And HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 175 of 1395

Oil Filter

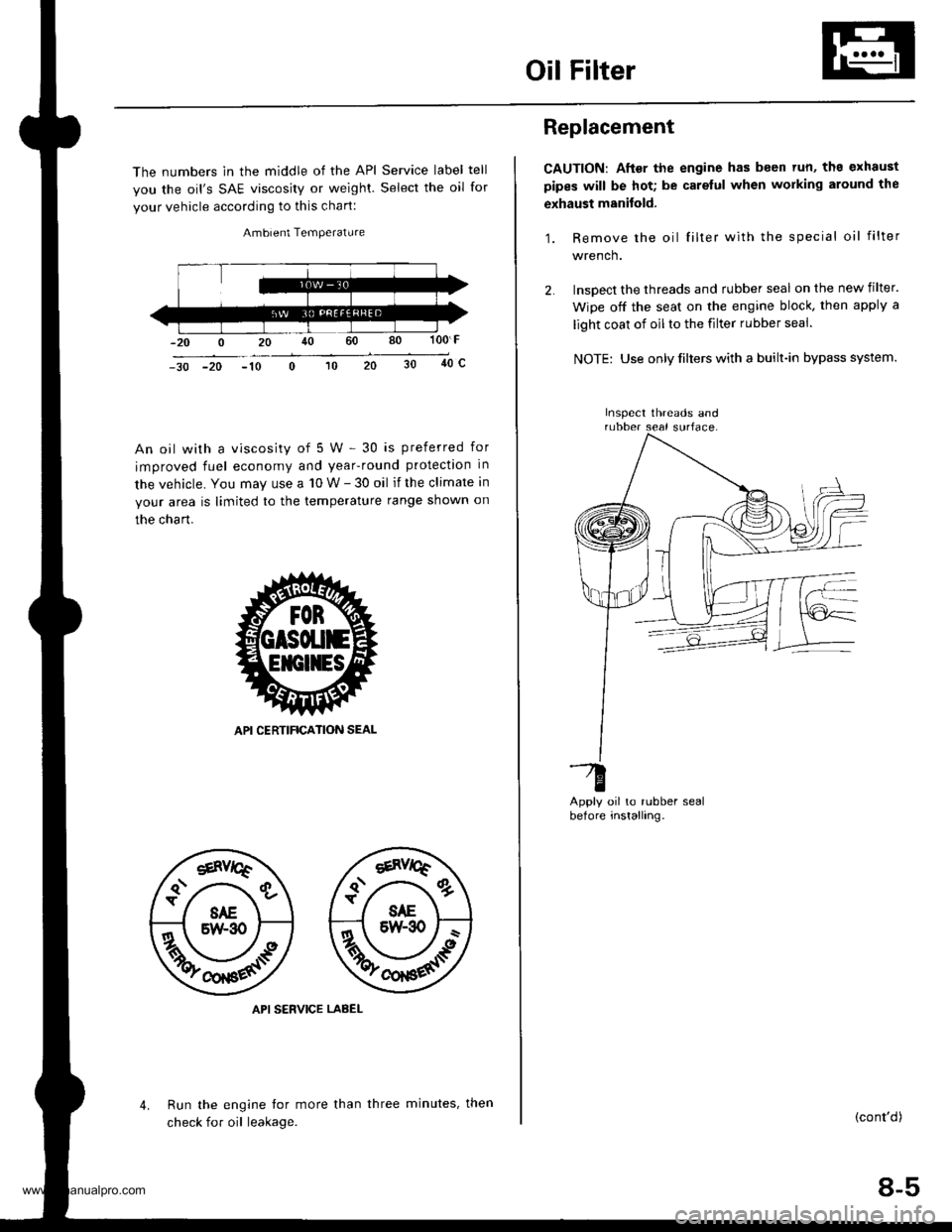

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weighl. Select the oil for

your vehicle according to this chart:

Ambient Temperature

100 F

40c-30 -20 -10

An oil with a viscosity of 5 W - 30 is preferred for

improved fuel economy and year-round protection in

the vehicle. You may use a 10 W - 30 oil if the climate in

your area is limited to the temperature range shown on

the chart.

API SERVICE LABEL

Run the engine tor more than

check for oil leakage.

4.three minutes, then

Replacement

CAUTION: After the engine has been tun, ths exhaust

pipes will be hot; be carelul when working around the

exhaust manitold.

1. Remove the oil filter with the special oil filter

wrench.

lnsoect the threads and rubber seal on the new filter.

Wipe off the seat on the engine block, then apply a

light coat of oil to the filter rubber seal.

NOTE: Use only filters with a built-in bypass system.

oil to rubber sealinstalling.

-G

Derore

(cont'd)

8-5

Inspect threads and

www.emanualpro.com

Page 176 of 1395

Oil Filter

Replacement (cont'd)

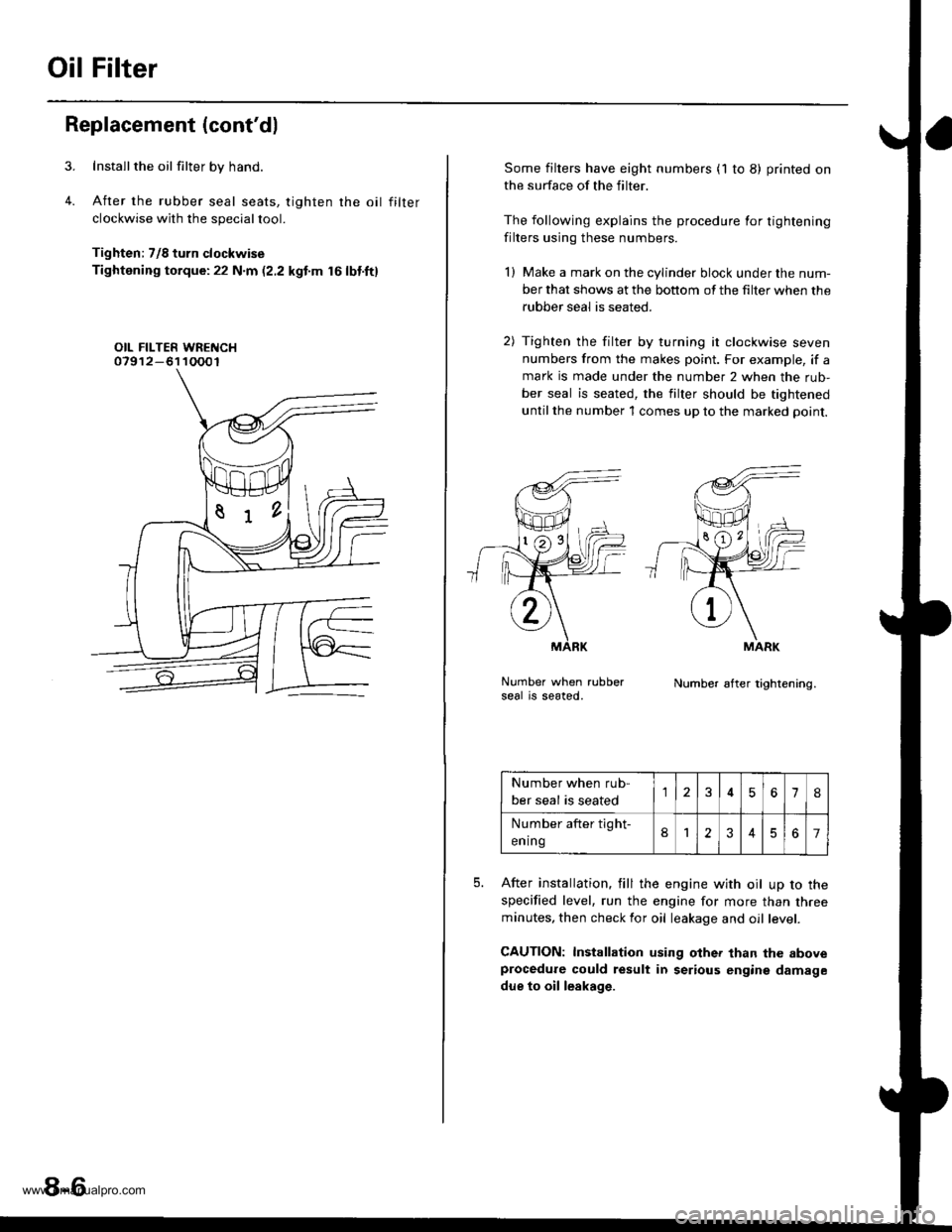

Installthe oil filter by hand.

After the rubber seal seats, tighten rhe oil filter

clockwise with the special tool.

Tighten: 7/8 turn clockwise

Tightening torque:22 N.m (2.2 kgt'm 16lbt.ft)

OIL FILTER WRENCH07912-61 10001

8-6

Some filters have eight numbers (1 to 8) printed on

the surface of the filter.

The following explains the procedure for tightening

filters using these numbers.

l) Make a mark on the cylinder block under the num-

ber that shows at the bottom of the filter when the

rubber seal is seated.

2) Tighten the filter by turning it clockwise seven

numbers from the makes point. For example, if a

mark is made under the number 2 when the rub-

ber seal is seated, the filter should be tightened

until the number 1 comes up to the marked point.

Number when rubberseal is seated.Number af ter tightening.

5.After installation. fill the engine with oil up to the

specified level, run the engine for more than threeminutes, then check for oil leakage and oil level.

GAUTION: Installation using other than the aboveprocedure could result in serious engine damage

due to oil leakage.

MARK

Number when rub-

ber seal is seated567IJ

Number after tight-

ening8123467

www.emanualpro.com

Page 177 of 1395

Oil Pressure SwitchOil Pressure

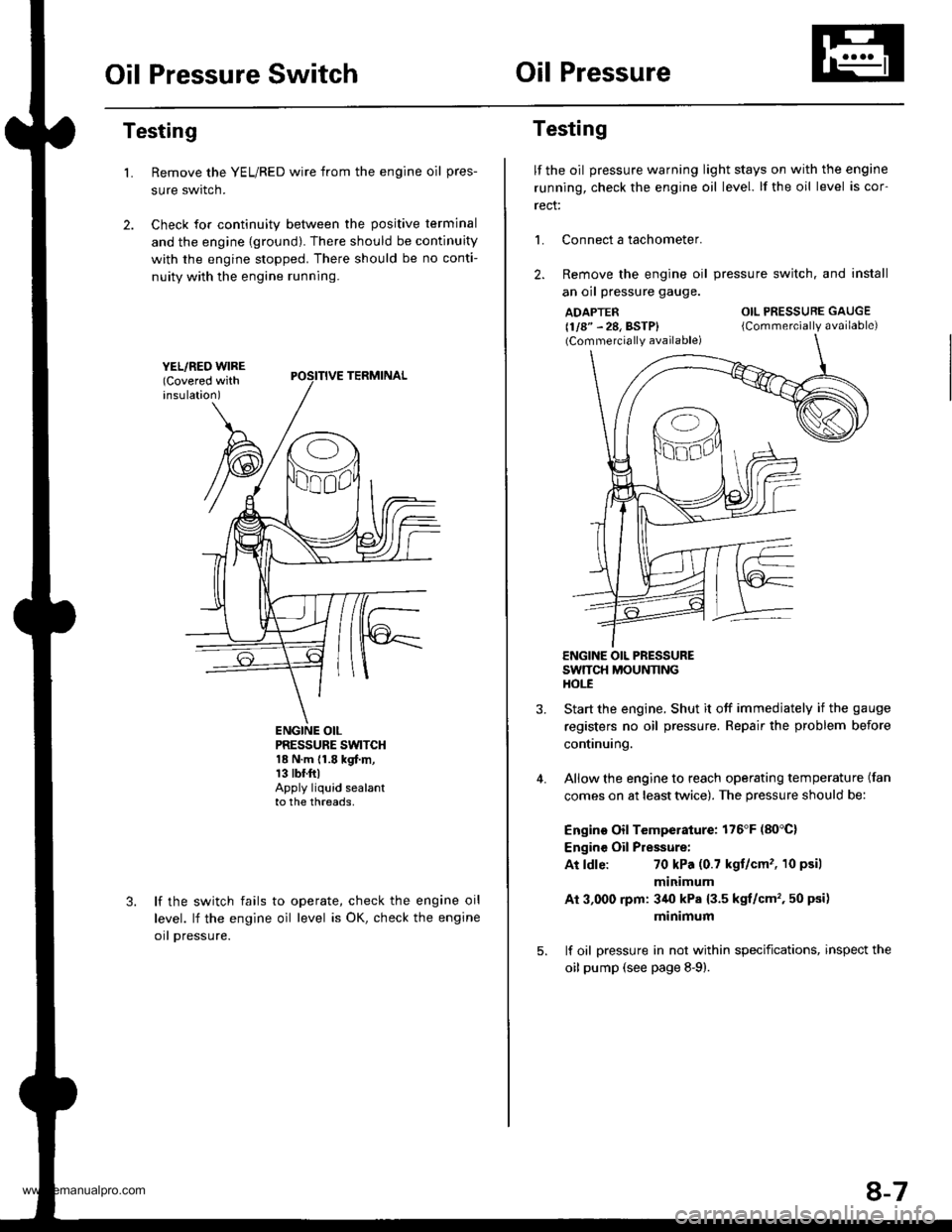

Testing

Remove the YEL/RED wire from the engine oil pres-

sure swrtcn.

Check for continuity between the positive terminal

and the engine {ground). There should be continuity

with the engine stopped. There should be no conti-

nuity with the engine running.

L

PRESSURE SWTCH18 N.m {1.8 kgf.m,13 tbr.ftlApply liquid sealantto the threads,

lf the switch fails

level. lf the engine

orl pressure.

to operate, check the engine oil

oil level is OK, check the engine

Testing

lf the oil pressure warning light stays on with the engine

running, check the engine oil level. lf the oil level is cor-

rect:

L Connect a tachometer.

2. Remove the engine oil

an oil pressure gauge.

ADAPTER(1/8" - 28, BSTP)(Commercially available)

pressure switch. and install

OIL PRESSURE GAUGE

{Commercially available)

4.

ENGINE OIL PRESSURESWTTCH MOUNNNGHOt-E

Start the engine. Shut it off immedjately if the gauge

registers no oil pressure. Repair the problem before

continuing.

Allow the engine to reach operating temperature (fan

comes on at least twice). The pressure should be:

Engino Oil Temperature: 176'F (80'C)

Engine Oil Pressure:

At ldle:70 kPa (0.7 kgt/cm'�, 10 psil

minimum

Ai 3,000 rpm: 3/r0 kPa {3.5 kgt/cm', 50 psi)

minimum

lf oil pressure in not within specifications, inspect the

oil pump (see page 8-9).

8-7

www.emanualpro.com

Page 179 of 1395

1.

2.

3.

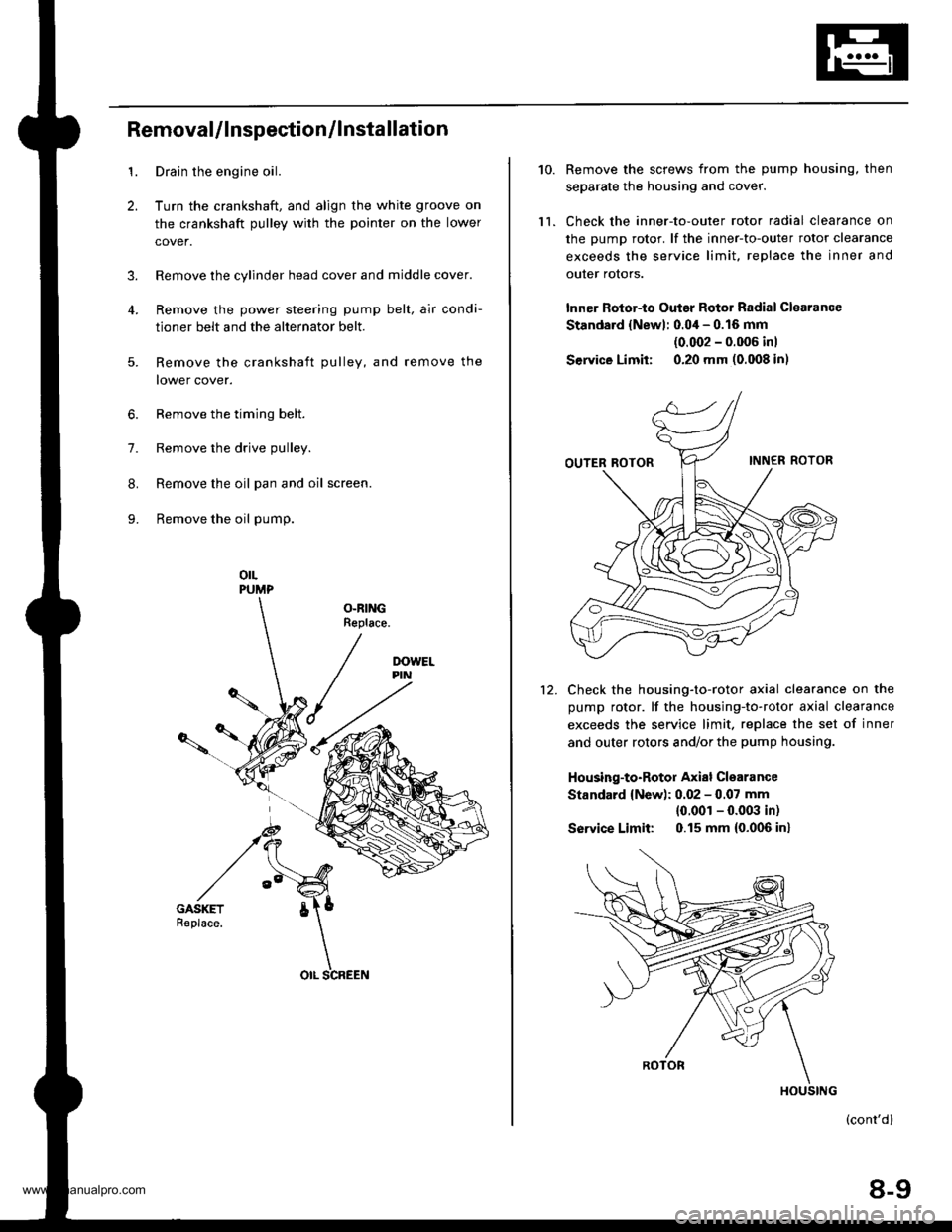

RemovaUlnspection/lnstallation

Drain the engine oil.

Turn the crankshaft, and align the white groove on

the crankshaft pulley with the pointer on the lower

cover.

Remove the cylinder head cover and middle cover.

Remove the power steering pump belt, air condi-

tioner belt and the alternator belt.

Remove the crankshaft pulley, and remove the

lower cover.

6. Remove the timing belt.

7. Remove the drive pulley.

8. Remove the oil pan and oil screen.

9. Remove the oil pump.

orLPUMP

OLRINGReplace.

5.

OIL SCREEN

10.

ll.

Remove the screws from the pump housing, then

separate the housing and cover.

Check the inner-to-outer rotor radial clearance on

the pump rotor. lf the inner-to-outer rotor clearance

exceeds the service limit. replace the inner and

outer rotors.

lnner Rotor-to Outar Rotor Radial Clearance

Standard {Newl: 0.04 - 0.16 mm

{0.002 - 0.006 inl

Service Limit: 0.20 mm (0.008 in)

Check the housing-to-rotor axial clearance on the

pump rotor. lf the housing-to-rotor axial clearance

exceeds the service limit. replace the set of inner

and outer rotors and/or the pump housing.

Housing-to-Rotor Axial Clearance

Standard {New): 0.02 - 0.07 mm

{0.001 - 0.003 in)

So|'�ice Limit: 0.15 mm (0.006 inl

(cont'd)

8-9

HOUSING

www.emanualpro.com

Page 180 of 1395

Oil Pump

13.

Removal/lnspection/lnstallation (cont'd)

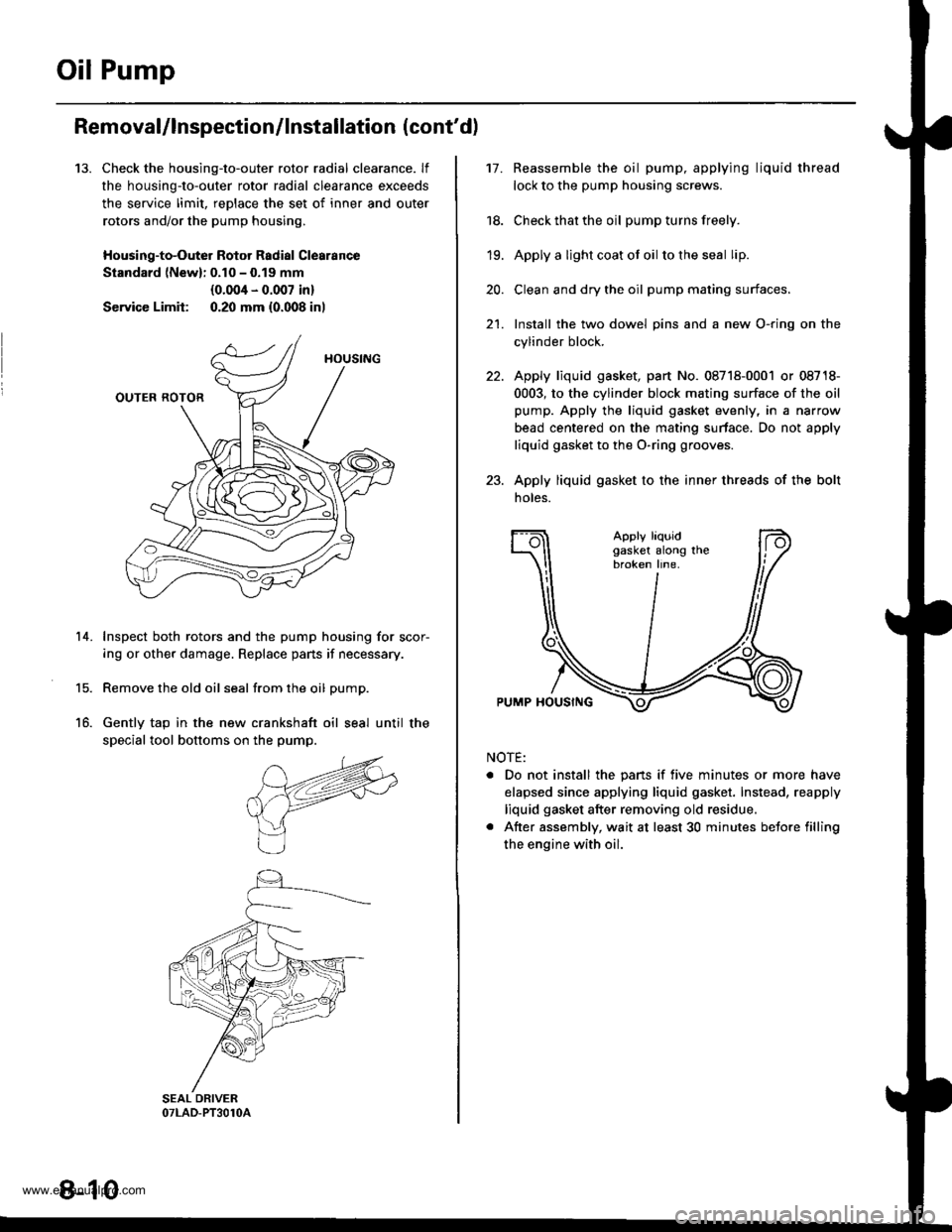

Check the housing-to-outer rotor radial clearance. lf

the housing-to-outer rotor radial clearance exceeds

the service limit, reDlace the set of inner and outer

rotors and/or the pump housing,

Housing-to-Outer Rotor Radial Clearance

Standard lNewl: 0.10 - 0.19 mm

{0.004 - 0.007 in}

Service Limit: 0.20 mm {0.008 inl

Inspect both rotors and the pump housing for scor-

ing or other damage. Replace pans if necessary.

Remove the old oil seal from the oil pump.

Gently tap in the new crankshaft oil seal until the

special tool bottoms on the pump.

14.

15.

16.

8-10

17.Reassemble the oil pump, applying liquid thread

lock to the pump housing screws.

Check that the oil pump turns freely.

Apply a light coat ot oil to the seal lip.

Clean and dry the oil pump mating surfaces.

Install the two dowel pins and a new O-ring on the

cylinder block.

Apply liquid gasket, part No. 08718-0001 or 08718-

0003, to the cylinder block mating surface of the oil

pump. Apply the liquid gasket evenly, in a narrow

bead centered on the mating surface. Do not apply

liquid gasket to the O-ring grooves.

Apply liquid gasket to the inner threads of the bolt

noles.

18.

19.

20.

21.

Apply liquidgasket along thebroken line.

PUMP HOUSING

NOTE:

. Do not install the pans if five minutes or more have

elapsed since applying liquid gasket. Instead, reapply

liquid gasket after removing old residue.

. After assembly, wait at least 30 minutes betore filling

the engine with oil.

www.emanualpro.com

Page 181 of 1395

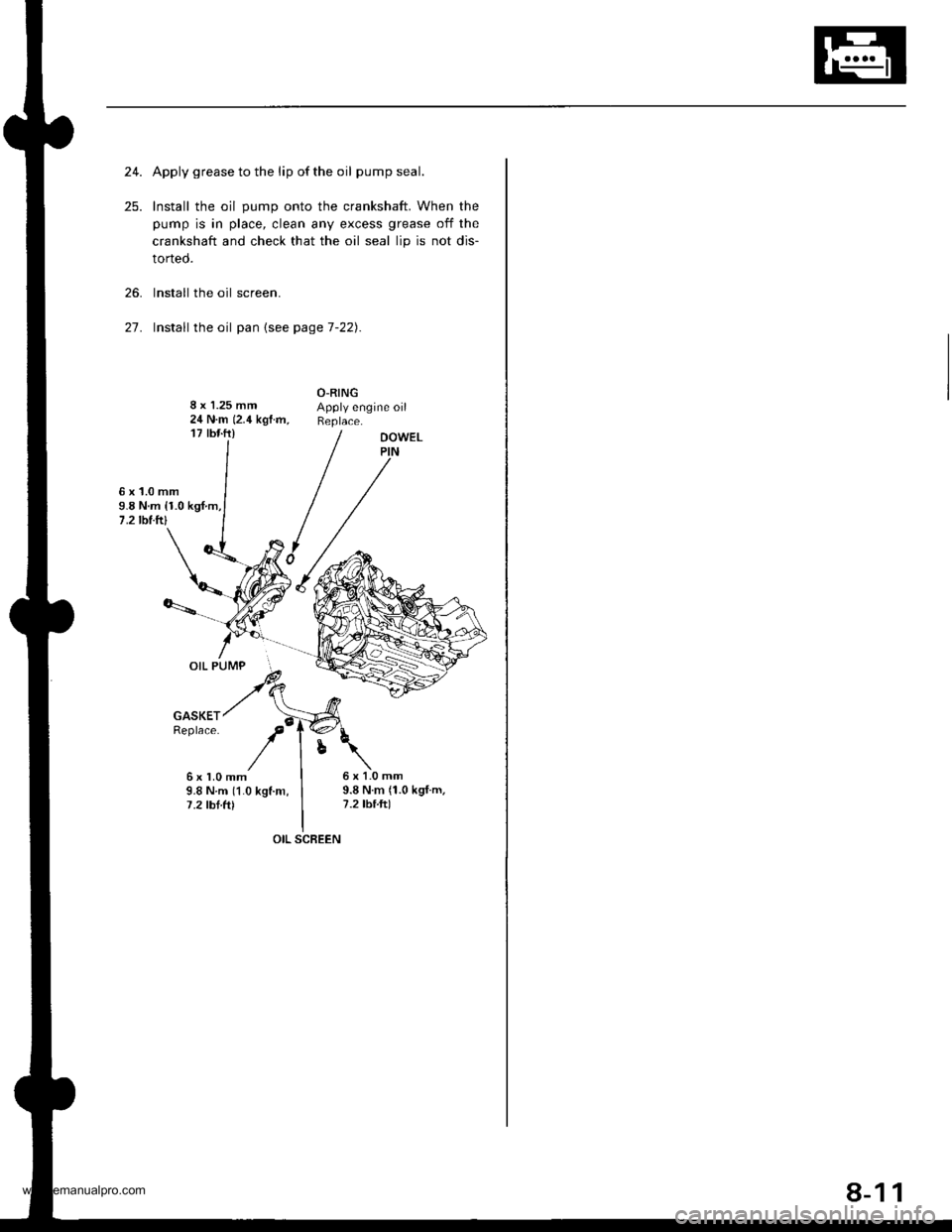

24.Apply grease to the lip of the oil pump seal.

Install the oil pump onto the crankshaft. When the

pump is in place, clean any excess grease off the

crankshaft and check that the oil seal lip is not dis-

torted.

lnstall the oil screen.

Install the oil pan {see page 7-22).2't .

8 x 1.25 mm24 N.m 12.4 kgf.m,'17 tbf.ft)

O-RINGApply engine oilReplace.

6x1.0mm9.8 N.m {1.0 kgf.m,1 .2lbfitl

DOWELPIN

6x1.0mm9.8 N.m (1.0 kgf.m.7.2 tbtftl

OIL PUMP

6x1.0mm9.8Nm(1.0kgf.m,7.2 tbt ft)

OIL SCBEEN

8-11

www.emanualpro.com

Page 182 of 1395

Intake Manifold/Exhaust System

Intake Manifold

Rep1acement ....................................... 9-2

Exhaust Manifold

Replacement ....................................... 9-4

Exhaust Pipe and Muffler

Replacement ....................................... 9-6

www.emanualpro.com

Page 183 of 1395

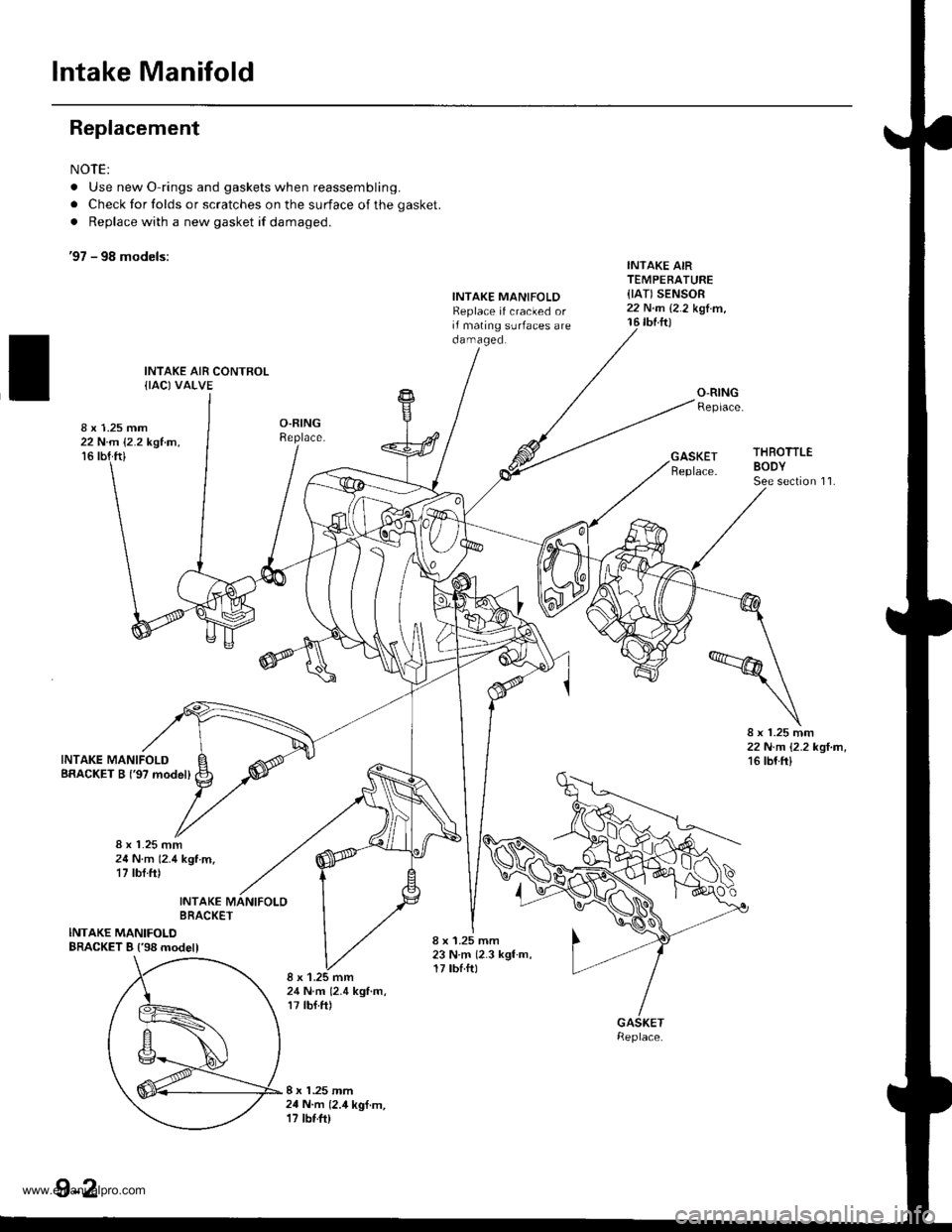

Intake Manifold

Replacement

NOTE:

. Use new O-rings and gaskets when reassembling.

. Check for folds or scratches on the surface of the gasket.

. Replace with a new gasket if damaged.

'97 - 98 models:

INTAK€ MANIFOLDReplace if cracked orif mating surfaces areoamageo,

INTAKE AIRTEMPERATURE

{IATI SENSOR22 N.n 12.2 kgl.m,16 rbf.ftl

8 x 1.25 mm22 N.m 12.2 kgtm.'t6 tbf ft)

8 x 1.25 mm22 N.m |.2.2 kgl.rn,'16 tbt ftl

I x 1.25 mm24 N m 12.4 kgf m.17 tbf.ft)

INTAKBRAC}

INTAKE MANIFOLOBRACKET B ('98 modell8 x 1.25 mm23 N m (2.3 kgt m,17 tbf.ftlI x 1.25 mm24 N.m 12.4 kgf.m,17 tbf.ft)

8 x 1.25 mm24 N.m (2.4 kgf.m,17 tbf.ft)

9-2

www.emanualpro.com

Page 185 of 1395

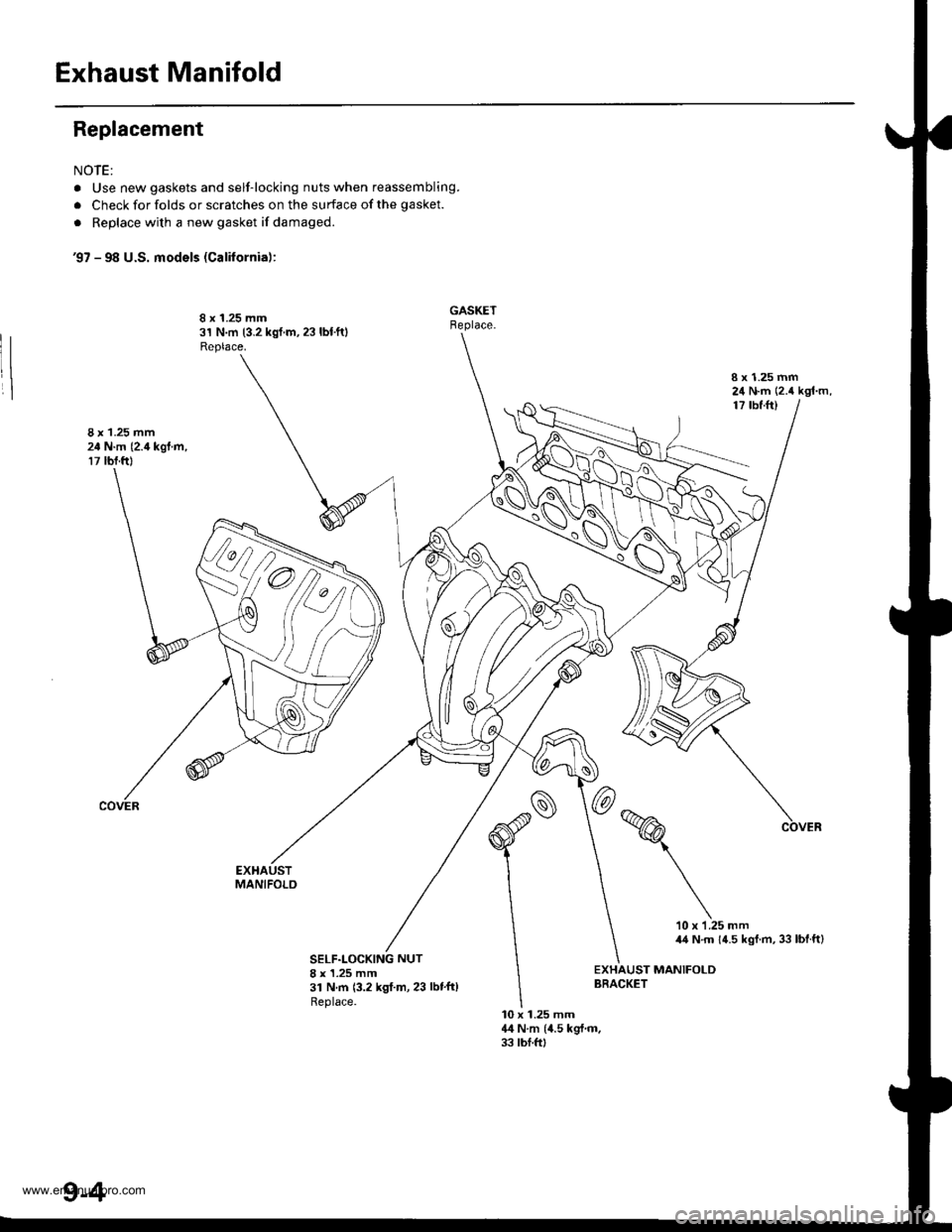

Exhaust Manifold

Replacement

NOTE:

. Use new gaskets and self-locking nuts when reassembling.

. Check for folds or scratches on the surface of the gasket.

. Replace with a new gasket if damaged.

'97 - 98 U.S. models (Calilornia):

8 x 1.25 mm31 N.m (3.2 kgf.m, 23 lbtft)Replace.

I x 1.25 mm24 N.m (2.4 kgl.m,1? tbf.ft)

8 x 1.25 mm24 N.m (2.i1kgt.m,

17 lbf.ftl

EXHAUSTMANIFOLO

10 x 1.25 mm44 N.m 14.5 kgf.m, 33 lbf.ft)

SELF.LOCKING NUT8 x 1.25 mm31 N m 13.2 kgt.m, 23 lbt'ft)Replace.

EXHAUST MANIFOLDBRACKET

10 x 1.25 mm44Nm{4.5kg{.m.33 lbf.ftl

NN

9-4

www.emanualpro.com

Page 187 of 1395

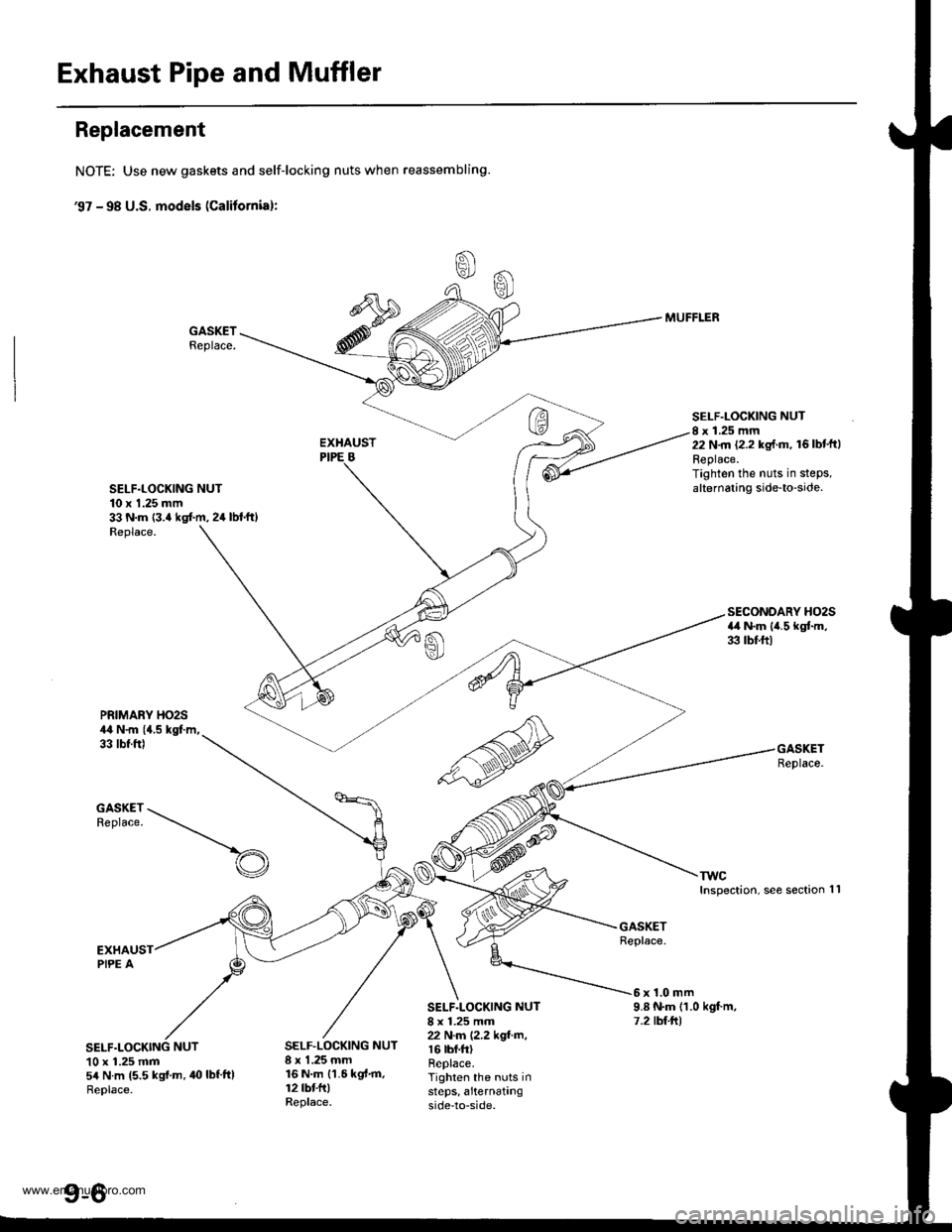

Exhaust Pipe and Muffler

Replacement

NOTE: Use new gaskets and self-locking nuts when reassembling.

€7 - 98 U.S. models (Calitornial:

GASKETReplace.

SELF.LOCKING NUT10 x 1.25 mm33 N.m {3.4 kgt m, 24 lbl.ft)Replace.

MUFFLER

SELF.LOCKING NUTI x 1.25 mm22 N.m (2.2 kg{.m, 16lbt'ftlReplace.Tighten the nuts in stePs,alternating side-to-side.

PRIMARY HO2S44 N.m {{.5 kgl.m,33 tbt.ft)

TWCInspection, see section

SECONDARY HO2S4il N.m lil.5 kgtm,33 tbf.ft)

GASKETReplace.

1l

S*S:--t-..-_

EXHAUSTPIPE A

NUT10 x 1.25 mm54 N.m 15.5 kgi.m,40lbf'tt)Replace.

GASKETReplace.

SELF.LOCKING NUT8 x 1.25 mm22 N.m (2.2 kgf.m,r 6 tbt.ft)Replace.Tighten the nuts insteps, a'ternatingside-to-side.

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbt.ltl

SELF.LOCKING NUT8 x 1.25 mm16 N.m {1.6 kgt.m,12 tbt fr)Replace.

www.emanualpro.com