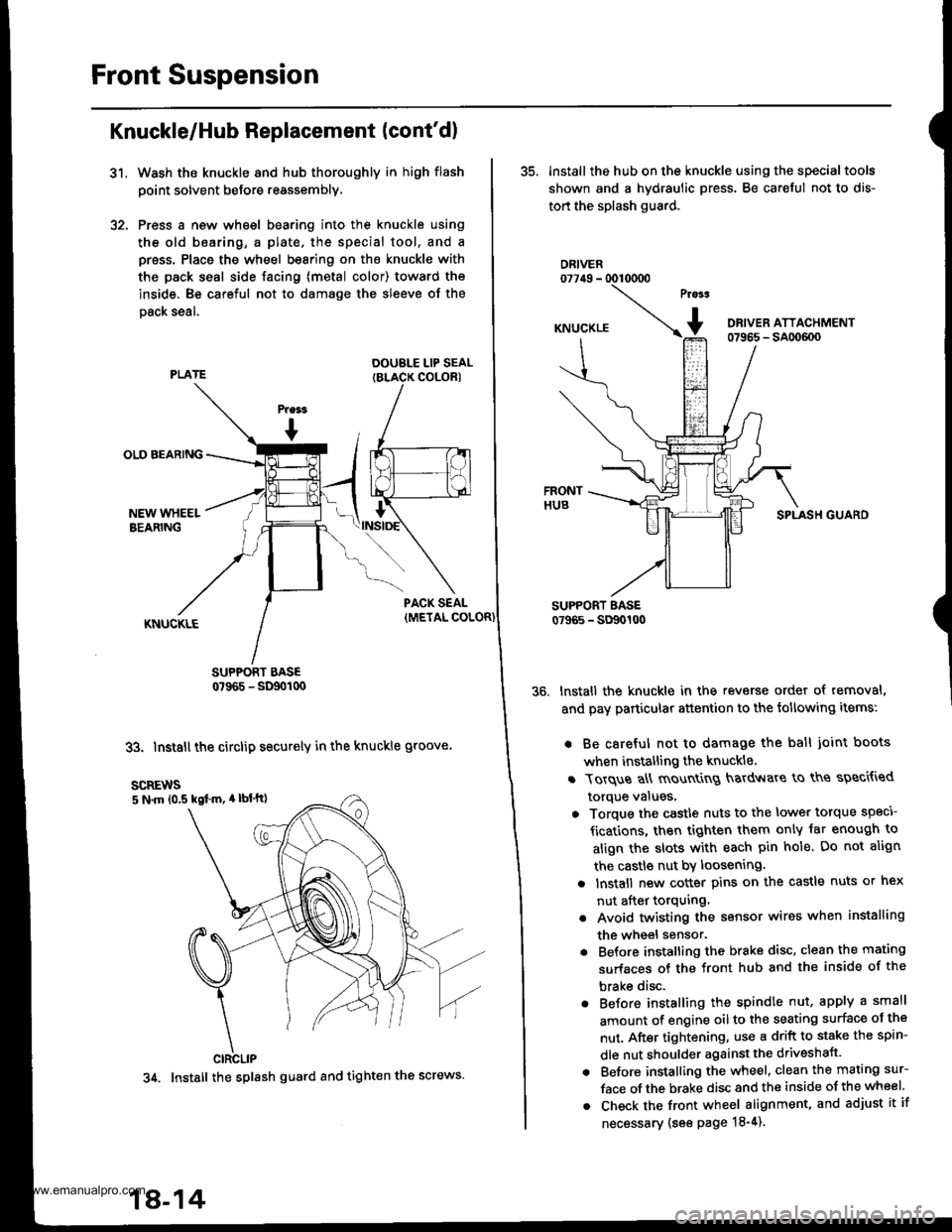

31.

Knuckle/Hub Replacement (cont'dl

Wash the knuckle and hub thoroughly in high flash

point solvent before reassembly,

Press a new wheel bearing into the knuckle using

the old b6aring, a plate. the special tool, and a

press. Place the wheel bearing on the knuckle with

the pack seal side facing (metal color) toward the

inside. Be careful not to damage the sleeve of the

Dack seal.

DOUBLE LIP SEALIBLACK COLORI

SUPPORT BASE0?965 - SD90t00

33. Install the circlip securely in the knuckle groove.

35. lnstall the hub on the knuckle using the specialtools

shown and a hydraulic press. Be careful not to dis-

tort the splash guard.

ORIVER077irg - 0010000

SPLASH GUARO

lnstall the knuckle in the reverse order of removal,

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle.

r Torque a\ mount

g hardv{are to ths speci{ied

torque values,

o Torque the castle nuts to the lower torque speci

fications, then tighten them only iat enough to

align the slots with each pin hole. Do not align

the castle nut by loosening.

a lnstall new cotter pins on the castle nuts or hex

nut after torquing.

. Avoid twisting the sensor wires when installing

the wheel sensor.

. Before installing the brake disc, clean the mating

surfaces of the front hub and the inside of the

brake disc.

. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface oJ the

nut. After tightening, use a drift to stake the spin-

dle nut shoulder against the driveshaft.

. Before installing the wheel. clean the mating sur-

face of the brake disc and the inside of the wheel.

. Check the front wheel alignment, and adjust it if

necessary {see page 18-4).

scREws5 N.m 10.5 kgl m, 4 lbl'tt)

CIRCLIP

34. Install the splash guard and tight€n the screws.

18-14

www.emanualpro.com

Page 913 of 1395

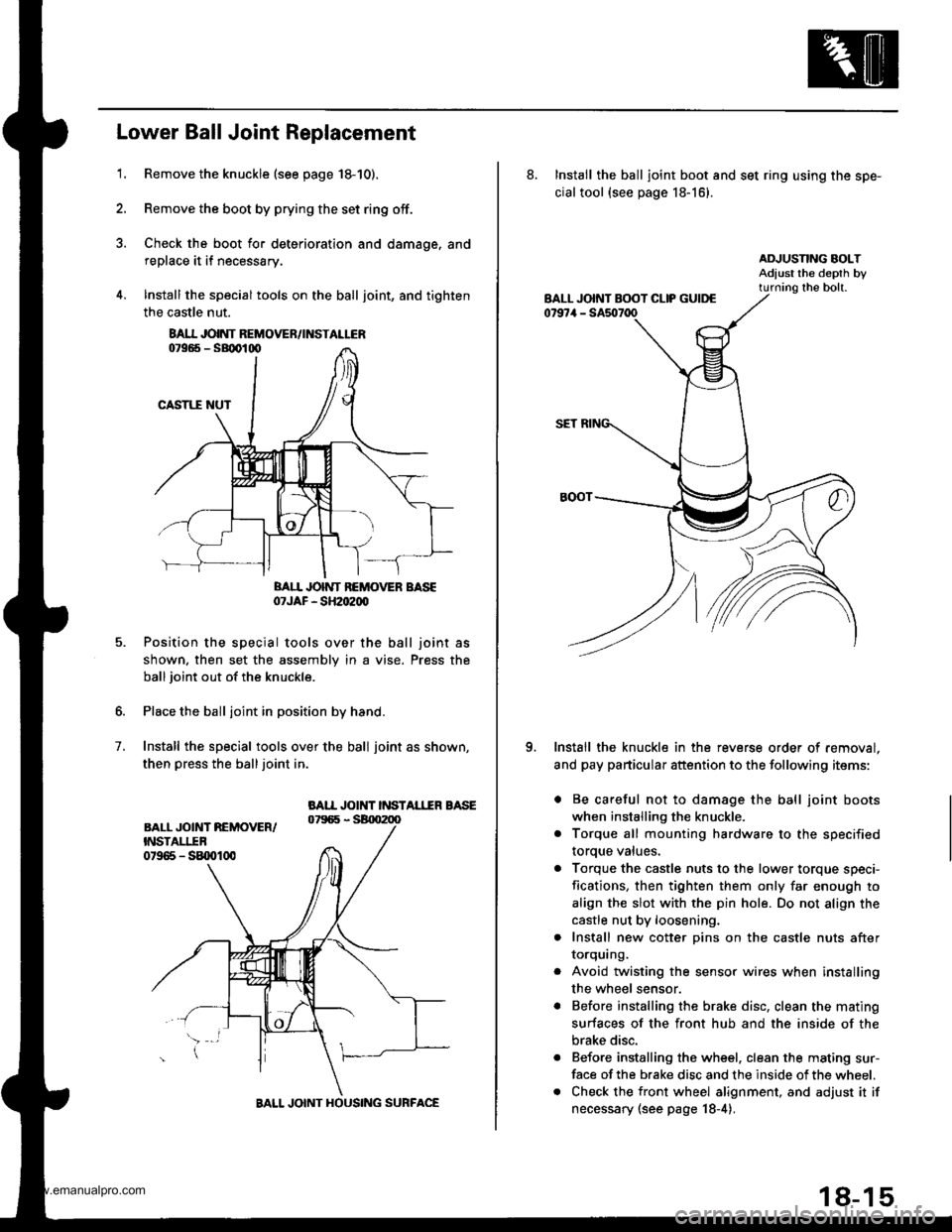

'1.

Lower Ball Joint Replacement

Remove the knuckle (see page 18-10).

Remove the boot by prying the set ring off.

Check the boot for deterioration and damage. and

replace it if necessary.

lnstall the special tools on the ball joint, and tighten

the castle nut.

BAII JOINT BEMOVER BASE07JAF - SH2oe00

Position the special tools over the ball joint as

shown. then set the assembly in a vise. Press the

ball joint out of the knuckle.

Place the ball joint in position by hand.

Install the special tools over the ball joint as shown,

then press the balljoint in.

BAII JOINT INSTAL1IR BASE

7.

8AI.I JOINT REMOVEN/INSTALLER

BALL JOINT HOUSING SURFACE

18-15

8. Install the ball joint boot and set ring using the spe-

cial tool {see page 18-16}.

Install the knuckle in the reverse order of removal.

and pay particular attention to the following items:

. Be careful not to damage the ball joint boots

when installing the knuckle.

. Torque all mounting hardware to the specified

toroue values.

a Torque the castle nuts to the lower torque speci-

fications, then tighten them only far enough to

align the slot with the pin hole. Do not align the

castle nut by loosening.

. Install new cotter pins on the castle nuts after

IOrqurng.

Avoid twisting the sensor wires when installing

the wheel sensor.

Before installing the brake disc, clean the mating

surfaces of the front hub and the inside of the

brake disc.

Before installing the wheel. clean the mating sur-

face of the brake disc and the inside of the wheel.

Check the front wheel alignment, and adjust it if

necessary (see page 18-4).

o

www.emanualpro.com

Page 914 of 1395

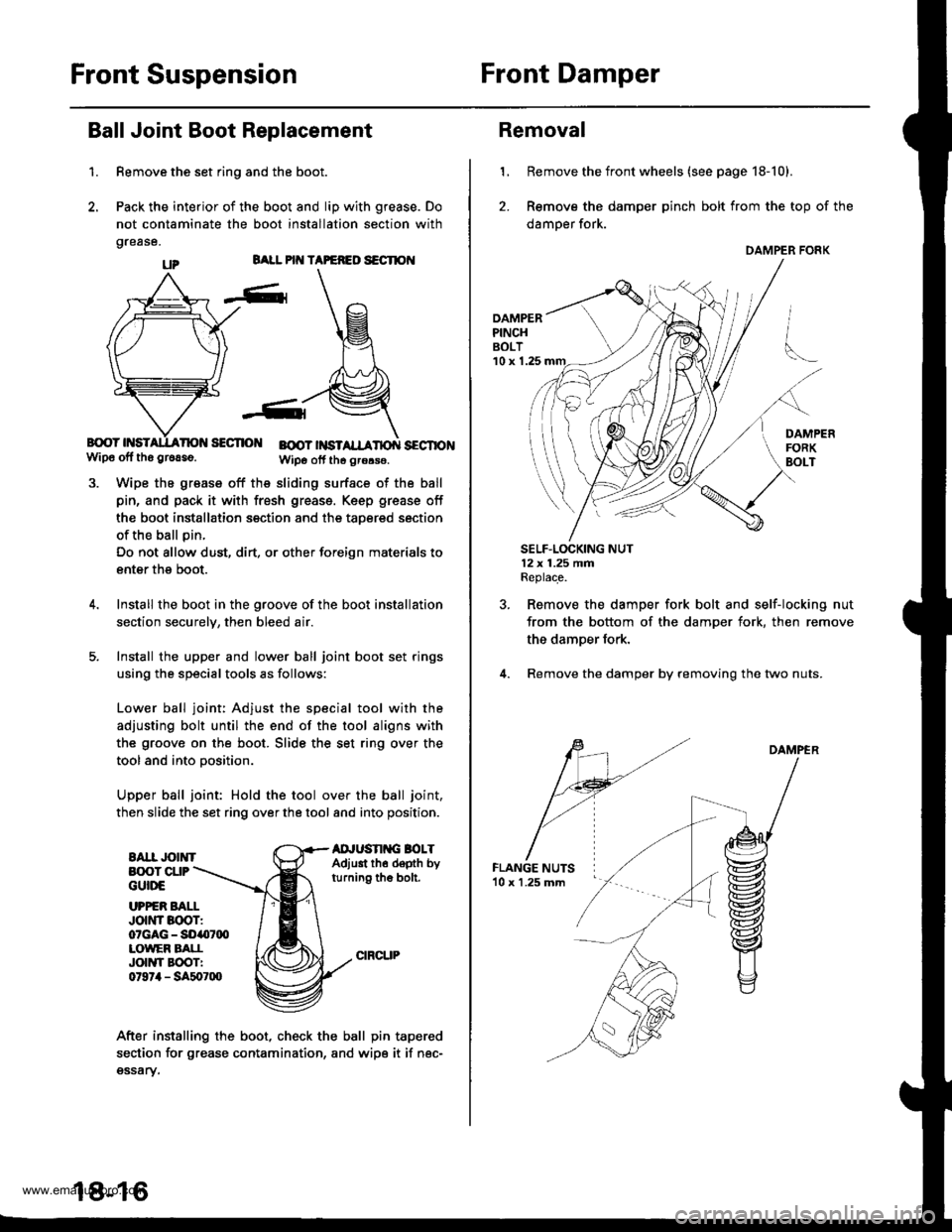

Front SuspensionFront Damper

Ball Joint Boot Replacement

1.

BALL PIT{ TAPEFEO S€CTION

B{rcY HSISECTIO BOOT |NSTSECTIONwip6 off tho gr6aso.Wipo otf th6 grors€.

Wipe the grease off the sliding surface of the ball

pin, and pack it with fresh greass. Keep grease off

the boot installation section and the taoered section

of the ball pin.

Do not allow dust, dirt, or other foreign materials to

enter the boot.

Install the boot in the groove of the boot installation

section securelv, then bleed air.

Install the upper and lower ball joint boot set rings

using the special tools as follows:

Lower ball joint: Adjust the special tool with the

adjusting bolt until the end of the tool aligns with

the groove on the boot. Slide the set ring over the

tool and into oosition.

Upper ball joint: Hold the tool over the ball joint,

then slide the set ring over the tool and into position.

EAII JOINTAD'USN G BOLTAdjust th6 depth byturning the bolt.

Remove the set ring and the boot.

Pack the interior of the boot and lip with grease. Do

not contaminate the boot installation section with

grease.

B(X)T CUPGUttrE

UPPER BAI.IJott'tr Boor:07GAG - SO407q)LOWEF BATIJOIIYI EOOTI0t97il - SA507lXl

After installing the boot, check the ball pin tapered

section for grease contamination, and wipe it if nec-gssary.

18-16

Removal

1, Remove the front wheels (see page 18-10).

2. Remove the damper pinch bolt from the top of the

damper fork.

DAMPERPINCHBOLT'10 x 1.25

SELF.LOCKING NUT12x 1.25 fifiReplace.

Remove the damper fork bolt and self-locking nut

from the bottom of the damper fork, then remove

the damper fork.

Remove the damper by removing the two nuts.

DAMPER

DAMPER FORK

www.emanualpro.com

Page 917 of 1395

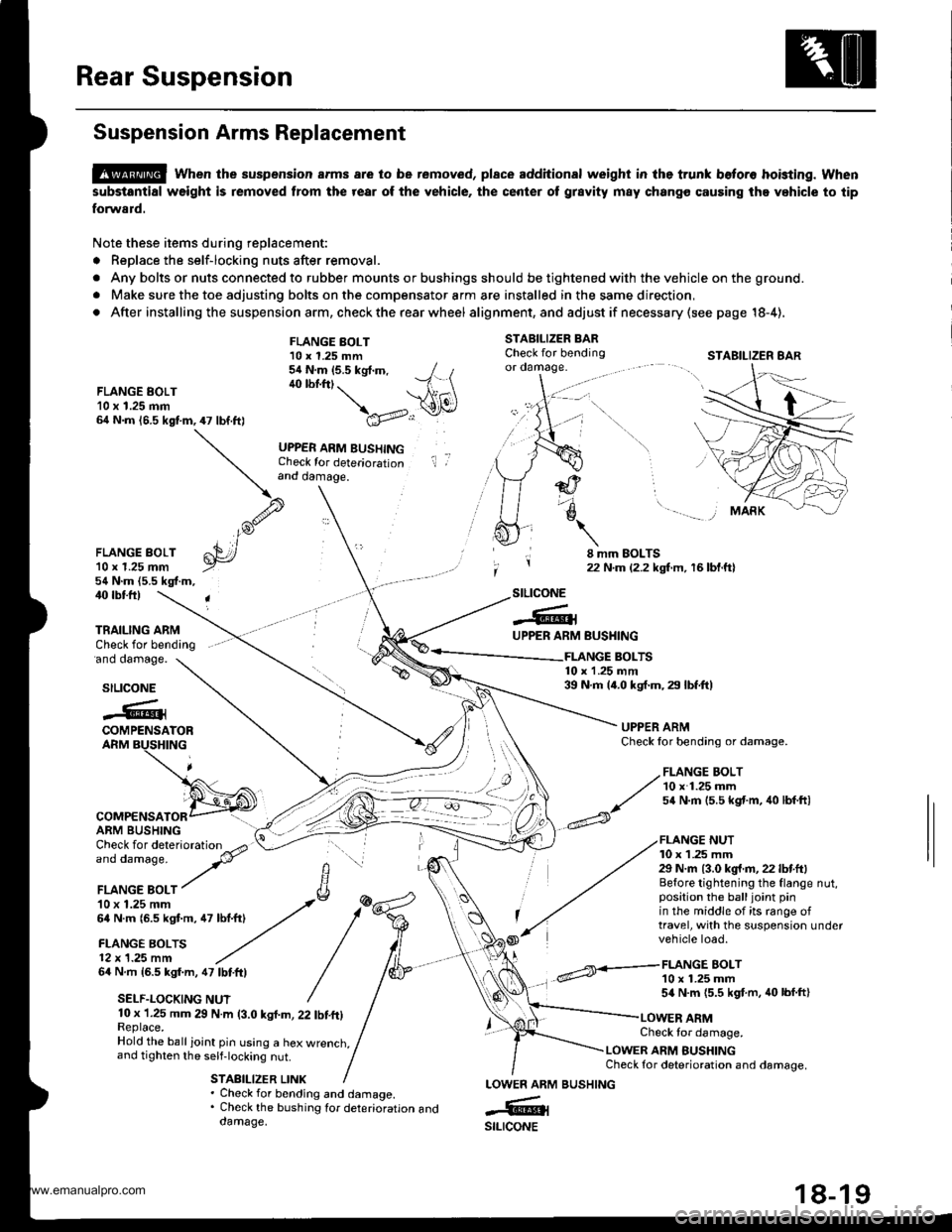

Rear Suspension

Suspension Arms Replacement

@ when the suspension arms are to be removed, plsce additional weight in lhe trunk beto.o hoisting. when

substantial weight is removed from the rear of the vehicle, the center ot grsvity m8y chango causing the vehicle to tip

forward.

Note these items during replacement:

. Replace the self-locking nuts after removal.

. Any bolts or nuts connected to rubber mounts or bushings should be tightened with the vehicle on the ground.

. Make sure the toe adjusting bolts on the compensator arm are installed in the same direction,

. After installing the suspension arm, check the rear wheel alig nment, and adjust if necessa ry (see page 18-4),

STABILIZER BARCheck for bendingor oamage.

FLANGE EOLT10 x 1.25 mm64 N.m 16.5 kgf.m,47 lbf.ft)

FLANGE BOLT10 x 1.25 mm54 N.m (5.5 kgt.m, / t40 lbf.ftt. --1 \ \A1(\

\a'v..:r

UPPER ARM BUSHINGCheck for deteriorationand damage.

il ,

FLANGE BOLT'l0 r 1.25 mm54 N.m (5.5 kgf.m,

8 mm EOLTS22 N.m {2.2 kgf.m, 16 bl.ftl

40 rbtft)

'ano oamage.

TRAILING ARMCheck for bending

stLtcoNE

-6lUPPER ARM

COMPENSATORARM BUSHING

64 N.m 16.5 kgf.m, 47 lbtftl

SELF.LOCKING NUT

BUSHING

FLANGE BOLT10 x 1.25 mm54 N.m {5.5 kgf.m, 40 lbf.ft}

FLANGE BOLTS10 x 1.25 mm39 N.m 14.0 kgf.m, 29 lbf.ft)stLtcoNE

.@iCOMPENSATORARM BUSHING

UPPER ARMCheck lor bending or damage.

FLANGE NUT10 x 1 .25 mm29 N.m {3.0 kg{.fl,22 lbf.ft}Before tightening the flange nut,position the balljoint pinin the middle of its range oftravel, with the suspension undervehicle load.

10 x 1.25 mm 29 N.m (3.0 kgl.m, 22 tbf.ft)Replace.Hold the ball ioint pin using a hex wrenct,,and tighten the self-locking nut.

STABILIZER LINK

Check tor damage.

LOWER ARM BUSHINGCheck for deterioration and damage.

. Check for bending and damage.. Check the bushing tor deterioration anddamage.

LOWEN ARM

-6ilstLrcoNE

STABILIZER 8AR

,/ FLANGE BOLT

// 10 x 1.25 mm

^/ s4 N.m 15.5 kst'm, 40 lbf ftl

BUSHING

www.emanualpro.com

Page 934 of 1395

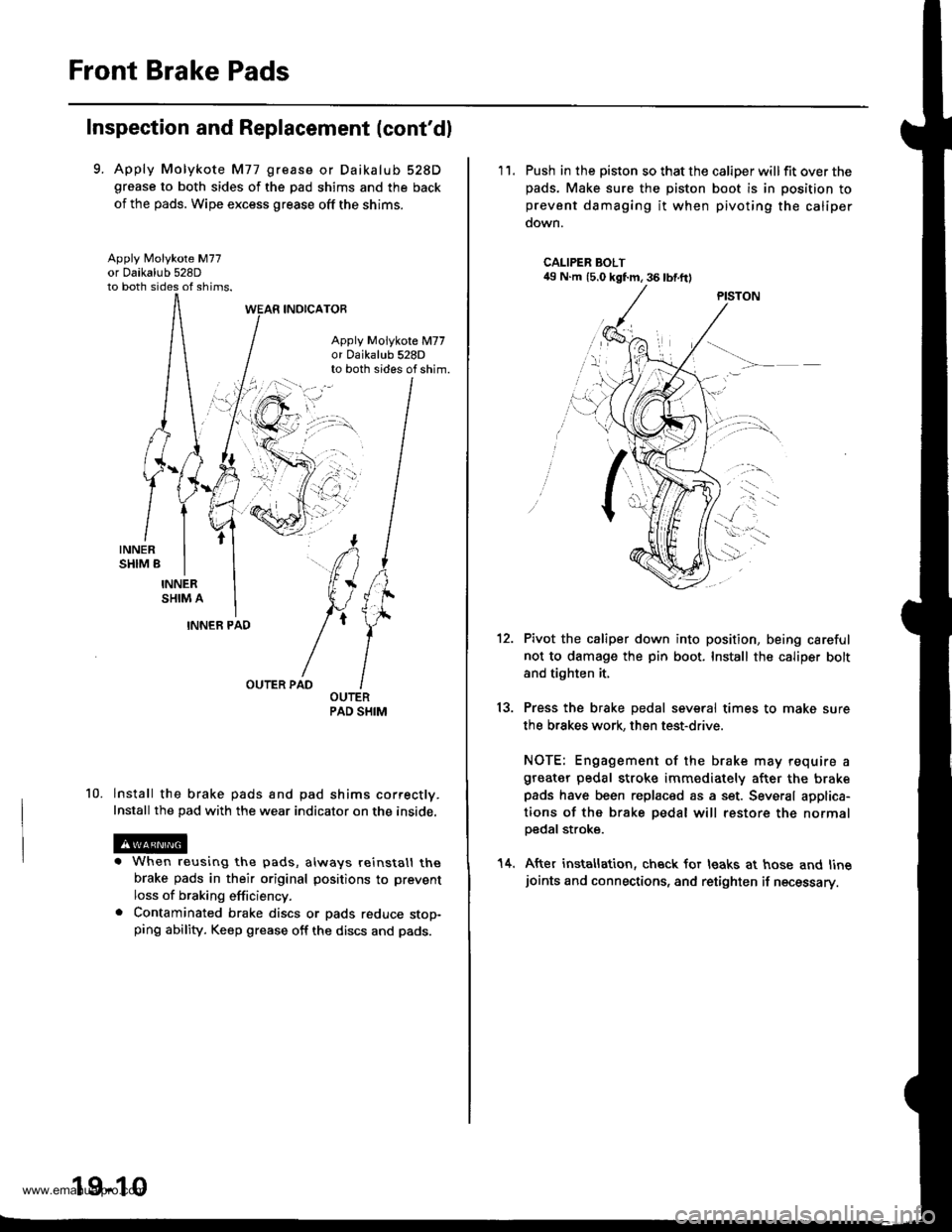

Front Brake Pads

Inspection and Replacement (cont'dl

9. Apply Molykote M77 grease or Daikalub 528Dgrease to both sides of the pad shims and the back

of the pads. Wipe excess grease off the shims.

Apply Molykote M77

to both sides of shims.

INOICATOR

Apply Molykote M77or 0aikalub 528Dto both sides of shim.

10.

INNER PAD

OUTER PAD

lnstall the brake pads and pad shims correctly.

Install the pad with the wear indicator on the inside.

. When reusing the pads, always reinstall thebrake pads in their original positions to prevent

loss of braking efficiency.. Contaminated brake discs or pads reduce stop-ping ability. Keep grease off the discs and pads.

19-10

'11. Push in the piston so that the caliper willfit over thepads. Make sure the piston boot is in position toprevent damaging it when pivoting the caliper

down.

CALIPER BOLT49 N.m (5.0 kgf.m, 36 lbf.ftl

13.

Pivot the caliper down into position, being careful

not to damage the pin boot. Install the caliper bolt

and tighten it,

Press the brake pedal several times to make sure

the brakes work, then test-drive.

NOTE: Engagement of the brake may require agreater pedal stroke immediately after the brakepads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normalpedal stroke.

After installation, check for leaks at hose and linejoints and connections, and retighten if necessary.

14.

www.emanualpro.com