Power steering pump HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 35 of 1395

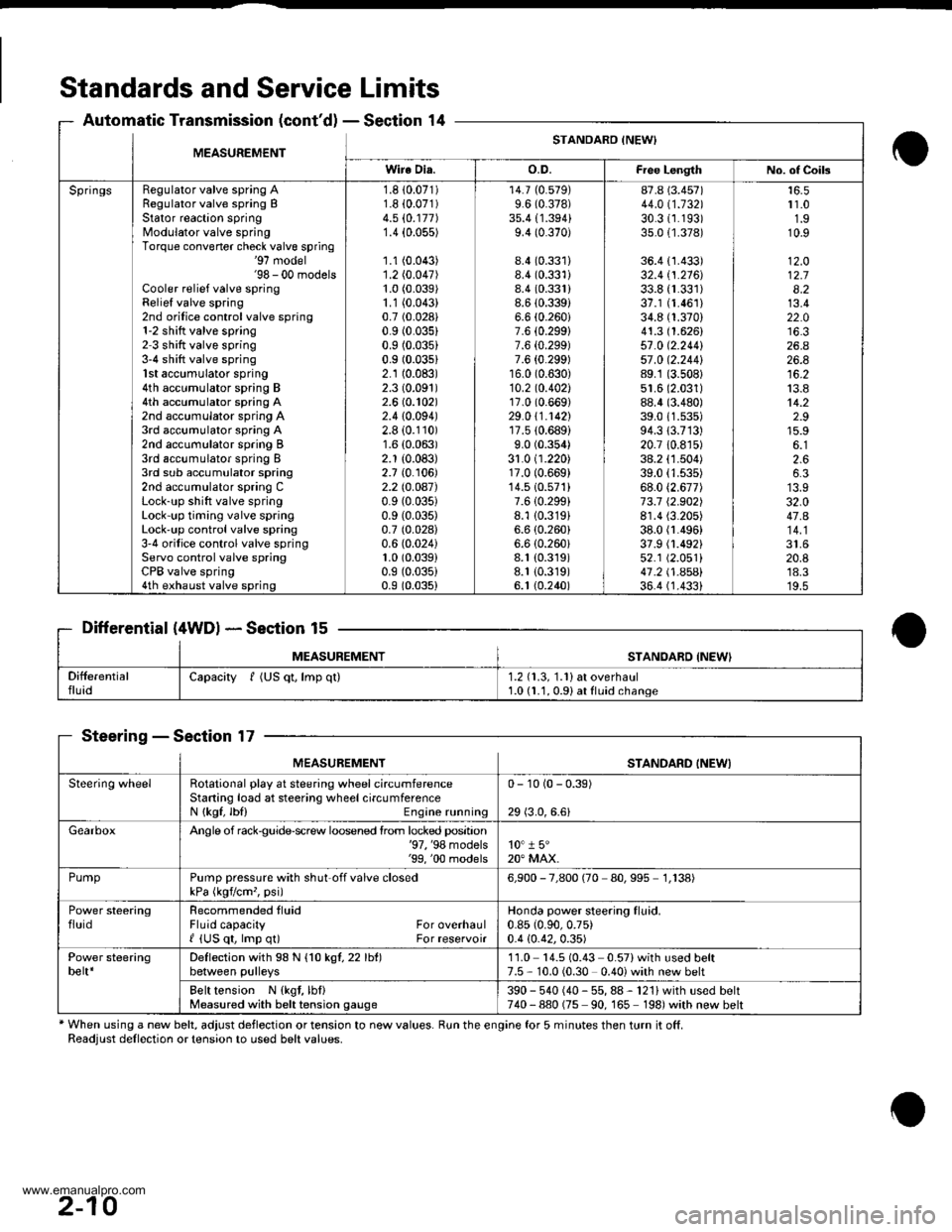

Standards and Service Limits

Automatic Transmission (cont'dl - Section 14

Differential (4WDl * Section 15

MEASUREMENTSTANOABD {NEW'

SteeringSection 17

* When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.Readjust dellection or tension to used belt values.

MEASUREMENTSTANDARO INEWI

Wire Dia.o.D.Fiee LengthNo. of Coils

SpringsRegulator valve spring ARegulator valve spring BStator reaction springModulator valve springTorque convener check valve spring'97 model'98 - 00 modelsCooler relief valve springRelief valve spring2nd orilice control valve spring1-2 shitt valve spring2 3 shift valve spring3-4 shift valve spring1st accumulator spring4th accumulator spring B4th accumulator spring A2nd accumulator spring A3rd accumulator spring A2nd accumulator spring B3rd accumulator spring I3rd sub accumulator spring2nd accumulator spring CLock-up shift valve springLock-up timing valve springLock'up control valve spring3'4 orifice control valve springServo control valve springCPB valve spring4th exhaust valve spring

1.8 10.071)1.8 i0.071)4.5 (0.177)

1.4 {0.055)

1.1 (0.043)

1.2 (0.047)

1.0 (0.039)

1.1 (0.043)

0.7 (0.028)

0.9 (0.035)

0.9 (0.035)

0.9 (0.03s1

2.1 (0.083)

2.3 (0.091)

2.6 (0.102)

2.410.094)2.8 (0.110)

1.6 (0.063)

2.1 (0.083)

2.7 {0. r06)2.2lO.OA7)0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

0.6 (0.024)

1.0 (0.039)

0.9 (0.035)

0.9 (0.035)

14.7 (0.579)

9.6 (0.378)

35.4 {1.394}9.4 (0.370)

8.4 (0.331)

8.4 (0.331)

8.4 (0.331)

8.6 (0.3391

6.6 (0.260i

7.6 {0.299}7.6 {0.299)7.6 {0.299)16.0 (0.630)

10.2 to.402l17.0 (0.669)

29.0 \1.1421'r7.510.689)

9.0 (0.354)

31.0 (1.220)17.0 (0.669)

14.510.571)7.610.299i8.1 {0.319}6.6 (0.260)

6.6 (0.260i

8.1 (0.319)

8.1 {0.319)6. t (0.240)

87.8 (3.457)

44.011.132130.31r.193)35.0 {1.378)

36.4 {1.433)32.4 tl.216J33.8 {r.331)37.1 (1.461)

34.8 (1.370)

41.3 (1.626)

57 .0 (2.2441

57 .0 12.244189.1 (3.508)

51.6 (2.031)

88.4 (3.480)

39.011.s35)94.313.713)20.7 10.8r5)38.2 (1.504)

39.0 (1.535)

68.0 (2.677)

73.7 12.902)8r.4 (3.205)

38.0 fl.496)37.9 (1.492)

52.1 (2.051)

41 .2 t .A5Al36.4 (1.4331

r 1.01.910.9

12.O12.78.213.422.0

26.426.8

13.814.22.915.9

2.66.3

32.047.A

20.8'18.3'19.5

Capacity f (US qt, lmp ql)1.2 (1.3, 1.1) at overhaul1.0 (1.1, 0.91 at fluid change

MEASUREMENTSTANDARD INEWI

Steering wheelRotational play at steering wheel circumferenceStaning load at steering wheelcircumferenceN {kgf, lbl) Engine running

0- 10 (0 - 0.39)

29 (3.0,6.6)

GearboxAngle of rack$uide-screw loosened lrom locked position'97, '98 models'99, '00 models10" 1 5"20" MAX.

PumpPump pressure with shut off valve closedkPa (kgvcm,, psi)6,900 - 7,800 (70 80,995 1,138)

Power steeringfluidRecommended tluidFluid capacity For overhaulI {US qt, lmp q0 For reservoir

Honda power steering fluid.0.85 (0.90,0.75)

0.4 {0.42,0.35)

Power steeringbelt*Deflection with 98 N {1O kgl,22lht)between pulleys11.0 14.5 (0.43 0.57)with used belt7.5 - 10.0 (0.30 0.40) with new belt

Belt tension N {kgt, lbf}Measured with belt tension gauge390 - 540 (40 - 55, 88 - 121) with used belt740-880 (75 90, 165 198)with new belt

2-10

www.emanualpro.com

Page 85 of 1395

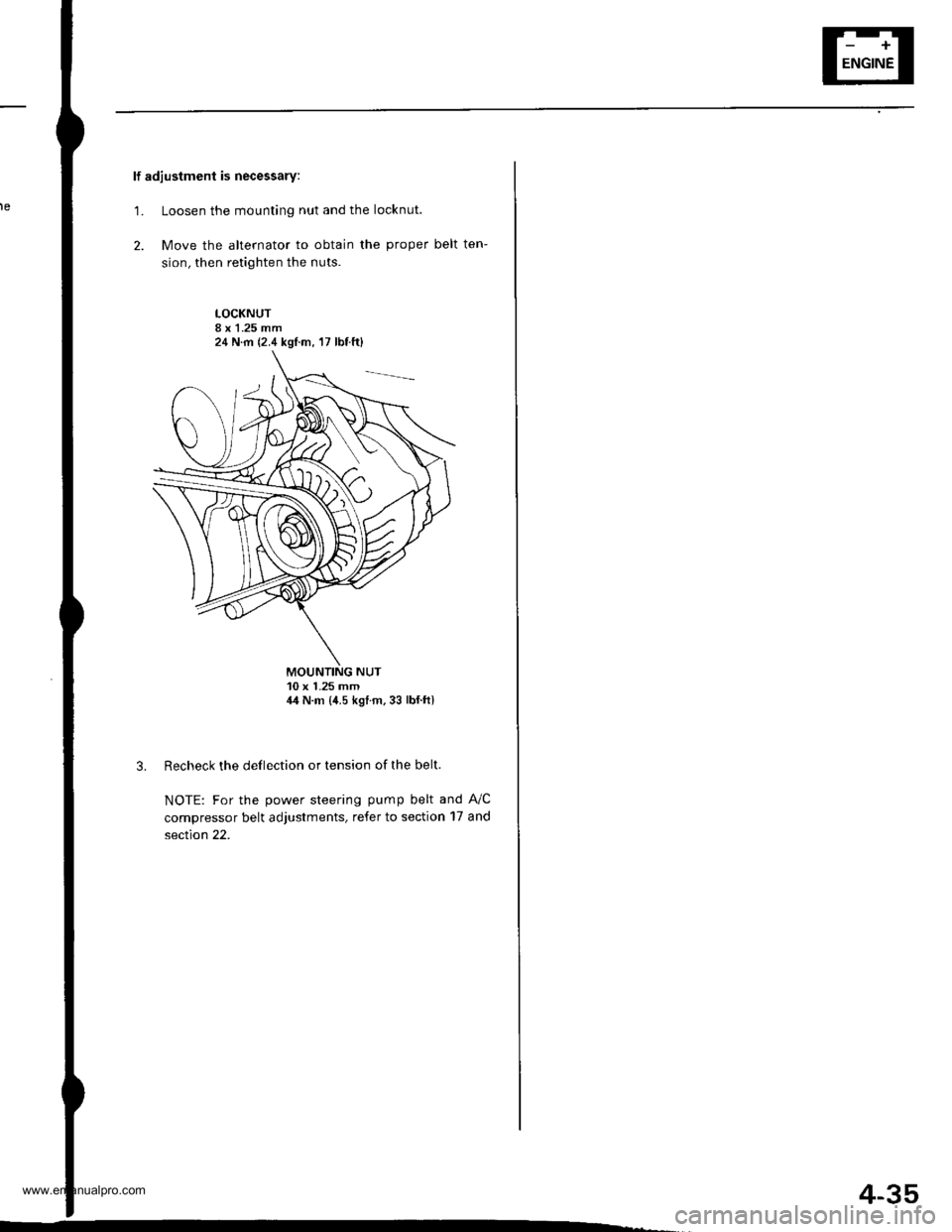

lf adjustment is necessary:

1. Loosen the mounting nut and the locknut.

2. Move the alternator to obtain the proper belt ten-

sion, then retighten the nuts.

LOCKNUT8 x 1.25 mm

MOUNTING NUT10 x 1.25 mm14 N.m {4.5 kgl.m.33 lbf.ft)

Recheck the deflection or tension of the belt.

NOTE: For the power steering pump belt and A,/C

compressor belt adjustments, refer to section 17 and

section 22.

24 N.m (2.4 kgtm,'17 lbf ft)

4-35

www.emanualpro.com

Page 91 of 1395

n-

n-

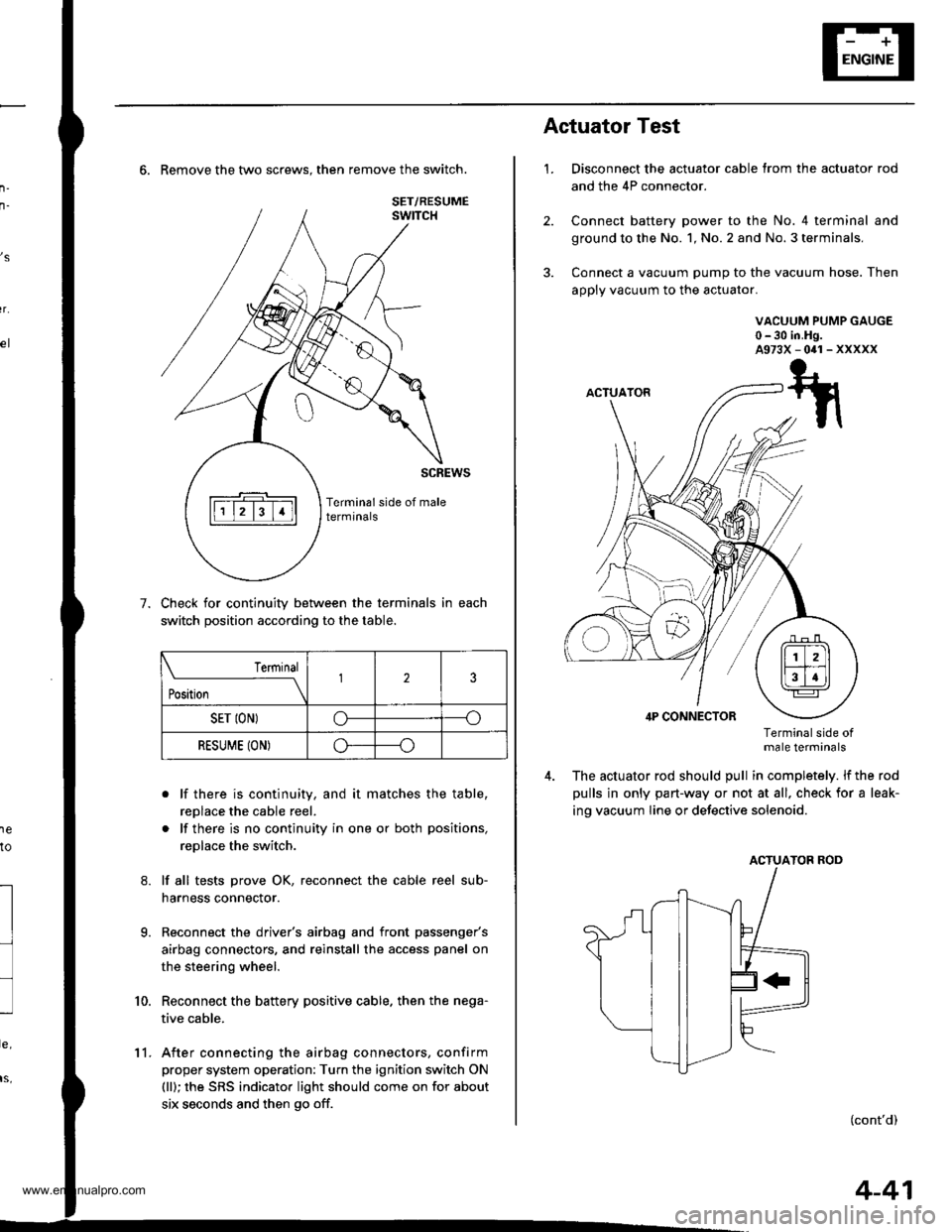

6. Remove the two screws. then remove the switch.

Check for continuity between the terminals in each

switch position according to the table.

. lf there is continuity, and it matches the table,

replace the cable reel.

. lf there is no continuity in one or both positions,

replace the switch.

lf all tests prove OK, reconnect the cable reel sub-

harness connector.

Reconnect the driver's airbag and front passenger's

airbag connectors, and reinstall the access panel on

the steering wheel.

Reconnect the battery positive cable. then the nega-

tive cable.

After connecting the airbag connectors, confirm

proper system operation: Turn the ignition switch ON

(ll); the SRS indicator light should come on for about

six seconds and then go off.

,s

r.

1e

to

7.

l

9.

10.

SET/RESUME

Terminal

t*,r*

-__\l23

SET ION)o----o

RESUME (ON)o----o

11.

4-41

1.

Actuator Test

Disconnect the actuator cable trom the actuator rod

and the 4P connector.

Connect battery power to the No. 4 terminal and

ground to the No. 1, No. 2 and No. 3 terminals,

Connect a vacuum pump to the vacuum hose. Then

apply vacuum to the actuator.

VACUUM PUMP GAUGE0-30 in.Hg.A973X-041-XXXXX

Terminalside otmale terminals

The actuator rod should pull in completely. lf the rod

pulls in only part-way or not at all, check for a leak-

ing vacuum Iine or defective solenoid.

ACTUATOB ROD

(cont'd)

www.emanualpro.com

Page 123 of 1395

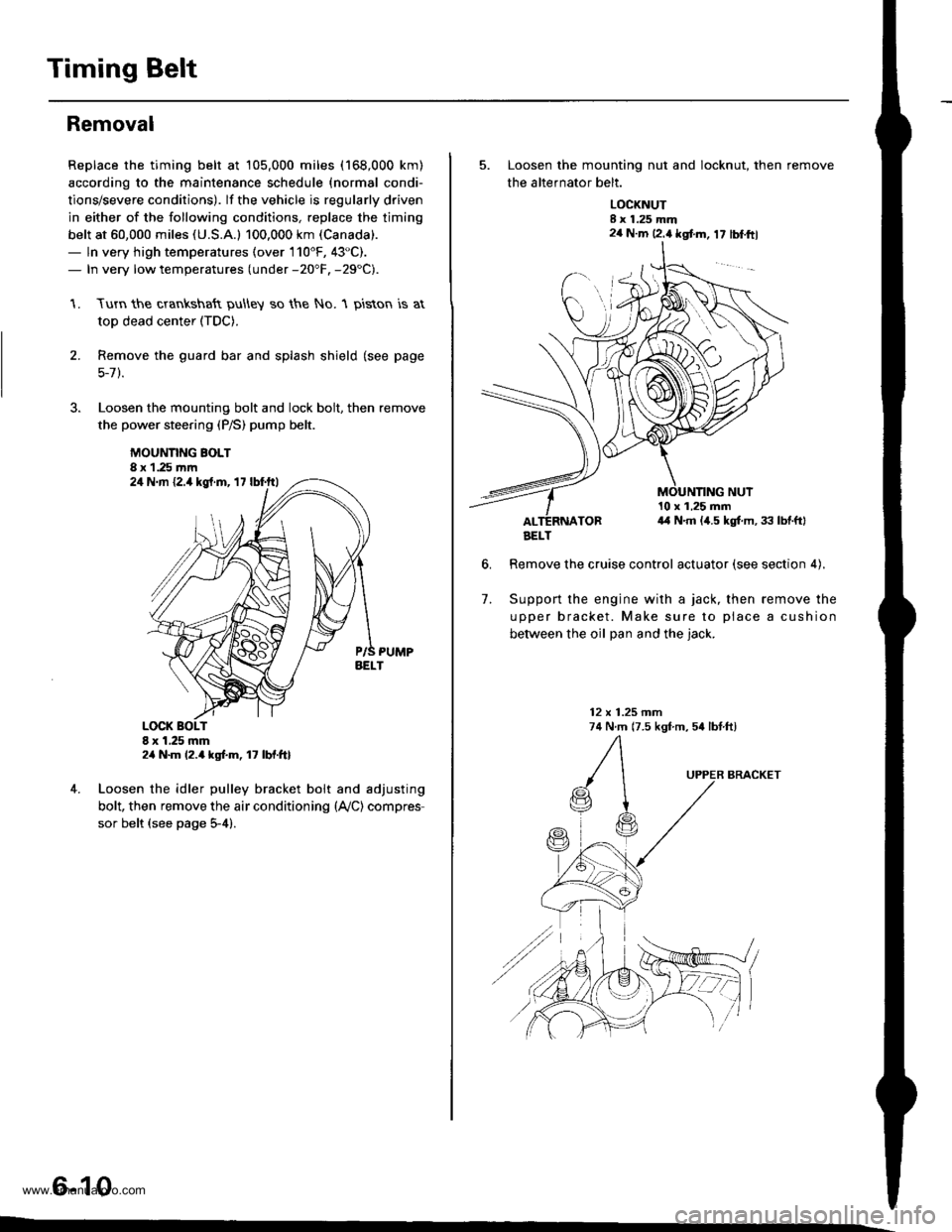

Timing Belt

Removal

Replace the timing belt at 105,000 miles (168,000 km)

according to the maintenance schedule {normal condi-

tions/severe conditions). lf the vehicle is regularly driven

in either of the following conditions, replace the timing

belt at 60,000 miles (U.S.A.l 100.000 km (Canada).

- ln very high temperatures (over 110'F, 43"C).- In very low temperatures (under -20"F. -29"C).

Turn the crankshaft pu\ley so the No. 1 piston is at

top dead center (TDC).

Remove the guard bar and splash shield (see page

5-7 ).

Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt.

MOUNNNG BOLT8 x 1.25 rnm

1.

2.

,l

4. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (lVC) compres

sor belt (see page 5-4).

6-10

24 N.m {2.4 kgt.m, 17 lbf.ftl

24 N.m 12.4 kgf.m, lt lbf.ftl

5. Loosen the mounting nut and locknut, then remove

the altefnator belt.

LOCKNUTI x 1.25 mm2a N.m 12.4 kgt m, 17 lblftl

6.

10 x 1,25 mm4,1 N.m (,1.5 kgt m, 33 lbtftl

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil Dan and the iack.

12 x 1.25 mm74 N.m (7.5 kgf m, 54 lbtftl

7.

BRACKET

AELT

www.emanualpro.com

Page 129 of 1395

Gylinder Head

Removal

Engine removal is not required for this procedure.

l!@ Make sure iacks and safety stands are

placed properly, and hoist blackels ale attachgd to the

correct position on the engine.

NOTE:

o Use fender covers to avoid damaging painted sur-

faces.

o To avoid damage, unplug the wiring connectors care-

fully while holding the connector portion.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F (38'C)

before loosening the retaining bolts.

. Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

2.

4.

5.

1.Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5). Remove

the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing(see page 5-2).

Remove the mounting bolt and lock bolt, then

remove the power steering (P/S) pump belt and

pump (see page 5-4).

Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A,/C) com,

pressor belt.

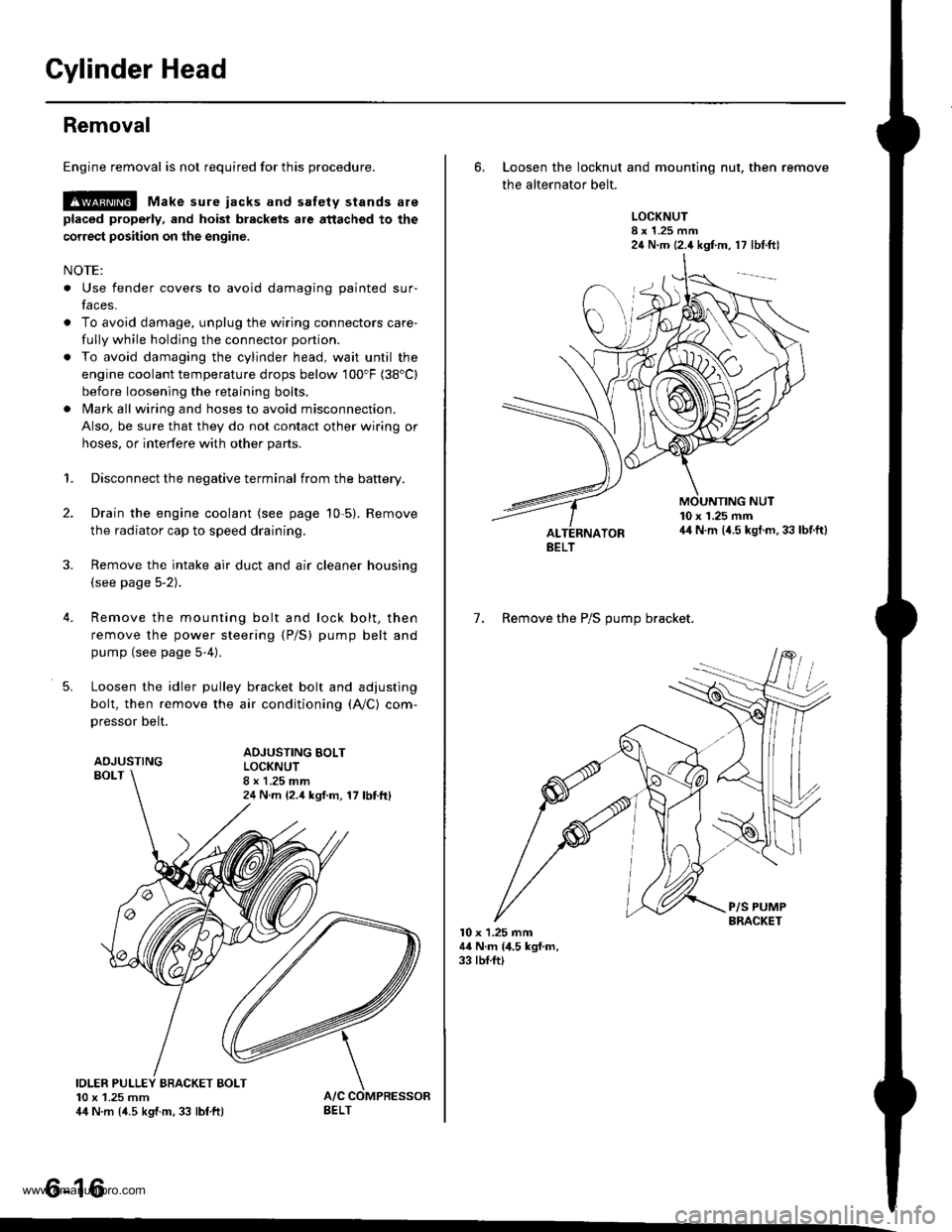

ADJUSTINGBOLT

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N m {2.4 ksf.m, 17 lbttt}

IOLER PULLEY BBACKET BOLT10 x 1.25 mm44 N.m {4.5 kgtm, 33 lbf ft)

tt aAo-Io

6. Loosen the locknut and mounting nut, then remove

the alternator belt.

LOCKNUT8 x 1.25 mm24 N.m (2.4 kgf.m, 17 lbt.ftl

10 x 1.25 mm44 N.m (4.5 kgt.m. 33 lbf.ft)

7. Remove the P/S OUmo bracket.

l0 x 1.25 mm44 N.m (4.5 kgf.m,33 rbf.ft)

BELT

www.emanualpro.com

Page 179 of 1395

1.

2.

3.

RemovaUlnspection/lnstallation

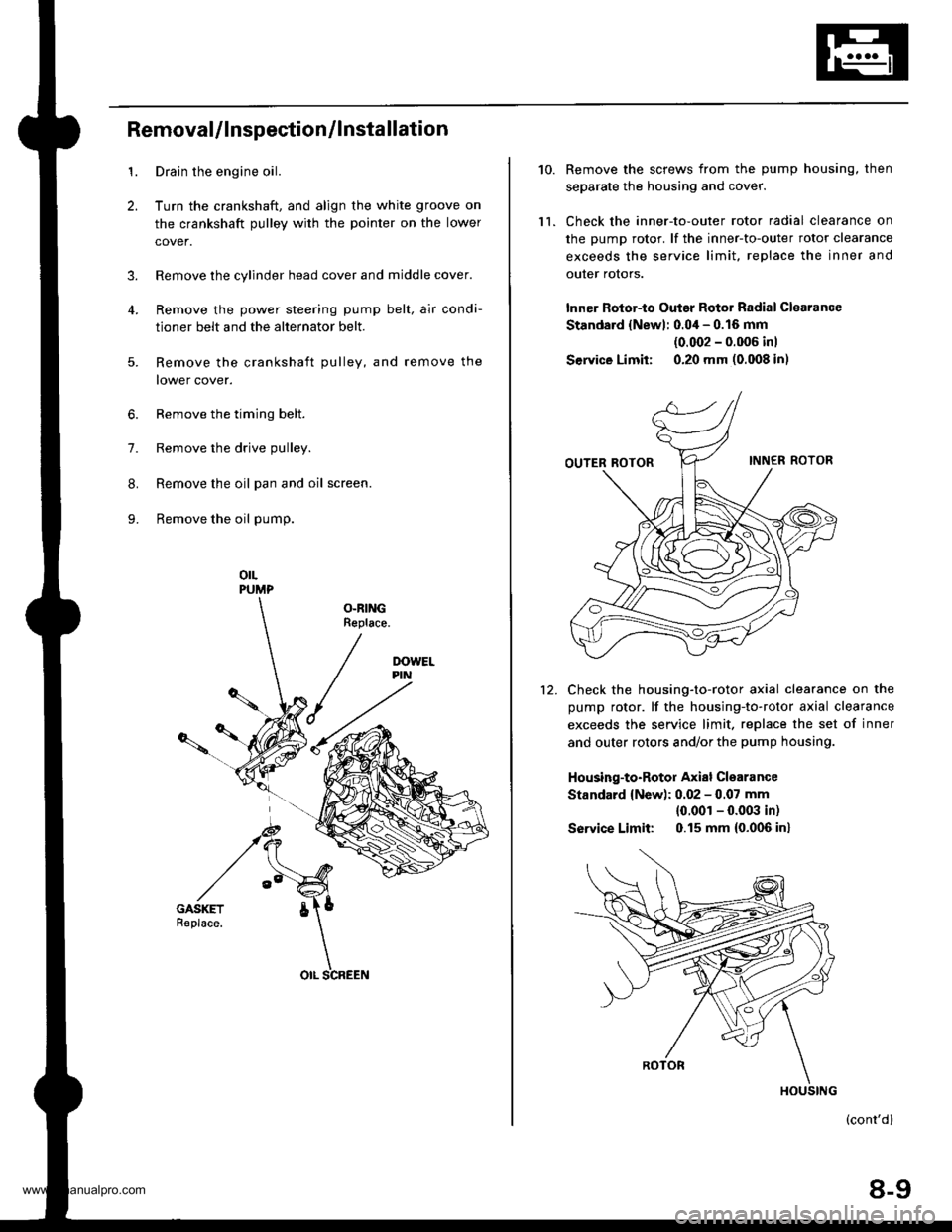

Drain the engine oil.

Turn the crankshaft, and align the white groove on

the crankshaft pulley with the pointer on the lower

cover.

Remove the cylinder head cover and middle cover.

Remove the power steering pump belt, air condi-

tioner belt and the alternator belt.

Remove the crankshaft pulley, and remove the

lower cover.

6. Remove the timing belt.

7. Remove the drive pulley.

8. Remove the oil pan and oil screen.

9. Remove the oil pump.

orLPUMP

OLRINGReplace.

5.

OIL SCREEN

10.

ll.

Remove the screws from the pump housing, then

separate the housing and cover.

Check the inner-to-outer rotor radial clearance on

the pump rotor. lf the inner-to-outer rotor clearance

exceeds the service limit. replace the inner and

outer rotors.

lnner Rotor-to Outar Rotor Radial Clearance

Standard {Newl: 0.04 - 0.16 mm

{0.002 - 0.006 inl

Service Limit: 0.20 mm (0.008 in)

Check the housing-to-rotor axial clearance on the

pump rotor. lf the housing-to-rotor axial clearance

exceeds the service limit. replace the set of inner

and outer rotors and/or the pump housing.

Housing-to-Rotor Axial Clearance

Standard {New): 0.02 - 0.07 mm

{0.001 - 0.003 in)

So|'�ice Limit: 0.15 mm (0.006 inl

(cont'd)

8-9

HOUSING

www.emanualpro.com

Page 204 of 1395

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 384 of 1395

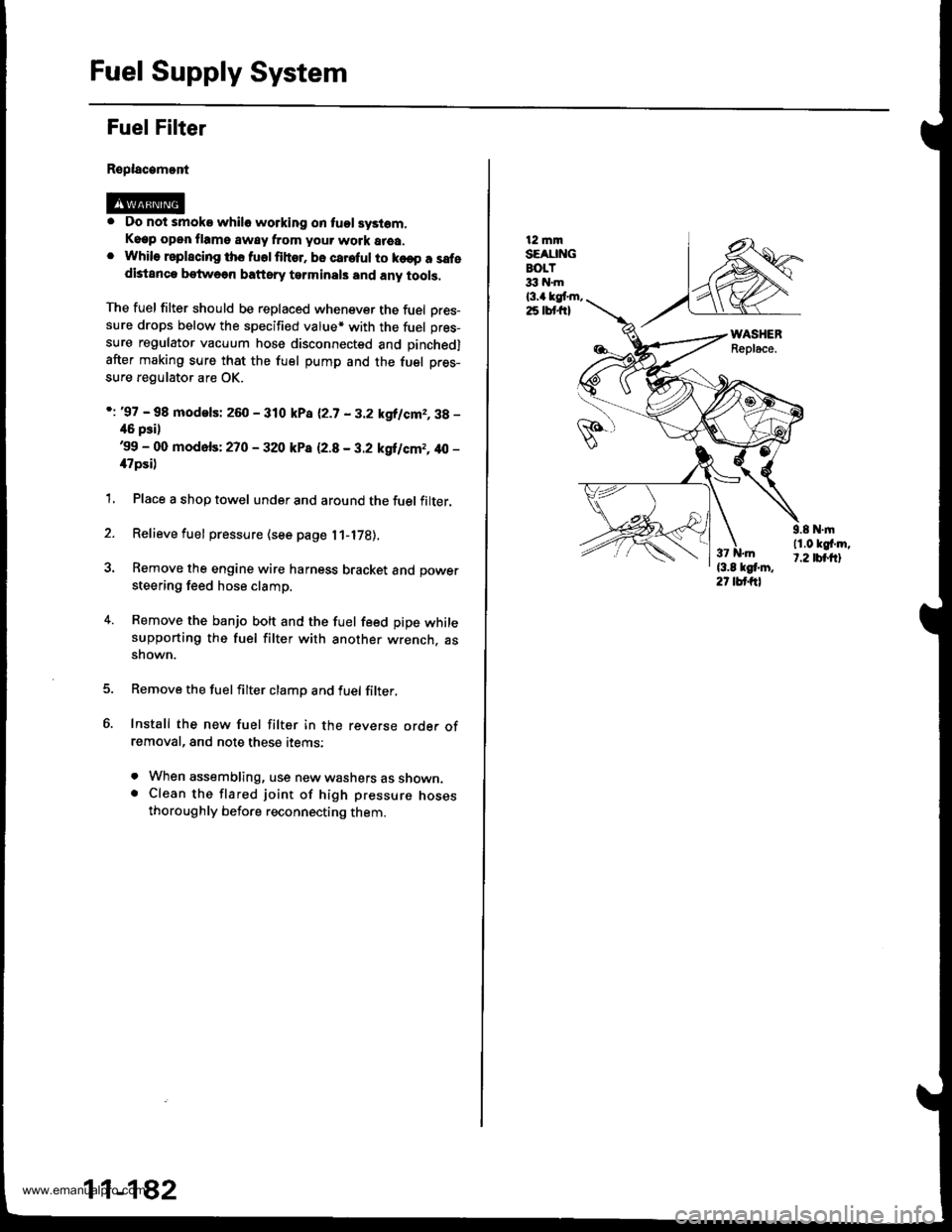

Fuel Supply System

Fuel Filter

Replacamont

. Do not smoke whilo working on tuol syslom,Keep open flame away from your work area.. While rsplscing ths fuolfihor. bo careful to ko€p a safedistanca betweon baftsry tarminals and any tools,

The fuel filter should be replaced whenever the fuel Dres-sure drops below the specified value* with the fuel pres-

sure regulator vacuum hose disconnected and pinchedl

after making sure that the fuel pump and the fuel pres-

sure regulator are OK.

i: '97 - 98 modelsi 260 - 310 kPa 12.7 - 3.2 kgllcm2,3g -

46 psil'99 - 00 mod6fs: 270 - 320 kP8 12.8 - 3.2 kgilcm2, 40 -

il7psi)

1, Place a shop towel under and around the fuel filter.

2. Relieve fuel pressure (see page l1-l7B).

3. Remove the engine wire harness bracket and power

steering feed hose clamp.

4. Remove the banjo bolt and the fuel feed pipe whilesupporting the fuel filter with another wrench. assnown.

Remove the fuelfilter clamp and fuel filter,

Install the new fuel filter in the reverse orde. ofremoval, and note these items:

. When assembling, use new washers as shown.. Clean the flared joint of high pressure nosesthoroughly before reconnecting them.

11-182

12 mmSEAUNGBOLT33 hl.m

l3.a kgt m,25 lbt frl

9.8 N.|n11.0 kgf'm,t.2 tbt.ftl

www.emanualpro.com

Page 846 of 1395

Steering

Special Toofs ............. 17-2

Component Locations

Index ................ ....... 17-3

Troubleshooting

General Troubleshooting ................ 1 7-4

Noise and Vibration ......................... 17-8

Fluid Leaks ............. 17-10

Inspection and Adiustment

Steering Operation .......................... 17-12

Power Assist Check

With Vehicle Parked ....................

Steering Linkage and Gearbox .......

Pump Belt

Rack Guide Adjustment ...................

Fluid Rep|acement ...................,,.,....

Pump Pressure Check .................,,...

*Steering Wheel

Removal ................. 17-18

*Steering Column

Removal/lnstallation ................ ....... 17 -2O

lnspection .............. 17-21

Steering Lock Replacement ............ 17 -22

Power Steering Hoses, Lines

Ffuid Leakage Inspection ................. 17 -23

Repfacement .......... 17-23

Power Steering Pump

Repfacement .......... 17-24

Disassembly ...........17-25

fnspection .............. 17-26

Reassembly ............ 17-28

Power Steering Gearbox

Removal ................. 17-31

Disassembly ........... 17-34

Reassembly ............ 17-40

Ball Joint Boot Replacement .......... 17-50

Installation ............. 17-51

17-12

17-13

17-14

l7-15

17-15

17-16

Disassembly/Reassembly............... 17-18

4'%/b.......... -r'-7--a/

SUPPLEN\EN AL RES\RA(N SYSTES{ (SRS\

This model has an SRS which includes a driver's airbag in the steering wheel hub. a passenger's airbag in the dashboardabove the glove box ('97 - 00 models), and seat belt tensioners in the seat belt retractors ('98 - 00 models). Informationnecessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contentspage include, or are located near, SBS components. Servicing. disassembling or replacing these items will require specialprecautions and tools, and should only be done by an authorized Honda oearer.

To avoid rendering the SRS inoperative, which could lead to peFonal iniury or death in the event of a sevore trontalcollision. allSRS service work must be performod by an authorized Honda dealer.lmproper service procedurgs, including incorrect removal and installalion of the SRS, could lead to personal iniurycaused by unintontional deployment of th€ airbags {'97 - 00 models), and seat belt tensioners ('98 - 00 modelsl.Do not bump the SRS unit. Otherwise, the system may lail in case ot a collision, or the airbags may deploy when theignition switch is ON (lll.

SRS electrical wiring harnesses are identitied by yellow colof coding. Ralated components are located in the steeringcolumn, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-trical test equipment on these cilcuits,

www.emanualpro.com

Page 849 of 1395

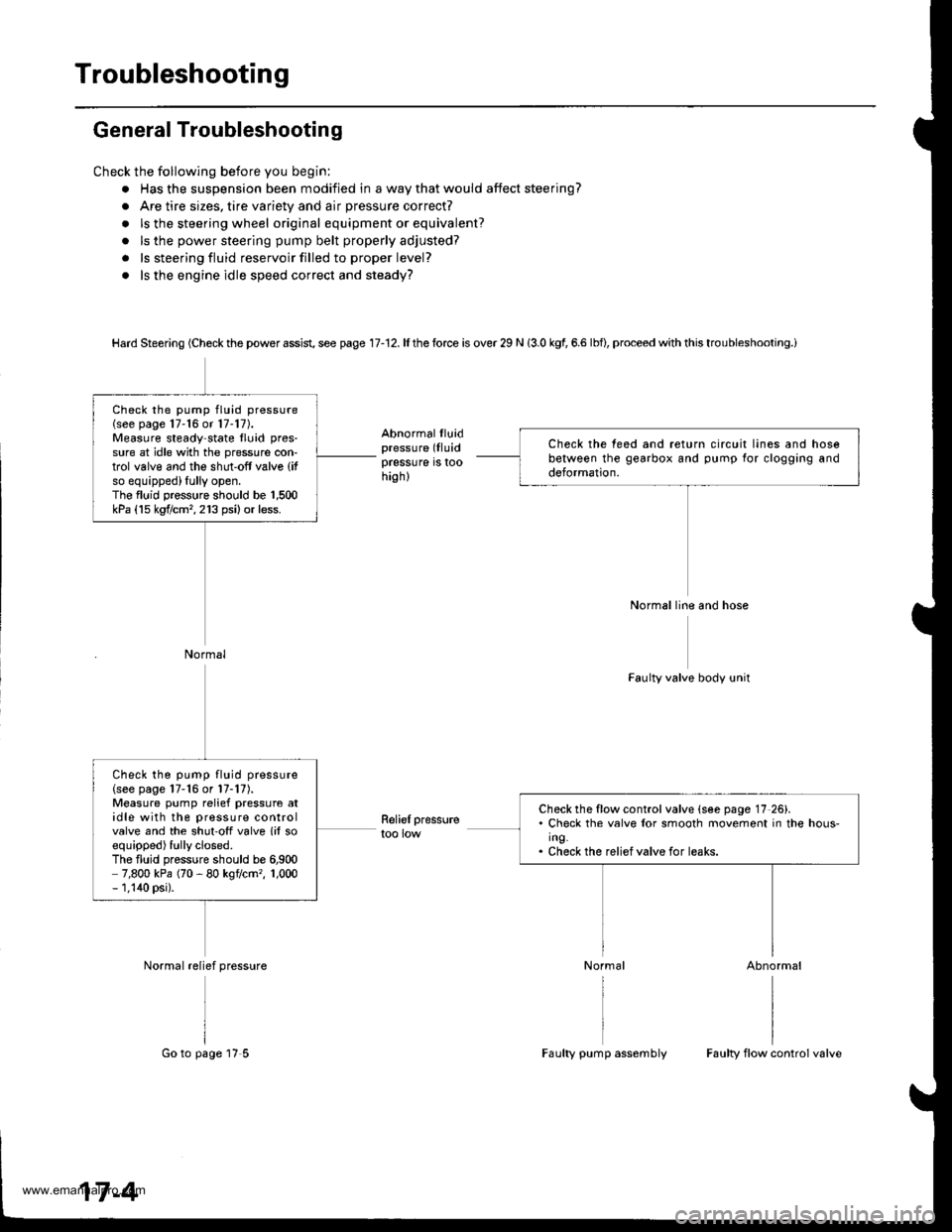

Troubleshooting

General Troubleshootin g

Check the following before you begin:

. Has the suspension been modified in a way that would affect steering?

. Are tire sizes, tire variety and air pressure correct?

. ls the steering wheel original equipment or equivalent?

. ls the power steering pump belt properly adjusted?

. ls steering fluid reservoir filled to proper level?

. ls the engine idle speed correct and steady?

Hard Steering (Check the power assist, see page 17-12. lf the force is over 29 N (3.0 kgl 6.6 lbfl, proceed with this troubleshooting.i

Abnormalthiidpressure (Iluidpressure is toohigh)

Relief pressuretoo low

Faulty valve body unit

Abnormal

Check the teed and return circuit lines and hosebetween the gearbox and pump for clogging anddeformation.

Normal line and hose

Check the pump fluid pressure(see page 17-16 or 17-17).Measure steady state lluid pres-

sure at idle with the pressure con-trol valve and the shut-off valve (it

so equipped) fully open.The fluid pressure should be 1,500kPa (15 kgf/cm,,213 psi)or less.

Normal

Check the flow control valve (see page 17 26).. Check the valv€ lor smooth movement in the hous-ing.. Check the relief valve for leaks.

Check the pump fluid pressure(see page 17-16 or l7-17).Measure pump relief pressure atidle with the pressure controlvalve and the shut'off valve lil soequipped) fully closed.The fluid pressure should be 6,9007,800 kPa (70 - 80 kgflcm,, 1,000- 1,140 psi).

Normal relief pressure

17-4

Go to page 17 5Faulty pump assemblyFaulty flow control valve

www.emanualpro.com