Gauge HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 658 of 1395

A/T Gear Position Indicator

1.

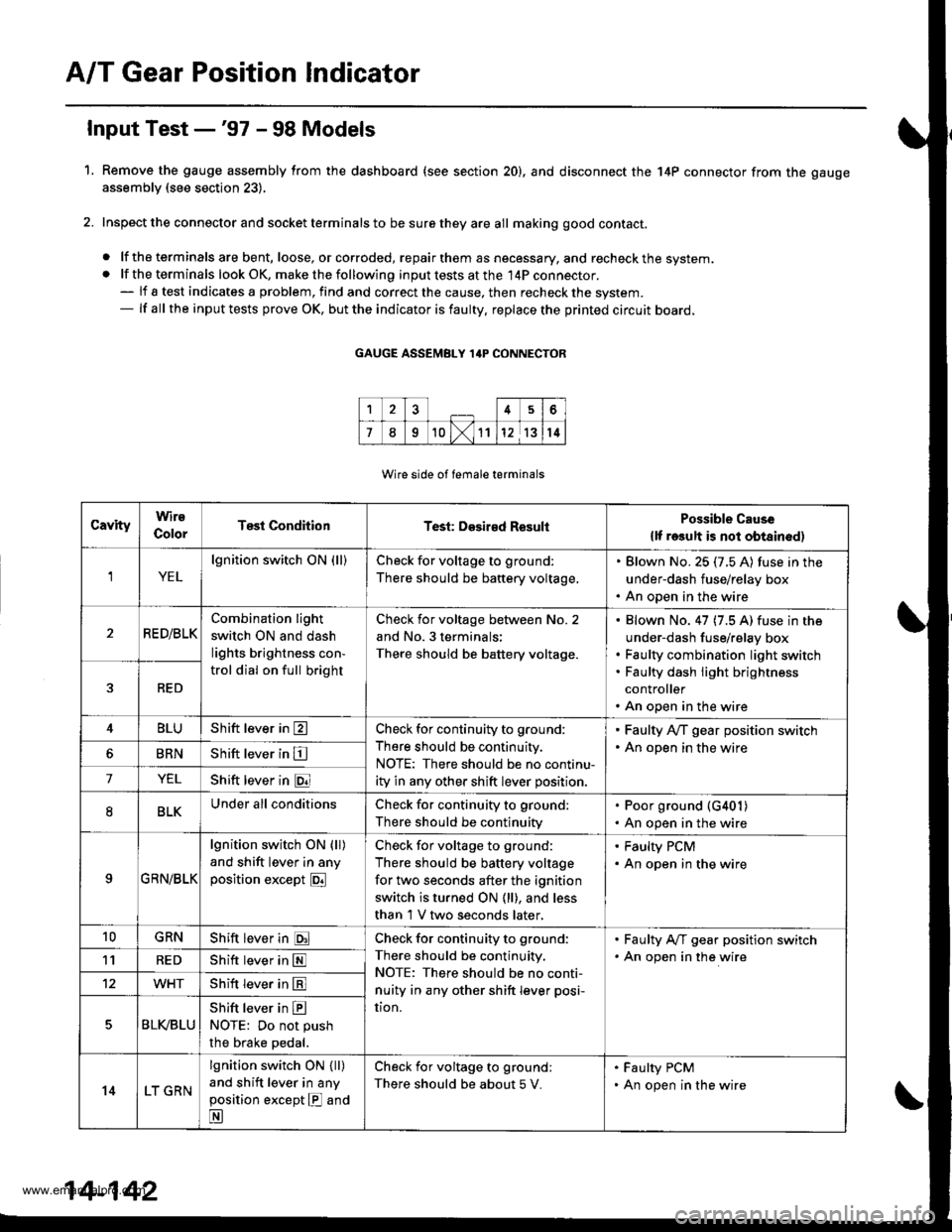

f nput Test -'97 - 98 Models

Remove the gauge assembly from the dashboard (see section 20). and disconnect the 14P connector from the gauge

assemblv (see section 23),

Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose, or corroded, repairthem as necessary, and recheck the system.. lf the terminals look OK, make the following input tests at the 14P connector.- lf I test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, but the indicator is faulty. replace the printed circuit board,

GAUGE ASSEMBLY 14P CONNECTOR

Wire side of female terminals

CavityWirs

ColorTest ConditionTest: Desir€d ResultPossible Cause

{lf rosult is not obtainod)

YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage,

. Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box. An open in the wire

RE D/BLKCombination light

switch ON and dash

lights brightness con-

trol dial on full bright

Check for voltage between No. 2

and No. 3 terminals;

There should be battery voltage.

Blown No. 47 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination Iight switch

Faulty dash iight brightness

controller

An open in the wire

RED

4BLUShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no continu-

ity in any other shift lever position.

' Faulty Ay'T gear position switch. An open in the wireBRNShift lever in E

7YELShift lever in @

8BLKUnder all conditionsCheck for continuity to ground:

There should be continuity

. Poor ground {G401). An open in the wire

9GRN/BLK

lgnition switch ON {ll)

and shift lever in any

position except E

Check for voltage to ground:

There should be battery voltage

for two seconds after the ignition

switch is turned ON {ll), and less

than 1 V two seconds later,

' Faulty PCM. An open in the wire

10GRNShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no conti-

nuity in any other shift lever posi-

UOn.

. Faulty A,ff gear position switch. An open in the wire1'lREDShift lever in @

12WHTShift lever in E

BLVBLU

Shift lever in ENOTE: Do not push

the brake pedal.

14LT GRN

lgnition switch ON { ll)

and shift lever in any

position except E and

E

Check for voltage to ground:

There should be about 5 V.

. Faulty PCM. An open in the wire

14-142

www.emanualpro.com

Page 659 of 1395

L

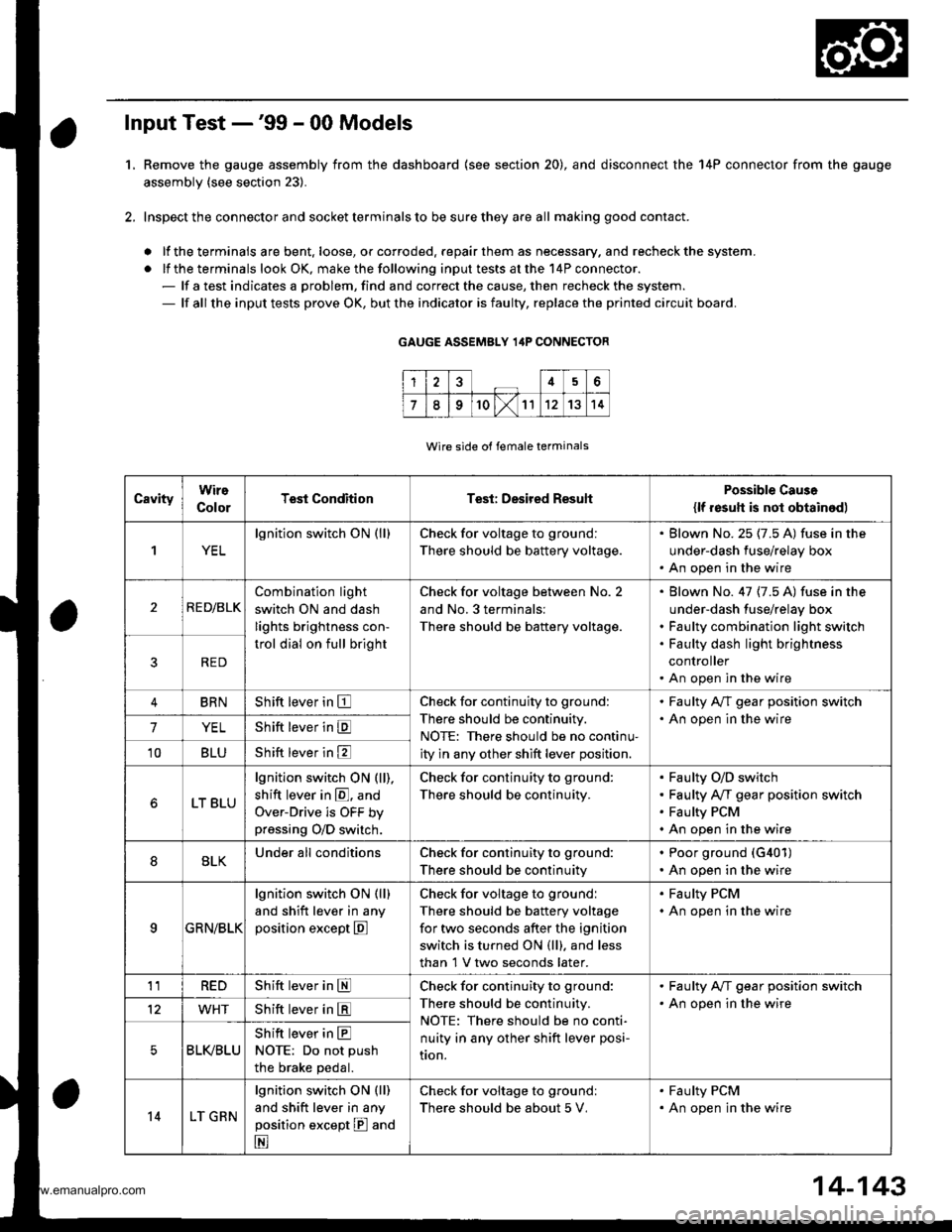

Input Test -'99 - 00 Models

Remove the gauge assembly from the dashboard {see section 20), and disconnect the 14P connector from the gauge

assembly (see section 23).

Inspect the connector and socket terminals to be sure they are all making good contact.

a lf the terminals are bent. loose, or corroded. repair them as necessary. and recheck the system.

. lf the terminals look OK, make the following input tests at the 14P connector.- lf a test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, but the indicator is faulty, replace the printed circuit board.

GAUGE ASSEMBLY 14P CONNECTOR

Wire side of female terminals

CavityWire

ColorTest ConditionTest: Desired ResuhPossible Caus6

{lf resutt is not obtainod)

1YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

. Blown No.25 (7.5 A) fuse in the

under-dash fuse/relay box. An open in the wire

2RE D/BLK

Combination light

switch ON and dash

lights brightness con-

trol dial on full bright

Check for voltage between No. 2

and No.3 terminals:

There should be battery voltage.

Blown No. 47 {7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination light switch

Faulty dash light brightness

controller

An open in the wire

5RED

BRNShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no continu-

ity in any other shift lever position.

. Faulty A/T gear position switch. An open in the wire7YELShift lever in E

'10BLUShift lever in E

LT BLU

lgnition switch ON (ll),

shift lever in E. and

Over-Drive is OFF bypressing O/D switch.

Check for continuity to ground:

There should be continuity.

Faulty O/D switch

Faulty A/T gear position switch

Faulty PCM

An open in the wire

8BLKUnder all conditionsCheck for continuity to ground:

There should be continuity

. Poor ground (G401)

. An open in the wire

9a:FI\|/Et| ta

lgnition switch ON (ll)

and shift lever in any

position except E

Check for voltage to groundl

There should be battery voltage

for two seconds after the ignition

switch is turned ON (ll). and less

than 1 V two seconds later.

. Faulty PCM. An open in the wire

11REDShift lever in SCheck for continuity to ground:

There should be continuity.

NOTE: There should be no conti-

nuity in any other shift lever posi-

Iton.

. Faulty A/T gear position switch. An open in the wire12WHTShift lever in E

BLI(BLU

Shift lever in ENOTE: Do not push

the brake pedal.

14LT GRN

lgnition switch ON (ll)

and shift lever in any

position except E and

E

Check for voltage to groundl

There should be about 5 V,

. Faulty PCM. An open in the wire

14-143

www.emanualpro.com

Page 675 of 1395

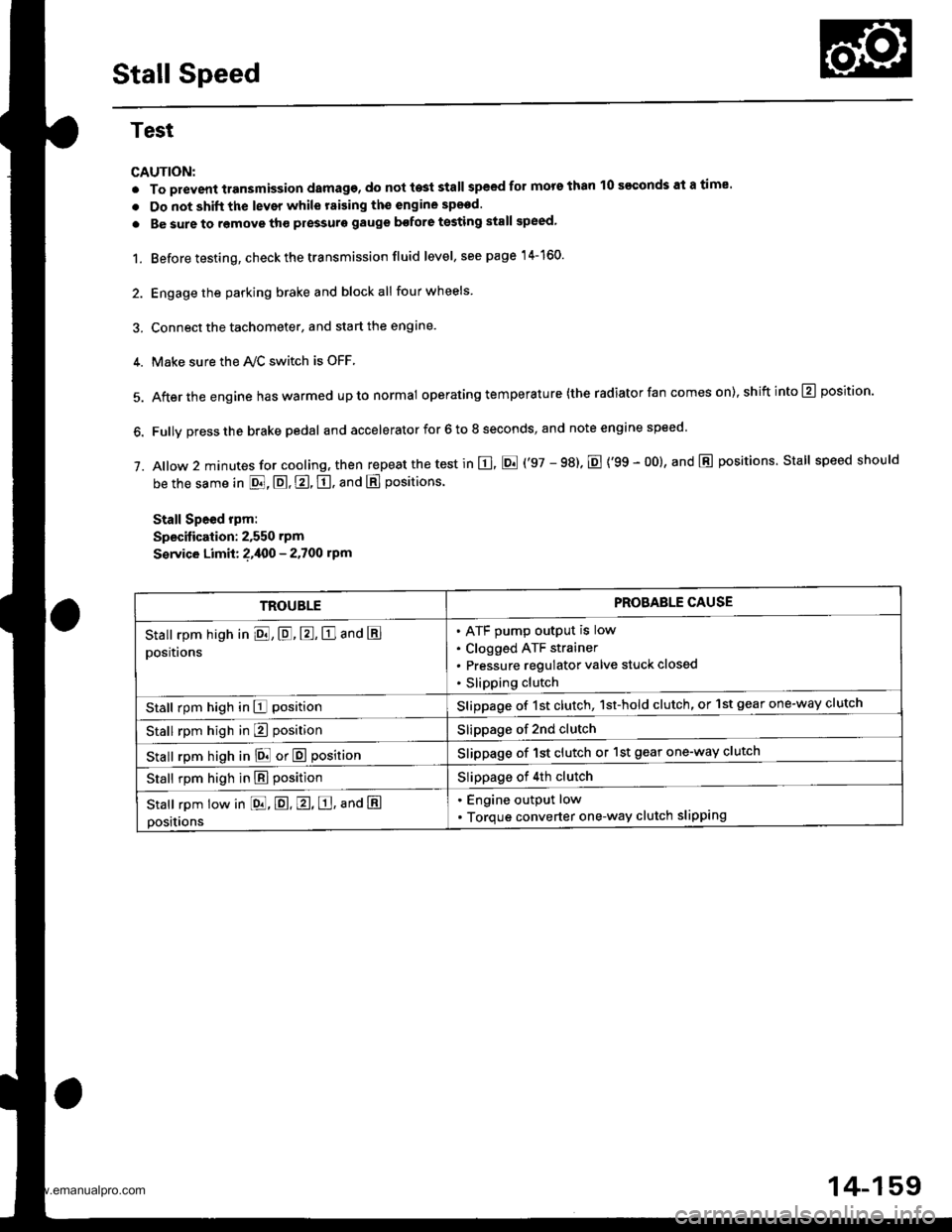

Stall Speed

Test

CAUTION:

. To prevent transmission damage, do not te3t stall speed for mors than 10 s€€onds at a time'

. Do not shift the lever while raising th€ engine spsed.

. Be sure to remove tho pressuro gauge bofore testing stall speed,

1. Before testing, check the transmission fluid level, s€e page 14-160.

2. Engage the parking brake and block all four wheels

3. Connect the tachometer, and start the engane.

4. Make sure the Ay'C switch is OFF

5. After the engine haswarmed upto normal operating temperature (the radiator fan comes on),shiftinto@ position.

6. Fully press the brake pedal and accelerator for 6 to 8 seconds, and note engine speed '

j. A|ow 2 minutes for cooling, then repeat the test in E, E ('97 - 98). E {'99 - 00}, and E positions. Stall speed should

be the same in E, E, E, tr. and E positions

Stall Speed rpm:

Specitication: 2,550 rpm

S€rvice Limit: ?,400 - 2.700 rpm

TROUBLEPROBAELE CAUSE

Stall rpm high in El, E, E, E and E

positions

ATF pump output is low

Clogged ATF strainer

Pressure regulator valve stuck closed

Slipping clutch

Stall rpm high in E positionSlippage of 1st clutch, 1st-hold clutch, or 1st gear one-way clutch

Stall rpm high in E positionSlippage of 2nd clutch

stall rpm high in E! or E positionSlippage of 1st clutch or 1st gear one-way clutch

Stall rpm high in E positionSlippage of 4th clutch

Stall rpm low in [dd, E. E, E, ana E

positions

. Engine output low

. Torque converter one-way clutch slipping

14-159

www.emanualpro.com

Page 677 of 1395

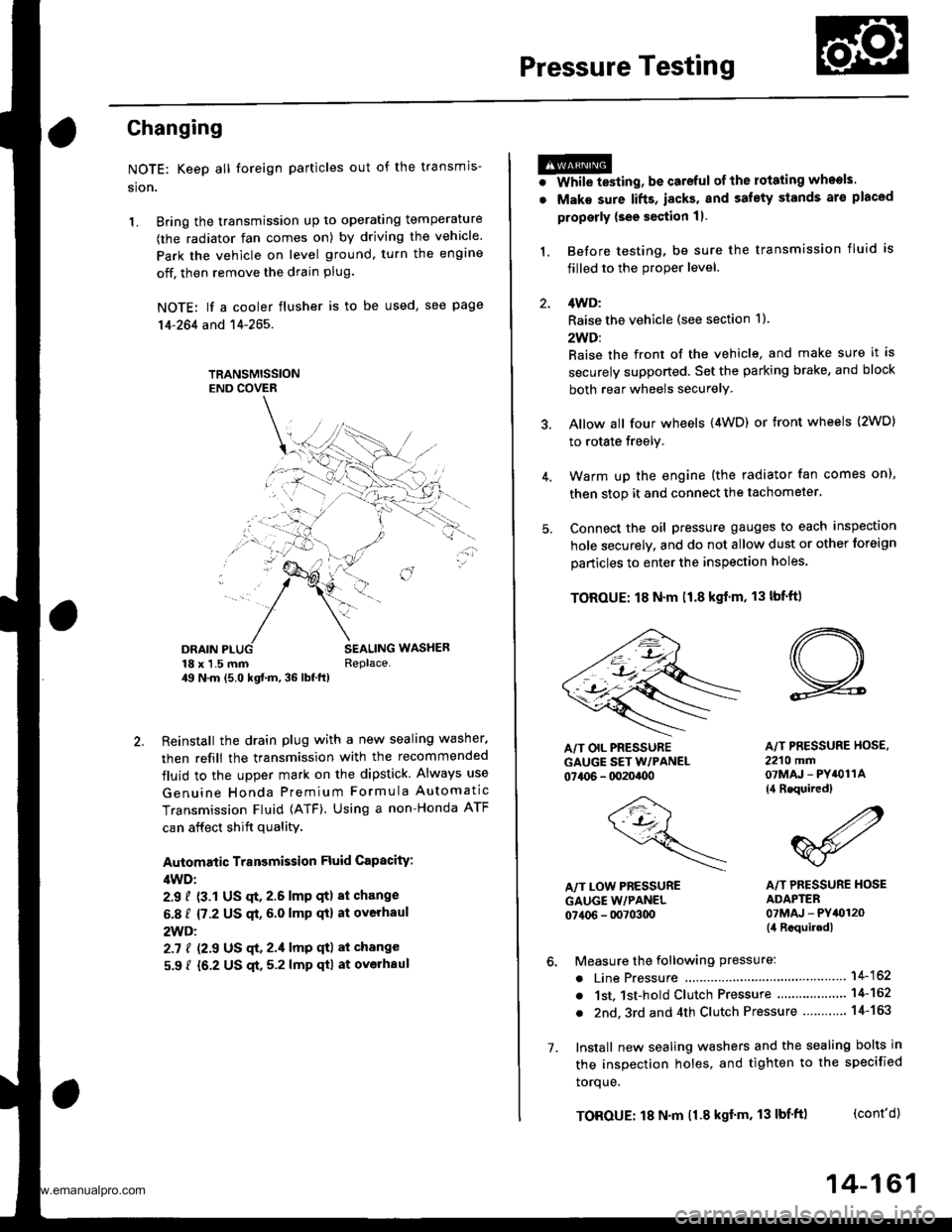

Pressure Testing

Changing

NOTE: Keep all foreign particles out of the transmis-

sion.

1. Bring the transmission up to operating temperature

(the radiator fan comes on) by driving the vehicle.

Park the vehicle on level ground. turn the engane

off. then remove the drain Plug.

NOTE: lf a cooler flusher is to be used, see page

14-264 and 14-265.

TRANSMISSIONEND COVER

DRAIN18 x 1.5 mmSEALING WASHEBReplace.49 N.m {5.0 kgt.m, 36 lbf.tl)

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid to the uDper mark on the dipstick. Always use

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF) Using a non-Honda ATF

can affect shift quality.

Automatic Transmission Fluid Capacity:

4WD;

2.9 { (3.1 US qt. 2.6 lmp qt) 8t change

5.8 ? {7.2 US $, 6.0 lmp qt} at ovethaul

2WD:

2.7 | l2.S US qt,2.1lmp qtl ai change

5.9 ? {6.2 US $, 5.2 lmp qtl at ovolhaul

2.

a

a

1.

Wlrile testing, be careful of the rotaling wheols.

Mako sure lifts, iacks, and safety stands ar€ placed

properly (see scction 11.

Before testing, be sure the transmission fluid is

filled to the proPer level.

4WD:

Raise the vehicle (see section 11.

2WD:

Raise the front of the vehicle, and make sure it is

securely supported. Set the parking brake, and block

both rear wheels securely.

Allow all four wheels {4WD) or front wheels (2wD}

to rotate freely.

Warm up the engine (the radiator fan comes on),

then stop it and connect the tachometer.

Connect the oil pressure gauges to each inspection

hole securely, and do not allow dust or other foreign

particles to enter the inspection holes.

TOROUE: 18 N'm ll.8 kgf'm, 13 lbf'ft)

5.

A/T PRESSURE HOS€,2210 mm07MAJ - PYiOllA

{4 Requircd}

,4'/"' ,a

W'

A/T PRESSURE HOSEADAPTER07MAJ - PYt0120(il Rcquiledl

6. Measure the following Pressure:. Line Pressure ..........,14-162

. 1st. 1st-hold Clutch Pressure .............'. 14-162

. 2nd,3rd and 4th Clutch Pressure .......... 14-163

7. Install new sealing washers and the sealing bolts in

the inspection holes, and tighten to the specified

toroue.

(cont'd)

A/T OIL PRESSUREGAUGE SET W/PANEL07{06 - 0020400

/4\\-J-- (

+..\.-.\-'-\

A/T LOW PBESSUREGAUGE w/PANEL07406 - 0070300

TOROUE: 18 N'm 11.8 kgf'm, 13 lbf'ft)

14-161

www.emanualpro.com

Page 719 of 1395

Inspection

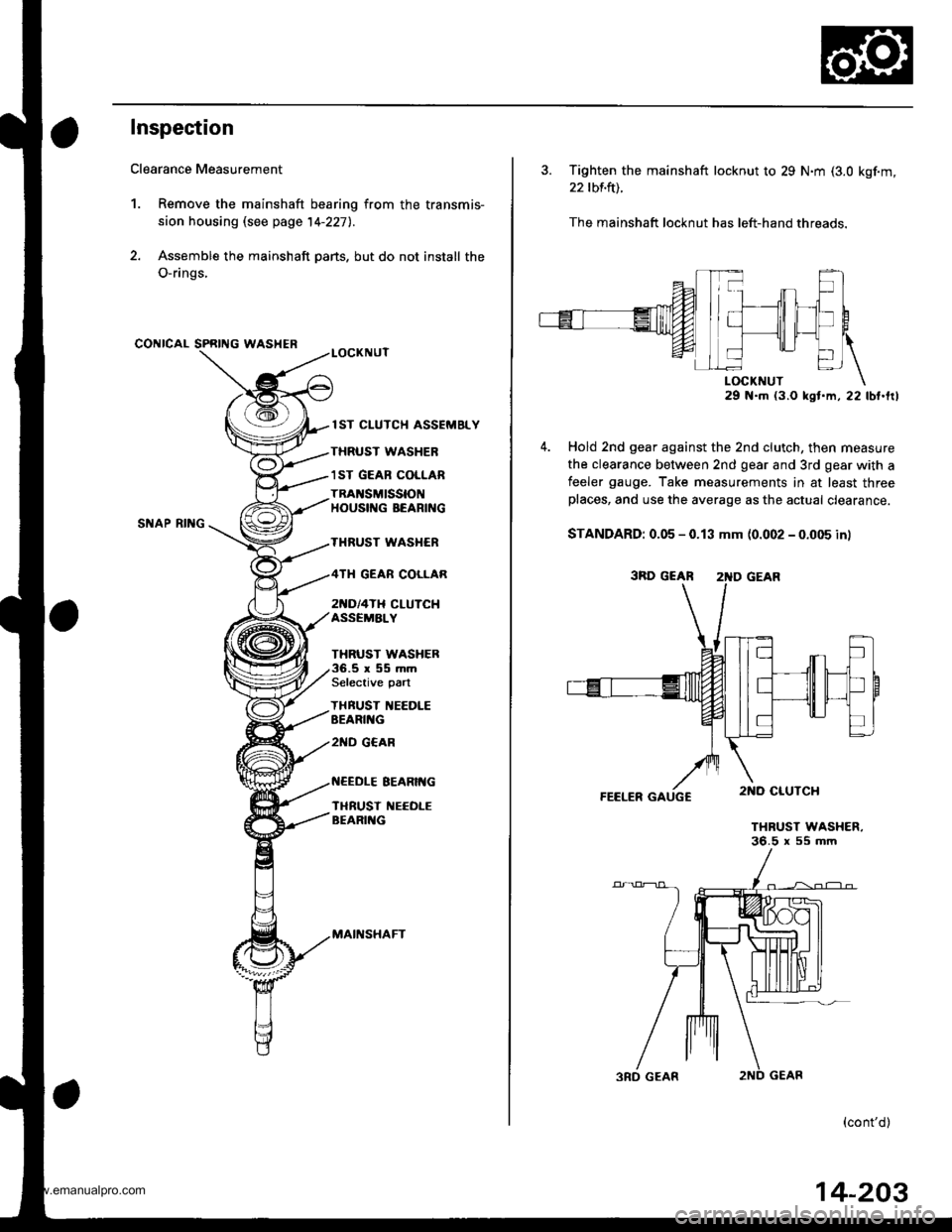

Clearance Measurement

1. Remove the mainshaft bearing from the transmis-

sion housing lsee page 14-227l..

2. Assemble the mainshaft parts, but do not install the

O-rings,

CONICAL SPRING WASHER

SNAP RII{G

lST CLUTCH ASSEMELY

THRUST WASHER

1ST GEAB COLLAR

TRAI{SMISSIONHOUSIf{G BEARING

THRUST WASI{ER

2[{D/4TH CLUTCHASSEMALY

GEAR COLLAR

THRUST WASHER.5r55mmSelective part

THBUST IIEEDLEEEARII{G

2ND G€AR

EEARIt{G

TI{RUST NEEOLEBEARII{G

MAII{SHAFT

3. Tighten the mainshaft locknut to 29 N.m (3.0 kgf.m,

22 tbf.ft).

The mainshaft locknut has left-hand threads.

29 N.m (3.O kst.m, 22 lbt.frl

Hold 2nd gear against the 2nd clutch, then measure

the clearance between 2nd gear and 3rd gear with a

feeler gauge. Take measurements in at least threeplaces, and use the average as the actual clearance.

STANDARD: 0.05 - 0.13 mm (0.002 - 0.005 in)

FEELER GAUGC

THRUST WASHER.36.5 x 55 mm

(cont'd)

3RD GEAR 2'{D GEAR

14-203

www.emanualpro.com

Page 724 of 1395

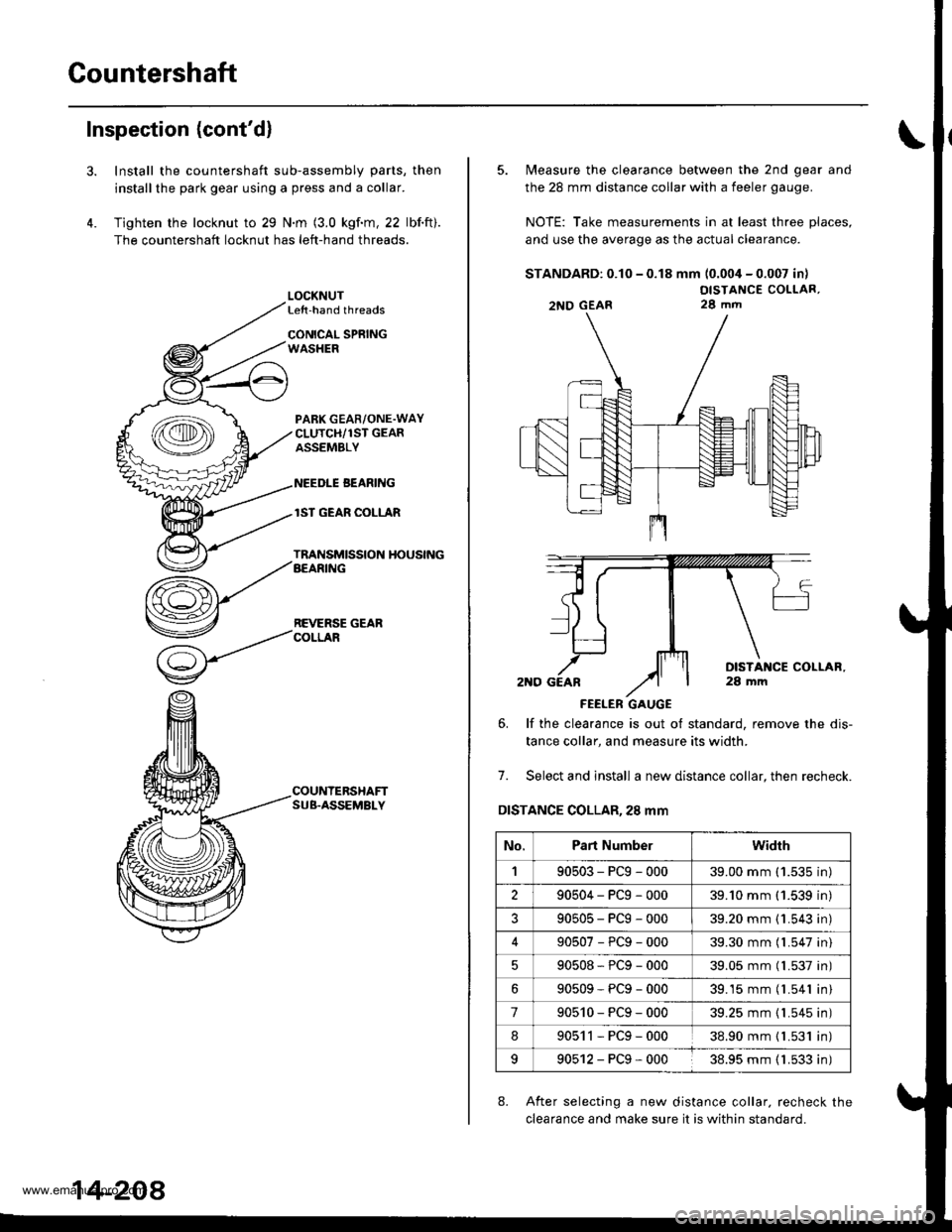

Countershaft

Inspection (cont'd)

3.

4.

Install the countershaft sub-assembly parts, then

installthe park gear using a press and a collar.

Tighten the locknut to 29 N.m (3.0 kgf.m, 22 lbf.ft).

The countershaft locknut has left-hand threads.

LOCKNUTLe{t-hand threads

CONICAL SPRINGWASHER

PABK GEAR/ONE.WAYCLUTCH/1ST GEARASSEMBLY

NEEDLE BEANING

lST GEAR COLLAR

TRANSMISSION HOUSINGAEARING

REVERSE GEARCOLLAR

COUNTERSHAFTSUB.ASSEMBLY

14-208

5. Measure the clearance between the 2nd gear and

the 28 mm distance collar with a feeler gauge.

NOTE: Take measurements in at least three places,

and use the average as the actual clearance.

STANDARD: 0.10 - 0.18 mm (0.004 - 0.007 in)

OISTANCE COLLAR,28 mm

FEELER GAUGE

6. lf the clearance is out ot standard, remove the dis-

tance collar, and measure its width.

7. Select and install a new distance collar, then recheck.

DISTANCE COLLAR,28 mm

8. After selecting a new distance collar. recheck the

clearance and make sure it is within standard.

2NO GEAR

No.Part Numberwidrh

190503-PCg-00039.00 mm ('1.535 in)

290504-PCg-00039.'10 mm (1.539 in)

?90505-PCg-00039.20 mm {1.543 in)

90507-PCg-00039.30 mm (l.547 in)

90508*PCg-00039.05 mm (l.537 in)

90509-PCg-00039.15 mm (l.541 in)

790510-PCg-00039.25 mm {1.545 in)

890511-PCg-00038.90 mm { L531 in)

990512-PCg-00038.95 mm ( 1.533 in)

www.emanualpro.com

Page 742 of 1395

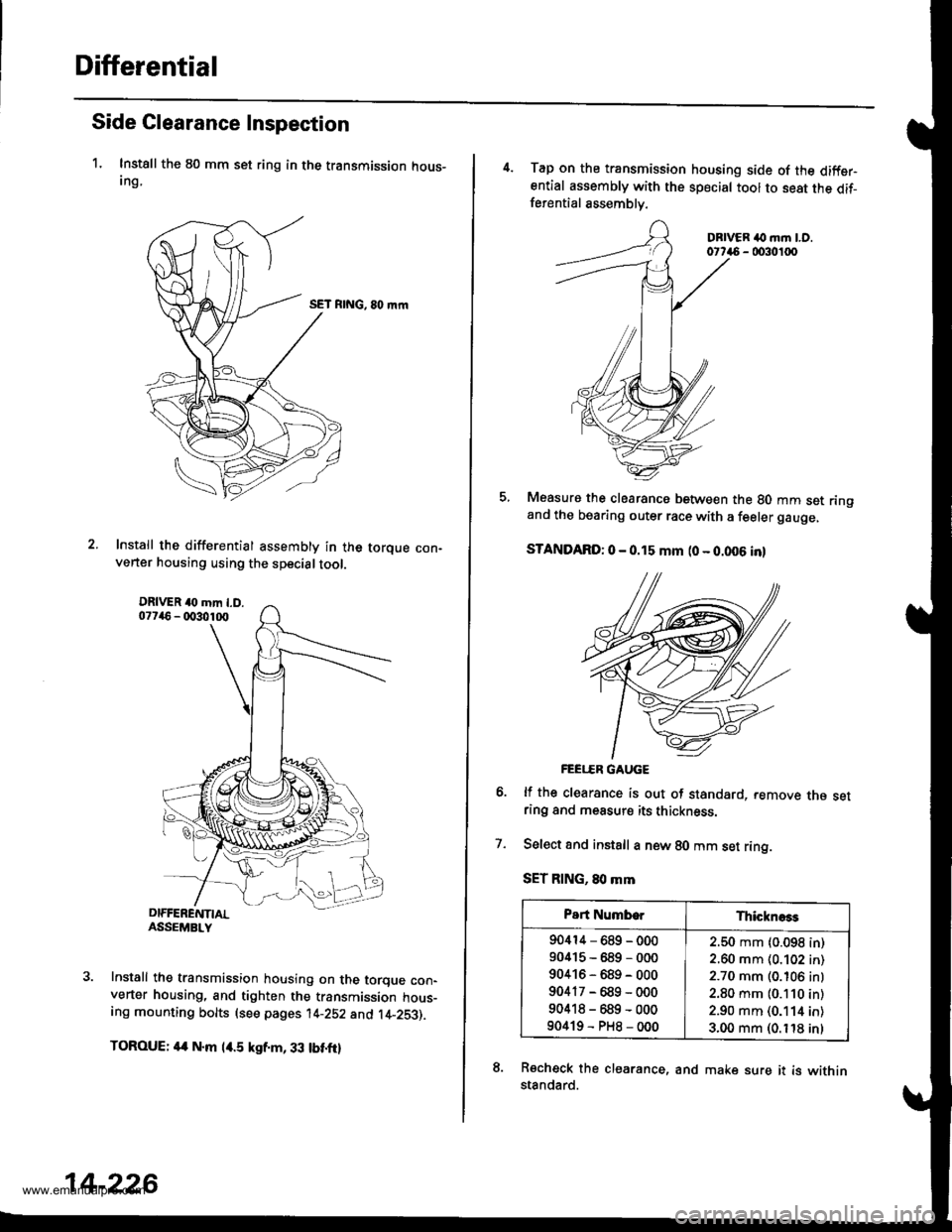

Differential

Side Clearance Inspection

1. Instsll the 80 mm set ring in the transmission hous-Ing,

SET RING, 80 mrn

Install the differential assembly in the torque con-verter housing using the specialtool.

Install the transmission housing on the torque con-verter housing, and tighten the transmission hous-ing mounting bolts (see pages 14-252 and t4-253).

TOROUE: 4a N.m l/r.5 kgf.m, 33 tbt.ftl

14-226

4. Tap on the transmission housing side of the diffsrential assembly with the special tool to seat the dif-ferential assemblv.

DBIVER ilo m.n LO.0t746 - 0030100

Measure the clearancs between the 80 mm set ringand the bearing outer race with a feeler gauge,

STANDARD: 0 - 0.15 mm (0 - 0.006 inl

FEEI..ER GAUGE

lf the clearance is out of standard, remove rne setring and measurs its thickness.

Select and instsll a new 80 mm set ring.

SET RING, 80 mm

Recheck the clearance, and make sure it is withinstandard.

7.

Part NumborThicknoss

90414-689-000

90415-689-000

90416-689-000

90417-689-000

90418-689-000

90419-PH8-000

2.50 mm (0.098 in)

2.60 mm (0.102 in)

2.70 mm (0.106 inl

2.80 mm (0.110 in)

2.90 mm (0.114 in)

3.00 mm (0. t'18 inl

www.emanualpro.com

Page 787 of 1395

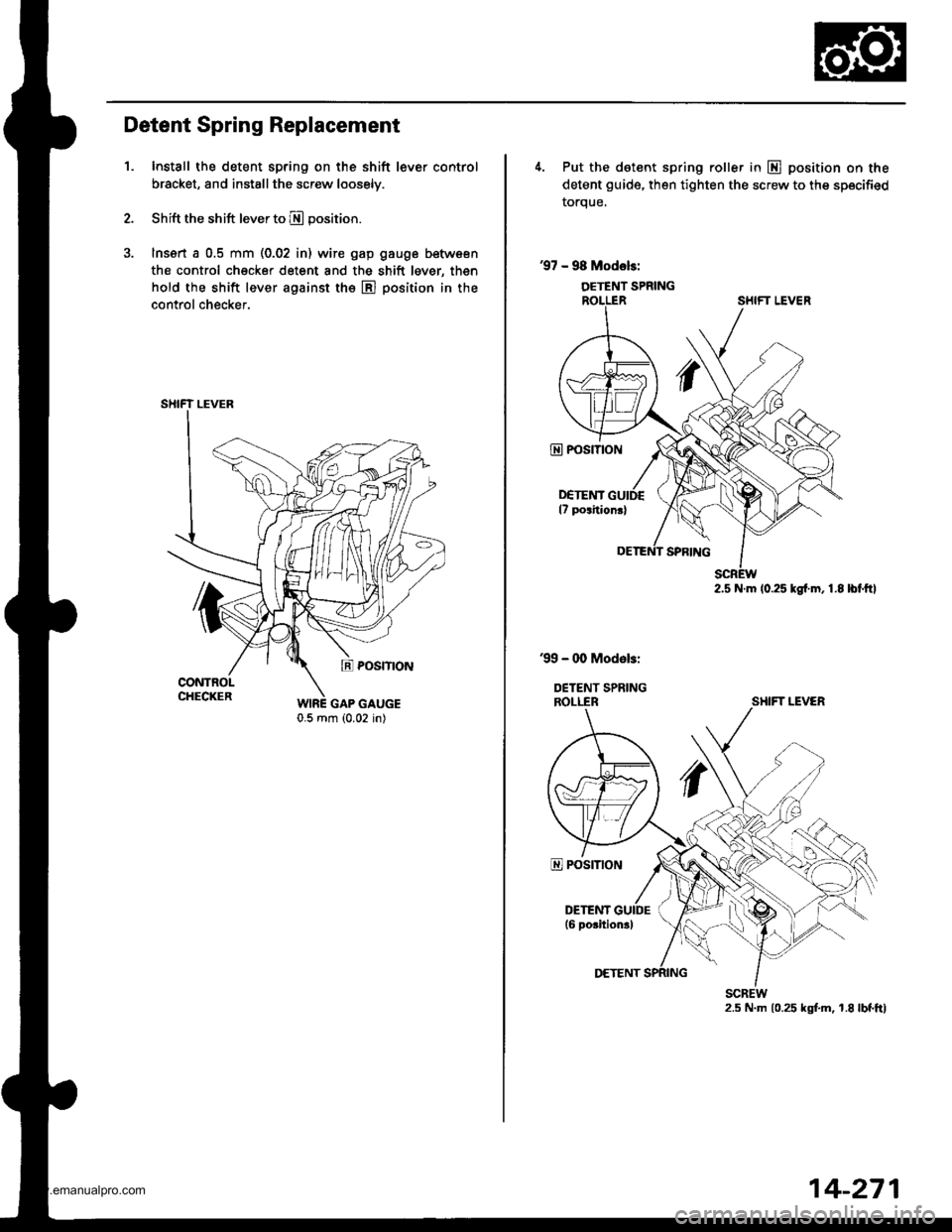

Detent Spring Replacement

1.Install the detent spring on th€ shift lever control

bracket, and installthe screw loosely.

Shift the shift lever to E position.

lnssrt a 0.5 mm (0.02 in) wire gap gauge between

the control chocker detent and the shift lever, then

hold the shift lever against the El position in the

control checker.

SHIFI LEVER

GAP GAUGE

4. Put the detent spring roller in E position on the

detent guide, then tighten the screw to the specified

torque,

'97 - 98 Modeb:

DETENT SPRING

2.5 N.m 10.25 kgf.m, 1.8lbl.ftl

SCREW2.5 N.m 10.25 kgl.m, 1.8lbtftl

14-271

www.emanualpro.com

Page 847 of 1395

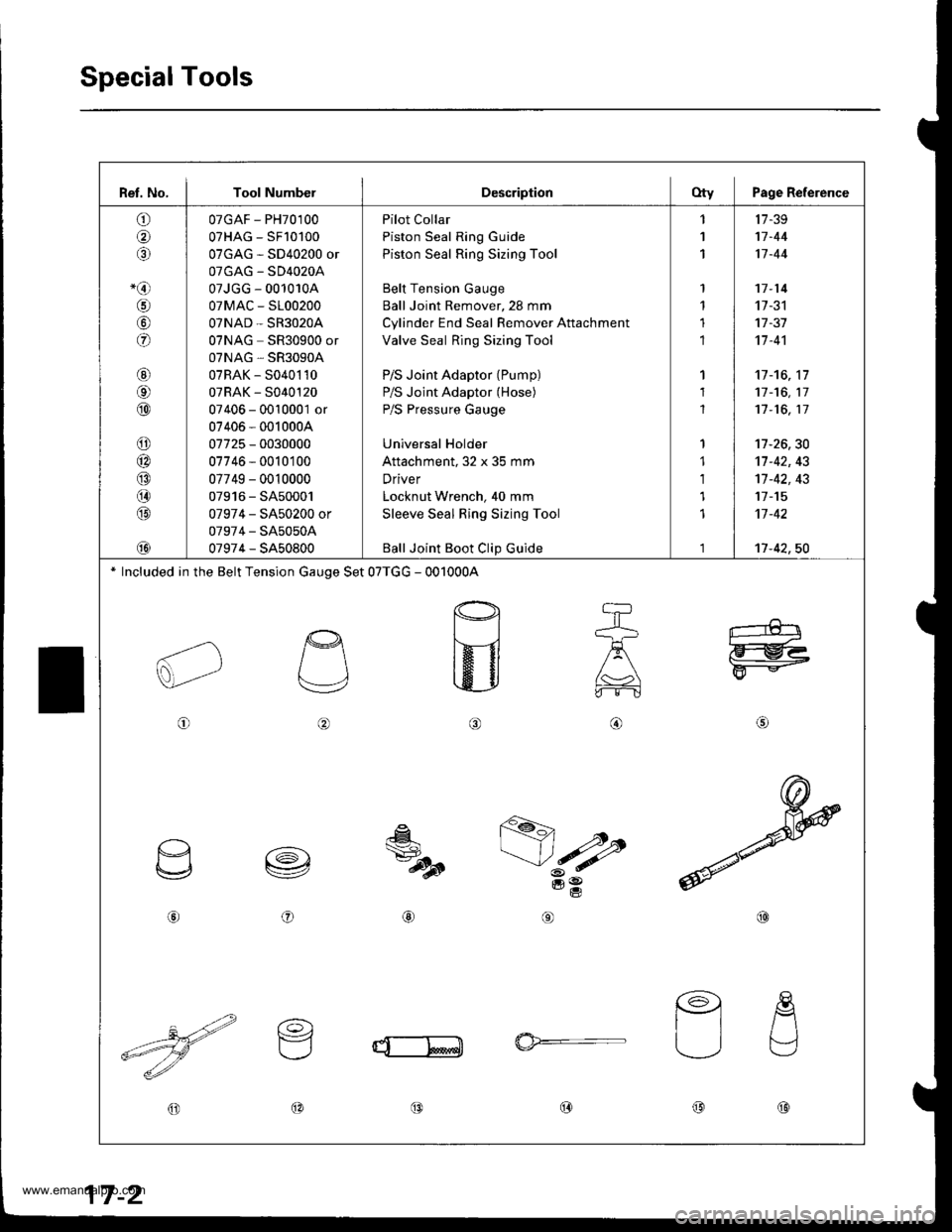

Ret. No, I Tool NumbelDescriptionfty Page Reference

o

o

-@

€r

o

@rol

@

o

@

@(}

@

@

07GAF - PH70100

07HAG - SF10100

07GAG - SD40200 or

OTGAG - SD4O2OA

07JGG - 001010A

07MAC - S100200

OTNAD _ SR3O2OA

07NAG SR30900 or

07NAG , SR3OgOA

07RAK - 50401 10

07RAK - 5040120

07406 - 0010001 or

07406 - 0010004

07725 - 0030000

07746 - 0010100

07749 - 0010000

07916 - SA50001

07974 - SA50200 or

07974 - SA5050A

07974 - SA50800

Pilot Collar

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Belt Tension Gauge

Ball Joint Remover,23 mm

Cylinder End Seal Remover Attachment

Valve Seal Ring Sizing Tool

P/S Joint Adaptor (Pump)

P/S Joint Adaptor (Hose)

P/S Pressure Gauge

Universal Holder

Attachment, 32 x 35 mm

Driver

Locknut Wrench, 40 mm

Sleeve Seal Ring Sizing Tool

Ball Joint Boot Clip Guide

'l

1

1

1

1

1

1

1

1

1

1

1

1,l

1

1

11-39

17-44

11-44

17 -14't]-31

17 -37't7 -4'l

17-'t6, 17

17-16, 17

11-16, 17

17-26,30't]-42, 43't1-42, 43

11-15't]-42

11-42, 50

* Included in the Belt Tension Gauge Set 07TGG - 001000,4

o@

\J

,/:\

I

o

,€l-

=tt

@@

aA)

l:I/\L----.--.--------_

@o(D(9@@

17-2

www.emanualpro.com

Page 852 of 1395

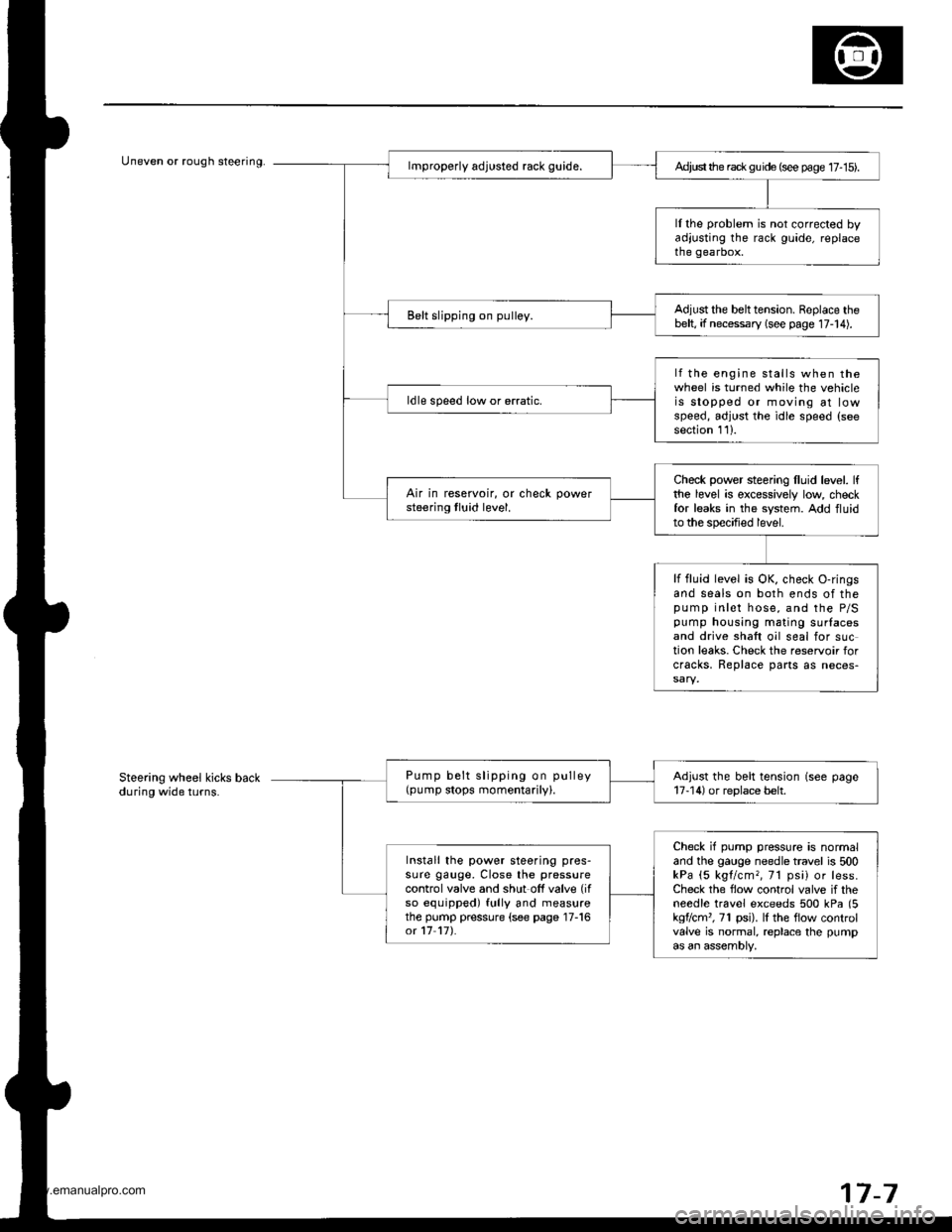

Uneven or rough steering.Ad,ust the rack gu ide (see page 17- 15).

ll the problem is not corrected byadjusting the rack guide, replacethe gearbox.

Adjust the belttension. Replace thebelt, if necessary (see page 17-14).Belt slipping on pulley.

lf the engine stalls when thewheel is turned while the vehicleis stopped or moving at lowspeed, adjust the idle speed (seesection 111.

ldle speed low or erratic.

Check power steering lluid level. lfthe level is excessively low checkfor leaks in the system. Add fluidto the specified level.

Air in reservoir, or check powersteering tluid level.

lf fluid level is OK, check O-ringsand seals on both ends of thepump inlet hose, and the P/Spump housing mating surlacesand drive shaft oil seal for suction leaks. Check the reservoir forcracks, Replace parts as neces-

Pump belt slipping on pulley(pump stops momentarily).Adjust the belt tension (see page17-14) or replace belt.

Check if pump pressure is normaland the gauge needle travel is 500kPa (5 kgl/cm,, 71 psi) or less.Check the flow control valve if theneedle travel exceeds 500 kPa (5kgflcm'�, 71 psi). lI the flow controlvalve is normal, replace the pumpas an assembly,

Install the power steering pres-sure gauge, Close the pressurecontrol valve and shut off valve (if

so equipped) fully and measurethe pump pressure (see page 17-16ot 17 17).

Steering wheel kicks backduring wide turns.

7-7

www.emanualpro.com