Gauge HONDA CR-V 1998 RD1-RD3 / 1.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 964 of 1395

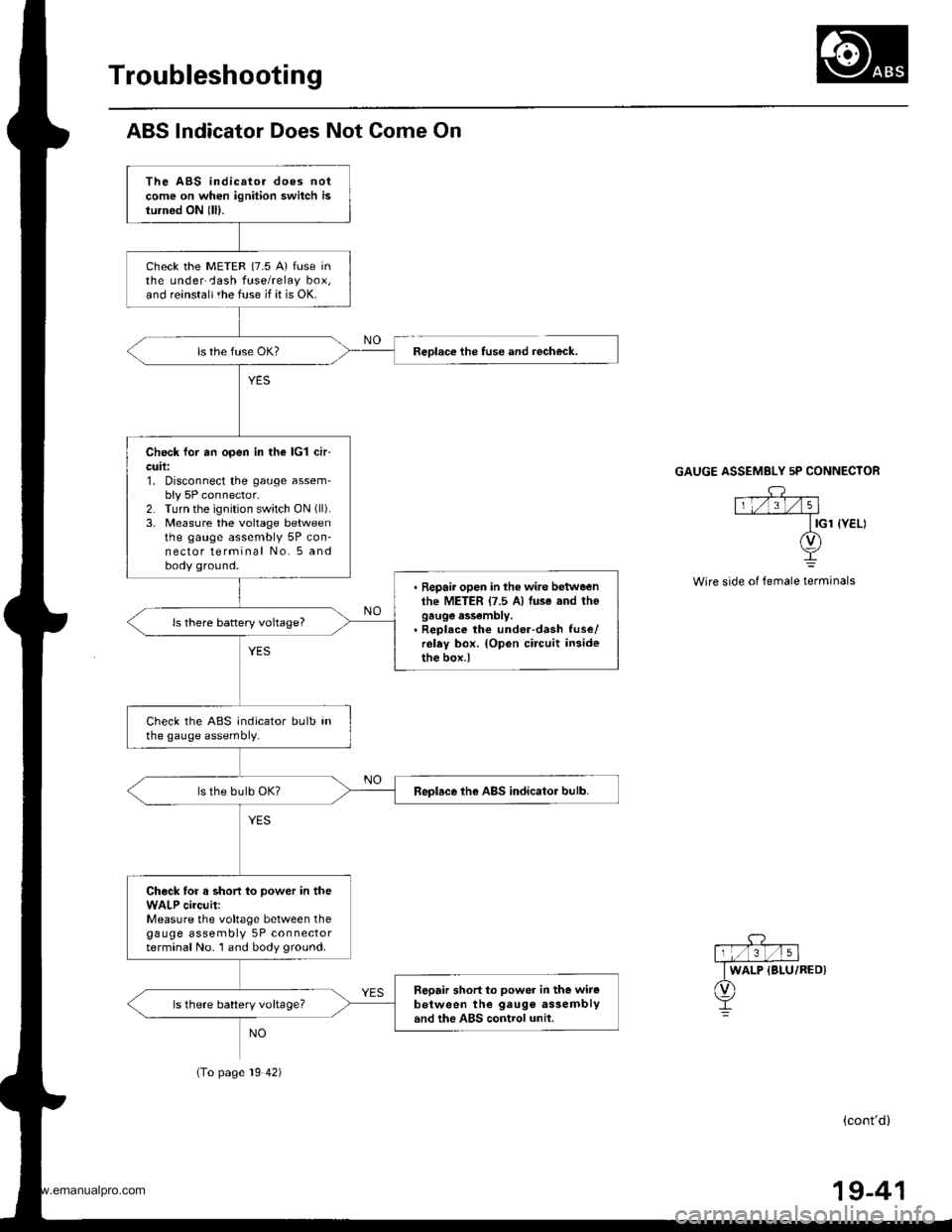

Troubleshooting

ABS lndicator Does Not Come On

The ABS indicator does notcome on when ignition switch isturnod ON lll).

check the METER {7.5 A} fuse inthe underCash fuse/relay box,and reinstaltthe fuse if it is OK.

Check for an open in the lcl ch-cuil:1. Disconnect the gauge assem-bly 5P connector.2. Turn the ignition switch ON (ll).

3. Measure the voltage betweenthe gauge assembly 5P con-nector terminal No. 5 andbody ground.

. Repair open in the wire betweenlhe METER {7.5 A) luse and thogauge assembly.. Reolece the under-dash fuse/relay box. (Opon circuit insidethe box.)

ls there battery voltage?

Check the ABS indicator bulb inthe gauge assembly.

Replace the ABS indicator bulb.

Check for a short to power in theWALP circuit:Measure the voltage between thegauge assembly 5P connectorterminal No. 1 and body ground.

Sepair short to power in the witeb€tween the gaug€ assemblyand the ABS control unil.ls there battery voltageT

Reolace the tuse and recheck.

(To page 19 42)

GAUGE ASSEMBLY 5P CONNECTOR

Wire side of female terminals

(cont'd)

19-41

www.emanualpro.com

Page 965 of 1395

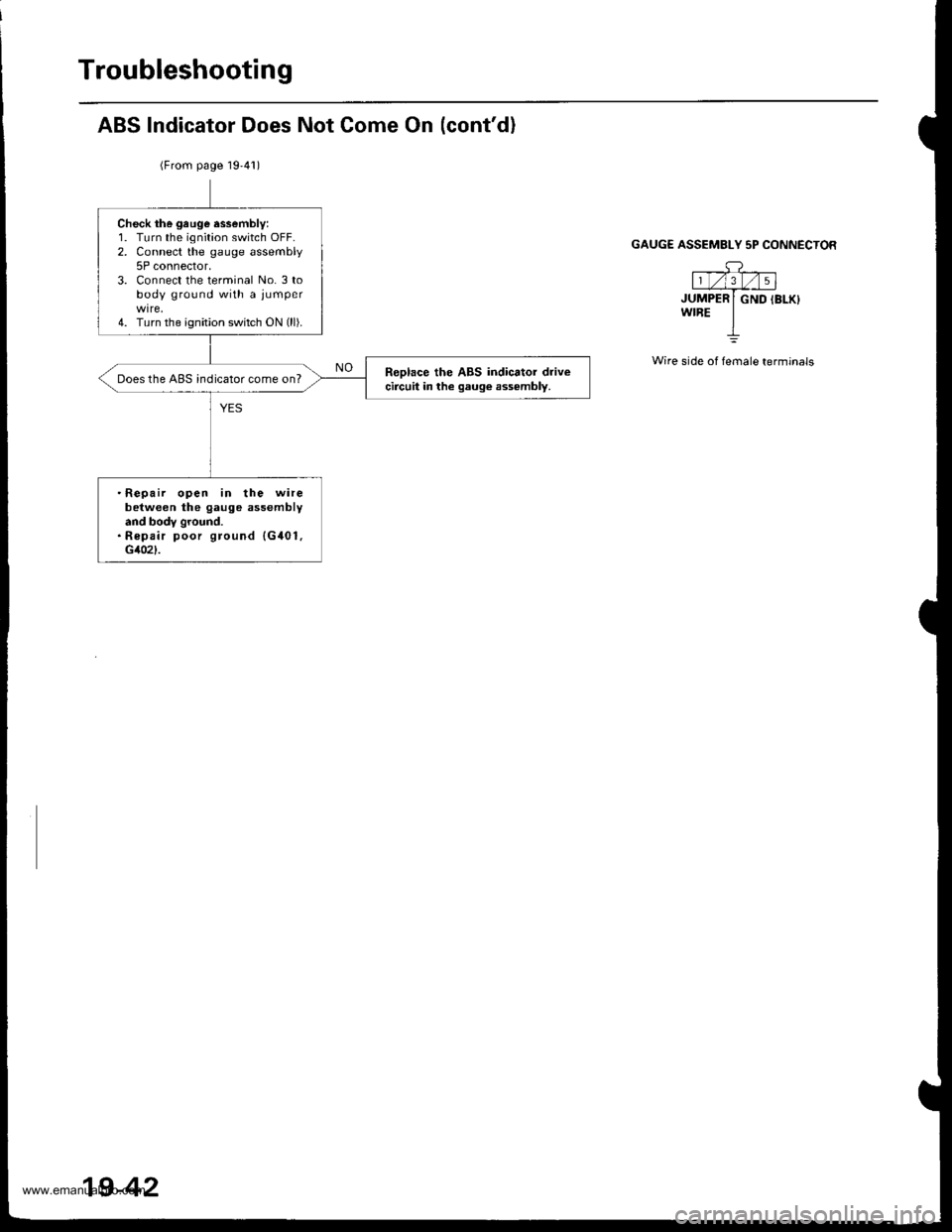

Troubleshooting

ABS Indicator Does Not Come On (cont'd)

(From page 19'41)

GAUG€ ASSEMBLY 5P CONNECTOR

---g-l1 t/l3_l/ | 5 |JUMPER I GND IBLK}wrBE IL

Wire side of female terminals

Check the gruge essembly:1. Turn the ignition switch OFF.2. Connect the gauge assembly5P connector,3. Connect the terminal No. 3 tobody ground with a jumper

4. Turn the ignition switch ON (ll).

Reolace the ABS indicator drivecircuit in the gaug€ ass€mbly.Does the ABS indicator come on?

.Repair open in the wirebetween the gauge assemblyand body ground.. Repair poor ground {G401,c102l-

19-42

www.emanualpro.com

Page 967 of 1395

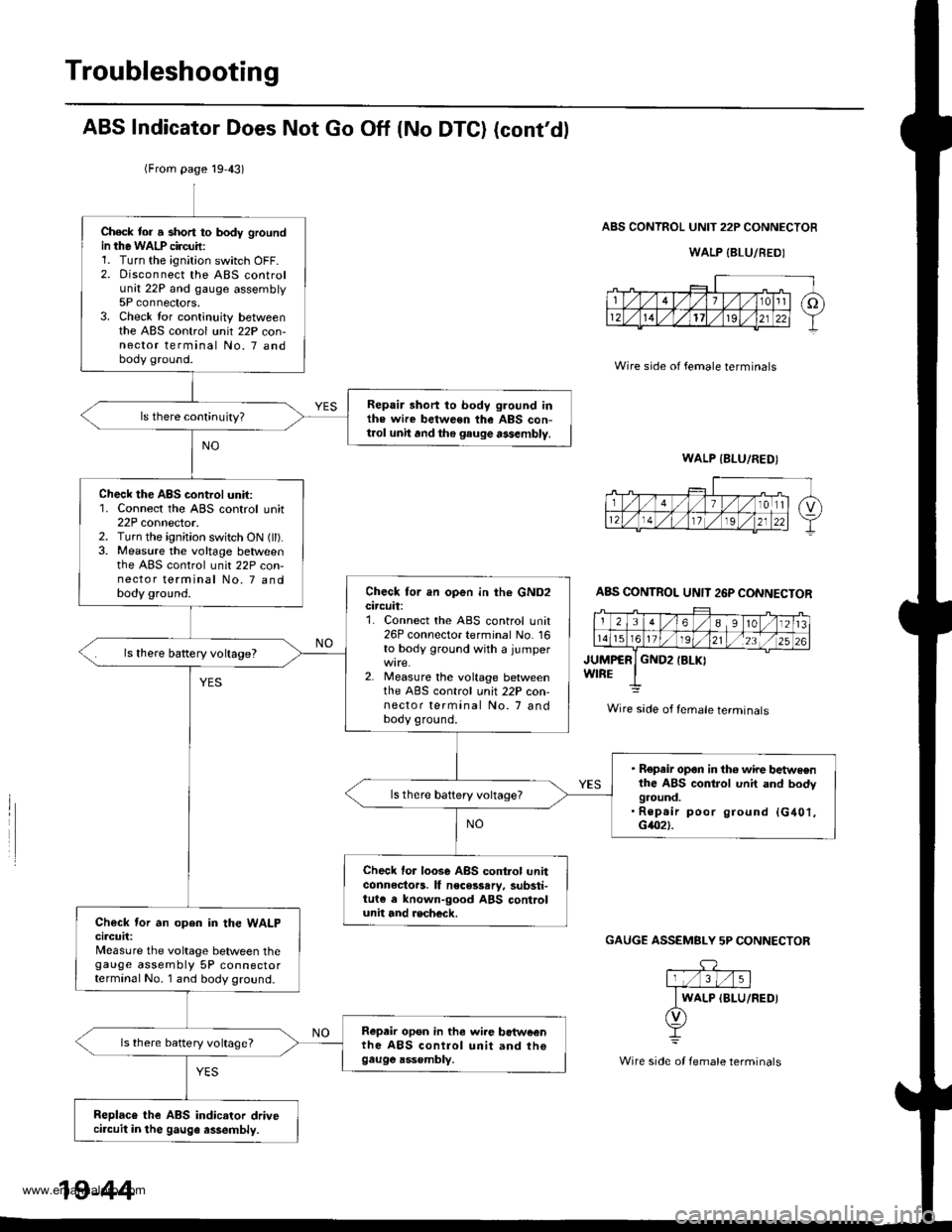

Troubleshooting

ABS Indicator Does Not Go Off (No DTC) (cont'dl

ABS CONTROL UNIT 22P CONNECTOR

WALP {BLU/REDI

Wire side of female terminals

JUMPCRWIREGND2IBLKI

GAUGE ASSEMBLY 5P CONNECTOF

(From page 19,43)

Check tor a short to body groundin the WALP circuil:1. Turn the ignition switch OFF.2. Disconnect the ABS controlunit 22P and gauge assembly5P connectors.3. Check lor continuity betweenthe ABS control unit 22P con-nector terminal No. 7 andbody ground.

Repair short to body ground inthe wire between the ABS con-t.ol unh and the gauge assembly.

Check the ABS control unit:1. Connect the ABS control unit22P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betweenthe ABS control unit 22P con-nector terminal No. 7 andbody ground.Check tor an open in the GND2circuit:1. Connect the ABS control unit26P connecto. terminal No. 16to body ground with a jumper

2. Measure the voltage betweenthe ABS control unit 22P con-nector terminal No. 7 andbody ground.

ls there battery voltage?

. Repeir op6n in th6 wire ttetweenthe ABS control unit and bodyground.. Rep.ir poor ground {G401,G4021.

Check lor loose ABS control unhconnectors. lf necesssry, substi-tuie e lnown-good ABS controlunit and recheck.Check tor an open in the WALPcircuit:Measure the voltage between thegauge assembly 5P connectorterminal No. 1 and body ground.

Repair op6n in the wi.e botw€enthe ABS control unit and th€gau9e ass€mbly.

ls there battery voltage?

Replaco the ABS indicator drivecircuit in the gauge assembly.

ABS CONTROL UNIT 26P CONNECTOR

Wire sade of female terminals

WALP IBLU/FEDI

19-44

www.emanualpro.com

Page 1036 of 1395

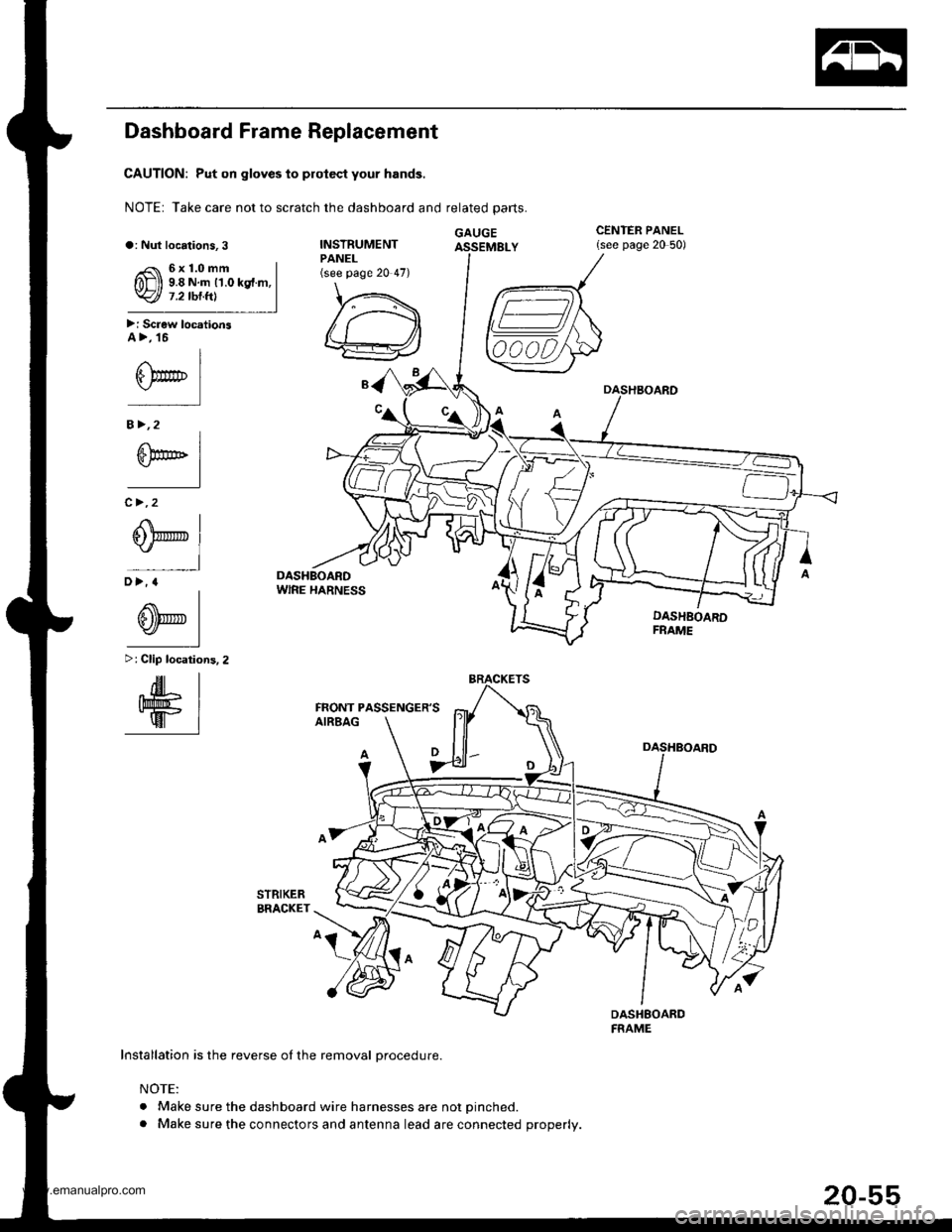

Dashboard Frame Replacement

CAUTION: Put on gloves to prolect your hands.

NOTE: Take care not to scratch the dashboard and related parts.

GAUGEa: Nut locations,3INSTRUMENTPANEL(see page 20 47)

\,.\

/ ,.-------f,\

lu /A

w

CENTER PANEL{see page 20 50)

6x1.0mm9.8 N.rn 11.0 kgf.m,7.2 tbt.ftl

>i Screw locationsA>,16

I

\,r*

B>,2

^l

S@t' 1-l

c >,2

I

0@l"l

D>.a

^l

0Fl-l

>: Clip localions.2

.dr IIhll'rifi- |-wr

i

DASHBOARDFRAME

DASHBOARDwlRE HARNESS

Installation is the reverse oI the removal orocedure.

NOTE:

. Make sure the dashboard wire harnesses are not Dinched.. Make sure the connectors and antenna lead are connected properly.

FRONT PASSENGER'S

www.emanualpro.com

Page 1092 of 1395

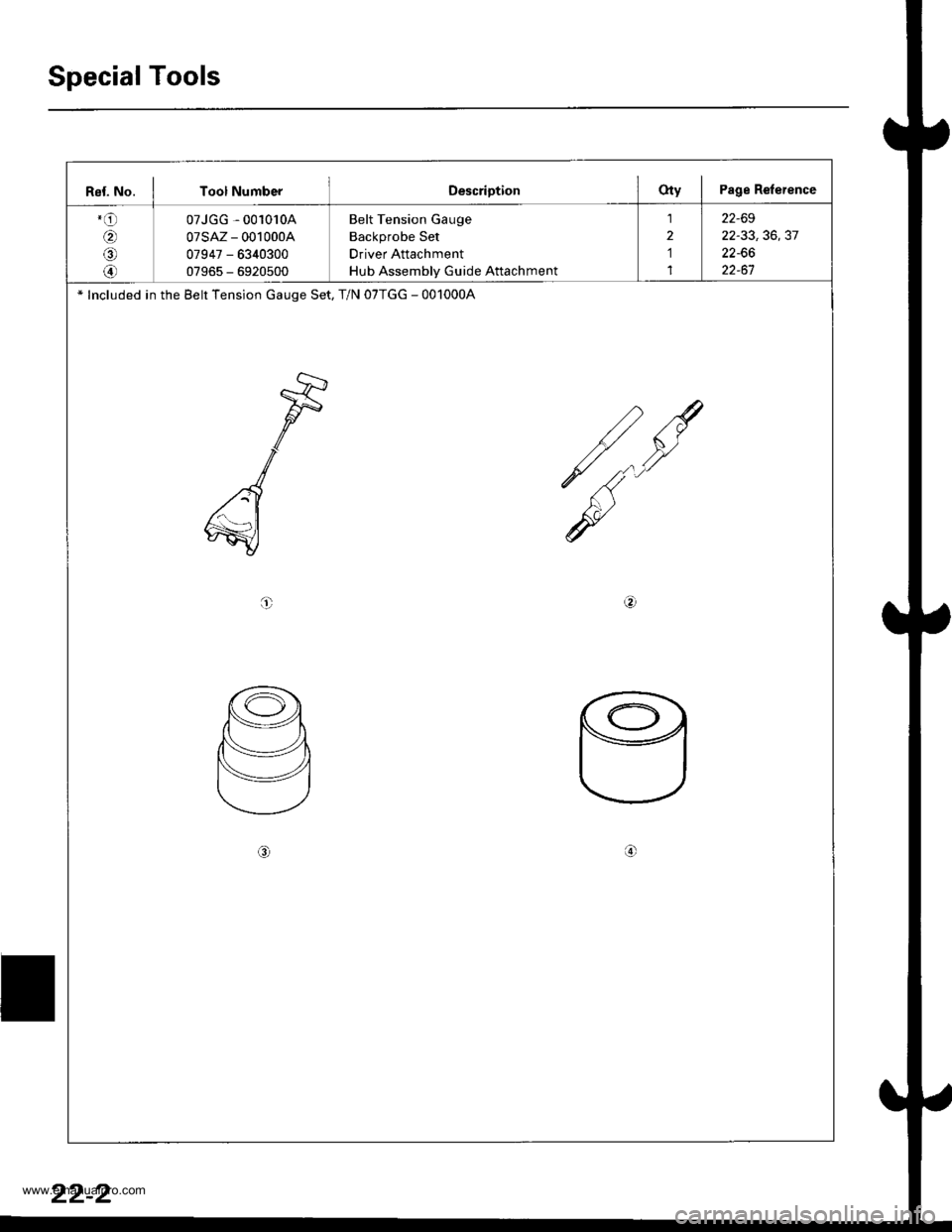

Special Tools

Rel. No. I Tool NumberDescriptionOty I Page Relerence

.o

6,

@

@

07JGG - 001010A

07sAz - 001000A

07947 - 6340300

07965 - 6920500

Belt Tension Gauge

Backprobe Set

Driver Attachment

Hub Assembly Guide Attachment

1

2

1

1

22-69

22-33,36,37

22-66

22-61

* Included in the Belt Tension Gauge Set, T/N 07TGG - 001000A

t

o

22-2

www.emanualpro.com

Page 1146 of 1395

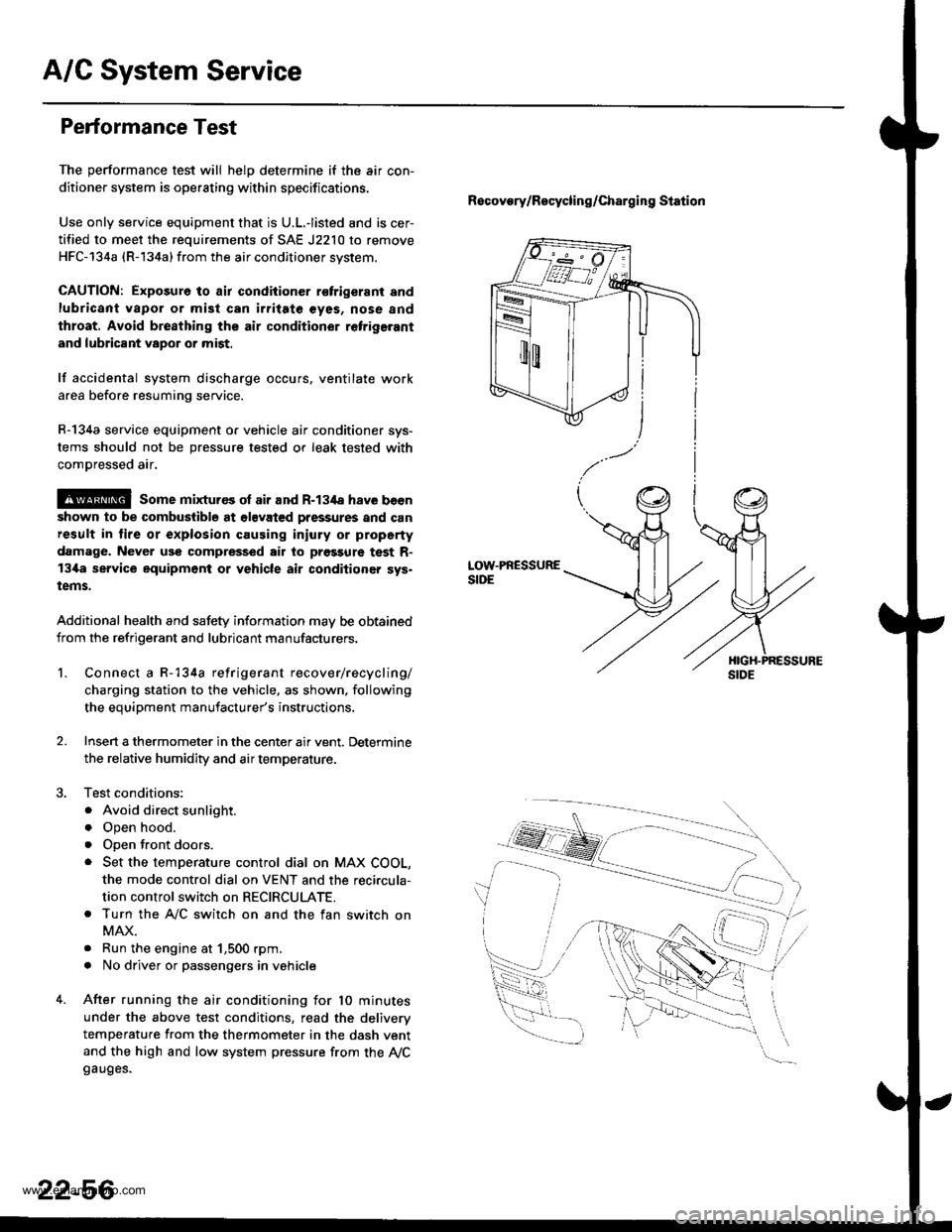

A/G System Service

Performance Test

The performance test will helD determine if the air con-

ditioner system is operating within specifications.

Use only service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner svstem.

CAUTION: Exposure to air condiiioner r€trigerant and

lubricant vapor or mist can irritate €yes, nose and

throat. Avoid bre8thing the air conditioner retrige.ant

and lubricant vapor or mist,

lf accidental system discharge occurs. ventilate work

area before resuming service.

R-134a service equipment o. vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

comDressed air.

@ some mixtur€s ol air and R-134a have becn

shown to be combuslible at olsvated pressures and can

result in lire or explosion causing iniury or property

damage. Never use compressed air to prgssure test R-

13i[a service equipment or vehicle air conditioner sys.

tems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

Recovory/Recycling/charging station

LOW.PRESSURESIDE

1.Connect a R-134a refrigerant recover/recycling/

charging station to the vehicle, as shown. following

the equipment manufacturer's instructions,

Insen a thermometer in the center air vent. Determine

the relative humidity and air temperature.

Test conditions:

. Avoid direct sunlight.

o Open hood.

. open front doors.

. Set the temperature control dial on MAX COOL,

the mode control dial on VENT and the reci.cula-

tion control switch on RECIRCULATE.

. Turn the A,/C switch on and the fan switch on

MAX.

. Run the engine at 1,500 rpm.

. No driver or passengers in vehicle

After running the air conditioning for 10 minutes

under the above test conditions, read the deliverv

temperature from the thermometer in the dash vent

and the high and low system pressure from the Ay'Cgauges.

2.

22-56

www.emanualpro.com

Page 1148 of 1395

A/C System Service

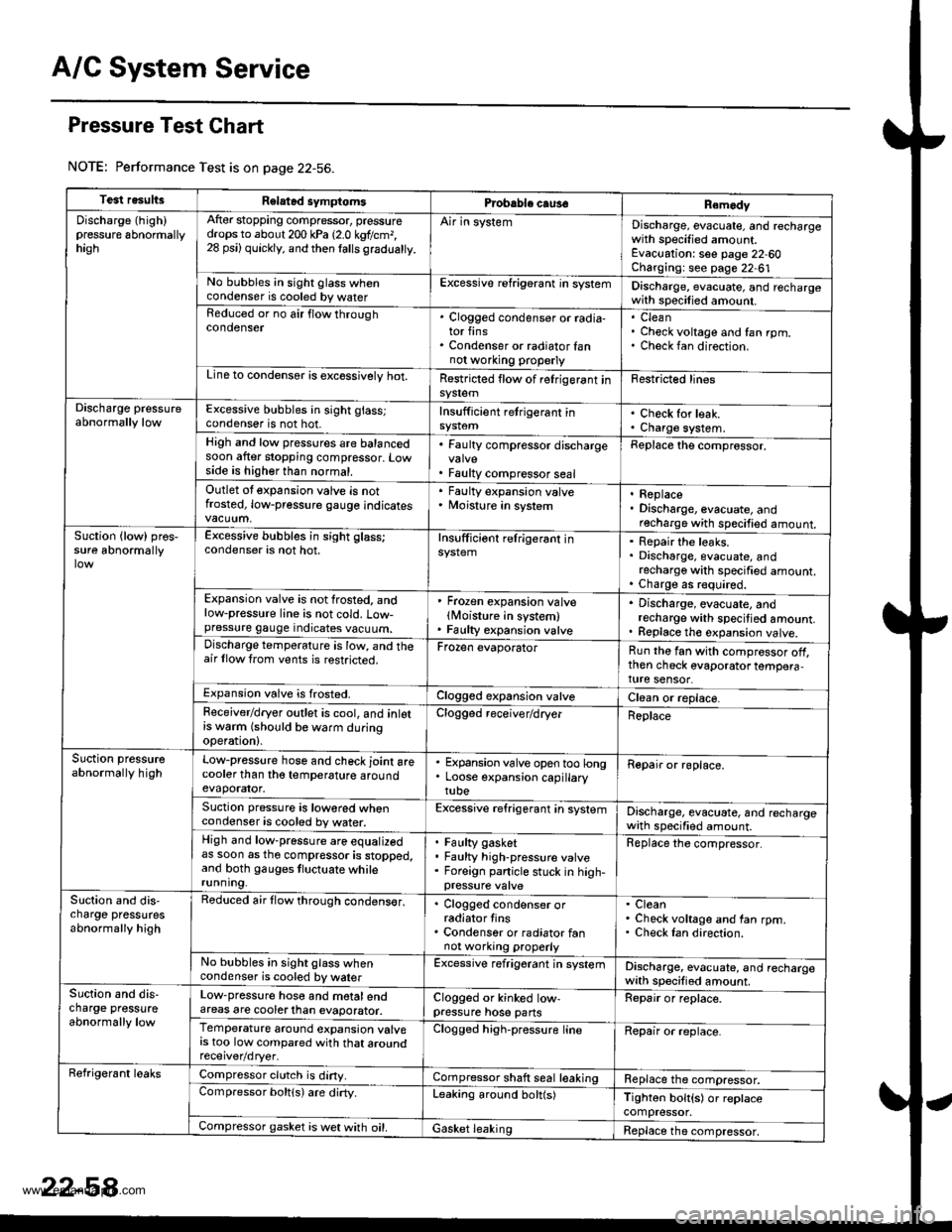

Pressure Test Chart

NOTE: Performance Test is on page 22-56.

Test resultsRelatad symptomsPrcbable caus€Remody

Discharge (high)pressure 6bnormallyhagh

After stopping compressor, pressuredrops to about 200 kPa 12.0 kgtlcm,,28 psi) quickly, and then lalls gradualty.

Air in systemDischarge, evacuate, and rechargewith specified amount.Evacuation: see page 22-60Charging: see page 22-61No bubbles in sight glass whencondenser is cooled by waterExcessive refrigerant in systemDischarge, evacuate, and rechargewith specilied amount.Reduced or no air flow throughcondenser. Clogged condenser or radia-tor fins. Condenser or radiator fannot wo.king properly

CleanCheck voltage and fan rpm.Check fan direction.

Line to condensor is excossivelv hot.Restricted flow of relrigerant insy$emFestricted lines

Discharge pressureabnormally lowExcessive bubbles in sight glass;condenser is not hot.Insufficient retrigerant inCheck for leak.Charge system.High and low pressures are balancedsoon after stopping compressor. Lowside is higher than normal.

. Faulty compressor discharge

. Faulty compressor seal

Replace the comprossor.

Outlet ot expansion valve is notfrosted, low-pressure gauge indicates

' Faulty expansion valve. Moisture in system. Replace. Discharge, evacuate, andrecharge with specified amount.Suction {low) pros,sure abnormallyExcessive bubbles in sight glass;condenser is not hot.Insufficiont relrigerant inRepair the leaks.Discharge, evacuate, andrecharge with specified amount.Charge as r€quired.Expansion valve is not frosted, andlow-pressure line is not cold. Low-pressure gauge indicates vacuum.

' Frozen expansion valvelMoisture in system). Faulty expansion valve

. Discharge, evacuate, andrecharge with specitied amount.. Replace th€ expansion valve.Discharge temperature is low, and theair llow trom vents is restricted.Frozen evaporatorRun the fan with compressor off,then check evaporator tempera,ture sensor.Expansion valve is frosted.Clogged expansion valveClean or replace.Feceiver/dryer outlet is cool, and inlotrs w6rm (should be warm duringoperation).

Clogged receiver/dryerReplace

Suction pressureabnormally highLow-pressure hose and check joint arecooler than tho temperature aroundevaporator.

. Expansion valve open too long. Loose expansion capillarytube

Repair or roplace.

Suction pressure is lowored whencondenser is cooled by water.Excessive refrigerant in systemDischarge, evacuate, and rechargewath specified amount.High and low-pressure are equalizedas soon as tho compressor is stopped,and both gauges tluctuate whilerunning.

Faulty gasketFaulty high-pressure valveForeign panicle stuck in high-

Replace the compressor.

Slction and dis,charge pressutesabnormally high

Reduced air flow through condens€r,. Clogged condenser orradiator tins. Condenser or radiator fannot working properly

CleanCheck voltage and fan rpm.Check Ian direction.

No bubbles in sight glass whencondenser is cooled by walerExcessive refrigerant jn systemDischarge, evacuate, and rechargewith specified amount.Suction and dis-charge pressureabnormally low

Low-pressure hose and motalendareas are cooterlhan evaporator.Clogged or kinked low-pressure hose pansRepair or replace.

Temperature around expansion valvers too low compared with that aroundClogged high-pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny.Compressor shaft seal leakingReplace the compressor.Compressor boltls) are dirty.Leaking around bolt(s)Tighton bolt{s) or replacecompressor.Compressor gasket is wet with oil.Gasket leakingReplace the compressor,

www.emanualpro.com

Page 1159 of 1395

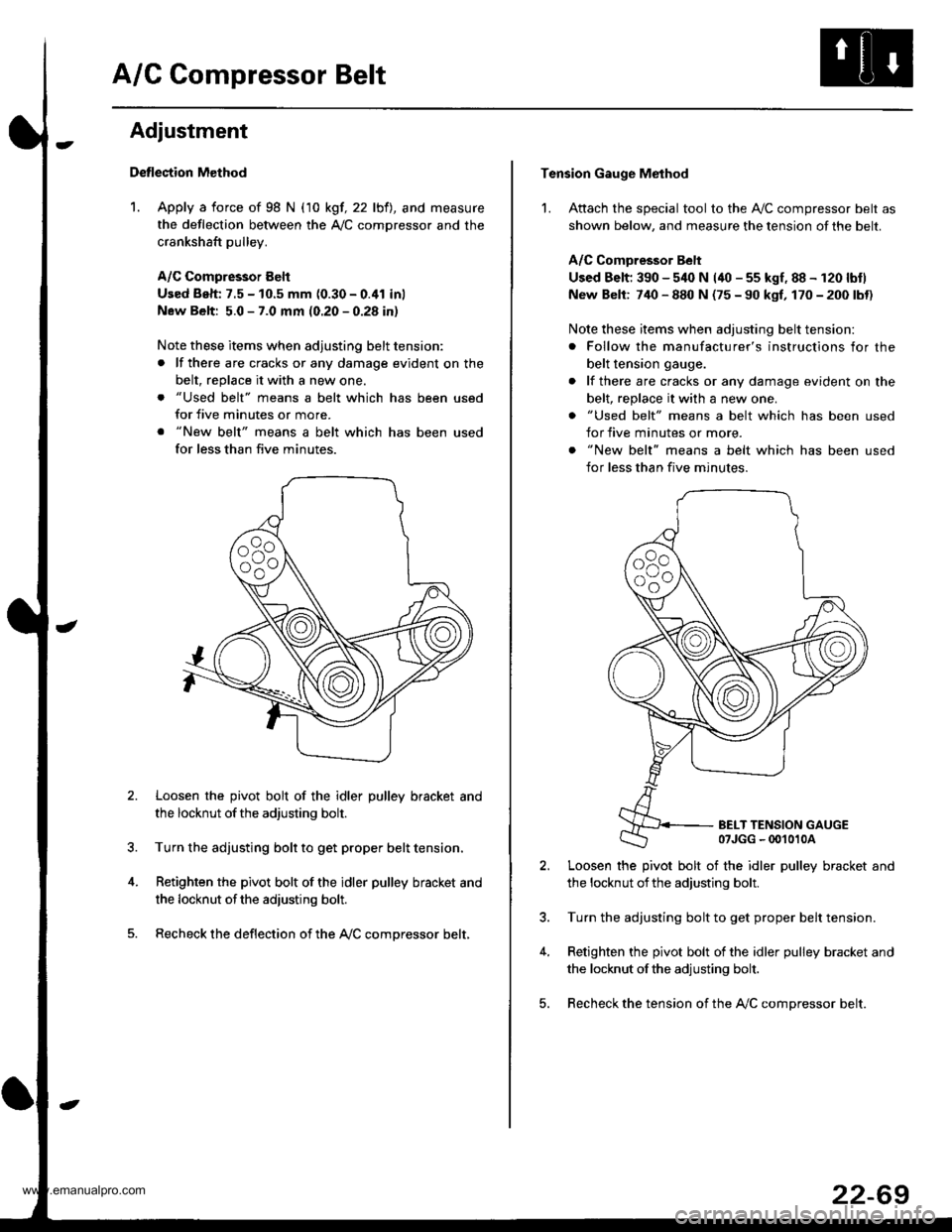

A/C Compressor Belt

Adjustment

Detlection Method

1. Apply a force of 98 N (10 kgf, 22 lbfl, and measure

the deflection between the A,/C comDressor and the

crankshaft pulley.

A/C Compressor Eelt

Used Beh: 7.5 - 10.5 mm (0.30 - 0.41 inl

New Belt: 5.0 - 7.0 mm (0.20 - 0.28 in)

Note these items when adjusting belt tension:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes.

Loosen the pivot bolt of the idler pulley bracket and

the locknut ofthe adjusting bolt.

Turn the adjusting bolt to get proper belt tension,

Retighten the pivot bolt of the idler pulley bracket and

the locknut ofthe adiusting bolt.

Recheck the deflection of the A,/C compressor belt,

Tension Gauge Method

1. Attach the special tool to the Ay'C compressor belt as

shown below, and measure the tension of the belt.

A/C Comoressor Belt

Used Belt; 390 - 540 N (40 - 55 kgf, 88 - 120 lbtl

New Belt: 740 - 880 N (75 - 90 kgf, 170 - 200 lbt)

Note these items when adjusting belt tension:

. Follow the manufacturer's instructions for the

belt tension gauge.

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes.

BELT TENSION GAUGE07JGG - 00't010A

Loosen the pivot bolt of the idler pulley bracket and

the locknut ofthe adjusting bolt.

Turn the adjusting bolt to get proper belt tension.

Retighten the pivot bolt of the idler pulley bracket and

the locknut ofthe adjusting bolt.

Recheck the tension of the A,/C compressor belt.

22-69

www.emanualpro.com

Page 1161 of 1395

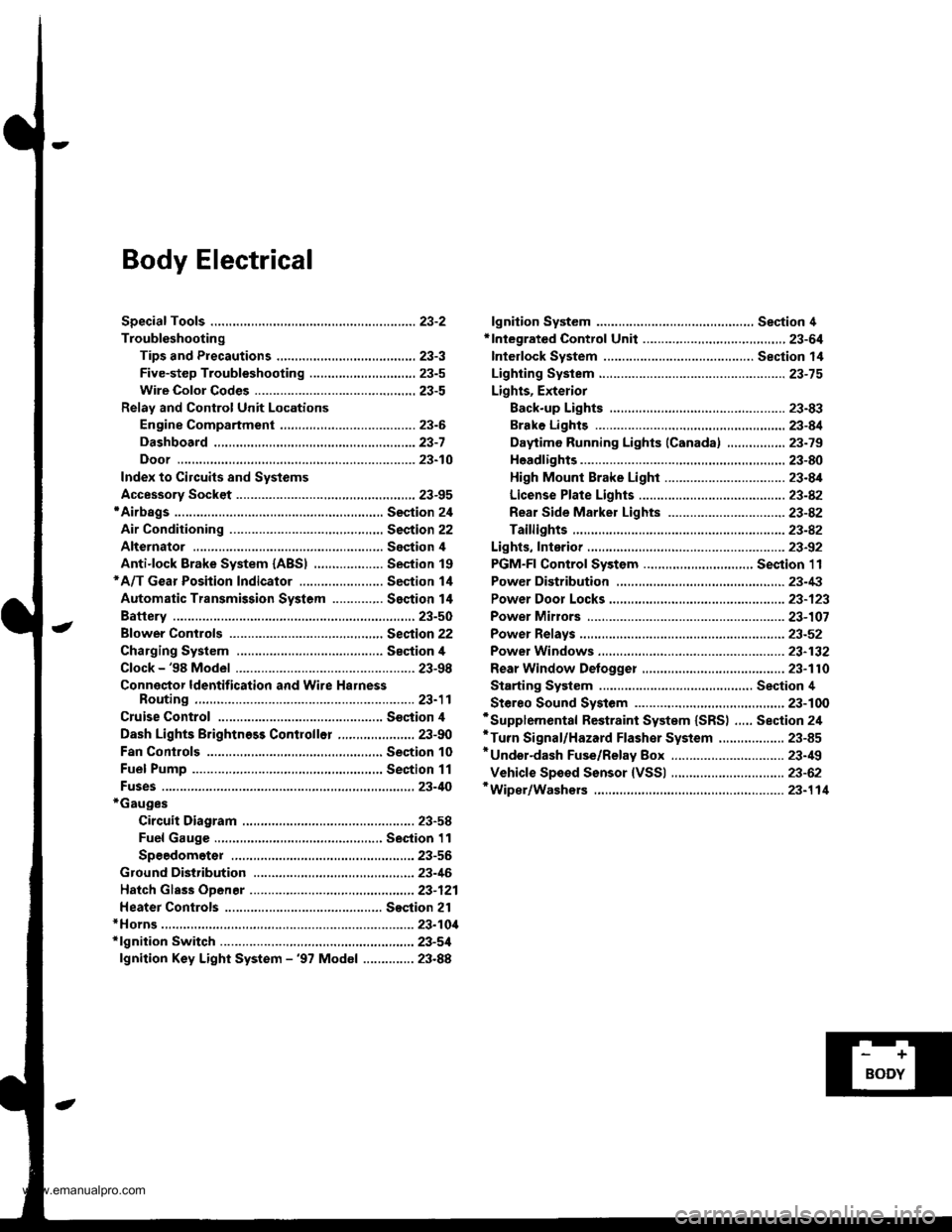

Body Electrical

Speciaf Toofs ,...,..,.............-.23-2

Troubleshooting

Tips and Precautions ......,.,..........,.................. 23-3

Five-step Troubleshooting ........,.,.,...,,.,......... 23-5

Wire Color Codes ...,....,.. 23-5

Relay and Control Unit Locations

Engine Compartment ..,.,......,......................... 23-6

Dashboard ,.,.,..............-.- 23-7

Door ....................... .........23-10

Index to Cilcuits and Sysiems

Accessory Socket .. ,....,.,..,.,. 23-95*Airbags ................ .,....,. Sestion 24

Air Conditioning ,.,.,.... Section 22

Alternator ................... Section 4

Anti-lock Brake System {ABSI ................... Section 19'A/T Gear Position Indicator ....................... Section 1,1

Automatic Transmission System ...........,.. Section 14

Battery ................... ..............23-50

Blower Controls .,...,.,, Section 22

Charging System ....... Seqtion il

Clock -'98 Model ................ 23-98

Connector ldentification and Wire HarnessRouting .................. ......... 23.11

Cruise Control ............ Ssction 4

Dash Lights Brightness Contlo||er ..................... 23-90

Fan Conlrols ...,......,.... Section 10

Fuel Pump ,..,.,...,....,.... Section 11

Fuses...................... .,,.,.,.,.,,.,23-40*Gauges

Circuit Diagram ......-....-..23-58

Fuel Gauge .....,.,..... Section 11

Speedometer ..,..........,... 23-56

Ground Distribution ,....,.,...23-46

Hatch Glsss ODenor .........................,.,.,.,.,..,.,.,.,,. 23-121

Heater Controls .-........ Soction 21*Horns.,...,..,.,.,....... ................23"104*fgnition Switch ,,.,.,..,.,.,,.,.,.,23-51

lgnition Key Light System -'97 Mod6l .............. 23.88

-+

BODY

www.emanualpro.com

Page 1184 of 1395

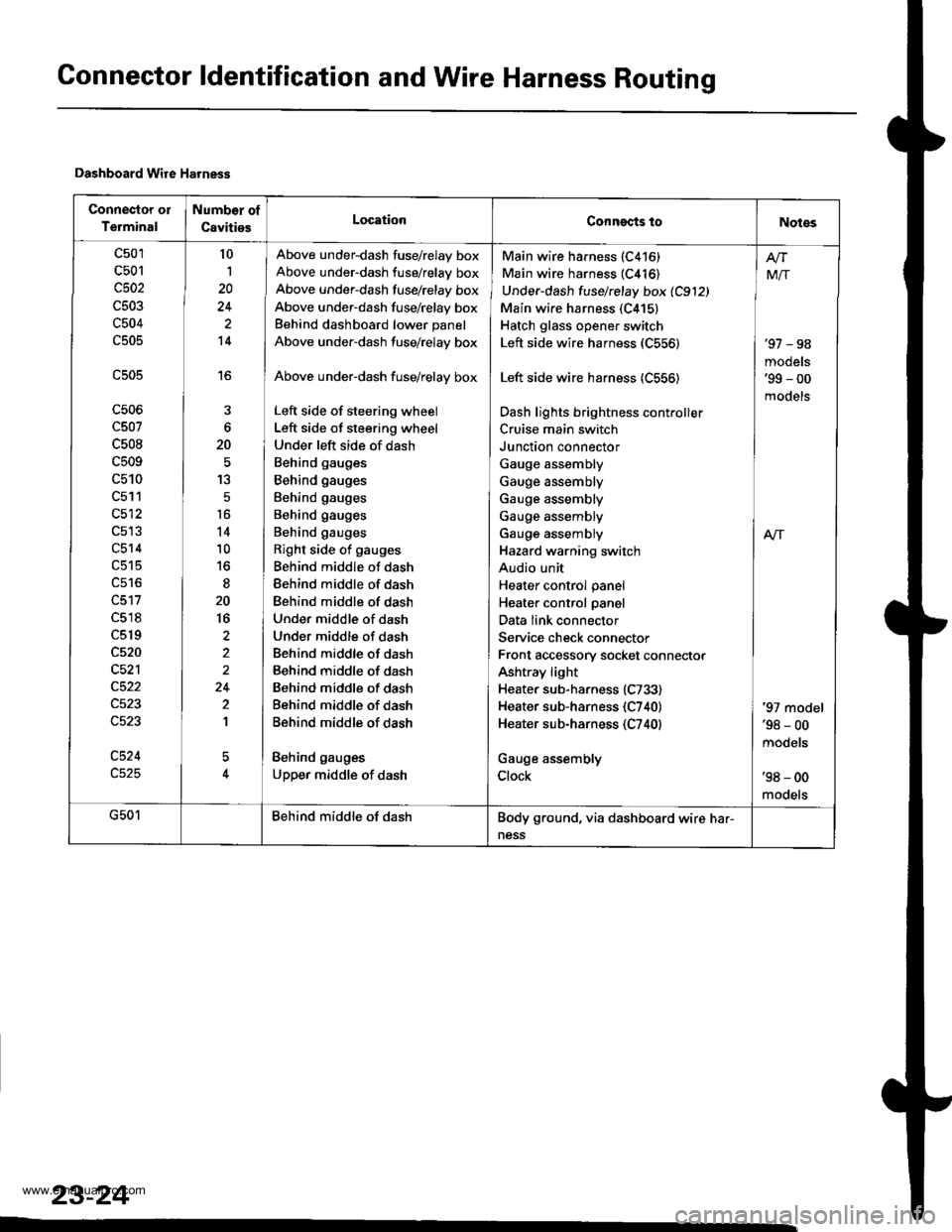

Connector ldentification and Wire Harness Routing

Dashboard Wire Harness

Connector ol

Terminal

Numb€r of

CavitiesLocationConngcts toNotes

c501

c501

c502

c503

c504

c505

c506

c507

c508

c509

c510

c511

c512

c514

c518

c519

c520

c521

c524

10

1

20

14

16

6

20

13

5

t6

14

10

to

20

16

2

24

2

1

5

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Above under-dash fusehelay box

Above under-dash fuse/relay box

Behind dashboard lower panel

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Left side of steering wheel

Left side of steering wheel

Under left side of dash

Behind gauges

Behind gauges

Behind gauges

Behind gauges

Behind gauges

Right side of gauges

Behind middle of dash

Behind middle of dash

Behind middle of dash

Under middle of dash

Under middle of dash

Behind middle of dash

Behind middle of dash

Behind middle of dash

Behind middle of dash

Behind middle of dash

Behind gauges

Upper middle of dash

Main wire harness (C416)

Main wire harness (C416)

Under-dash fuse/relay box 1C912)

Main wire harness (C415)

Hatch glass opener switch

Left side wire harness (C556)

Left side wire harness (C556)

Dash lights brightness cont.oller

Cruise main switch

Junction connector

Gauge assembly

Gauge assembly

Gauge assembly

Gauge assembly

Gauge assembly

Hazard warning switch

Audio unit

Heater control panel

Heater control panel

Data link connector

Service check connector

Front accessory socket connector

Ashtray light

Heater sub-harness (C733)

Heater sub-harness {C740}

Heater sub-harness (C740)

Gauge assembly

Clock

'97 - 98

models'99 - 00

models

Mir

A/r

'97 model'98 - 00

mooets

'98 - 00

models

G501Behind middle of dashBody ground, via dashboard wire har-

ness

23-24

www.emanualpro.com