main HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 441 of 1395

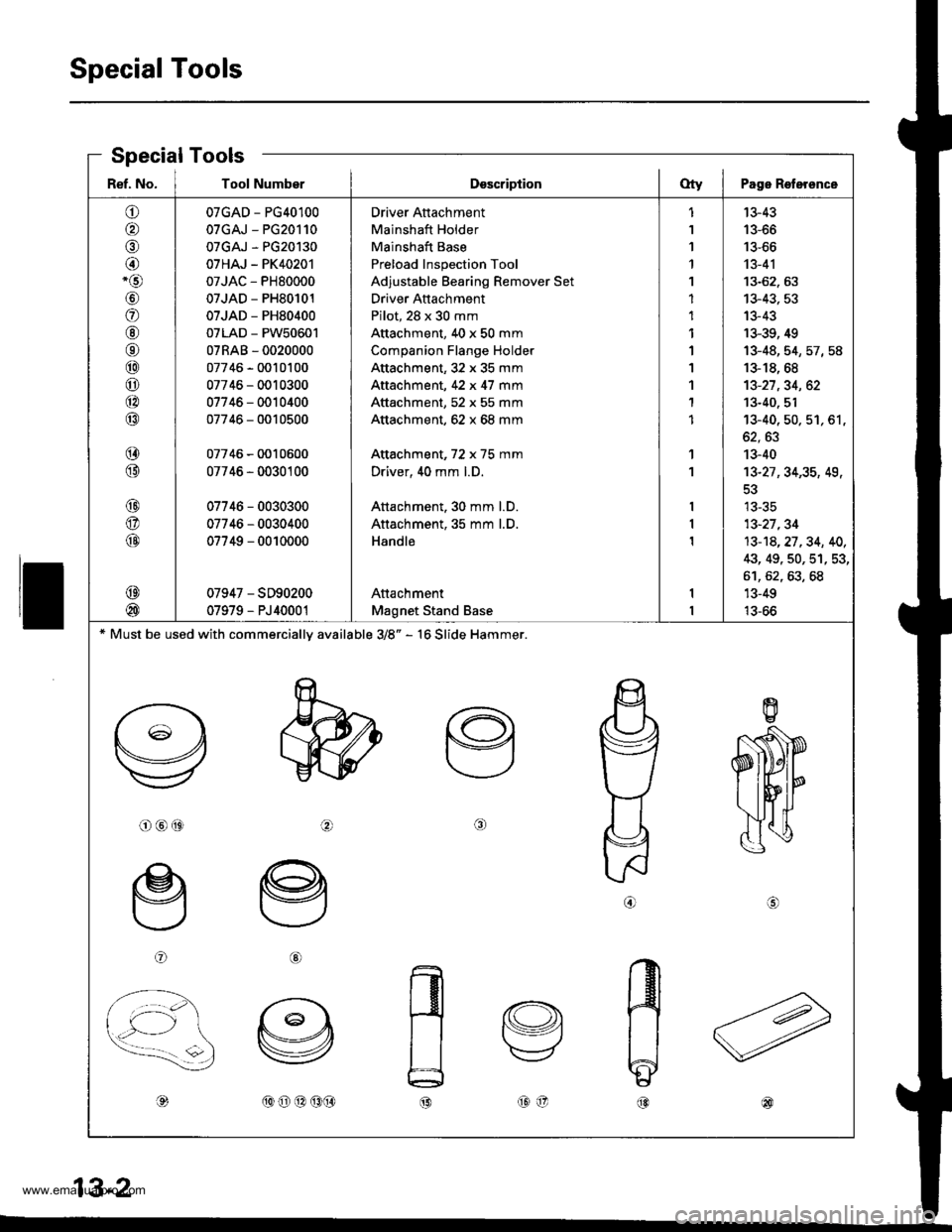

Special Tools

ll

Ref. No. I Tool NumberDsscriptionOty I Page Roterence

o

o,6)

@-o

\9'

a

@6r

@

o

@

@

@

@

@

@

@

@

@

07GAD - PG40100

07GAJ - PG20110

07GAJ - PG20130

07HAJ - PK40201

07JAC - PH80000

07JAD - PH80101

07JAD - PH80400

07LAD - PW50601

07RAB - 0020000

07746 - 0010100

07746 - 0010300

07746 - 0010400

07746 - 0010500

07746 - 0010600

07746 - 0030100

07746 - 0030300

07746 - 0030400

07749 - 0010000

07947 - SD90200

07979 - PJ40001

Driver Attachment

Mainshaft Holder

Mainshaft Base

Preload Inspection Tool

Adjustable Bearing Remover Set

Driver Attachment

Pilot, 28 x 30 mm

Attachment, 40 x 50 mm

Companion Flange Holder

Attachment,32 x 35 mm

Attachment, 42 x 47 mm

Attachment, 52 x 55 mm

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Driver, 40 mm l.D.

Attachment. 30 mm l.D.

Attachment, 35 mm l.D.

Handle

Attachment

Magnet Stand Base

1

1

1'l

1

1

1

1

1

1'I

1

1

1

1

13-43

13-66

13-66

13-41

13-62. 63

13-43, 53

13-43

13-39, 49

13-48,54,57,58

13-18, 68

13-27,34, 62

13-40. 51't3-40, 50. 51, 61,

oz, oJ

13-40

13-27 ,34,35, 49,

tJ-5C

13-27,34

13-14,27.34, 40,

43, 49, 50, 51, 53,

61,62,63,68'13-49

13-66

* Must be used with commercially available 3/8" - 16 Slide Hammer.

o@(9ta\

oG)

,d,(oo@(9(}@o@

.A IAa 5-z

Special Tools

www.emanualpro.com

Page 442 of 1395

MaintenanceBack-up Light Switch

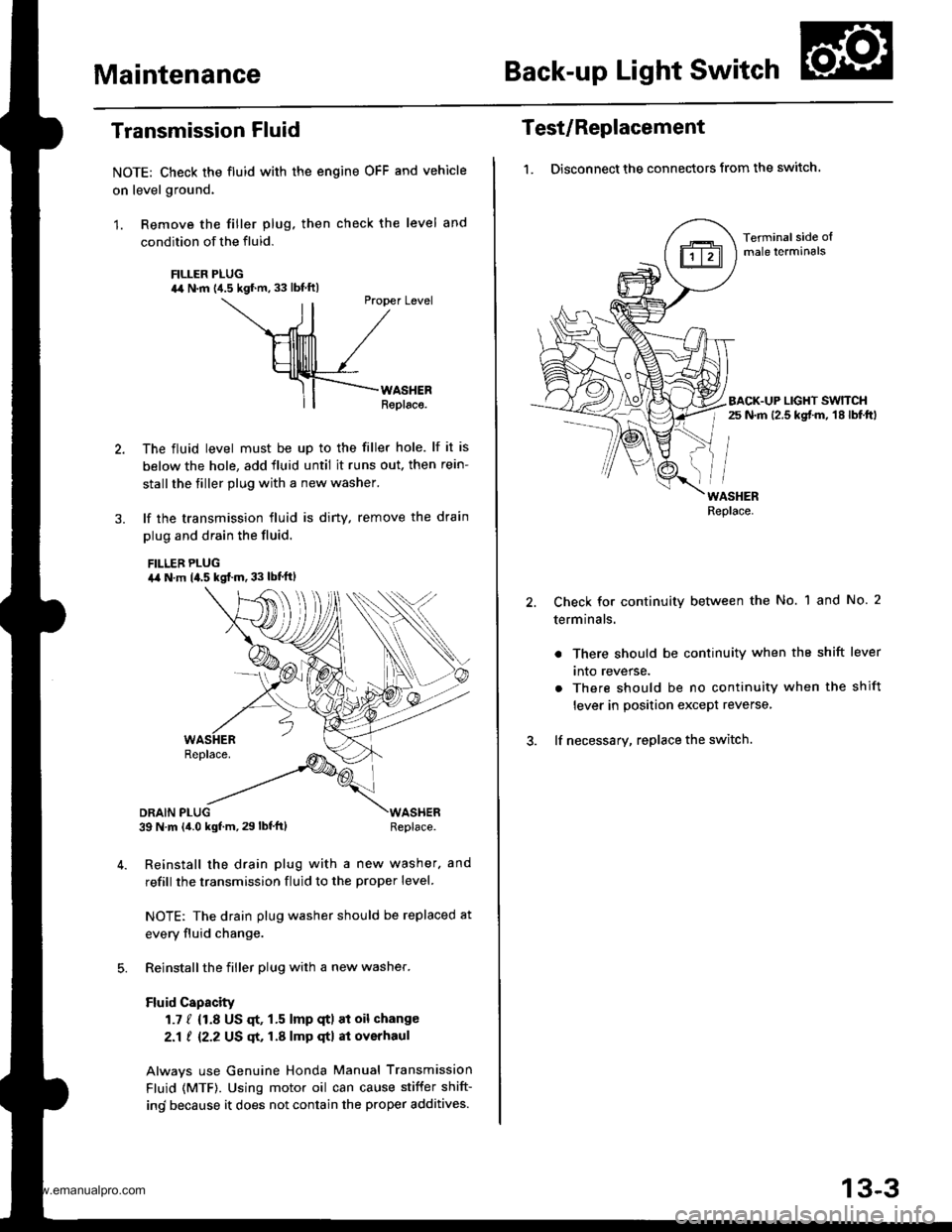

Transmission Fluid

NOTE: Check the fluid with the engine OFF and vehicle

on level ground.

1. Remove the filler plug. then check the level and

condition of the fluid.

FILLER PLUG44 N.m {4.5 kgf.m. 33 lbf ftl

ll

Ptopet Level

\--ril /

HllllllTl /

Hllllrlll /_rf-F{--rno."."

ll| | Replaco.

The fluid level must be up to the filler hole. lf it is

below the hole, add fluid until it runs out. then rein-

stall the tiller plug with a new washer.

lf the transmission fluid is diny, remove the drain

plug and drain the fluid.

FILLEB PLUGa,a N.m 14.5 kgf..n. 33 lbt'ftl

DRAIN PLUG39 N m (4.0 kgf.m, 29 lbf'ft)WASHERReplace.

Reinstall the drain plug with a new washer. and

refill the transmission fluid to the proper level.

NOTE: The drain plug washer should be replaced at

every fluid change.

Reinstall the filler plug with a new washer.

Fluid Capacity

1.7 / {1.8 US qt, 1.5 lmp qtl at oil change

2.1 ! 12.2 US qt, 1.A lmp qtl at overhaul

Alwavs use Genuine Honda Manual Transmission

Fluid (MTF). Using motor oil can cause stiffer shift-

ind because it does not contain the proper additives.

Test/Replacement

1. Disconnect the connectors from the switch.

Terminal side oImale lerminals

BACK.UP LIGHT SWTTCHr 25 N.m 12.5 kgt m, 18 lbf.ftl

WASHERReplace.

Check for continuity between the No. 1 and No. 2

terminals.

. There should be continuity when the shift lever

tnto reverse.

. There should be no continuity when the shift

lever in position except reverse,

lf necessary, replace the switch.

13-3

www.emanualpro.com

Page 450 of 1395

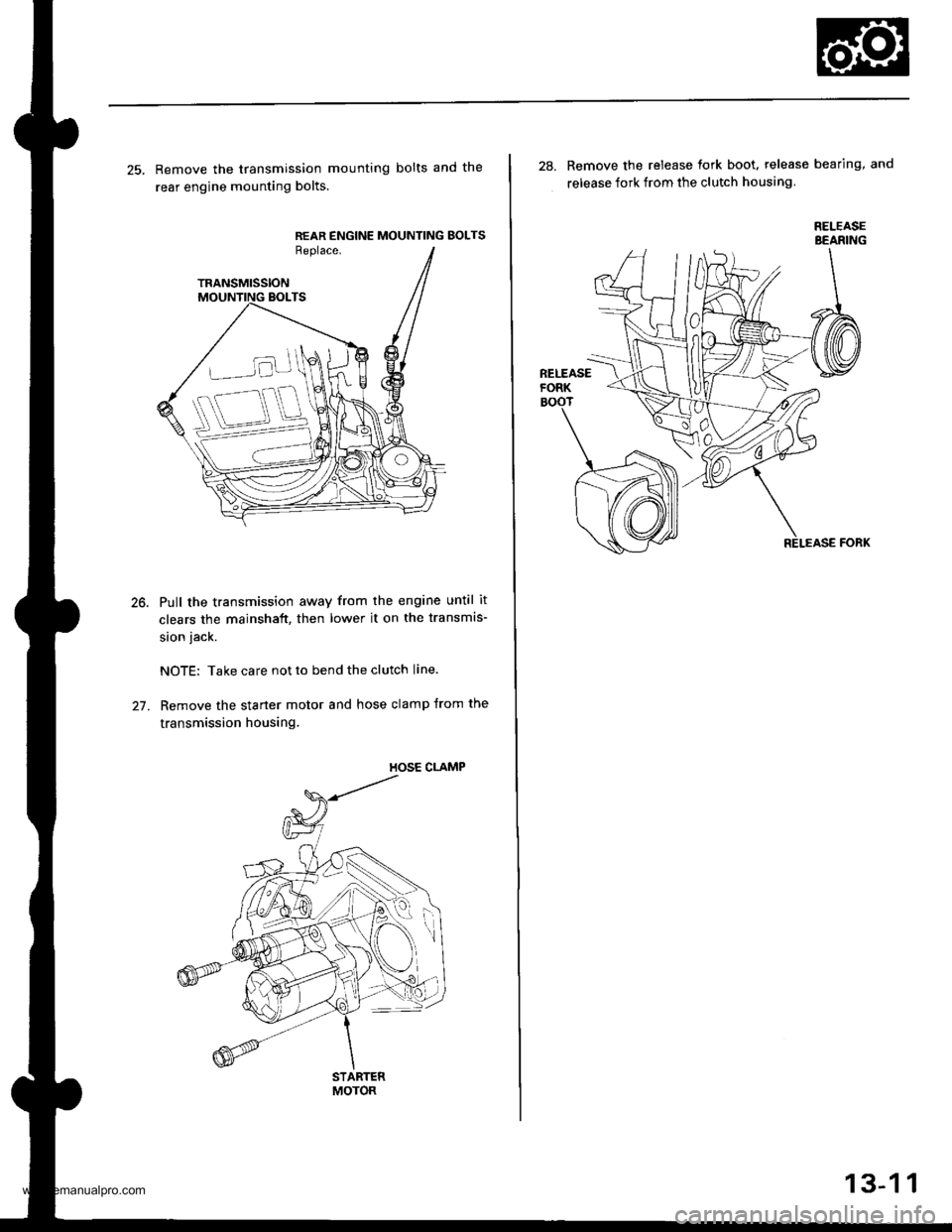

25. Remove the transmission mounting bolts and the

rear engine mounting bolts.

REAR ENGINE MOUNTING BOLTSReplace.

TRANSMISSION

Pull the transmission away from the engine until it

clears the mainshaft, then lower it on the transmis-

sion jack.

NOTE: Take care not to bend the clutch line.

Remove the starter motor and hose clamp from the

transmission housing.

STARTERMOTOR

28. Remove the release tork boot. release bearing, and

release fork from the clutch housing

RELEASEBEANING

13-1 1

www.emanualpro.com

Page 451 of 1395

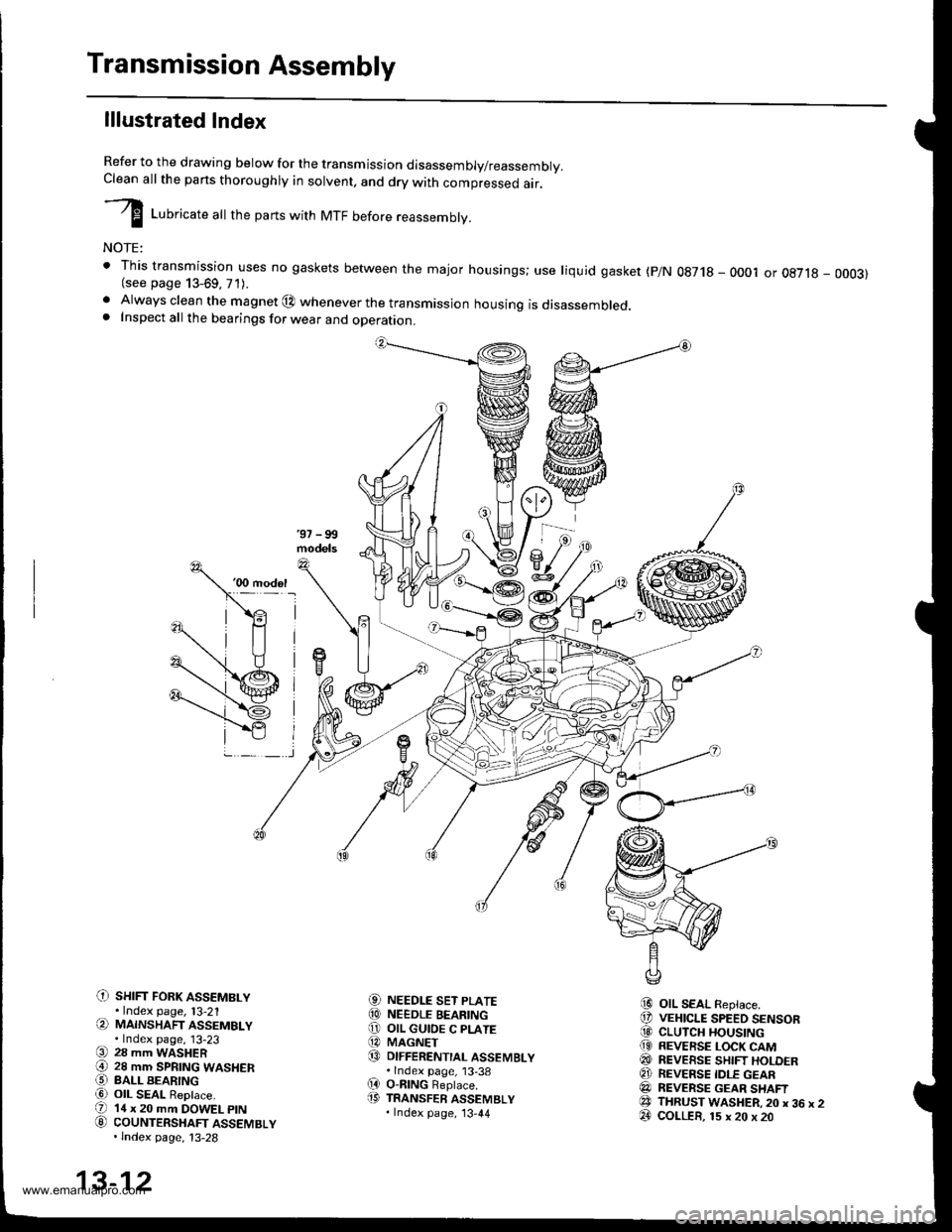

Transmission Assembly

lllustrated Index

Refer to the drawing below for the transmission disassembly/reassembly.Clean all the pans thoroughly in solvent, and drv with comoressed air.

I LuUri""r" utt the parts with MTF before reassembly.

NOTE:

t This transmission uses no gaskets between the major housings; use liquid gasket (p/N 0g718 - 0001 or oE7l8 - 0003)(see page 13-69, 71).. Always clean the magnet @ whenever the transmissjon housing is disassembled.. Inspect all the bearings for wear and operation.

C) sHrFr FoRK ASSEMBLY.Index page, l3-21(a MAINSHAFT ASSEMBLY.Index page, 13-23(9 28 mm WASHER€) 28 mm SPRTNG WASHERO BALL BEARINGa6) OIL SEAL ReDlace.(D 14 x 20 mm DOWEL ptN

G) couNTERSHAFT ASSEMBLY.lndex page, 13-28

NEEDLE SET PLATENEEDLE BEARINGOIL GUIOE C PLATEMAGNETDIFFERENTIAL ASSEMBLY.lndex page, 13-38O-nlNG Beplace.TRANSFER ASSEMBLY.Index page, '13,44

OIL SEAL Replace.VEHICLE SPEED SENSORCLUTCH HOUSINGREVERSE LOCK CAMREVEESE SHIFT HOLDERREVERSE IDLE GEARREVERSE GEAR SHAFTTHRUST WASHER,20 x 36 x 2COLLER, 15 x 20 x 20

aol

@o@@

(D

i9

@@@(9

@@@e3@

13-12

www.emanualpro.com

Page 456 of 1395

20.

2't.

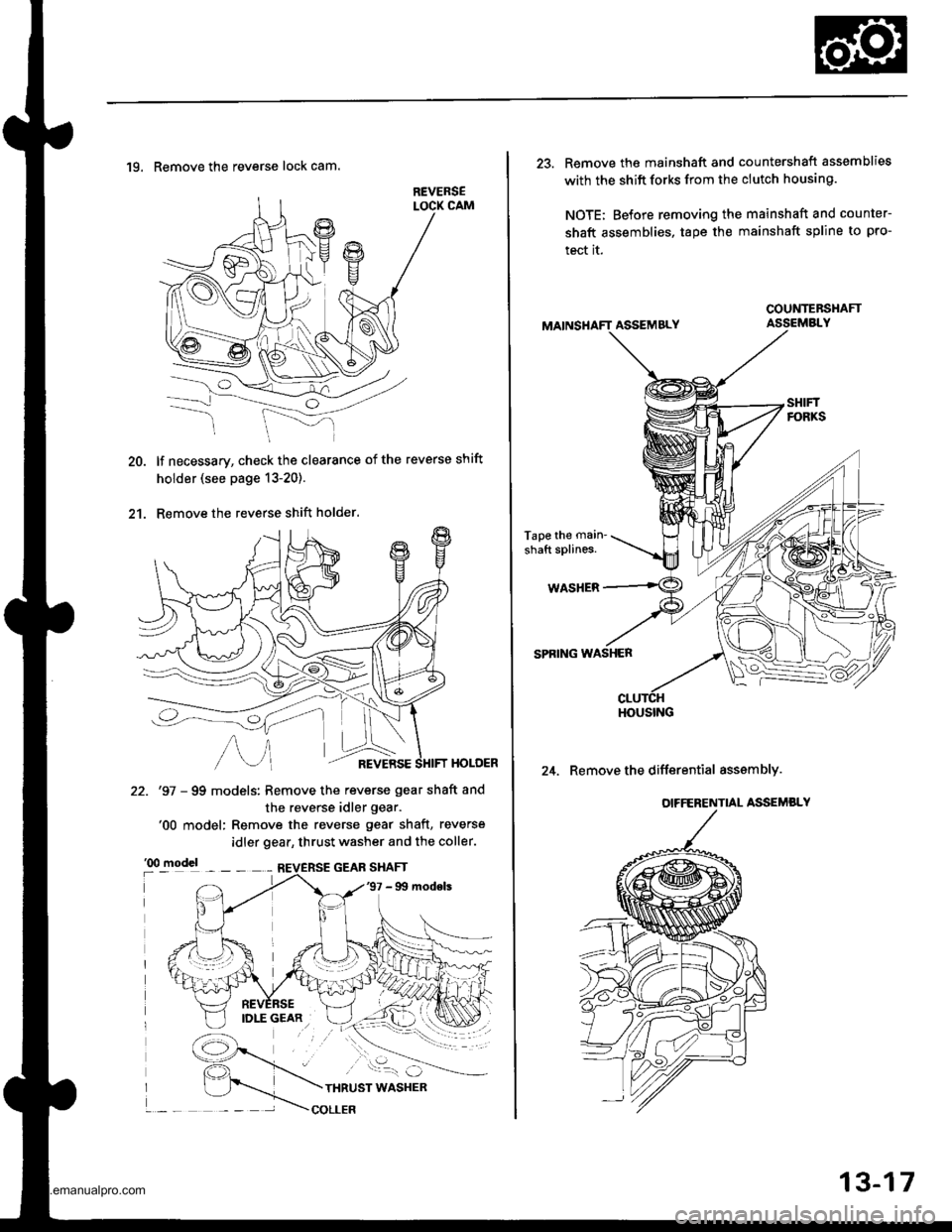

19. Remove the reverse lock cam.

lf necessary, check the clearance of the reverse shift

holder (see page 13-20).

Remove the reverse shift holder.

HOLOER

22. '97 - 99 models: Remove the reverse gear shaft and

the reverse idler gear.'00 model: Remove the reverse gear shaft, reverse

idler gear, thrust washer and the coller.

13-17

23. Remove the mainshaft and countershaft assemblies

with the shift forks from the clutch housing.

NOTE; Before removing the mainshaft and counter-

shaft assemblies, tape the mainshaft spline to pro-

tect it.

ASSEMBLY

Tape the main'

shaft splines.

WASHER

SPRING WASHER

24. Remove the differential asssmbly.

COUNTEBSHAFT

HOUSING

www.emanualpro.com

Page 462 of 1395

Mainshaft Assembly

lndex

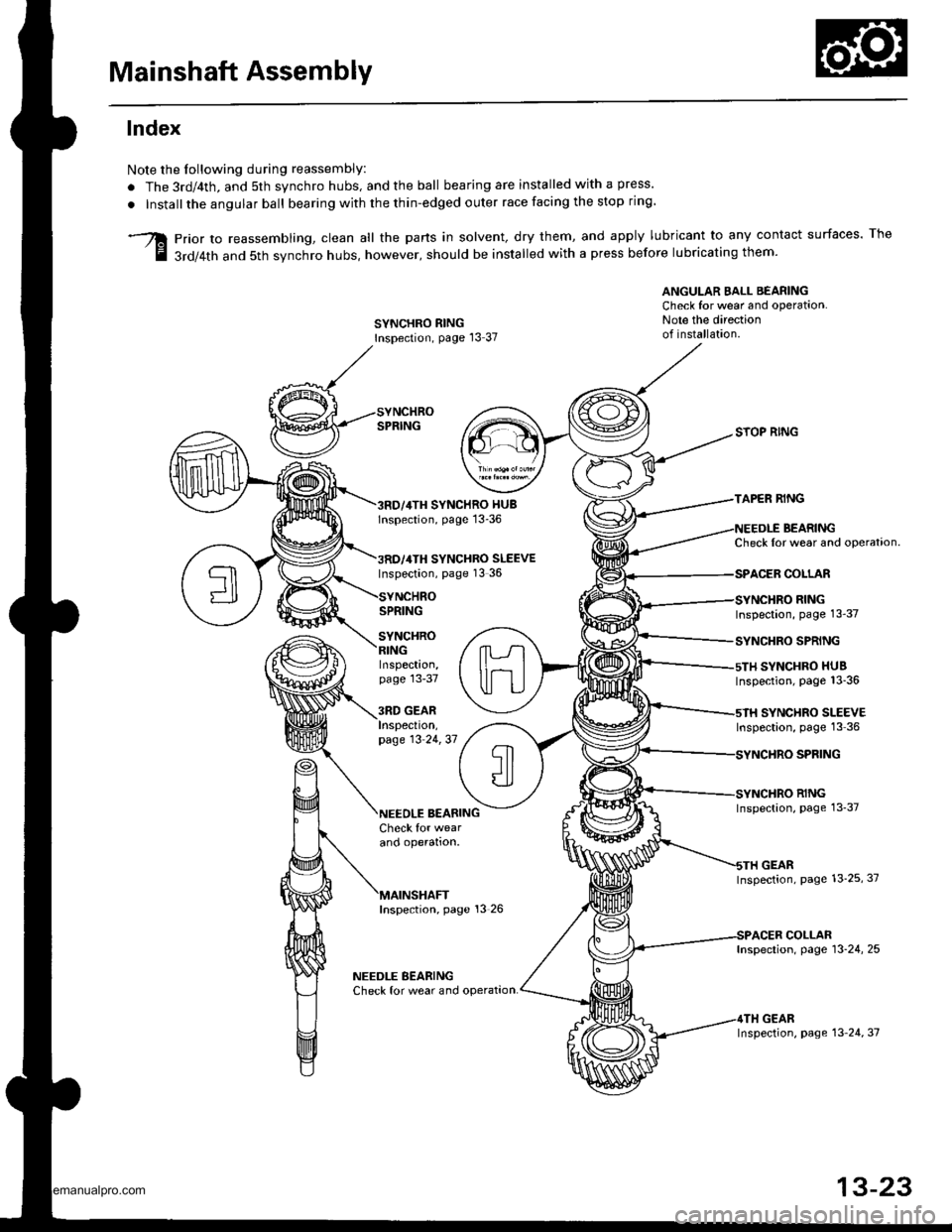

Note the Iollowing during reassembly:

. The 3rd/4th, and 5th synchro hubs, and the ball bearing are installed with a press.

. Installthe angular ball bearing with the thin-edged outer race facing the stop ring

prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact surfaces. The

3rd/4th and 5th svnchro hubs, however, should be installed with a press before lubricating them'

ANGULAR EALL BEARINGCheck for wear and operation.Note the directionof installation.SYNCHRO RINGInspection, page l3 37

SYNCHRO HUBlnspection, page 13-36

SYNCHRO SLEEVEInspection, page 13 36

SPRING

SYNCHRO

SYOP RING

TAPER RING

BEARINGCheck Ior wear and operataon.

COLLAR

RINGInspection, page 13-37

SYNCHRO SPRING

SYNCHRO HUBInspection, page 13_36

SYNCHRO SLEEVEInspection, page 13 36

SPFING

RINGInspection, page 13_37

GEARInspection, page 13_25, 37

COLLARInspection, page 13-24, 25

GEARInspection, page 13 24, 37

Inspection,page 13-37

3RD GEARInspeclton,page 13 24,37

BEARINGCheck for wearano operalton.

Inspection, page 13 26

NEEDLE BEARINGCheck for wear and operat,on.

13-23

www.emanualpro.com

Page 463 of 1395

Mainshaft Assembly

Clearance Inspection

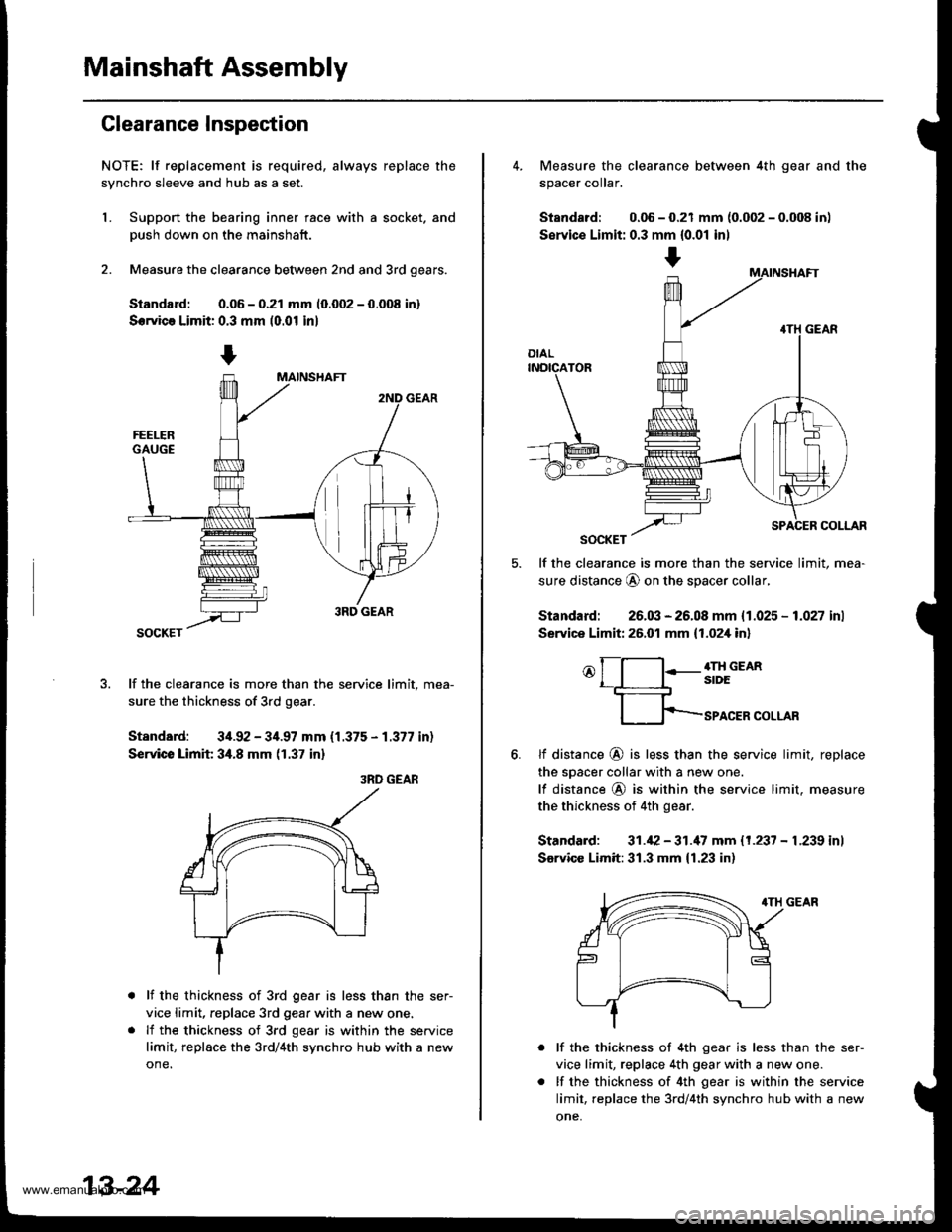

NOTE; lf replacement is required, always replace the

synchro sleeve and hub as a set.

L Support the bearing inner race with a socket. and

Dush down on the mainshaft.

2. Measure the clearance between 2nd and 3rd oears.

Siandard: 0.06 - 0.21 mm 10.002 - 0.008 in)

Servica Limit: 0.3 mm (0.01 in)

lf the clearance is more than the service limit, mea-

sure the thickness of 3rd gear.

Standard: 34.92 - 34.97 mm {1.375 - 1.377 in)

Service Limit 34.8 mm (1.37 in)

3RD GEAR

lf the thickness of 3rd gear is less than the ser-

vice limit, replace 3rd gear with a new one.

lf the thickness of 3rd gear is within the service

limit, replace the 3rd/4th synchro hub with a new

one.

13-24

+

4. Measure the clearance between 4th gear and the

spacer coIar,

Standard: 0.06 - 0.21 mm {0.002 - 0.008 in)

Servic€ Limit: 0.3 mm {0.01 inl

lf the clearance is more than the service limit, mea-

sure distance @ on the spacer collar,

Standard: 26.03 - 26.08 mm {1.025 - 1.027 inl

Service Limit: 26.01 mm {1.02,[ in]

o[-l:-g;;em

fp-rro.ERcoLLAR

6.tf distance @ is less than the service limit, replace

the sDacer collar with a new one.

lf distance @ is within the service limit. measure

the thickness of 4th gear.

Standard: 31.42 - 31.'17 mm 11.237 - L239 inl

Sarvicc Limit:31.3 mm {1.23 in)

lf the thickness of 4th gear is less than the ser-

vice limit, replace 4th gear with a new one.

lf the thickness of 4th gear is within the service

limit, replace the 3rd/4th synchro hub with a new

one,

www.emanualpro.com

Page 464 of 1395

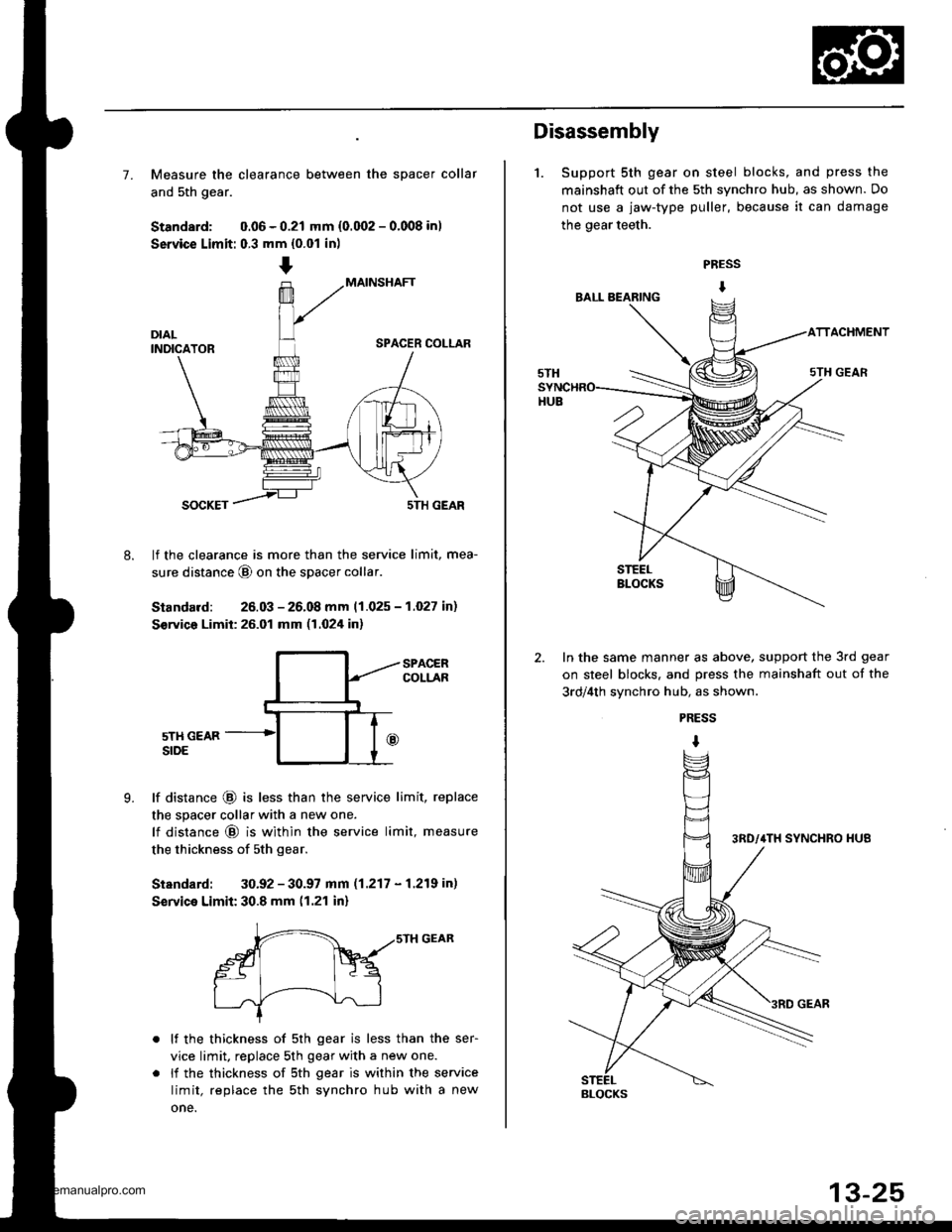

7. Measure the clearance between the spacer collar

and 5th gear.

Standard: 0.06 - 0.21 mm {0.002 - 0.008 in)

Service Limit: 0.3 mm {0.01 in)

MAINSHAFT

SPACER COLLAR

8.

SOCKET5TH GEAR

lf the clearance is more than the service limit, mea-

sure distance @ on the spacer collar

Standard: 26.03 - 26.08 mm 11.025 - 1.027 in)

S€rvico Limit: 26.01 mm (1.024 in)

9.

SPACERCOLLAR

5TH GEARSIDE

lf distance @ is less than the service limit, replace

the spacer collar with a new one.

lf distance @ is within the service limit, measure

the thickness of sth gear.

Standard: 30.92 - 30.97 mm (1.217 - 1.219 in)

Service Limit: 30.8 mm (1.21 in)

r-- ,,srH GEAR

gt Fq

I .J'-----!--\--J-l

lf the thickness of 5th gear is less than the ser-

vice limit, replace 5th gear with a new one.

li the thickness of sth gear is within the service

limit, replace the sth synchro hub with a new

one.

Disassembly

1. Support 5th gear on steel blocks, and press the

mainshaft out of the 5th synchro hub, as shown. Do

not use a jaw-type puller, because it can damage

the gear teeth.

PRESS

I

ACHMENT

In the same manner as above, support the 3rd gear

on steel blocks. and press the mainshaft out of the

3rd/4th svnchro hub, as shown.

PRESS

I

BLOCKS

www.emanualpro.com

Page 465 of 1395

Mainshaft Assembly

Inspection

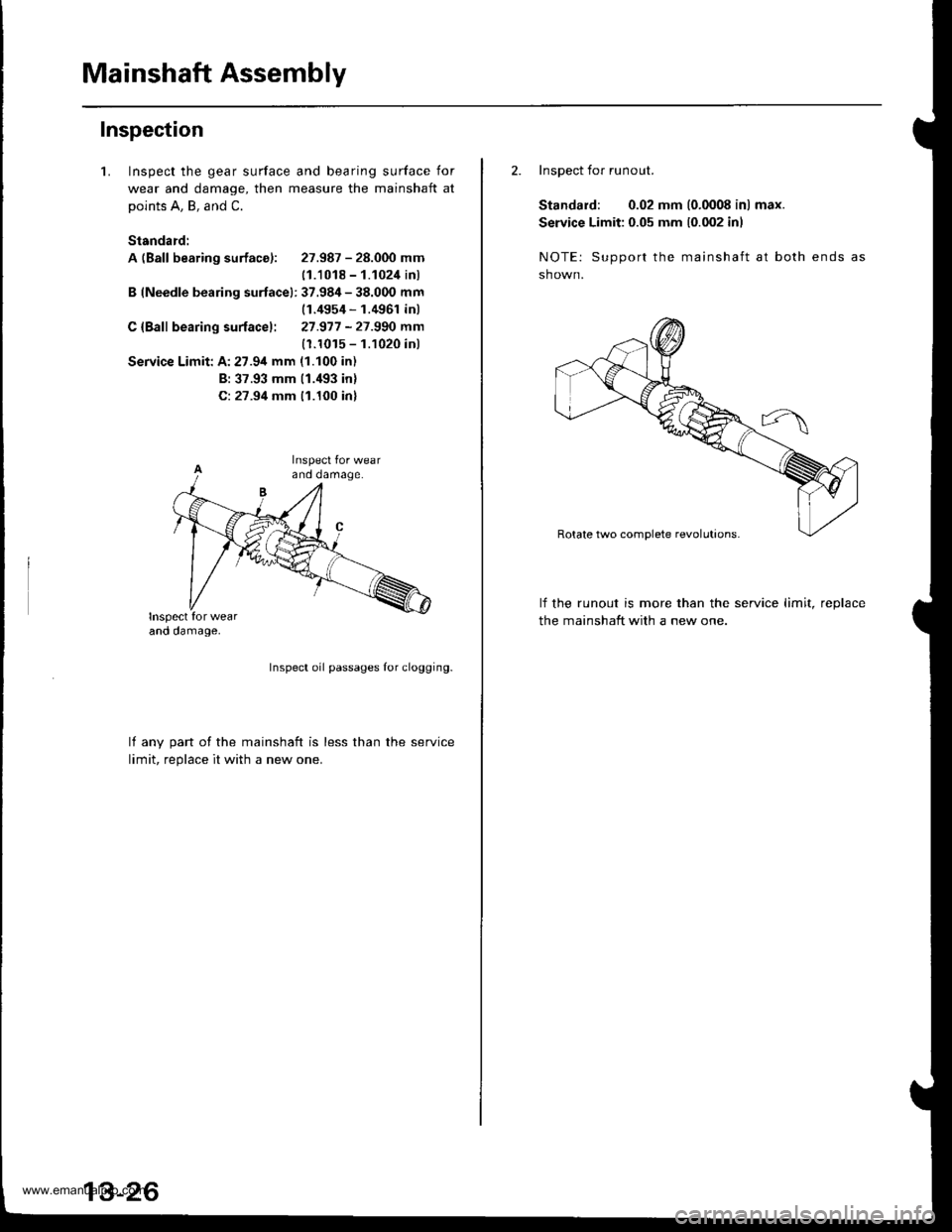

1.Inspect the gear surface and bearing surface for

wear and damage, then measure the mainshaft at

points A, B, and C.

Standard:

A (Ball bearing surface): 27.987 - 28.000 mm

11.1018 - 1.1024 inl

B (Needle bearing surfacel: 37.984 - 38.000 mm(1.4954 - 1.4961 inl

C {Bafl bearing surfacel: 27.977 -27.990 mm

(1.1015 - 1.1020 inl

Service Limit: A:27.94 mm (1.100 in)

B: 37.93 mm (1.'193 inl

C: 27.94 mm 11.100 inl

Inspect oil passages Ior clogging.

lf anv oart of the mainshaft is less than the service

limit. reolace it with a new one.

2. Inspect for runout.

Standard: 0.02 mm (0.0008 in) max.

Service Limit: 0.05 mm 10.002 inl

NOTE: Support the mainshaft at both ends

sh own.

lf the runout is more than the service limit, reDlace

the mainshaft with a new one.

www.emanualpro.com

Page 480 of 1395

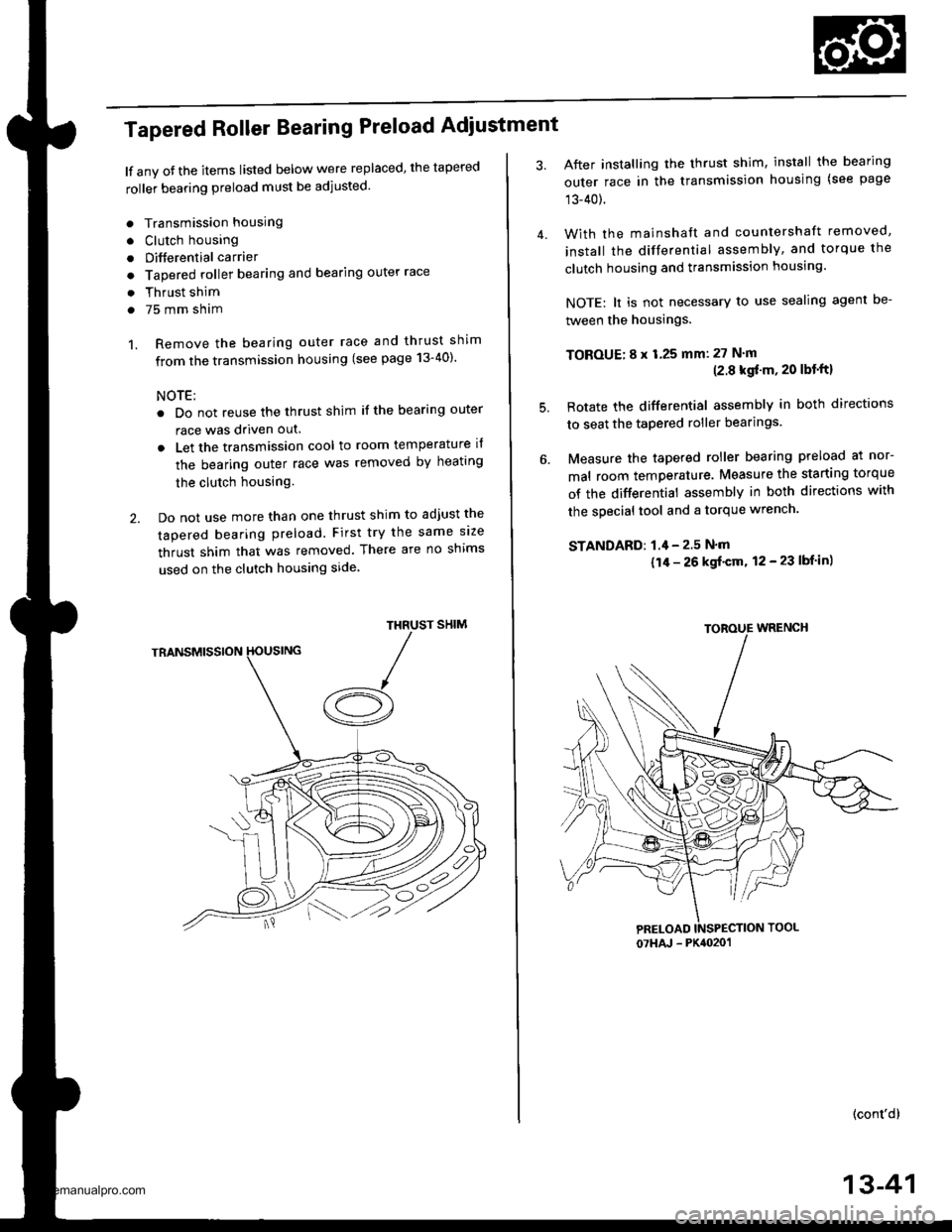

Tapered Roller Bearing Preload Adiustment

lf any oJ the items listed below were replaced, the tapered

roller bearing preload must be adjusted.

. Transmission housing

. Clutch housing

. Differential carrier

o Tapered roller bearing and bearing outer race

. Thrust shim

. 75 mm sham

1. Remove the bearing outer race and thrust shim

from the transmission housing (see page 13-40)'

NOTE:

. Do not reuse the thrust shim if the bearing outer

race was driven out.

. Let the transmission cool to room temperature il

the bearing outer race was removed by heating

the clutch housing.

2. Do not use more than one thrust shim to adjust the

tapered bearing preload. First try the same size

thrust shim that was removed. There are no shims

used on the clutch housing side

SHIMTHRUST

/A

After installing the thrust shim, install the bearing

outer race in the transmission housing (see page

13-40).

With the mainshaft and countershaft removed,

install the differential assembly, and torque the

clutch housing and transmission housing.

NOTE: lt is not necessary to use sealing agent be-

tween the housings.

TOBOUE; 8 x 1.25 mm: 27 N'm(2.8 kgf'm, 20 lbt'ftl

Rotate the differential assembly in both directions

to seat the tapered roller bearings.

Measure the tapered roller bearing preload at nor-

mal room temperature. Measure the starting torque

of the differential assembly in both directions with

the special tool and a torque wrench.

STANDAFD: 1.4 - 2.5 N'm

{1/r - 26 kgf'cm, 12 - 23 lbf in)

(cont'd)

4.

5.

07HAJ - PK4020'�1

13-41

www.emanualpro.com