Codes HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 3 of 1395

General lnformation

Chassis and Paint Codes ....................... 1-2

ldentification Number Locations ......... 1-10

Warning/Caution Label Locations ....... 1-11

Under-hood Emissions Control

Label .......... ..................... 1-15

Lift and Support Points

Lift and Safety Stands ....................... 1-19

Floor Jack ....................... 1-20

Towing .........1-21

Service Precautions

Pafts Marking Locations ..,................. 1-22

Precautions for Real-time 4WD

(Four-wheel Drivel ......... ................. 1 -23

www.emanualpro.com

Page 4 of 1395

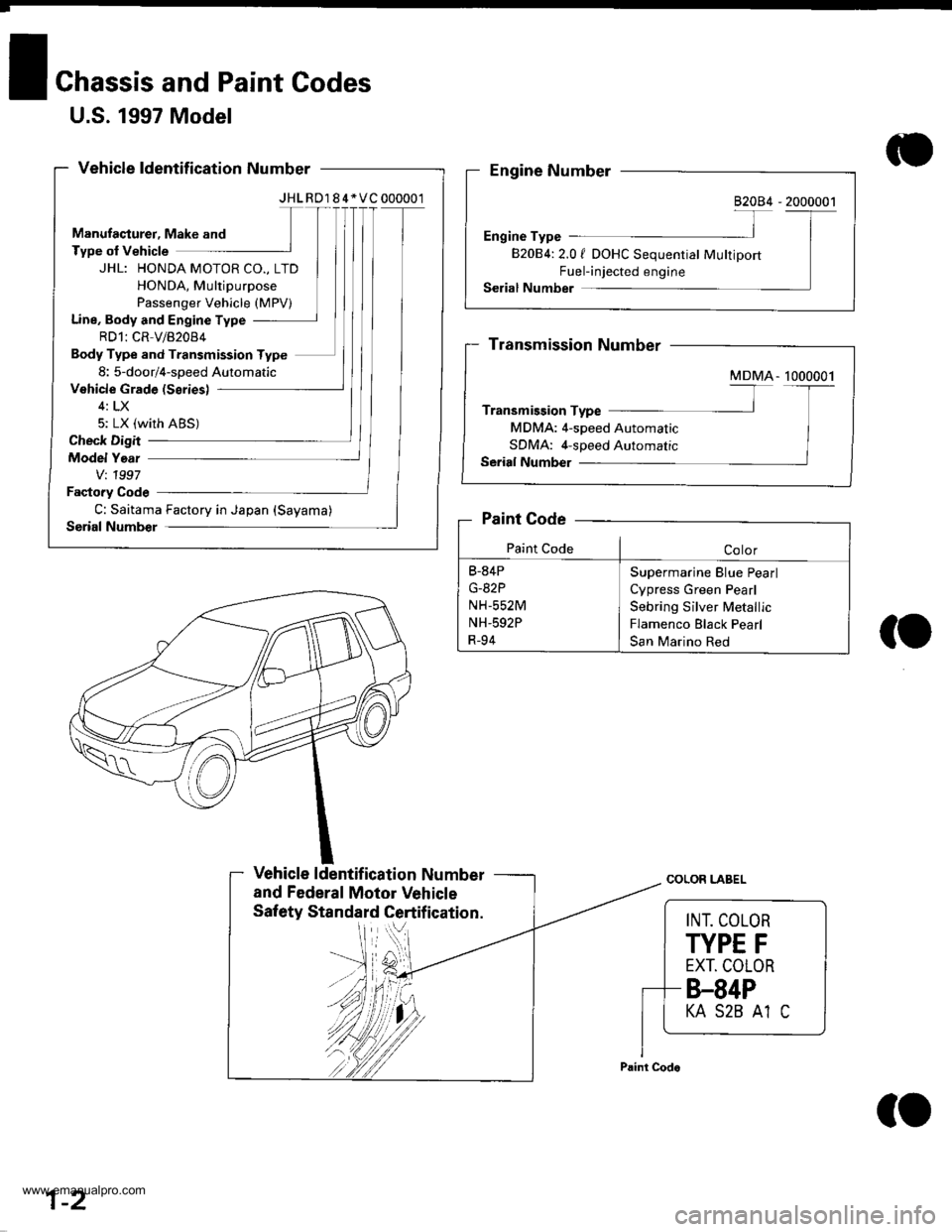

U.S. 1997 Model

Vehicle ldentification Number

JHLRD184*VC000001

JHL: HONDA MOTOR CO., LTD

HONDA, Multipurpose

Passenger Vehicle (MPV)

line, Body and Engine Type

RDl: CR V/82084

Body Type and Transmission Type

8: 5-door/4-soeed Automatic

Vehicle Grade (Series)

4: LX

5: LX (with ABS)

Check Digit

Model Year

Vt 1997

C: Saitama Factory in Japan (Sayama)

Chassis and Paint Codes

(o

COLOR LABEL

B-84P

NH-552M

NH-592P

R-94

Supermarine Blue Pearl

Cypress Green Pearl

Sebring Silver Metallic

Flamenco Black Pearl

San Marino Red

Vehicle ldentif ication Number

and Federal Motor Vehicle

INT. COLOR

WPE F

EXT. COLOR

B-84P

KA S2B A1 C

1-2

to

www.emanualpro.com

Page 6 of 1395

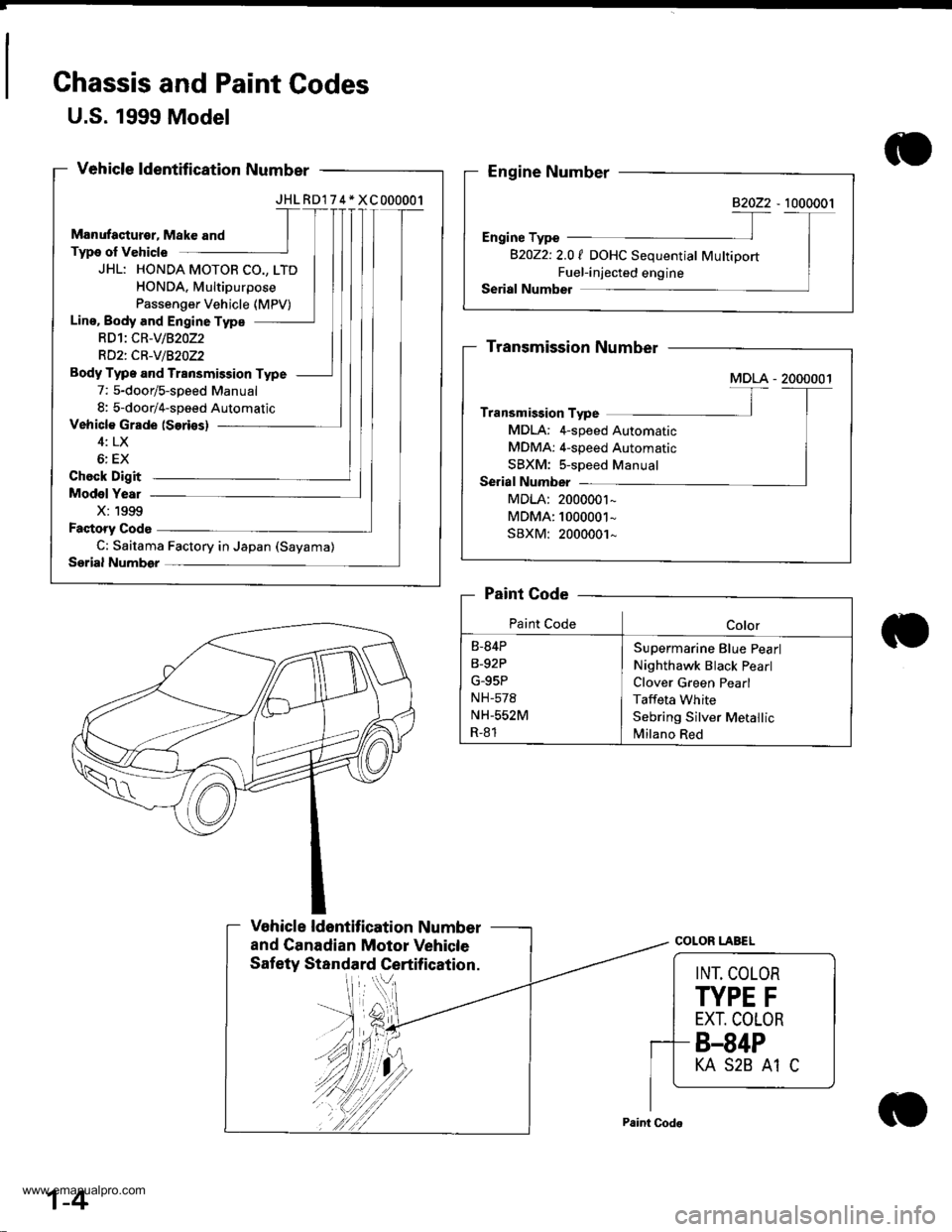

Chassis and Paint Codes

U.S. 1999 Model

Vehicle ldentification Number

JHLRDIT4*XC000001

JHL: HONDA MOTOR CO., LTD

HONDA. Multipurpose

RDlt CR-vlB20Z2

RD2t CR-V1B2OZ2

Body Type and Transmission Type

7: 5-door/5-speed Manual

8: 5-door/4-spsed Automatic

4: LX

6: Ex

Chock Digit

Model Year

X: 1999

C: Saitama Factory in Japan (Sayama)

B2OZ2:2.0 | DOHC Sequential Multiport

Fuel-injected engine

MDLA: 4-speed Automatic

MDMA: 4-speed Automatic

SBXM: s-speed Manual

MDLA: 2000001-

MDMA: 1000001-

SBXM: 2000001-

B-84P

B-92P

G.95P

NH-578

NH-552M

R,81

Supermarine Blue Pearl

Nighthawk Black Pearl

Clover Green Pearl

Taffeta White

Sebring Silver Metallic

Milano Red

Vehicle ldentification Number

and Canadian Motor VehicleCOLOR LABEL

INT. COLOR

TYPE F

EXT. COLOR

B.84P

KA S2B A1 C

1-4

www.emanualpro.com

Page 8 of 1395

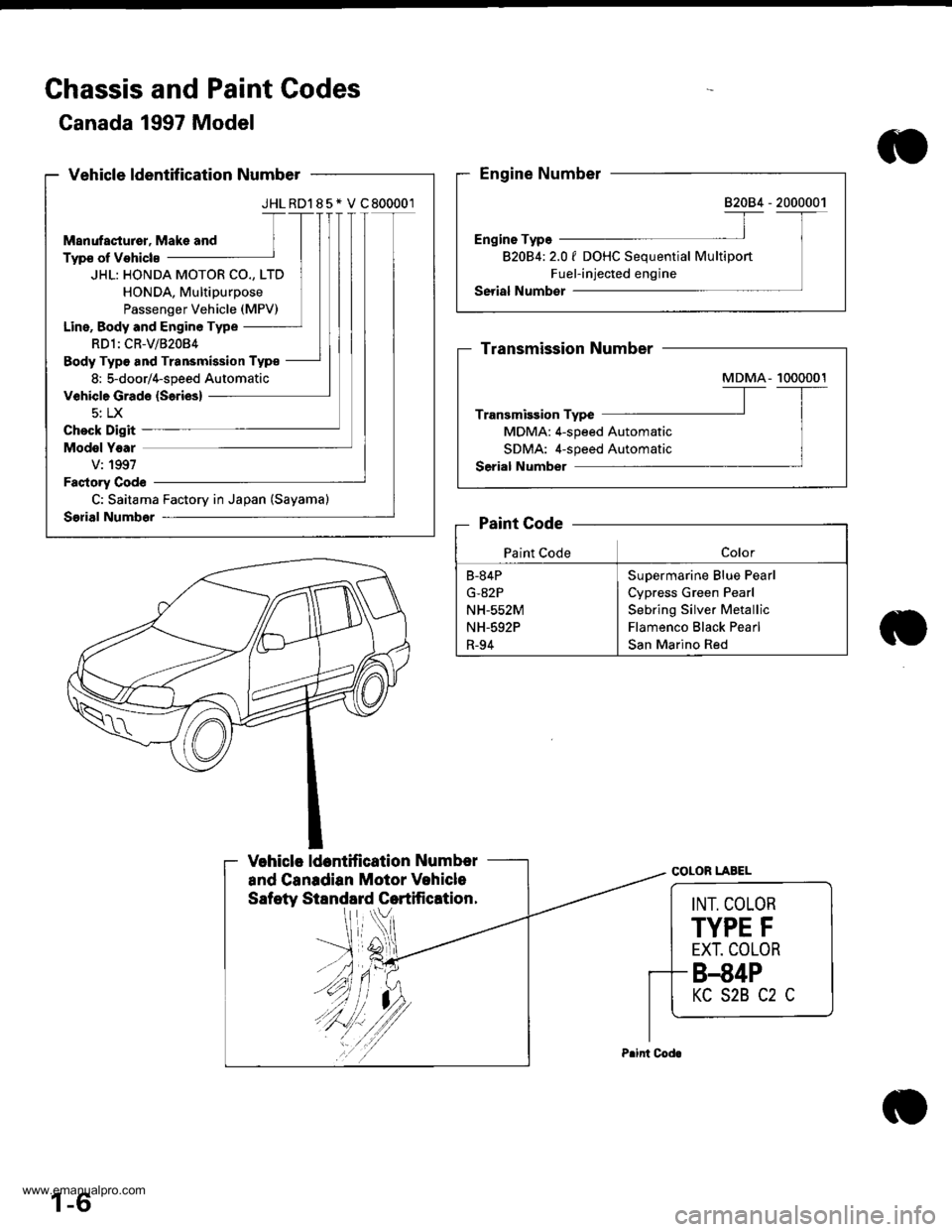

Chassis and Paint Codes

Canada 1997 Model

JHLRD185* V C 800001

HONDA MOTOR CO., LTD

HONDA, Multipurpose

Passenger Vehicle (MPV)

Line, Body and Engine Type

RDl: CR-V/B2084

Body Typ€ and Transmission Typ€

8: s-door/4-soeed Automatic

C: Saitama Factory in Japan (Sayama)

B20g4t 2.0 | DOHC Seouential MultiDort

Fuel-injected engine

MDMA- 1000001

MDMA: 4-speed Automatic

SDMA: 4-speed Automatic

Supermarine Blue Pearl

Cypress Green Pearl

Sebring Silver Metallic

Flamenco Black Pearl

San Marino Red

B-84P

G-82P

NH-552M

NH-592P

R-94

Vehicle ldentification Number

and Canadian Motor Vehicle

Saf ety Standard Certifi cation.

COLOR LABEL

INT. COLOR

TYPE F

EXT. COLOR

B-84P

KC S2B C2 C

1-6

www.emanualpro.com

Page 10 of 1395

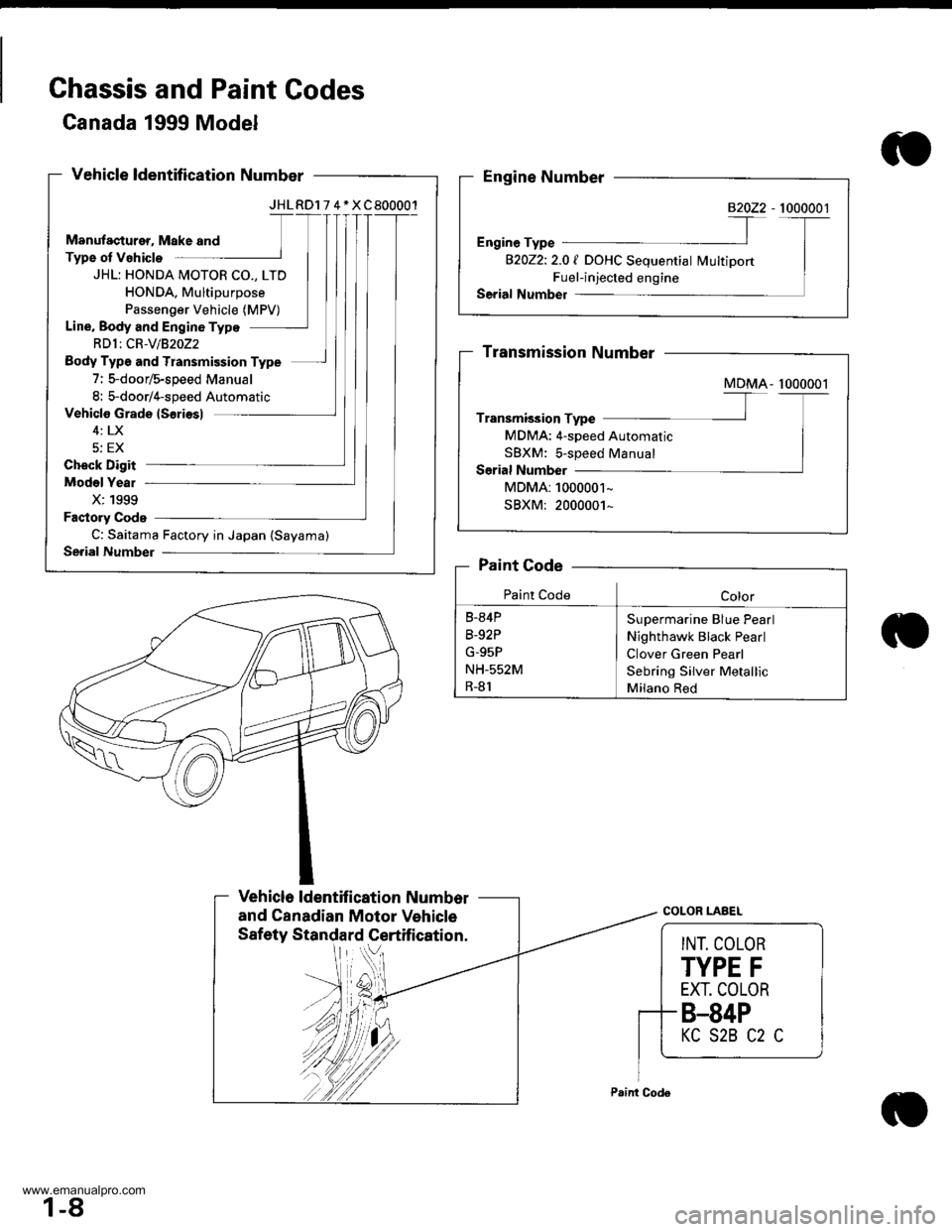

Canada 1999 Model

Vehicle ldentification Number

JHL RDl T 4*XC800001

JHL: HONDA MOTOR CO., LTD

HONDA, Multipurpose

Passen0er Vehicle {MPV)Line, Body and Engin6 Type

RD1: CB-Y/B2OZ2

Eody Typ6 and Transmi$ion Type

7: 5-door/5-speed Manual

8: s-door/4-speed Automatic

4: LX

5: EX

Chock Digit

Model Yeal

X: 1999

C: Saitama Factory in Japan {Sayama)

Chassis and Paint Codes

COLOR LABEL

B20Z2i 2.0 I DOHC Sequential Multiport

Fuel-injected engine

MDMA: 4-speed Automatic

SBXM: s-speed Manual

B-84P

a-92P

G.95P

NH.552M

R-81

Supermarine Blue Pearl

Nighthawk Black Pearl

Clover Green Pearl

Sebring Silver Metallic

Milano Red

Vehiclo ldentification Number

and Canadian Motor Vehicle

Safety Standard Certification.INT. COLOR

TYPE F

EXT. COLOR

B-84P

KC S2B C2 C

1-8

www.emanualpro.com

Page 55 of 1395

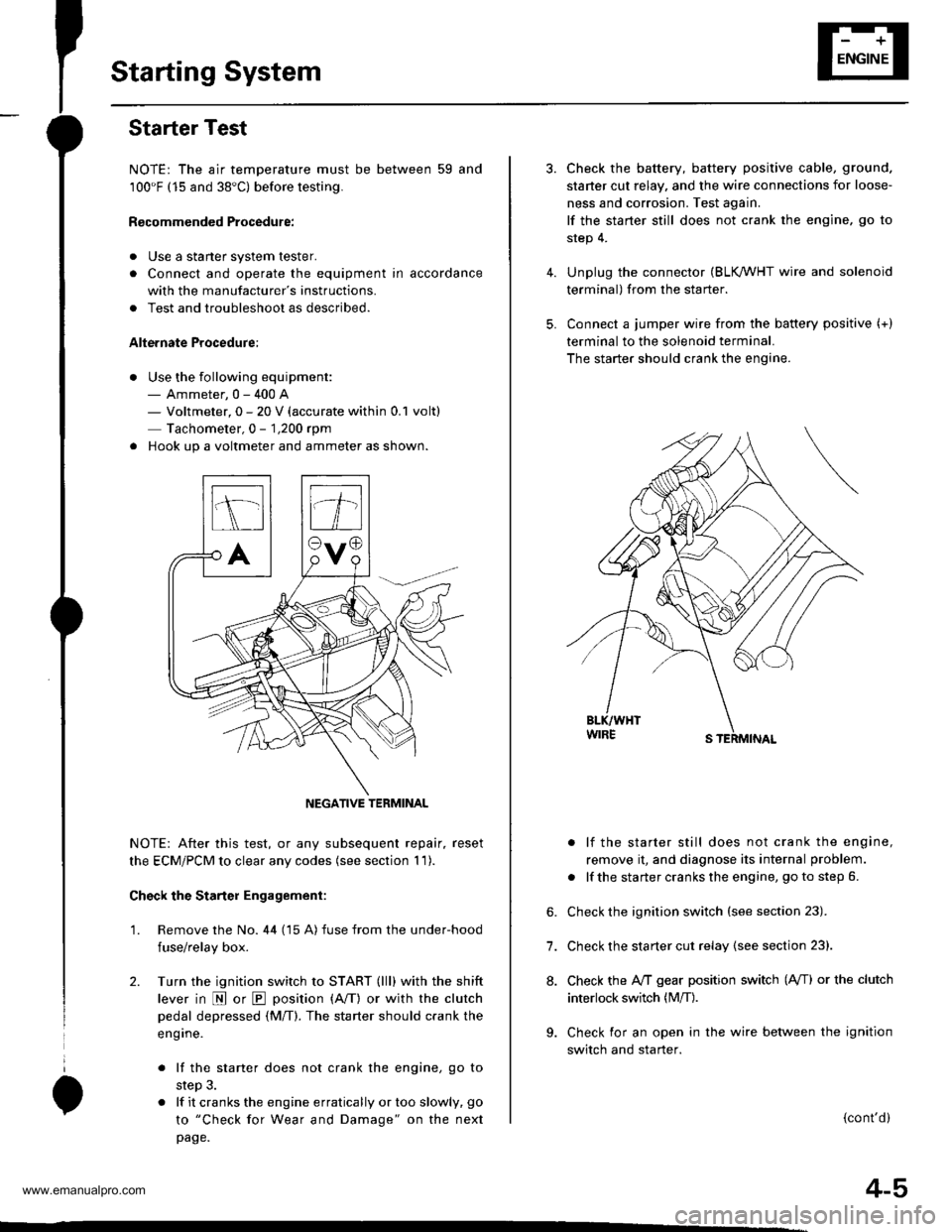

Starting System

Starter Test

NOTE: The air temperature must be between 59 and'100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described.

Alte.nate Procedure:

. Use the following equipment:- Ammeter, 0 - 400 A- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

Tachometer,0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section 1 1).

Check the Starter Engagement:

'1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box.

2. Turn the ignition switch to START (lll) with the shift

lever in E or E position (A/T) or with the clutch

pedal depressed {M/T). The starter should crank the

eng ine.

. lf the starter does not crank the engine, go to

step 3.

. lf it cranks the engine erratically or too slowly, go

to "Check for Wear and Damage" on the next

page.

NEGATIVE TERMINAL

4.

5.

6.

7.

8.

Check the battery, battery positive cable, ground.

staner cut relay, and the wire connections for loose-

ness and corrosion. Test again.

lf the staner still does not crank the engine, go to

step 4.

Unplug the connector (BLK /VHT wire and solenoid

terminal) from the starter.

Connect a jumper wire from the baftery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem.

. lf the starter cranks the engine, go to step 6.

Check the ignition switch (see section 23).

Check the starter cut relay {see section 23}.

Check the IVT gear position switch (A/T) or the clutch

interlock switch (M[).

Check for an open in the wire between the ignition

switch and starter.

(cont'd)

4-5

www.emanualpro.com

Page 154 of 1395

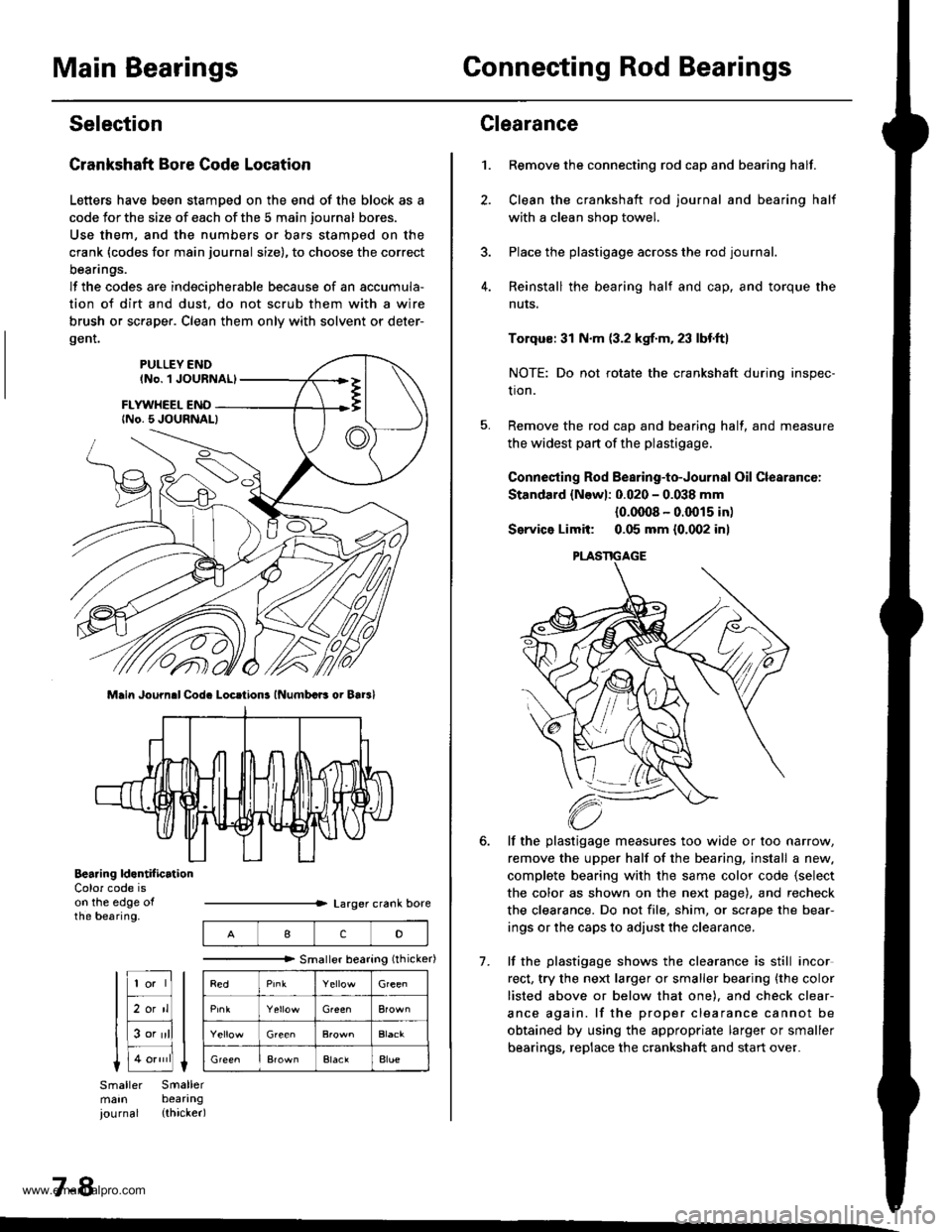

Main BearingsConnecting Rod Bearings

Selection

Crankshaft Bore Code Location

Letters have been stamDed on the end of the block as a

code Jor the size of each of the 5 main journal bores.

Use them, and the numbers or bars stamped on the

crank (codes for main journal size), to choose the correct

beanngs.

lf the codes are indecipherable because of an accumula-

tion of dirt and dust. do not scrub them with a wire

brush or sc.aper. Clean them only with solvent or deter-

gent.

Main Journ.l Cod. Locrtions lNumbcB oi Bar3l

Bearing ld.ntif icrtionColor code ison the edge ofthe bearing.

7-8

IcD

"""""""" Smallerbearing(rhicker)

Green

Green

ElaclAlue

Clearance

Remove the connecting rod cap and bearing half.

Clean the crankshaft rod journal and bearing half

with a clean shop towel.

Place the plastigage across the rod journal.

Reinstall the bearing half and cap, and torque the

nuts.

1.

7.

Torqus: 31 N.m (3.2 kgf.m. 23 lbf.ft)

NOTE: Do not rotate the crankshaft during inspec-

tion.

Remove the rod cap and bearing half, and measure

the widest part of the plastigage.

Connesting Rod Bearing-to-Journal Oil Clearancc:

Standard {Newl: 0.020 - 0.038 mm

{0.0008 - 0.0015 in)

Service Limit: 0.05 mm {0.002 inl

lf the plastigage measures too wide or too narrow,

remove the upper half of the bearing, install a new.

complete bearing with the same color code {select

the color as shown on the next page), and recheck

the clearance. Do not file, shim, or sc.ape the bear-

ings or the caps to adjust the clearance.

lf the plastigage shows the clearance is still incor

rect, try the next larger or smaller bearing {the color

listed above or below that one). and check clear-

ance again. lf the proper clearance cannot be

obtained by using the appropriate larger or smaller

bearings. replace the crankshaft and start over.

PLASTIGAGE

www.emanualpro.com

Page 155 of 1395

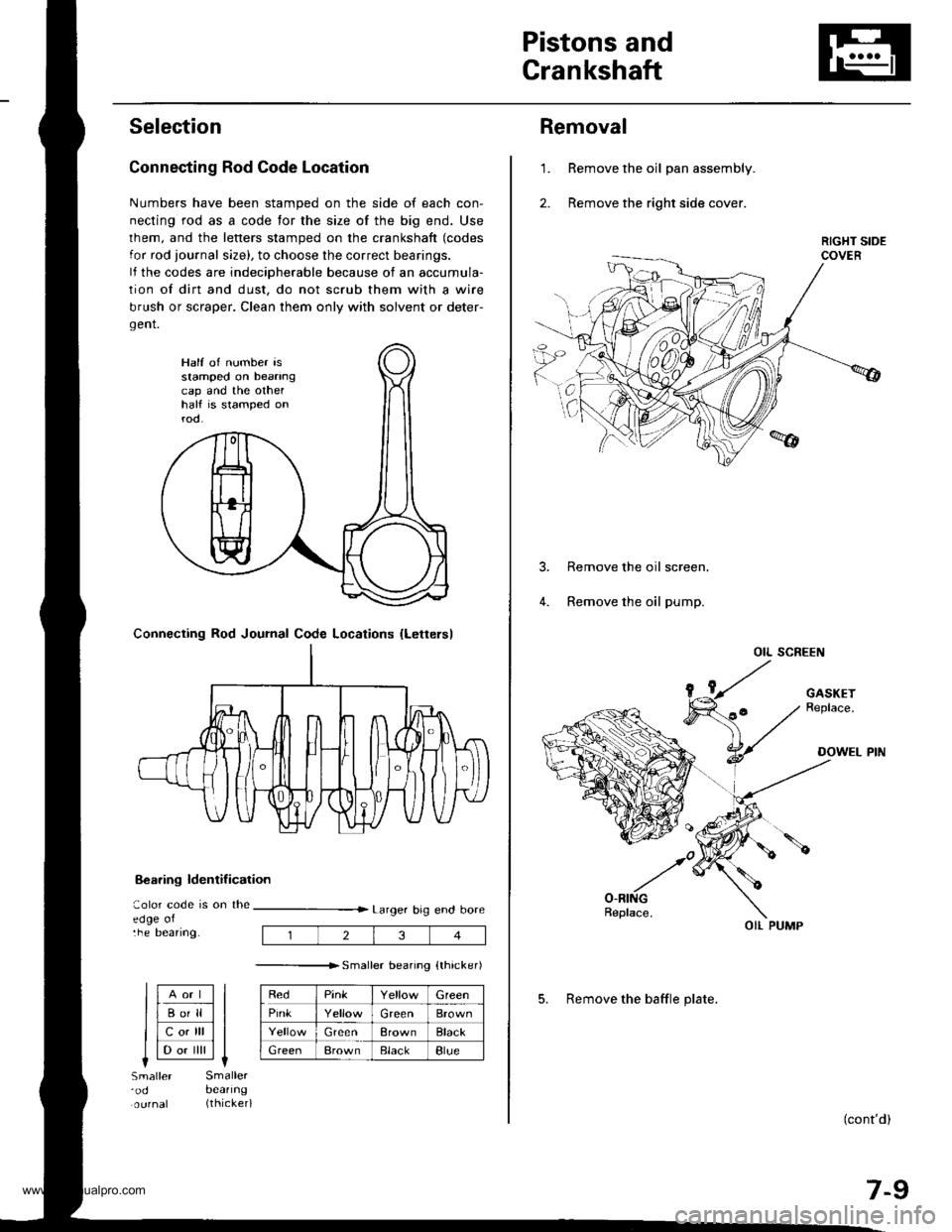

Pistons and

Crankshaft

Selection

Connecting Rod Code Location

Numbers have been stamped on the side of each con-

necting rod as a code for the size of the big end. Use

lhem, and the letters stamped on the crankshaft (codes

for rod journal size), to choose the correct bearings.

lf the codes are indeciDherable because of an accumula-

tion of dirt and dust, do not scrub them with a wire

brush or scraper. Clean them only with solvent or deter-

gent.

8€aring ldentif ication

aolor code is on theedge oltne Deanng.

Larger big end bore

---------------r. sma er bearino {thicker)

RedPinkGreen

PinkGreenBrown

GreenBrownBlack

GreenBrownElackBlue

Half of number isstamped on beanngcap and the othelhalf is stamped onrod.

Connecting Rod Journal Code Locations {Lettersl

llAort ll

llBo'll ll

llcotrll ll

I l-.. ilril It-lSmaller'odSmallerbeanng(thicker)

234

Removal

Remove the oil pan assembly.

Remove the right side cover.

1.

Remove the oil screen.

Remove the oil pump.

OIL SCREEN

(cont'd)

7-9

OIL PUMP

5. Remove the baffle plate.

www.emanualpro.com

Page 262 of 1395

Troubleshooting

Troubleshooting Procedures

How To Begin Troubleshooting

When the Malfunction indicator Lamp (MlLl has been reported on, or there is a driveability problem, use the appropri-ate procedure below to diagnose and repair the problem.

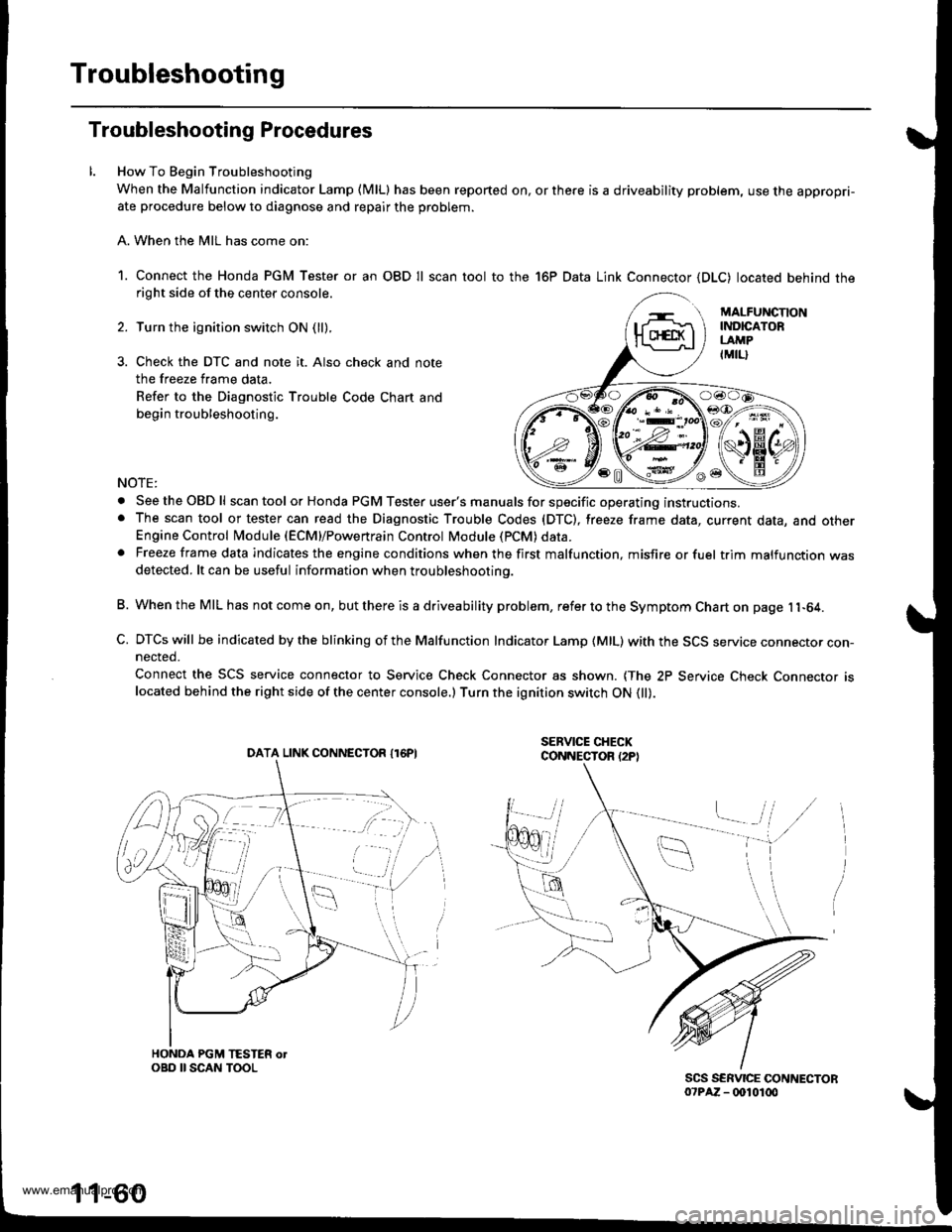

A. When the MIL has come on:

1. Connect the Honda PGM Tester or an OBD Il scan tool to the 16P Data Link Connector (DLC) located behind theright side of the center console.

Turn the ignition switch ON (ll).

Check the DTC and note it. Also check and note

the freeze frame data.

Refer to the Diagnostic Trouble Code Chart and

begin troubleshooting.

NOTE:

. SeetheOBDll scan tool or Honda PGM Tester user's manuals for specific operating instructions.. The scan tool or tester can read the Diagnostic Trouble Codes (DTC), freeze frame data, current data, and otherEngine Control Module (ECM}/Powertrain Control Module (PCM) data.. Freeze frame data indicates the engine conditions when the first malfunction, misfire or fuel trim malfunction wasdetected. lt can be useful information when troubleshootino.

B. When the MIL has not come on, but there is a driveability problem, refer to the Symptom Chart on page 11-64.

C. DTCs will be indicated by the blinking of the Malfunction Indicator Lamp {MlL) with the SCS service connector con-nected.

Connect the SCS service connector to Service Check Connector as shown. {The 2P Service Check Connecror rslocated behind the right side of the center console.) Turn the ignition switch ON 0l).

DATA LINK CONNECTOR I16PI

1 1-60

www.emanualpro.com

Page 573 of 1395

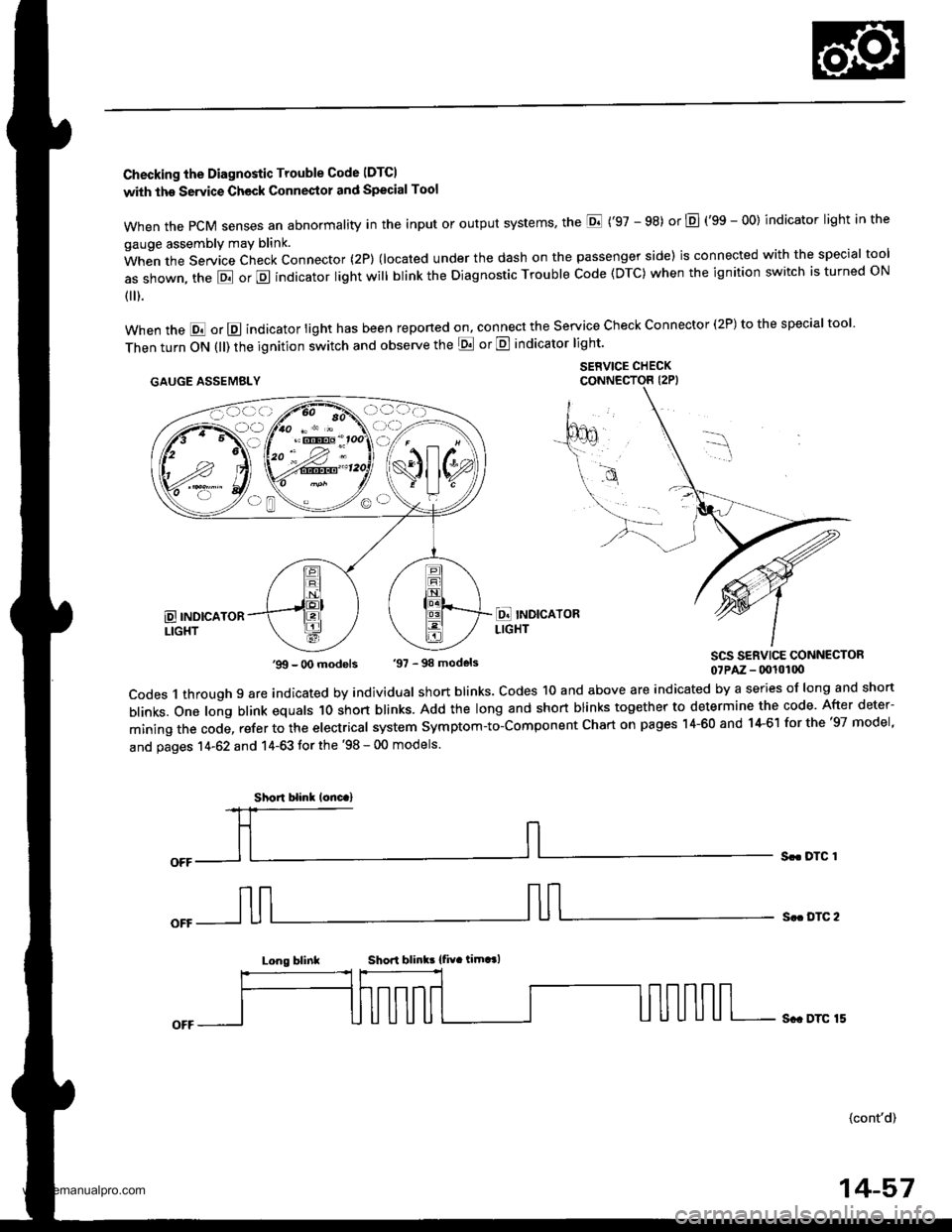

Checking the Diagnostic Trouble Code IDTCI

with the Servic€ Check Connestol and Special Tool

when the PcM senses an abnormality in the input or output systems' the E ('97 - 98) or E (gS - OO) indicator light in the

gauge assembly may blink.

When the Service Check Connector (2P) (located under the dash on the passenger side) is connected with the special tool

as shown, the E or E indicator light will blink the Diagnostic Trouble Code (DTC) when the ignition switch is turned ON

{ ).

when the E or E indicator light has been reponed on, connect the service check connector (2P) to the special tool

Then turn ON (ll) the ignition switch and observe the E or E indicator light'

.AUGE AssEMaLY $1,"^f:tT"'ff,

SCS SERVICE CONNECTOR07PAz - (x!l0100

codes 1 through 9 are indicated by individual short blinks. codes 1o and above are indicated by a series of long and short

blinks. one long blink equals 1o short blinks. Add the long and short blinks together to determine the code. After deter-

mining the code, refer to the electrical system symptom-to-component chart on pages 14-60 and 14-61 for the '97 model,

and pages 14-62 and 14-63 tor the '98 - 00 models.

Sr. DTC 1

S.. DTC 2

Long blinkShori blink! {fiv. timt l

Sc. DTC 15

(cont'd)

'99 - O0 models '97 - 98 models

Short blinl lonc.)

14-57

www.emanualpro.com