Transmission drain HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 103 of 1395

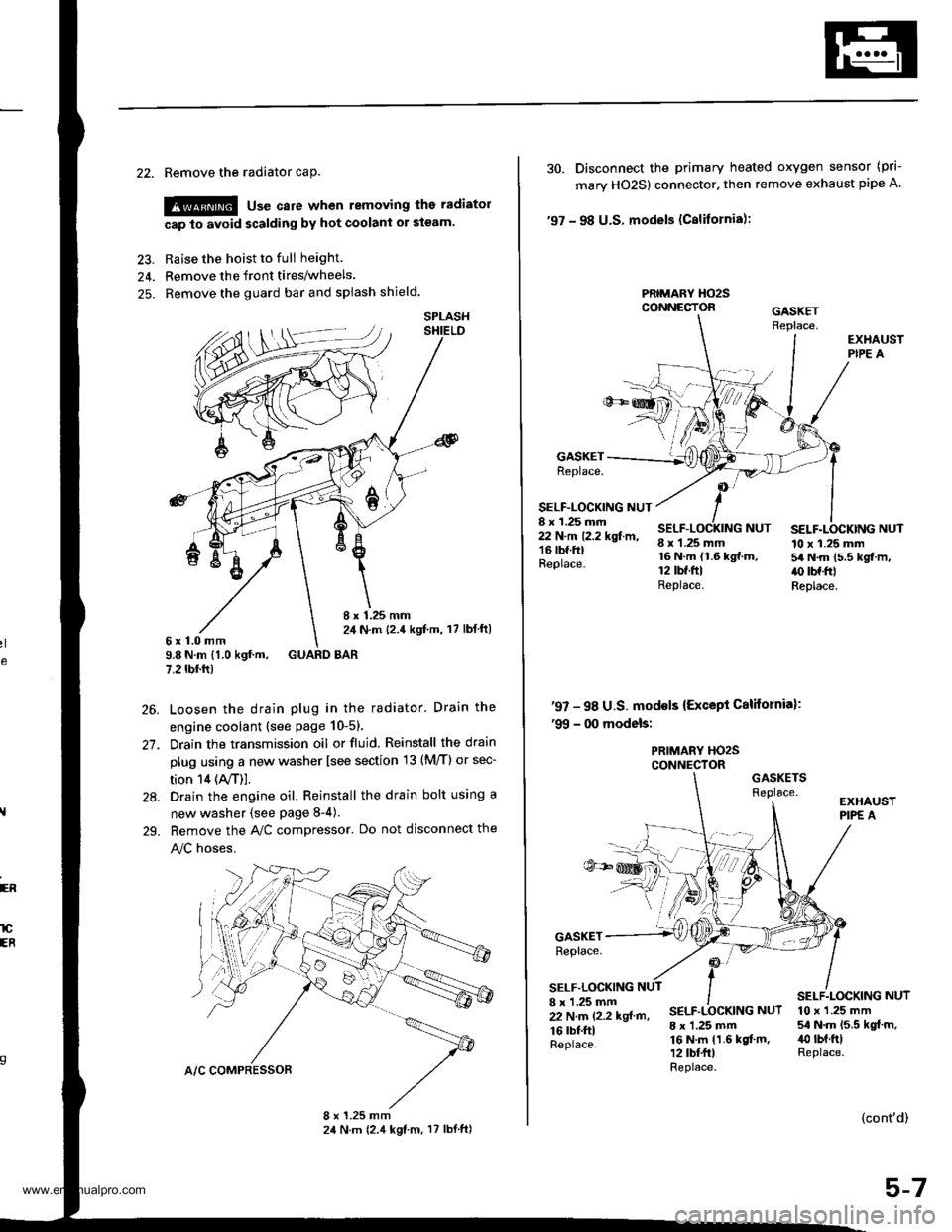

22. Remove the radiator caP.

!@ use care when removing the radiatol

cap to avoid scalding by hot coolani or steam.

23. Raise the hoist to full height

24. Remove the front tires/wheels.

25. Remove the guard bar and splash shield.

8 x 1.25 mm2,1 N.m {2.4 kgf,m, 17 lbl ft)6x1.0mm9.8 N.m {1.0 kgf.m, GUARD BAR7.2 tbf.rr)

Loosen the drain plug in the radiator. Drain the

engine coolant (see page 10-51.

Drain the transmission oil or fluid. Reinstall the drain

plug using a new washer lsee section 13 (M/T) or sec-

tion 14 (ly'T)].

Drain the engine oil. Reinstall the drain bolt using a

new washer {see page 8-4).

Bemove the A,/C compressor. Do not disconnect the

!y'C hoses.

SPLASH

26.

27.

28.

29.

ER

lCEB

30. Disconnect the primary heated oxygen sensor (prl-

mary HO2S) connector. then remove exhaust pipe A

'97 - 98 U.S. models (Cslifornia):

PRIMARY HO2SCONNECTOR

GASKETReplace.

SELF-LOCKING NUT8 x 1.25 mm22 N.m 12.2 kgf.m,16 lbf.ftlReplace.

8 x 1.25 mm16 N.m {1.6 kgf.m.12 tbt.ftlReplace.

SELF.LOCKING NUT10 x 1.25 mm54 N.m 15.5 kgf.m,.() tbf.frlReplace.

NUT

'97 - 98 U.S. mod€ls {Except California):'99 - 00 models:

PRIMARY HO2SCONNECTORGASKETSReplace.

GASKETReplace.

SELF.LOCKING8 x 'l.25 mm22 N.m (2.2 kgf m,

16 rbf.ftlReplace.

SELF.LOCKING NUT

8 x 1.25 mm16 N.m 11.6 kgf.m,12 tbt fr)Replace.

10 x 1.25 mm54 N.m 15.5 kgt.m,40 rbt.ftlReplace.

{cont'd)

5-7

www.emanualpro.com

Page 442 of 1395

MaintenanceBack-up Light Switch

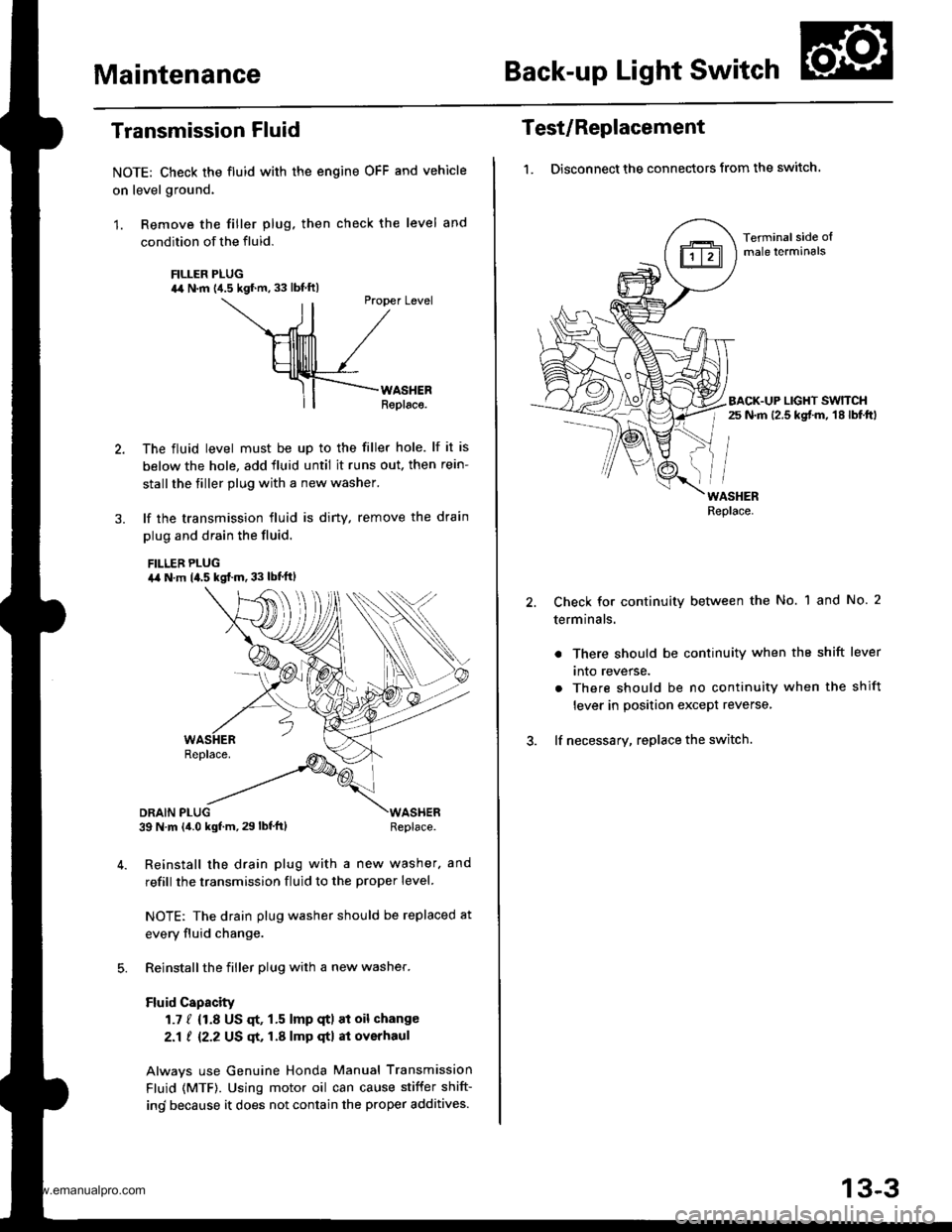

Transmission Fluid

NOTE: Check the fluid with the engine OFF and vehicle

on level ground.

1. Remove the filler plug. then check the level and

condition of the fluid.

FILLER PLUG44 N.m {4.5 kgf.m. 33 lbf ftl

ll

Ptopet Level

\--ril /

HllllllTl /

Hllllrlll /_rf-F{--rno."."

ll| | Replaco.

The fluid level must be up to the filler hole. lf it is

below the hole, add fluid until it runs out. then rein-

stall the tiller plug with a new washer.

lf the transmission fluid is diny, remove the drain

plug and drain the fluid.

FILLEB PLUGa,a N.m 14.5 kgf..n. 33 lbt'ftl

DRAIN PLUG39 N m (4.0 kgf.m, 29 lbf'ft)WASHERReplace.

Reinstall the drain plug with a new washer. and

refill the transmission fluid to the proper level.

NOTE: The drain plug washer should be replaced at

every fluid change.

Reinstall the filler plug with a new washer.

Fluid Capacity

1.7 / {1.8 US qt, 1.5 lmp qtl at oil change

2.1 ! 12.2 US qt, 1.A lmp qtl at overhaul

Alwavs use Genuine Honda Manual Transmission

Fluid (MTF). Using motor oil can cause stiffer shift-

ind because it does not contain the proper additives.

Test/Replacement

1. Disconnect the connectors from the switch.

Terminal side oImale lerminals

BACK.UP LIGHT SWTTCHr 25 N.m 12.5 kgt m, 18 lbf.ftl

WASHERReplace.

Check for continuity between the No. 1 and No. 2

terminals.

. There should be continuity when the shift lever

tnto reverse.

. There should be no continuity when the shift

lever in position except reverse,

lf necessary, replace the switch.

13-3

www.emanualpro.com

Page 444 of 1395

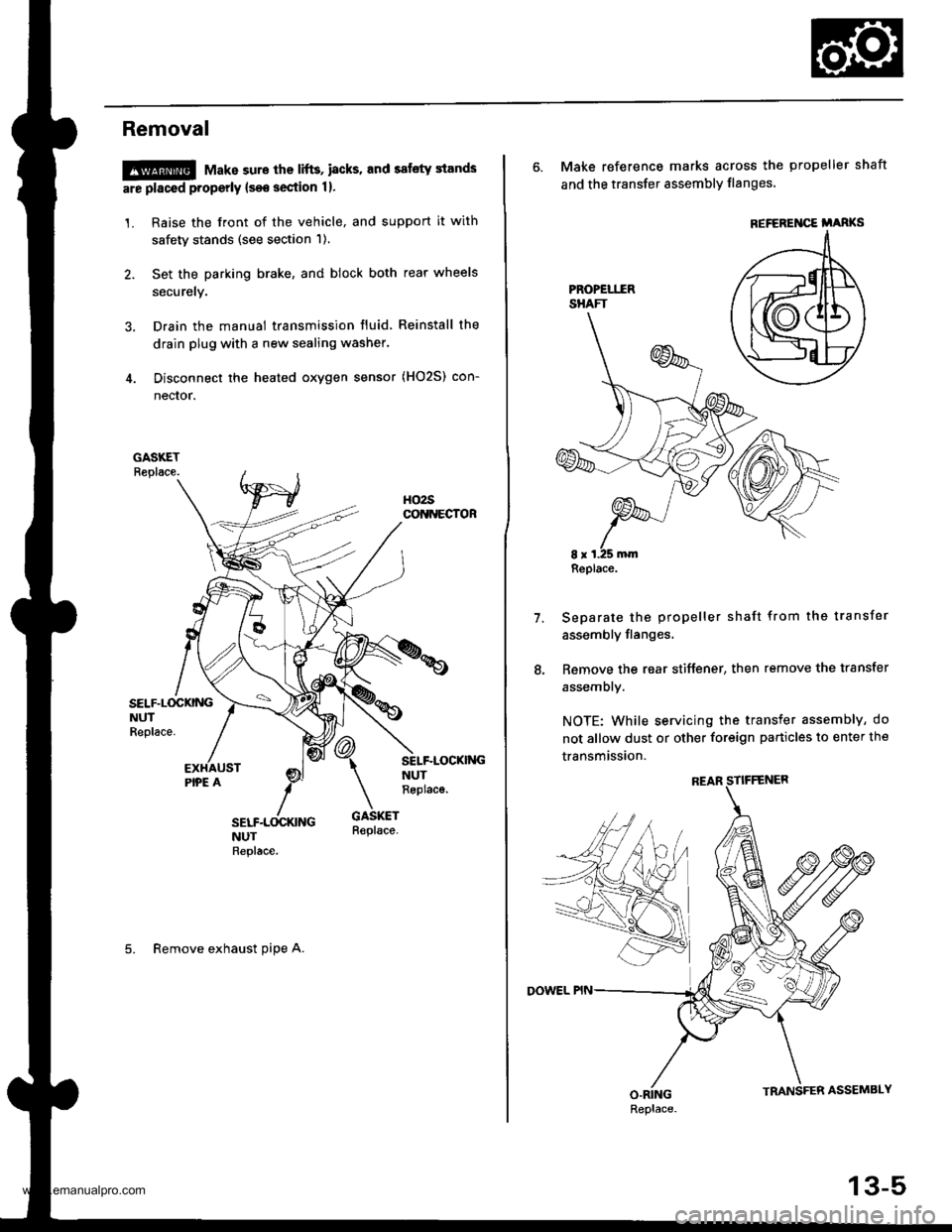

Removal

!@@ Make sure the lifts, i8cks. and safety stands

are placed properly {see section 1}.

1. Raise the front of the vehicle, and support it with

safety stands (see section 1).

2. Set the parking brake, and block both rear wheels

securely.

3. Drain the manual transmission fluid Reinstall the

drain plug with a new sealing washer.

4. Disconnect the heated oxygen sensor (HO2S) con-

nector.

SELF.L(rcKNGNUTReplace.

SELF-LOCKI'{GNUTReplac€.

5. Remove exhaust oipe A.

6. Make reference marks across the propeller shaft

and the transfer assembly flanges'

Separate the propeller shaft from the transfer

assembly flanges,

Remove the rear stiffener, then remove the transfer

assembly.

NOTE: While servicing the transfer assembly, do

not allow dust or other foreign particles to enter the

transmission.

7.

REFEREI{CE i'ARKS

Replace.

Replace.

13-5

www.emanualpro.com

Page 447 of 1395

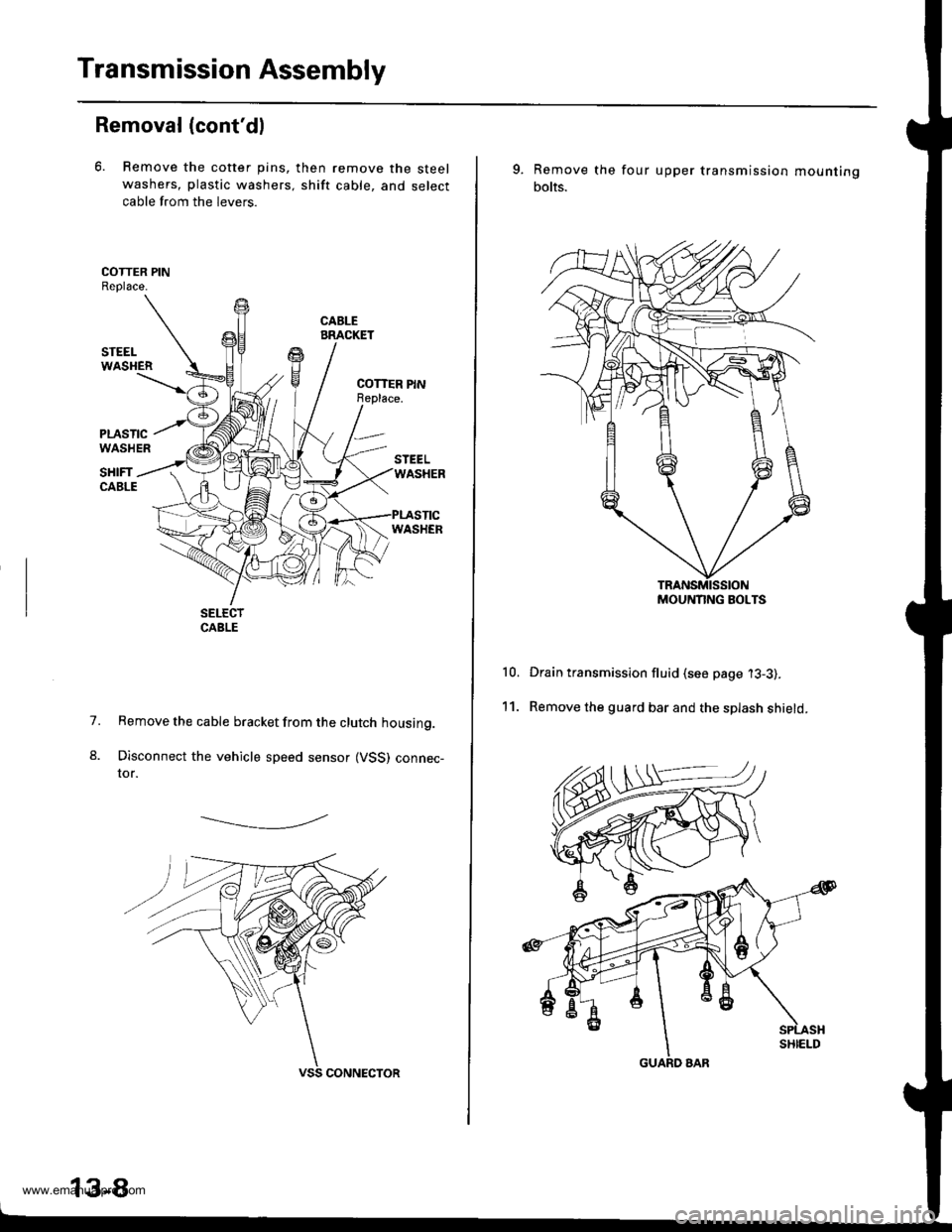

Transmission Assembly

Removal (cont'dl

6. Remove the cotter pins,

washers, plastic washers.

cable from the levers.

then remove the steel

shift cable, and select

1.

8.

Remove the cable bracket from the clutch housing.

Disconnect the vehicle speed sensor (VSS) connec-tor.

-------------.2

13-8

9. Remove the

bolts.

four upper transmission mou nting

10.

11.

Drain transmission fluid (see page '13-3).

Remove the guard bar and the splash shield.

MOUNNNG BOLTS

www.emanualpro.com

Page 452 of 1395

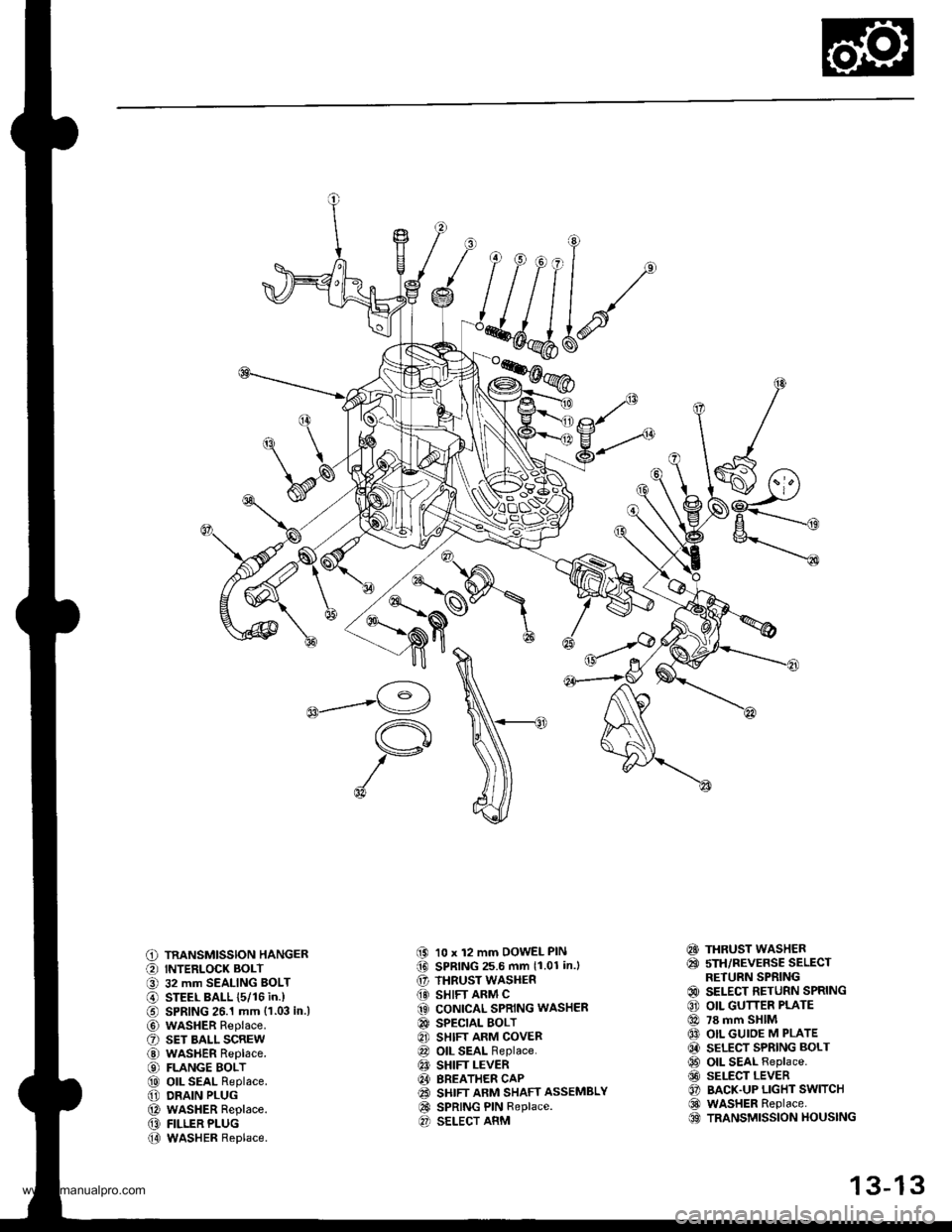

C) TRANSMISSION HANGER

O INTERLOCK BOLT

O 32 mm SEALING BOLT

@ STEEL BALL {5/16 in.)

€) SPRING 26.1 mm {1.03 in.l

@ wasHER Replace.

O sET BALL scREw

@ WASHER Replace.

€) FLANGE BOLT

@ oll SEAL Replace.

@ DRAIN PLUG

@ WASHER Replace.

@ FILLER PLUG

@ WASHER Replace.

(9 10 x 12 mm DOWEL PIN(D SPRING 25.6 mm 11.01 in.l

€' THRUST WASHER

@} SHIFT ARM C(3 CONICAL SPRING WASHER

@ SPECTAL BOLT

8] SHIFT ARM COVER

@ OIL SEAL Replace.

€! SHIFT LEVER

@I BREATHER CAP(2! SHIFT ARM SHAFT ASSEMBLY

@ SPRING PIN Replace.O SELECT ARM

€!} THRUST WASHER

@ sTH/REVERSE SELECTRETURN SPRING

@ SELECT RETURN SPRING

€) OIL GUTTER PLATE

@ 78 mm SHIM

@ OIL GUIOE M PLATE

@ SELECT SPRING BOLT

@ OIL SEAL Replace.

@ SELECT LEVER

O BACK.UP LIGHT SWITCH

@ WASHER Replace.OO TRANSMISSION HOUSING

13-13

www.emanualpro.com

Page 454 of 1395

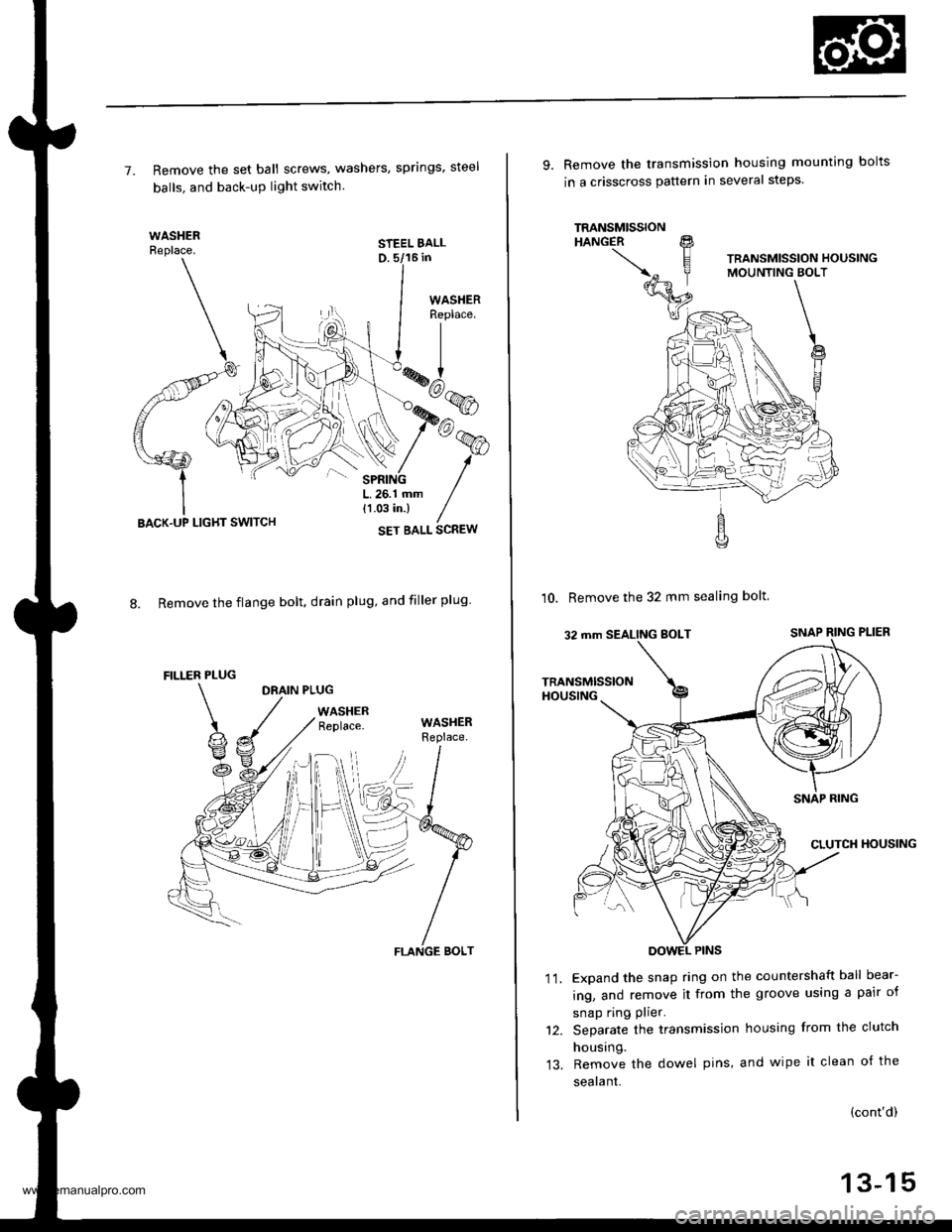

7. Remove the set ball screws, washers, springs, steel

balls. and back-uP light switch.

STEEL BALLD. 5/16 in

8. Remove the flange bolt. drain plug, and filler plug

DRAIN PLUG

WASHERReplace.

LIGHT SWITCH

FILLER PLUG

WASHERReplace.

FLANGE BOLT

9. Remove the transmission housing mounting bolts

in a crisscross pauern in several steps.

10. Remove the 32 mm sealing bolt

Expand the snap ring on the countershaft ball bear-

ing, and remove it from the groove using a pair of

snap ring plier.

Separate the transmission housing from the clutch

housing.

Remove the dowel pins, and wipe it clean of the

sealant.

'I t.

(cont'd)

13-15

www.emanualpro.com

Page 509 of 1395

Transmission Assembly

Reassembly lcont'd)

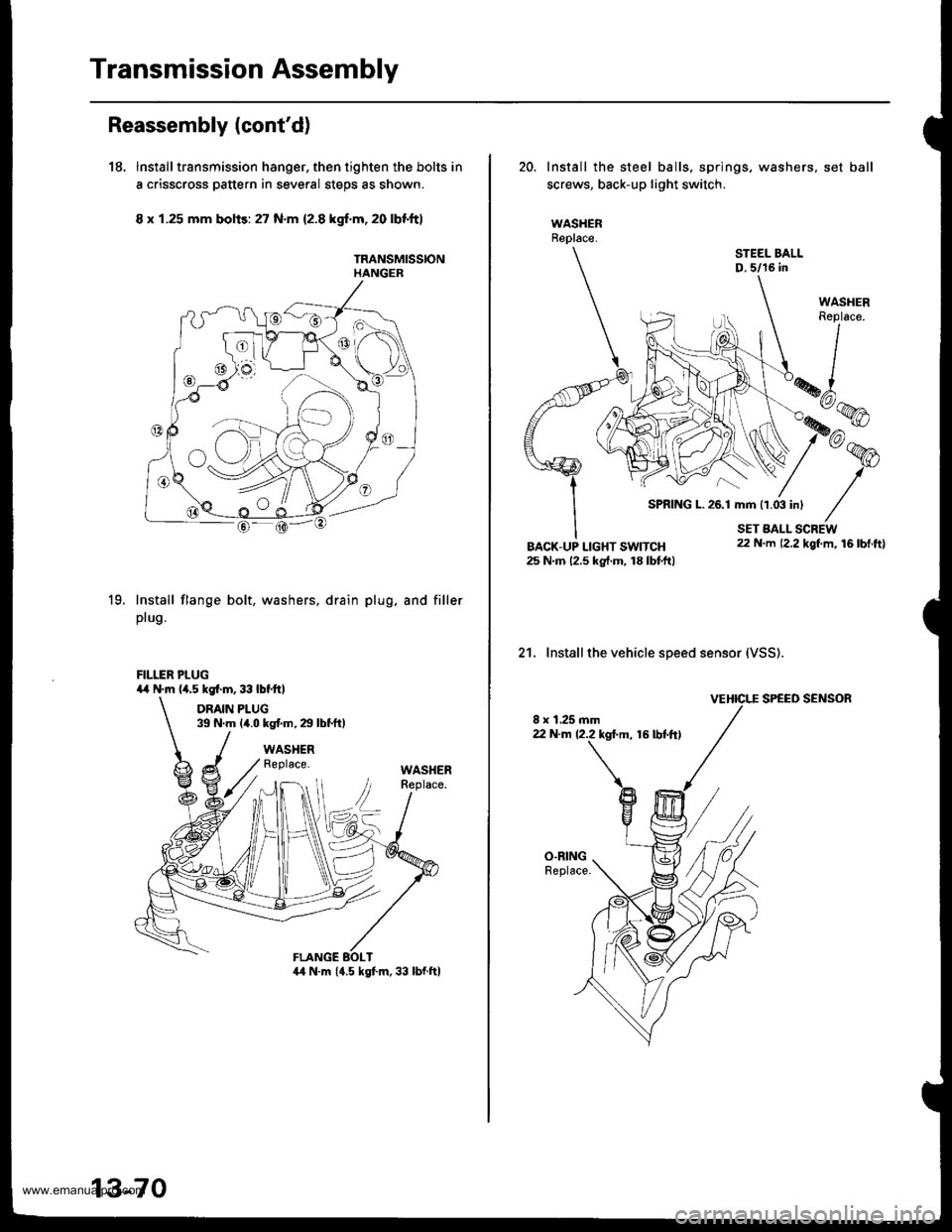

18. Installtransmission hanger, then tighten the bolts in

a crisscross pattern in several steps as shown.

8 x 1.25 mm bolis: 27 N.m 12.8 kgf.m,20 lbf'ft}

TRANSMISSIONHANGER

19.Install flange bolt,

plug.

washers, drain plug. and filler

FILLER PLUG4,r N.m (a.5 kgl.m,33lbtftl

DRAIN PLUG39 N.m {4.0 kg{.m,29lbtftl

WASHERReplace.WASHER

13-70

20. Install the steel balls, springs. washers, set ball

screws, back-up light switch.

WASHERReplace.

STEEL BALLD,5/16 in

21. Installthe vehicle speed sensor (VSS).

VEHICI."E SPEED SENSOR

8 x 1.25 mm22 N.m 12.2 kgl.m, 16 lbt.ftl

SPRING L.26.1 mm 11.03 inl

www.emanualpro.com

Page 519 of 1395

Description

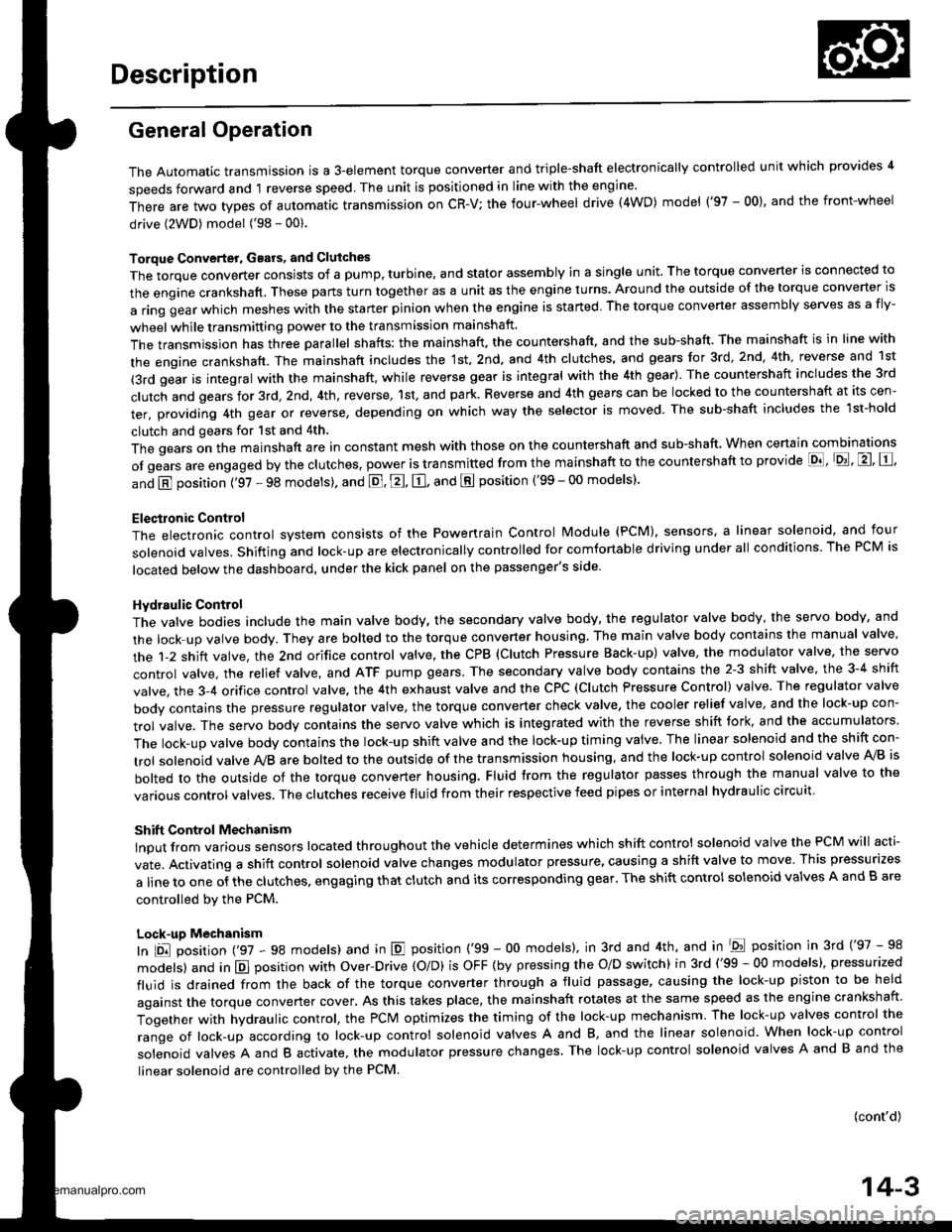

General Operation

The Automatic transmission is a 3-element torque converter and triple-shaft electronically controlled unit which provides 4

speeds forward and 1 reverse speed The unit is positioned in line with the engine'

There are two tvoes of automatic transmission on CR-V; the four-wheel drive (4WD) model ('97 - 00)' and the front-wheel

drive (2WD) model ('98 - 00).

Toroue Converter, G€ars, and Clutches

The torque converter consists of a pump. turbine. and stator assembly in a single unit. The torque converter is connected to

the engine crankshatt. These parts turn together as a unit as the engine turns. Around the outside of the torque converter is

a ring gear which meshes with the starter pinion when the engine is started. The torque converter assembly serves as a fly-

wheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts: the mainshaft. the countershaft, and the sub-shaft. The mainshaft is in line with

the engine crankshaft. The mainshaft includes the 1st, 2nd. and 4th clutches, and gears lor 3rd,2nd,4th. reverse and 1st

(3rd gear is integral with the mainshaft, while reverse gear is integral with the 4th gear). The countershaft includes the 3rd

clutch and gears for 3rd,2nd, 4th, reverse, 1st, and park. Reverse and 4th gears can be locked to the countershaft at its cen-

ter, providing 4th gear or reverse, depending on which way the selector is moved. The sub-shaft includes the lst-hold

clutch and gears for lst and 4th.

The gears on the mainshaft are in constant mesh with those on the countershaft and sub-shaft. When certain combinations

of gears are engaged by the ctutches, power is transmitted from the mainshaft to the countershaft to provide E, D!, tr, tr,

and E position ('97 - 98 models). and E. E, E, and E position ('99 - 00 models)'

Electlonic Control

The electronic controt system consists of the Powenrain Control Module (PCM), sensors, a linear solenoid, and four

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions. The PCM is

located below the dashboard, under the kick panel on the passenger's side.

Hydraulic Control

The valve bodies include the main valve body, the secondary valve body, the regulator valve body, the servo body, and

the lock up valve body. They are bolted to the torque converter housing. The main valve body contains the manual valve,

the 1-2 shift valve, the 2nd orifice control valve. the CPB {Clutch Pressure Back-up) valve, the modulator valve, the servo

control valve. the relief valve, and ATF pump gears. The secondary valve body contains the 2-3 shift valve, the 3-4 shift

valve, the 3,4 orifice control valve. the 4th exhaust valve and the CPC (Clutch Pressure Control) valve. The regulator valve

bodv contains the pressure regulator valve, the torque converter check valve, the cooler relief valve, and the lock-up con-

trol valve. The servo body contains the servo valve which is integrated with the reverse shift tork, and the accumulators

The lock-up valve body contains the lock-up shift valve and the lock-up timing valve. The linear solenoid and the shift con-

trol solenoid valve Ay'B are bolted to the outside of the transmission housing, and the lock-up control solenoid valve Ay'B is

bolted to the outside of the torque converter housing. Fluid trom the regulator passes through the manual valve to the

various control valves. The clutches receive fluid from their respective feed pipes or internal hydraulic circuit

ShiftControl Mechanism

input from various sensors located throughout the vehicle determines which shift control solenoid valve the PCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches. engaging that clutch and its corresponding gear. The shift control solenoid valves A and B are

controlled by the PCM.

Lock-up Mechanism

tn E! position (,97 - 98 modets) and in E position ('99 - O0 models), in 3rd and 4th, and in Del position in 3rd ('97 - 98

models) and in El position with Over,Drive (O/D) is OFF (by pressing rhe O/D switchl in 3rd ('99 - 00 models), pressurized

fluid is drained from the back of the torque converter through a fluid passage, causing the lock-up piston to be held

against the torque converter cover, As this takes place, the mainshaft rotates at the same speed as the engine crankshaft.

Together with hydraulic control, the PcM optimizes the timing of the lock-up mechanism The lock-up valves control the

range of lock-up according to lock-up control solenoid valves A and B, and the linear solenoid. When lock-up control

solenoid valves A and B activate, the modulator pressure changes. The lock-up control solenoid valves A and B and the

linear solenoid are controlled by the PCM.

{cont'd)

14-3

www.emanualpro.com

Page 555 of 1395

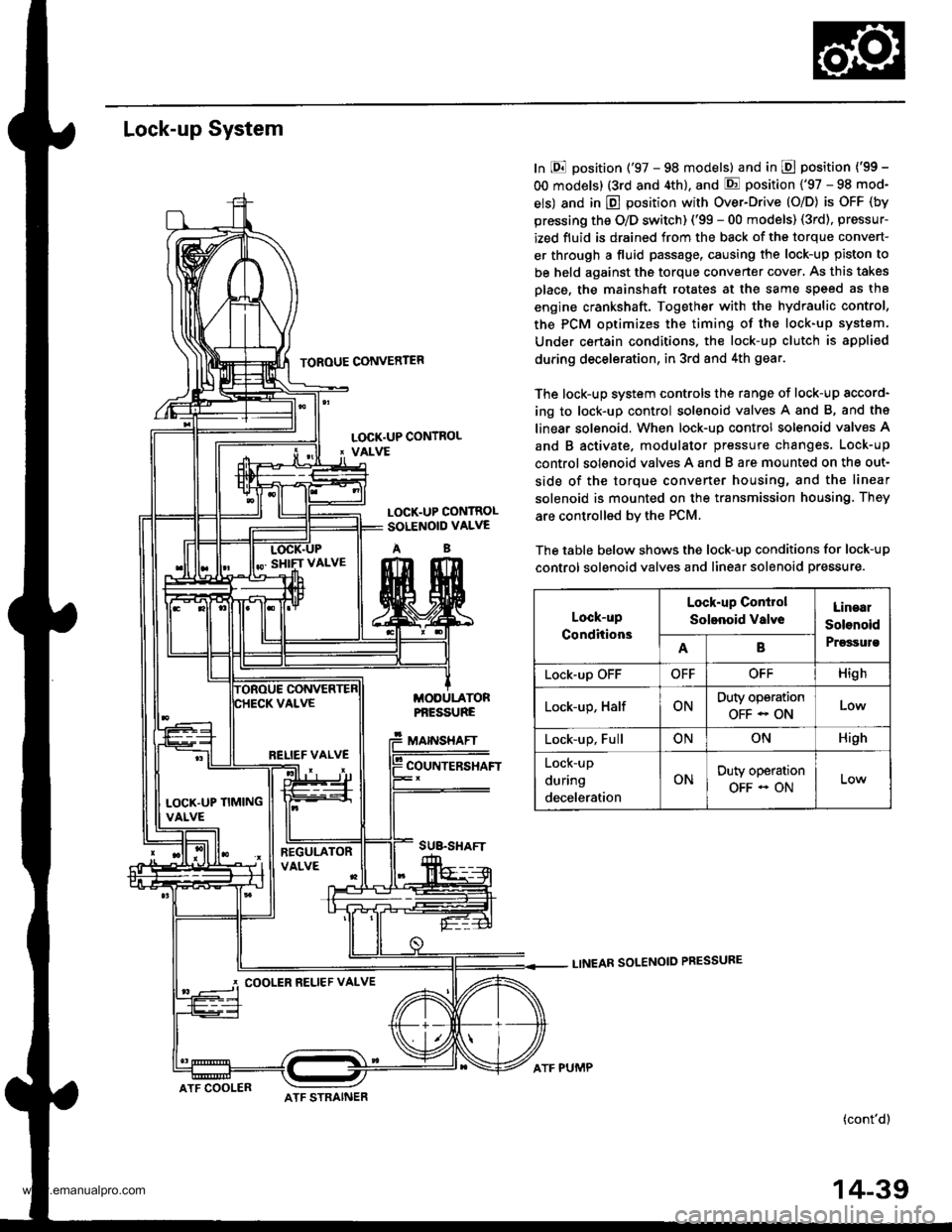

Lock-up System

TOROUE CONVERTER

In E position ('97 - 98 models) and in E position ('99 -

OO models) (3rd and 4th), and E position ('97 - 98 mod-

els) and in E position with Over-Drive (O/D) is OFF (by

pressing the O/D switch) ('99 - 00 models) (3rd), pressur-

ized fluid is drained from the back of the torque convert-

er through a fluid passage, causing the lock-up piston to

be held against the torque converter cover, As this takes

Dlace, the mainshaft rotates at the same speed as th8

engine crankshaft. Together with the hydraulic control,

the PCM optimizes the timing of the lock-up system.

Under certain condltions. the lock-up clutch is appli€d

during deceleration, in 3rd and 4th gear.

The lock-up system controls the range of lock-up sccord-

ing to lock-up control solenoid valves A and B, and ths

linear solenoid. When lock-up control solenoid valves A

and B activate. modulator pressure changes. Lock-up

control solenoid valves A and B are mounted on the out-

side of the torque converter housing, and the linear

solenoid is mounted on the transmission housing. They

are controlled bv the PCM.

The table below shows the lock-up conditions for lock-up

control solenoid valves and linear solenoid pressure.

LINEAR SOLENOID PRESSURE

(cont'd)

LOCK.UP CONTROL' VALVE

LOCK.UP CONTROLSOLENOID VALVE

AB

MODULATORPf,ESSURE

MAINSHAFT

COUNTERSHAFT

SUB.SHAFT

Lock-up

Conditions

Lock-up Conirol

Solenoid valveLinaal

Solenoid

PrgssulsAB

Lock-up OFFOFFOFFHigh

Lock-up, HalfONDuty operation

OFF - ONLow

Lock-up, FullONONHigh

Lock-up

during

deceleration

ONDuty operation

OFF - ON

RELIEF VALVE

LOCK'UP TIMINGVALVE

COOLER RELIEF VALVE

ATF COOLERATF STRAINER

ATF PUMP

14-39

www.emanualpro.com

Page 677 of 1395

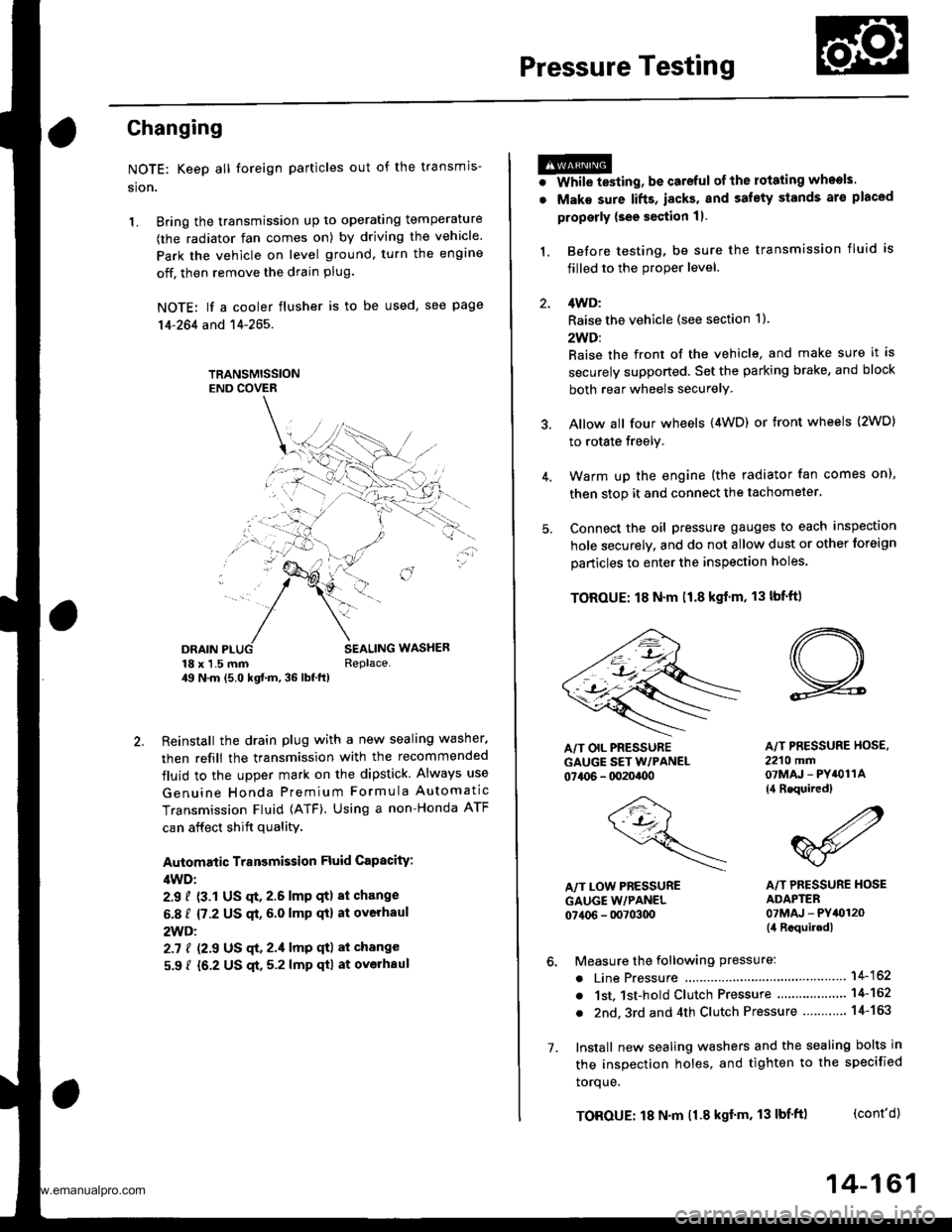

Pressure Testing

Changing

NOTE: Keep all foreign particles out of the transmis-

sion.

1. Bring the transmission up to operating temperature

(the radiator fan comes on) by driving the vehicle.

Park the vehicle on level ground. turn the engane

off. then remove the drain Plug.

NOTE: lf a cooler flusher is to be used, see page

14-264 and 14-265.

TRANSMISSIONEND COVER

DRAIN18 x 1.5 mmSEALING WASHEBReplace.49 N.m {5.0 kgt.m, 36 lbf.tl)

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid to the uDper mark on the dipstick. Always use

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF) Using a non-Honda ATF

can affect shift quality.

Automatic Transmission Fluid Capacity:

4WD;

2.9 { (3.1 US qt. 2.6 lmp qt) 8t change

5.8 ? {7.2 US $, 6.0 lmp qt} at ovethaul

2WD:

2.7 | l2.S US qt,2.1lmp qtl ai change

5.9 ? {6.2 US $, 5.2 lmp qtl at ovolhaul

2.

a

a

1.

Wlrile testing, be careful of the rotaling wheols.

Mako sure lifts, iacks, and safety stands ar€ placed

properly (see scction 11.

Before testing, be sure the transmission fluid is

filled to the proPer level.

4WD:

Raise the vehicle (see section 11.

2WD:

Raise the front of the vehicle, and make sure it is

securely supported. Set the parking brake, and block

both rear wheels securely.

Allow all four wheels {4WD) or front wheels (2wD}

to rotate freely.

Warm up the engine (the radiator fan comes on),

then stop it and connect the tachometer.

Connect the oil pressure gauges to each inspection

hole securely, and do not allow dust or other foreign

particles to enter the inspection holes.

TOROUE: 18 N'm ll.8 kgf'm, 13 lbf'ft)

5.

A/T PRESSURE HOS€,2210 mm07MAJ - PYiOllA

{4 Requircd}

,4'/"' ,a

W'

A/T PRESSURE HOSEADAPTER07MAJ - PYt0120(il Rcquiledl

6. Measure the following Pressure:. Line Pressure ..........,14-162

. 1st. 1st-hold Clutch Pressure .............'. 14-162

. 2nd,3rd and 4th Clutch Pressure .......... 14-163

7. Install new sealing washers and the sealing bolts in

the inspection holes, and tighten to the specified

toroue.

(cont'd)

A/T OIL PRESSUREGAUGE SET W/PANEL07{06 - 0020400

/4\\-J-- (

+..\.-.\-'-\

A/T LOW PBESSUREGAUGE w/PANEL07406 - 0070300

TOROUE: 18 N'm 11.8 kgf'm, 13 lbf'ft)

14-161

www.emanualpro.com