Adjust Ac HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1062 of 1395

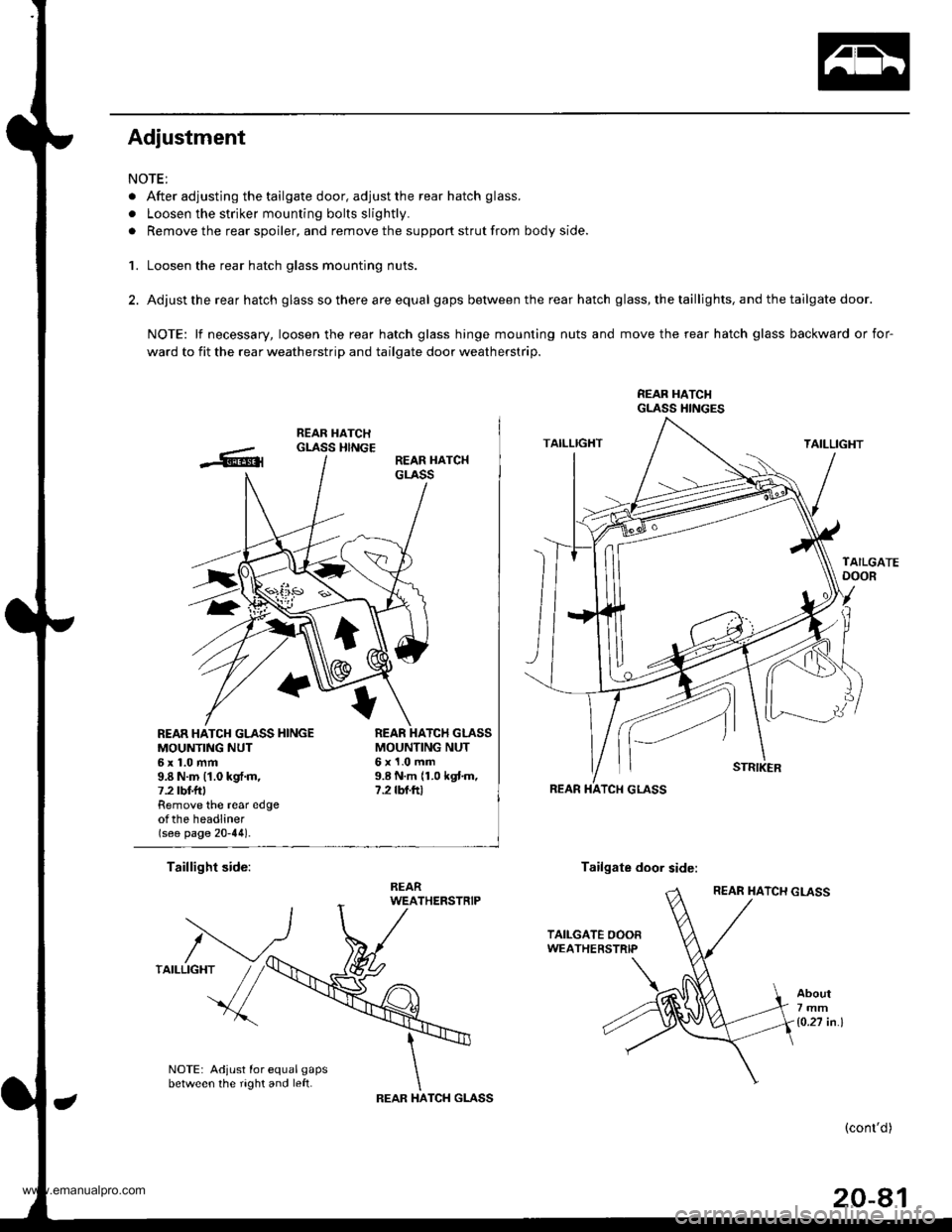

Adjustment

NOTE:

. After adjusting the tailgate door, adjust the rear hatch glass.

. Loosen the striker mounting bolts slightly.

. Remove the rear spoiler, and remove the support strut from body side.

1. Loosen the rear hatch glass mounting nuts.

2. Adjust the rear hatch glass so there are equal gaps between the rear hatch glass, the taillights, and the tailgate door.

NOTE: lf necessary, loosen the rear hatch glass hinge mounting nuts and move the rear hatch glass backward or for-

ward to fit the rear weatherstrip and tailgate door weatherstrip.

REAR HATCI{GLASS HINGES

REAR HATCH GLASS HINGEMOUNTING NUT6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbt f Remove the rear edgeotthe headliner(see page 20-44).

MOUNTING NUT6x1.0mm9.8 N.m 11.0 kgtm,7.2 rbf.ftt

Taillight side:Tailgate door side:

About7mm

1o.27 in.l

NOTE: Adjust for equal gapsbetween the right and left.TCH GLASSIHAREAR

(cont'd)

20-81

www.emanualpro.com

Page 1063 of 1395

Rear Hatch Glass

3.

4.

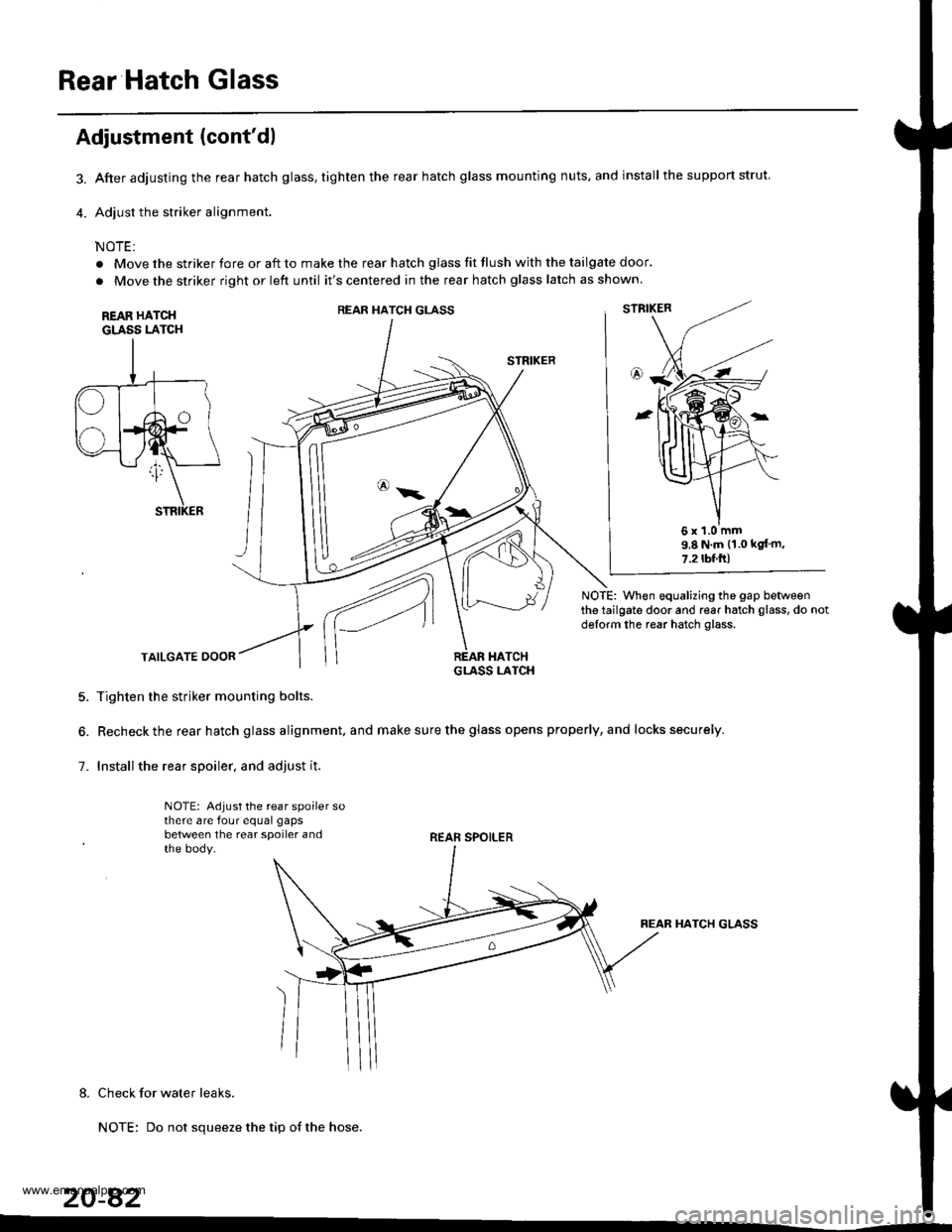

Adjustment (cont'dl

After adjusting the rear hatch glass, tighten the rear hatch glass mounting nuts, and installthe support strut.

Adjust the striker alignment.

NOTE:

. Move the striker fore or aft to make the rear hatch glass fit flush with the tailgate door'

. Move the striker right or left until it's centered in the rear hatch glass latch as shown.

REAR HATCHGLASS LATCH

STRIKER

NOTE: When equalizing the gap betweenthe tailgate door and rear hatch glass, do notdglorm the rear hatch glass.

TAILGATE DOOR

5. Tighten the striker mounting bolts.

6. Recheck the rear hatch glass alignment. and make sure the glass opens properly, and locks securely.

7. Installthe rear spoiler. and adjust it.

NOTE: Adjust the rear spoiler sothere are four equal gaps

between the rear spoiler andthe body.REAR SPOILER

REAR HATCH GLASS

8. Check for water leaks.

NOTE: Do not squeeze the tip of the hose.

20-82

REAR HATCH GLASS

6x1.0mm9.8 N.m (1.0 kgt'm,

7.2tbl.ftl

www.emanualpro.com

Page 1076 of 1395

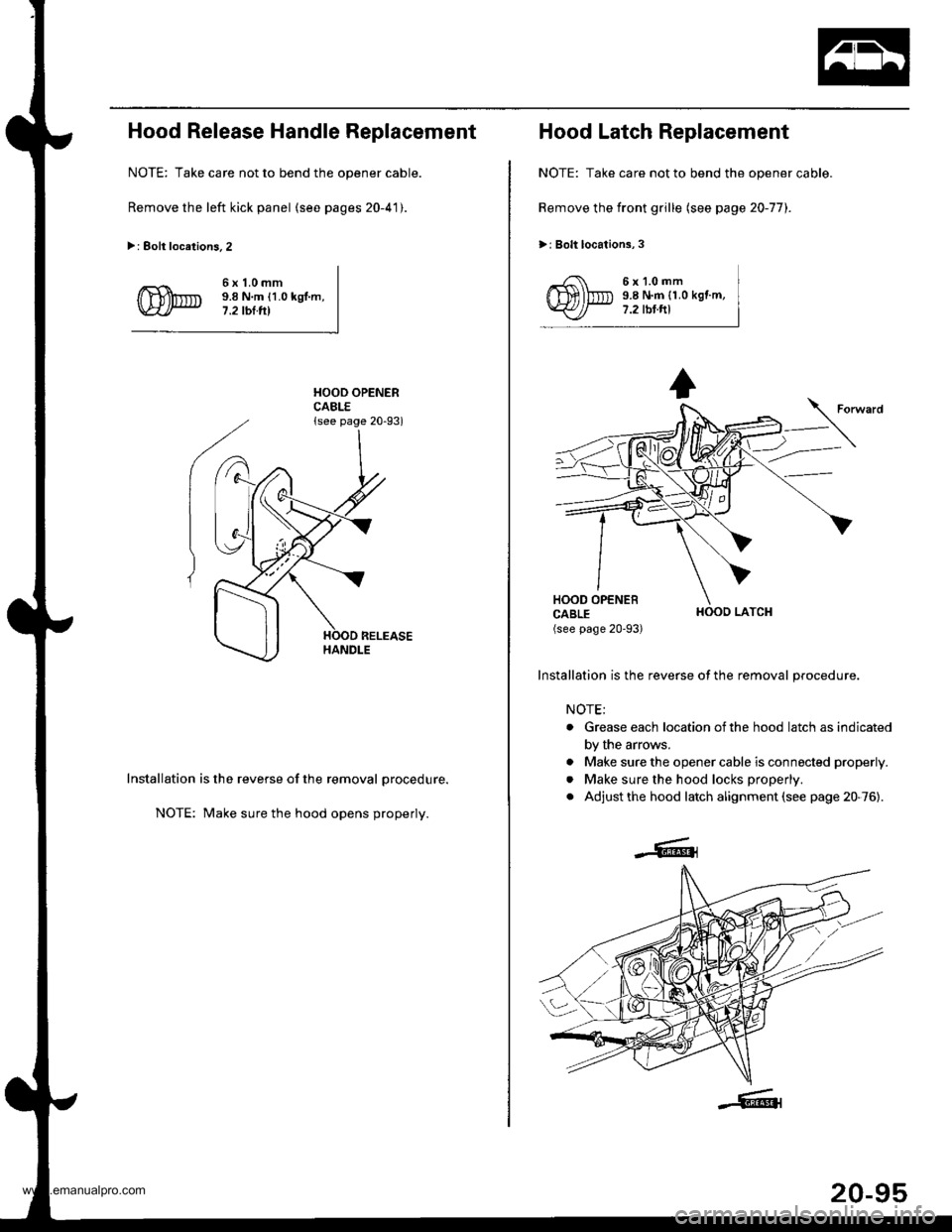

Hood Release Handle Replacement

NOTE: Take care not to bend the opener cable.

Remove the left kick panel (see pages 20-41).

>: Eolt locations.2

6x1.0mm9.8 N.m {1.0 kgl.m,7.2 tbl.tll

HOOD OPENERCABLE{see page 20-93)

Installation is the reverse of the removal procedure.

NOTE: Make sure the hood opens properly.

Hood Latch Replacement

NOTE: Take care not to bend the opener cable.

Remove the front grille (see page 20-77).

>: Bolt locations,3

6x1.0mm9.8 N.m {1.0 kgf.m,7.2 tbt.ftl

HOOO LATCH

Installation is the reverse of the removal procedure.

NOTE;

. Grease each location ofthe hood latch as indicated

by the arrows.

. Make sure the opener cable is connected properly.

. Make sure the hood locks properly.

. Adjust the hood latch alignment (see page 20-76).

20-95

www.emanualpro.com

Page 1079 of 1395

Wiper/Washer

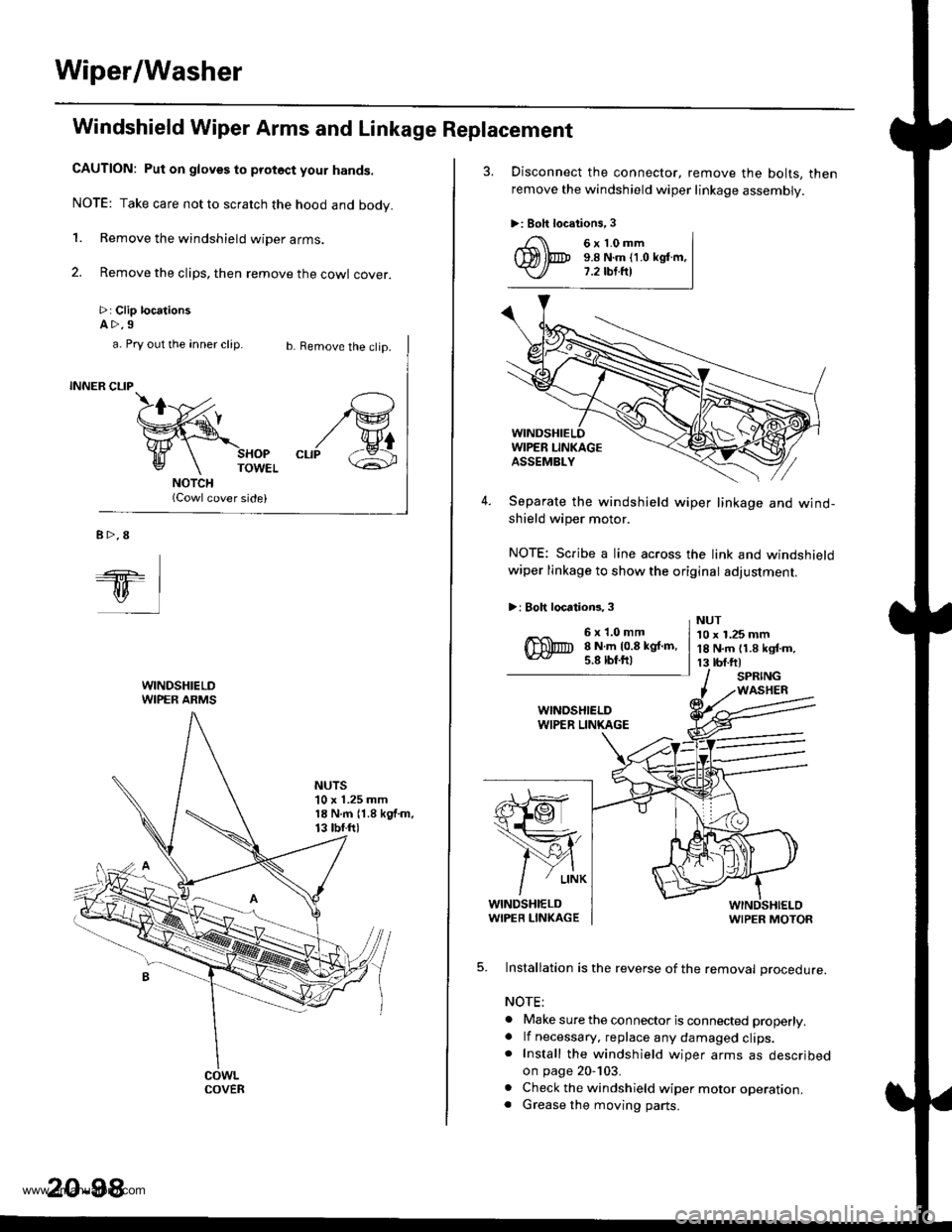

Windshield Wiper Arms and Linkage Replacement

CAUTION: Put on gloves to protoct your hands.

NOTE: Take care not to scratch the hood and body.

1. Remove the windshield wiper arms.

2. Remove the clips, then remove the cowl cover.

>: Clip locationsA>.9

b. Remove the clip.

SHOPTOWEL

(Cowl cover side)

/G

"rr/ &

a. Pry out the anner clip.

INNER CLIP

B>.8

ql

WINDSHIELDWIPER ARMS

NUTS'10 x 1.25 mm18 N.m 11.8 kgf.m.13 tbf.ftl

COVER

20-98

3. Disconnect the connector, remove the bolts, then

remove the windshield wiper linkage assembly.

>: Boh locations,3

4. Separate the windshield wiper linkage and wind-shield wiper motor.

NOTE: Scribe a line across the link and windshieldwiper linkage to show the original adjustment.

>: Boh locations, 3

s}@

1ffi,

/Y{

/

' L|NK

WINDSHIELDWIPER LIN(AGEWIPER MOTOR

5. Installation is the reverse of the removal procedure.

NOTE:

. Make sure the connector is connected properly.. lf necessary. replace any damaged clips.. Install the windshield wiper arms as describedon page 20-103.

. Check the windshield wiper motor operation.. Grease the moving parts.

6x1.0mm9.8 N.m (1.0 kglm,7.2 tbt.fr)

6x1.0mm8 N.m 10.8 kgf.m,5.8 lbf.ftl

NUT10 x 1.25 mm18 N.m 11.8 kgf.m,13 tbf.ftlSPRINGWASHER

www.emanualpro.com

Page 1081 of 1395

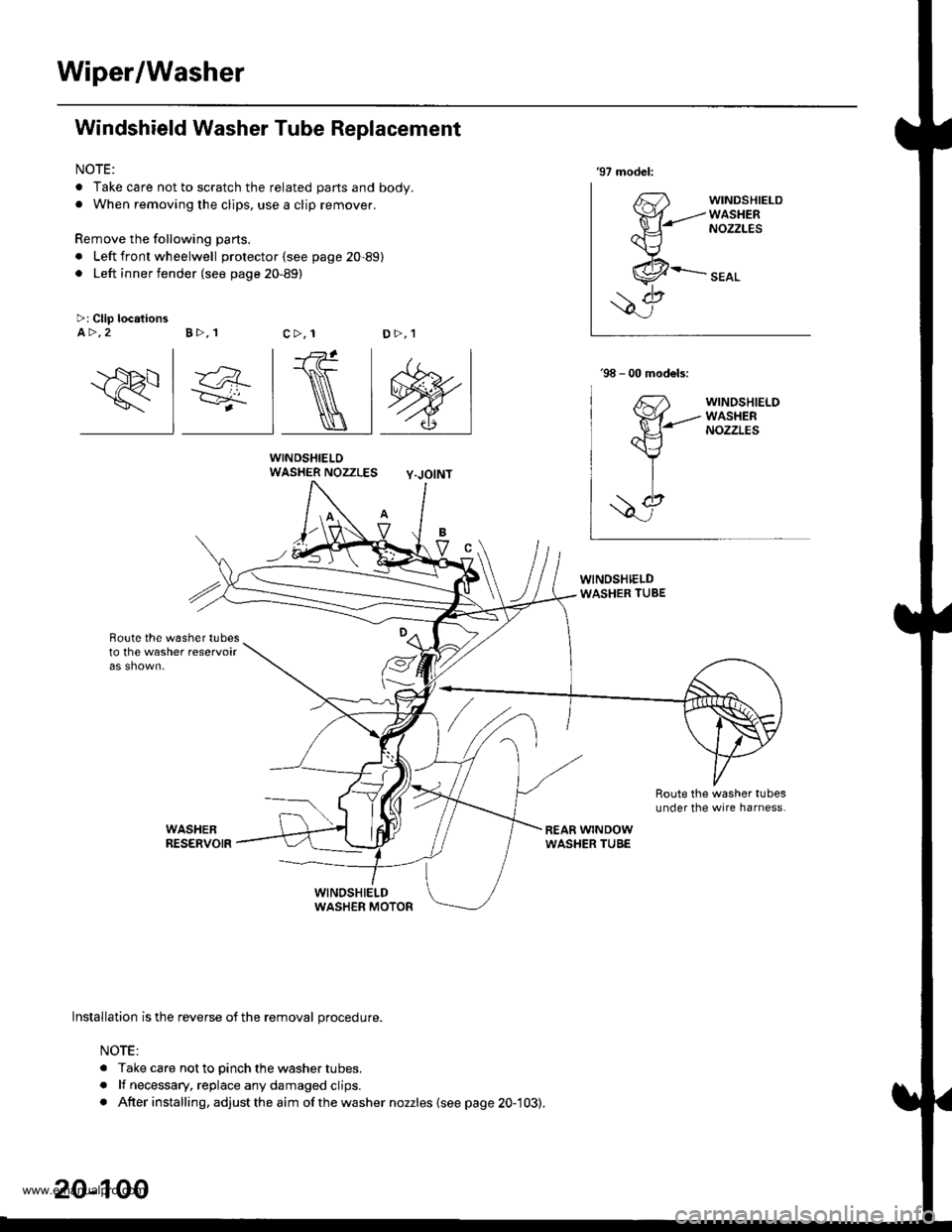

Wiper/Washer

Windshield Washer Tube Replacement

NOTE:

. Take care not to scratch the related parts and body.. When removing the clips, use a clip remover.

Remove the following parts.

. Left front wheelwell protector (see page 20-89). Left inner fender (see page 20-89)

WINDSHIELOWASHER NOZZLES Y-JOINT

Boute the w6sher tubesto the washer reservoir

'97 model:

63'fr{-------

ax---\J

,.&--

\7>: Clip locationsA >,2 B >,1c>, 1D>,1

\

lnstallation is the reverse of the removal procedure.

NOTE:

. Take care not to pinch the washer tubes.

. lf necessary, replace any damaged clips.. After installing, adjust the aim ofthe washer nozzles (see page 20-103).

20-100

www.emanualpro.com

Page 1083 of 1395

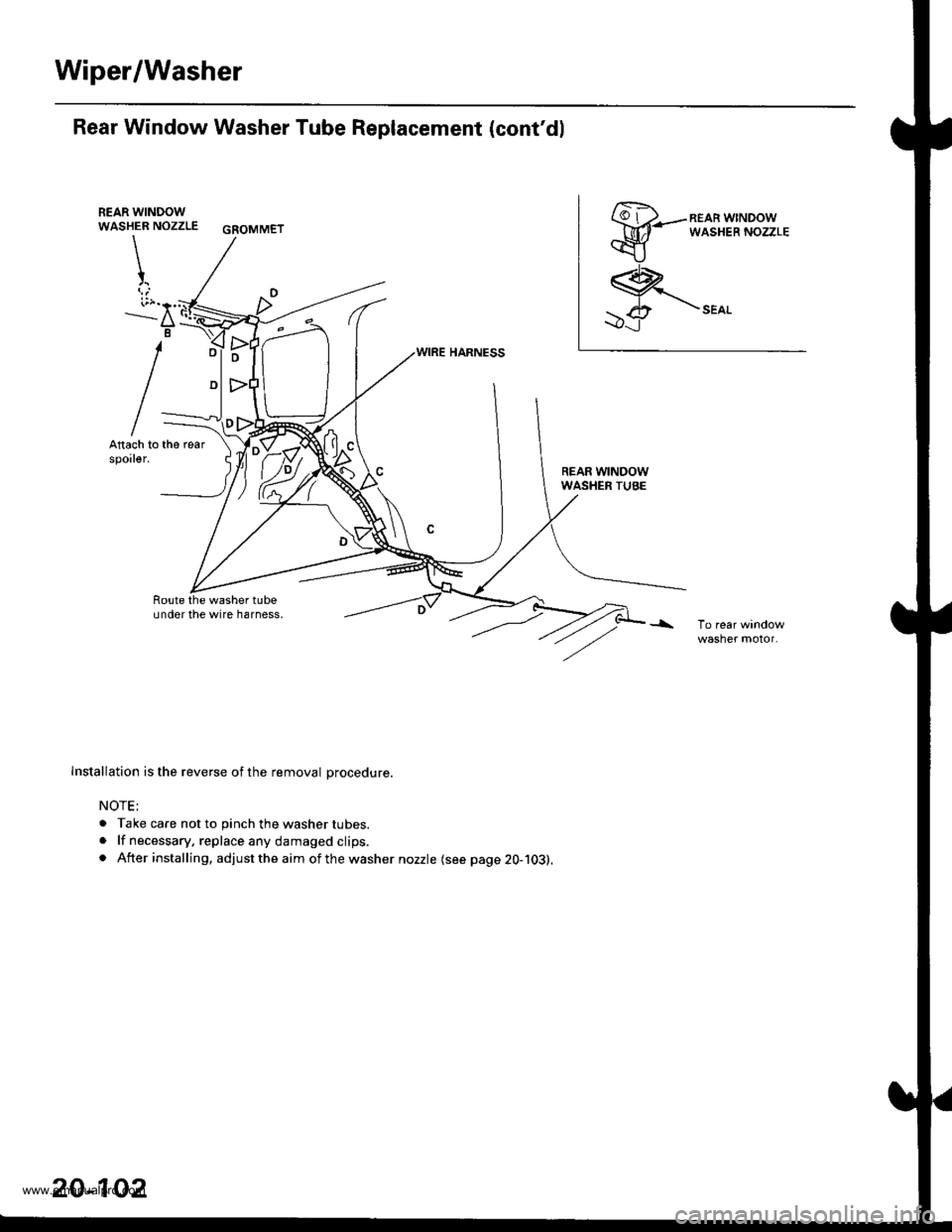

Wiper/Washer

Rear Window Washer Tube Replacement (cont'dl

REAR WINDOWWASHER NOZZLE GSOMMET

\

t

i;r."'..--a

B

REAR WINDOWWASHER TUBE

Route the washer tubeundor the wire harness,

Installation is the reverse of the removal Drocedure.

NOTE;

. Take care not to pinch the washer tubes.. lf necessary, replace any damaged clips.. After installing, adjust the aim of the washer nozzle (see page 20-103).

20-102

www.emanualpro.com

Page 1084 of 1395

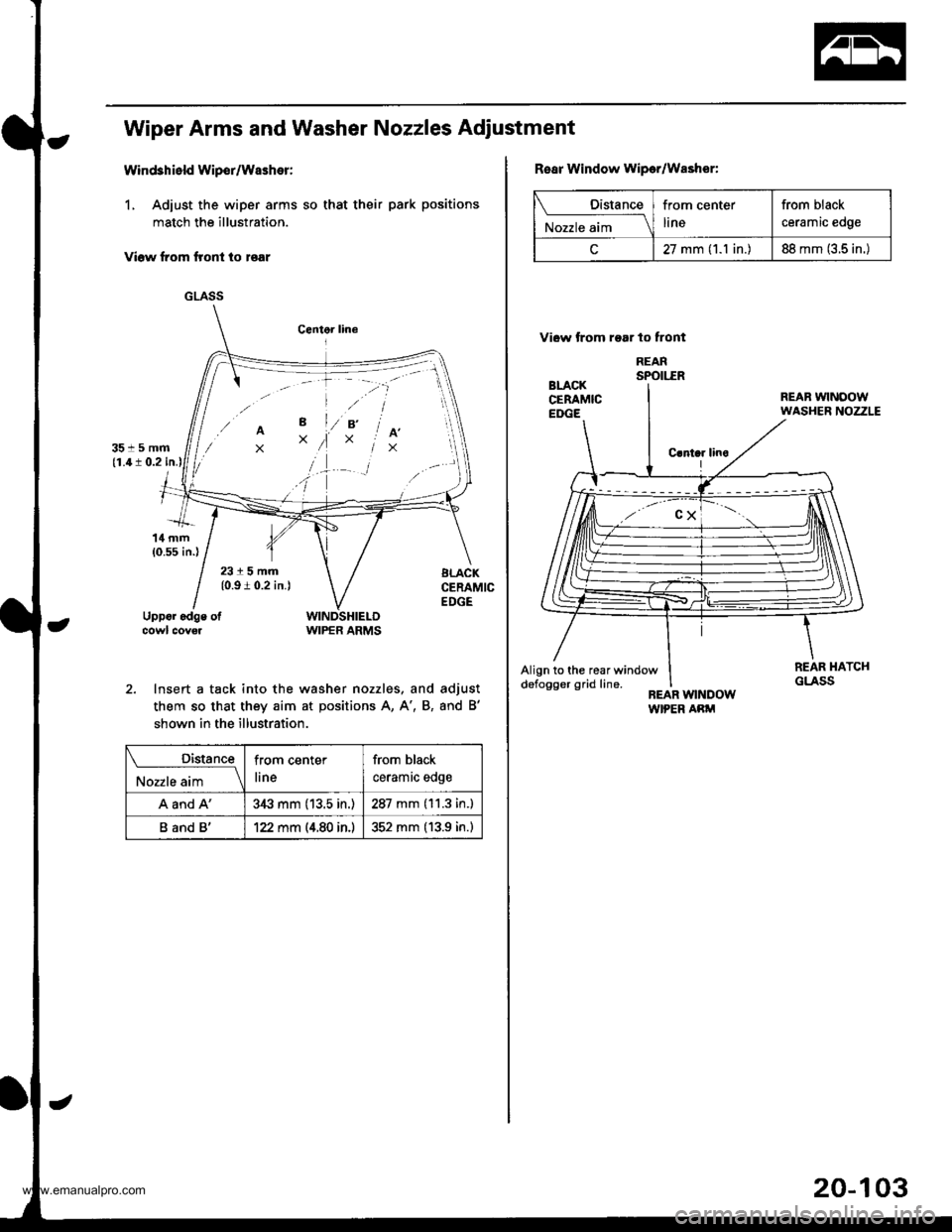

Wiper Arms and Washer Nozzles Adiustmenl

Wind3hield Wipor/Washer:

1, Adiust the wiper arms so that their park positions

match the illustration.

Viow from flont io roar

GLASS

2. Insert a tack into the washer nozzles. and

them so that they aim at positions A, A', B,

shown in the illustration.

adjust

and B'

Distance

^,J;-ll\

from center

line

from black

ceramic edge

A and A'3,$ mm (13.5 in.)287 mm (11.3 in.)

B and B'122 mm (4.80 in.)352 mm (13.9 in.)

Rear Window wipor/Washer:

Vi6w trom roar to lront

REARsPo[.-ER

C.nlar linoL

Align to the rear windowdefogger grid line.

Distance

ru"rrr. "i.

'_\from center

ltne

from black

ceramic edge

27 mm (1.1 in.)88 mm (3.5 in.)

20-103

www.emanualpro.com

Page 1094 of 1395

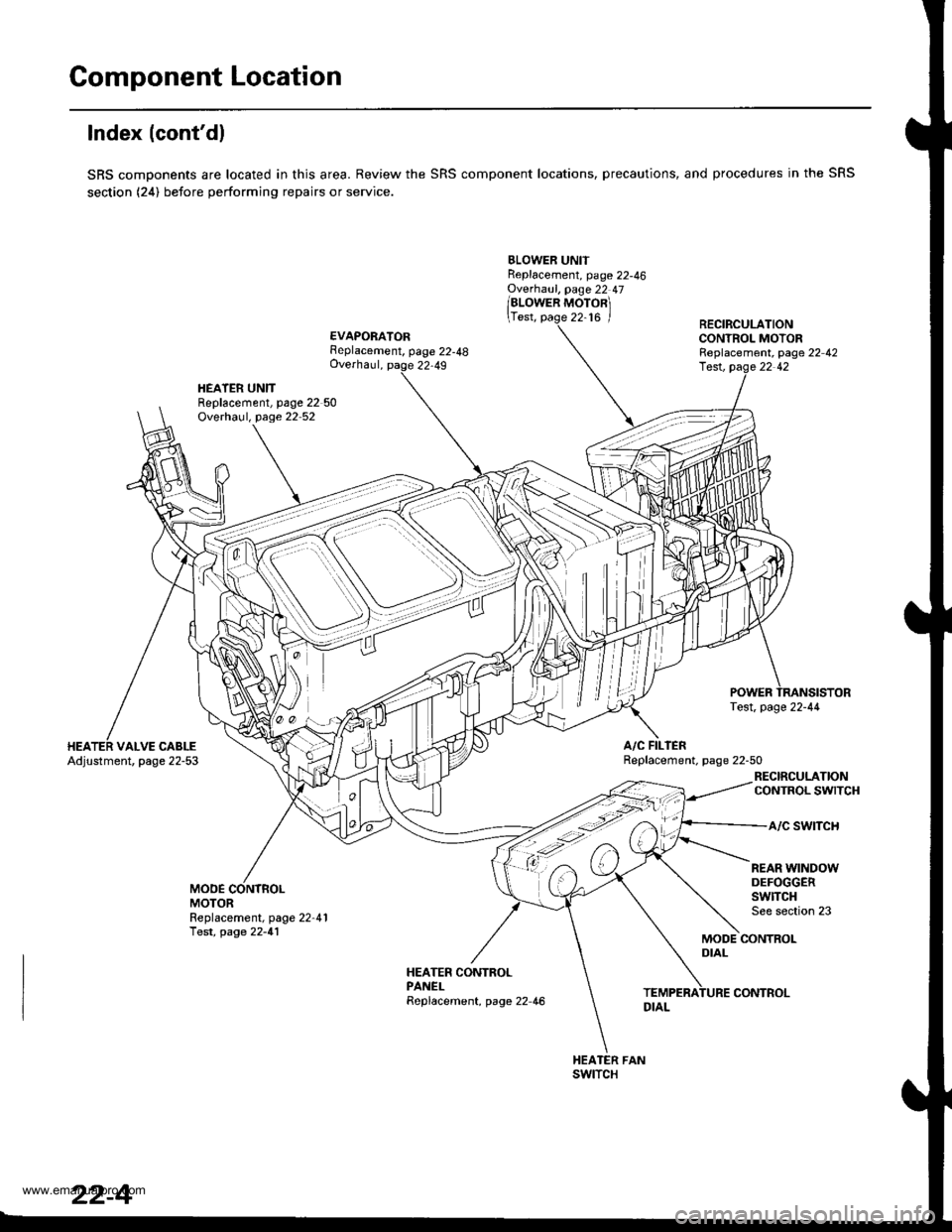

Component Location

lndex (cont'dl

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

BLOWER UNITReplacement, page 22-46Ovethaul, page 22 47

/alowen ruoronl

\Test, page 22-16 /

EVAPORATORFeplacement, page 22-48Overhaul, page 22,49

RECIRCULATIONCONTROL MOTORReplacement, page 22 42

HEATER UNITReplacement, page 22 50Overhaul, page 22 52

lest, pag.e 22 42

A/C FILIERReplacement. page 22-50VALVE CABLEAdjustment, page 22-53

RECIRCULATIONCONTROL SWITCH

a/c swtTcH

MODEMOTOR

REAR WINDOWDEFOGGERSwlTCHSee section 23Replacement, page 22-41Test, page 22-41MODE CONTROLDIAL

HEATER CONTROLPANELReplacement, page 22 46

swtTcH

22-4

CONTROL

www.emanualpro.com

Page 1143 of 1395

Temperature Control

Adjustment

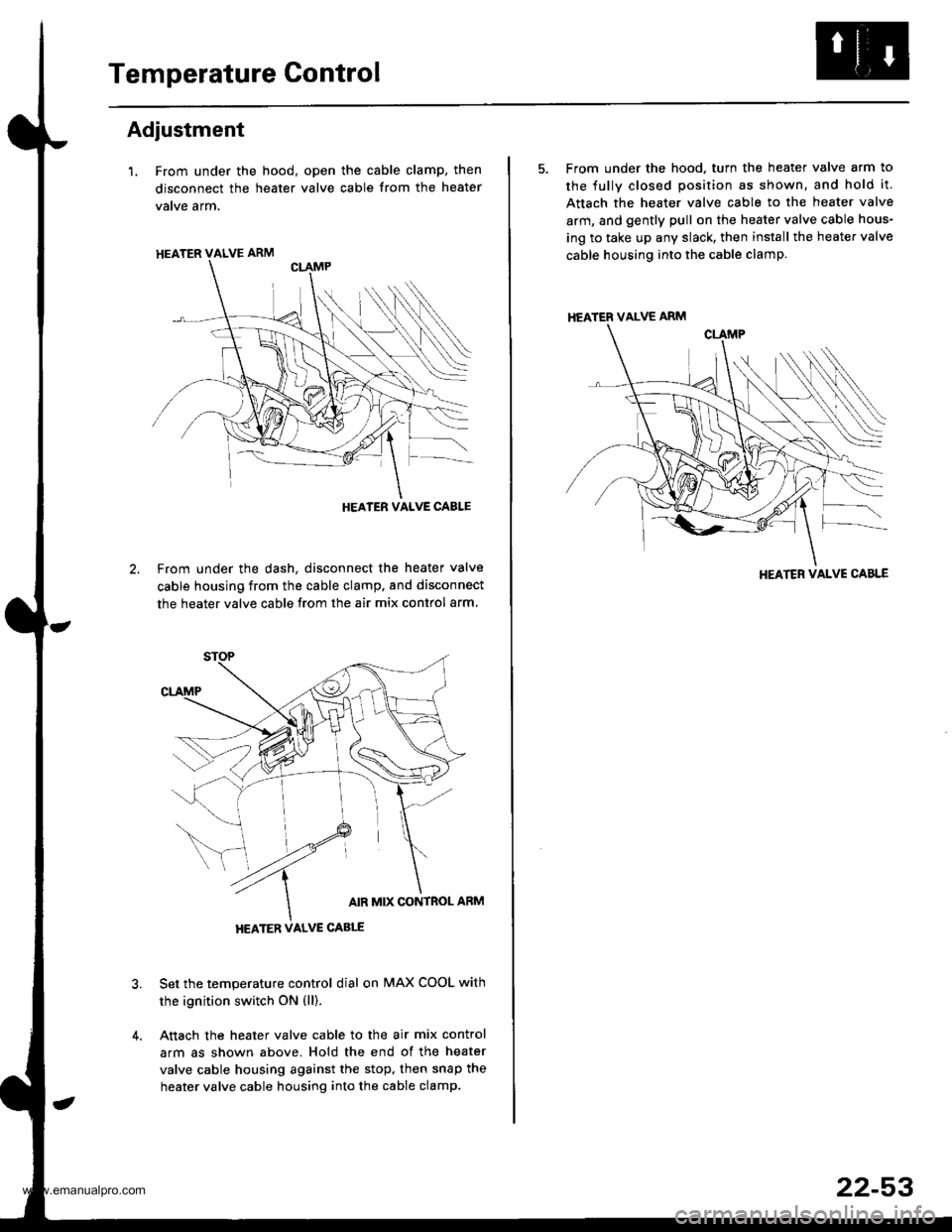

l. From under the hood, open the cable clamp, then

disconnect the heater valve cable from the heater

vatve arm.

From under the dash, disconnect the heater valve

cable housing from the cable clamp. and disconnect

the heater valve cable from the air mix contlol arm

Set the temperature control dial on MAX COOL with

the ignition switch ON (ll).

Attach the heater valve cable to the air mix control

arm as shown above. Hold the end of the heater

valve cable housing against the stop, then snap the

heater valve cable housing into the cable clamp.

HEATER VALVE ARM

HEATER VALVE CABLE

5. From under the hood. turn the heater valve arm to

the fullv closed position as shown, and hold it.

Attach the heater valve cable to the heater valve

arm, and gently pull on the heater valve cable hous-

ing to take up any slack, then install the heate. valve

cable housing into the cable clamp.

HEATER VALVE ARM

HEATER VALVE CABLE

22-53

www.emanualpro.com

Page 1153 of 1395

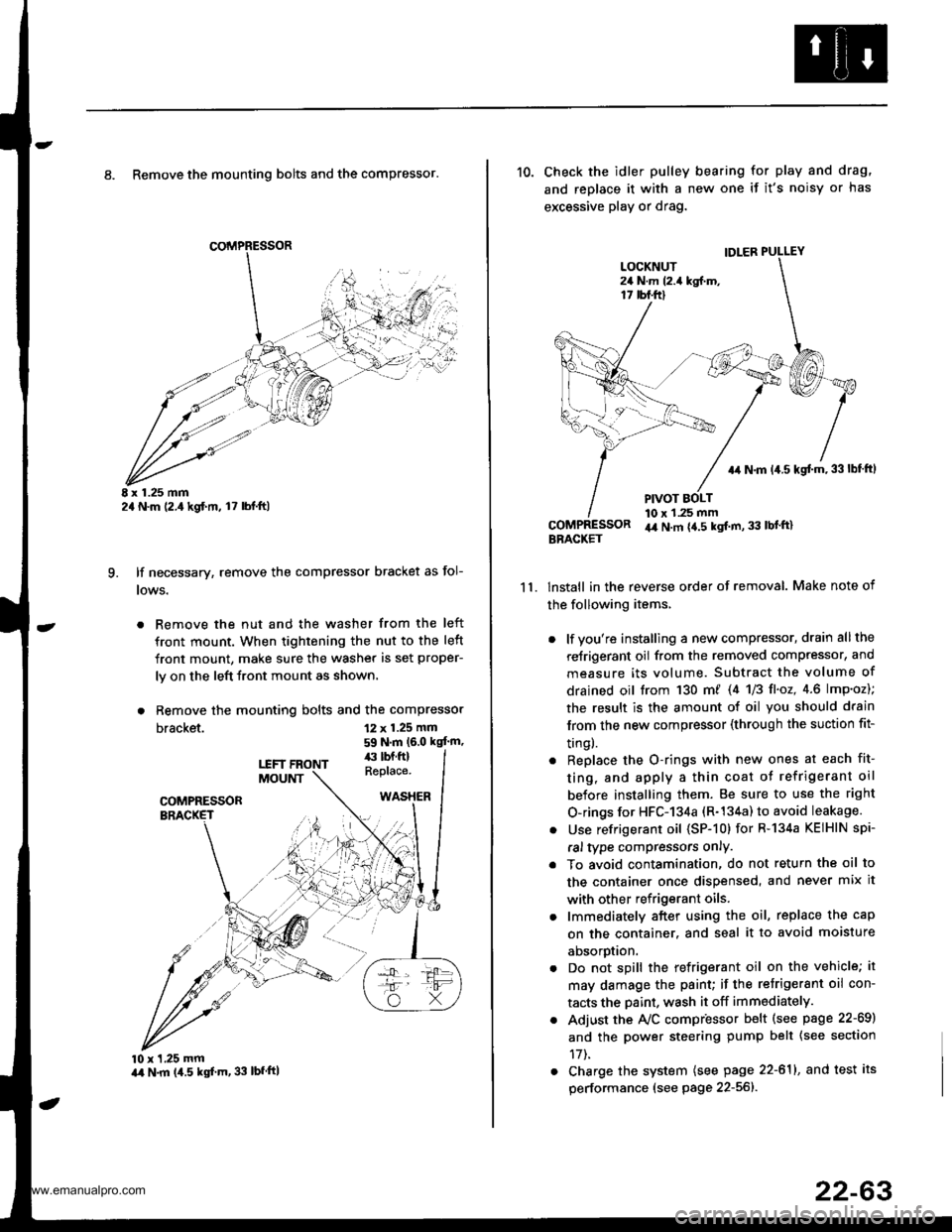

8. Remove the mounting bolts and the compressor.

E x 1.25 mm2a N.m (2.,1kgf.m, l7 lbl.ft)

lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer from the left

front mount. When tightening the nut to the left

front mount, make sure the washer is set proper-

ly on the left front mount as shown.

. Remove the mounting bolts and the compressor

bracket.

q

12 x 1.25 mm

59 N.m (6.0 kgt'm,

10 x 1,25 mmart N.m (4.5 kgf'm, 33 lbfftl

11.

10. Check the idler pulley bearing for play and drag,

and replace it with a new one if it's noisy or has

excessive play or drag.

lnstall in the reverse order of removal. Make note of

the following items,

. lf you're installing a new compressor, drain all the

reJrigerant oil from the removed compressor, and

measure its volume. Subtract the volume of

drained oil trom 130 m/ 14 U3 fl'o2,4.6 lmp'oz);

the result is the amount of oil you should drain

lrom the new compressor (through the suction fit-

trngl.

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat o{ refrigerant oil

before installing them. Be sure to use the right

O-rings for HFC-134a (R-134a) to avoid leakage.

. Use refrigerant oil (SP-10) for R-134a KEIHIN spi-

ral type compressors only.

. To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediately after using the oil, replace the cap

on the container. and seal it to avoid moisture

aDsorprlon.

. Do not spill the refrigerant oil on the vehicle; it

may damage the paint; if the retrigerant oil con-

tacts the Daint, wash it off immediately.

. Adjust the Ay'C compr'essor b€lt (see psge 22-69)

and the power steering pump belt {see section

17t.

. Charge the system (see page 22-611, and test its

performance (see page 22-56]-.

IDLER PULLEY

+r N.m 14.5 kgt m,33lbf ftl

PIVOT BOLT10 x 1.25 mmir4 N.m {4.5 kgt m, 33 lbl'ft}BBACKET

www.emanualpro.com