rod HONDA CR-V 1998 RD1-RD3 / 1.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1000 of 1395

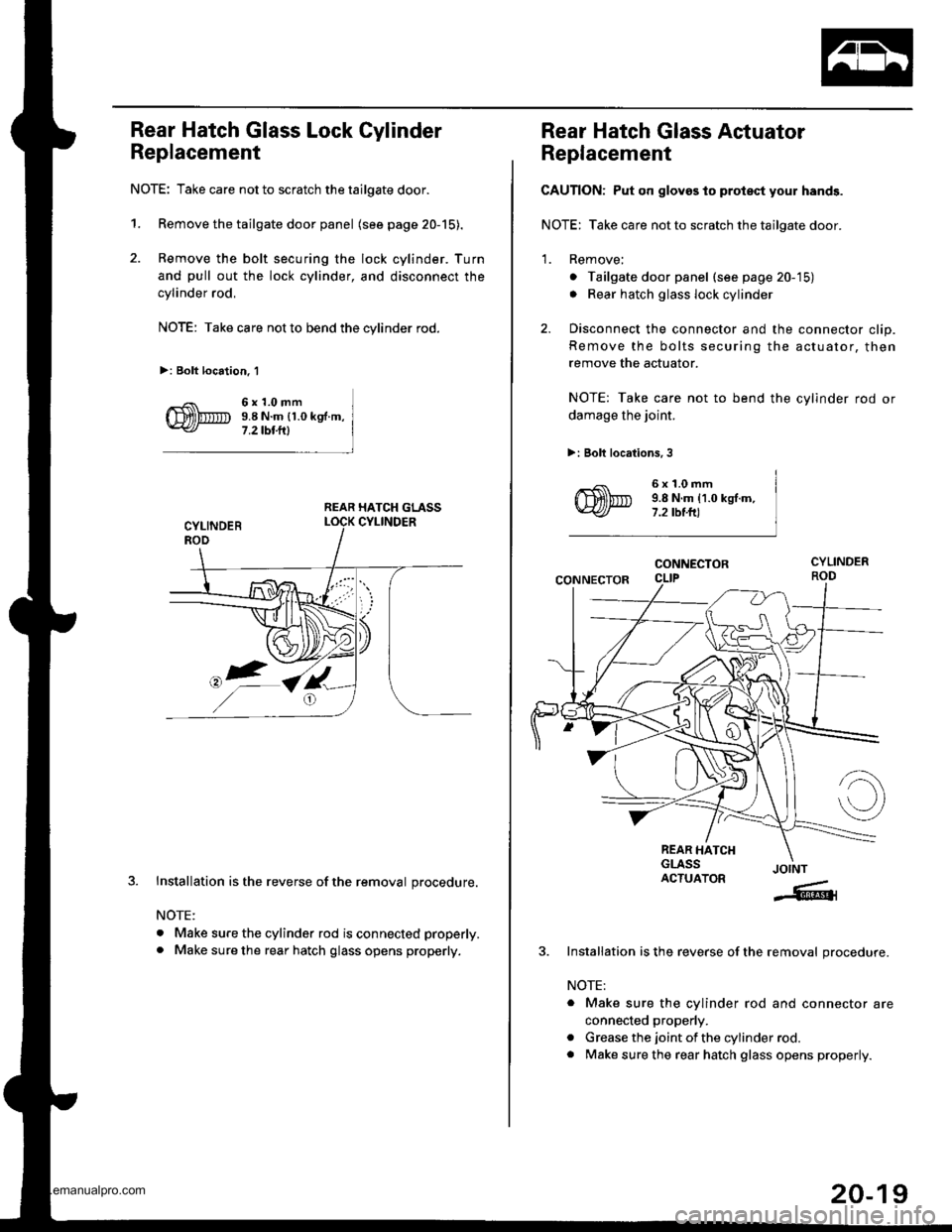

Rear Hatch Glass Lock Cylinder

Replacement

NOTE: Take care not to scratch the tailgate door.

1. Remove the tailgate door panel (see page 20-15).

2. Remove the bolt securing the lock cylinder. Turn

and pull out the lock cylinder, and disconnect the

cylinder rod,

NOTE: Take care not to bend the cylinder rod.

>: Bolt location. 1

6x1.0mm9.8 N.m {1.0 kg .m,

7 .2 tbt.lll

REAR HATCH GLASS

J.Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod is connected properly.

. Make sure the rear hatch glass opens properly.

Rear Hatch Glass Actuator

Replacement

CAUTION: Put on gloves to protsct your hands.

NOTE: Take care not to scratch the tailgate door.

1. Remove;

o Tailgate door panel (see page 20-'15)

. Rear hatch glass lock cylinder

2. Disconnect the connector and the connector clip.

Remove the bolts securing the actuator, then

remove the actuator.

NOTE: Take care not to bend the cylinder rod or

damage the joint.

>: Bolt locations, 3

6x1.0mm9.8 N.m 11.0 kgt.m,7.2 tbt.ft)

CONNECTOR

CONNECTOR

REAR HATCHGLASSACTUATORJOINT

-6{

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod and connector are

connected properly.

. Grease the joint of the cylinder rod.

. Make sure the rear hatch glass opens properly.

20-19

www.emanualpro.com

Page 1046 of 1395

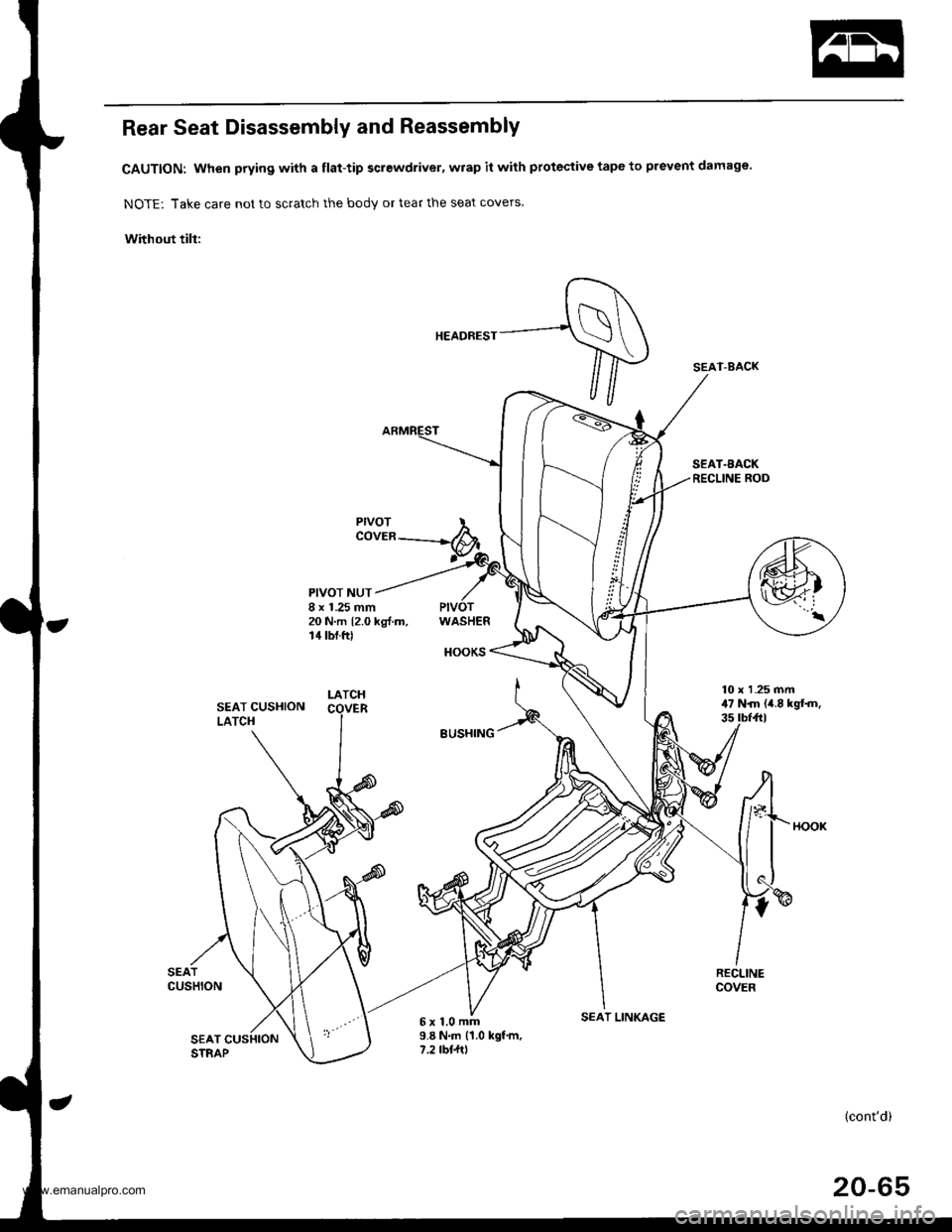

Rear Seat Disassembly and Reassembly

CAUTION: When prying with a flat-tip screwdriver, wrap it with protective tape to prevent damage.

NOTE: Take care not to scratch the body or tear the seat covers.

Without till:

SEAT.AACKRECLINE ROD

PIVOTCOVER

PIVOT NUT8 x 1.25 mm20 N.m 12.0 kg{.m.14 tbf.ftlWASHER

HOOKS

5x1.0mm9.8 N'm (1.0 kgf.m,7 .2 tbl.ltl

(cont'd)

20-65

SEAT-BACK

SEAT CUSHIONLATCH

SEATCUSHION

SEAT CUSHIONSTRAP

SEAT LINKAGE

www.emanualpro.com

Page 1049 of 1395

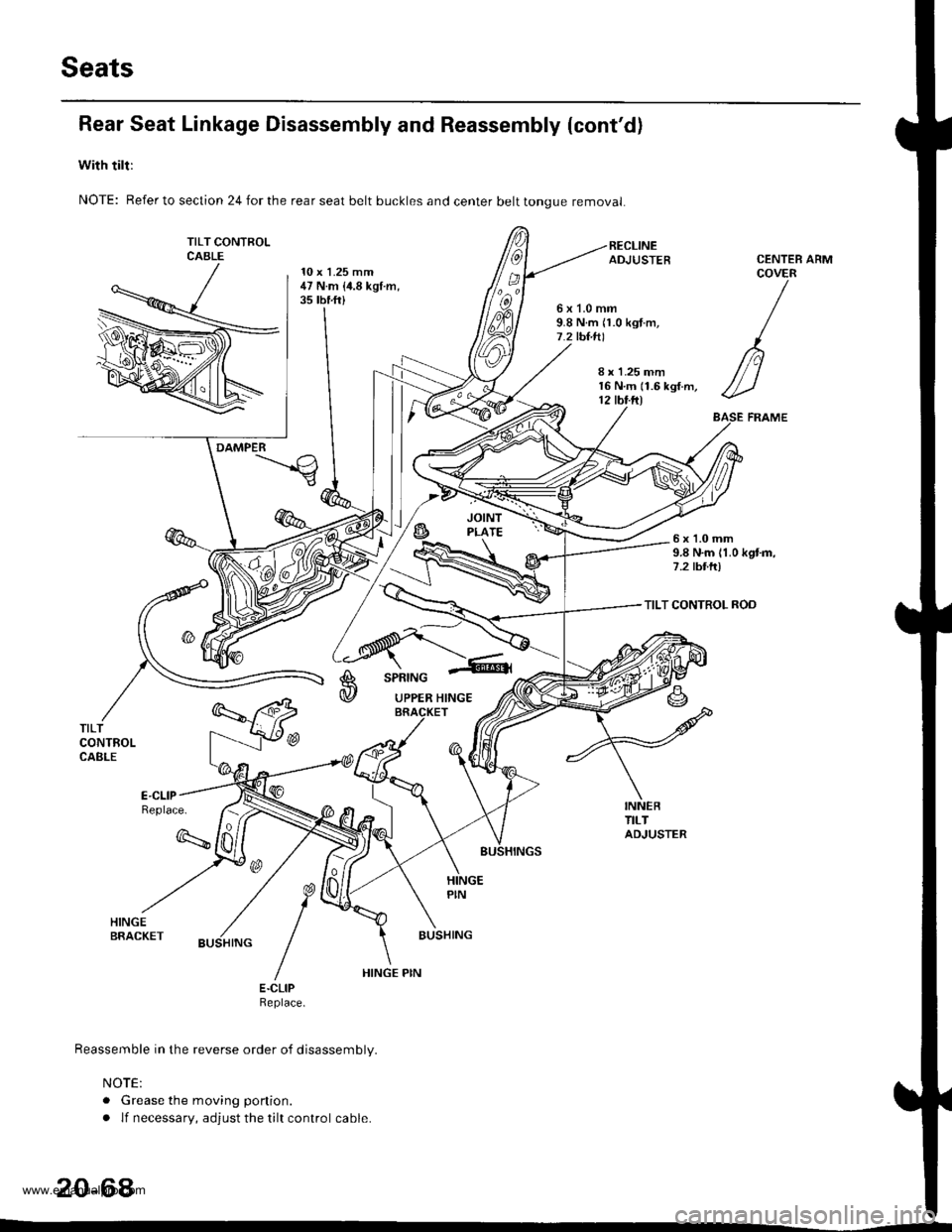

Seats

Rear Seat Linkage Disassembly and Reassembly (cont'd)

with tilt:

NOTE: Refer to section 24 for the rear seat belt buckles and center belt tongue removal

TILT CONTFOLCABLE10 x 1.25 mm47 N.m {i1.8 kgt.m,35 tbf.ft)

ARM

6x1.0mm9.8 N.m n.0 kgt.m,7.2 tbt.tll

CENTEBCOVER

/

n

//-)

ASE FRAME

8 r 1.25 mm16 N.m (1.6 kgf.m,12 tbt.ftl

DAMPER

6x1.0mm9.8 N.m 11.0 kgtm,7.2 tbttr)

TILT CONTROL ROD

A

@

SPRING

UPPER HINGE

TILTCONTROLCABLE

Replace.

q

BUSHING

E.CLIPReptace.

Reassemble in the reverse order of disassembly.

NOTE:

. Grease the moving ponion.

. lf necessary, adjust the tilt control cable.

20-64

HINGE PIN

www.emanualpro.com

Page 1050 of 1395

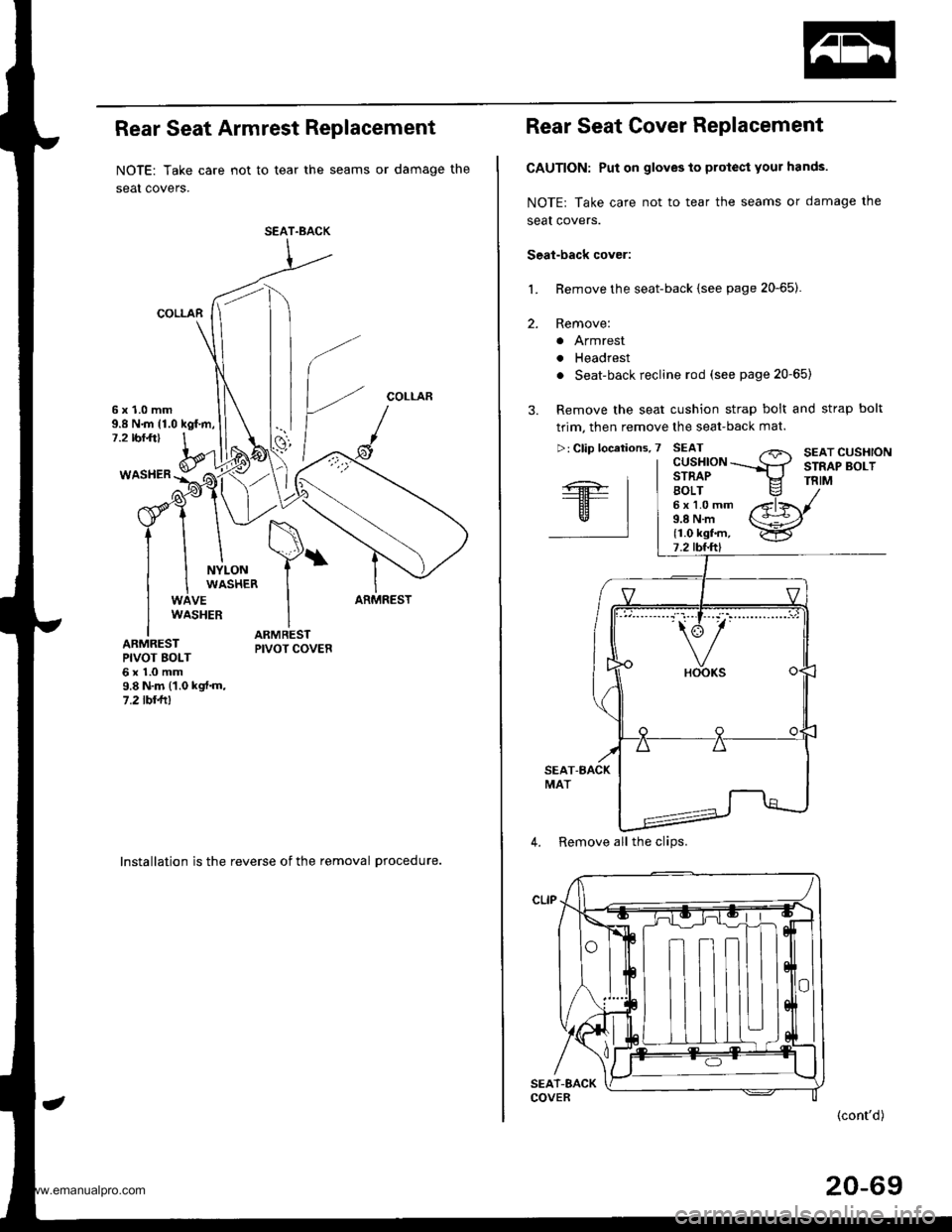

Rear Seat Armrest Replacement

NOTE: Take care not to tear the seams or damage the

seat covers.

COLLAR

COLLAR6x1.0mm9.8 N.m {1.0 kgf.m,7.2 rbr.ft)

WASHER

NYLONWASHER

VEARMRESTWASHER

ARMRESTPIVOT BOLT6x1.0mm9.8 N.m (1.0 kgt.m,7.2lbllll

lnstallation is the reverse of the removal procedure.

SEAT.BACK

Rear Seat Cover Replacement

CAUTION: Put on gloves to protect your hands.

NOTE: Take care not to tear the seams or damage the

seal covers.

Seal-back cover:

Remove the seat-back {see page 20-65).

Remove:

a Armrest

. Headrest

. Seat-back recline rod (see page 20-65)

Remove the seat cushion strap bolt and strap bolt

trim, then remove the seat-back mat.

L

2.

"'---.' t.-r" t-- i,': "" '

4. Remove all the clips.

(cont'd)

20-69

www.emanualpro.com

Page 1131 of 1395

Mode Control Motor

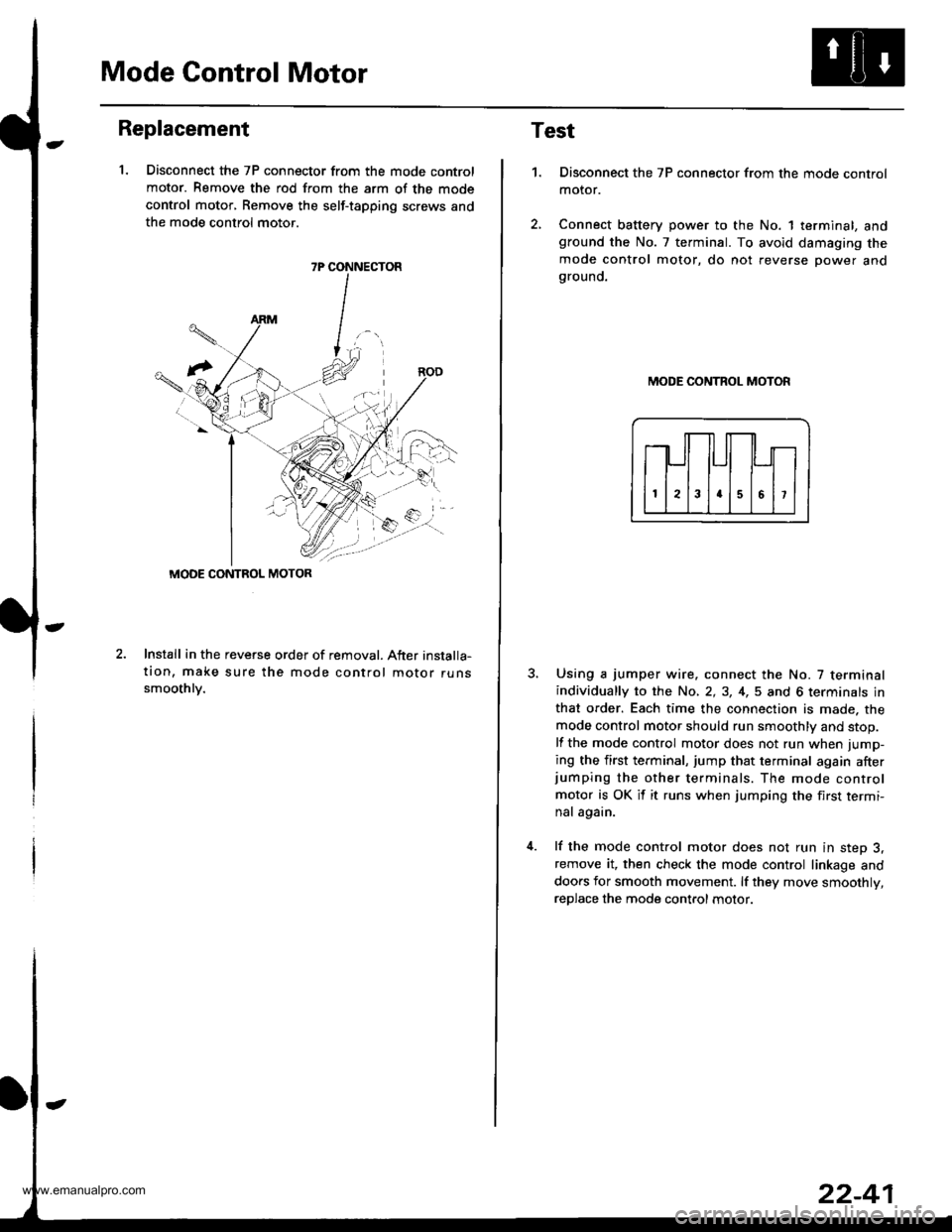

Replacement

1. Disconnect the 7P connector from the mode control

motor. Remove the rod from the arm of the mode

control motor, Remove the self-tapping screws and

the mode control motor.

2.Install in the reveGe order of removal. After installa-

tion, make sure the mode control motor runssmoothlv.

7P CONNECTOR

MODE CONTROL MOTOR

Test

1.Disconnect the 7P connector from the mode control

motor.

Connect battery power to the No. 1 terminal, andground the No. 7 terminal. To avoid damaging the

mode control motor, do not reverse power andgrouno.

MODE CONTROL MOTOR

Using a jumper wire. connect the No. 7 terminalindividually to the No, 2,3, 4,5 and 6 terminals in

that order. Each time the connection is made. the

mode control motor should run smoothly and stop.

lf the mode control motor does not run when jump-

ing the first terminal, jump that terminal again afterjumping the other terminals. The mode control

motor is OK it it runs when jumping the first termi-

nal again.

lf the mode control motor does not run in step 3,remove it, then check the mode control linkage and

doors for smooth movement. lf they move smoothly,

reDlace the mode control motor.

www.emanualpro.com

Page 1225 of 1395

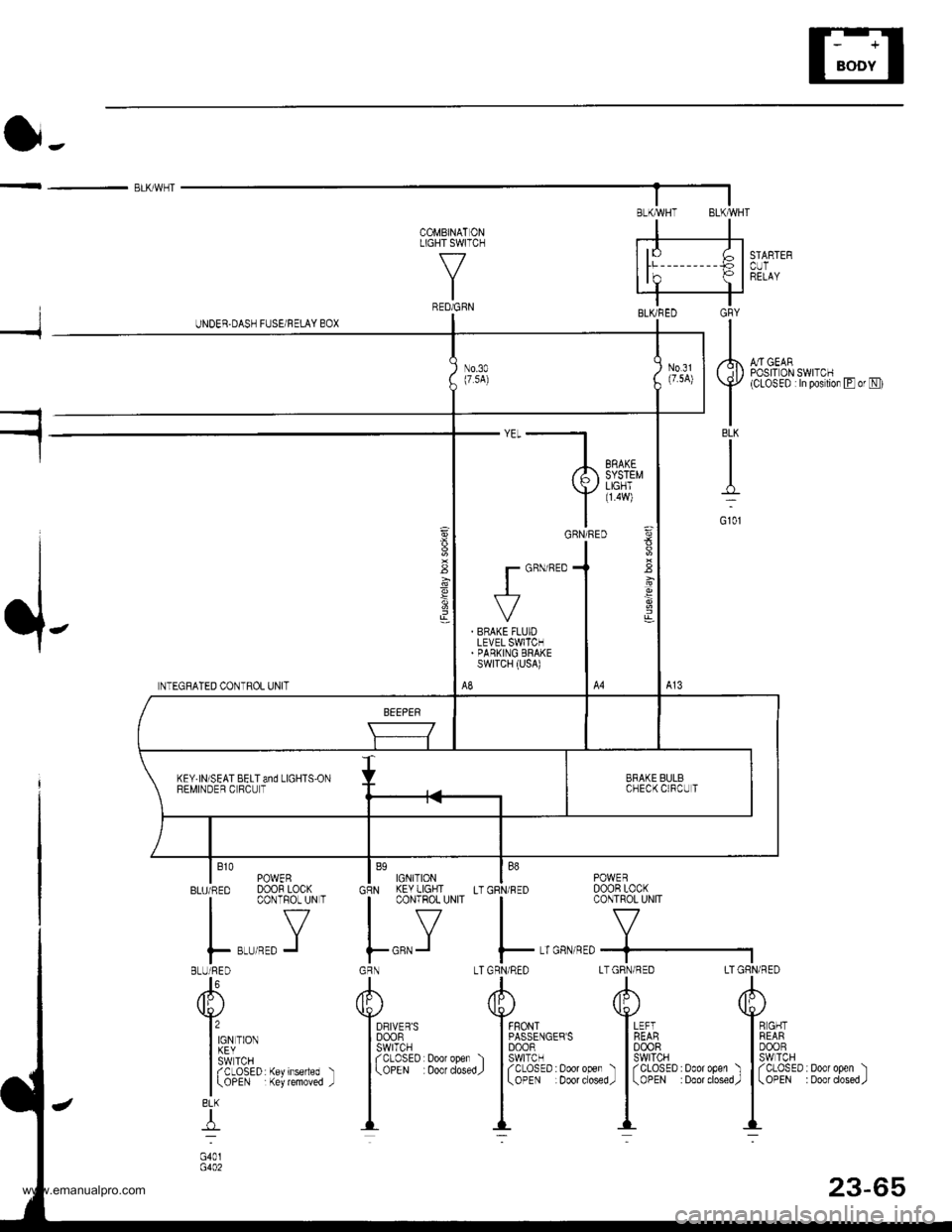

< - ELK/WHT

S'TARTEBCUTRELAY

A,/rGEARPOSrr 0N SWTTCH(CLOSED :ln postion Eor N)

COMBINATONLIGHT SWITCH

\-/

IRED/GRN

I

.l-

NTEGRATED CONTROL UNIT

POWERDOOR LOCKCONTROL UNIT

I B1o PowERBLU/RED DOOR LOCK

I CONTFOL UN T

IY

F r,r'tro J

BLUi RED

"l\

u/

llon. no*

155,1'*IaCLOSED Keylnseded

| \oPEN Key rcmoved

8LK

4

G40r

LTGRN/RED LTGRN/RED LTtl

/rh d[)v !s-l

I FFONT I LEFTI PASSENGEBS I REABI DOOR | 00ORoDen ) lSwlTcH I SWITCHdosedJ J f C-OSED : ooot ooer ) | f CLOSED : Door opel

| ( ooE Doot dosed,r | \oPEN Doo' closed

tl_L -._:-

1,,,,,"

Yilei'rGRN/RED

. BNAKE FLUIOLEVEL SWITCH.PARKING ERAKEswrTcH (usA)

A8

BRAKE BULBCHECKCIFCUTKEY.IN]SEAT BELT and LIGHTS'ONREMINDER C RCU T

23-65

www.emanualpro.com

Page 1228 of 1395

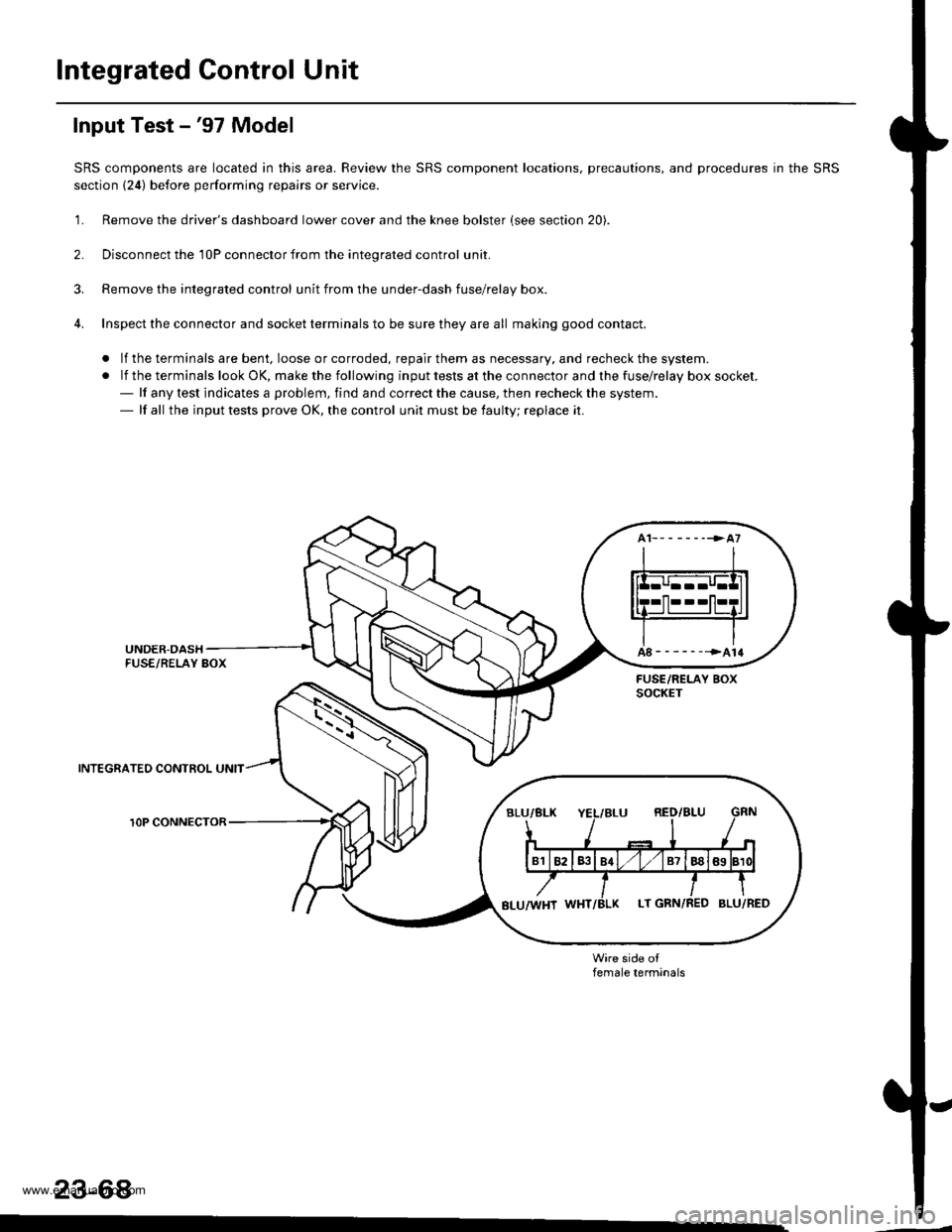

Integrated Gontrol Unit

Input Test -'97 Model

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24) before performing repairs or service.

'1. Remove the driver's dashboard lower cover and the knee bolster (see section 20).

2. Disconnect the 'l0P connector from the inteorated control unit.

3. Remove the integrated control unit from the under-dash fuse/relay box.

4. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or corroded, repair them as necessary, and recheck the system.

.lftheterminalslookOK,makethefollowinginputtestsattheconnectorandthefuse\

/relayboxsocket.- lf any test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, the control unit must be faulty; replace it.

INTEGRATEO CONTROL UNIT

rOP CONNECTOR

female terminals

23-68

www.emanualpro.com

Page 1231 of 1395

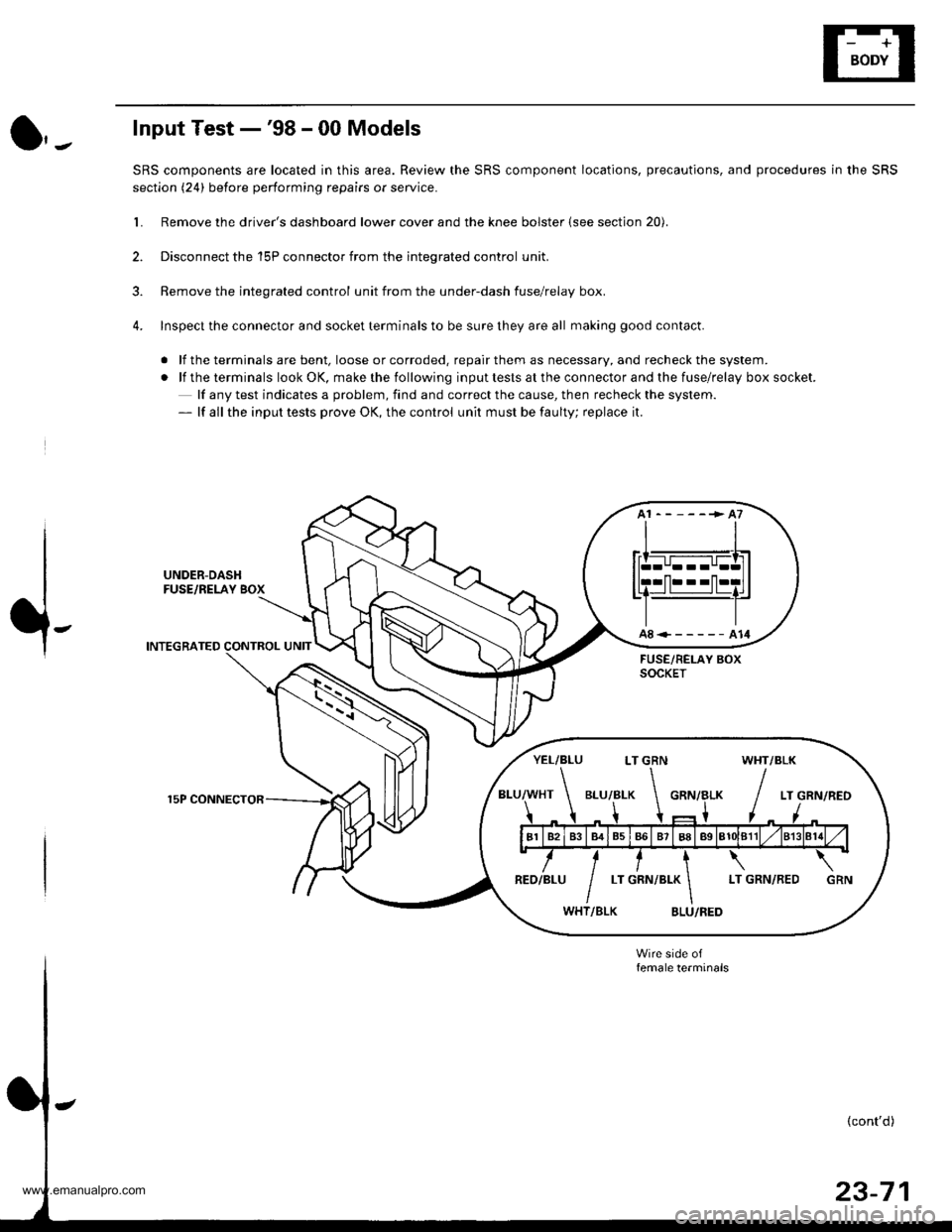

Input Test -'98 - 00 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

L Remove the driver's dashboard lower cover and the knee bolster (see section 20).

2. Disconnect the 'l5P connector from the inteqrated control unit.

3. Remove the integrated control unit from the under-dash fuse/relay box.

4. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or corroded. repair them as necessary, and recheck the system.

.lftheterminalslookOK,makethefollowinginputtestsattheconnectorandthefuse\

/relayboxsocket.

lf any test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, the control unit must be faulty; replace it.

UNDER-DASHFUSE/RELAY BOX

INTEGRATED CONTROL UNIT

15P CONNECTOR

A8<------A14

YEL/BLU LT GRN WHT/BLK

www.emanualpro.com

Page 1239 of 1395

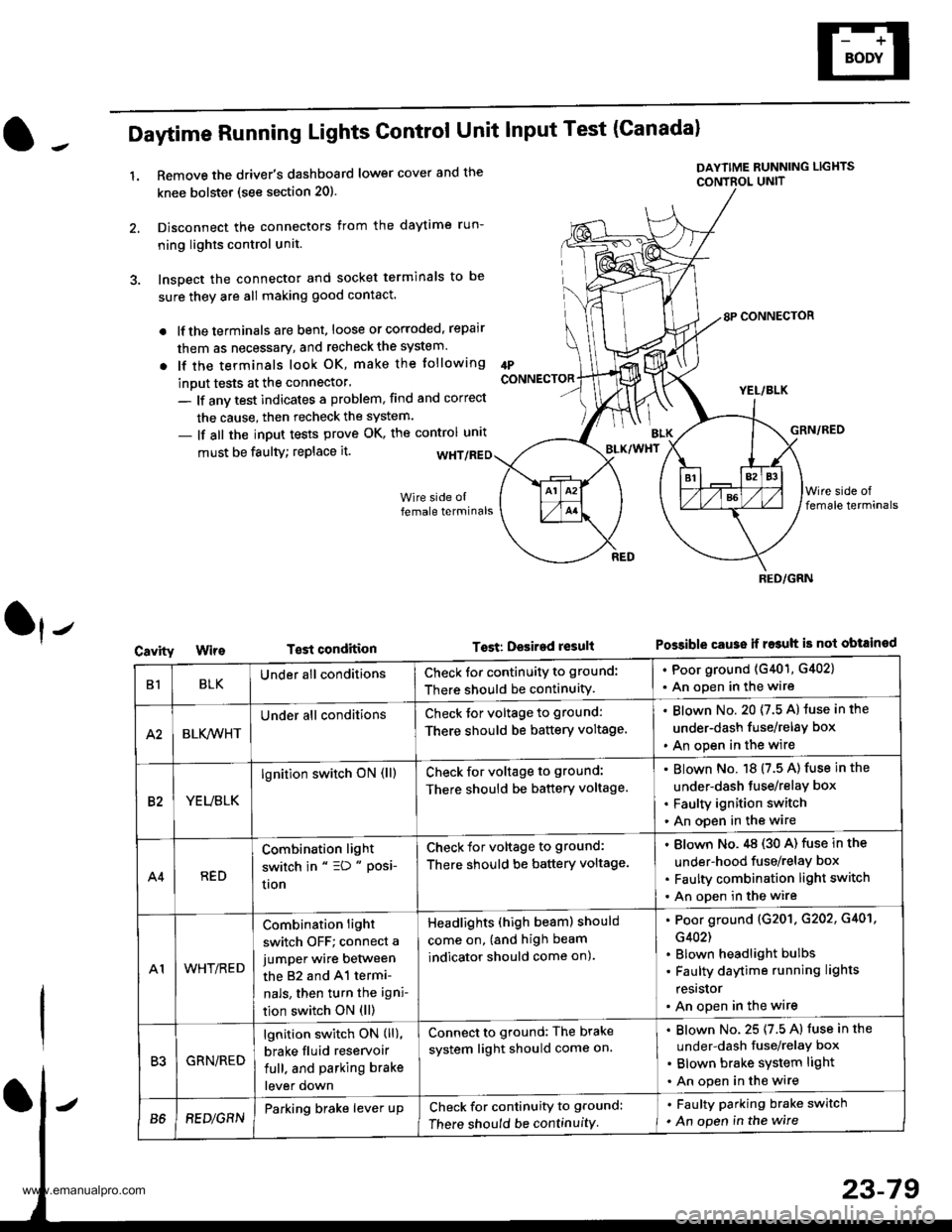

Daytime Running Lights Control Unit Input Test (Canadal

1.Remove the driver's dashboard lower cover and the

knee bolstet (see section 20).

Disconnect the connectors from the daytime run-

ning lights control unit.

Inspect the connector and socket terminals to be

sure they are all making good contact.

lf the terminals are bent, loose or corroded, repair

them as necessary, and recheck the system.

lf the terminals look OK, make the tollowing

inout tests at the connector'

- lf anv test indicates a problem, find and correct

the cause, then recheck the system.

- lf all the input tests prove OK, the control unrt

IPCONNECTOR

must be faulty; replace it.

T€st condition

DAYTIME RUNNING LIGHTS

CONTBOL UNIT

Tost: Desired result

8P CONNECTOR

YEL/BLK

GRN/RED

Possible cause ii r$uh is not obtained

BLK/WHT

Cavity

RED/GRN

B1BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401, G402)

. An open in the wire

A2BLK,4iVHT

Under all conditionsCheck tor voltage to ground:

There should be battery voltage.

Blown No. 20 (7.5 A) luse in the

under-dash fuse/relay box

An open in the wire

82YEUBLK

lgnition switch oN (ll)Check for voltage to ground:

There should be battery voltage.

Blown No. 18 (7.5 A) fuse in the

under-dash tuse/relay box

Faulty ignition switch

An open in the wire

A4RED

Combination light

switch in " =D " Posi-

uon

Check for voltage to ground:

There should be battery voltage.

Blown No.,tg (30 A) fuse in the

under-hood fuse/relay box

Faulty combination light switch

An open in the wire

A1WHT/RED

Combination light

switch OFF; connect a

jumper wire between

the 82 and 41 termi-

nals, then turn the igni-

tion switch ON (ll)

Headlights (high beam) should

come on, (and high beam

indicator should come on).

Poor ground (G201. G202, G401,

G402)

Blown headlight bulbs

Faulty daytime running lights

resrslor

An open in the wire

R'IGRN/RED

lgnition switch ON (ll),

brake fluid reservoir

full. and parking brake

lever down

Connect to ground: The brake

system light should come on.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relaY box

Blown brake system light

An open in the wire

B68EDlGRNParking brake lever upCheck for continuity to ground:

There should be continuity

. Faulty parking brake switch

. An open in the wire

www.emanualpro.com

Page 1246 of 1395

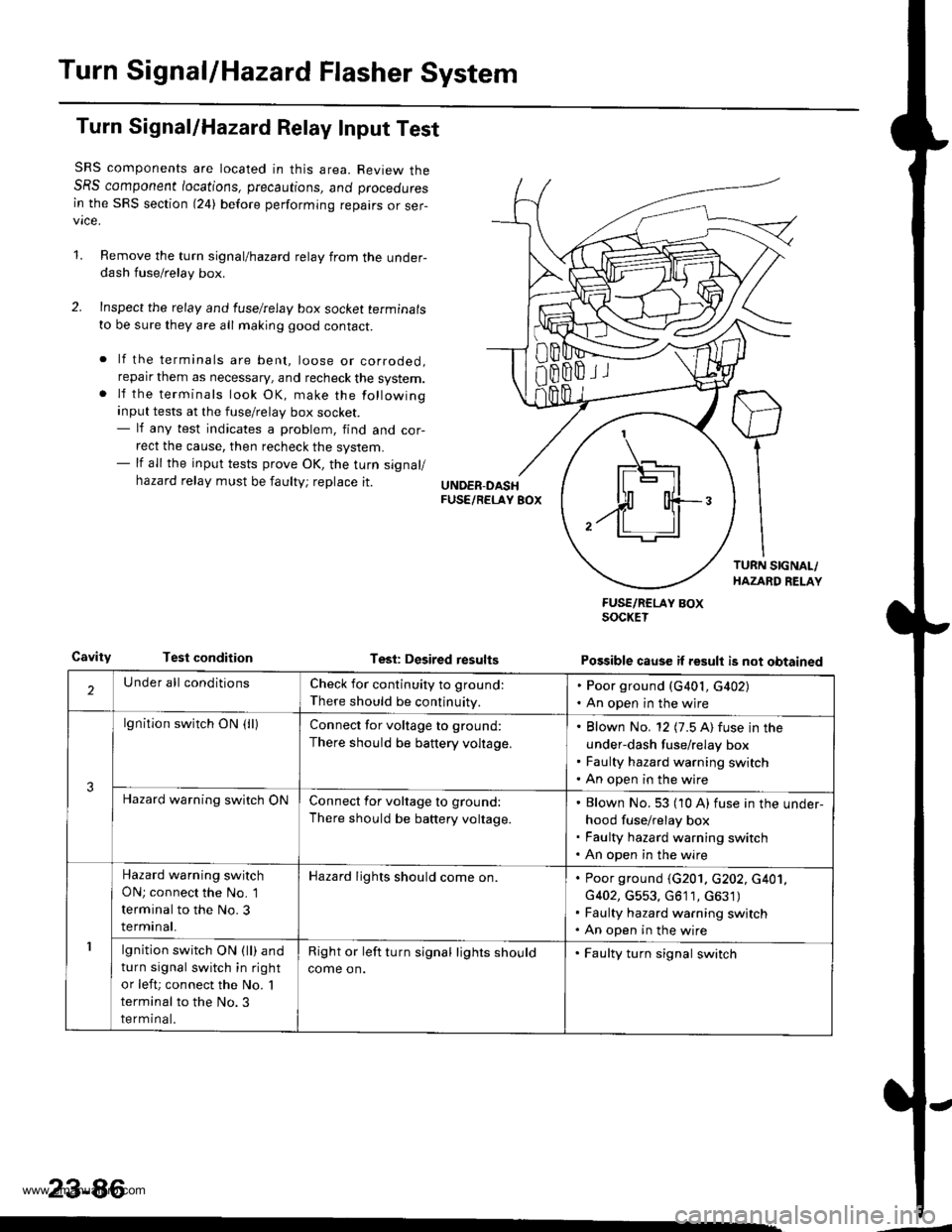

Turn SignallHazard Flasher System

Turn Signal/Hazard Relay Input Test

SRS components are located in this area. Review theSRS component /ocations, precautions, ano proceoures

in the SRS section (24) before performing repairs or ser-vice.

1.Remove the turn signal/hazard relay from the under-dash fuse/relay box.

Inspect the relay and luselrelay box socket terminals

to be sure they are all making good contact.

lf the terminals are bent, loose or corroded,reparr them as necessary, and recheck the system.lf the terminals look OK, make the following

input tests at the fuse/relay box socket.- lf any test indicates a problem, find and cor-

rect the cause, then recheck the system.- lf all the input tests prove OK, the turn signal/

hazard relay must be faulty; replace it.

CavityTest conditionTesl: Desired results

FUSE/RCLAY BOXSOCKET

Possible cause if result is not obtained

'1

IF\_-'l -]l

$ o{+-/ll ll

2Under all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401, G402). An open in the wjre

3

lgnition switch ON (lllConnect for voltage to ground:

There should be battery voltage.

Blown No. 12 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty hazard warning switch

An open in the wire

Hazard warning switch ONConnect for voltage to ground:

There should be battery voltage.

Blown No. 53 (10 A) fuse in the under-

hood fuse/relay box

Faulty hazard warning switch

An open in the wire

1

Hazard warning switch

ON; connect the No. 1

terminal to the No. 3

terminal.

Hazard lights should come on.Poor ground (G201. c202, c401,

G402, G553, G611, c631)

Faulty hazard warning switch

An open in the wire

lgnition switch ON (ll) and

turn signal switch in right

or left; connect the No. 'l

terminal to the No.3

terminal.

Right or left turn signal lights should

come on.

. Faulty turn signal switch

23-86

www.emanualpro.com